®

ISL89410, ISL89411, ISL89412

Data Sheet July 1, 2009

High Speed, Dual Channel Power

MOSFET Drivers

The ISL89410, ISL89411, ISL89412 ICs are similar to the

EL7202, EL7212, EL7222 series but with greater VDD

ratings. These are very high speed matched dual drivers

capable of delivering peak currents of 2.0A into highly

capacitive loads. The high speed performance is achieved

by means of a proprietary “Turbo-Driver” circuit that speeds

up input stages by tapping the wider voltage swing at the

output. Improved speed and drive capability are enhanced

by matched rise and fall delay times. These matched delays

maintain the integrity of input-to-output pulse-widths to

reduce timing errors and clock skew problems. This

improved performance is accompanied by a 10-fold

reduction in supply currents over bipolar drivers, yet without

the delay time problems commonly associated with CMOS

devices. Dynamic switching losses are minimized with

non-overlapped drive techniques.

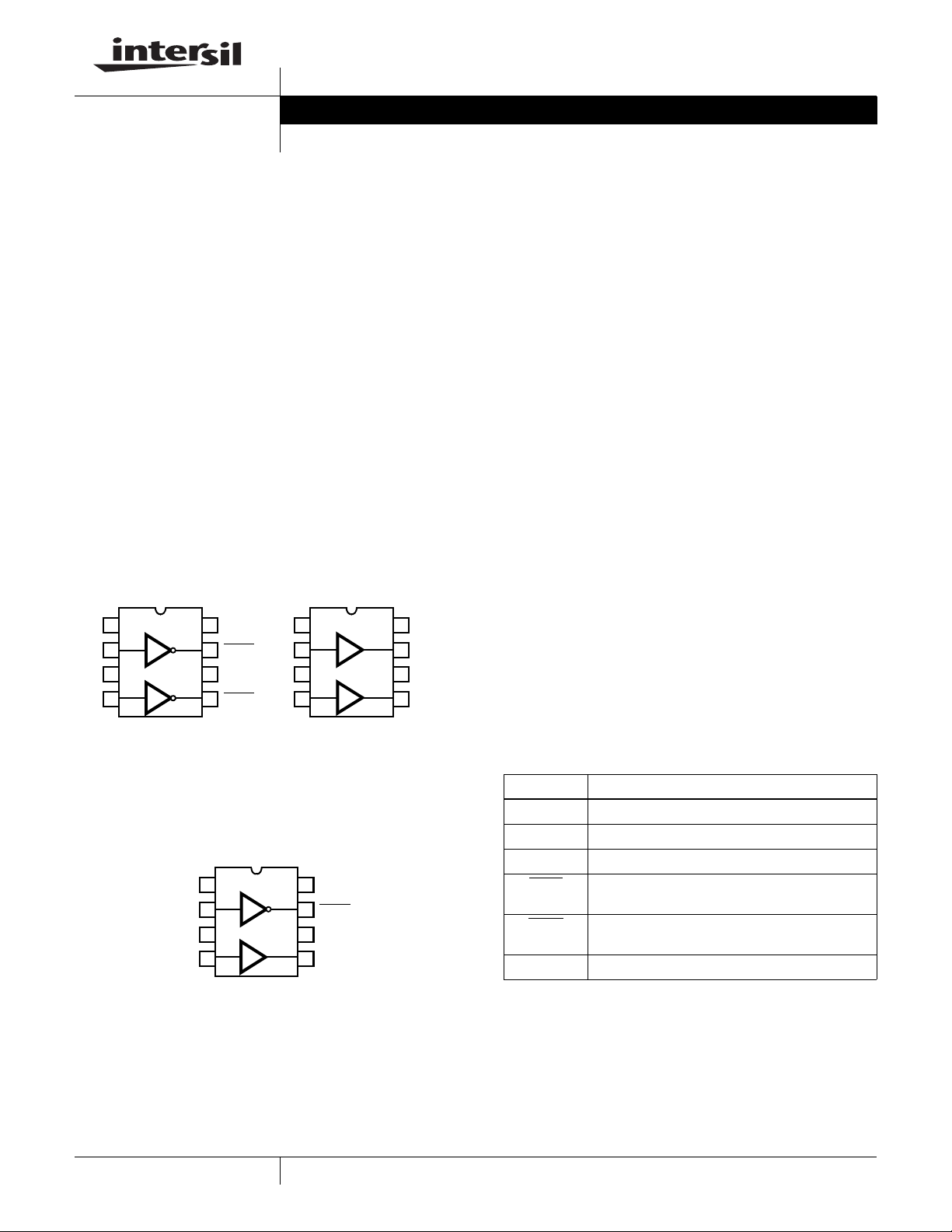

Pinouts

ISL89410

(8 LD PDIP, SOIC)

TOP VIEW

1

2

3

4

8

7

6

5

NC

OUTA

V+

OUTB

(8 LD PDIP, SOIC)

NC

1

2

INA

3

GND

4

INB

ISL89411

TOP VIEW

8

7

6

5

NC

OUTA

V+

OUTB

NC

INA

GND

INB

FN6798.1

Features

• Industry Standard Driver Replacement

• Improved Response Times

• Matched Rise and Fall Times

• Reduced Clock Skew

• Low Output Impedance

• Low Input Capacita n c e

• High Noise Immunity

• Improved Clocking Rate

• Low Supply Current

• Wide Operating Voltage Range

• Pb-Free Available (R oHS compliant)

Applications

• Clock/line Drivers

• CCD Drivers

• Ultra-Sound Transducer Drivers

• Power MOSFET Drivers

• Switch Mode Power Supplies

• Class D Switching Amplifiers

• Ultrasonic and RF Generators

INVERTING

DRIVERS

ISL89412

(8 LD PDIP, SOIC)

TOP VIEW

NC

1

2

INA

3

GND

4

INB

COMPLEMENTARY

DRIVERS

Manufactured under U.S. Patent Nos. 5,334,883, #5,341,047

1

NON-INVERTING

DRIVERS

8

NC

7

OUTA

6

v+

5

OUTB

1-888-INTERSIL or 1-888-468-3774

• Pulsed Circuits

Pin Descriptions

SYMBOL PIN DESCRIPTIONS

V

GND Power voltage return

INA, INB Logic inputs.

OUTA

OUTA

OUTB

OUTB

NC These pins must be left unconnected.

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

Power voltage from 4.5V to 18V.

+

Non-inverted ouput for ISL89410. Inverted output

for ISL89411 and ISL89412.

Non-inverted output for ISL89410 and ISL89412.

Inverted output for ISL89411.

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright Intersil Americas Inc. 2008, 2009. All Rights Reserved

All other trademarks mentioned are the property of their respective owners.

Ordering Information

ISL89410, ISL89411, ISL89412

PART

NUMBER

ISL89410IP ISL 89410IP -40 to +85 8 Ld PDIP E8.3

ISL89410IPZ (Note) 89410 IPZ -40 to +85 8 Ld PDIP** (Pb-free) E8.3

ISL89410IBZ (Note) 89410 IBZ -40 to +85 8 Ld SOIC (Pb-free) MDP0027

ISL89410IBZ-T13* (Note) 89410 IBZ -40 to +85 8 Ld SOIC (Tape and Reel)

ISL89411IP ISL 89411IP -40 to +85 8 Ld PDIP E8.3

ISL89411IPZ (Note) ISL 89411IPZ -40 to +85 8 Ld PDIP** (Pb-free) E8.3

ISL89411IBZ (Note) 89411 IBZ -40 to +85 8 Ld SOIC (Pb-free) MDP0027

ISL89411IBZ-T13* (Note) 89411 IBZ -40 to +85 8 Ld SOIC (Tape and Reel)

ISL89412IP ISL 89412IP -40 to +85 8 Ld PDIP E8.3

ISL89412IPZ 89412 IPZ -40 to +85 8 Ld PDIP** (Pb-free) E8.3

ISL89412IBZ (Note) 89412 IBZ -40 to +85 8 Ld SOIC (Pb-free) MDP0027

ISL89412IBZ-T13* (Note) 89412 IBZ -40 to +85 8 Ld SOIC (Tape and Reel)

*Please refer to TB347 for details on reel specifications.

**Pb-free PDIPs can be used for through-hole wave solder processing only. They are not intended for use in Reflow solder processing applications

NOTE: These Intersil Pb-free plastic packaged products employ special Pb-free material sets, molding compounds/die attach materials, and 100%

matte tin plate plus anneal (e3 termination finish, which is RoHS compliant and compatible with both SnPb and Pb-free soldering operations). Intersil

Pb-free products are MSL classified at Pb-free peak reflow temperatures that meet or exceed the Pb-free requirements of IPC/JEDEC J STD-020.

PART

MARKING

TEMP. RANGE

(°C) PACKAGE

(Pb-free)

(Pb-free)

(Pb-free)

PKG.

DWG. #

MDP0027

MDP0027

MDP0027

2

FN6798.1

July 1, 2009

ISL89410, ISL89411, ISL89412

Absolute Maximum Ratings Thermal Information

Supply (V+ to GND). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19.0V

Input Pins. . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to +0.3V above V+

Combined Peak Output Current. . . . . . . . . . . . . . . . . . . . . . . . . . .4A

Maximum Recommended Operating Conditions

Recommended Operating V+ Range. . . . . . . . . . . . . . 4.5V to 18.0V

Input Pins. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0V to V+

CAUTION: Do not operate at or near the maximum ratings listed for extended periods of time. Exposure to such conditions may adversely impact product reliability and

result in failures not covered by warranty.

Operating Junction Temperature . . . . . . . . . . . . . . . . . . . . . .+125°C

Power Dissipation

8 Ld SOIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .570mW

8 Ld PDIP* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1050mW

Storage Temperature Range . . . . . . . . . . . . . . . . . .-65°C to +150°C

Ambient Operating Temperature . . . . . . . . . . . . . . . .-40°C to +85°C

Pb-Free Reflow Profile. . . . . . . . . . . . . . . . . . . . . . . . .see link below

http://www.intersil.com/pbfree/Pb-FreeReflow.asp

*Pb-free PDIPs can be used for through-hole wave solder

processing only. They are not intended for use in Reflow solder

processing applications.

IMPORTANT NOTE: All parameters having Min/Max specifications are guaranteed. Typical values are for information purposes only. Unless otherwise noted, all tests

are at the specified temperature and are pulsed tests, therefore: T

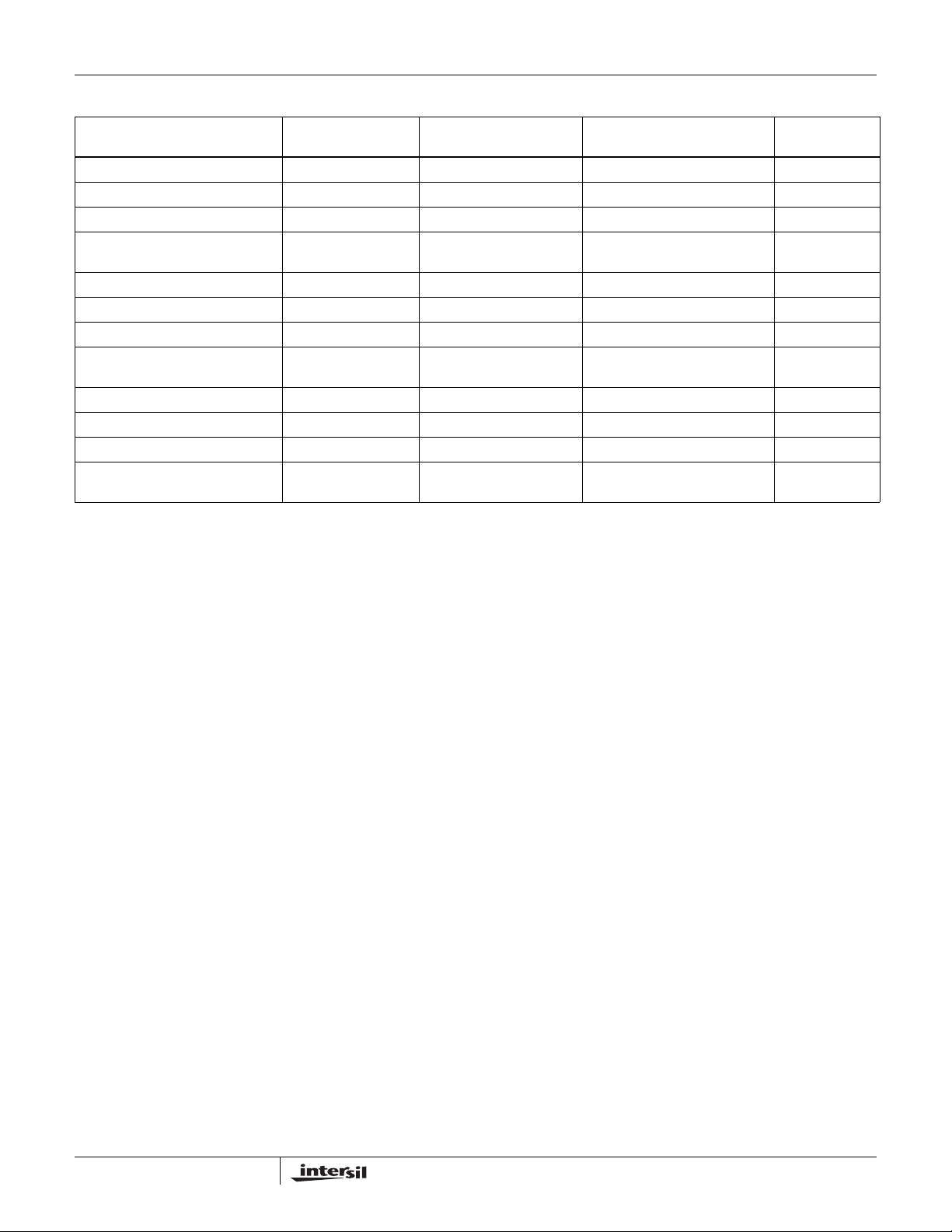

DC Electrical Specifications T

= +25°C, V = 18V unless otherwise specified; Parameters with MIN and/or MAX limits are 100% tested

A

= TC = T

J

A

at +25°C, unless otherwise specified. Temperature limits established by characterization and are not

production tested.

PARAMETER DESCRIPTION TEST CONDITIONS MIN TYP MAX UNITS

INPUT

V

I

IH

V

I

IL

V

IH

IL

HVS

Logic “1” Input Voltage 2.4 V

Logic “1” Input Current @V+ 0.1 10 µA

Logic “0” Input Voltage 0.8 V

Logic “0” Input Current @0V 0.1 10 µA

Input Hysteresis 0.3 V

OUTPUT

R

OH

R

OL

I

PK

Pull-Up Resistance I

Pull-Down Resistance I

Peak Output Current Source 2 A

= -100mA 3 6 Ω

OUT

= +100mA 4 6 Ω

OUT

Sink 2 A

I

DC

Continuous Output Current Source/Sink 100 mA

POWER SUPPLY

I

S

Power Supply Current Inputs High/ISL89410 4.5 7.5 mA

Inputs High/ISL89411 1 2.5 mA

Inputs High/ISL89412 2.5 5.0 mA

V

S

Operating Voltage 4.5 18 V

AC Electrical Specifications T

= +25°C, V = 18V unless otherwise specified.

A

PARAMETER DESCRIPTION TEST CONDITIONS MIN TYP MAX UNITS

SWITCHING CHARACTERISTICS

t

R

t

F

t

D1

t

D2

Rise Time (Note 1) CL = 500pF 7.5 ns

= 1000pF 10 20 ns

C

L

Fall Time (Note 1) CL = 500pF 10 ns

= 1000pF 13 20 ns

C

L

Turn-On Delay Time (Note 1) See “Timing Table” on page 4 18 25 ns

Turn-Off Delay Time (Note 1) See“Timing Table” on page 4 20 25 ns

NOTE:

1. Limits established by characterization and are not production tested.

3

FN6798.1

July 1, 2009

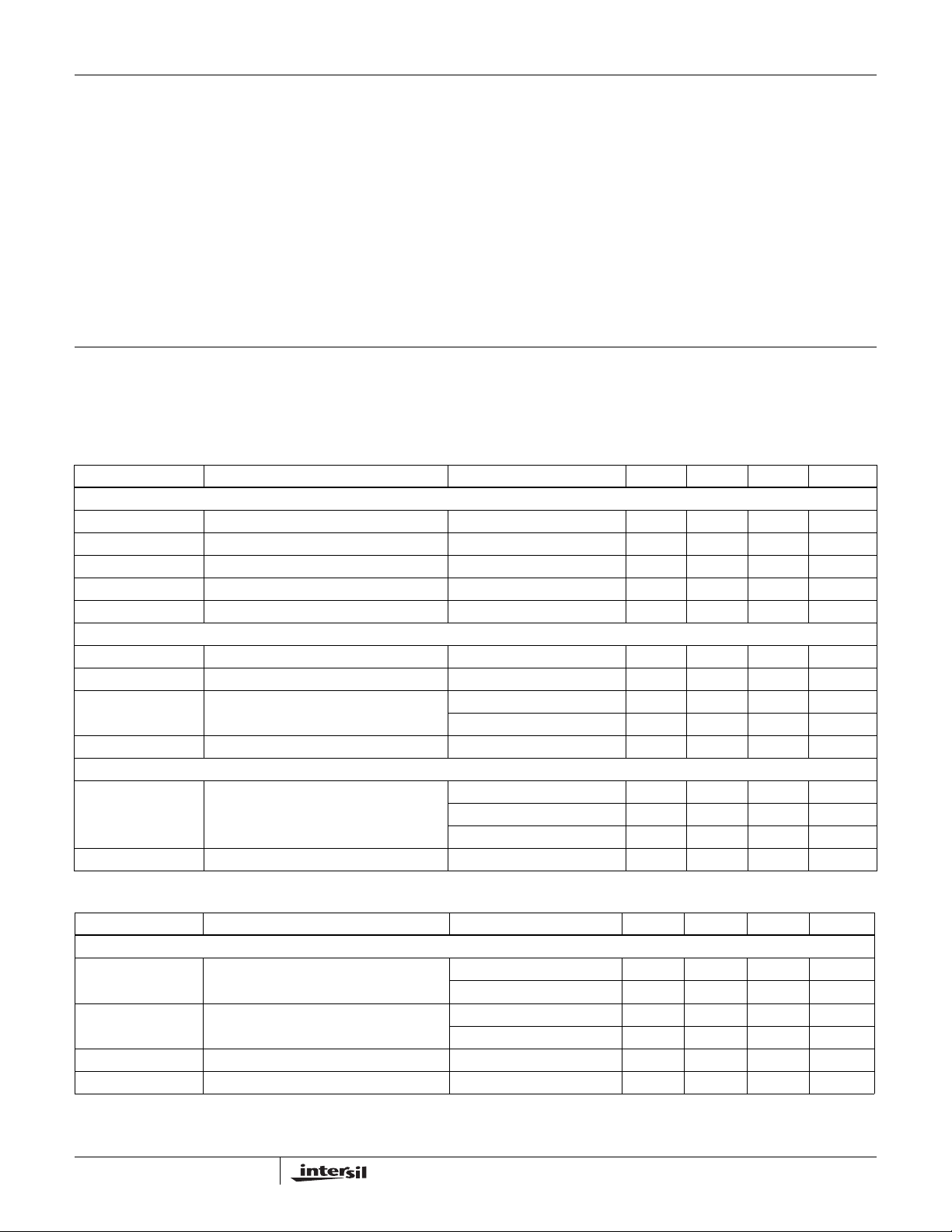

Timing Table

ISL89410, ISL89411, ISL89412

5V

INPUT 2.5V

0

NON-INVERTED

Standard Test Configuration

INVERTED

OUTPUT

OUTPUT

90%

10%

90%

10%

V+

INPUT

2

t

D1

46

t

4.7µF

TAN+

OUTPUT

1000pF

D2

t

R

t

F

t

F

t

R

7

Simplified Schematic

V+

INPUT

INPUT

BUFFER

+

-

+

V

REF

-

REFERENCE

AND LEVEL

SHIFTER

3

INVERTING

BUFFER

WITH

HYSTERESIS

2ND

INVERTING

BUFFER

SUPER

INVERTER

OUTPUT

4

FN6798.1

July 1, 2009

Typical Performance Curves

FIGURE 1. MAX POWER/DERATING CURVES FIGURE 2. SWITCH THRESHOLD vs SUPPLY VOLTAGE

ISL89410, ISL89411, ISL89412

FIGURE 3. INPUT CURRENT vs VOLTAGE

FIGURE 5. QUIESCENT SUPPLY CURRENT

5

FIGURE 4. PEAK DRIVE vs SUPPLY VOLTAGE

ISL89410

ISL89411

ISL89412

FN6798.1

July 1, 2009

ISL89410, ISL89411, ISL89412

Typical Performance Curves (Continued)

FIGURE 6. “ON” RESISTANCE vs SUPPLY VOLTAGE

FIGURE 8. AVERAGE SUPPL Y CURRENT vs CAP ACITIVE

LOAD

FIGURE 7. AVERAGE SUPPLY CURRENT vs VOLTAGE AND

FREQUENCY

FIGURE 9. RISE/FALL TIME vs LOAD

FIGURE 10. RISE/FALL TIME vs SUPPLY VOLTAGE

6

FIGURE 11. PROPAGATION DELAY vs SUPPLY VOLTAGE

FN6798.1

July 1, 2009

ISL89410, ISL89411, ISL89412

Typical Performance Curves (Continued)

FIGURE 12. RISE/FALL TIME vs TEMPERATURE FIGURE 13. DELAY vs TEMPERATURE

ISL89411 Macro Model

**** ISL89411 Model ****

* input

* | gnd

* | | Vsupply

* | | | Vout

.subckt M89411 2 3 6 7

V1 12 3 1.6

R1 13 15 1k

R2 14 15 5k

R5 11 12 100

C1 15 3 43.3 pF

D1 14 13 dmod

X1 13 11 2 3 comp1

X2 16 12 15 3 comp1

sp 6 7 16 3 spmod

sn 7 3 16 3 snmod

g1 11 0 13 0 938µ

.model dmod d

.model spmod vswitch ron3 roff2meg von1 voff1.5

.model snmod vswitch ron4 roff2meg von3 voff2

.ends M89411

7

FN6798.1

July 1, 2009

ISL89410, ISL89411, ISL89412

.subckt comp1 out inp inm vss

e1 out vss table { (v(inp) v(inm))* 5000} (0,0) (3.2,3.2)

Rout out vss 10meg

Rinp inp vss 10meg

Rinm inm vss 10meg

.ends comp1

Application Guidelines

It is important to minimize inductance to the power FET by

keeping the output drive current loop as short as possible.

Also, the decoupling capacitor, Cq, should be a high quality

ceramic capacitor with a Q that should be a least 10x the

gate Q of the power FET. A ground plane under this circuit is

also recommended.

V+

Cq SHOULD BE AS CLOSE AS

POSSIBLE TO THE V+ AND

GND PINS

C

q

LOOP AS

SHORT AS

POSSIBLE

V+

C

q

GND

FIGURE 15. SUGGESTED CONFIGURATION FOR DRIVING

INDUCTIVE LOADS

PARASITIC LEAD

INDUCTANCE

Where high supply voltage operation is required (15V to

18V), input signals with a minimum of 3.3V input drive is

suggested and a minimum rise/fall time of 100ns. This is

recommended to minimize the internal bias current power

dissipation.

Excessive power dissipation in the driver can result when

driving highly capacitive FET gates at high frequencies.

These gate power losses are defined by Equation 1:

P2QCVgs•• fSW•=

(EQ. 1)

GND

FIGURE 14. RECOMMENDED LAYOUT METHODS

In applications where it is difficult to place the driver very

close to the power FET (which may result with excessive

parasitic inductance), it then may be necessary to add an

external gate resistor to dampen the inductive ring. If this

resistor must be too large in value to be effective, then as an

alternative, Schottky diodes can be added to clamp the ring

voltage to V+ or GND.

where:

P = Power

Q

= Charge of the Power FET at V

c

gs

Vgs = Gate drive voltage (V+)

f

= switching Frequency

SW

Adding a gate resistor to the output of the driver will transfer

some of the driver dissipation to the resisto r. Another

possible solution is to lower the gate driver voltage which

also lowers Q

.

c

8

FN6798.1

July 1, 2009

ISL89410, ISL89411, ISL89412

Small Outline Package Family (SO)

A

D

NN

(N/2)+1

h X 45¬

PIN #1

E

C

SEATING

PLANE

0.004 C

E1

B

0.010 BM CA

I.D. MARK

1

e

0.010 BM CA

(N/2)

c

SEE DETAIL ‚Ä ú

L1

H

A2

GAUGE

PLANE

A1

b

DETAIL X

L

4¬× ¬±

MDP0027

SMALL OUTLINE PACKAGE FAMILY (SO)

INCHES

SO16

SYMBOL

(0.150”)

A 0.068 0.068 0.068 0.104 0.104 0.104 0.104 MAX -

A1 0.006 0.006 0.006 0.007 0.007 0.007 0.007 ±0.003 -

A2 0.057 0.057 0.057 0.092 0.092 0.092 0.092 ±0.002 -

b 0.017 0.017 0.017 0.017 0.017 0.017 0.017 ±0.003 -

c 0.009 0.009 0.009 0.011 0.011 0.011 0.011 ±0.001 -

D 0.193 0.341 0.390 0.406 0.504 0.606 0.704 ±0.004 1, 3

E 0.236 0.236 0.236 0.406 0.406 0.406 0.406 ±0.008 -

E1 0.154 0.154 0.154 0.295 0.295 0.295 0.295 ±0.004 2, 3

e 0.050 0.050 0.050 0.050 0.050 0.050 0.050 Basic -

L 0.025 0.025 0.025 0.030 0.030 0.030 0.030 ±0.009 -

L1 0.041 0.041 0.041 0.056 0.056 0.056 0.056 Basic -

h 0.013 0.013 0.013 0.020 0.020 0.020 0.020 Reference -

N 8 14 16 16 20 24 28 Reference -

NOTES:

1. Plastic or metal protrusions of 0.006” maximum per side are not included.

2. Plastic interlead protrusions of 0.010” maximum per side are not included.

3. Dimensions “D” and “E1” are measured at Datum Plane “H”.

4. Dimensioning and tolerancing per ASME Y14.5M-1994

SO16 (0.300”)

(SOL-16)

SO20

(SOL-20)

SO24

(SOL-24)

SO28

(SOL-28)

TOLERANCE NOTESSO-8 SO-14

A

0.010

Rev. M 2/07

9

FN6798.1

July 1, 2009

ISL89410, ISL89411, ISL89412

Dual-In-Line Plastic Packages (PDIP)

N

D1

-C-

E1

-B-

A2

A

L

A

1

e

C

e

e

INDEX

AREA

BASE

PLANE

SEATING

PLANE

D1

B1

12 3 N/2

-AD

e

B

0.010 (0.25) C AM BS

NOTES:

1. Controlling Dimensions: INCH. In case of conflict between

English and Metric dimensions, the inch dimensions control.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Symbols are defined in the “MO Series Symbol List” in Section

2.2 of Publication No. 95.

4. Dimensions A, A1 and L are measured with the package seated

in JEDEC seating plane gauge GS-3.

5. D, D1, and E1 dimensions do not include mold flash or protrusions. Mold flash or protrusions shall not exceed 0.010 inch

(0.25mm).

6. E and are measured with the leads constrained to be per-

7. e

e

pendicular to datum .

A

and eC are measured at the lead tips with the leads uncon-

B

strained. e

must be zero or greater.

C

-C-

8. B1 maximum dimensions do not include dambar protrusions.

Dambar protrusions shall not exceed 0.010 inch (0.25mm).

9. N is the maximum number of terminal positions.

10. Corner leads (1, N, N/2 and N/2 + 1) for E8.3, E16.3, E18.3,

E28.3, E42.6 will have a B1 dimension of 0.030 - 0.045 inch

(0.76 - 1.14mm).

E8.3 (JEDEC MS-001-BA ISSUE D)

8 LEAD DUAL-IN-LINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A - 0.210 - 5.33 4

E

A1 0.015 - 0.39 - 4

A2 0.115 0.195 2.93 4.95 -

B 0.014 0.022 0.356 0.558 -

C

L

A

C

B

B1 0.045 0.070 1.15 1.77 8, 10

C 0.008 0.014 0.204 0.355 -

D 0.355 0.400 9.01 10.16 5

D1 0.005 - 0.13 - 5

E 0.300 0.325 7.62 8.25 6

E1 0.240 0.280 6.10 7.11 5

e 0.100 BSC 2.54 BSC -

e

A

e

B

0.300 BSC 7.62 BSC 6

- 0.430 - 10.92 7

L 0.115 0.150 2.93 3.81 4

N8 89

NOTESMIN MAX MIN MAX

Rev. 0 12/93

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implicat ion or oth erwise u nde r any p a tent or p at ent r ights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

10

FN6798.1

July 1, 2009

Loading...

Loading...