®

ISL78010

Data Sheet May 30, 2007

Automotive Grade TFT-LCD Power Supply

The ISL78010 is a multiple output regulator for use in all

TFT-LCD automotive applications. It features a single boost

converter with an integrated 2A FET, two positive LDOs for

V

and V

ON

V

generation. The boost converter can be programmed

OFF

generation, and a single negative LDO for

LOGIC

to operate in either P-mode for optimal transient response or

PI-mode for improved load regulation.

The ISL78010 includes fault protection for all four channels.

Once a fault is detected on either the V

BOOST

, VON or V

OFF

channels, the device is latched off until the input supply or

EN is cycled. If a fault is detected on the V

LOGIC

channel,

the device is latched off until the input supply is cycled. The

V

channel is not affected by the EN function.

LOGIC

The ISL78010 also includes an integrated start-up sequence

for V

V

BOOST

LOGIC

, V

BOOST

, V

, then VON or for V

OFF

LOGIC

, and VON. The latter sequence requires a single

, V

OFF

external transistor. The timing of the start-up sequence is set

using an external capacitor.

The ISL78010 comes in a 32 Ld 5x5 TQFP package and is

specified for operation over a -40°C to +105°C temperature

range.

Ordering Information

FN6501.0

Features

• 2A current FET

• 3V to 5V input

• Up to 20V boost output

• 1% regulation on boost output

•V

LOGIC-VBOOST-VOFF-VON

V

LOGIC-VOFF-VBOOST-VON

• Programmable sequence delay

or

sequence control

• Fully fault protected

• Thermal shutdown

• Internal soft-start

• 32 Ld 5x5 TQFP packages

,

• Pb-free plus anneal available (RoHS compliant)

Applications

• All Automotive LCD Displays

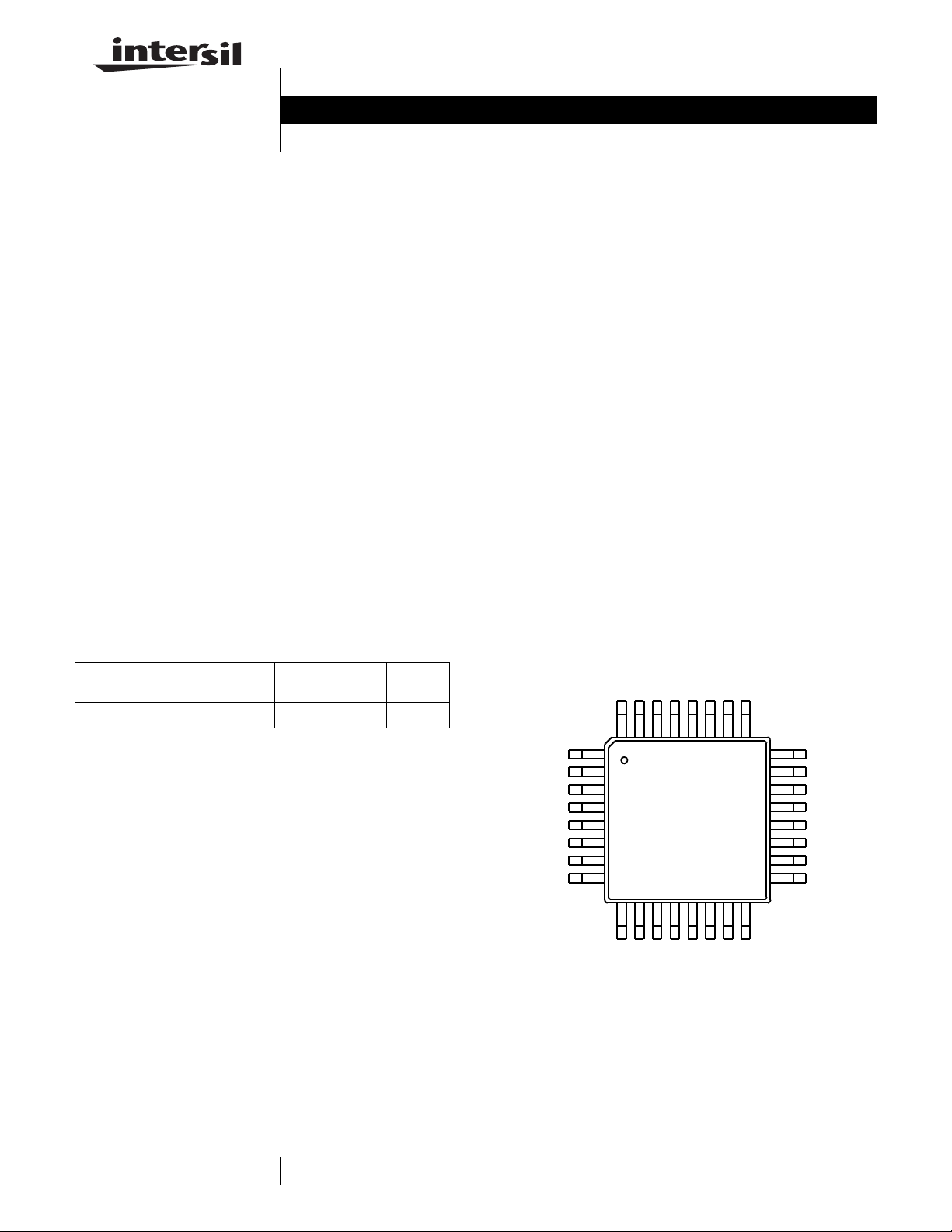

Pinout

ISL78010

(32 LD 5X5 TQFP)

TOP VIEW

PART NUMBER

(Note)

ISL78010ANZ* 78010ANZ 32 Ld 5x5 TQFP Q32.5x5

*Add “-T” or “-TK” suffix for tape and reel. Please refer to TB347 for

details on reel specifications.

NOTE: Intersil Pb-free plus anneal products employ special Pb-free

material sets; molding compounds/die attach materials and 100%

matte tin plate termination finish, which are RoHS compliant and

compatible with both SnPb and Pb-free soldering operations. Intersil

Pb-free products are MSL classified at Pb-free peak reflow

temperatures that meet or exceed the Pb-free requirements of

IPC/JEDEC J STD-020.

PART

MARKING

PACKAGE

(Pb-free)

PKG.

DWG. #

NC

NC

DELB

NC

LX

NC

DRVP

NC

SGND

EN

VDD

PG

CDLY

NC

32 31 30 29 28 27 26 25

1

2

3

4

5

6

7

8

NC

FBP

NC

DRVL

FBL

SGND

CINT

FBB

161514131211109

NC

DRVN

24

23

22

21

20

19

18

17

VREF

NC

PGND

PGND

PGND

PGND

NC

FBN

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright Intersil Americas Inc. 2007. All Rights Reserved

ISL78010

Absolute Maximum Ratings (T

V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24V

DELB

V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36V

DRVP

V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -20V

DRVN

V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.5V

DD

V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24V

LX

V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.5V

DRVL

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

IMPORTANT NOTE: All parameters having Min/Max specifications are guaranteed. Typical values are for information purposes only. Unless otherwise noted, all tests

are at the specified temperature and are pulsed tests, therefore: T

Electrical Specifications V

= +25°C) Thermal Information

A

Storage Temperature. . . . . . . . . . . . . . . . . . . . . . . .-65°C to +150°C

Ambient Operating Temperature . . . . . . . . . . . . . . .-40°C to +105°C

Power Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Curves

Maximum Continuous Junction Temperature . . . . . . . . . . . +125°C

Pb-free reflow profile . . . . . . . . . . . . . . . . . . . . . . . . . .see link below

http://www.intersil.com/pbfree/Pb-FreeReflow.asp

= TC = T

J

= 5V, V

DD

+105°C temperature range, unless otherwise specified.

BOOST

= 11V, I

A

LOAD

= 200mA, V

ON

= 15V, V

OFF

= -5V, V

= 2.5V, limits over -40°C to

LOGIC

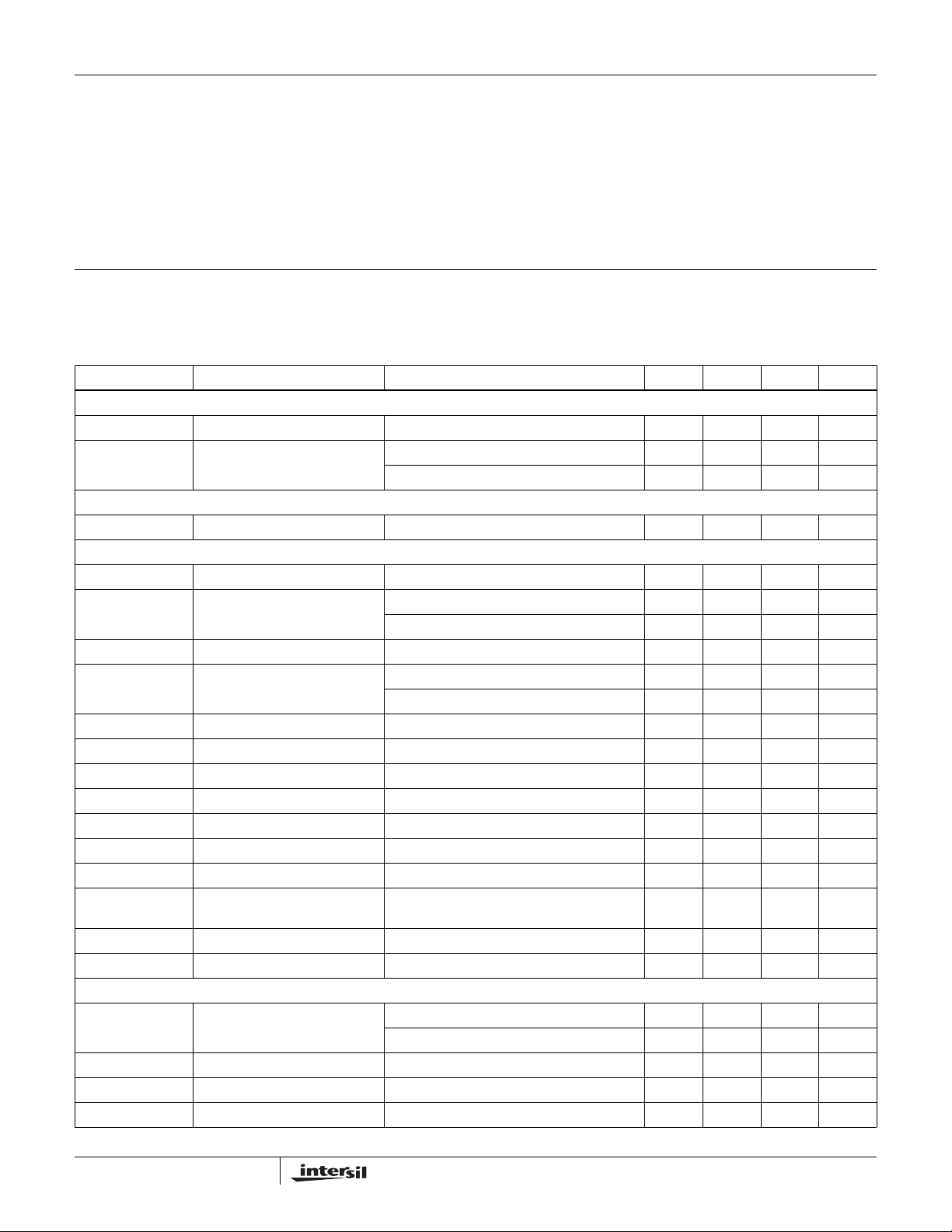

PARAMETER DESCRIPTION CONDITION MIN TYP MAX UNIT

SUPPLY

V

S

I

Quiescent Current Enabled, LX not switching 1.7 2.5 mA

S

Supply Voltage 3 5.5 V

Disabled 750 900 µA

CLOCK

f

OSC

Oscillator Frequency 900 1000 1100 kHz

BOOST

V

V

Boost Output Range 5.5 20 V

BOOST

FBB

Boost Feedback Voltage TA= +25°C 1.192 1.205 1.218 V

1.188 1.205 1.222 V

V

F_FBB

V

REF

FBB Fault Trip Point 0.9 V

Reference Voltage TA= +25°C 1.19 1.215 1.235 V

1.187 1.215 1.238 V

D

MAX

I

LXMAX

I

LEAK

r

DS(ON)

Maximum Duty Cycle 85 %

Current Switch 2.0 A

Switch Leakage Current VLX = 16V 10 µA

Switch ON-Resistance 320 mΩ

Eff Boost Efficiency See curves 85 92 %

I(V

) Feedback Input Bias Current Pl mode, V

FBB

ΔV

BOOST

ΔV

BOOST

ΔV

BOOST

V

CINT_T

V

ON

V

FBP

V

F_FBP

I

FBP

LDO

/ΔV

/ΔI

/ΔI

BOOST

BOOST

Line Regulation C

IN

Load Regulation - “P” Mode C

Load Regulation - “PI” Mode C

CINT Pl Mode Select Threshold 4.7 4.8 V

FBP Regulation Voltage I

FBP Fault Trip Point V

FBP Input Bias Current V

GMP FBP Effective Transconductance V

= 4.7nF , I

INT

pin strapped to VDD,

INT

50mA < I

= 4.7nF, 50mA < IO < 250mA 0.1 %

INT

= 0.2mA, TA = +25°C 1.176 1.2 1.224 V

DRVP

I

DRVP

falling 0.82 0.87 0.92 V

FBP

= 1.35V -250 250 nA

FBP

DRVP

= 1.35V 50 500 nA

FBB

= 100mA, VIN = 3V to 5.5V 0.05 %/V

OUT

3%

< 250mA

LOAD

= 0.2mA 1.172 1.2 1.228 V

= 25V, I

= 0.2mA to 2mA 50 ms

DRVP

2

FN6501.0

May 30, 2007

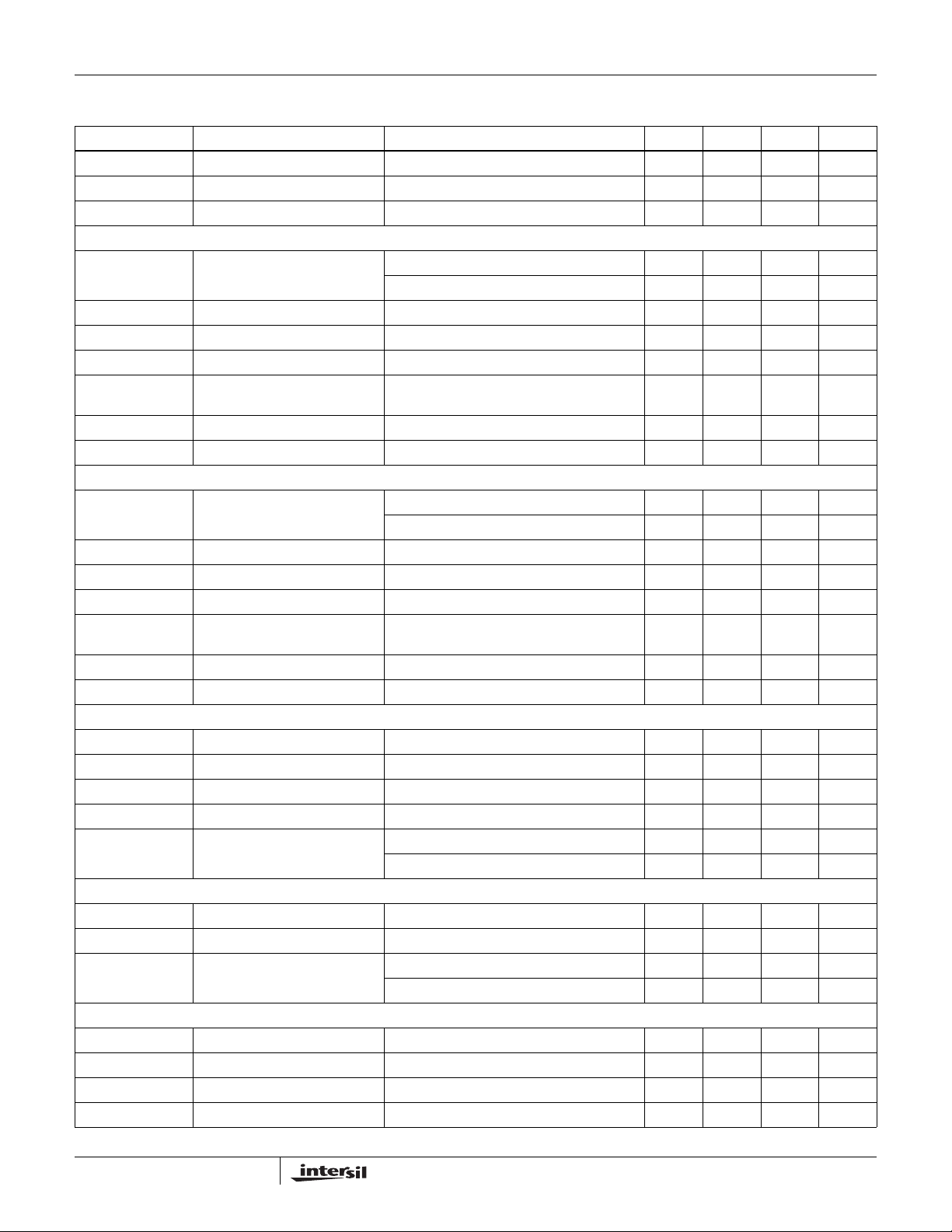

ISL78010

Electrical Specifications V

= 5V, V

DD

+105°C temperature range, unless otherwise specified. (Continued)

BOOST

= 11V, I

LOAD

= 200mA, V

ON

= 15V, V

OFF

= -5V, V

= 2.5V, limits over -40°C to

LOGIC

PARAMETER DESCRIPTION CONDITION MIN TYP MAX UNIT

ΔVON/ΔI(VON)VON Load Regulation I(VON) = 0mA to 20mA -0.5 %

I

DRVP

I

L_DRVP

V

OFF

V

FBN

V

F_FBN

I

FBN

LDO

DRVP Sink Current Max V

DRVP Leakage Current V

FBN Regulation Voltage I

FNN Fault Trip Point V

FBN Input Bias Current V

GMN FBN Effective Transconductance V

ΔV

OFF

ΔI(V

OFF

I

DRVN

I

L_DRVN

V

LOGIC

V

FBL

V

F_FBL

I

FBL

G

ML

ΔV

LOGIC

ΔI(V

LOGIC

I

DRVL

I

L_DRL

/

)

LDO

/

)

Load Regulation I(V

V

OFF

DRVN Source Current Max V

DRVN Leakage Current V

FBL Regulation Voltage I

FBL Fault Trip Point V

FBL Input Bias Current V

FBL Effective Transconductance V

Load Regulation I(V

V

LOGIC

DRVL Sink Current Max V

I

L_DRVL

= 1.1V, V

FBP

= 1.5V, V

FBP

= 0.2mA, TA = +25°C 0.173 0.203 0.233 V

DRVN

I

= 0.2mA 0.171 0.203 0.235 V

DRVN

falling 0.38 0.43 0.48 V

FBN

= 0.2V -250 250 nA

FBN

= -6V, I

DRVN

) = 0mA to 20mA -0.5 %

OFF

= 0.3V, V

FBN

= 0V, V

FBN

= 1mA, TA = +25°C 1.176 1.2 1.224 V

DRVL

I

= 1mA 1.174 1.2 1.226 V

DRVL

falling 0.82 0.87 0.92 V

FBL

= 1.35V -500 500 nA

FBL

= 2.5V, I

DRVL

) = 100mA to 500mA 0.5 %

LOGIC

= 1.1V, V

FBL

V

= 1.5V, V

FBL

= 25V 2 4 mA

DRVP

= 35V 0.1 5 µA

DRVP

= 0.2mA to 2mA 50 mS

DRVN

= -6V 2 4 mA

DRVN

= -20V 0.1 5 µA

DRVN

= 1mA to 8mA 200 mS

DRVL

= 2.5V 8 16 mA

DRVL

= 5.5V 0.1 5 µA

DRVL

SEQUENCING

t

ON

t

SS

t

DEL1

t

DEL2

I

DELB

Turn On Delay C

Soft-start Time C

Delay Between A

Delay Between VON and V

VDD

and V

OFFCDLY

OFFCDLY

DELB Pull-down Current V

= 0.22µF 30 ms

DLY

= 0.22µF 2 ms

DLY

= 0.22µF 10 ms

= 0.22µF 17 ms

>0.6V 50 µA

DELB

<0.6V 1.4 mA

V

DELB

FAULT DETECTION

t

FAULT

Fault Time Out C

= 0.22µF 50 ms

DLY

OT Over-temperature Threshold 140 °C

I

PG

PG Pull-down Current VPG > 0.6V 15 µA

VPG < 0.6V 1.7 mA

LOGIC ENABLE

V

HI

V

LO

I

LOW

I

HIGH

Logic High Threshold 2.3 V

Logic Low Threshold 0.8 V

Logic Low Bias Current 0.2 2 µA

Logic High Bias Current at VEN = 5V 12 18 24 µA

3

FN6501.0

May 30, 2007

ISL78010

Pin Descriptions

PIN NAME PIN NUMBER DESCRIPTION

1, 2, 4, 6, 8, 10, 12,

16, 18, 23, 32

3 DELB Open drain output for gate drive of optional V

5 LX Drain of the internal N-Channel boost FET

9 FBP Positive LDO voltage feedback input pin; regulates to 1.2V nominal

7 DRVP Positive LDO base drive; open drain of an internal N-Channel FET

11 DRVL Logic LDO base drive; open drain of an internal N-Channel FET

13 FBL Logic LDO voltage feedback input pin; regulates to 1.2V nominal

14, 27 SGND Low noise signal ground

15 DRVN Negative LDO base drive; open drain of an internal P-Channel FET

17 FBN Negative LDO voltage feedback input pin; regulates to 0.2V nominal

19, 20, 21, 22 PGND Power ground, connected to source of internal N-Channel boost FET

24 VREF Bandgap reference output voltage; bypass with a 0.1µF to SGND

25 CINT V

26 FBB Boost regulator voltage feedback input pin; regulates to 1.2V nominal

28 EN Enable pin; High = Enable; Low or floating = Disable

29 VDD Positive supply

30 PG Push-pull gate drive of optional fault protection FET; when chip is disabled or when a fault has been

31 CDLY A capacitor connected from this pin to SGND sets the delay time for start-up sequence and sets the fault

NC Not connected

integrator output; connect capacitor to SGND for PI-mode or connect to VDD for P-mode

BOOST

operation

detected, this is high

timeout time

BOOST

delay FET

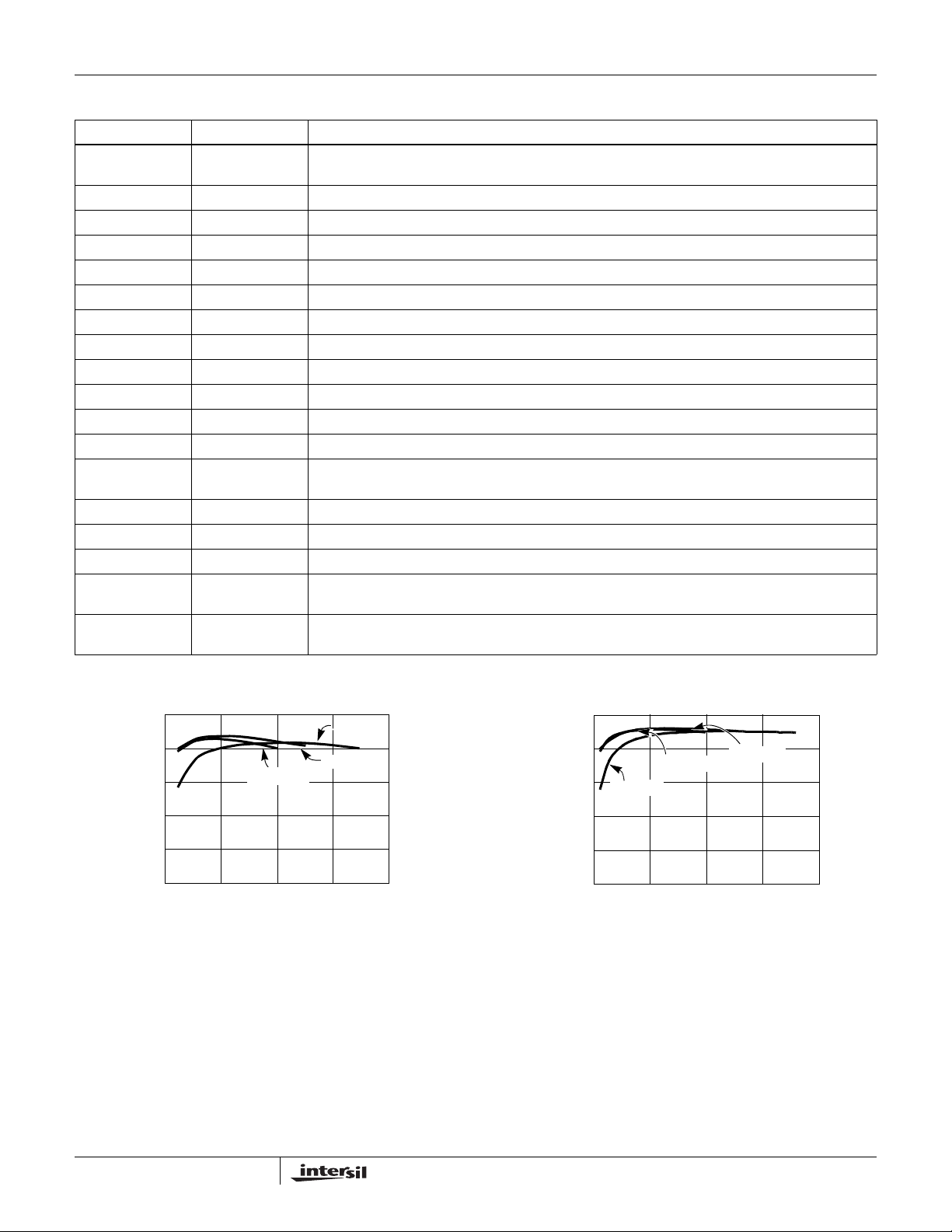

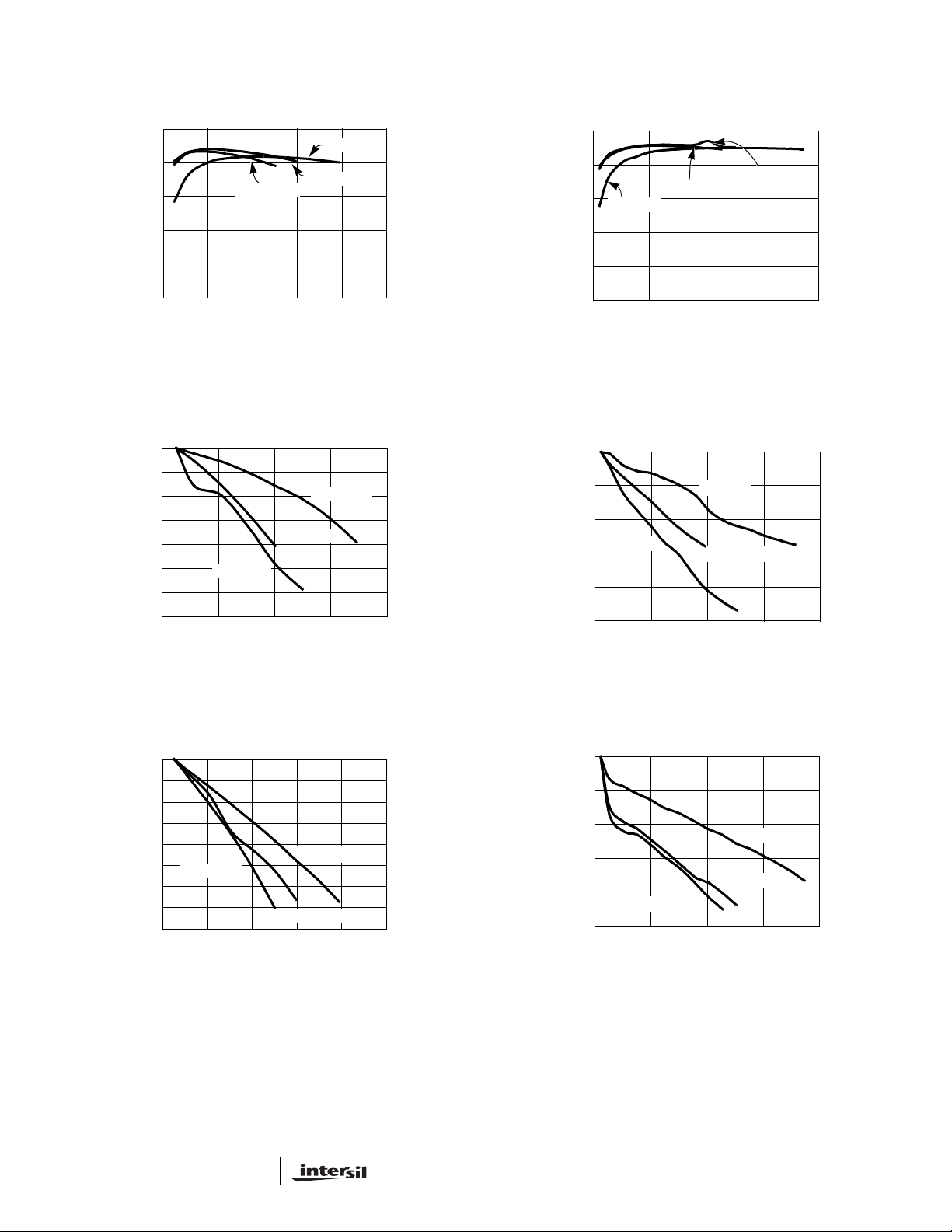

Typical Performance Curves T

100

80

60

40

EFFICIENCY (%)

20

0

FIGURE 1. V

A

= 15V

VDD

0 100 200 300 400

I

(mA)

OUT

EFFICIENCY AT VIN=3V (PI-MODE)

BOOST

A

A

VDD

VDD

= +25°C, unless otherwise specified.

A

= 9V

= 12V

FIGURE 2. V

100

80

60

40

EFFICIENCY (%)

20

0

0 200 400 600 800

BOOST

A

VDD

A

= 9V

VDD

I

EFFICIENCY AT VIN=5V (PI-MODE)

= 15V

OUT

(mA)

A

VDD

= 12V

4

FN6501.0

May 30, 2007

ISL78010

Typical Performance Curves T

EFFICIENCY (%)

FIGURE 3. V

LOAD REGULATION (%)

FIGURE 5. V

100

80

A

= 15V

60

40

20

0

0 100 200 300 400 500

BOOST

0

-0.1

-0.2

-0.3

-0.4

-0.5

-0.6

-0.7

0 100 200 300 400

LOAD REGULATION AT VIN=3V (PI-MODE)

BOOST

VDD

I

(mA)

OUT

EFFICIENCY AT VIN= 3V (P-MODE)

A

A

= 12V

VDD

I

(mA)

OUT

VDD

A

VDD

A

= 15V

A

VDD

VDD

= 12V

= 9V

= +25°C, unless otherwise specified. (Continued)

A

= 9V

FIGURE 6. V

100

80

60

40

EFFICIENCY (%)

20

0

FIGURE 4. V

0

-0.2

-0.4

-0.6

-0.8

LOAD REGULATION (%)

-1.0

BOOST

A

0 200 400 600 800

BOOST

A

VDD

0 200 400 600 800

A

= 12V

= 15V

(mA)

VDD

VDD

= 9V

A

VDD

I

OUT

EFFICIENCY AT VIN= 5V (P-MODE)

A

= 9V

VDD

= 12V

I

OUT

LOAD REGULATION AT V

A

VDD

(mA)

= 15V

IN

= 5V (PI-MODE)

-0.5

-1.0

-1.5

-2.0

-2.5

-3.0

LOAD REGULATION (%)

-3.5

-4.0

FIGURE 7. V

0

A

= 9V

A

(mA)

VDD

VDD

= 12V

A

= 15V

VDD

0 100 200 300 400 500

I

OUT

LOAD REGULATION AT VIN= 3V (P-MODE)

BOOST

5

LOAD REGULATION (%)

FIGURE 8. V

0

-1

-2

-3

-4

-5

0 200 400 600 800

BOOST

A

= 15V

VDD

I

OUT

LOAD REGULATION AT VIN=5V (P-MODE)

A

(mA)

VDD

A

VDD

= 9V

= 12V

FN6501.0

May 30, 2007

ISL78010

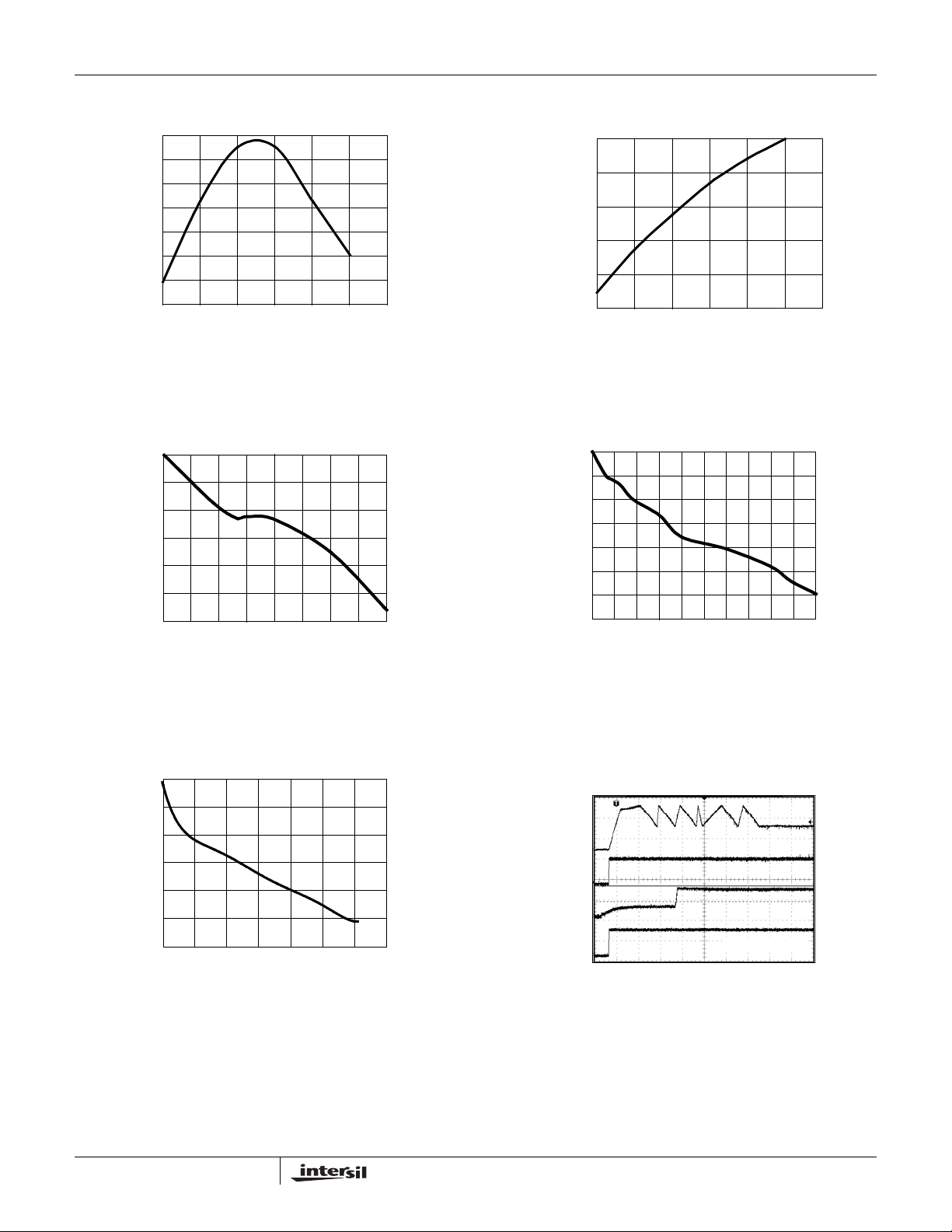

Typical Performance Curves T

0.05

0.04

0.03

0.02

0.01

0

LINE REGULATION (%)

-0.01

-0.02

3.0 3.5 4.0 4.5 5.0 5.5 6.0

V

(V)

IN

FIGURE 9. V

0

-0.1

-0.2

-0.3

-0.4

-0.5

LOAD REGULATION (%)

-0.6

0 20406080

FIGURE 11. V

LINE REGULATION (PI-MODE) FIGURE 10. V

BOOST

I

(mA)

OUT

LOAD REGULATION

ON

= +25°C, unless otherwise specified. (Continued)

A

0

-0.5

-1.0

1.5

-2.0

LINE REGULATION (%)

-2.5

3.0 3.5 4.0 4.5 5.0 5.5 6.0

0

-0.2

-0.4

-0.6

-0.8

-1.0

LOAD REGULATION (%)

-1.2

-1.4

020 6080100

FIGURE 12. V

(V)

V

IN

LINE REGULATION (P-MODE)

BOOST

40

I

(mA)

OUT

LOAD REGULATION

OFF

0

-0.2

-0.4

-0.6

-0.8

-1.0

LOAD REGULATION (%)

-1.2

0 100 200 500 700

FIGURE 13. V

LOGIC

400

300

I

(mA)

OUT

LOAD REGULATION

6

600

V

V

BOOST

V

LOGIC

CDLY

V

REF

TIME (10ms/DIV)

FIGURE 14. START-UP SEQUENCE

C

DLY

= 220nF

FN6501.0

May 30, 2007

ISL78010

Typical Performance Curves T

V

BOOST

V

LOGIC

V

OFF

C

V

ON

FIGURE 15. START-UP SEQUENCE

DLY

= 220nF

TIME (10ms/DIV)

= +25°C, unless otherwise specified. (Continued)

A

V

BOOST_DELAY

V

LOGIC

V

OFF

ON

C

V

FIGURE 16. START-UP SEQUENCE

DLY

= 220nF

TIME (10ms/DIV)

V

= 5V

IN

= 13V

V

OUT

= 30mA

I

OUT

TIME (400ns/DIV)

FIGURE 17. LX WAVEFORM - DISCONTINUOUS MODE

JEDEC JESD51-7 HIGH EFFECTIVE THERMAL

CONDUCTIVITY TEST BOARD

1.8

1.515W

1.5

(

5

T

1.2

0.9

0.6

POWER DISSIPATION (W)

0.3

0

0 25 75 100 125 15050

m

Q

m

θ

F

J

P

x

A

=

5

6

m

6

°

m

C

)

/

W

AMBIENT TEMPERATURE (°C)

FIGURE 19. PACKAGE POWER DISSIPA TION vs AMBIENT

TEMPERATURE

V

= 5V

IN

= 13V

V

OUT

= 200mA

I

OUT

TIME (400ns/DIV)

FIGURE 18. LX WAVEFORM - CONTINUOUS MODE

7

FN6501.0

May 30, 2007

ISL78010

Applications Information

The ISL78010 provide a highly integrated multiple output

power solution for TFT-LCD automotive applications. The

system consists of one high efficiency boost converter and

three linear-regulator controllers (V

with multiple protection functions. A block diagram is shown

in Figure 20. Table 1 lists the recommended components.

The ISL78010 integrates an N-Channel MOSFET boost

converter to minimize external component count and cost.

The A

VDD

, VON, V

OFF

, and V

LOGIC

independently set using external resistors. V

voltages require external charge pumps which are post

regulated using the integrated LDO controllers.

TABLE 1. RECOMMENDED TYPICAL APPLICATION

DIAGRAM COMPONENTS

DESIGNATION DESCRIPTION

C

D

11

, C2, C

1

C

, C

20

D

, D12, D

L

Q

Q

Q

Q

Q

1

1

1

2

3

4

5

10µF, 16V X7R ceramic capacitor (1206)

3

TDK C3216X7RIC106M

4.7µF, 25V X5R ceramic capacitor (1206)

31

TDK C3216X5R1A475K

1A, 20V low leakage Schottky rectifier (CASE

457-04) ON SEMI MBRM120ET3

200mA, 30V Schottky barrier diode (SOT-23)

21

Fairchild BAT54S

6.8µH, 1.3A Inductor

TDK SLF6025T-6R8M1R3-PF

-2.4, -20V P-Channel 1.8V specified

PowerTrench MOSFET (SuperSOT-3)

Fairchild FDN304P

200mA, 40V NPN amplifier (SOT-23)

Fairchild MMBT3904

200mA, 40V PNP amplifier (SOT-23)

Fairchild MMBT3906

-2A, -30V single P-Channel logic level

PowerTrench MOSFET (SuperSOT-3)

Fairchild FDN360P

1A, 30V PNP low saturation amplifier (SOT-23)

Fairchild FMMT549

, V

OFF

, and V

LOGIC

ON

output voltages are

, V

ON

OFF

)

Boost Converter

The main boost converter is a current mode PWM converter

at a fixed frequency of 1MHz, which enables the use of low

profile inductors and multi-layer ceramic capacitors. This

results in a compact, low cost power system for LCD panel

design.

The ISL78010 is designed for continuous current mode, but

it can also operate in discontinuous current mode at light

load. In continuous current mode, current flows continuously

in the inductor during the entire switching cycle in steady

state operation. The voltage conversion ratio in continuous

current mode is given by Equation 1:

A

VDD

--------------- -

V

IN

where D is the duty cycle of the switching MOSFET.

Figure 21 shows the block diagram of the boost regulator. It

uses a summing amplifier architecture consisting of GM

stages for voltage feedback, current feedback and slope

compensation. A comparator looks at the peak inductor

current cycle by cycle and terminates the PWM cycle if the

current limit is reached.

An external resistor divider is required to divide the output

voltage down to the nominal reference voltage. Current

drawn by the resistor network should be limited to maintain

the overall converter efficiency. The maximum value of the

resistor network is limited by the feedback input bias current

and the potential for noise being coupled into the feedback

pin. A resistor network in the order of 60kΩ is recommended.

The boost converter output voltage is determined by

Equation 2:

A

VDD

The current through the MOSFET is limited to 2A peak. This

restricts the maximum output current based on Equation 3:

I

OMAXILMT

Where ΔIL is peak to peak inductor ripple current, and is set

by Equation 4:

ΔI

1

-------------

=

1D–

R1R2+

---------------------

R

1

⎛⎞

–

⎝⎠

V

D

IN

---- -

---------

L

×=

L

f

S

×=

ΔI

--------

(EQ. 1)

V

REF

V

L

IN

---------

×=

2

V

O

(EQ. 2)

(EQ. 3)

(EQ. 4)

where f

8

is the switching frequency.

S

FN6501.0

May 30, 2007

ISL78010

VREF

SGND

FBB

CINT

VDD

PG

CDLY

DRVN

BUFFER

REFERENCE

GENERATOR

GM

AMPLIFIER

UVLO

COMPARATOR

THERMAL

SHUTDOWN

COMPENSATION

SS

+

-

SLOPE

VOLTAGE

AMPLIFIER

EN

SHUTDOWN

AND

START-UP

CONTROL

0.2V VREF

OSCILLATOR

OSC

COMP

Σ

COMPARATOR

PWM

LOGIC

CONTROLLER

CURRENT

AMPLIFIER

CURRENT

LIMIT COMPARATOR

UVLO

SS

VREF

+

-

BUFFER

CURRENT REF

+

-

EN

LX

PGND

DRVP

BUFFER

FBP

DELB

DRVL

BUFFER

FBN

0.4V

COMPARATOR

UVLO

FBL

UVLO

COMPARATOR

FIGURE 20. BLOCK DIAGRAM

9

FN6501.0

May 30, 2007

FBB

COMPENSATION

IFB

IREF

SLOPE

CURRENT

AMPLIFIER

GM

AMPLIFIER

ISL78010

CLOCK

PWM

LOGIC

SHUTDOWN

AND STARTUP

CONTROL

LX

BUFFER

IFB

IREF

VOLTAGE

AMPLIFIER

REFERENCE

GENERATOR

CINT

FIGURE 21. BLOCK DIAGRAM OF THE BOOST REGULATOR

PGND

10

FN6501.0

May 30, 2007

ISL78010

Table 2 gives typical values (margins are considered 10%,

3%, 20%, 10%, and 15%) on V

TABLE 2. TYPICAL VIN, VO, L, fS, AND I

(V) VO (V) L (µH)

V

IN

3.3 9 6.8 1 0.490686

3.3 12 6.8 1 0.307353

3.3 15 6.8 1 0.197353

5 9 6.8 1 0.743464

5 12 6.8 1 0.465686

5 15 6.8 1 0.29902

, VO, L, fS, and I

IN

OMAX

f

S

(MHz)

OMAX

VALUES

I

OMAX

(A)

:

Input Capacitor

An input capacitor is used to supply the peak charging

current to the converter. It is recommended that C

IN

be

larger than 10µF. The reflected ripple voltage will be smaller

with larger C

. The voltage rating of input capacitor should

IN

be larger than the maximum input voltage.

Boost Inductor

The boost inductor is a critical part which influences the

output voltage ripple, transient response, and efficiency.

Values of 3.3µH to 10µH are to match the internal slope

compensation. The inductor must be able to handle the

following average and peak current:

I

=

-------------

1D–

I

LAVG

I

LPKILAVG

O

ΔI

L

--------

+=

2

(EQ. 5)

(EQ. 6)

NOTE: Capacitors have a voltage coefficient that makes their

effective capacitance drop as the voltage across them increases.

C

in Equation 7 assumes the effective value of the capacitor at a

OUT

particular voltage and not the manufacturer’s stated value, measured

at zero volts.

Compensation

The ISL78010 can operate in either P-mode or PI-mode.

P-mode may be preferred in applications where excellent

transient load performance is required but regulation is not

critical. Connecting the C

pin directly to VIN will enable

INT

P-mode; For better load regulation, use PI-mode with a

4.7nF capacitor in series with a 10k resistor between C

INT

and ground. This value may be reduced to improve transient

performance, however, very low values will reduce loop

stability . Figures 5 through 10 show a comparison of P-mode

vs PI-mode performance.

Boost Feedback Resistors

As the boost output voltage, A

effective voltage feedback in the IC increases the ratio of

voltage to current feedback at the summing comparator

because R

decreases relative to R1. To maintain stable

2

operation over the complete current range of the IC, the

voltage feedback to the FBB pin should be reduced

proportionally, as A

is reduced, by means of a series

VDD

resistor-capacitor network (R

with a pole frequency (f

) set to approximately 10kHz for C2

p

(effective) = 10µF and 4kHz for C

1

⎛⎞

⎛⎞

--------------------- -

=

R

7

⎝⎠

⎝⎠

×

0.1 R

2

-------------------------------------------------

=

C

7

2 3.142 f

1

1

-------

–

R

1

×××

pR7

1–

, is reduced below 12V the

VDD

and C7) in parallel with R1,

7

(effective) = 30µF.

2

(EQ. 8)

(EQ. 9)

Rectifier Diode

A high-speed diode is necessary due to the high switching

frequency. Schottky diodes are recommended because of

their fast recovery time and low forward voltage. The rectifier

diode must meet the output current and peak inductor

current requirements.

Output Capacitor

The output capacitor supplies the load directly and reduces

the ripple voltage at the output. Output ripple voltage

consists of two components: the voltage drop due to the

inductor ripple current flowing through the ESR of output

capacitor, and the charging and discharging of the output

capacitor.

V

RIPPLEILPK

ESR

V

O

–

V

OVIN

----------------------- -

For low ESR ceramic capacitors, the output ripple is

dominated by the charging and discharging of the output

capacitor. The voltage rating of the output capacitor should

be greater than the maximum output voltage.

11

I

O

----------------

C

OUT

1

---- -

××+×=

f

S

(EQ. 7)

PI-Mode C

(C23) and R

INT

INT

(R10)

The IC is designed to operate with a minimum C23 capacitor

of 4.7nF and a minimum C

Note that, for high voltage A

ceramic capacitors (C

(effective) = 10µF.

2

, the voltage coefficient of

VDD

) reduces their effective capacitance

2

greatly; a 16V, 10µF ceramic can drop to around 3µF at 15V.

To improve the transient load response of A

a resistor may be added in series with the C

in PI-mode,

VDD

capacitor. The

23

larger the resistor the lower the overshoot but at the expense

of stability of the converter loop - especially at high currents.

With L = 10µH, A

should have a capacitance of greater than 10µF. R

can have values up to 5kΩ for C

up to 10k for C

Larger values of R

A

load currents less than the current limit are used. To

VDD

ensure A

stability, the IC should be operated at the

VDD

= 15V, C23 = 4.7nF, C2 (effective)

VDD

(effective) up to 20µF and

(effective) up to 30µF.

2

(R7) may be possible if maximum

INT

2

INT

(R7)

maximum desired current and then the transient load

response of A

maximum value of R

should be used to determine the

VDD

INT

.

FN6501.0

May 30, 2007

ISL78010

Operation of the DELB Output Function

An open drain DELB output is provided to allow the boost

output voltage, developed at C

(See “Typical Application

2

Diagram” on page 17), to be delayed via an external switch

(Q

) to a time after the V

4

supply and negative V

BOOST

OFF

charge pump supply have achieved regulation during the

start-up sequence shown in Figures 14 and 16. This then

allows the A

instead of the normal offset voltage of V

and VON supplies to start-up from 0V

VDD

IN-VDIODE (D1

) if Q4

were not present.

When DELB is activated by the start-up sequencer, it sinks

50µA allowing a controlled turn-on of Q

C

. C16 can be used to control the turn-on time of Q4 to

9

reduce inrush current into C

by R

and R8 can be used to limit the VGS voltage of Q4 if

9

. The potential divider formed

9

and charge-up of

4

required by the voltage rating of this device. When the

voltage at DELB falls to less than 0.6V, the sink current is

increased to ~1.2mA to firmly pull DELB to 0V.

The voltage at DELB is monitored by the fault protection

circuit so that if the initial 50µA sink current fails to pull DELB

below ~0.6V after the start-up sequencing has completed,

then a fault condition will be detected and a fault time-out

ramp will be initiated on the C

capacitor (C7).

DEL

Operation of the PG Output Function

The PG output consists of an internal pull -up PMOS device to

V

, to turn-off the external Q1 protection switch and a current

IN

limited pull-down NMOS device which sinks ~15µA allowing a

controlled turn-on of Q

control how fast Q

gate capacitance. CO is used to

1

turns-on - limiting inrush current into C1.

1

When the voltage at the PG pin falls to less than 0.6V, the PG

sink current is increased to ~1.2mA to firmly pull the pin to 0V.

The voltage at PG is monitored by the fault protection circuit

so that if the initial 15µA sink current fails to pull PG below

~0.6V after the start-up sequencing has completed, then a

fault condition will be detected and a fault time-out ramp will

be initiated on the C

capacitor (C7).

DEL

Cascaded MOSFET Application

A 20V N-Channel MOSFET is integrated in the boost

regulator. For the applications where the output voltage is

greater than 20V, an external cascaded MOSFET is needed

as shown in Figure 22. The voltage rating of the external

MOSFET should be greater than V

BOOST

.

V

IN

ISL78010

FIGURE 22. CASCADED MOSFET TOPOLOGY FOR HIGH

OUTPUT VOLTAGE APPLICATIONS

Linear-Regulator Controllers (VON, V

V

)

OFF

LX

FB

LOGIC

V

BOOST

, and

The ISL78010 includes three independent linear-regulator

controllers, in which two are positive output voltage (V

and V

V

LOGIC

), and one is negative. The VON, V

LOGIC

OFF

linear-regulator controller functional diagrams,

ON

, and

applications circuits are shown in Figures 23, 24, and 25

respectively.

Calculation of the Linear Regulator Base-Emitter

Resistors (R

For the pass transistor of the linear regulator, low frequency

gain (h

in the datasheet. The pass transistor adds a pole to the loop

transfer function at f

maintain phase margin at low frequency, the best choice for

a pass device is often a high frequency low gain switching

transistor. Further improvement can be obtained by adding a

base-emitter resistor R

Block Diagrams on page 13), which increase the pole

frequency to: f

re = KT/qIc. So choose the lowest value R

as long as there is still enough base current (I

the maximum output current (I

We will take as an example the V

Fairchild FMMT549 PNP transistor is used as the external

pass transistor (Q

maximum V

sheet indicates h

The base-emitter saturation voltage is: Vbe_max = 1.25V

(note this is normally a Vbe ~ 0.7V, however, for the Q

transistor an internal Darlington arrangement is used to

increase it's current gain, giving a 'base-emitter' voltage of

2xV

(Note that using a high current Darlington PNP transistor for

Q

voltage be required, then an ordinary high gain PNP

transistor should be selected for Q

collector-emitter saturation voltage).

) and unity gain frequency (fT) are usually specified

FE

).

BE

requires that VIN > V

5

, RBP and RBN)

BL

p=fT/hFE

*(1+ hFE *re/RBE)/hFE, where

p=fT

in the application diagram) then for a

5

operating requirement of 500mA, the data

LOGIC

(min) = 100.

FE

. Therefore, in order to

(RBP, RBL, RBN in the Functional

BE

in the design

BE

).

C

linear regulator. If a

LOGIC

+ 2V. Should a lower input

LOGIC

so as to allow a lower

5

) to support

B

5

12

FN6501.0

May 30, 2007

ISL78010

For the ISL78010, the minimum drive current is:

I

min()8mA=

DRVL

The minimum base-emitter resistor, R

, can now be

BL

(EQ. 10)

calculated as:

R

min()VBEmax()I

BL

1.25V 8mA 500mA 100⁄–()⁄ 417Ω=

DRVL

min()IChFEmin()⁄–() =⁄=

(EQ. 11)

This is the minimum value that can be used - so, we now

choose a convenient value greater than this minimum value;

say 500Ω. Larger values may be used to reduce quiescent

current, however, regulation may be adversely affected, by

supply noise if R

0.9V

PG_LDOP

+

-

GMP

FIGURE 23. VON FUNCTIONAL BLOCK DIAGRAM

is made too high in value.

BL

LDO_ON

1: Np

36V

ESD

CLAMP

DRVP

FBP

+

R

BP

7kΩ

V

R

P1

R

P2

20kΩ

BOOST

Q3

LX

0.1µF

CP (TO 36V)

0.1µF

VON (TO 35V)

C

ON

OR V

V

IN

PROT

(3V TO 6V)

0.9V

PG_LDOL

FIGURE 25. V

-

+

GML

LDO_LOG

R

+

-

1: N1

FUNCTIONAL BLOCK DIAGRAM

LOGIC

500Ω

DRVL

FBL

BL

R

R

20kΩ

L1

L2

Q5

V

LOGIC

(1.3V TO 3.6V)

C

LOG

10µF

The VON power supply is used to power the positive supply

of the row driver in the LCD panel. The DC/DC consists of an

external diode-capacitor charge pump powered from the

inductor (LX) of the boost converter, followed by a low

dropout linear regulator (LDO_ON). The LDO_ON regulator

uses an external PNP transistor as the pass element. The

on-board LDO controller is a wide band (>10MHz)

transconductance amplifier capable of 4mA drive current,

which is sufficient for up to 40mA or more output current

under the low dropout condition (forced beta of 10). Typical

V

voltage supported by the ISL78010 ranges from +15V

ON

to +36V. A fault comparator is also included for monitoring

the output voltage. The undervoltage threshold is set at 25%

below the 1.2V reference.

PG_LDON

0.4V

FIGURE 24. V

-

+

GMN

-

+

CLAMP

36V

ESD

LDO_OFF

FBN

1: Nn

DRVN

R

BN

3kΩ

FUNCTIONAL BLOCK DIAGRAM

OFF

R

20kΩ

R

V

N2

N1

13

REF

Q2

0.1µF

CP (TO -26V)

V

OFF

LX

0.1µF

(TO -20V)

C

OFF

The V

power supply is used to power the negative

OFF

supply of the row driver in the LCD panel. The DC/DC

consists of an external diode-capacitor charge pump

powered from the inductor (LX) of the boost converter,

followed by a low dropout linear regulator (LDO_OFF). The

LDO_OFF regulator uses an externa l NPN tran si sto r as th e

pass element. The on-board LDO controller is a wide band

(>10MHz) transconductance amplifier capable of 4mA drive

current, which is sufficient for up to 40mA or more output

current under the low dropout condition (forced beta of 10).

Typical V

voltage supported by the ISL78010 ranges

OFF

from -5V to -20V. A fault comparator is also included for

monitoring the output voltage. The undervoltage threshold is

set at 200mV above the 0.2V reference level.

The V

power supply is used to power the logic circuitry

LOGIC

within the LCD panel. The DC/DC may be powered directly

from the low voltage input, 3.3V or 5.0V, or it may be

powered through the fault protection switch. The

LDO_LOGIC regulator uses an external PNP transistor as

the pass element. The on-board LDO controller is a wide

band (>10MHz) transconductance amplifier capable of

16mA drive current, which is sufficient for up to 160mA or

FN6501.0

May 30, 2007

)

ISL78010

more output current under the low dropout condition (forced

beta of 10). Typical V

ISL78010 ranges from +1.3V to V

voltage supported by the

LOGIC

- 0.2V. A fault

DD

comparator is also included for monitoring the output

voltage. The undervoltage threshold is set at 25% below the

1.2V reference.

Set-Up Output Voltage

Refer to the “Typical Application Diagram” on page 17, the

output voltages of V

ON

, V

OFF

, and V

are determined

LOGIC

by Equations 12, 13 and 14:

V

ONVREF

V

OFFVREFN

V

LOGICVREF

where V

REF

12

--------- -

1

+

×=

⎜⎟

R

⎝⎠

11

R

22

----------

V

R

21

R

⎛⎞

42

----------

1

+

×=

⎜⎟

R

⎝⎠

41

= 1.2V, V

REFN

–()×+=

REFNVREF

= 0.2V.

(EQ. 12)

(EQ. 13)

(EQ. 14)

R

⎛⎞

Resistor networks in the order of 250kΩ, 120kΩ and 10kΩ

are recommended for V

ON

, V

OFF

and V

LOGIC

, respectively.

Charge Pump

T o generate an output voltage higher than V

multiple stages of charge pumps are needed. The number of

stages is determined by the input and output voltage. For

positive charge pump stages:

N

POSITIVE

where V

V

OUTVCEVINPUT

--------------------------------------------------------------

≥

V

INPUT

is the dropout voltage of the pass component of

CE

–+

2V

×–

F

the linear regulator. It ranges from 0.3V to 1V depending on

the transistor. V

is the forward-voltage of the charge pump

F

rectifier diode.

The number of negative charge pump stages is given by:

N

NEGATIVE

V

OUTPUTVCE

-------------------------------------------------

≥

V

INPUT

+

2V

×–

F

To achieve high efficiency and low material cost, the lowest

number of charge pump stages which can meet the above

requirements, is always preferred.

BOOST

, single or

(EQ. 15

(EQ. 16)

High Charge Pump Output Vo ltage (>36V)

Applications

In the applications where the charge pump output voltage is

over 36V, an external NPN transistor needs to be inserted

between DRVP pin and base of pass transistor Q

in Figure 26; or the linear regulator can control only one

stage charge pump and regulate the final charge pump

output as shown in Figure 27.

as shown

3

CHARGE PUMP

V

IN

Q3

VDD

NPN

0.1µF

OUTPUT

7kΩ

Q3

0.1µF 0.1µF

0.1µF

LX

A

VDD

V

ON

V

(>36V)

0.22µF

OR A

DRVP

ISL78010

FIGURE 26. CASCODE NPN TRANSISTOR CONFIGURATION

FOR HIGH CHARGE PUMP OUTPUT VOLTAGE

(>36V)

0.1µF

DRVP

ISL78010

FBP

FIGURE 27. THE LINEAR REGULATOR CONTROLS ONE

STAGE OF CHARGE PUMP

FBP

7kΩ

0.47µF

CASCODE

TRANSISTOR

Discontinuous/Continuous Boost Operation and

its Effect on the Charge Pumps

The ISL78010 VON and V

switching edges to drive diode charge pumps from which

LDO regulators generate the V

be appreciated that should a regular supply of LX switching

edges be interrupted, for example, during discontinuous

operation at light A

VDD

affect the performance of V

depending on their exact loading conditions at the time.

To optimize V

ON/VOFF

discontinuous/continuous operation of the boost converter

can be adjusted, by suitable choice of inductor given V

V

, switching frequency and the A

OUT

be in continuous operation.

architecture uses LX

OFF

ON

and V

supplies. It can

OFF

boost load currents, then this may

ON

and V

regulation -

OFF

regulation, the boundary of

current loading, to

VDD

IN

,

ON

14

FN6501.0

May 30, 2007

ISL78010

Equation 17 gives the boundary between discontinuous and

continuous boost operation. For continuous operation (LX

switching every clock cycle) we require that:

I

load()D1D–()× VIN×>

AVDD

---------------------------------------------------------------------------------------

2Lf

××

OSC

where the duty cycle, D = (A

For example, with V

IN

= 5V , f

- VIN)/A

VDD

= 1.0MHz and A

OSC

VDD

VDD

(EQ. 17)

= 12V

we find continuous operation of the boost converter can be

guaranteed for:

L10μ H and I

L6.8μ H and I

L3.3μ H and I

AVDD

AVDD

AVDD

61mA>=

89mA>=

184mA>=

(EQ. 18)

(EQ. 19)

(EQ. 20)

Charge Pump Output Capacitors

Ceramic capacitors with low ESR are recommended. With

ceramic capacitors, the output ripple voltage is dominated by

the capacitance value. The capacitance value can be

chosen by Equation 21:

I

C

OUT

where f

OUT

------------------------------------------------------

≥

2V

RIPPLEfOSC

is the switching frequency.

OSC

××

(EQ. 21)

Start-Up Sequence

Figure 28 shows a detailed start-up sequence waveform. For

a successful power up, there should be six peaks at V

When a fault is detected, the device will latch off until either

EN is toggled or the input supply is recycled.

When the input voltage is higher than 2.5V, an internal

current source starts to charge C

to an upper threshold

CDLY

using a fast ramp followed by a slow ramp. During the initial

slow ramp, the device checks whether there is a fault

condition. If no fault is found, C

first peak and V

REF

turns on.

is discharged after the

CDLY

During the second ramp, the device checks the status of

V

and over-temperature. At the peak of the second

REF

ramp, PG output goes low and enables the input protection

PMOS Q

current into V

Its rate of turn on is controlled by C

. Q1 is a controlled FET used to prevent in-rush

1

BOOST

before V

is enabled internally.

BOOST

. When a fault is

o

detected, M1 will turn off and disconnect the inductor from

V

.

IN

With the input protection FET on, NODE1 (See “Typical

Application Diagram” on page 17) will rise to ~V

the boost is not enabled so V

BOOST

rises to VIN-V

through the output diode. Hence, there is a step at V

during this part of the start-up sequence. If this step is not

desirable, an external P-MOSFET can be used to delay the

. Initially

IN

DIODE

CDLY

BOOST

output until the boost is enabled internally. The delayed

output appears at A

V

soft-starts at the beginning of the third ramp. The

BOOST

soft-start ramp depends on the value of the C

For C

V

REF

of 220nF, the soft-start time is ~2ms.

DLY

and V

LOGIC

.

VDD

capacitor.

DLY

turn on when input voltage (VDD)

exceeds 2.5V. When a fault is detected, the outputs and the

input protection will turn off but V

V

turns on at the start of the fourth peak. At the fifth

OFF

will stay on.

REF

peak, the open drain o/p DELB goes low to turn on the

external PMOS Q

VON is enabled at the beginning of the sixth ramp. A

PG, V

, DELB and VON are checked at end of this ramp.

OFF

to generate a delayed V

4

BOOST

output.

VDD

,

Fault Protection

Once the start-up sequence is complete, the voltage on the

C

capacitor remains at 1.15V until either a fault is

DLY

detected or the EN pin is disabled. If a fault is detected, the

voltage on C

rises to 2.4V at which point the chip is

DLY

disabled until the power is recycled or enable is toggled.

Component Selection for Start- Up Sequencing and

Fault Protection

The C

to stabilize the V

22nF to 1µF and should not be more than five times the

capacitor on C

The C

.

range from 47nF minimum to several microfarads - only

limited by the leakage in the capacitor reaching µA levels.

C

DEL

above). Note that with 220nF on C

be typically 50ms and the use of a larger/smaller value will

vary this time proportionally (e.g. 1µF will give a fault timeout period of typically 230ms).

capacitor is typically set at 220nF and is required

REF

capacitor is typically 220nF and has a usable

DEL

should be at least 1/5 of the value of C

output. The range of C

REF

to ensure correct start-up operation.

DEL

DEL

REF

REF

the fault time-out will

is from

(See

Fault Sequencing

The ISL78010 has advanced fault detection systems which

protects the IC from both adjacent pin shorts during

operation and shorts on the output supplies.

A high quality layout/design of the PCB, in respect of

grounding quality and decoupling is necessary to avoid

falsely triggering the fault detection scheme - especially

during start-up. The user is directed to the “Layout

Recommendation” on page 17 and “Component Selection

for Start-Up Sequencing and Fault Protection” on page 15 to

avoid problems during initial evaluation and prototype PCB

generation.

15

FN6501.0

May 30, 2007

ON

ISL78010

V

V

BOOST

V

LOGIC

CDLY

V

EN

V

REF

LOGIC

, V

REF

V

IN

t

ON

PG ON

SOFT-START

VDD

A

ON

OFF

V

t

OS

SOFT-START

DELB ON

V

ON

FAULT DETECTED

CHIP DISABLED

V

OFF

DELAYED

V

BOOST

V

ON

t

DEL1

t

t

DEL3

START-UP SEQUENCE

TIMED BY C

DLY

DEL2

FIGURE 28. START-UP SEQUENCE

NORMAL

OPERATION

FAULT

PRESENT

16

FN6501.0

May 30, 2007

ISL78010

Over-Temperature Protection

An internal temperature sensor continuously monitors the

die temperature. In the event that the die temperature

exceeds the thermal trip point of +140°C, the device will shut

down.

Layout Recommendation

Device performance including efficiency, output noise,

transient response and control loop stability is dramatically

affected by the PCB layout. PCB layout is critical, especially

at high switching frequency.

There are some general guidelines for layout:

1. Place the external power components (the input

capacitors, output capacitors, boost inductor and output

diodes, etc.) in close proximity to the device. Traces to

these components should be kept as short and wide as

possible to minimize parasitic inductance and resistance.

2. Place V

and VDD bypass capacitors close to the pins.

REF

3. Minimize the length of traces carrying fast signals and

high current.

Typical Application Diagram

L

SGND

1

6.8µH

LX

FBB

DELB

CINT

DRVP

FBP

DRVN

FBN

PGND

V

IN

C

10

4.7µF

NODE 1

V

LOGIC

(2.5V)

C

4.7µF

Q

1

1nF

R

C64.7µF

R

C

0.1µF

41

R

43

500Ω

Q

5

31

*

5.4kΩ

NODE 1

C

C

0

1

10µF

x2

PG

C

7

0.22µF

10Ω

6

10kΩ

7

V

REF

C

22

0.1µF

R

42

R

41

5kΩ

CDELAY

VDD

EN

VREF

*

DRVL

FBL

R

10

10kΩ

V

4. All feedback networks should sense the output voltage

directly from the point of load, and be as far away from LX

node as possible.

5. The power ground (PGND) and signal ground (SGND)

pins should be connected at only one point near the main

decoupling capacitors.

6. A signal ground plane, separate from the power ground

plane, should be used for ground return connections for

feedback resistor networks (R

capacitor, C22, the C

DELAY

, R11, R41) and the V

1

capacitor C7 and the

integrator capacitor C23.

7. Minimize feedback input track lengths to avoid switching

noise pick-up.

8. Connect all "NC" pins to the ground plane to improve the

thermal performance and switching noise immunity

between pins.

A demo board is available to illustrate the proper layout

implementation.

LX

D

R

REF

C

23

C

R

12

R

20kΩ

22

R

20k

1

46.5kΩ

R

5kΩ

4.7nF

1nF

P

R

13

7kΩ

230kΩ

11

R

23

3kΩ

104k

21

R

C

2-C3

OPEN

14

C

25

0.1µF D

9

1MΩ

C

0.1µF

12

21

R

2

10µF

X2

Q

Q

3

C

15

0.47µF

*

2

C

20

4.7µF

*

R7 OPEN

C

7

C

0.1µF

1

Q

4

C

16

22nF

LX

13

C

12

0.1µFD

C

24

0.1µF

R

8

10kΩ

D

LX

C

0.1µF

C

0.1µF

11

9

11

(15V)

*

V

A

(12V)

V

ON

OFF

(-5V)

VDD

REF

NOTE: SGND should be connected to PGND at one point only.

17

FN6501.0

May 30, 2007

ISL78010

Thin Plastic Quad Flatpack Packages (TQFP)

D

D1

-D-

-B-

e

A

C

M

0.09/0.16

0.004/0.006

BASE METAL

WITH PLATING

SEATING

PLANE

0.08

0.003

-C-

A-B

S

D

S

b

b1

0.09/0.20

0.004/0.008

E

E1

GAGE

PLANE

0o-7

-A-

PIN 1

-H-

0.08

0.003

o

0.020

MIN

0.008

0o MIN

L

0.25

o

0.010

11o-13

11o-13

A2

A1

o

Q32.5x5 (JEDEC MS-026AAA ISSUE B)

32 LEAD THIN PLASTIC QUAD FLATPACK PACKAGE

MILLIMETERS

SYMBOL

A - 1.20 -

A1 0.05 0.15 -

A2 0.95 1.05 -

b 0.17 0.27 6

b1 0.17 0.23 -

D 6.90 7.10 3

D1 4.90 5.10 4, 5

E 6.90 7.10 3

E1 4.90 5.10 4, 5

L 0.45 0.75 -

N327

e0.50 BSC-

NOTES:

1. Controlling dimension: MILLIMETER. Converted inch

dimensions are not necessarily exact.

2. All dimensions and tolerances per ANSI Y14.5M-1982.

3. Dimensions D and E to be determined at seating plane .

4. Dimensions D1 and E1 to be determined at datum plane .

5. Dimensions D1 and E1 do not include mold protrusion. Allowable

protrusion is 0.25mm (0.010 inch) per side.

6. Dimension b does not include dambar protrusion. Allowable dambar protrusion shall not cause the lead width to exceed the maximum b dimension by more than 0.08mm (0.003 inch).

7. “N” is the number of terminal positions.

NOTESMIN MAX

Rev. 0 2/07

-C-

-H-

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implicat ion or oth erwise u nde r any p a tent or p at ent r ights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

18

FN6501.0

May 30, 2007

Loading...

Loading...