®

www.BDTIC.com/Intersil

ISL6729

Data Sheet December 1, 2005

Low-Cost Single-Ended Current-Mode

PWM for Microcontroller Based Power

Converters

The ISL6729 pulse width modulating (PWM) current mode

controller is designed for power conversion applications that

are based on a microcontroller or other device which can

generate a digital clock signal at the desired switching

frequency. Similar to the ISL684x family of products, the

ISL6729 provides the basic current mode PWM control

features, but eliminates the error amplifier, the oscillator, and

the reference. An external clock signal applied to the

oscillator input provides the time base and sets the

maximum duty cycle. The reduced feature set is ideal for

those applications where a microcontroller is available to

provide the monitor and control functions. The analog PWM

provides the cycle by cycle peak current mode control,

leaving the monitor and control overhead to the

microcontroller.

Ordering Information

PAR T

NUMBER

ISL6729IB ISL6729IB -40 to 105 8 Ld SOIC M8.15

ISL6729IBZ

(See Note)

ISL6729IU 6729 -40 to 105 8 Ld MSOP M8.118

ISL6729IUZ

(See Note)

Add -T to part number for Tape and Reel packaging.

NOTE: Intersil Pb-free plus anneal products employ special Pb-free

material sets; molding compounds/die attach materials and 100%

matte tin plate termination finish, which are RoHS compliant and

compatible with both SnPb and Pb-free soldering operations. Intersil

Pb-free products are MSL classified at Pb-free peak reflow

temperatures that meet or exceed the Pb-free requirements of

IPC/JEDEC J STD-020.

PAR T

MARKING

6729IBZ -40 to 105 8 Ld SOIC

6729Z -40 to 105 8 Ld MSOP

TEMP.

RANGE (°C) PACKAGE

(Pb-free)

(Pb-free)

PKG.

DWG. #

M8.15

M8.118

FN9152.2

Features

• 5V Operation

• 1A MOSFET gate driver

•400µA startup current

• 30ns propagation delay current sense to output

• Fast transient response with peak current mode control

• Switching frequency to 2MHz

• 20ns rise and fall times with 1nF output load

• Maximum Duty Cycle Determined by Clock Input Duty

Cycle

• Tight tolerance current limit threshold

• Pb-free plus anneal available (RoHS compliant)

Applications

• Telecom and Datacom Power

• Wireless Base Station Power

• File Server Power

• Industrial Power Systems

• PC Power Supplies

• Isolated Buck and Flyback Regulators

• Boost Regulators

Pinout

ISL6729 (8 LD SOIC, MSOP)

TOP VIEW

COMP

N/C

CS

CLKS

1

2

3

4

8

N/C

7

VDD

6

OUT

5

GND

PART NUMBER RISING UVLO MAX. DUTY CYCLE

ISL6729 4.75V 100%

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright © Intersil Americas Inc. 2004 - 2005. All Rights Reserved.

All other trademarks mentioned are the property of their respective owners.

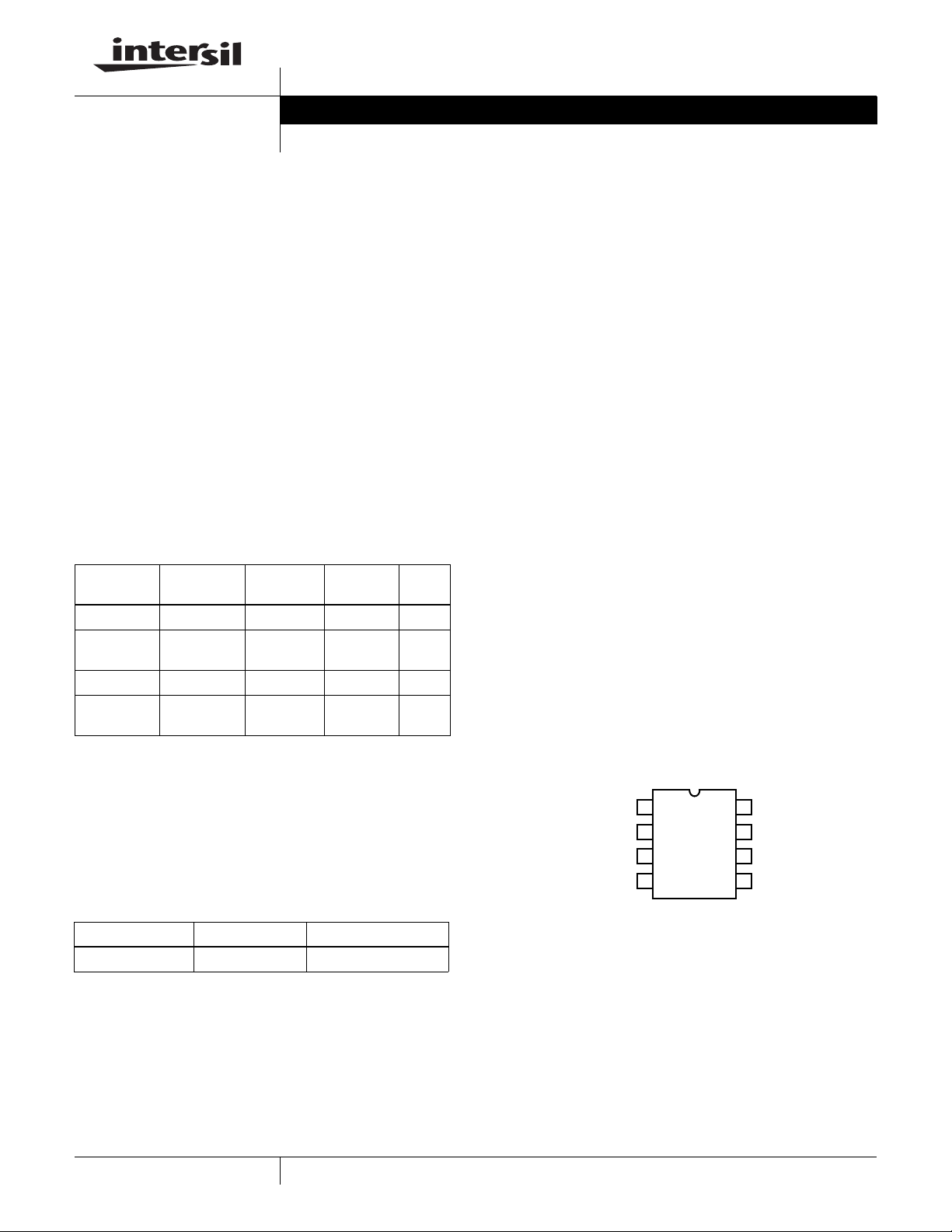

Functional Block Diagram

www.BDTIC.com/Intersil

V

DD

2

GND

START/STOP

UV COMPARATOR

+

-

BG

OK

V

+

-

DD

+

CS

COMP

CLK

December 1, 2005

-

100mV

2R

R

+

-

1.1V

CLAMP

PWM

COMPARATOR

SRQ

OUT

Q

ISL6729

FN9152.2

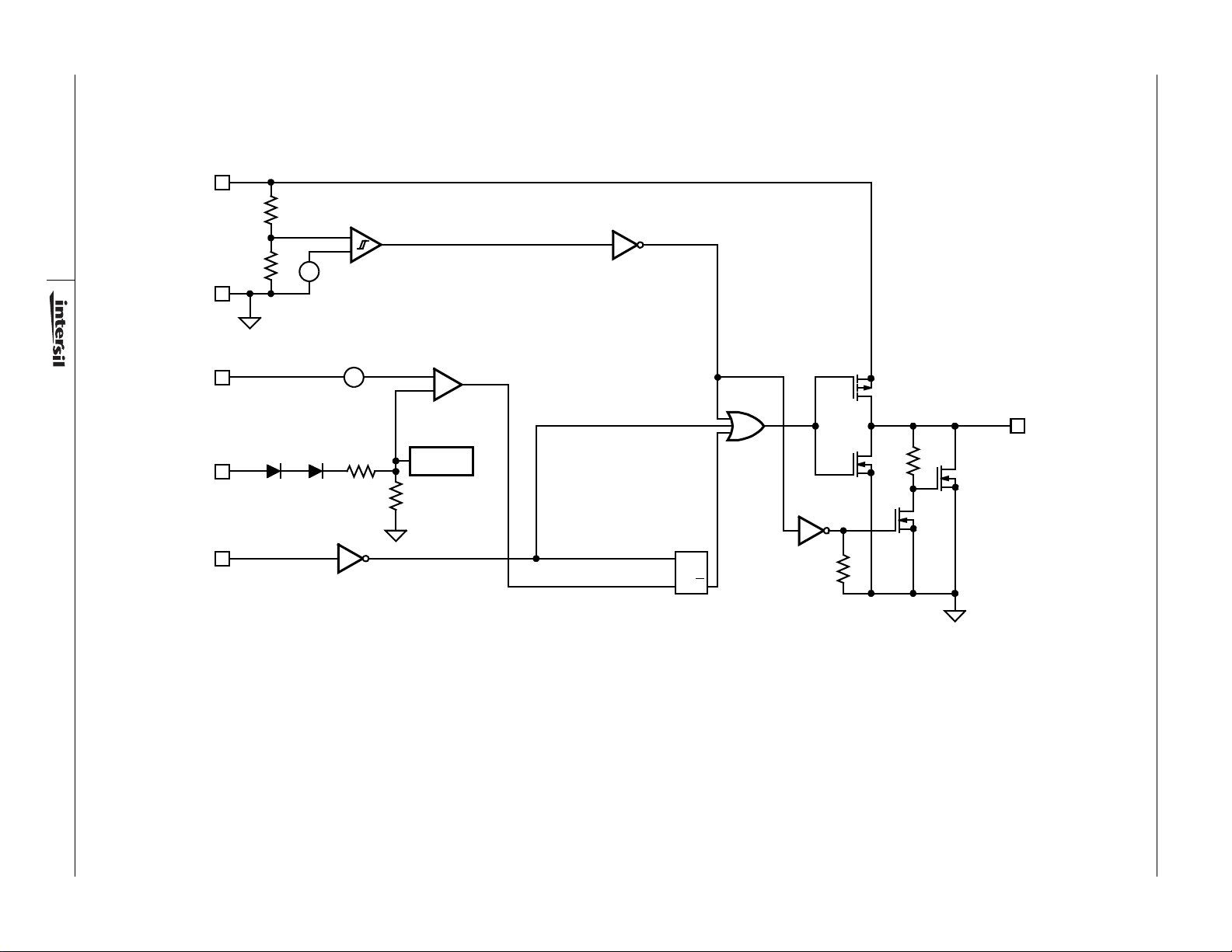

Typical Application - Interleaved Multi-Phase Isolated Converter

www.BDTIC.com/Intersil

VOLTAGE FEEDBACK

5V

VDD

OUT

GND

VDD

OUT

GND

VDD

OUT

GND

8

7

6

54

CURRENT FEEDBACK

8

7

6

54

CURRENT FEEDBACK

8

7

6

54

1COMP

3

CLOCK φ1

CLOCK φ2

MICROCONTROLLER

CLOCK φ3

2

3

CS

CLK

ISL6729

1COMP

2

3

CS

CLK

ISL6729

1COMP

2

3

CS

CLK

ISL6729

ISOLATION

POWER STAGE

POWER STAGE

POWER STAGE

ERROR

AMPLIFIER

VOUT

ISL6729

December 1, 2005

FN9152.2

CURRENT FEEDBACK

ISL6729

www.BDTIC.com/Intersil

Absolute Maximum Ratings Thermal Information

Supply Voltage, VDD . . . . . . . . . . . . . . . . . . . . GND - 0.3V to +6.5V

OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . .GND - 0.3V to V

Signal Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . GND - 0.3V to 6.5V

Peak GATE Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1A

ESD Classification

Human Body Model (Per MIL-STD-883 Method 3015.7) . . .2000V

Charged Device Model (Per EOS/ESD DS5.3, 4/14/93) . . .1000V

DD

+ 0.3V

Thermal Resistance (Typical, Note 1) θ

SOIC Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

MSOP Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Maximum Junction Temperature . . . . . . . . . . . . . . . . -55°C to 150°C

Maximum Storage Temperature Range. . . . . . . . . . . -65°C to 150°C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . . 300°C

(SOIC, MSOP- Lead Tips Only)

Operating Conditions

Temperature Range

ISL6729Ix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to 105°C

Supply Voltage Range (Typical)

ISL6729 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.75V-5.25V

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

1. θ

is measured with the component mounted on a high effective thermal conductivity test board in free air. See Tech Brief TB379 for details.

JA

2. All voltages are with respect to GND.

Electrical Specifications Recommended operating conditions unless otherwise noted. Refer to Block Diagram and Typical Application

schematic. V

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

UNDERVOLTAGE LOCKOUT

START Threshold 4.15 4.50 4.75 V

STOP Threshold 4.00 4.30 4.60

Hysteresis -0.2-V

Start-Up Current, I

Operating Current, I

Operating Supply Current, I

CURRENT SENSE

Input Bias Current V

CS Offset Voltage V

COMP to PWM Comparator Offset Voltage V

CS Input Signal, Maximum 0.91 0.97 1.03 V

Gain, A

CS

CS to OUT Delay (Note 5) - 25 40 ns

CLOCK

Input High Voltage Level, VIH - 2.8 - V

Input Low Voltage Level, VIL - 2.7 - V

Maximum Clock Rate (Note 5) 2 - - MHz

OUTPUT

Gate VOH V

Gate VOL OUT - GND, I

Peak Output Current C

Rise Time C

Fall Time C

= ∆V

DD

DD

D

/∆VCS 0 < VCS < 910mV, VFB = 0V. (Note 5) 2.5 3.0 3.5 V/V

COMP

= 5V, CLK = 50kHz, TA = -40 to 105°C (Note 3), Typical values are at TA = 25°C

DD

VDD < START Threshold - 0.4 12 mA

(Note 4) - 3.3 5.5 mA

Includes 1nF GATE loading - 4.1 6.0 mA

= 1V -1.0 - 1.0 µA

CS

= 0V (Note 5) 95 100 105 mV

CS

= 0V (Note 5) 0.80 1.15 1.30 V

CS

- OUT, I

DD

= 1nF (Note 5) 1.0 - - A

OUT

= 1nF (Note 5) - 20 40 ns

OUT

= 1nF (Note 5) - 20 40 ns

OUT

= -200mA - 1.0 2.0 V

OUT

= 200mA - 1.0 2.0 V

OUT

(°C/W)

JA

4

FN9152.2

December 1, 2005

ISL6729

www.BDTIC.com/Intersil

Electrical Specifications Recommended operating conditions unless otherwise noted. Refer to Block Diagram and Typical Application

schematic. V

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

PWM

Maximum Duty Cycle -99-%

Minimum Duty Cycle --0%

NOTES:

3. Specifications at -40°C are guaranteed by design, not production tested.

4. This is the V

5. Guaranteed by design, not 100% tested in production.

current consumed when the device is active but not switching. Does not include gate drive current.

DD

Pin Descriptions

CLK - This is the oscillator timing control pin. The

operational frequency and maximum duty cycle are set by

applying a 5V amplitude clock signal to CLK. The logic high

duration defines the maximum ON time for the output. A

maximum clock rate up to 2.0MHz is possible.

COMP - COMP is the input to the PWM comparator and is

typically controlled through an external error amplifier.

CS - This is the current sense input to the PWM comparator.

The range of the input signal is nominally 0 to 1.0V and has

an internal offset of 100mV.

GND - GND is the power and small signal reference ground

for all functions.

OUT - This is the drive output to the power switching device.

It is a high current output capable of driving the gate of a

power MOSFET with peak currents of 1.0A. This GATE

output is actively held low when V

threshold.

V

- VDD is the 5V power connection for the IC. The IC will

DD

operate from 4.75V to 5.25V. However, the accuracy of the

voltage clamp on the COMP signal, which determines the

over current threshold, is dependent on the accuracy of

VDD. A tight tolerance on VDD will result in a tight over

current threshold.

The total supply current will depend on the load applied to

OU T. To t a l I

and the average output current. Knowing the operating

frequency, f, and the MOSFET gate charge, Qg, the average

output current can be calculated from:

I

OUT

To optimize noise immunity, bypass V

ceramic capacitor as close to the VDD and GND pins as

possible.

current is the sum of the operating current

DD

Qg f×=

is below the UVLO

DD

DD

= 5V, CLK = 50kHz, TA = -40 to 105°C (Note 3), Typical values are at TA = 25°C (Continued)

DD

Ground Plane Requirements

Careful layout is essential for satisfactory operation of the

device. A good ground plane must be employed. A unique

section of the ground plane must be designated for high di/dt

currents associated with the output stage. V

bypassed directly to GND with good high frequency

capacitors.

should be

DD

Applications Information

Microcontrollers are becoming more popular for monitoring

and supervisory functions in power converters due to their

flexibility, capability, and declining prices. Many applications

would like to take advantage of this flexibility and use them

to perform the control loop function as well. There are many

examples of voltage mode control using digital signal

processing techniques. However, microcontrollers available

today do not have the execution speed required for peak

current mode control at the operational frequencies of

modern switch-mode power supplies. As such, they are

unable to detect the peak current and terminate the

switching cycle within the few nanosecond window required.

The ISL6729 provides the analog circuitry required to

perform peak current control, but delegates the oscillator

function to the microcontroller. This arrangement allows the

microcontroller to control soft-start, maximum duty cycle,

and operational frequency of the power converter, as well as

performing the traditional overhead functions such as fault

monitoring and system interface.

Application of the ISL6729 is similar to the ISL684x family of

PWM converters except that the input bias voltage has been

changed to 5V and the oscillator, reference, and error

amplifier functions have been removed. An external digital

(EQ. 1)

to GND with a

clock signal, such as the PWM output of a microcontroller,

must be supplied to control the frequency and maximum

duty cycle. The frequency of the applied clock signal and the

frequency of operation of the PWM are identical. The duty

cycle of the clock is the maximum duty cycle of the PWM.

Soft-start may be accomplished by incrementing the duty

cycle of the applied clock signal from zero to the maximum

desired value in a time frame appropriate for the application.

5

FN9152.2

December 1, 2005

The Typical Application block diagram illustrates how the

www.BDTIC.com/Intersil

ISL6729 may be used for an interleaved power converter. In

this example, three clock signals of equal duty cycle, but

phased 120º apart, are applied to separate power stages.

Each phase shares a common voltage feedback signal, but

uses separate current feed back signals from each power

stage for regulation. Excellent current sharing behavior is

assured since each phase must produce the same peak

current. Accuracy is determined by the variation of the

output inductor value and the feedback components.

Multiple output power supplies can be created in a similar

fashion. Only one clock signal is required if in-phase

operation is desired. Each stage may be independently

controlled using separate voltage and current feedback

loops.

ISL6729

6

FN9152.2

December 1, 2005

Small Outline Plastic Packages (SOIC)

www.BDTIC.com/Intersil

ISL6729

N

INDEX

AREA

123

-A-

E

-B-

SEATING PLANE

D

A

-C-

0.25(0.010) BM M

H

L

h x 45°

α

e

B

0.25(0.010) C AM BS

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of

Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm (0.006

inch) per side.

4. Dimension “E” does not include interlead flash or protrusions. Interlead flash and protrusions shall not exceed 0.25mm (0.010 inch) per

side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width “B”, as measured 0.36mm (0.014 inch) or greater

above the seating plane, shall not exceed a maximum value of

0.61mm (0.024 inch).

10. Controlling dimension: MILLIMETER. Converted inch dimensions

are not necessarily exact.

M

A1

C

0.10(0.004)

M8.15 (JEDEC MS-012-AA ISSUE C)

8 LEAD NARROW BODY SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.0532 0.0688 1.35 1.75 -

A1 0.0040 0.0098 0.10 0.25 -

B 0.013 0.020 0.33 0.51 9

C 0.0075 0.0098 0.19 0.25 D 0.1890 0.1968 4.80 5.00 3

E 0.1497 0.1574 3.80 4.00 4

e 0.050 BSC 1.27 BSC H 0.2284 0.2440 5.80 6.20 h 0.0099 0.0196 0.25 0.50 5

L 0.016 0.050 0.40 1.27 6

N8 87

α

0° 8° 0° 8° -

NOTESMIN MAX MIN MAX

Rev. 1 6/05

7

FN9152.2

December 1, 2005

ISL6729

www.BDTIC.com/Intersil

Mini Small Outline Plastic Packages (MSOP)

N

EE1

INDEX

AREA

AA1A2

TOP VIEW

-H-

SIDE VIEW

12

b

e

D

NOTES:

1. These package dimensions are within allowable dimensions of

JEDEC MO-187BA.

2. Dimensioning and tolerancing per ANSI Y14.5M-1994.

3. Dimension “D” does not include mold flash, protrusions or gate

burrs and are measured at Datum Plane. Mold flash, protrusion

and gate burrs shall not exceed 0.15mm (0.006 inch) per side.

4. Dimension “E1” does not include interlead flash or protrusions

and are measured at Datum Plane. Interlead flash and

protrusions shall not exceed 0.15mm (0.006 inch) per side.

5. Formed leads shall be planar with respect to one another within

0.10mm (0.004) at seating Plane.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. Dimension “b” does not include dambar protrusion. Allowable

dambar protrusion shall be 0.08mm (0.003 inch) total in excess

of “b” dimension at maximum material condition. Minimum space

between protrusion and adjacent lead is 0.07mm (0.0027 inch).

- H -

-A -

.

10. Datums and to be determined at Datum plane

11. Controlling dimension: MILLIMETER. Converted inch dimensions are for reference only.

-B-

0.20 (0.008) A

GAUGE

PLANE

SEATING

PLANE

0.10 (0.004) C

-A-

0.20 (0.008) C

- B -

0.25

(0.010)

-C-

SEATING

PLANE

a

0.20 (0.008) C

- H -

B

4X θ

C

D

4X θ

L1

C

C

L

E

1

END VIEW

R1

R

L

-B-

M8.118 (JEDEC MO-187AA)

8 LEAD MINI SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.037 0.043 0.94 1.10 A1 0.002 0.006 0.05 0.15 A2 0.030 0.037 0.75 0.95 -

b 0.010 0.014 0.25 0.36 9

c 0.004 0.008 0.09 0.20 -

D 0.116 0.120 2.95 3.05 3

E1 0.116 0.120 2.95 3.05 4

e 0.026 BSC 0.65 BSC -

E 0.187 0.199 4.75 5.05 -

L 0.016 0.028 0.40 0.70 6

L1 0.037 REF 0.95 REF -

N8 87

R 0.003 - 0.07 - R1 0.003 - 0.07 - -

05

α

o

o

0

15

o

o

6

o

5

o

0

15

o

o

6

Rev. 2 01/03

NOTESMIN MAX MIN MAX

-

-

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

8

FN9152.2

December 1, 2005

Loading...

Loading...