®

ISL6719

Data Sheet October 1, 2007

100V Linear Bias Supply

The ISL6719 is a low cost linear regulator for generating a

low voltage bias supply from intermediate distributed

voltages commonly used in telecom and datacom

applications. It provides a single adjustable output rated at

100mA from either the input source or an auxiliary source

such as a transformer winding. The auxiliary source is

selected whenever it has sufficient voltage to sustain the

output.

The ISL6719 may be used as a start-up or a continuous low

power regulator. When operating as a start-up regulator, it is

capable of sourcing 100mA from a 100V source for short

durations. This period of time allows the power supply to

start-up and provide an alternate power source, such as the

output of a transformer winding, to the AUXIN input. This

allows the regulated output to operate from a lower source

voltage to minimize power loss.

Ordering Information

PART

NUMBER

(Note)

ISL6719ARZ* 19AZ -40 to +105 9 Ld DFN L9.3x3

*Add “-T” suffix for tape and reel. Please refer to TB347 for details on

reel specifications.

NOTE: These Intersil Pb-free plastic packaged products employ

special Pb-free material sets; molding compounds/die attach

materials and 100% matte tin plate PLUS ANNEAL - e3 termination

finish, which is RoHS compliant and compatible with both SnPb and

Pb-free soldering operations. Intersil Pb-free products are MSL

classified at Pb-free peak reflow temperatures that meet or exceed

the Pb-free requirements of IPC/JEDEC J STD-020.

PART

MARKING

TEMP.

RANGE (°C)

PACKAGE

(Pb-Free)

PKG.

DWG. #

FN6555.1

Features

• 100+ Volt Input Capability

• Adjustable Output from 1.5V to 20V

• Up to 100mA Output Current

• Overcurrent Protection

• Over-Temperature Protection

• ENABLE and ENABLE_N Inputs

• Package Compliant with IPC2221A, Creepage and

Clearance Spacing Requirements

• Pb-Free (RoHS Compliant)

Applications

• Telecom/Datac om D C/ D C Conv e r te rs

• Low Power Bias Supplies

Pinout

ISL6719

(9 LD DFN)

TOP VIEW

VPWR

AUXIN

VSW

VSW_FB

1

2

3

4

GND

9

ENABLE_N

8

ENABLE

7

COMPB

6

COMPA

5

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright Intersil Americas Inc. 2007. All Rights Reserved

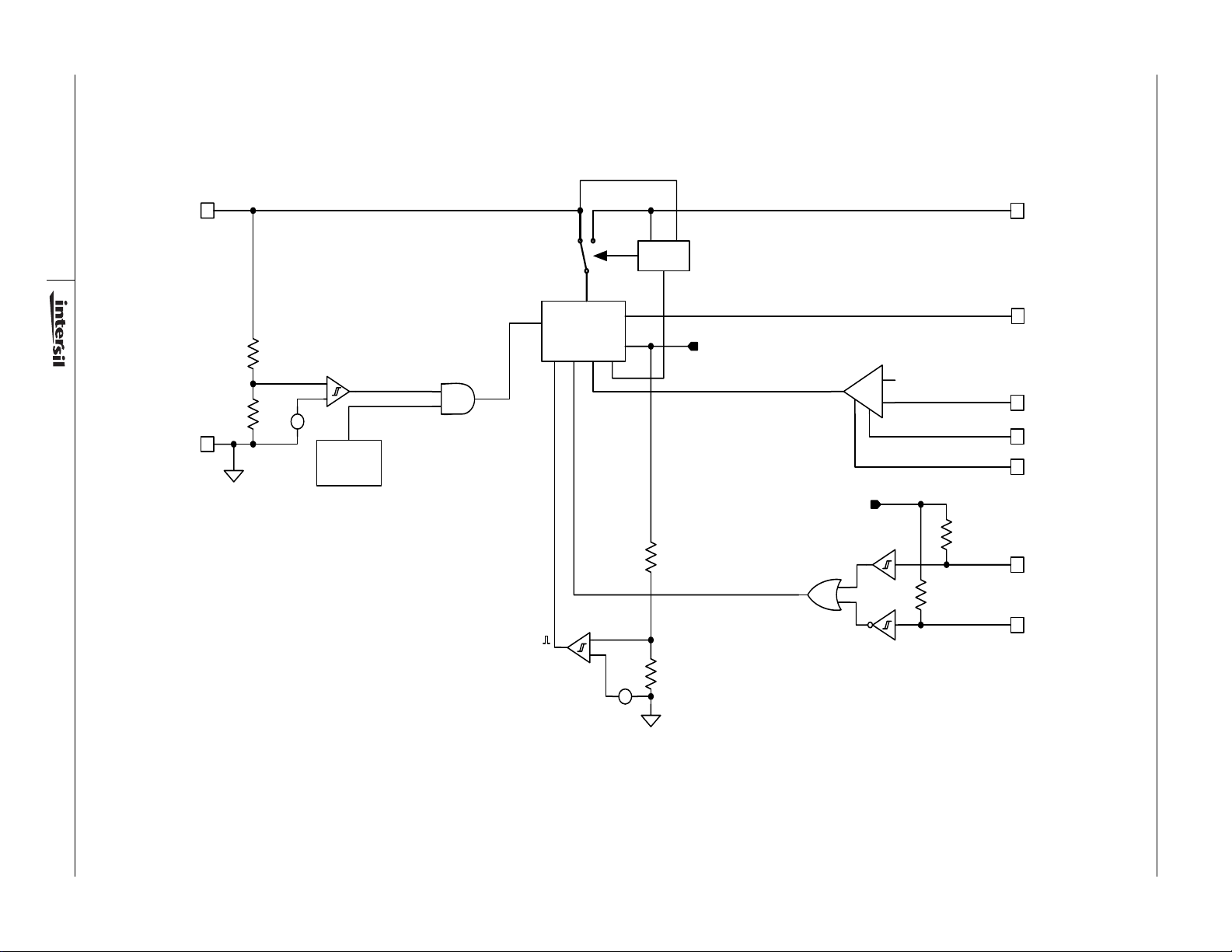

Functional Block Diagram

VPWR

105V MAX

2

VSW

POR

REGULATOR

INT . BIAS

-

+

GND

START/STOP

UV COMPARATOR

+

BG

-

+

-

TMON

+150ºC TRIP

+95ºC CLEAR

VPWR OK

TEMP OK

ENABLE

INP UT

SELECTOR

INT-ENABLE

INT. BIAS

INT . BIA S

1.5V REF

+

_

0V TO 40V

1.5V TO 20V

@ 100mA

AUXIN

VSW

VSW_FB

COMPA

COMPB

ENABLE

ENABLE_N

ISL6719

-

+

BG

October 1, 2007

FN6555.1

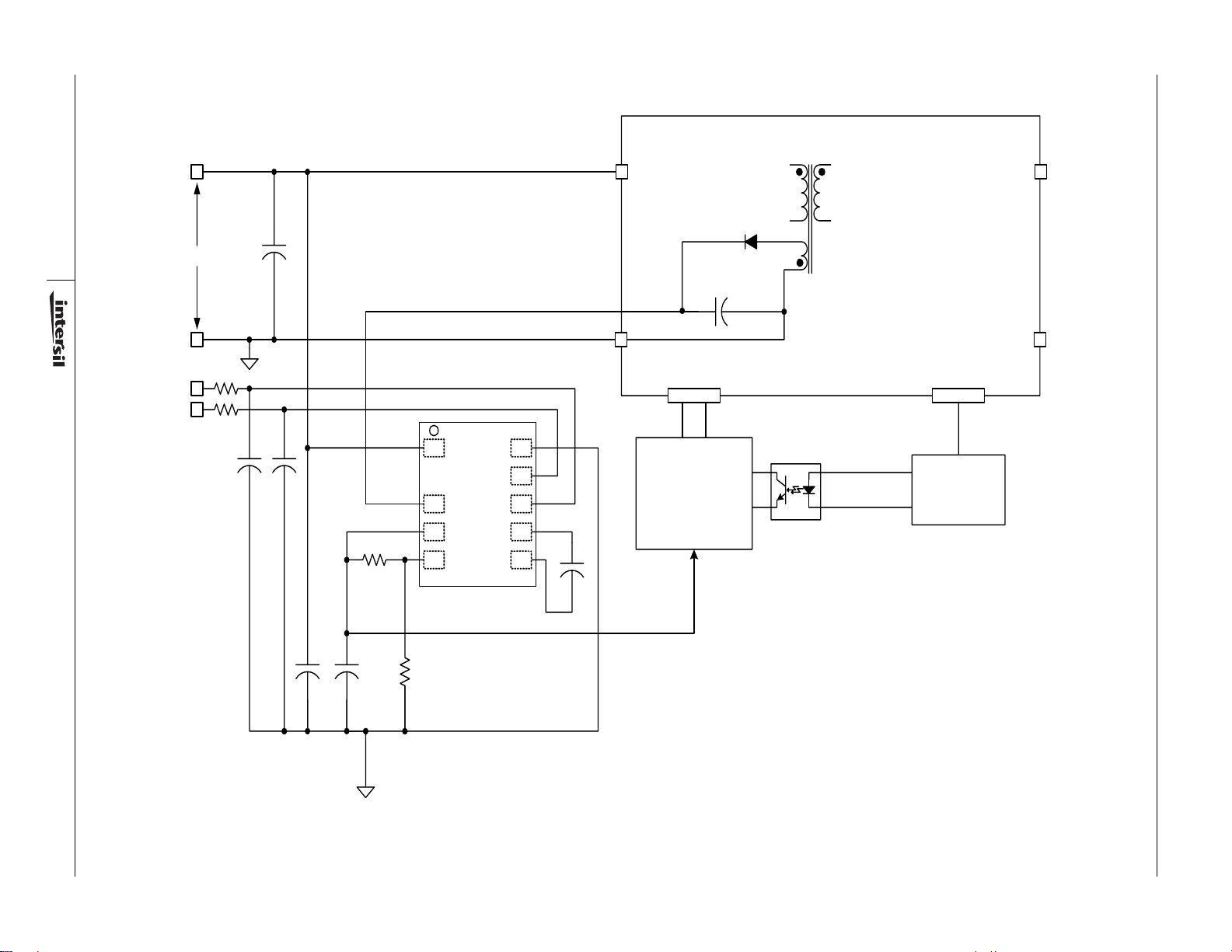

Typical Application

CONVERTER POWER STAGE

VIN

+

3

17V TO 100V

VIN-

ENABLE

DISABLE

1

VPWR

ENABLE_N

2

AUXIN

3

4

VSW_FB

R1

ISL6719

GND

ENABLE

COMPBVSW

COMPA

9

8

7

6

5

C3

220pF

PWM

FEEDBACK

AMP L IF IER

+VOUT

RETURN

ISL6719

C1

October 1, 2007

FN6555.1

C2

1.0μF

R2

ISL6719

Absolute Maximum Ratings Thermal Information

Supply Voltage, VPWR . . . . . . . . . . . . . . . . . .GND - 0.3V to +105V

AUXIN, VSW_FB. . . . . . . . . . . . . . . . . . . . . . . .GND - 0.3V to +40V

COMPB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .GND - 0.3V to +30V

VSW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GND - 0.3V to +25V

All Others. . . . . . . . . . . . . . . . . . . . . . . . . . . . . GND - 0.3V to +6.0V

Operating Conditions

Temperature Range

ISL6719AARZ . . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to +105°C

Supply Voltage Range (Typical). . . . . . . . . . . . . . 18VDC to 80VDC

CAUTION: Do not operate at or near the maximum ratings listed for extended periods of time. Exposure to such conditions may adversely impact product reliability and

result in failures not covered by warranty.

NOTES:

is measured with the component mounted on a high effective thermal conductivity test board in free air. See Tech Brief TB379 for details.

1. θ

JA

2. For θ

3. All voltages are with respect to GND.

, the “case temp” location is the center of the exposed metal pad on the package underside.

JC

Electrical Specifications Recommended operating conditions unless otherwise noted. Refer to “Functional Block Diagram” on page 2

and “Typical Application” on page 3. 17V < VPWR < 100V, C

T

= -40°C to +105°C (Note 4), Typical values are at TA = +25°C.

A

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

SUPPLY VOLTAGE (VPWR)

Supply Voltage 100 V

Start-Up Current (I

Operating Current (I

UVLO START Threshold VSW Disabled 13.0 16.5 V

UVLO STOP Threshold VSW Disabled 12.0 15.0 V

Hysteresis UVLO START - UVLO STOP 0.8 1.2 1.7 V

AUXILIARY VOLTAGE (AUXIN)

Maximum Bias VPWR = 17V, 100V 40 V

OUTPUT VOLTAGE (VSW)

Load Capacitance Range Note 5 0.47 1.0 1.5 µF

Overall Accuracy VPWR = 18V, 100V, VSW = 5V, 10V, 12V

Setpoint Range VPWR = 100V, AUXIN = 30V 1.55 20 V

Reference VSW_FB = VSW 1.45 1.50 1.55 V

Source Voltage Headroom (AUXIN - VSW) VPWR = 17V, VSW = 10V, I

Source Voltage Headroom (VPWR - VSW) VSW = 20V, AUXIN = 0V

Minimum Required Load -3 mA

) VPWR = 12V 250 450 µA

VPWR

) VSW Enabled, VPWR = 100V , VSW = 10V, 20V ,

VPWR

I

VPWR

- I

VSW

VSW Disabled, VPWR = 100V, 1.1 2.0 mA

AUXIN Biased at 40V, VSW Enabled,

VPWR = 100V, VSW = 10V, 20V,

= -100mA

I

VSW

AUXIN = 15V, I

I

= -100mA 1.8 3.0 V

VSW

I

= -50mA 1.4 2.0 V

VSW

I

= -100mA 6.2 V

VSW

I

= -50mA 5.2 V

VSW

= -3mA to -100mA

VSW

Thermal Resistance (Typical, Notes 1, 2) θ

(°C/W) θJC (°C/W)

JA

9 Ld DFN . . . . . . . . . . . . . . . . . . . . . . . 54 2.8

Maximum Junction Temperature . . . . . . . . . . . . . . .-55°C to +150°C

Maximum Storage Temperature Range. . . . . . . . . .-65°C to +150°C

Pb-free reflow profile . . . . . . . . . . . . . . . . . . . . . . . . . .see link below

http://www.intersil.com/pbfree/Pb-FreeReflow.asp

VSW

= 1μF, I

= -3mA, VSW Enabled,

VSW

1.1 2.0 mA

1.1 2.0 mA

-5 +5 %

= 0.95*I

AUXIN

VSW

4

FN6555.1

October 1, 2007

ISL6719

Electrical Specifications Recommended operating conditions unless otherwise noted. Refer to “Functional Block Diagram” on page 2

and “Typical Application” on page 3. 17V < VPWR < 100V, C

T

= -40°C to +105°C (Note 4), Typical values are at TA = +25°C. (Continued)

A

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Maximum VOUT, Faulted VSW_FB VSW_FB = 0V, VPWR = 100V, AUXIN = 40V 22 25 V

Long Term Stability T

= +125°C, 1000 hours (Note 5),

A

VPWR = 48V, VSW = 10V, I

AUXIN = 15V

VSW

= -10mA,

Operational Current (source) VPWR = 48V, AUXIN = 17V, VSW= 15V -100 mA

Current Limit VPWR = 48V, AUXIN = 15V, VSW= 10V -100 -230 -400 mA

VSW_FB Bias Current VPWR = 100V, AUXIN = 40V, VSW = 10V,

VSW_FB = 1.5V

COMPA, COMPB Recommended

Note 5 170 220 270 pF

Capacitance

COMPA Voltage 0.7 V

COMPB Voltage VSW + 5.0 V

ENABLE, ENABLE_N

High Level Input Voltage (VIH) VPWR = 48V, AUXIN = 0V 2.5 3.0 3.6 V

Low Level Input Voltage (VIL) VPWR = 48V, AUXIN = 0V 1.6 2.0 2.5 V

Hysteresis VPWR = 48V, AUXIN = 0V 0.7 1.0 1.3 V

Pull-Up Resistance V

Turn-On Delay T

Turn-Off Delay T

ENABLE =VN_ENABL

VSW,10%

I

VSW

VSW,10%

I

VSW

- T

ENABLE, TVSW,10%

= -3mA

- T

ENABLE, TVSW,10%

= -50mA

=0V - 100 - kΩ

- T

ENABLE_N,

- T

ENABLE_N,

THERMAL PROTECTION

Thermal Shutdown 150 °C

Thermal Shutdown Clear 95 °C

Hysteresis 55 °C

NOTE:

4. Specifications at -40°C and +105°C are guaranteed by +25°C test with margin limits.

5. Limits established by characterization and are not production tested.

VSW

= 1μF, I

= -3mA, VSW Enabled,

VSW

0.3 %

-0.5 1.5 µA

25 µs

40 µs

Typical Performance Curves

5.5

5.0

4.5

4.0

VPWR - VSW (V)

3.5

3.0

0 20 40 60 80 100

VSW CURRENT (mA)

FIGURE 1. VPWR - VSW vs I

@ AUXIN = 0V, +25°C FIGURE 2. AUXIN - VSW vs I

VSW

5

2.5

2.0

1.5

AUXIN - VSW (V)

1.0

0 20 40 60 80 100

VSW CURRENT (mA)

@ VPWR = 17V, +25°C

VSW

FN6555.1

October 1, 2007

Typical Performance Curves (Continued)

ISL6719

1.002

VSW = 1.5V, AUXIN = 15V

1.001

VSW = 5V, AUXIN = 15V

1.000

0.999

VSW = 12V, AUXIN = 15V

0.998

NORMALIZED REGULATION

0.997

FIGURE 3. VSW REGULATION vs TEMPERA TURE @

VSW = 15V, AUXIN = 30V

-40 -25 -10 5 20 35 50 65 80 95 1 10

TEMPERATURE (°C)

VPWR = 100V, I

VSW

VSW = 20V, AUXIN = 30V

= 3mA

Pin Descriptions

VPWR

VPWR is the power connection for the IC. UVLO

enables/disables the output and places the device into a

standby mode even if AUXIN is externally biased.

To optimize noise immunity, bypass VPWR to GND with a

ceramic capacitor as close to the VPWR and GND pins as

possible.

AUXIN

This is the input for an external bias source typically

provided by an auxiliary transformer winding. This input is

not required and may be grounded or left open. Maximum

input bias is 40V.

ENABLE

The positive logic on/off control input. A logic high enables

VSW. Asserting this signal low turns off VSW. ENABLE and

ENABLE_N are logically ORed. Either signal can enable

VSW, but both must be false to disable VSW.

ENABLE_N

The negative logic on/off control input. A logic low enables

VSW. Asserting this signal high turns off VSW . ENABLE and

ENABLE_N are logically ORed. Either signal can enable

VSW, but both must be false to disable VSW.

GND

Signal and power ground connections for this device.

VSW

This is the switched regulated low voltage output supply that

is derived from VPWR or AUXIN. Its output is adjustable

from 1.5V to 20V using an appropriate divider from VSW to

VSW_FB. Protection circuitry prevents the output from

exceeding 25V in the event of a fault on VSW_FB (short high

1.0010

1.0005

1.0000

0.9995

NORMALIZED OUTPUT VOLTAGE

0.9990

0 10 20 30 40 50 60 70 80 90 100

FIGURE 4. VSW REGULATION vs LOAD @ VPWR = 18V,

AUXIN = 15V, +25°C

VSW = 5V

VSW = 10V

VSW = 12V

LOAD (mA)

or low). The minimum output current capability is 100mA.

VSW requires a minimum load of 3mA.

VSW_FB

The feedback pin for VSW. A divider from VSW to ground

sets feedback for VSW and determines the output voltage.

COMPA, COMPB

A compensating capacitor is placed between COMPA and

COMPB to stabilize the control loop. The values may vary

depending on the output load and capacitance applied

between VSW and GND, but for all applications having a

1.0µF load capacitor, a 220pF compensation capacitor is

recommended. The voltage at COMPA is nominally 0.7V.

The voltage at COMPB is nominally VSW +5.0V.

Functional Description

Features

The control circuitry used in Telecom/Datacom DC/DC

converters typically requires an operating bias voltage

significantly lower than the source voltage available to the

converter. Many applications use a discrete linear regulator

from the input source to create the bias supply. Often an

auxiliary winding from the power transformer is used to

supplement or replace the linear supply once the converter

is operating. The auxiliary winding bias voltage may require

regulation as well to minimize the voltage variation inherent

in slave windings. When implemented discretely, this

circuitry occupies significant PWB area, a considerable

problem in today’s high density converters.

The ISL6719 linear regulator simplifies the start-up and

operating bias circuitry needed in Telecom and Datacom

DC/DC converters by integrating these functions, and more,

in a small 3mm x 3mm DFN package.

6

FN6555.1

October 1, 2007

AUXIN

AUXIN is the auxiliary input of the ISL6719, accepting bias

voltage whenever the input source voltage, VPWR, is above

its undervoltage lockout (UVLO) threshold. VSW selects

AUXIN as its source when it is capable supporting the load

on VSW. Otherwise VPWR is selected.

AUXIN can accept voltages up to 40V maximum. Voltages in

excess of 40V, including transients, will cause permanent

damage to the device. Care should be taken when

connecting external sources through very long traces or lead

wires. The lead inductance may cause unexpected

transients in excess of the device’s ratings. In such

circumstances it is recommended that a small resistor be

placed between AUXIN and the external source to dampen

the transient. A value of 10Ω to 100Ω is usually sufficient.

VSW

VSW is the switched output and may be turned on and off

using the ENABLE or ENABLE_N pins. VSW is adjustable

from 1.5V to 20V, but must always be at least 6.2V lower

than VPWR at rated load. Additionally, VSW must be at least

3.0V lower than AUXIN for it to function as the source for

VSW. As the differential voltage between AUXIN and VSW

drops below 3.0V, the input current will shift from AUXIN to

VPWR. The voltage headroom required is load dependent.

See Figures 1 and 2. VSW preferentially uses AUXIN as its

input source, but if AUXIN is unable to supply adequate

voltage, VPWR is selected as the alternate input source.

VSW is capable of delivering up to 100mA continuously,

depending on power dissipation and the thermal

environment in which the device is placed.

The output voltage is adjusted using the VSW_FB input.

VSW is set with a resistor divider from VSW to ground with

the central node connected to VSW_FB. Refer to Figure 5.

R1R2+

VSW V

Referring to Equation 1, V

has a maximum value of 1.5µA. The error introduced by the

VSW_FB bias current can be minimized by making the

product of R

desired output voltage. For example, setting R

equal to 0.5% of VSW yields a value for R

VSW (kΩ).

REF

---------------------

x I

1

–= V

I

BIASR1

R

2

is nominally 1.5V and I

REF

small, relative to the magnitude of the

BIAS

x I

1

equal to 3.33 x

1

BIAS

(EQ. 1)

BIAS

ISL6719

1

VPWR

ENABLE_N

ENABLE

2

AUXIN

VSW

3

VSW

4

VSW_FB

R2

VSW

R1

C2

1.0μF

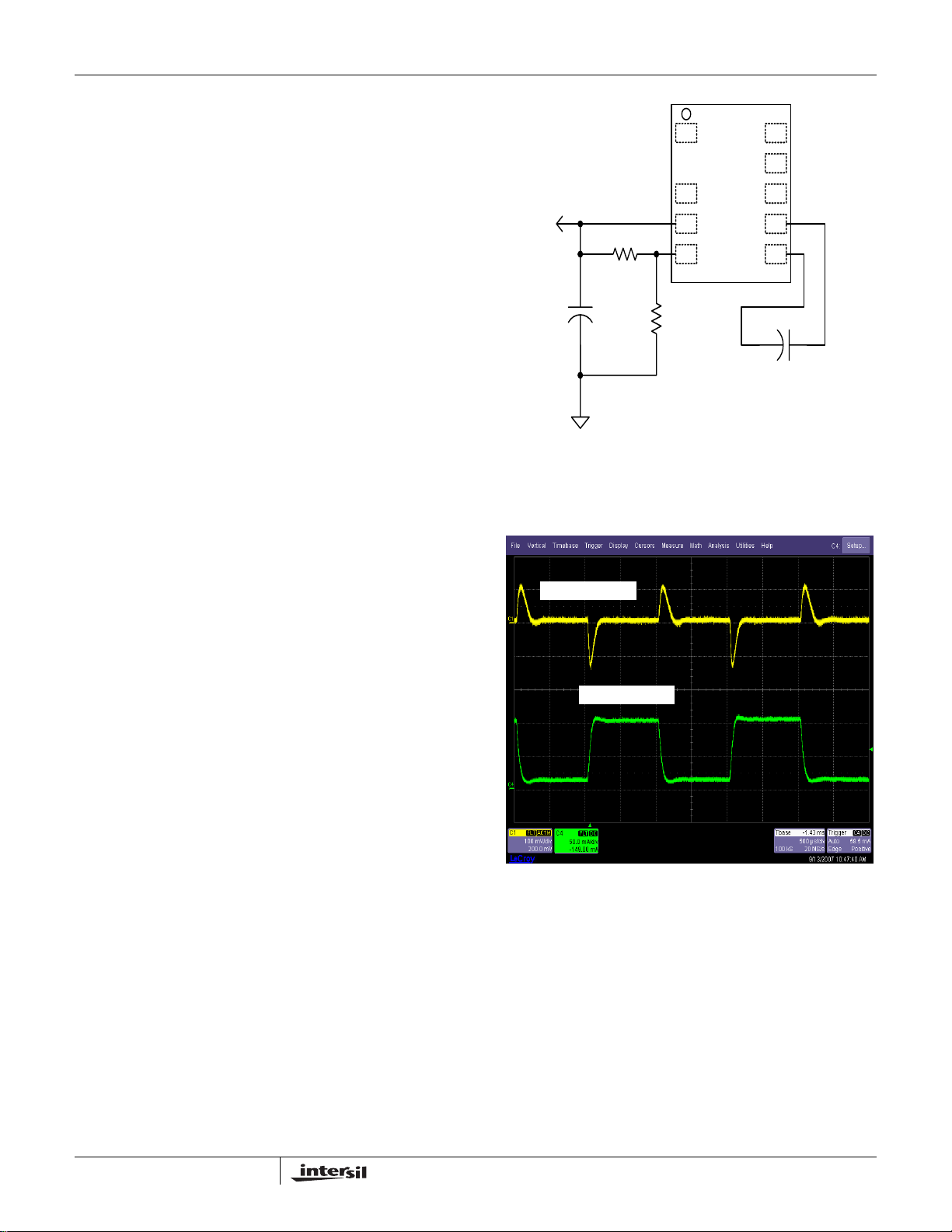

FIGURE 5. VSW ADJUSTMENT AND COMPENSATION

TRACE 1: VSW

TRACE 2: I

FIGURE 6. VSW TRANSIENT RESPONSE, 10mA TO 100mA

STEP, VPWR = 18V, AUXIN = 15V, VSW = 12V

GND

COMPB

COMPA

9

8

7

6

5

C3

220pF

VSW requires an external compensation capacitor to remain

stable across the output adjustment range, output

capacitance and loading. A value of 220pF between COMPA

and COMPB is recommended for all operating conditions

with a nominal load capacitance of 1.0µF (0.47µF to 1.5µF).

VSW requires a minimum load of 3mA.

7

Figure 6 depicts the transient response of VSW during a

10mA to 100mA step load when AUXIN is set to 15V and

VPWR is set to 18V.

VPWR

VPWR provides the source voltage for the IC and load until

AUXIN is back biased. VSW is disabled and the IC operates

in a standby (low power consumption) mode when UVLO is

active.

FN6555.1

October 1, 2007

ISL6719

If the application requires high currents or longer start-up

times than the thermal protection allows, the device

dissipation may be reduced by adding a resistor or resistors

in series between the input voltage and VPWR. The

dropping resistance must be selected such that VPWR

remains above the UVLO threshold of VPWR and at least

6.2V greater than VSW under maximum load and minimum

input voltage to maintain regulation.

VIN

1

VPWR

ENABL

2

ENABLE

AUXIN

3

VSW

COMPB

COMPA

4

VSW_FB

FIGURE 7. ADDING DROPPING RESISTORS TO VPWR

GND

E_N

9

8

7

6

5

ENABLE, ENABLE_N

ENABLE and ENABLE_N are complementary inputs used to

turn VSW on and off. Both polarities of the enable function

are provided to ease the interface to the application. VSW

may be enabled by either ENABLE or ENABLE_N, but both

inputs must be logically false to disable the output. Each

enable input has a nominal 100kΩ pull-up resistor to 5V .

TABLE 1. ENABLE, ENABLE_N TRUTH TABLE

INPUTS OUTPUT

ENABLE ENABLE_N VSW

00ON

01OFF

10ON

11ON

The inputs can accept voltages up to 6V maximum down to

0.3V below signal ground. Voltages beyond these limits,

including transients, may cause permanent damage to the

device. Care should be taken when connecting signal

sources through long connections or if significant ground

shift could occur between the source and the input. In such

circumstances, it is recommended that appropriate clamping

networks be used to prevent possible electrical overstress.

Over-Temperature Prot ection

The ISL6719 has an over-temperature shutdown

mechanism to protect the devic e from excessive dissipation.

VSW shutdown occurs approximately at +150°C. The

hysteresis is large so that the IC has sufficient time to

operate at start-up loading levels without re-triggering the

over-temperature protection.

8

FN6555.1

October 1, 2007

Dual Flat No-Lead Plastic Package (DFN)

ISL6719

(DAT UM B )

5

INDEX

AREA

(DATUM A)

5

INDEX

AREA

SEATING

PLANE

NX L

7

A

C

SIDE VIEW

12

N

BOTTOM VIEW

D

TOP

VIEW

D2

N-1

e

(Nd-1)Xe

REF .

D2/2

2X

A3

E2/2

NX b

4

76

0.10

E

A

NX k

E2

2X

L9.3x3

ABC0.15

0.15

CB

C

0.10

//

C

0.08

M

BAC

9 LEAD DUAL FLAT NO-LEAD PLASTIC PACKAGE

MILLIMETERS

SYMBOL

NOTESMIN NOMINAL MAX

A 0.80 0.90 1.00 A1 - - 0.05 A3 0.20 REF -

b 0.20 0.25 0.30 4, 7

D 3.00 BSC D2 1.85 2.00 2.10 6, 7

E 3.00 BSC E2 0.80 0.95 1.05 6, 7

e 0.50 BSC -

k0.60 - - -

L 0.25 0.35 0.45 7

N92

Rev. 0 3/06

NOTES:

1. Dimensioning and tolerancing conform to ASME Y14.5-1994.

2. N is the number of terminals.

3. All dimensions are in millimeters. Angles are in degrees.

4. Dimension b applies to the metallized terminal and is measured

between 0.15mm and 0.30mm from the terminal tip.

5. The configuration of the pin #1 identifier is optional, but must be

located within the zone indicated. The pin #1 identi fier may be

either a mold or mark feature.

6. Dimensions D2 and E2 are for the exposed pads which provide

improved electrical and thermal performance.

7. Nominal dimensions are provided to assist with PCB Land

Pattern Design efforts, see Intersil Technical Brief TB389.

8. COMPLIANT TO JEDEC MO-229-WEED-3 except for

dimensions E2 & D2.

C

L

NX (b)

4

SECTION "C-C"

(A1)

8

e

CC

FOR ODD TERMINAL/SIDE

TERMINAL TIP

L

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implicat ion or oth erwise u nde r any p a tent or p at ent r ights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

9

FN6555.1

October 1, 2007

Loading...

Loading...