intersil ISL6610, ISL6610A DATA SHEET

®

www.BDTIC.com/Intersil

ISL6610, ISL6610A

Data Sheet November 22, 2006

Dual Synchronous Rectified MOSFET

Drivers

The ISL6610, ISL6610A integrates two ISL6609, ISL6609A

drivers with enable function removed and is optimized to

drive two independent power channels in a synchronousrectified buck converter topology. These drivers, combined

with an Intersil ISL63xx or ISL65xx multiphase PWM

controller, form a complete high efficiency voltage regulator

at high switching frequency.

The IC is biased by a single low voltage supply (5V),

minimizing driver switching losses in high MOSFET gate

capacitance and high switching frequency applications.

Each driver is capable of driving a 3nF load with less than

10ns rise/fall time. Bootstrapping of the upper gate driver is

implemented via an internal low forward drop diode,

reducing implementation cost, complexity, and allowing the

use of higher performance, cost effective N-Channel

MOSFETs. Adaptive shoot-through protection is integrated

to prevent both MOSFETs from conducting simultaneously.

The ISL6610, ISL6610A features 4A typical sink current for

the lower gate driver, enhancing the lower MOSFET gate

hold-down capability during PHASE node rising edge,

preventing power loss caused by the self turn-on of the lower

MOSFET due to the high dV/dt of the switching node.

The ISL6610, ISL6610A also features an input that

recognizes a high-impedance state, working together with

Intersil multiphase PWM controllers to prevent negative

transients on the controlled output voltage when operation is

suspended. This feature eliminates the need for the schottky

diode that may be utilized in a power system to protect the

load from negative output voltage damage.

In addition, the ISL6610As bootstrap function is designed to

prevent the BOOT capacitor from overcharging, should

excessively large negative swings occur at the transitions of

the PHASE node.

Applications

• Core Voltage Supplies for Intel® and AMD®

Microprocessors

• High Frequency Low Profile High Efficiency DC/DC

Converters

• High Current Low Voltage DC/DC Converters

• Synchronous Rectification for Isolated Power Supplies

FN6395.0

Features

• 5V Quad N-Channel MOSFET Drives for Two

Synchronous Rectified Bridges

• Pin-to-pin Compatible with ISL6614 (12V Drive)

• Adaptive Shoot-Through Protection

•0.4Ω On-Resistance and 4A Sink Current Capability

• Supports High Switching Frequency

- Fast Output Rise and Fall

- Low Tri-State Hold-Off Time

• BOOT Capacitor Overcharge Prevention (ISL6610A)

•Low V

• Power-On Reset

• QFN Package

• Pb-Free Plus Anneal Available (RoHS Compliant)

Internal Bootstrap Diode

F

- Compliant to JEDEC PUB95 MO-220 QFN-Quad Flat

No Leads-Product Outline

- Near Chip-Scale Package Footprint; Improves PCB

Utilization, Thinner Profile

Related Literature

• Technical Brief TB389 “PCB Land Pattern Design and

Surface Mount Guidelines for QFN (MLFP) Packages”

• Technical Brief TB363 “Guidelines for Handling and

Processing Moisture Sensitive Surface Mount Devices

(SMDs)”

Ordering Information

PART

NUMBER

(Note)

ISL6610CBZ 6610CBZ 0 to +70 14 Ld SOIC M14.15

ISL6610CRZ 66 10CRZ 0 to +70 16 Ld 4x4 QFN L16.4x4

ISL6610IBZ 6610IBZ -40 to +85 14 Ld SOIC M14.15

ISL6610IRZ 66 10IRZ -40 to +85 16 Ld 4x4 QFN L16.4x4

ISL6610ACBZ 6610ACBZ 0 to +70 14 Ld SOIC M14.15

ISL6610ACRZ 66 10ACRZ 0 to +70 16 Ld 4x4 QFN L16.4x4

ISL6610AIBZ 6610AIBZ -40 to +85 14 Ld SOIC M14.15

ISL6610AIRZ 66 10AIRZ -40 to +85 16 Ld 4x4 QFN L16.4x4

Add “-T” suffix for tape and reel.

NOTE: Intersil Pb-free plus anneal products employ special Pb-free

material sets; molding compounds/die attach materials and 100%

matte tin plate termination finish, which are RoHS compliant and

compatible with both SnPb and Pb-free soldering operations. Intersil

Pb-free products are MSL classified at Pb-free peak reflow

temperatures that meet or exceed the Pb-free requirements of

IPC/JEDEC J STD-020.

PART

MARKING

TEMP.

RANGE

(°C)

PACKAGE

(Pb-Free)

PKG.

DWG. #

1

AMD® is a registered trademark of Advanced Micro Devices, Inc. All other trademarks mentioned are the property of their respective owners.

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright Intersil Americas Inc. 2006. All Rights Reserved

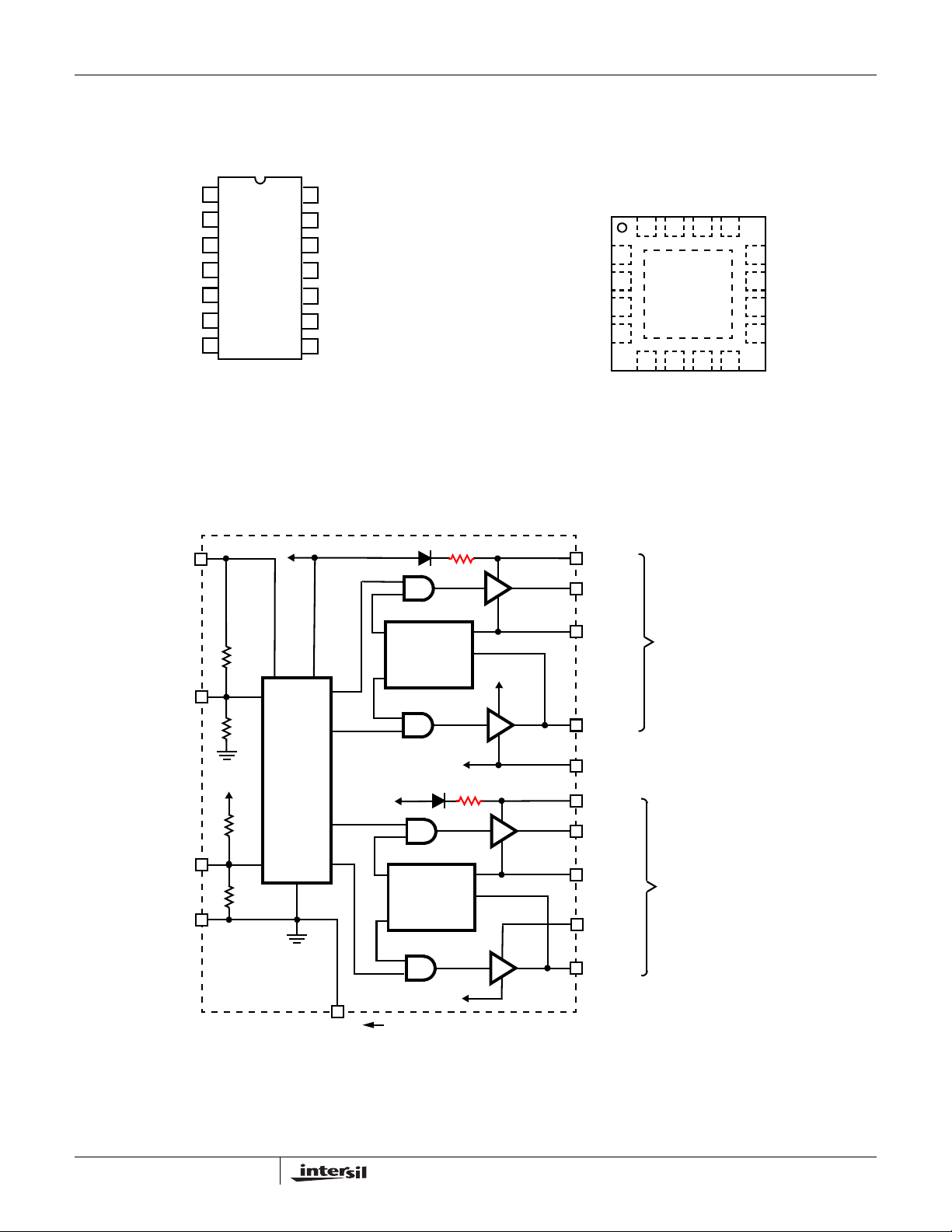

Pinouts

www.BDTIC.com/Intersil

ISL6610, ISL6610A

(14 LD SOIC)

TOP VIEW

ISL6610, ISL6610A

ISL6610, ISL6610A

(16 LD QFN)

TOP VIEW

PWM1

PWM2

GND

LGATE1

PVCC

PGND

LGATE2

Block Diagram

VCC

PWM1

1

1

2

2

3

4

5

6

14

13

12

11

10

9

87

VCC

PHASE1

UGATE1

BOOT1

BOOT2

UGATE2

PHASE2

GND

LGATE1

PVCC

PGND

PWM2

PWM1

15

16 14 13

1

2

3

4

GND

6578

NC1

LGATE2

17

VCC

PHASE1

NC2

PHASE2

12

11

10

9

UGATE1

BOOT1

BOOT2

UGATE2

ISL6610, ISL6610A

R

SHOOT-

BOOT

PVCC

BOOT1

UGATE1

PHASE1

CHANNEL 1

PVCC

4.9K

THROUGH

PROTECTION

PWM2

GND

VCC

4.6K

4.9K

4.6K

CONTROL

LOGIC

INTEGRATED 3Ω RESISTOR (R

PVCC

PAD

2

LGATE1

PGND

SHOOT-

THROUGH

PROTECTION

PGND

R

BOOT

PGND

BOOT2

UGATE2

PHASE2

PVCC

LGATE2

CHANNEL 2

FOR ISL6610CR/10ACR, THE PAD ON THE BOTTOM SIDE OF

THE QFN PACKAGE MUST BE SOLDERED TO THE CIRCUIT’S GROUND.

) AVAILABLE ONLY IN ISL6610A

BOOT

FN6395.0

November 22, 2006

ISL6610, ISL6610A

www.BDTIC.com/Intersil

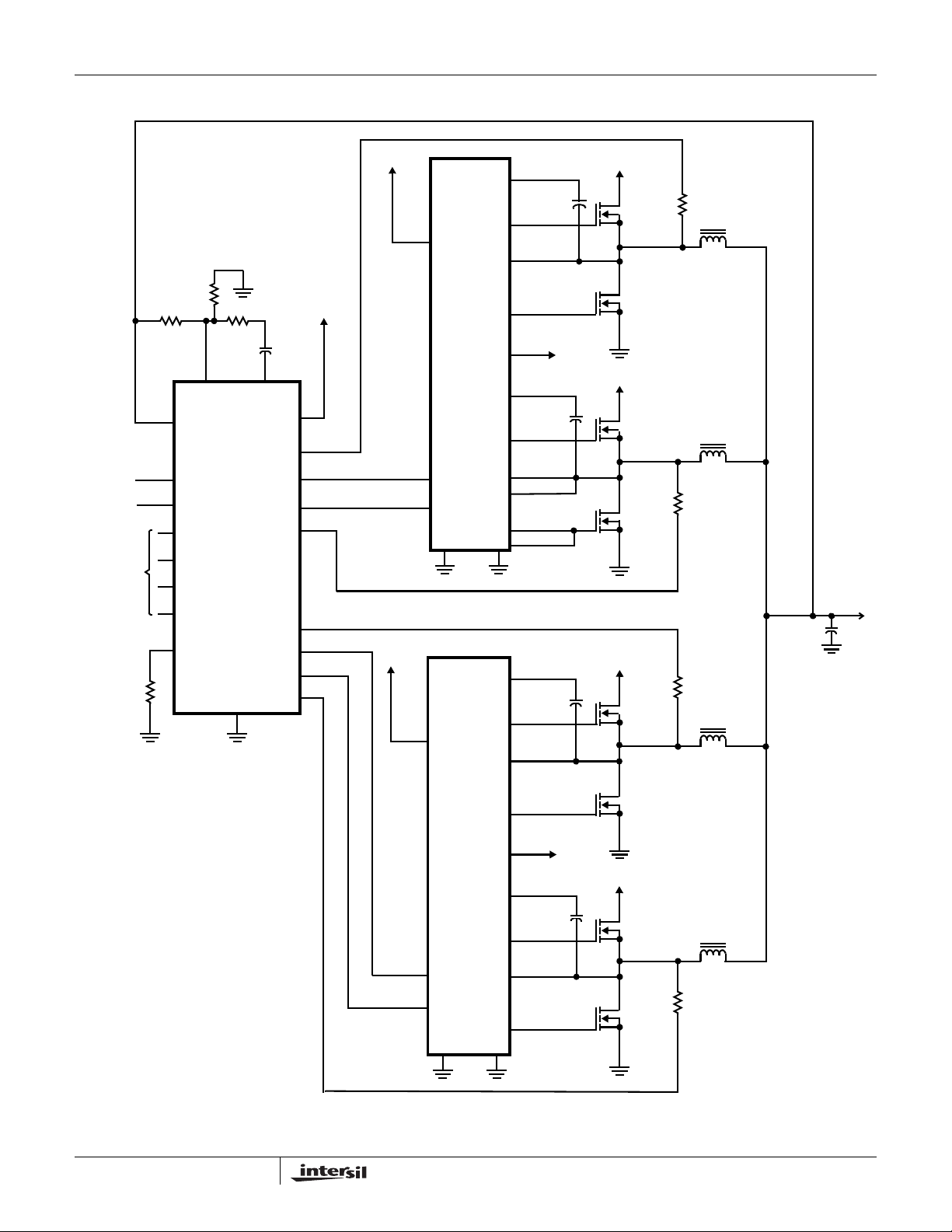

Typical Application - Multiphase Converter Using ISL6610 Gate Drivers

PGOOD

EN

VID

FB

VSEN

FS/DIS

COMP

MAIN

CONTROL

ISL65xx

GND

V

CC

ISEN1

PWM1

PWM2

ISEN2

ISEN3

PWM3

PWM4

ISEN4

+5V

+5V

VCC

PWM1

PWM2

+5V

VCC

DUAL

DRIVER

ISL6610

BOOT1

UGATE1

PHASE1

LGATE1

PVCC

BOOT2

UGATE2

PHASE2

NC2

LGATE2

NC1

PGNDGND

BOOT1

UGATE1

PHASE1

+5V

+12V

+12V

+12V

+V

CORE

LGATE1

DUAL

DRIVER

ISL6610

PWM1

PWM2

PVCC

+5V

BOOT2

UGATE2

PHASE2

LGATE2

PGNDGND

3

+12V

FN6395.0

November 22, 2006

ISL6610, ISL6610A

www.BDTIC.com/Intersil

Absolute Maximum Ratings Thermal Information

Supply Voltage (PVCC, VCC) . . . . . . . . . . . . . . . . . . . . -0.3V to 7V

Input Voltage (V

BOOT Voltage (V

BOOT To PHASE Voltage (V

PHASE Voltage . . . . . . . . . . . . . . . . . . . . . GND - 0.3V to 15V (DC)

UGATE Voltage . . . . . . . . . . . . . . . . V

LGATE Voltage . . . . . . . . . . . . . . . GND - 0.3V (DC) to VCC + 0.3V

Ambient Temperature Range. . . . . . . . . . . . . . . . . .-40°C to +125°C

HBM ESD Rating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2kV

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

+150°C max junction temperature is intended for short periods of time to prevent shortening the lifetime. Constantly operated at 150°C may shorten the life of the part.

NOTES:

is measured with the component mounted on a high effective thermal conductivity test board in free air. See Tech Brief TB379 for details.

1. θ

JA

2. θ

is measured in free air with the component mounted on a high effective thermal conductivity test board with “direct attach” features.

JA

, “case temperature” location is at the center of the package underside exposed pad. See Tech Brief TB379 for details.

3. θ

JC

, V

EN

BOOT-GND

GND -8V (<20ns Pulse Width, 10μJ) to 30V (<100ns)

V

GND - 2.5V (<20ns Pulse Width, 5μJ) to VCC + 0.3V

) . . . . . . . . . . . . . . . -0.3V to VCC + 0.3V

PWM

). . . -0.3V to 25V (DC) or 36V (<200ns)

BOOT-PHASE

- 5V (<20ns Pulse Width, 10μJ) to V

PHASE

). . . . . . -0.3V to 7V (DC)

-0.3V to 9V (<10ns)

- 0.3V (DC) to V

PHASE

BOOT

BOOT

Thermal Resistance (Typical) θ

SOIC Package (Note 1) . . . . . . . . . . . . 90 N/A

QFN Package (Notes 2 and 3). . . . . . . 46 8.5

Maximum Junction Temperature . . . . . . . . . . . . . . . . . . . . . . +150°C

Maximum Storage Temperature Range. . . . . . . . . .-65°C to +150°C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . +300°C

(SOIC - Lead Tips Only)

Recommended Operating Conditions

Ambient Temperature Range. . . . . . . . . . . . . . . . . . .-40°C to +85°C

Maximum Operating Junction Temperature. . . . . . . . . . . . . +125°C

Supply Voltage, VCC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5V ±10%

(°C/W) θJC(°C/W)

JA

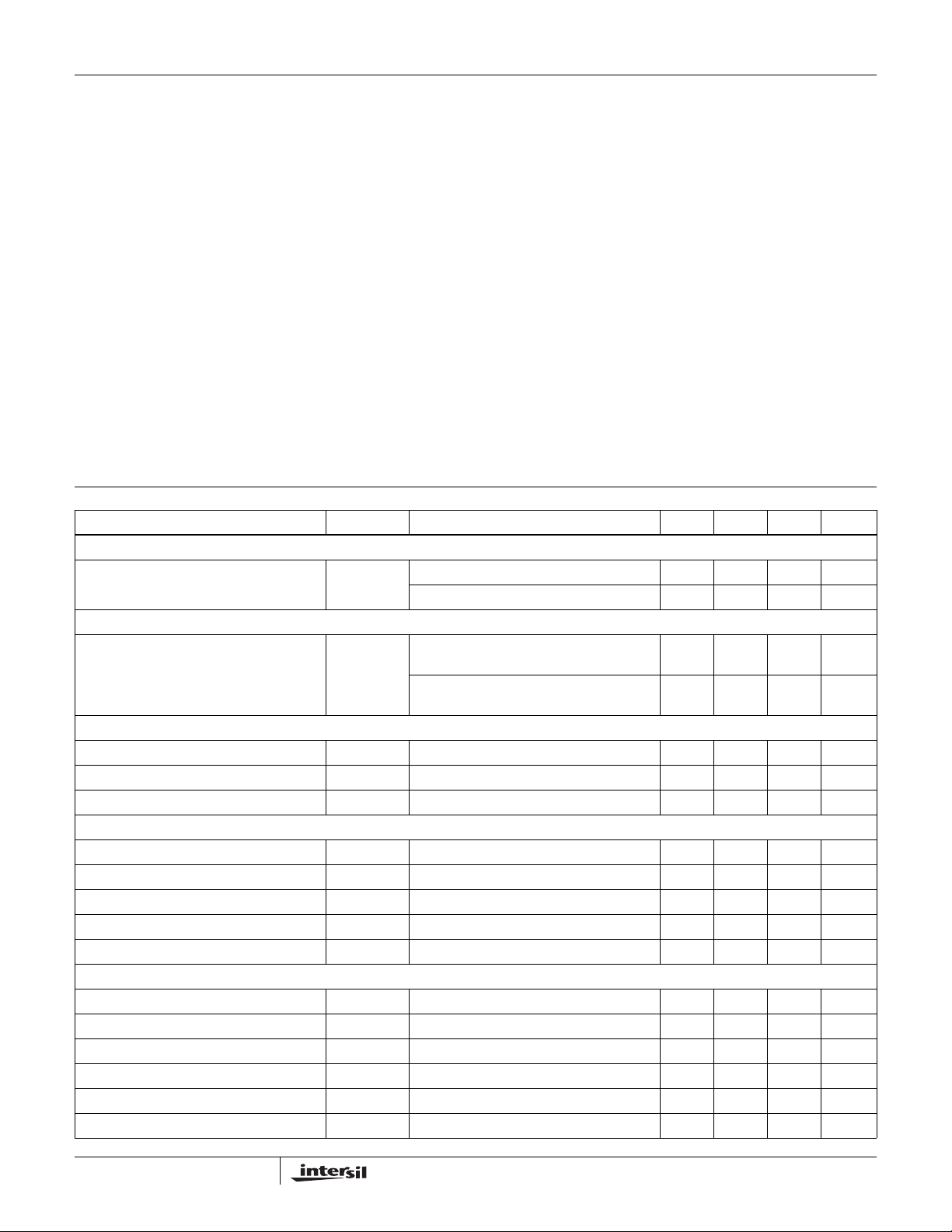

Electrical Specifications These specifications apply for T

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

SUPPLY CURRENT

Bias Supply Current I

BOOTSTRAP DIODE

Forward Voltage V

POWER-ON RESET

POR Rising -3.44.2V

POR Falling 2.6 3.0 - V

Hysteresis - 400 - mV

PWM INPUT

Sinking Impedance R

Source Impedance R

Tri-State Rising Threshold V

Tri-State Falling Threshold V

Tri-State Shutdown Holdoff Time t

SWITCHING TIME (Note 4, See Figure 1)

UGATE Rise Time t

LGATE Rise Time t

UGATE Fall Time t

LGATE Fall Time t

UGATE Turn-Off Propagation Delay t

LGATE Turn-Off Propagation Delay t

VCC+PVCC

F

PWM_SNK

PWM_SRC

TSSHD

RU

RL

FU

FL

PDLU

PDLL

= -40°C to +85°C, unless otherwise noted

A

PWM pin floating, V

= 300kHz, V

F

PWM

Forward bias current = 2mA

= 0°C to +70°C

T

A

Forward bias current = 2mA

T

= -40°C to +85°C

A

= V

VCC

= V

VCC

3nF Load - 8.0 - ns

3nF Load - 8.0 - ns

3nF Load - 8.0 - ns

3nF Load - 4.0 - ns

Outputs Unloaded - 18 - ns

Outputs Unloaded - 25 - ns

= 5V (250mV Hysteresis) 1.00 1.20 1.40 V

PVCC

= 5V(300mV Hysteresis) 3.10 3.41 3.70 V

PVCC

VCC

VCC

= V

= V

= 5V - 240 - μA

PVCC

= 5V - 1.6 - mA

PVCC

0.30 0.60 0.70 V

0.30 0.60 0.75 V

-4.6-kΩ

-4.9-kΩ

-80-ns

4

FN6395.0

November 22, 2006

Loading...

Loading...