®

www.BDTIC.com/Intersil

ISL6721

Data Sheet March 5, 2008

Flexible Single-ended Current Mode PWM

Controller

The ISL6721 is a low power, single-ended pulse width

modulating (PWM) current mode controller designed for a

wide range of DC/DC conversion applications including

boost, flyback, and isolated output configurations. Peak

current mode control effectively handles power transients

and provides inherent overcurrent protection. Other features

include a low power mode where the supply current drops to

less than 200µA during overvoltage and overcurrent

shutdown faults.

This advanced BiCMOS design features low operating

current, adjustable operating frequency up to 1MHz,

adjustable soft-start, and a bi-directional SYNC signal that

allows the oscillator to be locked to an external clock for

noise sensitive applications.

Ordering Information

PART

NUMBER

ISL6721AB* ISL6721AB -40 to +105 16 Ld SOIC

ISL6721ABZ*

(Note)

ISL6721AV* ISL67 21AV -40 to +105 16 Ld TSSOP

ISL6721AVZ*

(Note)

*Add “-T” suffix for tape and reel. Please refer to TB347 for details on

reel specifications.

NOTE: These Intersil Pb-free plastic packaged products employ

special Pb-free material sets; molding compounds/die attach materials

and 100% matte tin plate PLUS ANNEAL - e3 termination finish, which

is RoHS compliant and compatible with both SnPb and Pb-free

soldering operations. Intersil Pb-free products are MSL classified at

Pb-free peak reflow temperatures that meet or exceed the Pb-free

requirements of IPC/JEDEC J STD-020.

PART

MARKING

6721ABZ -40 to +105 16 Ld SOIC

ISL67 21AVZ -40 to +105 16 Ld TSSOP

TEMP

RANGE (°C) PACKAGE

(150 mil)

(150 mil)

(Pb-Free)

(4.4mm)

(4.4mm)

(Pb-free)

PKG.

DWG. #

M16.15

M16.15

M16.173

M16.173

FN9110.6

Features

• 1A MOSFET Gate Driver

• 100µA Startup Current

• Fast Transient Response with Peak Current Mode Control

• Adjustable Switching Frequency up to 1MHz

• Bi-directional Synchronization

• Low Power Disable Mode

• Delayed Restart from OV and OC Shutdown Faults

• Adjustable Slope Compensation

• Adjustable Soft-start

• Adjustable Overcurrent Shutdown Delay

• Adjustable UV and OV Monitors

• Leading Edge Blanking

• Integrated Thermal Shutdown

• 1% Tolerance Voltage Reference

• Pb-Free Available (RoHS Compliant)

Applications

• Telecom and Datacom Power

• Wireless Base Station Power

• File Server Power

• Industrial Power Systems

• Isolated Buck and Flyback Regulators

• Boost Regulators

Pinout

ISL6721

(16 LD SOIC, TSSOP)

TOP VIEW

GATE

ISENSE

SYNC

SLOPE

UV

OV

RTCT

ISET

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

VC

PGND

VCC

VREF

LGND

SS

COMP

FB

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright © Intersil Americas Inc. 2003-2005, 2007, 2008. All Rights Reserved.

All other trademarks mentioned are the property of their respective owners.

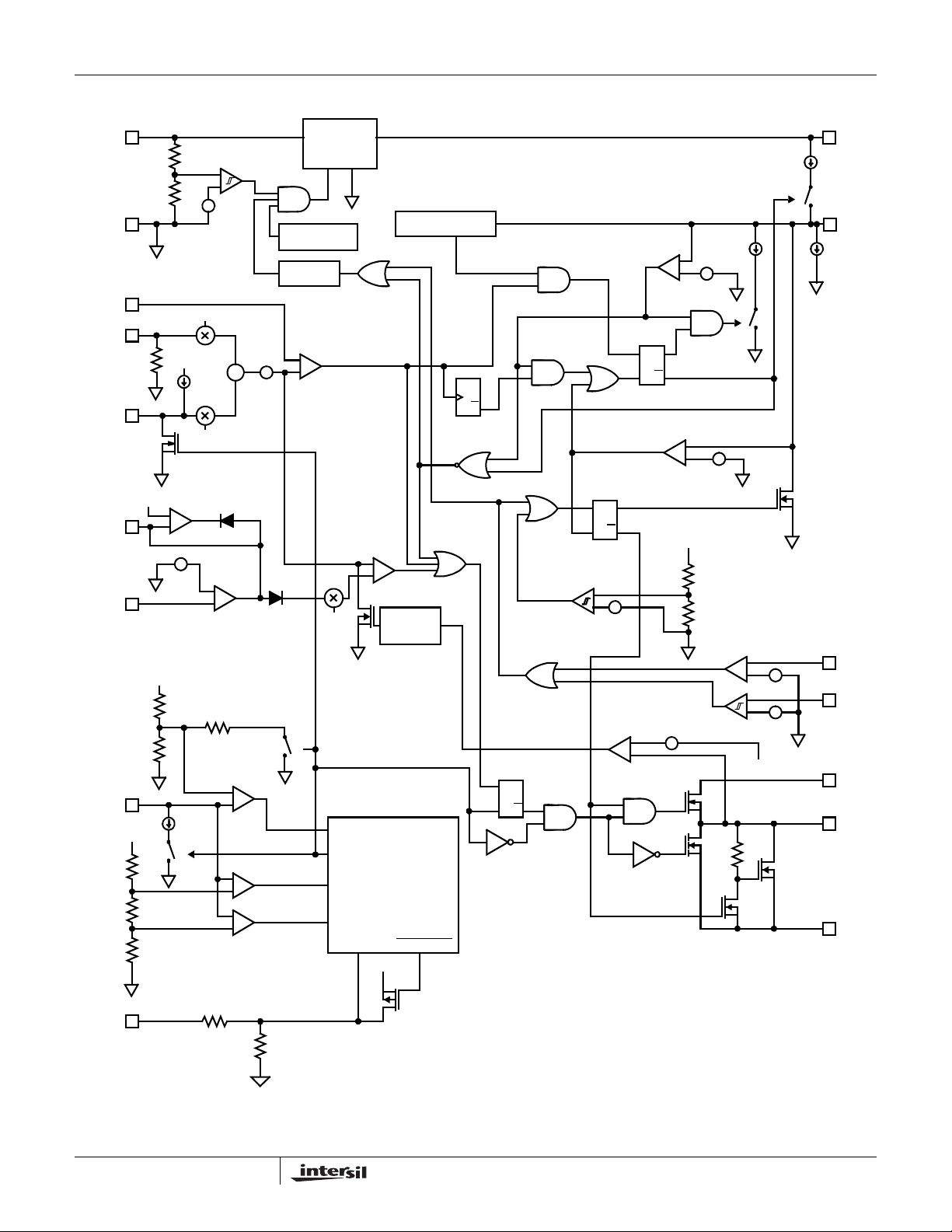

Functional Block Diagram

www.BDTIC.com/Intersil

ISL6721

VCC

LGND

ISET

ISENSE

SLOPE

COMP

VFB

VREF

START/STOP

UV COMPARATOR

+

-

+

BG

-

0.8

5k

VREF

SS

+

-

+

-

2.5V

53µA

0.1

SS CLAMP

ERROR

AMPLIFIER

+

-

+

S

+

+

-

100mV

ENABLE

PROTECTION

RESTART

5V

1%

THERMAL

DELAY

-

OC DETECT

+

OVERCURRENT

COMPARATOR

COMPARATOR

1/3

PWM

+

-

BLANKING

SS CHARGE

VOLTAGE CLAMP

SS CHARGED

Q

Q

50µs

RETRIGGERABLE

ONE SHOT

100ns

START

OVERCURRENT

SHUTDOWN

DELAY

FAULT

LATCH

SRQ

Q

SET DOMINANT

VREF

UV COMPARATOR

4.65V

-

+

SRQ

OC LATCH

SS LOW

SS LOW

COMPARATOR

-

+

BG

SOFT-START

CHARGE

CURRENT

-

+

VREF

-

+

4.375V

270mV

25µA

-

+

+

-

Q

70µA

ON

ON

VREF

SS

15µA

RTCT

SYNC

4V

2V

20k

30k

VREF

VREF

3.0V

12k

1.5V

OSCILLATOR

COMPARATOR

1mA

ON

100k

+

-

-

+

2.50V

36k

-

-

+

+

1.45V

BLANKING

COMPARATOR

ON

+

+

-

+

4.5k

BI-DIRECTIONAL

SYNCHRONIZATION

OSC IN

CLK OUT

NO EXT SYNC

EXT SYNC BLANKING

SYNC IN SYNC OUT

VREF

SRQ

Q

3.0V

-

+

-

+

OV

UV

VC

GATE

PGND

2

FN9110.6

March 5, 2008

ISL6721

www.BDTIC.com/Intersil

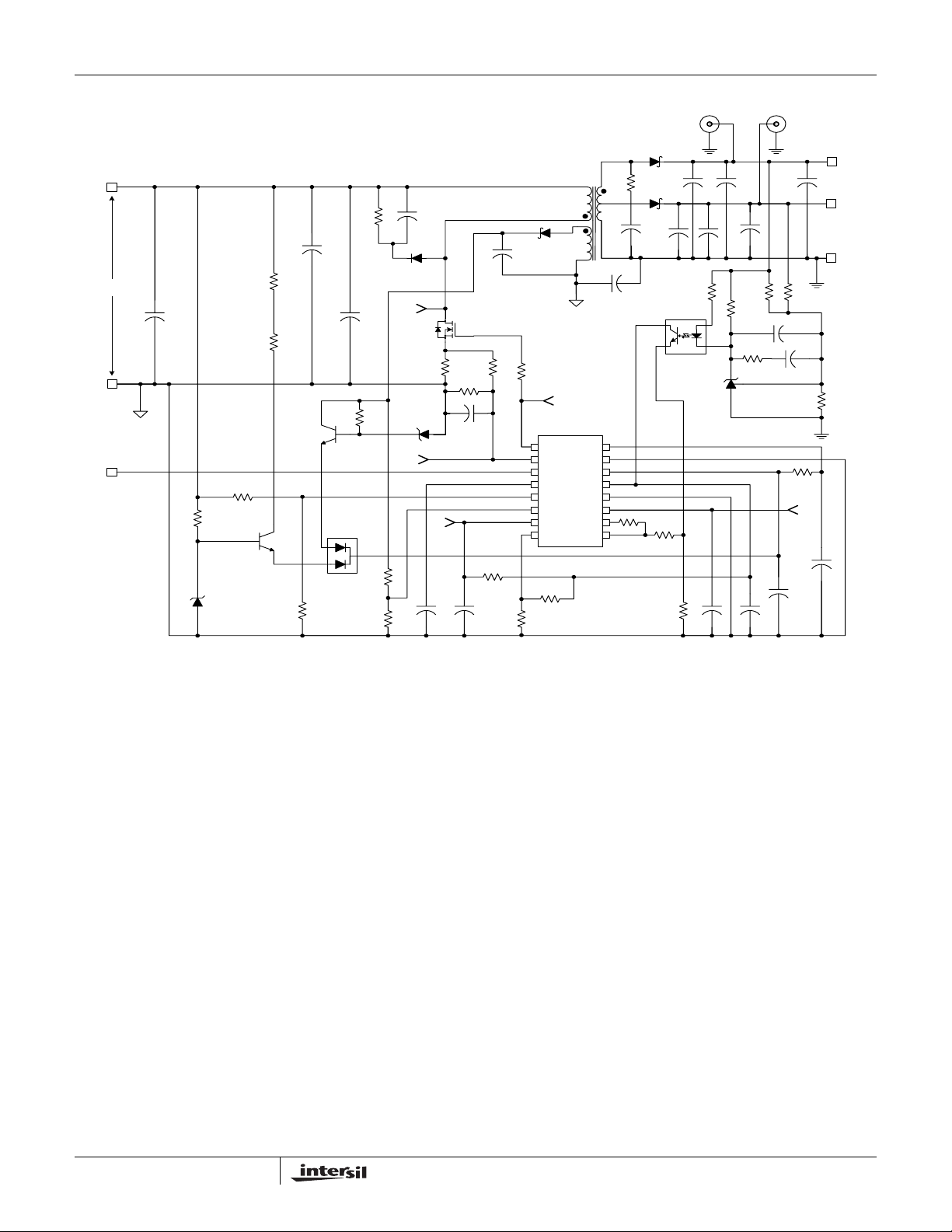

Typical Application - 48V Input Dual Output Flyback, 3.3V @ 2.5A, 1.8V @ 1.0A

SP1 SP2

CR5

T1

VIN+

SYNC

VIN-

P9

36-75V

ISOLA T IO N

XFMR

R24

C2

R1

C1

R2

R5

R6

Q3

VR1

C3

R25

Q2

D2

R8

R7

C18

CR2

C5

CR6

TP1

Q1

R4

D1

TP3

R9

R3

R23

C4 U4

TP5

C7

R10

C8

R22

TP2

V

GATE

ISENSE

SYNC

SLOPE

UV

OV

RTCT

ISET

R11

C

PGND

V

CC

ISL6721

VREF

LGND

SS

COMP

VFB

R12

R21

CR4

C17

C6

R26

C21

C15 C16

++

C19

R27

R13

C22

+

R16

U2

C9

R17

R19

R15

U3

+3.3V

+1.8V

+

C20

RETURN

R18

C14

C13

R20

R14

TP4

C12

C11

C10

3

FN9110.6

March 5, 2008

ISL6721

www.BDTIC.com/Intersil

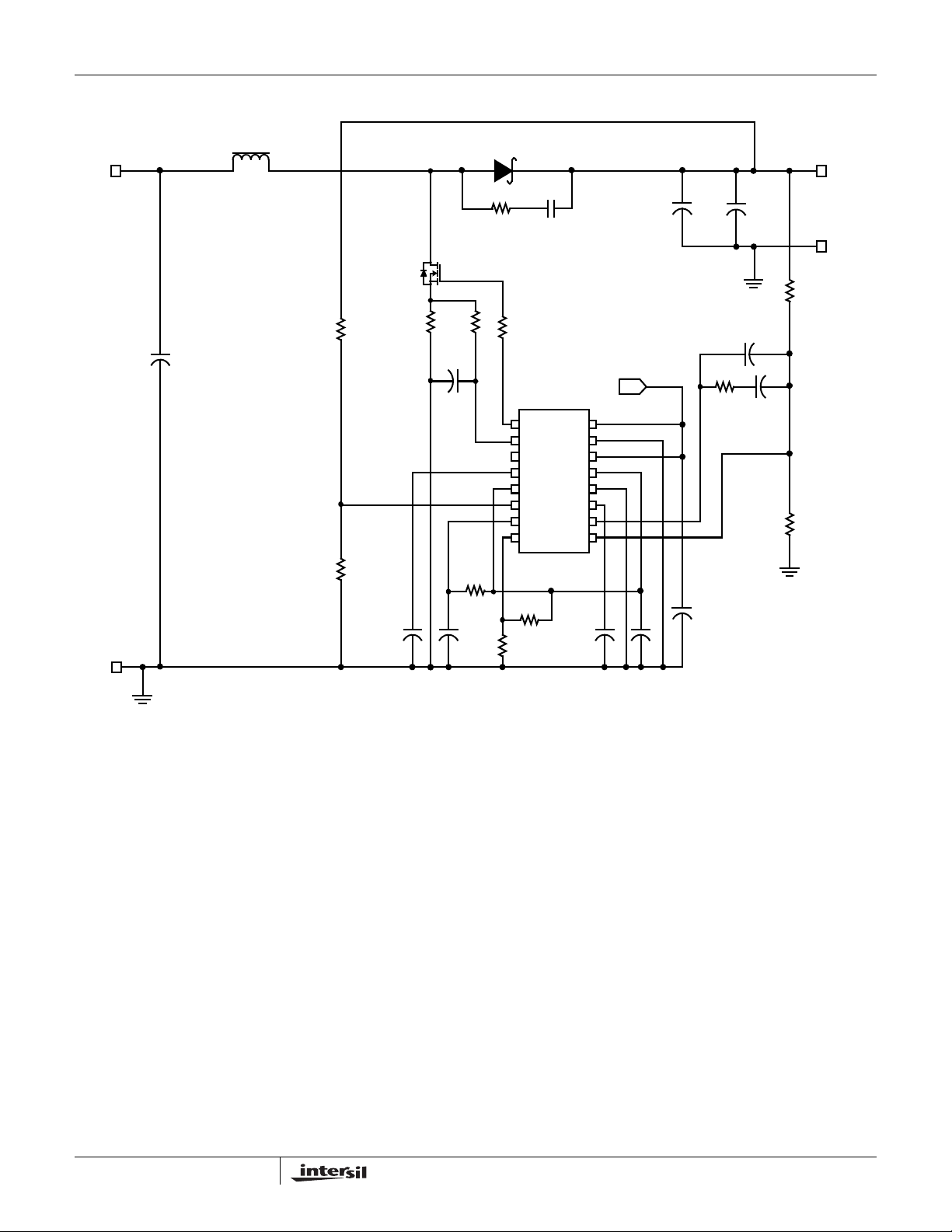

Typical Boost Converter Application Schematic

VIN+

C1

L1

R4

Q1

R1

R2

CR1

R12 C12

R3

+VOUT

+

C2

C3

RETURN

R8

C11

VIN-

R5

C9

C4

R11

C8

R7

U1

GATE

PGND

ISENSE

VCCSYNC

SLOPE

VREF

ISL6721

UV

LGND

OV

RTCT

ISET VFB

R6

SS

COMP

VIN+

VC

C7

C6

C5

R10

C10

R9

4

FN9110.6

March 5, 2008

ISL6721

www.BDTIC.com/Intersil

Absolute Maximum Ratings Thermal Information

Supply Voltage, V

GATE. . . . . . . . . . . . . . . . GND - 0.3V to Gate Output Limit Voltage

PGND to LGND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±0.3V

VREF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GND - 0.3V to 5.3V

Signal Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . GND - 0.3V to VREF

Peak GATE Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1A

Operating Conditions

Temperature Range

ISL6721Ax . . . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to +105°C

Supply Voltage Range (Typical, Note 2) . . . . . . . . 9VDC to 18VDC

CAUTION: Do not operate at or near the maximum ratings listed for extended periods of time. Exposure to such conditions may adversely impact product reliability and

result in failures not covered by warranty.

NOTES:

1. θ

is measured with the component mounted on a high effective thermal conductivity test board in free air. See Tech Brief TB379 for details.

JA

2. All voltages are with respect to GND.

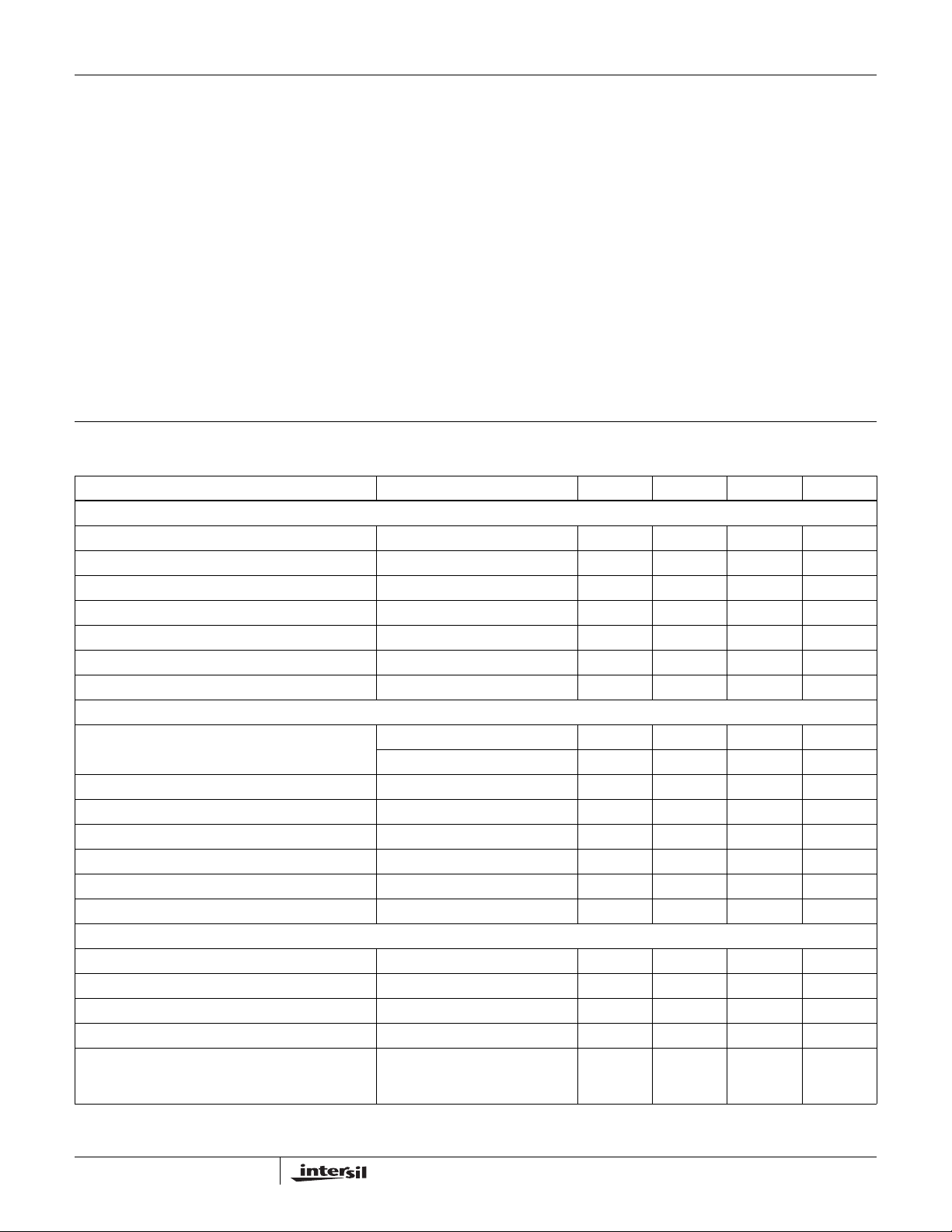

Electrical Specifications Recommended operating conditions unless otherwise noted. Refer to Block Diagram and Typical Application

UNDERVOLTAGE LOCKOUT

START Threshold 7.95 8.25 8.55 V

STOP Threshold 7.40 7.70 8.20 V

Hysteresis 0.50 0.55 1.00 V

Start-Up Current, I

OC/OV Fault Operating Current, I

Operating Current, I

Operating Supply Current, I

REFERENCE VOLTAGE

Overall Accuracy Line, load, 0°C to +105°C 4.95 5.00 5.05 V

Long Term Stability T

Fault Voltage 4.50 4.65 4.75 V

VREF Good Voltage 4.65 4.80 4.95 V

Hysteresis 75 165 250 mV

Operational Current -10 - - mA

Current Limit -20 - - mA

CURRENT SENSE

Input Impedance -5-kΩ

Offset Voltage 0.08 0.10 0.11 V

Input Voltage Range 0-1.5V

Blanking Time (Note 5) 30 60 100 ns

Gain, A

CS

. . . . . . . . . . . . . . . . .GND -0.3V to +20.0V

CC, VC

schematic on page 2 and page 3. 9V < V

Typical values are at T

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

CC

CC

CC

C

= +25°C.

A

VCC < START Threshold - 100 175 µA

Includes 1nF GATE loading - 8.0 12.0 mA

Line, load, -40°C to +105°C 4.90 5.00 5.05 V

= +125°C, 1000 hours (Note 5) - 5 - mV

A

V

= 0V, VFB = 2.3V,

SLOPE

V

= 0.35V, 1.5V

ISET

= ΔISET/ΔISENSE

A

CS

Thermal Resistance (Typical, Note 1) θ

16 Ld SOIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

16 Ld TSSOP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Maximum Junction Temperature . . . . . . . . . . . . . . .-55°C to +150°C

Maximum Storage Temperature Range. . . . . . . . . .-65°C to +150°C

Pb-free reflow profile . . . . . . . . . . . . . . . . . . . . . . . . . .see link below

http://www.intersil.com/pbfree/Pb-FreeReflow.asp

= VC < 20V, RT = 11kΩ, Ct = 330 pF, TA = -40 to +105°C (Note 3),

CC

- 200 300 µA

- 4.5 10.0 mA

0.77 0.79 0.81 V/V

(°C/W)

JA

5

FN9110.6

March 5, 2008

ISL6721

www.BDTIC.com/Intersil

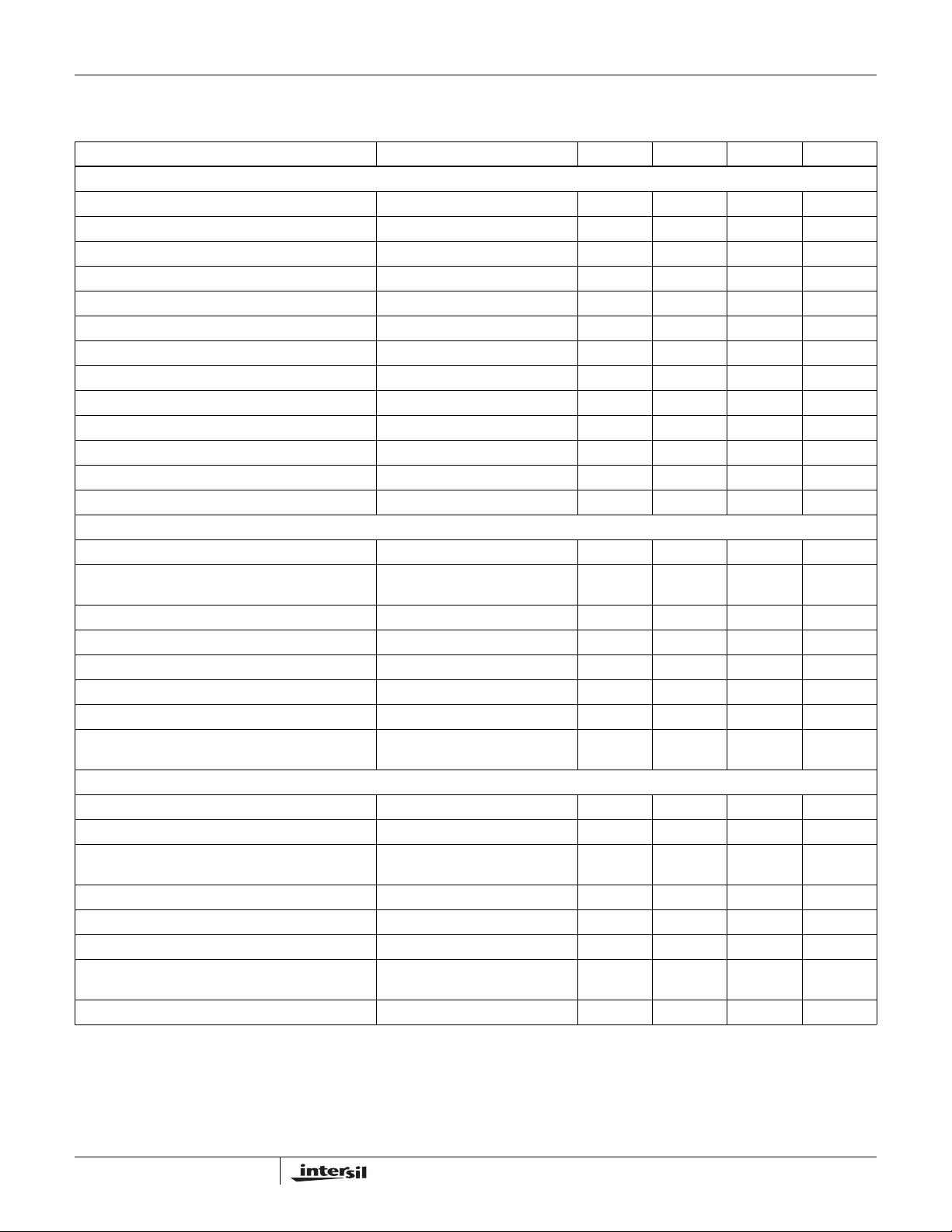

Electrical Specifications Recommended operating conditions unless otherwise noted. Refer to Block Diagram and Typical Application

schematic on page 2 and page 3. 9V < V

Typical values are at T

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

ERROR AMPLIFIER

Open Loop Voltage Gain (Note 5) 60 90 - dB

Gain-Bandwidth Product (Note 5) - 15 - MHz

Reference Voltage Initial Accuracy V

Reference Voltage V

COMP to PWM Gain, A

COMP to PWM Offset COMP = 4V (Note 5) 0.51 0.75 0.88 V

FB Input Bias Current V

COMP Sink Current COMP = 1.5V, V

COMP Source Current COMP = 1.5V, VFB = 2.3V -0.25 -0.5 - mA

COMP VOH V

COMP VOL V

PSRR Frequency = 120Hz (Note 5) 60 80 - dB

SS Clamp, V

OSCILLATOR

Frequency Accuracy 289 318 347 kHz

Frequency Variation with V

Temperature Stability (Note 5) - 8 - %

Maximum Duty Cycle (Note 6) 68 75 81 %

Comparator High Threshold - Free Running - 3.00 - V

Comparator High Threshold - with External SYNC (Note 5) - 4.00 - V

Comparator Low Threshold - 1.50 - V

Discharge Current 0°C to +105°C

SYNCHRONIZATION

Input High Threshold --2.5V

Input Pulse Width 25 - - ns

Input Frequency Range (Note 5) 0.65 x Free

Input Impedance -4.5-kΩ

VOH R

VOL R

SYNC Advance SYNC rising edge to GATE falling

Output Pulse Width C

COMP

COMP

CC

= +25°C. (Continued)

A

= COMP, TA = +25°C (Note 5) 2.465 2.515 2.565 V

FB

= COMP 2.44 2.515 2.590 V

FB

COMP = 4V, TA = +25°C 0.31 0.33 0.35 V/V

= 0V -2 0.1 2 µA

FB

= 2.3V 4.25 4.4 5.0 V

FB

= 2.7V 0.4 0.8 1.2 V

FB

SS = 2.5V, VFB = 0V, ISET = 2V 2.4 2.5 2.6 V

T = +105°C (f

T = -40°C (f

-40°C to +105°C

LOAD

LOAD

edge, C

SYNC

20V

20V

= 4.5kΩ 2.5 - - V

= open - - 0.1 V

= C

GATE

= 100pF 50 - - ns

= VC < 20V, RT = 11kΩ, Ct = 330 pF, TA = -40 to +105°C (Note 3),

CC

= 2.7V 2 6 - mA

FB

- f9V)/f

-f9V)/f

SYNC

9V

9V

= 100pF

-223

3

0.75

0.70

Running

-2555ns

1.0

1.0

-1.0MHz

1.2

1.2

%

mA

6

FN9110.6

March 5, 2008

ISL6721

www.BDTIC.com/Intersil

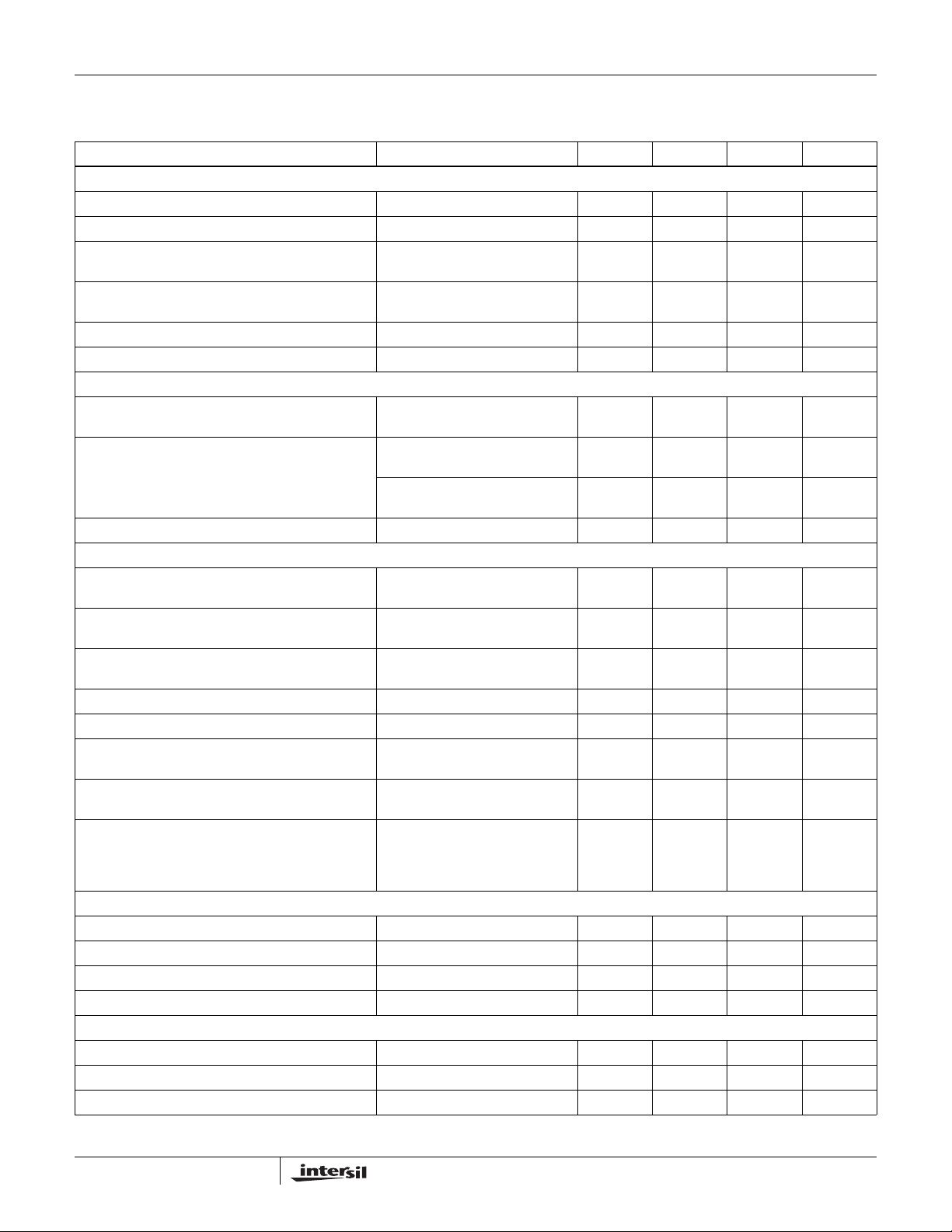

Electrical Specifications Recommended operating conditions unless otherwise noted. Refer to Block Diagram and Typical Application

schematic on page 2 and page 3. 9V < V

Typical values are at T

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

SOFT-START

Charging Current SS = 2V -40 -55 -70 µA

Charged Threshold Voltage 4.26 4.50 4.74 V

Initial Overcurrent Discharge Current Sustained OC Threshold < SS <

Overcurrent Shutdown Threshold Voltage Charged Threshold minus,

Fault Discharge Current SS = 2V 0.25 1.0 - mA

Reset Threshold Voltage T

SLOPE COMPENSATION

Charge Current SLOPE = 2V, 0°C to +105°C

Slope Compensation Gain Fraction of slope voltage added to

Discharge Voltage V

GATE OUTPUT

Gate Output Limit Voltage V

Gate VOH V

Gate VOL GATE - PGND, IOUT = 150mA

Peak Output Current V

Output “Faulted” Leakage VC = 20V, UV = 0V, GATE = 2V 1.2 2.6 - mA

Rise Time V

Fall Time V

Minimum ON time ISET = 0.5V; V

OVERCURRENT PROTECTION

Minimum ISET Voltage - - 0.35 V

Maximum ISET Voltage 1.2 - - V

ISET Bias Current V

Restart Delay T

OV AND UV VOLTAGE MONITOR

Overvoltage Threshold 2.4 2.5 2.6 V

Undervoltage Fault Threshold 1.38 1.45 1.52 V

Undervoltage Clear Threshold 1.41 1.53 1.62 V

= +25°C. (Continued)

A

Charged Threshold

= +25°C

T

A

= +25°C 0.22 0.27 0.31 V

A

-40°C to +105°C

, TA = +25°C

I

SENSE

Fraction of slope voltage added to

I

(Note 3)

SENSE

= 4.5V - 0.1 0.2 V

RTCT

= 20V, C

C

I

OUT

- GATE, VC = 10V,

C

I

OUT

IOUT = 10mA

= 20V, C

C

= 20V, C

C

1V < GATE < 9V

= 20V, C

C

1V < GATE < 9V

ISENSE to GATE w/10:1 Divider

RTCT = 4.75V through 1kΩ

(Note 5)

ISET

= +25°C 150 295 445 ms

A

GATE

= 0mA

= 150mA

GATE

GATE

GATE

FB

= 1.00V -1.0 - 1.0 µA

= VC < 20V, RT = 11kΩ, Ct = 330 pF, TA = -40 to +105°C (Note 3),

CC

30 40 55 µA

0.095 0.125 0.155 V

-45

-41

0.097 - 0.103 V/V

0.082 - 0.118 V/V

= 1nF,

= 1nF (Note 5) - 1.0 - A

= 1nF

= 1nF

= 0V; VC = 11V

11.0 13.5 16.0 V

-1.52.2V

-1.2

-60100ns

-1540ns

--110ns

-53

-53

0.6

-65

-65

1.5

0.8

µA

V

7

FN9110.6

March 5, 2008

ISL6721

www.BDTIC.com/Intersil

Electrical Specifications Recommended operating conditions unless otherwise noted. Refer to Block Diagram and Typical Application

schematic on page 2 and page 3. 9V < V

Typical values are at T

= +25°C. (Continued)

A

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Undervoltage Hysteresis Voltage 20 50 100 mV

UV Bias Current V

OV Bias Current V

= 2.00 V -1.0 - 1.0 µA

UV

= 2.00 V -1.0 - 1.0 µA

OV

THERMAL PROTECTION

Thermal Shutdown (Note 5) 120 130 140 °C

Thermal Shutdown Clear (Note 5) 105 120 135 °C

Hysteresis (Note 5) - 10 - °C

NOTES:

3. Specifications at -40°C and +105°C are guaranteed by +25°C test with margin limits.

4. This is the V

current consumed when the device is active but not switching. Does not include gate drive current.

CC

5. Limits should be considered typical and are not production tested.

6. This is the maximum duty cycle achievable using the specified values of RT and CT . Larger or smaller maximum duty cycles may be obtained

using other values for RT and CT. See Equations 1, 2, 3 and 4.

= VC < 20V, RT = 11kΩ, Ct = 330 pF, TA = -40 to +105°C (Note 3),

CC

Typical Performance Curves

1.002

1.002

1.002

1.002

1.000

1

0.998

0.998

0.995

0.995

0.993

0.993

NORMALIZED EA REFERENCE

Normalized EA Reference

0.991

0.991

-40 -10 20 50 80 110

TEMPERATURE (°C)

1.000

REF

0.998

0.998

0.995

0.995

NORMALIZED V

0.993

Normalized Vref

0.993

0.991

0.991

1

-10 20 50 80 110-40

TEMPERATURE (°C)

FIGURE 1. EA REFERENCE VOLTAGE vs TEMPERATURE FIGURE 2. VREF REFERENCE VOLTAGE vs TEMPERATURE

1.002

0.996

0.989

0.983

0.976

NORMALIZED FREQUENCY

0.970

-10205080110-40

TEMPERATURE (°C)

3

10

100

FREQUENCY (kHz)

10

10 20 40 50 60 70 80 90 100

30

RT (kΩ)

100pF

220pF

330pF

470pF

680pF

1000pF

2000pF

FIGURE 3. OSCILLATOR FREQUENCY vs TEMPERATURE FIGURE 4. RESISTANCE FOR CT CAPACITOR VALUES GIVEN

8

FN9110.6

March 5, 2008

ISL6721

www.BDTIC.com/Intersil

Pin Descriptions

SLOPE - Means by which the ISENSE ramp slope may be

increased for improved noise immunity or improved control

loop stability for duty cycles greater than 50%. An internal

current source charges an external capacitor to GND during

each switching cycle. The resulting ramp is scaled and

added to the ISENSE signal.

SYNC - A bidirectional synchronization signal used to

coordinate the switching frequency of multiple units.

Synchronization may be achieved by connecting the SYNC

signal of each unit together or by using an external master

clock signal. The oscillator timing capacitor, C

required, even if an external clock is used. The first unit to

assert this signal assumes control.

RTCT - This is the oscillator timing control pin. The

operational frequency and maximum duty cycle are set by

connecting a resistor, R

timing capacitor, C

, between V

T

, from this pin to LGND. The oscillator

T

REF

produces a sawtooth waveform with a programmable

frequency range of 100kHz to 1.0MHz. The charge time, t

the discharge time, t

, the switching frequency, fsw, and the

D

maximum duty cycle, Dmax, can be calculated from

Equations 1, 2, 3 and 4:

tC0.655 RTCT••≈ S

, is still

T

and this pin and a

C

(EQ. 1)

UV - Undervoltage monitor input pin. This signal is

compared to an internal 1.45V reference to detect an

undervoltage condition.

ISENSE - This is the input to the current sense comparators.

The IC has two current sensing comparators, a PWM

comparator for peak current mode control, and an

overcurrent protection comparator. The overcurrent

comparator threshold is adjustable through the ISET pin.

Exceeding the overcurrent threshold will start a delayed

shutdown sequence. Once an overcurrent condition is

detected, the soft-start charge current source is disabled and

a discharge current source is enabled. The soft-start capacitor

begins discharging, and if it discharges to less than 4.375V

(sustained overcurrent threshold), a shutdown condition

occurs and the GA TE output is forced lo w. At this point a

reduced discharge current takes over until the soft-start

voltage reaches 0.27V (reset threshold). The GATE output

remains low until the reset threshold is attained. At this point,

a soft-start cycle begins.

,

If the overcurrent condition ceases, and then an additional

50µs period elapses before the shutdown threshold is

reached, no shutdown occurs and the soft-start voltage is

allowed to recharge.

LGND - LGND is a small signal reference ground for all

analog functions on this device.

t

RT– CTLN

D

1

-----------------

f

= Hz

sw

Dmax t

+

t

DtC

Cfsw

-------------------------------------------

••≈ S

⎝⎠

0.001 RT1.9–•

•=

(EQ. 2)

(EQ. 3)

(EQ. 4)

0.001 RT3.6–•

⎛⎞

Figure 4 may be used as a guideline in selecting the

capacitor and resistor values required for a given frequency.

COMP - COMP is the output of the error amplifier and the

input of the PWM comparator. The control loop frequency

compensation network is connected between the COMP and

FB pins.

The ISL6721 features a built-in full cycle soft-start. Soft-start

is implemented as a clamp on the maximum COMP voltage.

FB - Feedback voltage input connected to the inverting input

of the error amplifier. The non-inverting input of the error

amplifier is internally tied to a reference voltage. Current

sense leading edge blanking is disabled when the FB input

is less than 2.0V.

OV - Overvoltage monitor input pin. This signal is compared

to an internal 2.5V reference to detect an overvoltage

condition.

PGND - This pin provides a dedicated ground for the output

gate driver. The LGND and PGND pins should be connected

externally using a short printed circuit board trace close to

the IC. This is imperative to prevent large, high frequency

switching currents flowing through the ground metallization

inside the IC. (Decouple V

to PGND with a low ESR 0.1µF

C

or larger capacitor.)

GATE - This is the device output. It is a high current power

driver capable of driving the gate of a power MOSFET with

peak currents of 1.0A. This GATE output is actively held low

when V

is below the UVLO threshold.

CC

The output high voltage is clamped to ~13.5V. Voltages

exceeding this clamp value should not be applied to the

GA TE pin. The output stage provides very low impedance to

overshoot and undershoot.

VC - This pin is for separate collector supply to the output

gate drive. Separate V

and PGND helps decouple the IC’s

C

analog circuitry from the high power gate drive noise.

(Decouple V

to PGND with a low ESR 0.1µF or larger

C

capacitor.)

VCC - V

quiescent current, I

is the power connection for the device. Although

CC

, is low, it is dependent on the

CC

frequency of operation. To optimize noise immunity, bypass

V

to LGND with a ceramic capacitor as close to the VCC

CC

and LGND pins as possible.

9

FN9110.6

March 5, 2008

ISL6721

www.BDTIC.com/Intersil

The total supply current (IC plus ICC) will be higher,

depending on the load applied to GATE. Total current is the

sum of the quiescent current and the average gate current.

Knowing the operating frequency, f

gate charge, Qg, the average GATE output current can be

calculated in Equation 5:

Igate Qg f

VREF - The 5V reference voltage output. Bypass to LGND

with a 0.01µF or larger capacitor to filter this output as

needed. Using capacitance less than this value may result in

unstable operation.

SS - Connect the soft-start capacitor between this pin and

LGND to control the duration of soft-start. The value of the

capacitor determines both the rate of increase of the duty

cycle during start-up, and also controls the overcurrent

shutdown delay.

ISET - A DC voltage between 0.35V and 1.2V applied to this

input sets the pulse-by-pulse overcurrent threshold. When

overcurrent inception occurs, the SS capacitor begins to

discharge and starts the overcurrent delayed shutdown

cycle.

•= A

sw

, and the MOSFET

sw

(EQ. 5)

Functional Description

Features

The ISL6721 current mode PWMs make an ideal choice for

low-cost flyback and forward topology applications requiring

enhanced control and supervisory capability. With adjustable

overvoltage and undervoltage thresholds, overcurrent

threshold, and hic-cup delay, a highly flexible design with

minimal external components is possible. Other features

include peak current mode control, adjustable soft-start,

slope compensation, adjustable oscillator frequency, and a

bi-directional synchronization clock input.

Oscillator

The ISL6721 have a sawtooth oscillator with a

programmable frequency range to 1MHz, which can be

programmed with a resistor and capacitor on the RTCT pin.

(Please refer to Figure 4 for the resistance and capacitance

required for a given frequency.)

Implementing Synchronization

The oscillator can be synchronized to an external clock

applied at the SYNC pin or by connecting the SYNC pins of

multiple ICs together. If an external master clock signal is

used, it must be at least 65% of the free running frequency of

the oscillator for proper synchronization. The external

master clock signal should have a pulse width greater than

20ns. If no master clock is used, the first device to assert

SYNC assumes control of the SYNC signal. An external

SYNC pulse is ignored if it occurs during the first 1/3 of the

switching cycle.

During normal operation the RTCT voltage charges from

1.5V to 3.0V and back during each cycle. Clock and SYNC

signals are generated when the 3.0V threshold is reached. If

an external clock signal is detected during the latter 2/3 of

the charging cycle, the oscillator switches to external

synchronization mode and relies upon the external SYNC

signal to terminate the oscillator cycle. The generation of a

SYNC signal is inhibited in this mode. If the RTCT voltage

exceeds 4.0V (i.e. no external SYNC signal terminates the

cycle), the oscillator reverts to the internal clock mode and a

SYNC signal is generated.

Soft-Start Operation

The ISL6721 features soft-start using an external capacitor

in conjunction with an internal curren t so urce . Soft-start is

used to reduce voltage stresses and surge currents during

start up.

Upon start up, the soft-start circuitry clamp s the error amplifier

output (COMP pin) to a value proportional to the soft-start

voltage. The error amplifier output rises as the soft-sta rt

capacitor voltage rises. This has the effect of increasing the

output pulse width from zero to the steady state operatin g duty

cycle during the soft-start period. When the soft-start voltage

exceeds the error amplifier voltage, soft-st art is compl eted.

Soft-start forces a controlled output voltage rise. Sof t-start

occurs during start-up and after recovery from a fault condition

or overcurrent shutdown. The soft-start voltage i s clamped to

4.5V.

Gate Drive

The ISL6721 is capable of sourcing and sinking 1A peak

current. Separate collector supply (V

(PGnd) pins help isolate the IC’s analog circuitry from the

high power gate drive noise. To limit the peak current

through the IC, an external resistor may be placed between

the totem-pole output of the IC (GATE pin) and the gate of

the MOSFET. This small series resistor also damps any

oscillations caused by the resonant tank of the parasitic

inductances in the traces of the board and the FET’s input

capacitance.

) and power ground

C

Slope Compensation

For applications where the maximum duty cycle is less than

50%, slope compensation may be used to improve noise

immunity, pa rticularly at lighter loads. The amount of slope

compensation required for noise immunity is determined

empirically, but is generally about 10% of the full scale

current feedback signal. For applications where the duty

cycle is greater than 50%, slope compensation is required to

prevent instability. Slope compensation is a technique in

which the current feedback signal is modified by adding

additional slope to it. The minimum amount of slope

compensation required corresponds to 1/2 the inductor

downslope. However, adding excessive slope compensation

results in a control loop that behaves more as a voltage

mode controller than as current mode controller.

10

FN9110.6

March 5, 2008

ISL6721

www.BDTIC.com/Intersil

DOWNSLOPE

TIME

Time

Downslope

CURRENT SENSE SIGNAL

Current Sense Signal

ISENSE SIGNAL (V)

FIGURE 5.

The minimum amount of capacitance to place at the SLOPE

pin is calculated in Equation 6:

C

SLOPE

where t

4.246–×10

is the On time and V

ON

-----------------------

•= F

V

ON

SLOPE

is the amount of

SLOPE

(EQ. 6)

t

voltage to be added as slope compensation to the current

feedback signal. In general, the amount of slope

compensation added is 2 to 3 times the minimum required.

Example:

Assume the inductor current signal presented at the ISENSE

pin decreases 125mV during the Off period, and:

Switching Frequency, f

= 250kHz

sw

Duty Cycle, D = 60%

tON = D/fsw = 0.6/250E3 = 2.4µs

t

= (1 - D)/fsw = 1.6µs

OFF

Determine the downslope:

Downslope = 0.125V/1.6µs = 78mV/µs. Now determine the

amount of voltage that must be added to the current sense

signal by the end of the On time.

1

-- -

V

SLOPE

0.078 2.4•• 94mV==

2

(EQ. 7)

Therefore,

C

SLOPE MIN()

4.246–×10

2.4

-----------------------

• 110pF≈=

0.094

(EQ. 8)

6–

×10

An appropriate slope compensation capacitance for this

example would be 1/2 to 1/3 the calculated value, or

between 68pF and 33pF.

Overvoltage and Undervoltage Monitor

The OV and UV signals are inputs to a window comparator

used to monitor the input voltage level to the converter. If the

voltage falls outside of the user designated operating range,

a shutdown fault occurs. For OV faults, the supply current,

I

, is reduced to 200µA for ~295ms at which time recovery

CC

is attempted. If the fault is cleared, a soft-start cycle begins.

Otherwise another shutdown cycle occurs. A UV condition

also results in a shutdown fault, but the device does not

enter the low power mode and no restart delay occurs when

the fault clears.

A resistor divider between V

and LGND to each input

IN

determines the operational thresholds. The UV threshold

has a fixed hysteresis of 75mV nominal.

Overcurrent Operation

The overcurrent threshold level is set by the voltage applied

at the ISET pin. Setting the overcurrent level may be

accomplished by using a resistor divider network from VREF

to LGND. The ISET threshold should be set at a level that

corresponds to the desired peak output inductor current plus

the additive effects of slope compensation.

Overcurrent delayed shutdown is enabled once the soft-start

cycle is complete. If an overcurrent condition is detected, the

soft-start charging current source is disabled and the

discharging current source is enabled. The soft-start

capacitor is discharged at a rate of 40µA. At the same time,

a 50µs retriggerable one-shot timer is activated amd it

remains active for 50µs after the overcurrent condition stops.

The soft-start discharge cycle cannot be reset until the oneshot timer becomes inactive. If the soft-start capacitor

discharges by more than 0.125V to 4.375V, the output is

disabled and the soft-start capacitor is discharged. The

output remains disabled and I

drops to 200µA for

CC

approximately 295ms. A new soft-start cycle is then initiated.

The shutdown and restart behavior of the OC protection is

often referred to as hic-cup operation due to its repetitive

start-up and shutdown characteristic.

If the overcurrent condition ceases at least 50µs prior to the

soft-start voltage reaching 4.375V, the soft-start charging

and discharging currents revert to normal operation and the

soft-start voltage is allowed to recover.

Hiccup OC protection may be defeated by setting ISET to a

voltage that exceeds the Error Amplifier current control

voltage, or about 1.5V.

Leading Edge Blanking

The initial 100ns of the current feedback signal input at

ISENSE is removed by the leading edge blanking circuitry.

The blanking period begins when the GATE output leading

edge exceeds 3.0V . Leading edge blanking prevents current

spikes from parasitic elements in the power supply from

causing false trips of the PWM comparator and the

overcurrent comparator.

Fault Conditions

A Fault condition occurs if VREF falls below 4.65V, the OV

input exceeds 2.50V, the UV input falls below 1.45V, or the

junction temperature of the die exceeds ~+130°C. When a

Fault is detected the GATE output is disabled and the

soft-start capacitor is quickly discharged. When the Fault

condition clears and the soft-start voltage is below the reset

threshold, a soft-start cycle begins.

11

FN9110.6

March 5, 2008

Ground Plane Requirements

www.BDTIC.com/Intersil

Careful layout is essential for satisfactory operation of the

device. A good ground plane must be employed. A unique

section of the ground plane must be designated for high di/dt

currents associated with the output stage. Power ground

(PGND) can be separated from the logic ground (LGND) and

connected at a single point. V

should be bypassed directly

C

to PGND with good high frequency capacitors. The return

connection for input power and the bulk input capacitor

should be connected to the PGND ground plane.

Reference Design

The Typical Application Schematic on page 3 features the

ISL6721 in a conventional dual output 10W discontinuous

mode flyback DC/DC converter. The ISL6721EVAL1

demonstration unit implements this design and is available

for evaluation.

The input voltage range is from 36VDC to 75VDC, and the

two outputs are 3.3V @ 2.5A and 1.8V @ 1.0A. Cross

regulation is achieved using the weighted sum of the two

outputs.

Circuit Element Descriptions

The converter design may be broken down into the following

functional blocks:

Input Storage and Filtering Capacitance: C

Isolation Transformer: T1

Primary voltage Clamp: CR6, R24, C

Start Bias Regulator: R1, R2, R6, Q3, V

Operating Bias and Regulator: R25, Q2, D1, C5, CR2, D

Main MOSFET Power Switch: Q

1

Current Sense Network: R4, R3, R23, C

Feedback Network:, R13, R15, R16, R17, R18, R19, R20,

R

, R27, C13, C14, U2, U

26

3

Control Circuit:C7, C8, C9, C10, C11, C12, R5, R6, R8, R9,

R

, R11, R12, R14, R

10

22

Output Rectification and Filtering: CR4, CR5, C15, C16, C19,

C

, C21, C

20

Secondary Snubber: R21, C

22

17

Design Criteria

The following design requirements were selected:

Switching Frequency, f

VIN: 36V to 75V

V

V

V

: 3.3V @ 2.5A

OUT(1)

: 1.8V @ 1.0A

OUT(2)

OUT(BIAS)

: 12V @ 50mA

: 200kHz

sw

18

R1

4

, C2, C

1

3

2

ISL6721

P

: 10W

OUT

Efficiency: 70%

Maximum Duty Cycle, D

MAX

: 0.45

Transformer Design

The design of a flyback transformer is a non-trivial affair. It is

an iterative process which requires a great deal of

experience to achieve the desired result. It is a process of

many compromises, and even experienced designers will

produce different designs when presented with identical

requirements. The iterative design process is not presented

here for clarity.

The abbreviated design process follows:

• Select a core geometry suitable for the application.

Constraints of height, footprint, mounting preference, and

operating environment will affect the choice.

• Select suitable core material(s).

• Select maximum flux density desired for operation.

• Select core size. Core size will be dictated by the

capability of the core structure to store the required

energy, the number of turns that have to be wound, and

the wire gauge needed. Often the window area (the space

used for the windings) and power loss determine the final

core size. For flyback transformers, the ability to store

energy is the critical factor in determining the core size.

The cross sectional area of the core and the length of the

air gap in the magnetic path determine the energy storage

capability.

• Determine maximum desired flux density. Depending on

the frequency of operation, the core material selected, and

the operating environment, the allowed flux density must

be determined. The decision of what flux density to allow

is often difficult to determine initially. Usually the highest

flux density that produces an acceptable design is used,

but often the winding geometry dictates a larger core than

is required based on flux density and energy storage

calculations.

• Determine the number of primary turns.

• Determine the turns ratio.

• Select the wire gauge for each winding.

• Determine winding order and insulation requirements.

• Verify the design.

Input Power:

/Efficiency = 14.3W (use 15W)

P

OUT

Max On Time: t

ON(MAX)

Average Input Current: I

Peak Primary Current:

2I

•

AVG IN()

I

-----------------------------------------

PPK

f

swtON MAX()

•

= D

MAX/fsw

AVG(IN)

1.87==A

= 2.25µs

= PIN/V

IN(MIN)

= 0.42A

(EQ. 9)

12

FN9110.6

March 5, 2008

ISL6721

www.BDTIC.com/Intersil

Maximum Primary Inductance:

Lp max()

V

---------------------------------------------------------

•

IN MIN()tON MAX()

I

PPK

43.3==μH

(EQ. 10)

Choose desired primary inductance to be 40µH.

The core structure must be able to deliver a certain amount

of energy to the secondary on each switching cycle in order

to maintain the specified output power.

ΔwP

OUT

V

------------------------------------

•= joules

f

Vd+〈〉

OUT

•

swVOUT

(EQ. 11)

where Δw is the amount of energy required to be transferred

each cycle and Vd is the drop across the output rectifier.

The capacity of a gapped ferrite core structure to store

energy is dependent on the volume of the airgap and can be

expressed in Equation 12:

Δw••

2 μ

o

== m

Vg Aeff lg•

-----------------------------

2

ΔB

3

(EQ. 12)

where Aeff is the e f fectiv e cross sectional area of the core in

2

m

, lg is the length of the airgap in meters, µo is the

permeability of free space (4π • 10

-7

), and ΔB is the change

in flux density in Tesla.

A core structure having less airgap volume than calculated will

be incapable of providing the full output power over some

portion of its operating range. On the other hand, if the length

of the airgap becomes large, magnetic field fringing around

the gap occurs. This has the effect of increasing the airgap

volume. Some fringing is usually acceptable, but excessive

fringing can cause increased losses in the windings around

the gap resulting in excessive heating. Once a suitable core

and gap combination are found, the iterative design cycle

begins. A design is developed and checked for ease of

assembly and thermal performance. If the core does not allow

adequate space for the windings, then a core with a larger

window area is required. If the transformer runs hot, it may be

necessary to lower the flux density (more primary turns, lower

operating frequency), select a less lossy core material,

change the geometry of the windings (winding order), use

heavier gauge wire or multi-filar windings, and/or change the

type of wire used (Litz wire, for example).

For simplicity, only the final design is further described.

An EPCOS EFD 20/10/7 core using N87 material gapped to

an A

value of 25nH/N2 was chosen. It has more than the

L

required air gap volume to store the energy required, but

was needed for the window area it provides.

-6

Aeff = 31 • 10

2

m

lg = 1.56 • 10-3 m

The flux density ΔB is only 0.069T or 690 gauss, a relatively

low value.

Since:

2

μoN

----------------------------------------

L

= μH

p

the number of primary turns, N

result is N

Aeff••

p

lg

, may be calculated. The

= 40 turns. The secondary turns may be

p

p

(EQ. 13)

calculated as follows:

Ig Vout Vd+〈〉tr••

--------------------------------------------------------

≤

N

s

Ippk μoAeff•••

N

p

(EQ. 14)

where tr is the time required to reset the core. Since

discontinuous MMF mode operation is desired, the core

must completely reset during the off time. To maintain

discontinuous mode operation, the maximum time allowed to

reset the core is t

sw

- t

ON(MAX)

where tsw = 1/fsw. The

minimum time is application dependent and at the designers

discretion knowing that the secondary winding RMS current

and ripple current stress in the output capacitors increases

with decreasing reset time. The calculation for maximum N

for the 3.3 V output using t = t

sw

- t

ON (MAX)

= 2.75µs is 5.52

turns.

The determination of the number of secondary turns is also

dependent on the number of outputs and the required turns

ratios required to generate them. If Schottky output rectifiers

are used and we assume a forward voltage drop of 0.45V,

the required turns ratio for the two output voltages, 3.3V and

1.8V, is 5:3.

With a turns ratio of 5:3 for the secondary windings, we will

use N

= 5 turns and Ns2 = 3 turns. Checking the reset time

s1

using these values for the number of secondary turns yields

a duration of Tr = 2.33µs or about 47% of the switching

period, an acceptable result.

The bias winding turns may be calculated similarly, only a

diode forward drop of 0.7V is used. The rounded off result is

17 turns for a 12V bias.

The next step is to determine the wire gauge. The RMS

current in the primary winding may be calculated using

Equation 15:

t

I

PRMS()IPPK

ON MAX()

-------------------------- -•= A

3tsw•

(EQ. 15)

The peak and RMS current values in the remaining windings

may be calculated using Equations 16 and 17:

2I

-------------------------------------

= A

I

SPK

RMS

2I

I

OUTtsw

Tr

•

OUT

••

t

sw

-------------- -•= A

3Tr•

(EQ. 16)

(EQ. 17)

The RMS current for the primary winding is 0.72A, fo r the

3.3V output, 4.23A, for the 1.8V output, 1.69A, and for the

bias winding, 85mA.

s

13

FN9110.6

March 5, 2008

ISL6721

www.BDTIC.com/Intersil

T o minimize the transformer leakage inductance, the primary

was split into two sections connected in parallel and

positioned such that the other windings were sandwiched

between them. The output windings were configured so that

the 1.8V winding is a tap off of the 3.3V winding. Tapping the

1.8V output requires that the shared portion of the

secondary conduct the combined current of both outputs.

The secondary wire gauge must be selected accordingly.

The determination of current carrying capacity of wire is a

compromise between performance, size, and cost. It is

affected by many design constraints such as operating

frequency (harmonic content of the waveform) and the

winding proximity/geometry. It generally ranges between 250

and 1000 circular mils per ampere. A circular mil is defined

as the area of a circle 0.001” (1 mil) in diameter. As the

frequency of operation increases, the AC resistance of the

wire increases due to skin and proximity effects. Using

heavier gauge wire may not alleviate the problem. Instead

multiple strands of wire in parallel must be used. In some

cases, Litz wire is required.

The winding configuration selected is:

Primary #1: 40T, 2 #30 bifilar

Secondary: 5T, 0.003” (3 mil) copper foil tapped at 3T

Bias: 17T #32

Primary #2: 40T, 2 #30 bifilar

The internal spacing and insulation system was designed for

1500VDC dielectric withstand rating between the primary

and secondary windings.

Power MOSFET Selection

Selection of the main switching MOSFET requires

consideration of the voltage and current stresses that will be

encountered in the application, the power dissipated by the

device, its size, and its cost.

The input voltage range of the converter is 36VDC to

75VDC. This suggests a MOSFET with a voltage rating of

150V is required due to the flyback voltage likely to be seen

on the primary of the isolation transformer.

device to enter a thermal runaway situation without proper

heatsinking. As a general rule of thumb, doubling the +25°C

r

specification yields a reasonable value for

DS(ON)

estimating the conduction losses at +125°C junction

temperature.

The switching losses have two components, capacitive

switching losses and voltage/current overlap losses. The

capacitive losses occur during turn on of the device and may

be calculated in Equation 19:

Pswcap

1

-- -

Cfet Vin

2

2

fsw•••= W

(EQ. 19)

where Cfet is the equivalent output capacitance of the

MOSFET. Device output capacitance is specified on

datasheets as Coss and is non-linear with applied voltage.

To find the equivalent discrete capacitance, Cfet, a charge

model is used. Using a known current source, the time

required to charge the MOSFET drain to the desired

operating voltage is determined and the equivalent

capacitance may be calculated in Equation 20:

Ichg t•

------------------- -

Cfet

= F

V

(EQ. 20)

The other component of the switching loss is due to the

overlap of voltage and current during the switching

transition. A switching transition occurs when the MOSFET

is in the process of either turning on or off. Since the load is

inductive, there is no overlap of voltage and current during

the turn on transition, so only the turn off transition is of

significance. The power dissipation may be estimated using

Equation 21:

P

sw

where t

1

-- -

• VINtOLfsw•••≈

I

PPK

x

is the duration of the overlap period and x ranges

OL

(EQ. 21)

from about 3 through 6 in typical applications and depends

on where the waveforms intersect. This estimate may predict

higher dissipation than is realized because a portion of the

turn off drain current is attributable to the charging of the

device output capacitance (Coss) and is not dissipative

during this portion of the switching cycle.

The losses associated with MOSFET operation may be

divided into three categories: conduction, switching, and

Ippk

gate drive.

The conduction losses are due to the MOSFET’s ON

resistance.

Pcond r

where r

DS(ON)

DS ON()

is the ON resistance of the MOSFET and

2

Iprms

•= W

(EQ. 18)

Iprms is the RMS primary current. Determining the

conduction losses is complicated by the variation of r

DS(ON)

with temperature. As junction temperature increases, so

does r

, which increases losses and raises the

DS(ON)

V

D-S

The final component of MOSFET loss is caused by the

charging of the gate capacitance through the device gate

resistance. Depending on the relative value of any external

junction temperature more, and so on. It is possible for the

14

Tol

FIGURE 6. SWITCHING CYCLE

FN9110.6

March 5, 2008

ISL6721

www.BDTIC.com/Intersil

resistance in the gate drive circuit, a portion of this power will

be dissipated externally.

Pgate QgVgfsw••= W

(EQ. 22)

Once the losses are known, the device package must be

selected and the heatsinking method designed. Since the

design requires a small surface mount part, a 8 Ld SOIC

package was selected. A Fairchild FDS2570 MOSFET was

selected based on these criteria. The overall losses are

estimated at 400mW.

Output Filter Design

In a flyback design, the primary concern for the design of the

output filter is the capacitor ripple current stress and the

ripple and noise specification of the output.

The current flowing in and out of the output capacitors is the

difference between the winding current and the output current.

The peak secondary current, I

output and 4.29A for the 1.8V output. The current flowing into

the output filter capacitor is the difference between the winding

current and the output current. Looking at the 3.3V output, the

peak winding current is I

SPK

store this amount minus the output current of 2.5A, or 8.23A.

The RMS ripple current in the 3.3V output capacitor is about

3.5A

is about 1.4A

. The RMS ripple current in the 1.8V output capacitor

RMS

RMS

.

Voltage deviation on the output during the switching cycle

(ripple and noise) is caused by the change in charge of the

output capacitance, the equivalent series resistance (ESR),

and equivalent series inductance (ESL). Each of these

components must be assigned a portion of the total ripple

and noise specification. How much to allow for each

contributor is dependent on the capacitor technology used.

For purposes of this discussion, we will assume the following:

3.3V output: 100mV total output ripple and noise

ESR: 60mV

Capacitor

ΔQ: 10mV

ESL: 30mV

1.8V output: 50mV total output ripple and noise

ESR: 30mV

Capacitor ΔQ: 5mV

ESL: 15mV

, is 10.73A for the 3.3V

SPK

= 10.73A. The capacitor must

6–

Ispk Iout–()Tr•

----------------------------------------------

C

≥

2 ΔV•

10.73 2.5–()2.33

------------------------------------------------------------------ -

20.010•

×10•

960μF==

(EQ. 24)

ESL adds to the ripple and noise voltage in proportion to the

rate of change of current into the capacitor (V = L • di/dt).

9–

Vdt•

-------------- -

L

≤

di

0.030 200

----------------------------------------------

10.73

×10•

0.56nH==

(EQ. 25)

Capacitors having high capacitance usually do not have

sufficiently low ESL. High frequency capacitors such as

surface mount ceramic or film are connected in parallel with

the high capacitance capacitors to address the effects of

ESL. A combination of high frequency and high ripple

capability capacitors is used to achieve the desired overall

performance. The analysis of the 1.8V output is similar to

that of the 3.3V output and is omitted for brevity. Two

OSCON 4SEP560M (560µF) electrolytic capacitors and a

22µF X5R ceramic 1210 capacitor were selected for both the

3.3 and 1.8V outputs. The 4SEP560M electrolytic capacitors

are each rated at 4520mA ripple current and 13mΩ of ESR.

The ripple current rating of just one of these capacitors is

adequate, but two are needed to meet the minimum ESR

and capacitance values.

The bias output is of such low power and current that it

places negligible stress on its filter capacitor. A single 0.1µF

ceramic capacitor was selected.

Control Loop Design

The major components of the feedback control loop are a

programmable shunt regulator, an opto-coupler, and the

inverting amplifier of the ISL6721. The opto-coupler is used

to transfer the error signal across the isolation barrier. The

opto-coupler offers a convenient means to cross the

isolation barrier, but it adds complexity to the feedback

control loop. It adds a pole at about 10kHz and a significant

amount of gain variation due the current transfer ratio (CTR).

The CTR of the opto-coupler varies with initial tolerance,

temperature, forward current, and age.

A block diagram of the feedback control loop is shown in

Figure 7.

PRIMARY SIDE AMPLIFIER

+

REF

Z

3

-

Z

4

PWM

ERROR AMPLIFIER

POWER

STAGE

V

OUT

For the 3.3V output:

ΔV

-------------------------------- -

≤

ESR

–

I

SPKIOUT

0.060

-----------------------------

10.73 2.5–

7.3mΩ==

(EQ. 23)

ISOLATION

The change in voltage due to the change in charge of the

output capacitor, ΔQ, determines how much capacitance is

required on the output.

FIGURE 7. FEEDBACK CONTROL LOOP

15

Z

2

-

+

REF

Z

1

FN9110.6

March 5, 2008

A

ISL6721

www.BDTIC.com/Intersil

The loop compensation is placed around the Error Amplifier

(EA) on the secondary side of the converter. The primary

side amplifier located in the control IC is used as a unity gain

inverting amplifier and provides no loop compensation. A

Type 2 error amplifier configuration was selected as a

precaution in case operation in continuous mode should

occur at some operating point.

V

OUT

V

ERROR

FIGURE 8. TYPE 2 ERROR AMPLIFIER

-

REF

+

Development of a small signal model for current mode

control is rather complex. The method of reference

1

was

selected for its ability to accurately predict loop behavior. To

further simplify the analysis, the converter will be modeled as

a single output supply with all of the output capacitance

reflected to the 3.3V output. Once the “single” output system

is compensated, adjustments to the compensation will be

required based on actual loop measurements.

The first parameter to determine is the peak current

feedback loop gain. Since this application is low power, a

resistor in series with the source of the power switching

MOSFET is used for the current feedback signal. For higher

power applications, a resistor would dissipate too much

power and current transformer would be used instead.

There is limited flexibility to adjust the current loop behavior

due to the need to provide overcurrent protection. Current

limit and the current loop gain are determined by the current

sense resistor and the ISET threshold. ISET was set at 1.0V,

near its maximum, to minimize noise effects. When

determining ISET, the internal gain and offset of the ISENSE

signal in the control IC must be taken into account. The

maximum peak primary current was determined earlier to be

1.87A, so a choice of 2.25A peak primary current for current

limit is reasonable. A current gain, A

, of 0.5V/A was

EXT

selected to achieve this.

ISET 2.25 0.8 0.5 0.100+•• 1.00==V

The control to output transfer function may be represented as

s

------

1

v

----- -

v

K

R

oLsfsw

---------------------------------

2

o

c

••

---------------- -

••=

1

+

ω

z

s

------ -

+

ω

p

(EQ. 26)

2

(EQ. 27)

If we ignore the current feedback sampled-data effects:

I

spk max()

------------------------- -

K

=

V

cmax()

LoadResis cetan=

R

o

SecondaryInduc cetan=

L

s

2

--------------------

= or f

ω

p

•

R

oCo

1

--------------------

= or f

ω

z

•

R

cCo

C

OutputCapaci cetan=

o

R

OutputCapaci ceEtan SR=

c

V

cmax()

ControlVoltageRange=

-----------------------------

=

p

π R

--------------------------------------

=

z

2 π• R

1

••

oCo

1

cCo

••

(EQ. 28)

(EQ. 29)

(EQ. 30)

(EQ. 31)

(EQ. 32)

(EQ. 33)

(EQ. 34)

(EQ. 35)

The value of K may be determined by assuming all of the

output power is delivered by the 3.3V output at the threshold

of current limit. The maximum power allowed was

determined earlier as 15W, therefore:

P

out

----------- -

2

I

spk max()

v

cmax()VISENSEAEXT

where A

network, A

----------------------------------- -

is the external gain of the current feedback

EXT

CS

••

t

sw

V

out

Tr

• A

is the IC internal gain, and A

15

------- -

2

3.3

------------------------------------------

2.33

•• 2.93==V

CS

×10••

5

6–

×10

1

-------------------- -

A

COMP

6–

COMP

19.5== =A

(EQ. 36)

(EQ. 37)

is the gain

between the error amplifier and the PWM comparator.

The Type 2 compensation configuration has two poles and

one zero. The first pole is at the origin, and provides the

integration characteristic which results in excellent DC

regulation. Referring to the Typical Application Schematic on

page 3, the remaining pole and zero for the compensator are

located at:

C13C14+

------------------------------------------------------------

f

pc

2 π R

--------------------------------------------

f

=

zc

2 π R

The ratio of R

≈=

15C14C13

1

••••

•••

15C13

to the parallel combination of R17 and R18

15

1

--------------------------------------------

2 π R15C14•••

(EQ. 38)

(EQ. 39)

determine the mid band gain of the error amplifier.

:

midband

R15R17R18+()•

------------------------------------------------

=

R

•

17R18

(EQ. 40)

From Equation 27, it can be seen that the control to output

transfer function frequency dependence is a function of the

output load resistance, the value of output capacitance, and

the output capacitance ESR. These variations must be

considered when compensating the control loop. The worst

case small signal operating point for the converter is at

16

FN9110.6

March 5, 2008

ISL6721

www.BDTIC.com/Intersil

minimum VIN, maximum load, maximum C

OUT

, and

minimum ESR.

The higher the desired bandwidth of the converter, the more

difficult it is to create a solution that is stable over the entire

operating range. A good rule of thumb is to limit the bandwid th

to about f

/4. For this example, the bandwidth will be further

sw

limited due to the low GBWP of the LM431-based Error

Amplifier and the opto-coupler . A bandw id th of app roximatel y

5kHz was selected.

For the EA compensation, the first pole is placed at the

origin by default (C

zero is placed below the crossover frequency, f

around 1/3 f

co

is an integrating capacitor). The first

14

, usually

co

. The second pole is placed at the lower of the

ESR zero or at one half of the switching frequency. The

midband gain is then adjusted to obtain the desired

crossover frequency. If the phase margin is not adequate,

the crossover frequency may have to be reduced.

Using this technique to determine the compensation, the

following values for the EA components were selected.

R

= R18 = R15 = 1kΩ

17

R20 = open

C13 = 100nF

C14 = 100pF

A Bode plot of the closed loop system at low line, max load

appears in Figures 9A and 9B.

50

40

30

20

10

0

-10

GAIN (dB)

-20

-30

-40

-50

10k 100k 1M 10M 100M

FREQUENCY (Hz)

FIGURE 9A. GAIN

200

150

100

50

0

PHASE MARGIN (°)

-50

-100

10k 100k 1M 10M 100M

FREQUENCY (Hz)

FIGURE 9B. PHASE MARGIN

Regulation Performance

TABLE 1. OUTPUT LOAD REGULATION, V

(A), 3.3V I

I

OUT

0 0.030 3.351 1.825

0.39 0.030 3.281 1.956

0.88 0.030 3.251 1.988

1.38 0.030 3.223 2.014

1.87 0.030 3.204 2.029

2.39 0.030 3.185 2.057

2.89 0030 3.168 2.084

3.37 0.030 3.153 2.103

0 0.52 3.471 1.497

0.39 0.52 3.283 1.800

0.88 0.52 3.254 1.836

1.38 0.52 3.233 1.848

1.87 0.52 3.218 1.855

2.39 0.52 3.203 1.859

2.89 0.52 3.191 1.862

0 1.05 3.619 1.347

0.39 1.05 3.290 1.730

0.88 1.05 3.254 1.785

1.38 1.05 3.235 1.805

1.87 1.05 3.220 1.814

2.39 1.05 3.207 1.820

0 1.55 3.699 1.265

0.39 1.55 3.306 1.682

0.88 1.55 3.260 1.750

1.38 1.55 3.239 1.776

1.87 1.55 3.224 1.789

0 2.07 3.762 1.201

0.39 2.07 3.329 1.645

0.88 2.07 3.270 1.722

1.38 2.07 3.245 1.752

0 2.62 3.819 1.142

0.39 2.62 3.355 1.612

0.88 2.62 3.282 1.697

0 3.14 3.869 1.091

0.39 3.14 3.383 1.581

(A), 1.8V V

OUT

OUT

(V), 3.3V V

IN

OUT

= 48V

(V), 1.8V

Waveforms

Typical waveforms can be found in Figures 10 through 12.

Figure 10 shows the steady state operation of the sawtooth

oscillator waveform at RTCT (Trace 2), the SYNC output

pulse (Trace 1), and the GATE output to the converter FET

(Trace 3). Figure 11 shows the converter behavior while

operating in an overcurrent fault condition. Trace 1 is the

soft-start voltage, which increases from 0V to 4.5V, at which

point the OC fault function is enabled. The OC condition is

detected and the soft-start capacitor is discharged to the

17

FN9110.6

March 5, 2008

4.375V OC fault threshold at which point the IC enters the

www.BDTIC.com/Intersil

fault shutdown mode. Trace 2 shows the behavior of the

timing capacitor voltage during a shutdown fault. Most of the

functions of the IC are de-powered during a fault, and the

oscillator is among those functions. During a fault, the IC is

turned off until the restart delay has timed out. After the

delay, power is restored and the IC resumes normal

operation. Trace 3 is the GATE output during the soft-start

cycle and OC fault.

ISL6721

NOTE:

Trace 1: V

Trace 3: V

FIGURE 12. GATE AND DRAIN-SOURCE WAVEFORMS

D-S

G-S

NOTE:

Trace 1: SYNC Output

Trace 2: RTCT Sawtooth

Trace 3: GATE Output

NOTE:

Trace 1: SS

Trace 2: RTCT Sawtooth

Trace 3: GATE Output

FIGURE 11. SOFT-START WITH OVERCURRENT FAULT

Figure 12 shows the switching FET waveforms during

steady state operation. Trace 1 is drain-source voltage and

Trace 2 is gate-source voltage.

FIGURE 10. TYPICAL WAVEFORMS

18

FN9110.6

March 5, 2008

ISL6721

www.BDTIC.com/Intersil

Component List

REFERENCE DESIGNATOR VALUE DESCRIPTION

, C2, C

C

1

C5, C

13

, C16, C19, C

C

15

C

17

C

18

, C

C

21

22

, C

C

4

14

C

6

C

7

C

8

C9, C10, C11, C

, C

C

R2

R6

, C

C

R4

R5

D

1

D

2

Q

1

Q

2

Q

3

, R

R

1

2

R

10

R7, R9, R11, R26, R

R

12

, R15, R17, R18, R19, R

R

13

R

14

R

16

R

21

R

22

R

24

, R

R

3

23

R

4

R

5

R

6

, R

R

8

20

T

1

U

2

U

3

U

4

V

R1

3

20

12

27

25

1.0µF Capacitor, 1812, X7R, 100V, 20%

0.1µF Capacitor, 0603, X7R, 25V, 10%

560µF Capacitor, Radial, SANYO 4SEP560M

470pF Capacitor, 0603, COG, 50V, 5%

0.01µF Capacitor, 0805, X7R, 50V, 10%

22µF Capacitor, 1210, X5R, 10V, 20%

100pF Capacitor, 0603, COG, 50V, 5%

1500pF Capacitor, Disc, Murata DE1E3KX152MA5BA01

0Ω Jumper, 0603

330pF Capacitor, 0603, COG, 50V, 5%

0.22µF Capacitor, 0603, X7R, 16V, 10%

Diode, Fairchild ES1C

Diode, IR 12CWQ03FN

Zener, 18V, Zetex BZX84C18

Diode, Schottky, BAT54C

FET, Fairchild FDS2570

Transistor, Zetex FMMT491A

Transistor, ON MJD31C

1.00k Resistor, 1206, 1%

20.0k Resistor, 0603, 1%

10.0k Resistor, 0603, 1%

38.3k Resistor, 0603, 1%

1.00k Resistor, 0603, 1%

10 Resistor, 0603, 1%

165 Resistor, 0603, 1%

10.0 Resistor, 1206, 1%

5.11 Resistor, 0603, 1%

3.92k Resistor, 2512, 1%

100 Resistor, 0603, 1%

1.00 Resistor, 2512, 1%

221k Resistor, 0603, 1%

75.0k Resistor, 0603, 1%

OMIT

Transformer, MIDCOM 31555

Opto-coupler, NEC PS2801-1

Shunt Reference, National LM431BIM3

PWM, Intersil ISL6721IB

Zener, 15V, Zetex BZX84C15

19

FN9110.6

March 5, 2008

References

www.BDTIC.com/Intersil

1. Ridley, R., “A New Continuous-Time Model for Current

Mode Control”, IEEE Transactions on Power Electronics,

Vol. 6, No. 2, April 1991.

2. Dixon, Lloyd H., “Closing the Feedback Loop”, Unitrode

Power Supply Design Seminar, SEM-700, 1990.

ISL6721

20

FN9110.6

March 5, 2008

ISL6721

www.BDTIC.com/Intersil

Thin Shrink Small Outline Plastic Packages (TSSOP)

N

INDEX

AREA

123

0.05(0.002)

-AD

e

b

0.10(0.004) C AM BS

NOTES:

1. These package dimensions are within allowable dimensions of

JEDEC MO-153-AB, Issue E.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate

burrs. Mold flash, protrusion and gate burrs shall not exceed

0.15mm (0.006 inch) per side.

4. Dimension “E1” does not include interlead flash or protrusions.

Interlead flash and protrusions shall not exceed 0.15mm (0.006

inch) per side.

5. The chamfer on the body is optional. If it is not present, a visual

index feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. Dimension “b” does not include dambar protrusion. Allowable

dambar protrusion shall be 0.08mm (0.003 inch) total in excess

of “b” dimension at maximum material condition. Minimum space

between protrusion and adjacent lead is 0.07mm (0.0027 inch).

10. Controlling dimension: MILLIMETER. Converted inch dimensions are not necessarily exact. (Angles in degrees)

E1

-B-

SEATING PLANE

A

-C-

M

0.25(0.010) BM M

E

α

A1

0.10(0.004)

GAUGE

PLANE

0.25

0.010

A2

M16.173

16 LEAD THIN SHRINK SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A-0.043 - 1.10 -

A1 0.002 0.006 0.05 0.15 -

L

c

A2 0.033 0.037 0.85 0.95 -

b 0.0075 0.012 0.19 0.30 9

c 0.0035 0.008 0.09 0.20 -

D 0.193 0.201 4.90 5.10 3

E1 0.169 0.177 4.30 4.50 4

e 0.026 BSC 0.65 BSC -

E 0.246 0.256 6.25 6.50 -

L 0.020 0.028 0.50 0.70 6

N16 167

o

α

0

o

8

o

0

o

8

NOTESMIN MAX MIN MAX

-

Rev. 1 2/02

21

FN9110.6

March 5, 2008

Small Outline Plastic Packages (SOIC)

www.BDTIC.com/Intersil

ISL6721

N

INDEX

AREA

123

-A-

E

-B-

SEATING PLANE

D

A

-C-

0.25(0.010) BM M

H

L

h x 45°

α

e

B

0.25(0.010) C AM BS

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of

Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm (0.006

inch) per side.

4. Dimension “E” does not include interlead flash or protrusions. Interlead

flash and protrusions shall not exceed 0.25mm (0.010 inch) per side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width “B”, as measured 0.36mm (0.014 inch) or greater above

the seating plane, shall not exceed a maximum value of 0.61mm

(0.024 inch).

10. Controlling dimension: MILLIMETER. Converted inch dimensions are

not necessarily exact.

M

A1

C

0.10(0.004)

M16.15 (JEDEC MS-012-AC ISSUE C)

16 LEAD NARROW BODY SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.0532 0.0688 1.35 1.75 -

A1 0.0040 0.0098 0.10 0.25 -

B 0.013 0.020 0.33 0.51 9

C 0.0075 0.0098 0.19 0.25 D 0.3859 0.3937 9.80 10.00 3

E 0.1497 0.1574 3.80 4.00 4

e 0.050 BSC 1.27 BSC H 0.2284 0.2440 5.80 6.20 h 0.0099 0.0196 0.25 0.50 5

L 0.016 0.050 0.40 1.27 6

N16 167

α

0° 8° 0° 8° -

NOTESMIN MAX MIN MAX

Rev. 1 6/05

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implic atio n or other wise u nde r any p a tent or patent rights of Intersil or it s subs idi aries.

For information regarding Intersil Corporation and its products, see www.intersil.com

22

FN9110.6

March 5, 2008

Loading...

Loading...