®

www.BDTIC.com/Intersil

ISL6740, ISL6741

Data Sheet July 13, 2007

Flexible Double Ended Voltage and

Current Mode PWM Controllers

The ISL6740, ISL6741 family of adjustable frequency, low

power, pulse width modulating (PWM) voltage mode

(ISL6740) and current mode (ISL6741) controllers is

designed for a wide range of power conversion applications

using half-bridge, full bridge, and push-pull configurations.

These controllers provide an extremely flexible oscillator that

allows precise control of frequency, duty cycle , an d

deadtime.

This advanced BiCMOS design features low operating

current, adjustable switching frequency up to 1MHz,

adjustable soft-start, internal and external over-temperature

protection, fault annunciation, and a bidirectional SYNC

signal that allows the oscillator to be locked to paralleled

units or to an external clock for noise sensitive applications.

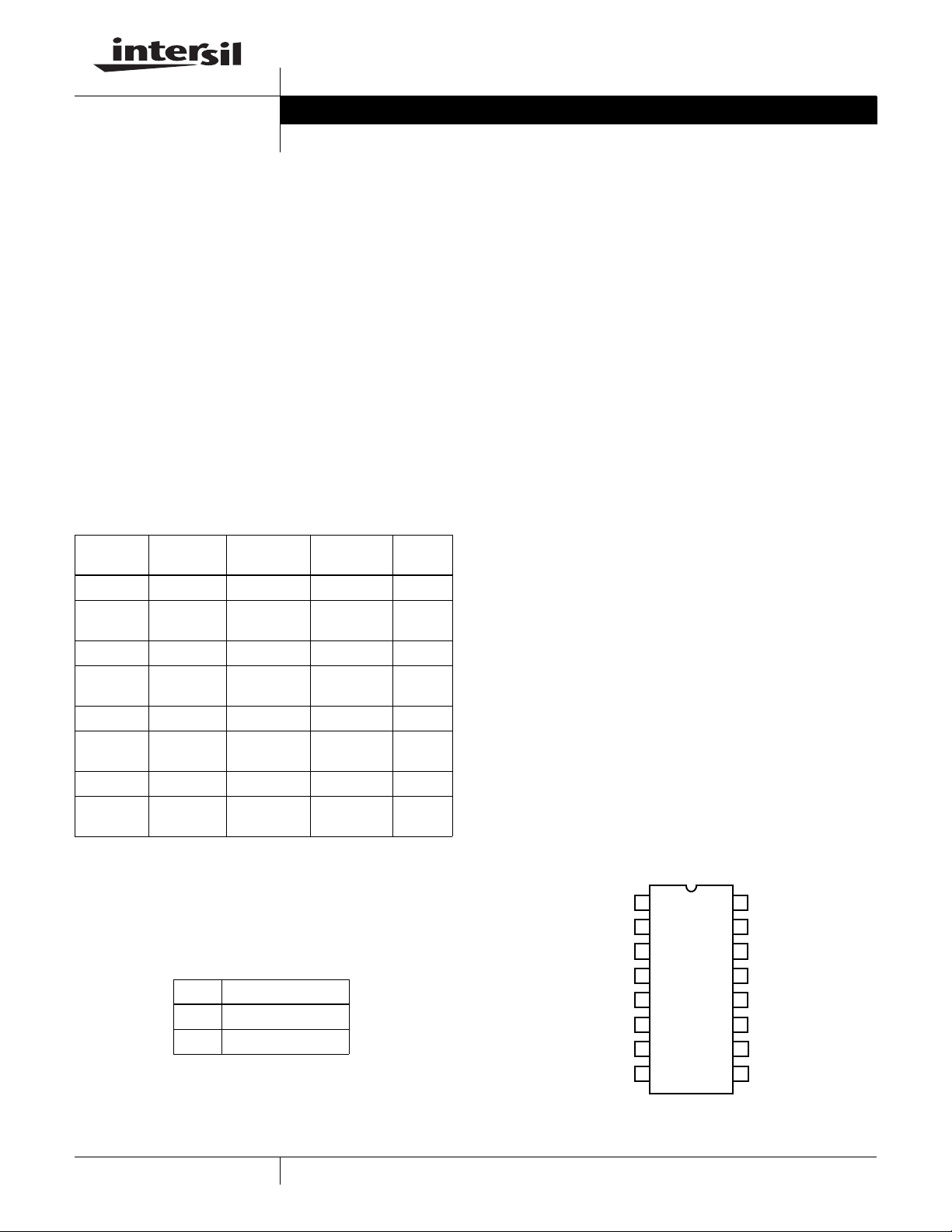

Ordering Information

PART

NUMBER

ISL6740IB ISL6740IB -40 to +105 16 Ld SOIC M16.15

ISL6740IBZ

(See Note)

ISL6740IV ISL67 40IV -40 to +105 16 Ld TSSOP M16.173

ISL6740IVZ

(See Note)

ISL6741IB ISL6741IB -40 to +105 16 Ld SOIC M16.15

ISL6741IBZ

(See Note)

ISL6741IV ISL67 41IV -40 to +105 16 Ld TSSOP M16.173

ISL6741IVZ

(See Note)

Add -T suffix to part number for tape and reel packaging

NOTE: Intersil Pb-free plus anneal products employ special Pb-free

material sets; molding compounds/die attach materials and 100%

matte tin plate termination finish, which are RoHS compliant and

compatible with both SnPb and Pb-free soldering operations. Intersil

Pb-free products are MSL classified at Pb-free peak reflow

temperatures that meet or exceed the Pb-free requirements of

IPC/JEDEC J STD-020.

PART

MARKING

6740IBZ -40 to +105 16 Ld SOIC

ISL67 40IVZ -40 to +105 16 Ld TSSOP

6741IBZ -40 to +105 16 Ld SOIC

ISL67 41IVZ -40 to +105 16 Ld TSSOP

x =CONTROL MODE

0 Voltage Mode

1 Current Mode

TEMP.

RANGE (°C) PACKAGE

(Pb-free)

(Pb-free)

(Pb-free)

(Pb-free)

PKG.

DWG. #

M16.15

M16.173

M16.15

M16.173

FN9111.4

Features

• Precision Duty Cycle and Deadtime Control

•95μA Startup Current

• Adjustable Delayed Overcurrent Shutdown and Re-start

(ISL6740)

• Adjustable Short Circuit Shutdown and Re-start

• Adjustable Oscillator Frequency Up to 2MHz

• Bidirectional Synchronization

• Inhibit Signal

• Internal Over-Temperature Protection

• System Over-Temperature Protection Using a Thermistor

or Sensor

• Adjustable Soft-start

• Adjustable Input Undervoltage Lockout

• Fault Signal

• Tight Tolerance Voltage Reference Over Line, Load, and

Temperature

• Pb-Free Plus Anneal Available (RoHS Compliant)

Applications

• Telecom and Datacom Power

• Wireless Base Station Power

• File Server Power

• Industrial Power Systems

• DC Transformers and Buss Regulators

Pinout

ISL6740, ISL6741

(16 LD SOIC, 16 LD TSSOP)

TOP VIEW

OUTA

SCSET

SYNC

V

ERROR

GND

C

CS

1

2

3

4

T

5

6

7

89UV

16

15

14

13

12

11

10

OUTB

V

REF

V

DD

R

TD

R

TC

OTS

FAULT

SS

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright Intersil Americas Inc. 2003, 2004, 2007. All Rights Reserved

All other trademarks mentioned are the property of their respective owners.

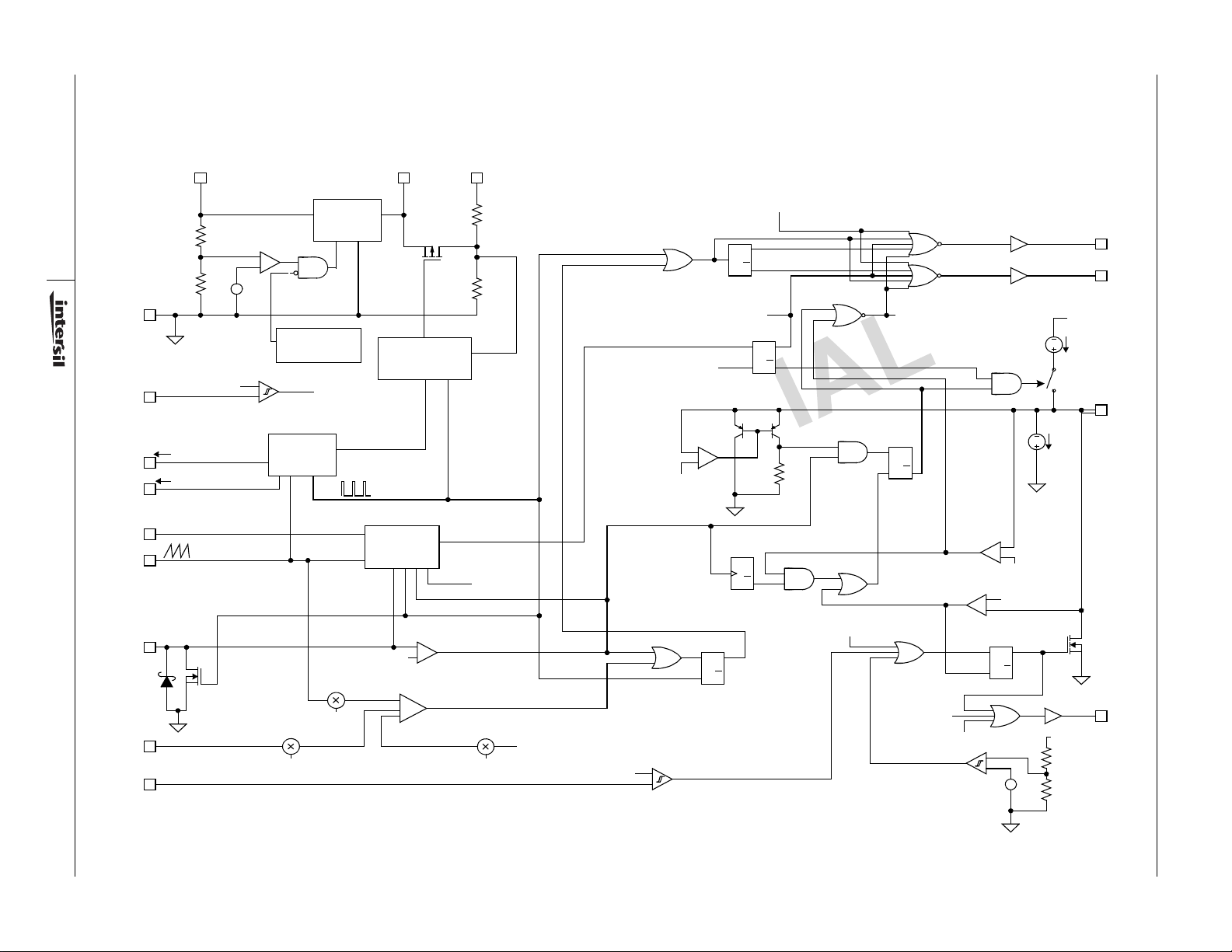

Functional Block Diagram

T

www.BDTIC.com/Intersil

ISL6740

VDD

VREF

5.00 V

1%

2

+-BG

GND

INHIBIT/VIN UV

UV

RTC

RTD

SCSET

CT

CS

VERROR

OTS

July 13, 2007

FN9111.4

1.00V

IRTC

IRTD

ENABLE

+

-

INTERNAL

OT SHUTDOWN

+130°C TO +150°C

+

-

OSCILLATOR

0.4

INHIBIT

CLK

0.4

VREF

N_SYNC OUT

BI-DIRECTIONAL

SYNCHRONIZATION

EXT. SYNC

SHORT CIRCUIT

DETECTION

+

-

0.6V

+

-

-

SYNC

100

4.5k

OC DETECT

PWM

COMPARATOR

SYNC IN

SS DONE

0.5

FL

V

REF

70µA

OUTA

OUTB

ISL6740, 1SL6741

SS

FAUL

Q

T

Q

PWM TOGGLE

SC S/D

SRQ

SS LOW

+

4.5V

SS CLAMP

RETRIGGERABLE

SRQ

Q

PWM LATCH

RESET

DOMINANT

SS

VREF/2

+

Q

SC LATCH

SS DONE

300k

Q

Q

50µS

ONE SHOT

INHIBIT

OC S/D

OC LATCH

SRQ

Q

VREF UV 4.65V

SS LOW

SC S/D

SS HI

FAULT LATCH

SET DOMINANT

OC S/D

ON

15µA

+

-

4.25V

0.27V

+

-

SRQ

FL

Q

V

REF

-

+

+

BG

-

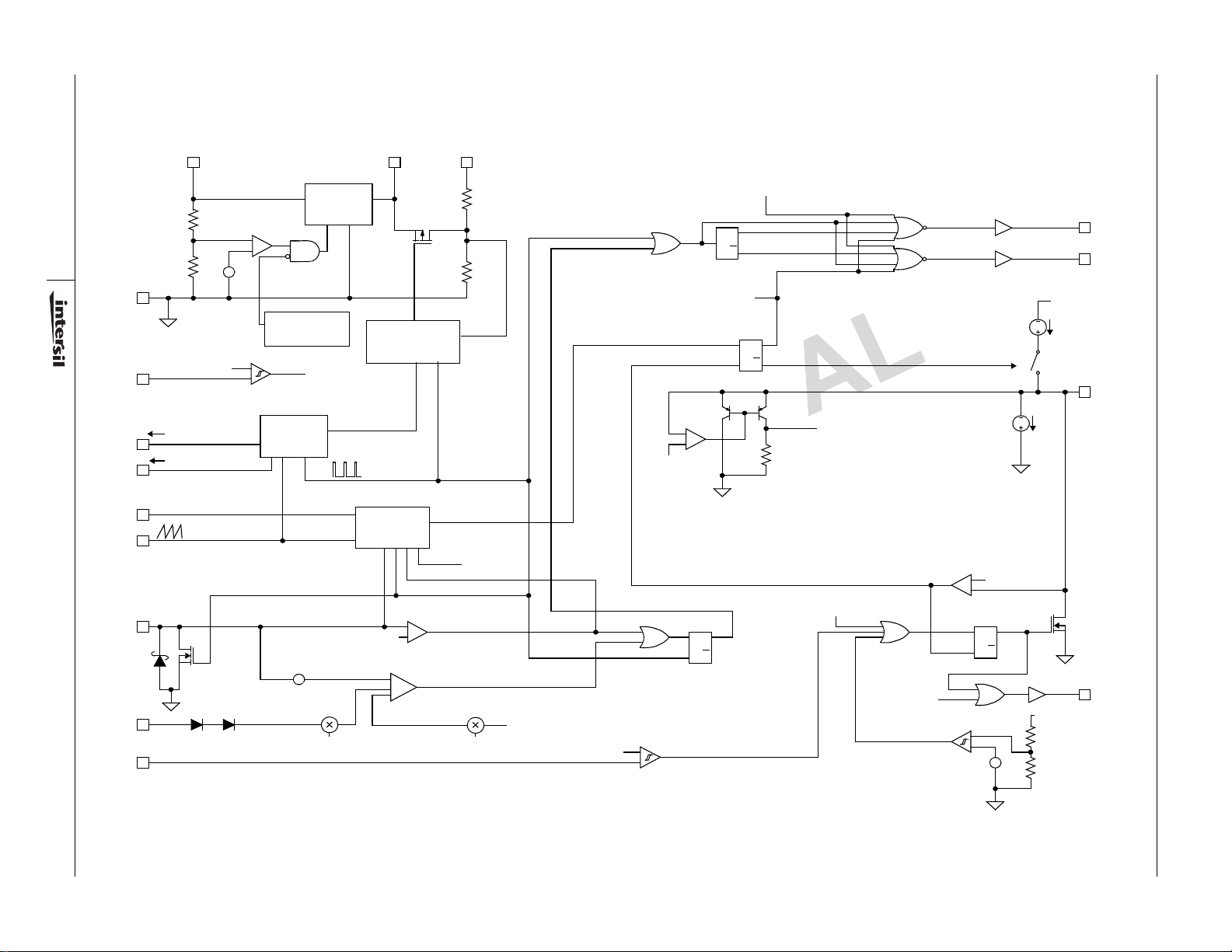

Functional Block Diagram (Continued)

www.BDTIC.com/Intersil

VDD

VREF

ISL6741

SYNC

Q

T

Q

SC S/D

SC LATCH

300k

SRQ

FL

OUTA

OUTB

V

REF

70µA

SRQ

BG

ON

SS

15µA

0.27VSS LOW

FL

Q

FAULT

V

REF

+

-

ISL6740, 1SL6741

Q

SS DONE

+

-

INHIBIT

SC S/D

VREF UV 4.65V

FAULT LATCH

SET DOMINANT

-

+

VREF

5.00 V

1%

ENABLE

+

3

GND

UV

RTC

RTD

SCSET

CT

CS

VERROR

OTS

1.00 V

IRTC

IRTD

BG

+

-

-

INTERNAL

OT SHUTDOWN

+130°C TO +150°C

INHIBIT/VIN UV

+

-

OSCILLATOR

80mV

-

+

INHIBIT

CLK

0.25

N_SYNC OUT

BI-DIRECTIONAL

SYNCHRONIZATION

EXT. SYNC

SHORT CIRCUIT

DETECTION

0.6V

+

-

-

100

4.5k

OC DETECT

+

-

PWM

COMPARATOR

SYNC IN

SS DONE

0.2

PWM TOGGLE

+

4.5V

SS CLAMP

SRQ

Q

PWM LATCH

RESET

DOMINANT

SS

VREF/2

+

July 13, 2007

FN9111.4

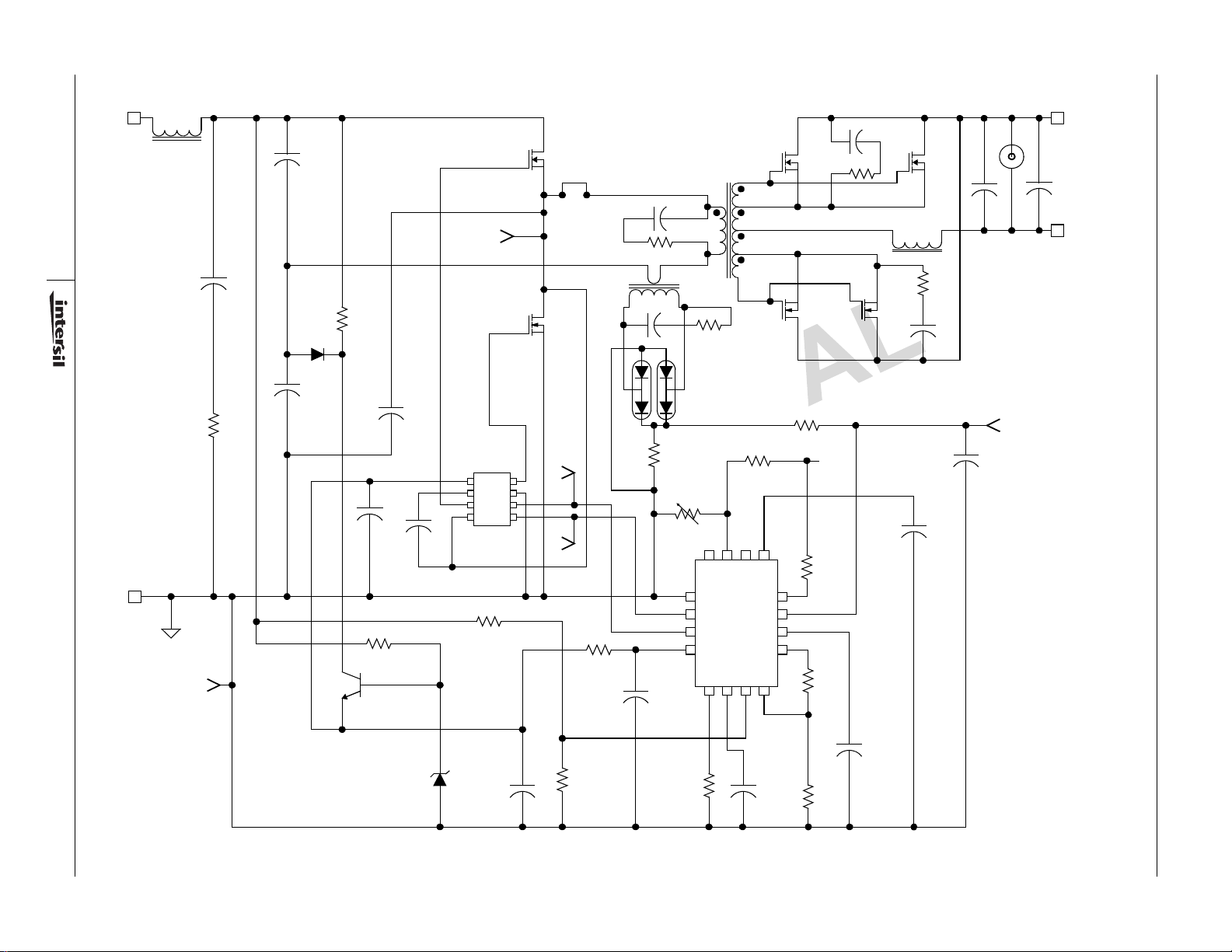

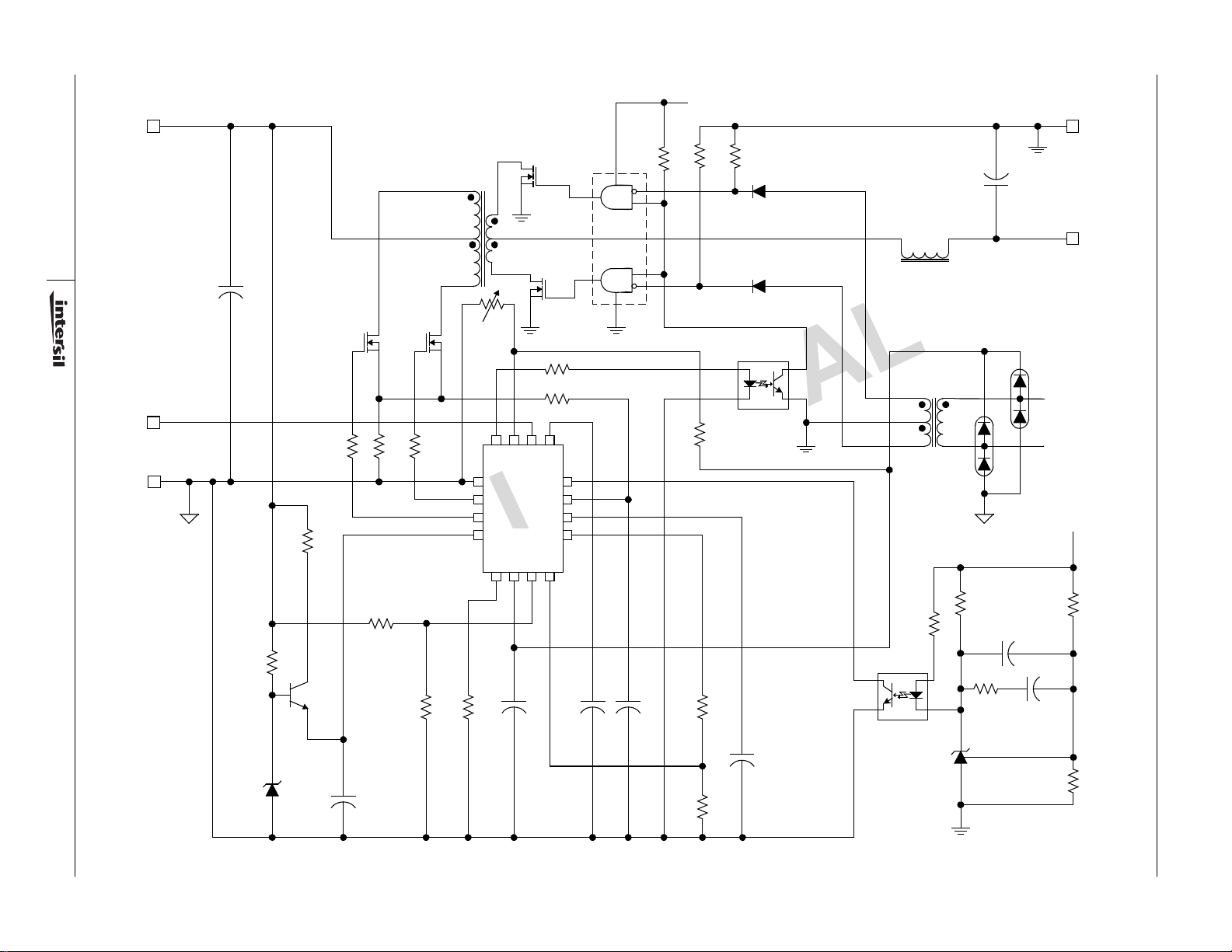

Typical Application (ISL6740) - 48V Input DC Transformer, 12V @ 8A Output (ISL6740EVAL1)

www.BDTIC.com/Intersil

VIN+

L1

C2

4

C1

TP1

QH

L3

C13

R10

T2

T1

QR1

SP1

C11

QR3

R8

C9

L2

R9

+12V

C8

RTN

VIN-

R1

TP6

CR3

C3

QR4

C12

ISL6740, 1SL6741

TP2

C10

C18

RTD

OTS

VERROR

ISL6740

VREF

SYNC

R14

UV

QR2

RTC

R6

V

REF

SS

CS

CT

SCSET

R19

R13

U1

U1

HIP2101

VDD

LO

VSS

HB

HO

HS

R17

QL

C14

CR1

TP4

LI

HI

TP5

R3

C15

R11

CR2

R5

RT1

FAULT

U3

GND

OUTB

OUTA

V

DD

R2

C7

C4

C5

R7

Q5

D1

July 13, 2007

FN9111.4

C6

R18

R12

C16

C17

R15

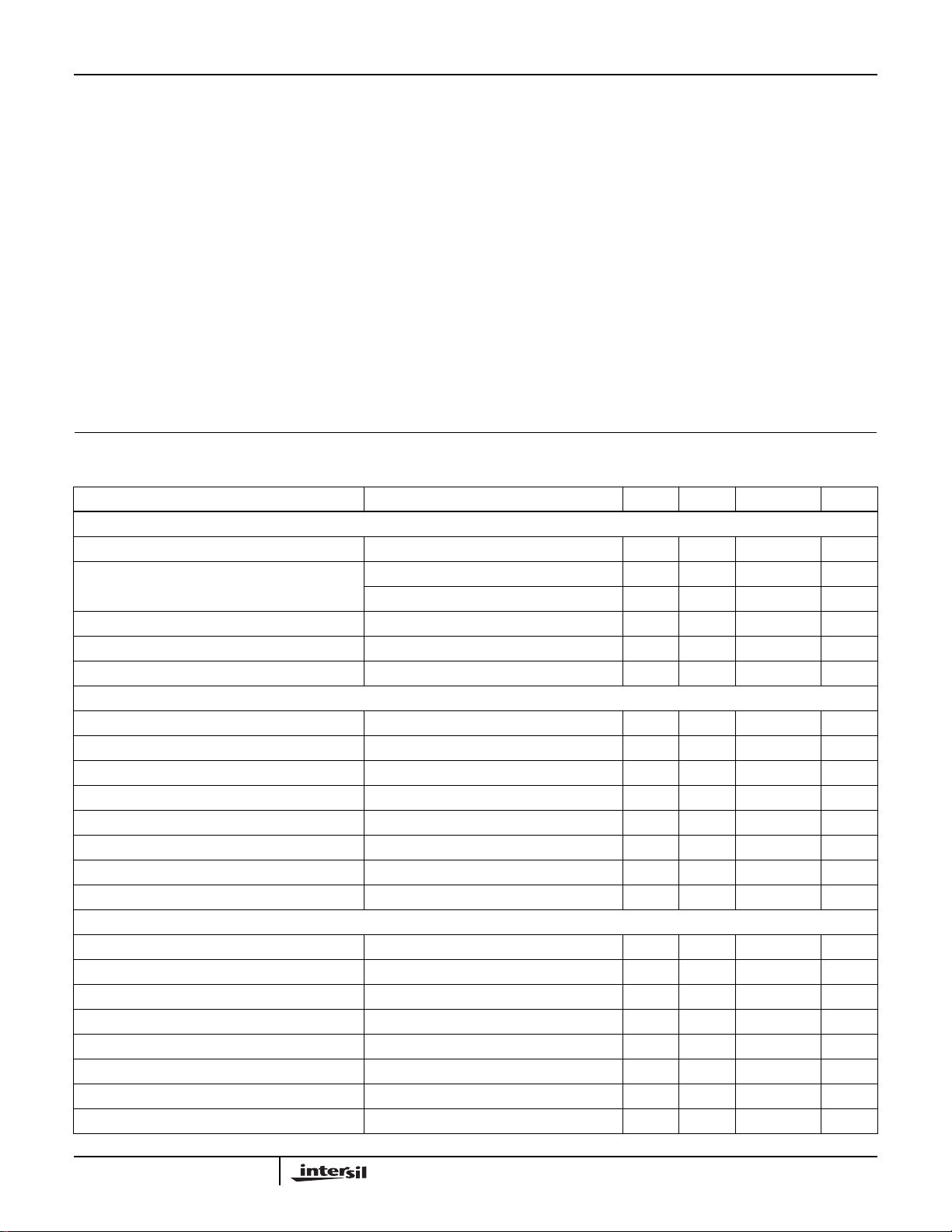

Typical Application (ISL6740) - 36V to 75V Input, Regulated 12V @ 8A Output (ISL6740EVAL2Z)

www.BDTIC.com/Intersil

VIN+

L1

C2

5

36V TO 75V

VIN-

C1

R1

TP6

R2

CR3

C3

C7

C4

C5

R7

Q5

D1

TP1

U1

HIP2101

VDD

HB

VSS

HO

HS

R17

C6

LO

QH

L3

C13

R10

T2

QL

C14

CR1

TP4

LI

HI

TP5

R3

C15

R18

CR5

CR6

R11

CR2

R5

RT1

FAULT

U3

GND

OUTB

OUTA

VDD

RTD

R12

T1

OTS

VERROR

ISL6740

VREF

SYNC

R14

UV

C16

RTC

R27

CS

CT

SS

SCSET

R26

QR1

R6

QR2

V

R19

R13

C17

R15

R8

CR4

REF

C11

QR4

C18

SP1

QR3

+

C9

L2

R9

C12

+12V

C21

C8

RTN

ISL6740, 1SL6741

TP2

C10

R19

R25

U2

D2

R20

C20

R21

U4

R23

+ 12V

R4

C22

C19

R24

July 13, 2007

FN9111.4

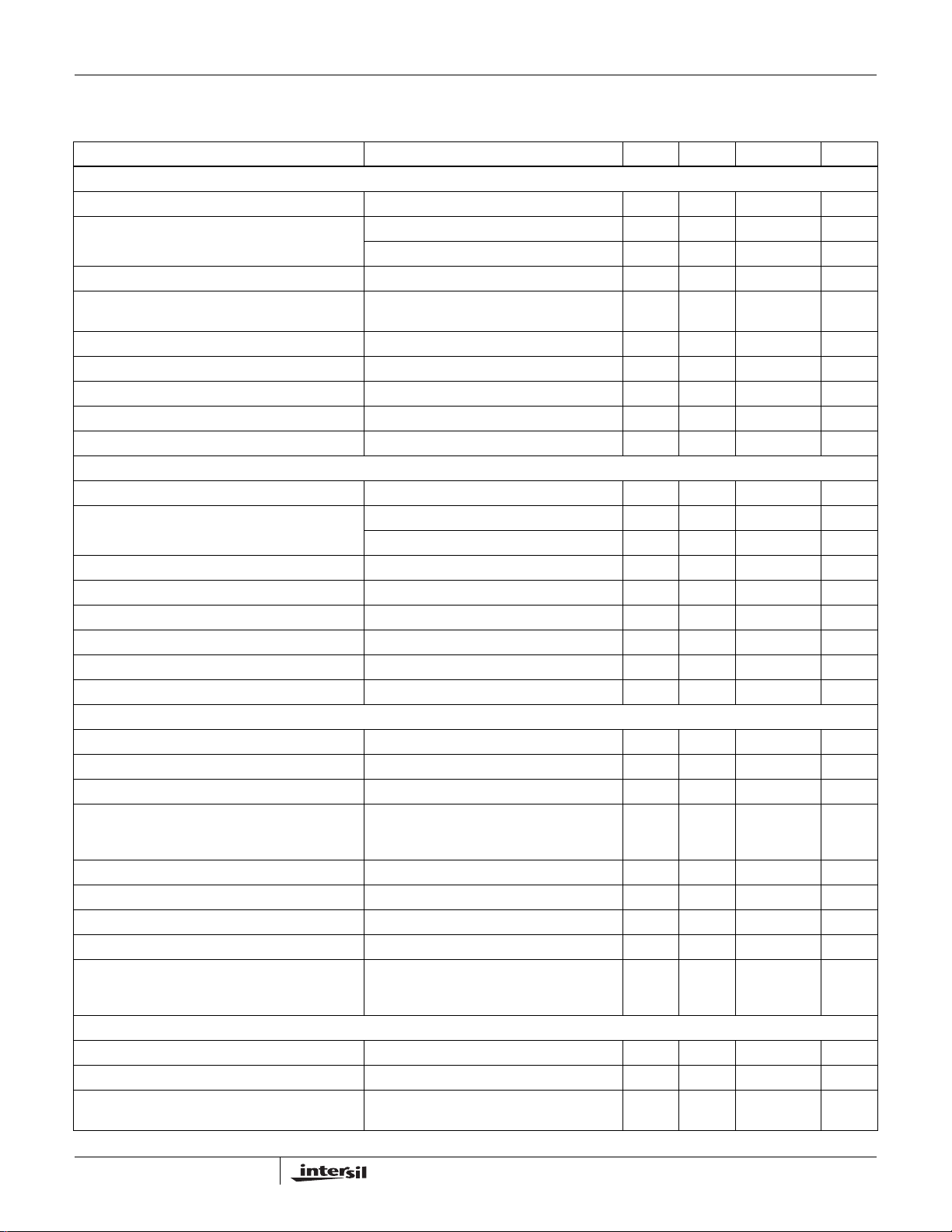

Typical Application (ISL6741) - 48V to 5V Push-Pull DC/DC Converter

www.BDTIC.com/Intersil

+48V

+ 5V

RTN

QR1

T1

EL7242

6

SYNC

VIN-

C1

Q1

R2 R3R1

R4

R5

Q2

R6

RT1

FAULT

GND

OUTB

OUTA

VDD

RTD

OTS

VERROR

ISL6741

VREF

QR2

R12

R11

SYNC

SS

CS

CT

RTC

SCSET

UV

R18

R19 R20

+

R14

C9

+5V

OUTB

CR3

OUTA

+ 5V

R15

C8

ISL6740, 1SL6741

CR1

L1

CR2

U5

T3

U3

R21

CR4

R13

Q3

VR1

July 13, 2007

FN9111.4

C2

R8

R7

C3

C4

C5

R10

U2

C6

R9

R16

U4

C7

R17

ISL6740, 1SL6741

www.BDTIC.com/Intersil

Absolute Maximum Ratings Thermal Information

Supply Voltage, VDD . . . . . . . . . . . . . . . . . . . GND - 0.3V to +20.0V

OUTA, OUTB, Signal Pins. . . . . . . . . . . . . . . . .GND - 0.3V to V

VREF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GND - 0.3V to 6.0V

Peak GATE Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5A

ESD Classification

Human Body Model (Per MIL-STD-883 Method 3015.7) . . .1500V

Charged Device Model (Per EOS/ESD DS5.3, 4/14/93) . . .1000V

REF

Thermal Resistance Junction to Ambient (Typical) θ

16 Lead SOIC (Note 1) . . . . . . . . . . . . . . . . . . . . . . 77

16 Lead TSSOP (Note 1). . . . . . . . . . . . . . . . . . . . . 102

Maximum Junction Temperature . . . . . . . . . . . . . . .-55°C to +150°C

Maximum Storage Temperature Range. . . . . . . . . .-65°C to +150°C

Pb-free reflow profile . . . . . . . . . . . . . . . . . . . . . . . . . .see link below

http://www.intersil.com/pbfree/Pb-FreeReflow.asp

Operating Conditions

Temperature Range

ISL6740Ix . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to +105°C

ISL6741Ix . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to +105°C

Supply Voltage Range (Typical). . . . . . . . . . . . . . . . 9VDC - 16VDC

CAUTION: Do not operate at or near the maximum ratings listed for extended periods of time. Exposure to such conditions may adversely impact product reliability and

result in failures not covered by warranty.

1. θJA is measured with the component mounted on a high effective thermal conductivity test board in free air. See Tech Brief TB379 for details.

2. All voltages are with respect to GND.

(°C/W)

JA

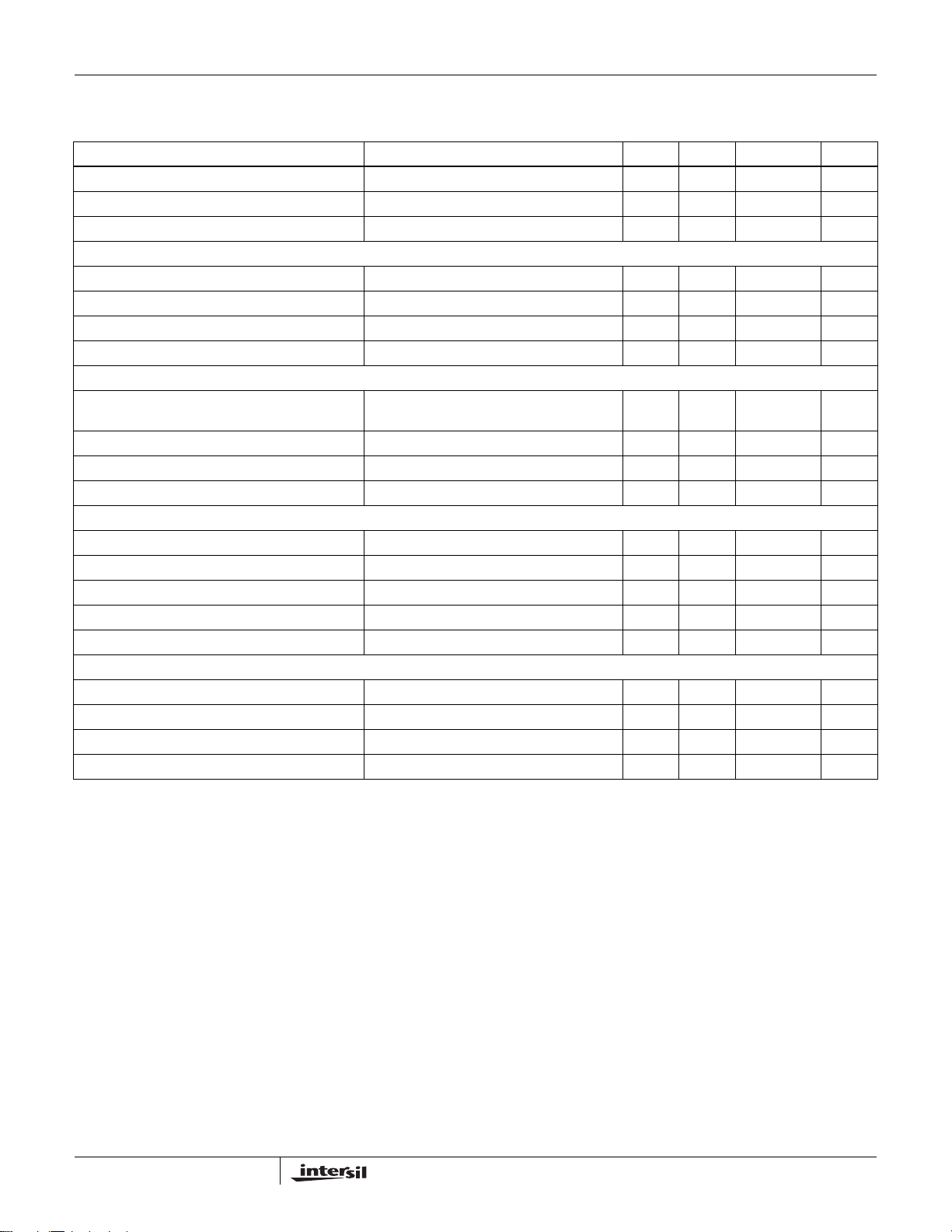

Electrical Specifications Recommended operating conditions unless otherwise noted. Refer to Block Diagram and Typical Application

Schematic. 9V < V

values are at T

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

SUPPLY VOLTAGE

Start-Up Current, I

Operating Current, I

UVLO START Threshold 6.50 7.25 8.00 V

UVLO STOP Threshold 6.00 6.75 7.50 V

Hysteresis 0.25 0.50 0.75 V

REFERENCE VOLTAGE

Overall Accuracy I

Long Term Stability T

Fault Voltage 4.10 4.55 4.75 V

Good Voltage 4.25 4.75 V

V

REF

Hysteresis 75 165 250 mV

Operational Current (source) -20 - - mA

Operational Current (sink) 5- - mA

Current Limit -25 - -100 mA

CURRENT SENSE

Current Limit Threshold V

CS to OUT Delay -35 50 ns

CS Sink Current -10 - mA

Input Bias Current -1.00 - 1.00 μA

CS to PWM Comparator Input Offset (ISL6741) (Note 4) - 80 - mV

Gain (ISL6741) A

SCSET Input Impedance 1- - MΩ

SC Setpoint Accuracy -10 - %

DD

DD

< 20 V, RTD = 51.1kΩ, R

DD

= +25°C

A

V

< START Threshold - 95 140 μA

DD

R

, C

LOAD

C

OUTA,B

= 0, -20mA 4.900 5.000 5.050 V

VREF

= +125°C, 1000 hours (Note 4) - 3 - mV

A

= V

ERROR

= ΔV

CS

= 0 - 5.0 8.0 mA

OUTA,B

= 1nF - 7.0 12.0 mA

REF

/ΔV

ERROR

CS

= 10kΩ, CT = 470pF, TA = -40°C to +105°C (Note 3), Typical

TC

- 0.05 V

REF

0.55 0.6 0.65 V

(Note 4) - 4 - V/V

7

FN9111.4

July 13, 2007

ISL6740, 1SL6741

www.BDTIC.com/Intersil

Electrical Specifications Recommended operating conditions unless otherwise noted. Refer to Block Diagram and Typical Application

Schematic. 9V < V

values are at T

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

PULSE WIDTH MODULATOR

V

Minimum Duty Cycle V

Maximum Duty Cycle V

V

(ISL6741)

V

V

CT to PWM Comparator Input Gain (ISL6740) (Note 4) - 0.4 - V/V

SS to PWM Comparator Input Gain (ISL6740) (Note 4) - 0.5 - V/V

SS to PWM Comparator Input Gain (ISL6741) (Note 4) - 0.2 - V/V

OSCILLATOR

Frequency Accuracy T

Frequency Variation with V

Temperature Stability (Note 4) - 8 - %

Charge Current Gain 1.88 2.0 2.12 μA/μA

Discharge Current Gain 45 55 65 μA/μA

C

C

RTD, RTC Voltage R

SYNCHRONIZATION

Input High Threshold (VIH), Minimum 4.0 - - V

Input Low Threshold (VIL), Maximum - - 0.8 V

Input Impedance 4.5 - kΩ

Input Frequency Range (Note 4) 0.6x

High Level Output Voltage (VOH) I

Low Level Output Voltage (VOL) I

SYNC Output Current VOH > 2.0V (Note 4) -10 - - mA

SYNC Output Pulse Duration (minimum) (Notes 4, 5) 250 - 400 ns

SYNC Advance SYNC rising edge to GATE falling edge,

SOFTSTART

Charging Current SS = 2V -45 -55 -75 μA

SS Clamp Voltage 4.35 4.5 4.65 V

Sustained Over Current Threshold Voltage

(ISL6740)

Input Impedance 400 - - kΩ

ERROR

to PWM Comparator Input Offset

ERROR

to PWM Comparator Input Gain (ISL6741) (Note 4) - 0.25 -

ERROR

to PWM Comparator Input Gain (ISL6740) (Note 4) - 0.4 - V/V

ERROR

DD

Valley Voltage 0.75 0.80 0.85 V

T

Peak Voltage 2.70 2.80 2.90 V

T

< 20 V, RTD = 51.1kΩ, R

DD

= +25°C (Continued)

A

< CS Offset (ISL6741) - - 0 %

ERROR

V

(Note 4) 0.4 1.0 1.25 V

T = +105°C (f

T = -40°C (f

C

(Note 4)

Charged Threshold minus: 0.20 0.25 0.30 V

< CT Valley Voltage (ISL6740) - - 0 %

ERROR

> 4.75V (Note 6) - 83 - %

ERROR

= +25°C 333 351 369 kHz

A

- - f9V)/f

20V

- - f9V)/f

20V

= 0 - 2.000 - V

LOAD

= -1mA - 4.5 - V

LOAD

= 10μA - - 100 mV

LOAD

= C

GATE

SYNC

9V

= 100pF

= 10kΩ, CT = 470pF, TA = -40°C to +105°C (Note 3), Typical

TC

9V

-2 3 %

-2 3 %

- Free Running Hz

Free

Running

-5 - ns

8

FN9111.4

July 13, 2007

ISL6740, 1SL6741

www.BDTIC.com/Intersil

Electrical Specifications Recommended operating conditions unless otherwise noted. Refer to Block Diagram and Typical Application

Schematic. 9V < V

values are at T

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Overcurrent/Short Circuit Discharge Current SS = 2V 13 18 23 μA

Fault SS Discharge Current SS = 2V - 10.0 - mA

Reset Threshold Voltage 0.25 0.27 0.33 V

FAULT

Fault High Level Output Voltage (VOH) I

Fault Low Level Output Voltage (VOL) I

Fault Rise Time C

Fault Fall Time C

OUTPUT

High Level Output Voltage (VOH) V

Low Level Output Voltage (VOL) OUTA or OUTB - GND, I

Rise Time C

Fall Time C

THERMAL PROTECTION

Thermal Shutdown (Note 4) 135 145 155 °C

Thermal Shutdown Clear (Note 4) 120 130 140 °C

Hysteresis, Internal Protection (Note 4) - 15 - °C

Reference, External Protection 2.375 2.50 2.625 V

Hysteresis, External Protection 18 25 30 μA

SUPPLY UVLO/INHIBIT

Input Voltage Low/Inhibit Threshold 0.97 1.00 1.03 V

Hysteresis, Switched Current Amplitude 7 10 15 μA

Input High Clamp Voltage 4.8 - - V

Input Impedance 1- - MΩ

NOTES:

3. Specifications at -40°C and 105°C are guaranteed by 25°C test with margin limits.

4. This parameter, although guaranteed by characterization or correlation testing, is not 100% tested in production.

5. SYNC pulse width is the greater of this value or the C

6. This is the maximum duty cycle achievable using the specified values of R

obtained using other values for these components. See Equations 2 through 4.

< 20 V, RTD = 51.1kΩ, R

DD

= +25°C (Continued)

A

= -10mA 2.85 3.5 - V

LOAD

= 10mA - 0.4 0.9 V

LOAD

= 100pF (Note 4) - 15 - ns

LOAD

= 100pF (Note 4) - 15 - ns

LOAD

- OUTA or OUTB,

REF

= -50mA

I

OUT

= 1nF, VDD = 15V (Note 4) - 50 100 ns

GATE

= 1nF, VDD = 15V (Note 4) - 40 80 ns

GATE

discharge time.

T

= 10kΩ, CT = 470pF, TA = -40°C to +105°C (Note 3), Typical

TC

-0.5 1.0 V

= 50mA - 0.5 1.0 V

OUT

, RTD, and CT. Larger or smaller maximum duty cycles may be

TC

9

FN9111.4

July 13, 2007

Typical Performance Curves

www.BDTIC.com/Intersil

ISL6740, 1SL6741

1.001

1.000

REF

0.999

0.998

NORMALIZED V

0.997

-40 -25 -10 5 20 35 50 65 80 95 110

TEMPERATURE (°C)

FIGURE 1. REFERENCE VOLTAGE vs TEMPERATURE FIGURE 2. OSCILLATOR CT DISCHARGE CURRENT GAIN

4

1•10

CT (pF) =

1000

680

470

330

3

1•10

220

100

100

DEADTIME - TD (ns)

10

10 20 30 40 50 60 70 80 90 100

RTD (kΩ)

65

60

55

50

45

DISCHARGE CURRENT GAIN

T

40

C

0 50 100 150 200 250 300 350 400 450 500

RTD CURRENT (µA)

6

1•10

5

1•10

RTD = 10k

FREQUENCY (Hz)

CT (pF) =

100

220

330

470

4

1•10

10 20 30 40 50

680

1000

60 70 80 90 100

RTC (kΩ)

FIGURE 3. DEADTIME (TD) vs CAPACITANCE FIGURE 4. CAPACITANCE vs FREQUENCY

Pin Descriptions

VDD - VDD is the power connection for the IC. To optimize

noise immunity, bypass V

capacitor as close to the V

The total supply current, I

applied to outputs OUTA a nd OUTB. Total I

sum of the quiescent current and the average output current.

Knowing the operating frequency, f

loading capacitance charge, Q, per output, the average

output current can be calculated from:

I

2QfSW••= A

OUT

SYNC - A bidirectional synchronization signal used to

coordinate the switching frequency of multiple units.

Synchronization may be achieved by connecting the SYNC

signal of each unit together or by using an external master

clock signal. The oscillator timing capacitor, C

required regardless of the synchronization method used.

The paralleled unit with the highest oscillator frequency

assumes control.

to GND with a ceramic

DD

and GND pins as possible.

DD

, will be dependent on the load

DD

, and the output

SW

current is the

DD

, is always

T

(EQ. 1)

RTC - This is the oscillator timing capacitor charge current

control pin. A resistor is connected between this pin and

GND. The current flowing through the resistor determines

the magnitude of the charge current. The charge current is

nominally twice this current. The PWM maximum ON time is

determined by the timing capacitor charge duration.

RTD - This is the oscillator timing capacitor discharge

current control pin. A resistor is connected between this pin

and GND. The current flowing through the resistor

determines the magnitude of the discharge current. The

discharge current is nominally 50x this current. The PWM

deadtime is determined by the timing capacitor discharge

duration.

CT - The oscillator timing capacitor is connected between

this pin and GND.

VERROR - The inverting input of the PWM comparator. The

error voltage is applied to this pin to control the duty cycle.

Increasing the signal level increases the duty cycle. The

10

FN9111.4

July 13, 2007

ISL6740, 1SL6741

www.BDTIC.com/Intersil

node may be driven with an external error amplifier or optocoupler.

The ISL6740, ISL6741 features a built-in soft-start. Soft-start

is implemented as a clamp on the error voltage input.

OTS - The non-inverting input to the over-temperature

shutdown comparator. The signal input at this pin is

compared to an internal threshold of V

this pin exceeds the threshold, the Fault signal is asserted

and the outputs are disabled until the condition clears. There

is a nominal 25μA switched current source used for

hysteresis. The amount of hysteresis is adjustable by

varying the source impedance of the signal into this pin.

OTS may be used to monitor parameters other than

temperature, such as voltage. Any signal for which a high

out-of-bounds monitor is desired may utilize the OTS

comparator.

FAULT - The Fault signal is asserted high whenever the

outputs, OUTA and OUTB, are disa bled. This occurs during

an over-temperature fault, an input UV fault, a V

fault, or during an overcurrent (ISL6740) or short circuit

shutdown fault. Fault can be used to disable synchronous

rectifiers whenever the outputs are disabled.

/2. If the voltage at

REF

REF

UV

(Sustained Overcurrent Threshold), a shutdown condition

occurs and the OUTA and OUTB outputs are forced low.

When the soft-start voltage reaches 0.27V (Reset

Threshold) a soft-start cycle begins.

An overcurrent condition must be absent for 50μs before the

delayed shutdown control resets. If the overcurrent condition

ceases, and an additional 50μs period elapses before the

shutdown threshold is reached, no shutdown occurs. The SS

charging current is re-enabled and the soft-start voltage is

allowed to recover.

ISL6741 - The ISL6741 current mode controller does not

shutdown due to an overcurrent condition. The pulse-bypulse current limit characteristic of peak current mode

control limits the output current to acceptable levels.

GND - Reference and power ground for all functions on this

device. Due to high peak currents and high frequency

operation, a low impedance layout is necessary. Ground

planes and short traces are highly recommended.

OUTA and OUTB - Alternate half cycle output stages. Each

output is capable of 0.5A peak currents for driving logic level

power MOSFETs or MOSFET drivers. Each output provides

very low impedance to overshoot and undershoot.

Fault is a three-state output and is high impedance during

the soft-start cycle. Adding a pull-up resistor to VREF or a

pull-down resistor to ground determines the state of Fault

during soft-start. This feature allows the designer to use the

Fault signal to enable or disable output synchronous

rectifiers during soft-start.

UV - Undervoltage monitor input pin. A resistor divider

between the input source voltage and GND sets the

undervoltage lock out threshold. The signal is compared to

an internal 1.00V reference to detect an undervoltage or

inhibit condition.

CS - This is the input to the current sense comparator(s).

The IC has the PWM comparator for peak current mode

control (ISL6741) and an overcurrent protection comparator.

The overcurrent comparator threshold is set at 0.600V

nominal.

The CS pin is shorted to GND at the end of each switching

cycle. Depending on the current sensing source impedance,

a series input resistor may be required due to the delay

between the internal clock and the external power switch.

This delay may allow an overlap such that the CS signal may

be discharged while the current signal is still active. If the

current sense source is low impedance, it will cause

increased power dissipation.

ISL6740 - Exceeding the overcurrent threshold will start a

delayed shutdown sequence. Once an overcurrent condition

is detected, the soft-start charge current source is disabled.

The soft-start capacitor begins discharging through a 25μA

current source, and if it discharges to less than 4.25V

VREF - The 5.00V reference voltage output. +1%/-2%

tolerance over line, load and operating temperature. Bypass

to GND with a 0.047μF to 2.2μF ceramic capacitor.

Capacitors outside of this range may cause oscillation.

SS - Connect the soft-start timing capacitor between this pin

and GND to control the duration of soft-start. The value of

the capacitor determines the rate of increase of the duty

cycle during start up, controls the overcurrent shutdown

delay (ISL6740), and the overcurrent and short circuit hiccup

restart period.

SCSET - Sets the duty cycle threshold that corresponds to a

short circuit condition. A resistive divider between R

GND or R

be used to adjust the SCSET threshold. If using a resistor

divider from either RTC or RTD, the impedance to GND

affects the oscillator timing and should be considered when

determining the oscillator timing components. Connecting

SCSET to GND disables short circuit shutdown and hiccup.

and GND, or a voltage between 0V and 2V may

TD

TC

and

Functional Description

Features

The ISL6740, ISL6741 PWMs are an excellent choice for

low cost bridge and push-pull topologies for applications

requiring accurate duty cycle and deadtime control. With its

many protection and control features, a highly flexible design

with minimal external components is possible. Among its

many features are current mode control (ISL6741),

adjustable soft-start, overcurrent protection, thermal

protection, bidirectional synchronization, fault indication, and

adjustable frequency.

11

FN9111.4

July 13, 2007

ISL6740, 1SL6741

www.BDTIC.com/Intersil

Oscillator

The ISL6740, ISL6741 have an oscillator with a

programmable frequency range to 2MHz, which can be

programmed with two resistors and capacitor. The use of

three timing elements, R

, RTD, and CT allow great

TC

flexibility and precision when setting the oscillator frequency.

The switching period may be considered the sum of the

timing capacitor charge and discharge durations. The charge

duration is determined by R

duration is determined by R

TC0.5 RTC• CT•≈ S

0.02 RTD• CT•≈ S

T

D

1

T

== S

SWTCTD

where T

and TD are the charge and discharge times,

C

respectively, T

------------

+

F

SW

is the oscillator free running period, and f

SW

and CT. The discharge

TC

and CT.

TD

(EQ. 2)

(EQ. 3)

(EQ. 4)

is the oscillator frequency. One output switching cycle

requires two oscillator cycles. The actual times will be

slightly longer than calculated due to internal propagation

delays of approximately 10ns/transition. This delay ads

directly to the switching duration, but also causes overshoot

of the timing capacitor peak and valley voltage thresholds,

effectively increasing the peak-to-peak voltage on the timing

capacitor. Additionally, if very low charge and discharge

currents are used, there will be increased error due to the

input impedance at the C

T

pin.

The maximum duty cycle, D, and percent deadtime, DT, can

be calculated from:

T

C

------------

=

D

T

SW

DT 1 D–= (EQ. 6)

(EQ. 5)

Implementing Synchronization

The oscillator can be synchronized to an external clock

applied to the SYNC pin or by connecting the SYNC pins of

multiple ICs together. If an external master clock signal is

used, the free running frequency of the oscillator should be

~10% slower than the desired synchronous frequency. The

external master clock signal should have a pulse width

greater than 20ns. The SYNC circuitry will not respond to an

external signal during the first 60% of the oscillator switching

cycle.

The SYNC input is edge triggered and its duration does not

affect oscillator operation. However, the deadtime is af fected

by the SYNC frequency. A higher frequency signal applied to

the SYNC input will shorten the deadtime. The shortened

deadtime is the result of the timing capacitor charge cycle

being prematurely terminated by the external SYNC pulse.

Consequently, the timing capacitor is not fully charged when

the discharge cycle begins. This effect is only a concern

when an external master clock is used, or if units with

different operating frequencies are paralleled.

Soft-start Operation

The ISL6740, ISL6741 feature a soft-start using an external

capacitor in conjunction with an internal current source. softstart reduces stresses and surge currents during start up.

Upon start up, the soft-start circuitry clamps the error voltage

input (V

pin) indirectly to a value equal to the soft-

ERROR

start voltage. The soft-start clamp does not actually clamp

the error voltage input as is done in many implementations.

Rather the PWM comparator has two inverting inputs such

that the lower voltage is in control.

The output pulse width increases as the soft-start capacitor

voltage increases. This has the effect of increasing the duty

cycle from zero to the regulation pulse width during the softstart period. When the soft-start voltage exceeds the error

voltage, soft-start is completed. soft-start occurs during

start-up, after recovery from a Fault condition or

overcurrent/short circuit shutdown. The soft-start voltage is

clamped to 4.5V.

The Fault signal output is high impedance during the softstart cycle. A pull-up resistor to VREF or a pull-down resistor

to ground should be added to achieve the desired state of

Fault during soft-start.

Gate Drive

The ISL6740, ISL6741 are capable of sourcing and sinking

0.5A peak current, but are primarily intended to be used in

conjunction with a MOSFET driver due to the 5V drive level.

To limit the peak current through the IC, an external resistor

may be placed between the totem-pole output of the IC

(OUTA or OUTB pin) and the gate of th e MOSFET. This

small series resistor also damps any oscillations caused by

the resonant tank of the parasitic inductances in the traces of

the board and the FET’s input capacitance.

Undervoltage Monitor and Inhibit

The UV input is used for input source undervoltage lockout

and inhibit functions. If the node voltage falls below 1.00V a

UV shutdown fault occurs. This may be caused by low

source voltage or by intentional grounding of the pin to

disable the outputs. There is a nominal 10μA switched

current source used to create hysteresis. The current source

is active only during an UV/Inhibit fault; otherwise, it is

inactive and does not affect the node voltage. The

magnitude of the hysteresis is a function of the external

resistor divider impedance. If the resistor divider impedance

results in too little hysteresis, a series resistor between the

UV pin and the divider may be used to increase the

hysteresis. A soft-start cycle begins when the UV/Inhibit fault

clears.

12

FN9111.4

July 13, 2007

ISL6740, 1SL6741

www.BDTIC.com/Intersil

The voltage hysteresis created by the switched current

source and the external impedance is generally small due to

the large resistor divider ratio required to scale the input

voltage down to the UV threshold level. A small capacitor

placed between the UV input and ground may be required to

filter noise out.

V

IN

R1

+

1.00V

-

R3

R2

FIGURE 5. UV HYSTERESIS

As V

decreases to a UV condition, the threshold level is:

IN

R1 R2+

V

IN DOWN()

----------------------

= V

R2

10μA

ON

(EQ. 7)

The hysteresis voltage, ΔV, is:

ΔV10

5–

R1 R3

R1 R2+

⎛⎞

----------------------

•+〈〉•= V

⎝⎠

R2

(EQ. 8)

Setting R3 equal to zero results in the minimum hysteresis,

and yields:

5–

ΔV10

As V

IN

V

IN UP()VIN DOWN()

R1•= V

(EQ. 9)

increases from a UV condition, the threshold level is:

ΔV+= V

(EQ. 10)

Over Current Operation

ISL6740 - Overcurrent delayed shutdown is enabled once

the soft-start cycle is complete. If an overcurrent condition is

detected, the soft-start charging current source is disabled

and the soft-start capacitor is allowed to discharge through a

15μA source. At the same time a 50μs re-triggerable oneshot timer is activated. It remains active for 50μs after the

overcurrent condition ceases. If the soft-start capacitor

discharges by more then 0.25V to 4.25V, the output is

disabled and the Fault signal asserted. This state continues

until the soft-start voltage reaches 270mV, at which time a

new soft-start cycle is initiated. If the overcurrent condition

stops at least 50μs prior to the soft-start voltage reaching

4.25V, the soft-start charging currents revert to normal

operation and the soft-start voltage is allowed to recover.

The duration of the OC shutdown period can be increased

by adding a resistor between VREF and SS. The value of

the resistor must be large enough so that the minimum

specified SS discharge current is not exceeded. Using a

422kΩ resistor, for example, will result in a small current

being injected into SS, effectively reducing the discharge

current. This will increase the OFF time by about 60%,

nominally. The external pull-up resistor will also decrease

the SS duration, so its effect should be considered when

selecting the value of the SS capacitor.

Latching OC shutdown is also possible by using a lower

valued resistor between VREF and SS. If the SS node is not

allowed to discharge below the SS reset threshold, the IC

will not recover from an overcurrent fault. The value of the

resistor must be low enough so that the maximum specified

discharge current is not sufficient to pull SS below 0.33V. A

200kΩ resistor, for example, prevents SS from discharging

below ~0.4V. Again, the external pull- up resistor will

decrease the SS duration, so its effect should be considered

when selecting the value of the SS capacitor.

ISL6741 - Overcurrent results in pulse-by-pulse duty cycle

reduction as occurs in any peak current mode controller. This

results in a well controlled decrease in output volt age wi th

increasing current beyond the overcurrent threshold. An

overcurrent condition in the ISL6741 will not cause a

shutdown.

Short Circuit Operation

A short circuit condition is defined as the simultaneous

occurrence of current limit and a reduced duty cycle. The

degree of reduced duty cycle is user adjustable using the

SCSET input. A resistor divider between either R

and GND to RCSET sets a threshold that is compared to the

voltage on the timing capacitor, C

. The resistor divider

T

percentage corresponds to the fraction of the maximum duty

cycle below which a short circuit may exist. If the timing

capacitor voltage fails to exceed the threshold before an

overcurrent pulse is detected, a short circuit condition exists.

A shutdown and soft-start cycle will begin if 8 short circuit

events occur within 32 oscillator cycles. Connecting SCSET

to GND disables this feature.

Since the current sourced from both R

and RTD determine

TC

the charge and discharge currents for the timing capacitor,

the effect of the SCSET divider must be included in the

timing calculations. Typically the resistor between R

GND is formed by two series resistors with the center node

connected to SCSET.

Alternatively, SCSET may be set u sing a voltage between

0V and 2V. This voltage divided by 2 dete rmines the

percentage of the maximum duty cycle that corresponds to a

short circuit when current limit is active. For example, if the

maximum duty cycle is 95% and 1V is applied to SCSET,

then the short circuit duty cycle is 50% of 95% or 47.5%.

or RTC

TD

TC

and

13

FN9111.4

July 13, 2007

ISL6740, 1SL6741

www.BDTIC.com/Intersil

Fault Conditions

A fault condition occurs if V

input falls below 1.00V , the thermal protection is triggered, or

if OTS faults. When a fault is detected, OUTA and OUTB

outputs are disabled, the Fault signal is asserted, and the

soft-start capacitor is quickly discharged. When the fault

condition clears and the soft-start voltage is below the reset

threshold, a soft-start cycle begins. The Fault signal is high

impedance during the soft-start cycle.

An overcurrent condition that results in shutdown (ISL6740),

or a short circuit shutdown also cause assertion of the Fault

signal. The difference between a current fault and the faults

described earlier is that the soft-start capacitor is not quickly

discharged. The initiation of a new soft-start cycle is delayed

while the soft-start capacitor is discharged at a 15μA rate.

This keeps the average output current to a minimum.

falls below 4.65V, the UV

REF

Thermal Protection

Two methods of over-temperature protection are provided.

The first method is an on board temperature sensor that

protects the device should the junction temperature exceed

145°C. There is approximately 15°C of hysteresis.

The second method uses an internal comparator with a 2.5V

reference (V

comparator is accessible through the OTS pin. A thermistor

or thermal sensor located at or near the area of interest may

be connected to this input. There is a nominal 25μA switched

current source used to create hysteresis. The current source

is active only during an OT fault; otherwise, it is inactive and

does not affect the node voltage. The magnitude of the

hysteresis is a function of the external resistor divider

impedance. Either a positive temperature coefficient (PTC)

or a negative temperature coefficient (NTC) thermistor may

be used. If a NTC is desired, position R1 may be substituted.

/2). The non-inverting input to the

REF

V

V

REF

R1

R3

R2

REF

25μA

V

REF

ON

+

/2

-

If a PTC is desired, then position R2 may be substituted. The

threshold with increasing temperature is set by making the

fixed resistance equal in value to the thermistor resistance at

the desired trip temperature.

V

↑ = 2.5V and R1 = R2 (HOT)

TH

To determine the value of the hysteresis resistor, R3, select

the value of thermistor resistance that corresponds to the

desired reset temperature.

5

R1 R2–()• R1 R2•–

10

--------------------------------------------------------------------- -

R3

R1 R2+

Ω=

(EQ. 11)

If the hysteresis resistor, R3, is not desired, the value of the

thermistor resistance at the reset temperature can be

determined from:

R1

2.5 10

-----------------------------------------

R2

= Ω PTC()

2.5 10

2.5 R1•

5–

R2•–

5–

R1•+

(EQ. 12)

(EQ. 13)

2.5 R2•

----------------------------------------

= Ω NTC()

The OTS comparator may also be used to monitor signals

other than suggested above. It may also be used to monitor

any voltage signal for which an excess requires a response

as described above. Input or output voltage monitoring are

examples of this.

Ground Plane Requirements

Careful layout is essential for satisfactory operation of the

device. A good ground plane must be employed. V

DD

should

be bypassed directly to GND with good high frequency

capacitance.

Typical Application

The Typical Application Schematic features the ISL6740 in

an unregulated half-bridge DC/DC converter configuration,

often referred to as a DC Transformer or Bus Regulator. The

ISL6740EVAL1 demonstration unit implements this design

and is available for evaluation.

The input voltage range is 48 ±10%VDC. The output is a

nominal 12V when the input voltage is at 48V. Since this is

an unregulated topology, the output voltage will vary

proportionately with input voltage. The load regulation is a

function of resistance between the source and the converter

output. The output is rated at 8A.

FIGURE 6. OTS HYSTERESIS

14

FN9111.4

July 13, 2007

ISL6740, 1SL6741

www.BDTIC.com/Intersil

Circuit Element Descriptions

The converter design may be broken down into the following

functional blocks:

Input Filtering: L

Half-Bridge Capacitors: C2, C

Isolation Transformer: T

Primary Snubber: C13, R

Start Bias Regulator: CR3, R2, R7, C6, Q5, D

Supply Bypass Components: R3, C15, C4, C

, C1, R

1

1

3

1

10

1

5

Main MOSFET Power Switch: QH, QL

Current Sense Network: T2, CR1, CR2, R5, R6, R11, C10, C

14

Control Circuit: U3, RT1, R14, R19, R13, R15, R17, R18, C16,

C

, C

18

17

Output Rectification and Filtering: QR1, QR2, QR3, QR4, L2,

C

, C

9

8

Secondary Snubber: R8, R9, C11, C

FET Driver: U

1

ZVS Resonant Delay (Optional): L3, C

12

7

Design Criteria

The following design requirements were selected:

energy, the number of turns that have to be wound, and

the wire gauge needed. Often the window area (the space

used for the windings) and power loss determine the final

core size.

• Determine maximum desired flux density. Depending on

the frequency of operation, the core material selected, and

the operating environment, the allowed flux density must

be determined. The decision of what flux density to allow

is often difficult to determine initially. Usually the highest

flux density that produces an acceptable design is used,

but often the winding geometry dictates a larger core than

is indicated based on flux density alone.

• Determine the number of primary turns.

• Select the wire gauge for each winding.

• Determine winding order and insulation requirements.

• Verify the design.

n

SR

n

n

P

FIGURE 7. TRANSFORMER SCHEMATIC

S

n

S

n

SR

Switching Frequency, Fsw: 235kHz

VIN: 48 ±10%V

V

: 12V (nominal) @ I

OUT

P

: 100W

OUT

OUT

= 8A

Efficiency: 95%

Ripple: 1%

Transformer Design

The design of a transformer for a half-bridge application is a

straight forward affair, although iterative. It is a process of

many compromises, and even experienced designers will

produce different designs when presented with identical

requirements. The iterative design process is not presented

here for clarity.

The abbreviated design process follows:

• Select a core geometry suitable for the application.

Constraints of height, footprint, mounting preference, and

operating environment will affect the choice.

• Determine the turns ratio.

• Select suitable core material(s).

• Select maximum flux density desired for operation.

• Select core size. Core size will be dictated by the

capability of the core structure to store the required

For this application we have selected a planar structure to

achieve a low profile design. A PQ style core was selected

because of its round center leg cross section, but there are

many suitable core styles available.

Since the converter is operating open loop at nearly 100%

duty cycle, the turns ratio, N, is simply the ratio of the input

voltage to the output voltage divided by 2.

N

V

IN

------------------------ -

V

OUT

48

---------------

2•

12 2•

2===

(EQ. 14)

The factor of 2 divisor is due to the half-bridge topology. Only

half of the input voltage is applied to the primary of the

transformer.

A PC44HPQ20/6 “E-Core” plus a PC44PQ20/3 “I-Core” from

TDK were selected for the transformer core. The ferrite

material is PC44.

The core parameter of concern for flux density is the

effective core cross sectional area, Ae. For the PQ core

pieces selected:

Ae = 0.62cm

2

or 6.2e -5m

2

Using Faraday’s Law, V = N d Φ/dt, the number of primary

turns can be determined once the maximum flux density is

set. An acceptable Bmax is ultimately determined by the

allowable power dissipation in the ferrite material and is

15

FN9111.4

July 13, 2007

ISL6740, 1SL6741

www.BDTIC.com/Intersil

influenced by the lossiness of the core, core geometry,

operating ambient temperature, and air flow. The TDK

datasheet for PC44 material indicates a core loss factor of

~400mW/cm

3

with a ±2000 gauss 100kHz sinusoidal

excitation. The application uses a 235kHz square wave

excitation, so no direct comparison between the application

and the data can be made. Interpolation of the data is

required. The core volume is approximately 1.6cm

3

, so the

estimated core loss is

f

P

loss

mW

-----------

cm

3

cm

•• 0.4 1.6

3

act

---------------

f

meas

200kHz

---------------------

•• 1.28==≈ W

100kHz

(EQ. 15)

1.28W of dissipation is significant for a core of this size.

Reducing the flux density to 1200 gauss will reduce the

dissipation by about the same percentage, or 40%.

Ultimately, evaluation of the transformer’s performance in

the application will determine what is acceptable.

From Faraday’s Law and using 1200 gauss peak flux density

(ΔB = 2400 gauss or 0.24 tesla)

N

•

V

INTON

----------------------------- -

2A

ΔB••

e

53210

-----------------------------------------------------

26.210

6–

••

5–

0.24•••

3.56== =turns

(EQ. 16)

trace width results in a copper thickness of 4.44 mils

(0.112 mm). Using 1.3 mils/oz. of copper requires a copper

weight of 3.4oz. For reasons of cost, 3oz. copper was

selected.

One layer of each secondary winding also contains the

synchronous rectifier winding. For this layer the secondary

trace width is reduced by 0.025 inches to 0.100 inches(0.015

inches for the SR winding trace width and 0.010 inches

spacing between the SR winding and the secondary

winding).

The choice of copper weight may be validated by calculating

the DC copper losses of the secondary winding as follows.

Ignoring the terminal and lead-in resistance, the resistance

of each layer of the secondary may be approximated using

Equation 18.

2πρ

----------------------- -

R

= Ω

r

⎛⎞

2

---- -

ln•

t

⎜⎟

r

⎝⎠

1

(EQ. 18)

where

R = Winding resistance

ρ = Resistivity of copper = 669e-9Ω-inches at 20°C

Rounding up yields 4 turns for the primary winding. The peak

flux density using 4 turns is ~1100 gauss. From Equation 1,

the number of secondary turns is 2.

The volts/turn for this design ranges from 5.4V at V

to 6.6V at V

= 53V. Therefore, the syn chronous rectifier

IN

= 43V

IN

(SR) windings may be set at 1 turn each with proper FET

selection. Selecting 2 turns for the synchronous rectifier

windings would also be acceptable, but the gate drive losses

would increase.

The next step is to determine the equivalent wire gauge for

the planar structure. Since each secondary winding

conducts for only 50% of the period, the RMS current is

I

RMSIOUT

D• 10 0.5• 7.07===A

(EQ. 17)

where D is the duty cycle. Since an FR-4 PWB planar

winding structure was selected, the width of the copper

traces is limited by the window area width, and the number

of layers is limited by the window area height. The PQ core

selected has a usable window area width of 0.165 inches.

Allowing one turn per layer and 0.020 inches clearance at

the edges allows a maximum trace width of 0.125 inches.

Using 100 circular mils(c.m.)/A as a guideline for current

density, and from Equation 17, 707c.m. are required for each

of the secondary windings (a circular mil is the area of a

circle 0.001 inches in diameter). Converting c.m. to square

mils yields 555mils

2

(0.785 sq. mils/c.m.). Dividing by the

t = Thickness of the copper (3 oz.) = 3.9e-3 inches

r

= Outside radius of the copper trace = 0.324 or 0.299

2

inches

r

= Inside radius of the copper trace = 0.199 inches

1

The winding without the SR winding on the same layer has a

DC resistance 2.21mΩ. The winding that shares the layer

with the SR winding has a DC resistance of 2.65mΩ. With

the secondary configured as a 4 turn center tapped winding

(2 turns each side of the tap), the total DC power loss for the

secondary at +20°C is 486mW.

The primary windings have an RMS current of approximately

5A (I

x NS/NP at ~ 100% duty cycle). The primary is

OUT

configured as 2 layers, 2 turns per layer to minimize the

winding stack height. Allowing 0.020 inches edge clearance

and 0.010 inches between turns yields a trace width of

0.0575 inches. Ignoring the terminal and lead-in resistance,

and using Equation 18, the inner trace has a resistance of

4.25mΩ, and the outer trace has a resistance of 5.52mΩ.

The resistance of the primary then is 19.5mΩ at +20°C. The

total DC power loss for the secondary at +20°C is 489mW.

Improved efficiency and thermal performance could be

achieved by selecting heavier copper weight for the wind ings.

Evaluation in the application will determine its need.

16

FN9111.4

July 13, 2007

ISL6740, 1SL6741

www.BDTIC.com/Intersil

The order and geometry of the windings affects the AC

resistance, winding capacitance, and leakage inductance of

the finished transformer. To mitigate these effects,

interleaving the windings is necessary. The primary winding

is sandwiched between the two secondary windings. The

winding layout appears below.

FIGURE 7A. TOP LAYER: 1 TURN SECONDARY AND SR

WINDINGS

FIGURE 7D. INT. LAYER 3: 2 TURNS PRIMARY WINDING

FIGURE 7B. INT. LAYER 1: 1 TURN SECONDARY WINDING

FIGURE 7C. INT. LAYER 2: 2 TURNS PRIMARY WINDING

FIGURE 7E. INT. LAYER 4: 1 TURN SECONDARY WINDING

FIGURE 7F . BOTTOM LAYER: 1 TURN SECONDARY AND SR

WINDINGS

∅0.689

∅0.358

0.807

0.639

0.403

17

1.0540.7740.4790.1840.000

FIGURE 7G. PWB DIMENSIONS

0.169

0.000

FN9111.4

July 13, 2007

ISL6740, 1SL6741

www.BDTIC.com/Intersil

MOSFET Selection

The criteria for selection of the primary side half-bridge FETs

and the secondary side synchronous rectifier FETs is largely

based on the current and voltage rating of the device.

However, the FET drain-source capacitance and gate

charge cannot be ignored.

The zero voltage switch (ZVS) transition timing is dependent

on the transformer’s leakage inductance and the

capacitance at the node between the upper FET source and

the lower FET drain. The node capacitance is comprised of

the drain-source capacitance of the FETs and the

transformer parasitic capacitance. The leakage inductance

and capacitance form an LC resonant tank circuit which

determines the duration of the transition. The amount of

energy stored in the LC tank circuit determines the transition

voltage amplitude. If the leakage inductance energy is too

low, ZVS operation is not possible and near or partial ZVS

operation occurs. As the leakage energy increases, the

voltage amplitude increases until it is clamped by the FET

body diode to ground or V

conducts. When the leakage energy exceeds the minimum

required for ZVS operation, the voltage is clamped until the

energy is transferred. This behavior increases the time

window for ZVS operation. This behavior is not without

consequences, however. The transition time and the period

of time during which the voltage is clamped reduces the

effective duty cycle.

, depending on which FET

IN

devices are used in parallel for a total of four SR FETs. The

FDS5670 is rated at 60V and 10A (r

DS(ON)

= 14mΩ).

Oscillator Component Selection

The desired operating frequency of 235kHz for the converter

was established in the Design Criteria section. The

oscillator frequency operates at twice the frequency of the

converter because two clock cycles are required for a

complete converter period.

During each oscillator cycle the timing capacitor, C

charged and discharged. Determining the required

discharge time to achieve zero voltage switching (ZVS) is

the critical design goal in selecting the timing components.

The discharge time sets the deadtime between the two

outputs, and is the same as ZVS transition time. Once the

discharge time is determined, the remainder of the period

becomes the charge time.

The ZVS transition duration is determined by the

transformer’s primary leakage inductance, L

Coss, by the transformer’s parasitic winding capacitance,

and by any other parasitic elements on the node. The

parameters may be determined by measurement,

calculation, estimate, or by some combination of these

methods.

π Llk2C

------------------------------------------------------------------- -

t

≈ S

zvs

+()•

ossCxfrmr

2

, must be

T

, by the FET

lk

(EQ. 19)

The gate charge affects the switching speed of the FETs.

Higher gate charge translates into higher drive requirements

and/or slower switching speeds. The energy required to

drive the gates is dissipated as heat.

The maximum input voltage, V

, plus transient voltage,

IN

determines the voltage rating required. With a maximum

input voltage of 53V for this application, and if we allow a

10% adder for transients, a voltage rating of 60V or higher

will suffice.

The RMS current through the each primary side FET can be

determined from Equation 17, substituting 5A of primary

current for I

FETs, rated at 100V and 7.5A (r

. The result is 3.5A RMS. Fairchild FDS3672

OUT

DS(ON)

= 22mΩ), were

selected for the half-bridge switches.

The synchronous rectifier FETs must withstand

approximately one half of the input voltage assuming no

switching transients are present. This suggests a device

capable of withstanding at least 30V is required. Empirical

testing in the circuit revealed switching transients of 20V

were present across the device indicating a rati ng of at least

60V is required.

The RMS current rating of 7.07A for each SR FET requires a

low r

to minimize conduction losses, which is difficult to

DS(ON)

find in a 60V device. It was decided to use two devices in

parallel to simplify the thermal design. T wo Fai rchild FDS5670

Device output capacitance, Coss, is non-linear with applied

voltage. To find the equivalent discrete capacitance, Cfet, a

charge model is used. Using a known current source, the

time required to charge the MOSFET drain to the desired

operating voltage is determined and the equivalent

capacitance is calculated.

Ichg t•

------------------- -

Cfet

= F

V

(EQ. 20)

Once the estimated transition time is determined, it must be

verified directly in the application. The transformer leakage

inductance was measured at 125nH and the combined

capacitance was estimated at 2000pF. Calculations indicate

a transition period of ~ 25ns. Verification of the performance

yielded a value of T

closer to 45ns.

D

The remainder of the switching half-period is the charge

time, T

T

where F

, and can be found from

C

1

----------------

–

C

2F

T

D

•

S

is the converter switching frequency.

S

1

----------------------------------

••

2 235 10

9–

•– 2.08== =μ s

45 10

3

(EQ. 21)

Using Figure 4, the capacitor value appropriate to the

desired oscillator operating frequency of 470kHz can be

selected. A C

value of 100pF, 220pF, or 330pF is

T

18

FN9111.4

July 13, 2007

ISL6740, 1SL6741

www.BDTIC.com/Intersil

appropriate for this frequency. A value of 220pF was

selected.

To obtain the proper value for R

, Equation 3 is used.

TD

Since there is a 10ns propagation delay in the oscillator

circuit, it must be included in the calculation. The value of

R

selected is 8.06kΩ.

TD

A similar procedure is used to determine the value of R

Equation 2. The value of R

selected is the series

TC

TC

using

combination of 17.4kΩ and 1.27kΩ. See section “Overcurrent

Component Selection” on page 19 for further explanation.

Output Filter Design

The output filter inductor and capacitor selection is simple

and straightforward. Under steady state operating conditions

the voltage across the inductor is very small due to the large

duty cycle. Voltage is applied across the inductor only during

the switch transition time, about 45ns in this application.

Ignoring the voltage drop across the SR FETs, the voltage

across the inductor during the ON time with V

VLVSV

–

OUT

V

INNS

----------------------------------------------- -

2N

1D–()••

P

250≈== mV

where

= 48V is

IN

(EQ. 22)

of an open loop converter. In particular, the low inductor

ripple current under steady state operation increases

significantly as the duty cycle decreases.

14

13

12

11

10

9

8

0.9950 0.9960 0.9970 0.9980 0.9990 1.000

TIME (ms)

FIGURE 8. STEADY STA TE SECONDAR Y WINDING

VOLTAGE AND INDUCTOR CURRENT

15

V (L1:1)

I (L1)

V (L1:1)

I (L1)

VL is the inductor voltage

VS is the voltage across the secondary winding

V

is the output voltage

OUT

If we allow a current ramp, ΔI, of 5% of the rated output

current, the minimum inductance required is

•

≥

L

V

LTON

------------------------ -

ΔI

0.25 2.08•

---------------------------- -

0.5

1.04==μH

(EQ. 23)

An inductor value of 1.4μH, rated for 18A was selected.

With a maximum input voltage of 53V, the maximum output

voltage is about 13V. The closest higher voltage rated

capacitor is 16V . Under steady state operating conditions the

ripple current in the capacitor is small, so it would seem

appropriate to have a low ripple current rated capacitor.

However, a high rated ripple current capacitor was selected

based on the nature of the intended load, multiple buck

regulators. To minimize the output impedance of the filter, a

Sanyo OSCON 16SH150M capacitor in parallel with a 22μF

ceramic capacitor were selected.

Overcurrent Component Selection

There are two circuit areas to consider when selecting the

components for overcurrent protection, current limit and

short circuit shutdown. The current limit threshold is fixed at

0.6V while the short circuit threshold is set to a fraction of the

duty cycle the designer wishes to define as a short circuit.

The current level that corresponds to the overcurrent

threshold must be chosen to allow for the dynamic behavior

10

5

0.986 0.988 0.990 0.992 0.994 1.000

TIME (ms)

FIGURE 9. SECONDARY WINDING VOLT AGE AND

INDUCTOR CURRENT DURING CURRENT LIMIT

OPERATION

0.996 0.998

Figures 8 and 9 show the behavior of the inductor ripple

under steady state and overcurrent conditions. In this

example, the peak current limit is set at 11A. The peak

current limit causes the duty cycle to decrease resulting in a

reduction of the average current through the inductor. The

implication is that the converter can not supply the same

output current in current limit that it can supply under steady

state conditions. The peak current limit setpoint must take

this behavior into consideration. A 3.32Ω current sense

resistor was selected for the rectified secondary of current

transformer T2, corresponding to a peak current limit

setpoint of 16.5A.

The short circuit protection involves setting a voltage

between 0 and 2V on the SCSET pin. The applied voltage

divided by 2 is the percent of maximum duty cycle that

corresponds to a short circuit when the peak current limit is

active. A divider from RTC to ground provides an easy

19

FN9111.4

July 13, 2007

ISL6740, 1SL6741

www.BDTIC.com/Intersil

method to achieve this. The divider between RTC and GND

formed by R13 and R15 determines the percent of maximum

duty cycle that corresponds to a short circuit. The divider

ratio formed by R13 and R15 is

R15

-----------------------------

R13 R15+

1.27k

------------------------------------

1.27k 17.4k+

0.068==

(EQ. 24)

Therefore, the duty cycle that corresponds to a short circuit

is 6.8% of D max (97.9%), or ~6.6%.

Performance

The major performance criteria for the converter are

efficiency, and to a lesser extent, load regulation. Efficiency,

load regulation and line regulation performance are

demonstrated in the following Figures.

100

95

90

85

80

EFFICIENCY (%)

75

70

01234567

LOAD CURRENT (A)

FIGURE 10. EFFICIENCY vs LOAD V

= 48V

IN

9

8

t

regulation is not required, such as those application that use

downstream DC/DC converters, this design approach is

viable.

Waveforms

Typical waveforms can be found in the following Figures.

Figure 13 shows the output voltage during start up.

FIGURE 13. OUTPUT SOFT-START

Figure 14 shows the output voltage ripple and noise at a 5A

load.

12.5

12.25

12.00

11.75

11.50

11.25

OUTPUT VOLTAGE (V)

11

01234567

LOAD CURRENT (A)

FIGURE 11. LOAD REGULATION AT VIN = 48V

14.0

13.5

13.0

12.5

12.0

11.5

OUPUT VOLTAGE (V)

11.0

45 46 47 48 49 50 51 52 53 54

INPUT VOLTAGE (V)

FIGURE 12. LINE REGULATION AT I

OUT

8

= 1A

9

As expected, the output voltage varies considerably with line

and load when compared to an equivalent converter with

closed loop feedback. However, for applications where tight

FIGURE 14. OUTPUT RIPPLE AND NOISE (20MHz BW)

Figures 15 and 16 show the voltage waveforms at the

switching node shared by the upper FET source and the lower

FET drain. In particular, Figure 16 shows near ZVS operation

at 8A of load when the upper FET is turning off and the lower

FET turning on. There is insufficient energy stored in the

leakage inductance to allow complete ZVS operation.

However, since the energy stored in the n ode cap acit an ce is

proportional to V

2

, a significant portion of the energy is still

recovered. Figure 17 shows the switching transition between

outputs, OUTA and OUTB during steady state operation. The

deadtime duration of 48.6ns is clearly shown.

20

FN9111.4

July 13, 2007

ISL6740, 1SL6741

www.BDTIC.com/Intersil

FIGURE 15. FET DRAIN-SOURCE VOLTAGE

FIGURE 16. FET D-S VOLTAGE NEAR-ZVS TRANSITION

FIGURE 17. OUTA TO OUTB TRANSITION

Component List

REFERENCE

DESIGNAT OR VALUE DESCRIPTION

C

1

, C

C

2

3

, C

C

4

6

, C15, C160.1μF Capacitor, 0603, X7R, 50V, 10%

C

5

C

7

C

8

C

9

, C11, C12,

C

10

, C

C

13

14

C

17

C

18

, C

C

R1

R2

C

R3

D

1

L

1

L

2

L

3

Q

5

, Q

Q

L

H

, QR2,

Q

R1

, Q

Q

R3

R

, R

1

10

R

2

, R

R

3

6

R

5

R

7

, R

R

8

9

R

11

R

12

R

13

R

14

R

15

R

17

R

18

, R

R

19

T1

T

1

T

2

U

1

U

3

1.0μF Capacitor, 1812, X7R, 100V, 20%

TDK C4532X7R2A105M

3.3μF Capacitor, 1812, X5R, 50V, 20%

TDK C4532X5R1H335M

1.0μF Capacitor, 0805, X5R, 16V, 10%

TDK C2012X5R1C105K

TDK C1608X7R1H104K

Open Capacitor, 0603, Open

22μF Capacitor, 1812, X5R, 16V, 20%

TDK C4532X5R1C226M

150μF Capacitor, Radial, Sanyo 16SH150M

1000pF Capacitor, 0603, X7R, 50V, 10%

TDK C1608X7R1H102K

220pF Capacitor, 0603, COG, 16V, 5%

TDK C1608COG1C221J

0.047μF Capacitor, 0603, X7R, 16V, 10%

TDK C1608X7R1C473K

Diode, Schottky, BAT54S

Diode, Schottky, BAT54

Zener, 10V, Philips BZX84-C10

190nH Pulse, P2004T

1.5μH Pulse, PG0077.142

Short Jumper or Optional Discrete Leakage

Inductance

Transistor, ON MJD31C

FET, Fairchild FDS3672

FET, Fairchild FDS5670

R4

3.3 Resistor, 2512, 5%

3.01k Resistor, 2512, 1%

10.0 Resistor, 0603, 1%

3.32 Resistor, 0603, 1%

75.0k Resistor, 0805, 1%

20.0 Resistor, 0805, 1%

100 Resistor, 0603, 1%

8.06k Resistor, 0603, 1%

17.4k Resistor, 0603, 1%

Open Resistor, 0603, Open

1.27k Resistor, 0603, 1%

97.6k Resistor, 0603, 1%

3.01k Resistor, 0603, 1%

10.0k Resistor, 0603, 1%

Midcom 31718

Pulse P8205T

Intersil HIP2101IB

ISL6740IB

21

FN9111.4

July 13, 2007

ISL6740, 1SL6741

www.BDTIC.com/Intersil

Adding Line Only Regulation - Feed Forward

Output voltage variation caused by changes in the supply

voltage may be virtually removed through a technique known

as feed forward compensation. Using feed forward, the duty

cycle is directly controlled based on changes in the input

voltage only. No closed loop feedback system is required.

Voltage feed forward may be implemented as shown in

Figure 18..

1.5V

R103

49.9k

+

-

R104

100k

C100

1nF

R110

698

U100A

R105

100k

R109

3.48k

VREF

+VIN

R100

69.8k

R102

100k

R101

2k

FIGURE 18. VOLTAGE FEED FORWARD CIRCUIT

The circuit provides feed forward compensation for a 2:1

input voltage range. Resistors R

voltage divider to generate a 1V signal at the input voltage

that corresponds to maximum duty cycle (V

Resistors R

109

, R

110

, and R

111

VREF to create reference voltages for the amplifiers. The

first stage uses U

100A

, R

102

, R

a unity gain inverting amplifier. Its output varies inversely

with input voltage and ranges from 1V to 2V. The bandwidth

of the circuit may be controlled by varying the value of C

The gain of the first amplifier stage is:

V

VD3.00+–= V

A

where:

VA = Output voltage of U

100A

VD = The input divider voltage

R111

806

0.8V

R106

100K

U100B

100

R108

100k

and R

+

-

R107

100k

101

to VERROR

set the input

minimum).

IN

form a voltage divider from

, R

103

104

, and C

100

to form

100

(EQ. 25)

Other duty ranges are possible, but are still limited to a 2:1

ratio. The voltage applied to V

peak-to-peak voltage on C

Since the peak-to-peak C

, and offset by the valley voltage.

T

voltage is 2.00V nominal, the

T

must be scaled to the

ERROR

voltage at the output of U100A must be divided by 2.0V to

obtain the desired duty cycle. For example, if an 80% duty

cycle was required at the minimum operating voltage, the

output of U100A must be 1.60V (80% of 2.00V). From

(Equation 25), the divider voltage must be set to 1.4V for the

input voltage that corresponds to the 80% duty cycle.

It should be noted that the synchronous rectifiers (SRs),

being driven from the transformer secondary, are only gated

on during the ON time of the primary FETs. Conduction

continues through the body diodes during the OFF time

when operating in continuous inductor current mode. This

mode of operation usually results in significant conduction

and switching losses in the SR FETs. These losses may be

reduced considerably by either adding schottky diodes in

parallel to the SR FETs or by driving the SR FETs directly

with a control signal.

Adding Regulation - Closed Loop Feedback

The second Typical Application schematic adds closed loop

feedback with isolation. The ISL6740EVAL2Z demonstration

platform implements this design and is available for

evaluation. The input voltage range was increased to 36V to

75V , which necessitates a few modifications to the open loop

design. The output inductor value was increased to 4.0μH,

schottky rectifier CR4 was added to minimize SR FET body

diode conduction, the turns ratio of the main transformer was

changed to 4:3, and the synchronous rectifier gate drives

were modified. The design process is essentially the same

as it was for the unregulated version, so only the feedback

control loop design will be discussed.

The major components of the feedback control loop are a

.

programmable shunt regulator and an opto-coupler. The

opto-coupler is used to transfer the error signal across the

isolation barrier. The opto-coupler offers a convenient means

to cross the isolation barrier, but it adds complexity to the

feedback control loop. It adds a pole at about 10kHz and a

significant amount of gain variation due the current transfer

ratio (CTR). The CTR of the opto-coupler varies with initial

tolerance, temperature, forward current, and age.

The second stage uses U

100B

, R

105

, R

106

, R

107

, and R

108

to form a summing amplifier which offsets the first stage

output by 0.8V (the value of C

applied to the V

input now matches the offset and

ERROR

valley voltage). The signal

T

amplitude of the oscillator sawtooth so that the duty cycle

varies linearly from 100% to 50% of maximum with a 2:1

input voltage variation.

22

FN9111.4

July 13, 2007

ISL6740, 1SL6741

www.BDTIC.com/Intersil

A block diagram of the feedback control loop follows in

Figure 19.

PWM

ISOLATION

FIGURE 19. CONTROL LOOP BLOCK DIAGRAM

POWER

STAGE

ERROR AMPLIFIER

Z

V

OUT

2

-

+

REF

Z

1

The loop compensation is placed around the Error Amplifier

(EA) on the secondary side of the converter. A Type 3 error

amplifier configuration was selected.

V

OUT

V

ERR

-

REF

+

40

30

20

10

GAIN (dB)

0

-10

-20

10 100 1•10

3

1•10

FREQUENCY (Hz)

1•10

4

1•10

FIGURE 21A. CONTROL-TO-OUTPUT GAIN

50

0

-50

-100

PHASE (DEGREES)

-150

5

6

FIGURE 20. TYPE 3 ERROR AMPLIFIER

The control to output transfer function may be represented

as [1]

s

------

1

v

----- -

v

N

V

o

IN

----------------

VS2•

c

S

------- -

•=

•

N

P

+

ω

s

---------------- -

Q()ω

o

z

s

⎛⎞

------ -

⎝⎠

ω

o

------------------------------------------------++

1

2

(EQ. 26)

where

R

o

--------------- -

Q

=

ωoL•

1

----------- -

ω

= or f

o

LC

1

-----------

ω

= or f

z

C

R

c

R

= Output Load Resistance

o

o

z

=

=

-------------------

2π R

1

-------------------

2π LC

1

C

c

L = Output Inductance

C = Output Capacitance

Rc = Output Capacitance ESR