Page 1

®

ISL6590

Data Sheet April 2003

Digital Multi-Phase PWM Controller for

Core-Voltage Regulation

Processors that operate above a GHz require fast, intelligent

power systems. The Intersil ISL6590 controller offers

intelligent digital, multi-phase control that provides high

bandwidth, optimal control frequency response, noise

immunity and active transient response control algorithms.

The design is fully scalable for controlling up to six phases,

each featuring the Intersil ISL6580 intelligent power stage.

The user can configure and monitor the power system via

the Asynchronous Serial Interface (ASI). The ISL6590

controller flexibility can be extended with the addition of an

external EEPROM for updating key circuit operating

parameters in the control loop and overall system design.

The digital architecture reduces the design time for

engineers with the use of our software. The software allows

the designer the freedom to choose output stage

components and still achieve optimized system

performance.

The ISL6590 digital controller communicates with the

ISL6580 integrated power stages via 100% digital signaling.

Serial communication allows for separation of the controller

and the power stage, providing placement and layout

freedom to the power stage. The digital controller

implements phase balancing to ensure even distribution of

phase currents. The ISL6590 controller configures the

ISL6580 power stage current limit, VID reference, nonoverlap period, Active Transient Response (ATR) trigger

levels and maximum temperature limit. The digital controller

also monitors the ISL6580 power stage peak currents, overtemperature fault, input under voltage, output over/under

voltage to ensure proper operation of the power supply.

Pinout

ISL6590 (QFN)

TOP VIEW

FN9061

Features

• Open Architecture features software programmable

control loop compensation enabling optimal system

performance

- User accessible asynchronous serial interface

• Intel VR10

- 6-bit Dynamic VID™

- Output voltage regulation range of 0.8375V to 1.600Vdc

• 250kHz to 1MHz switching frequency

• 100% digital control and signaling

• Active Transient Response (ATR) control algorithms for

minimized voltage droop and overshoot

• Controls up to six ISL6580 intelligent power stages (20A

per phase, 120A total system current)

• Programmable Adaptive voltage positioning (AVP) load

line

• Configurable control loop parameters (with optional

external EEPROM)

• Programmable MOSFET dead time control

• High speed voltage and current control loops

• PWRGD and OUTEN

• Serial interface to ISL6580 power stages for system

monitoring and configuration

• 64 Ld 9x9 QFN package

• QFN Package Option

- QFN Compliant to JEDEC PUB95 MO-220 QFN - Quad

Flat No Leads - Product Outline

- QFN Near Chip Scale Package Footprint; Improves

PCB Efficiency, Thinner in Profile.

Ordering Information

OUTEN

VID [0]

VID [1]

VID [2]

VID [3]

VID [4]

VID [5]

VDD_CORE

PWRGD

VDD_IO

MCLK

MDO

MCS

NDRIVE1

PWM1

PART NUMBER TEMP. (oC) PACKAGE PKG. NO.

ISL6590DR 0 to 85 64 Ld 9x9 QFN L64.9x9-S

PLL_FILTER

PLL_ANALOG_VDD

PLL_ANALOG_VSS

PLL_DIGITAL_VSS

OSC_IN

OSC_OUT

ARX

ATX

VDD_IO

SCLK

SDATA

TEST4

TEST3

PLL_DIGITAL_VDD

VDD_CORE

64

01

MDI

16

IDIG1

IDIG2

VDD_CORE

NDRIVE3

IDIG3

PWM3

VDD_IO

NDRIVE4

NDRIVE2

PWM2

1

ATRH

49

TEST 2

48

ATRL

SOC

ERR

VDD_IO

SYS_CLK

VDD_IO

NC

NC

VDD_CORE

NC

NC

IDIG6

PWM6

NDRIVE6

33

TEST1

3217

IDIG4

IDIG5

PWM5

PWM4

NDRIVE5

EXT_RESETB

CCAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

All other trademarks mentioned are the property of their respective owners. Dynamic VID™ is a trademark of Intersil Americas Inc.

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright © Intersil Americas Inc. 2003. All Rights Reserved

Page 2

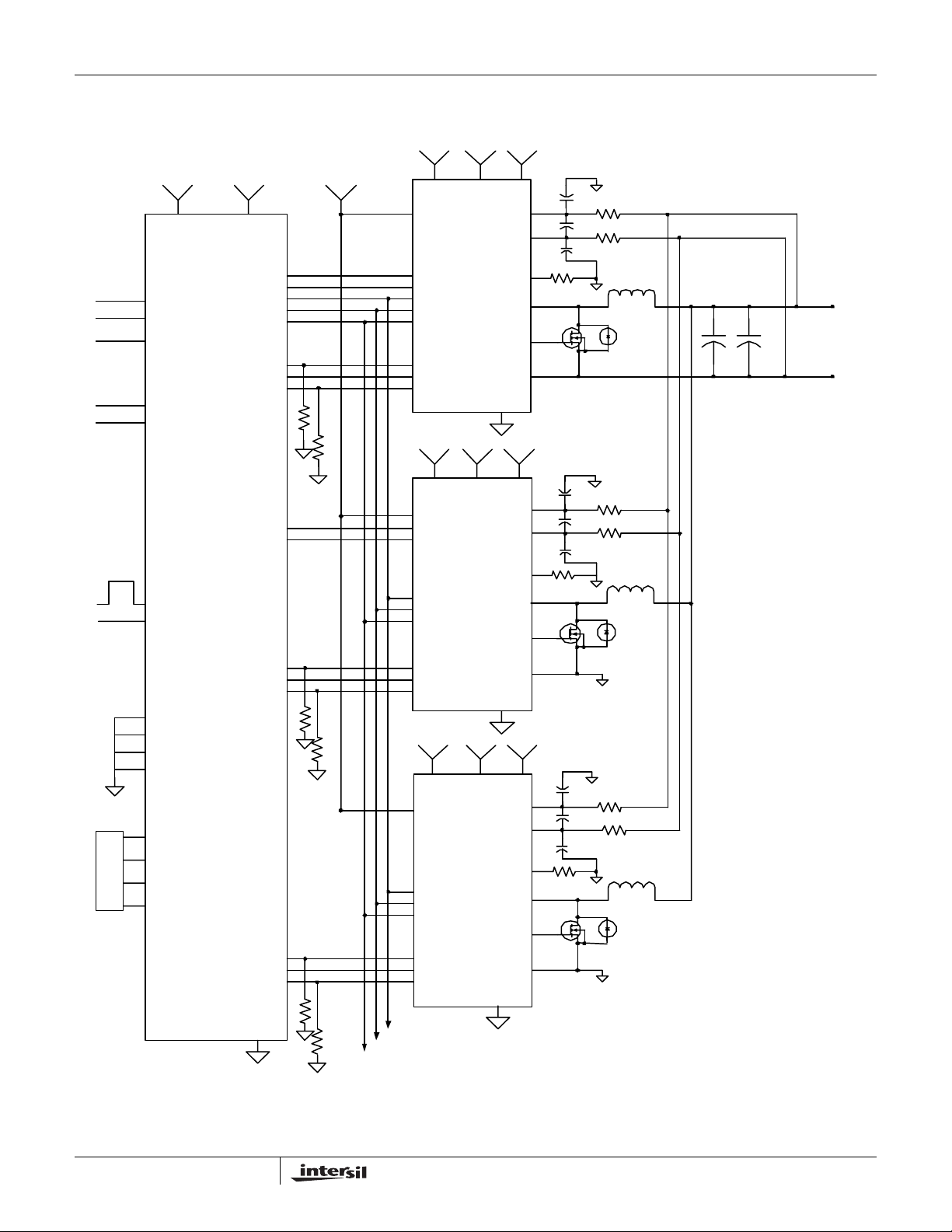

Typical Application Circuit

ISL6590

3.3 V

5-12 V 12 V

3.3 V

V DD_IO V DD_CORE

VID[0:5]

PWRGD

OUTEN

ARX

ATX

1.8 V

SCLK

SDATA

SYSCLK

PWM

NDRIV E

ISL6590

ATRH

ATRL

OSC_IN

OSC_OUT

ERR

SOC

IDIG

2.5 V

VDD VDRIVEVCC

VREF

ATRH

ATRL

ISL6580

ERR

SOC

SCLK

SDATA

CLK

PWM

IDIG

NDRIV E

3.3 V

VDD VDRIVEVCC

VREF

ATRH

ATRL

ISENSE

5-12 V

ISL6580

ERR

SOC

SCLK

SDATA

CLK

ISENS E

VSENP

VSENN

VSW

NGA TE

PGND

GND

12 V

VSENP

VSENN

VSW

NGA TE

REGULATION

CHANNEL

Vout

Vout

RTN

PWM

IDIG

NDRIV E

TEST1

TEST2

TEST3

TEST4

MDO

MDI

EEPROM

MCS

MCL K

PWM

IDIG

NDRIV E

GND

CONTROLLER

INTE RFACE BUS

PWM

IDIG

NDRIV E

5-12 V 12 V

3.3 V

VDD VD RI VEVCC

VREF

ATRH

ATRL

ISL6580

ERR

SOC

SCLK

SDATA

CLK

PWM

IDIG

NDRIV E

PGND

GND

VSENP

VSENN

ISENS E

VSW

NGA TE

PGND

GND

ATR CHANNEL

UV/OV CHANNEL

2

Page 3

ISL6590

Absolute Maximum Ratings

Supply Voltage

(VDD_IO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +3.63V

(VDD_Core) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +1.98V

ESD Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5kV

Recommended Operating Conditions

Supply Voltage

(VDD_IO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +3.3V ±5%

(VDD_Core) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +1.8V ±5%

(Analog PLL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +1.8V ±5%

(Digital PLL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +1.8V ±5%

Ambient Temperature . . . . . . . . . . . . . . . . . . . . . . . . . .0

CAUTION: Stress above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational section of this specification is not implied.

o

C to 85oC

Thermal Information

Thermal Resistance (oC/W)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

θ

JC

θ

JA-0 LFPM AIR

θ

JA-100 LFPM AIR

θ

JA-200 LFPM AIR

θ

JA-400 LFPM AIR

θ

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

JB

Maximum Storage Temperature Range . . . . . . . . . -65

Maximum Lead Temperature (Soldering 10s). . . . . . . . . . . . .300

Maximum Junction Temperature. . . . . . . . . . . . . . . . . . . . . . .125

Maximum Storage Temperature Range . . . . . . . . . -65

Maximum Lead Temperature (Soldering 10s). . . . . . . . . . . . .300

. . . . . . . . . . . . . . . . . . . 29.0

. . . . . . . . . . . . . . . . . 26.6

. . . . . . . . . . . . . . . . . 25.0

. . . . . . . . . . . . . . . . . 23.2

o

C to 150oC

o

C to 150oC

o

o

o

NOTE:

is measured with the component mounted on a “High Effective” Thermal Conductivity Board with “Direct Attach” features. (See Tech Brief

1. θ

JA

TB379 for details.)

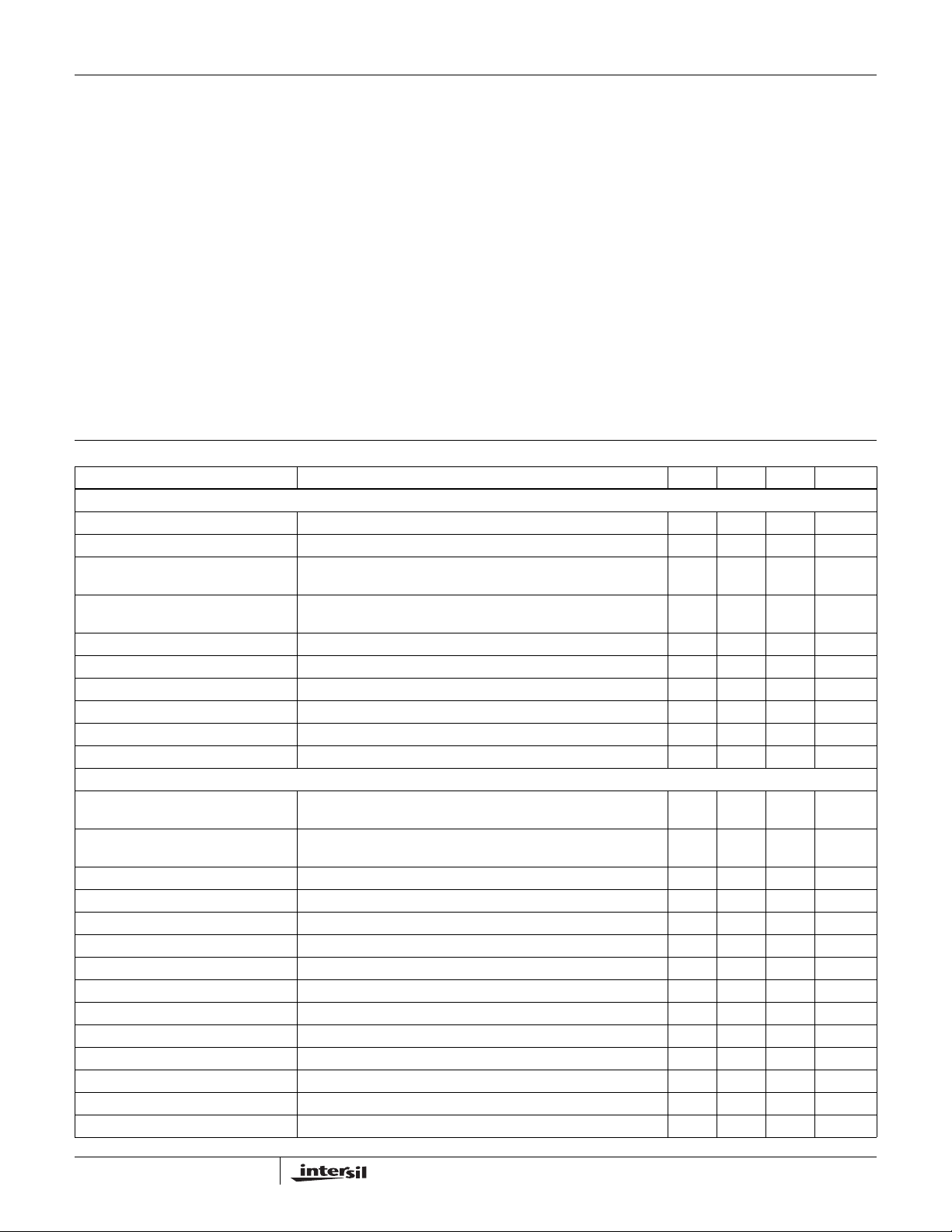

Electrical Specifications Operating Conditions: V

DDIO

= 3.3V, V

DDCORE

= 1.8V, TA = 25oC, Unless Otherwise Specified

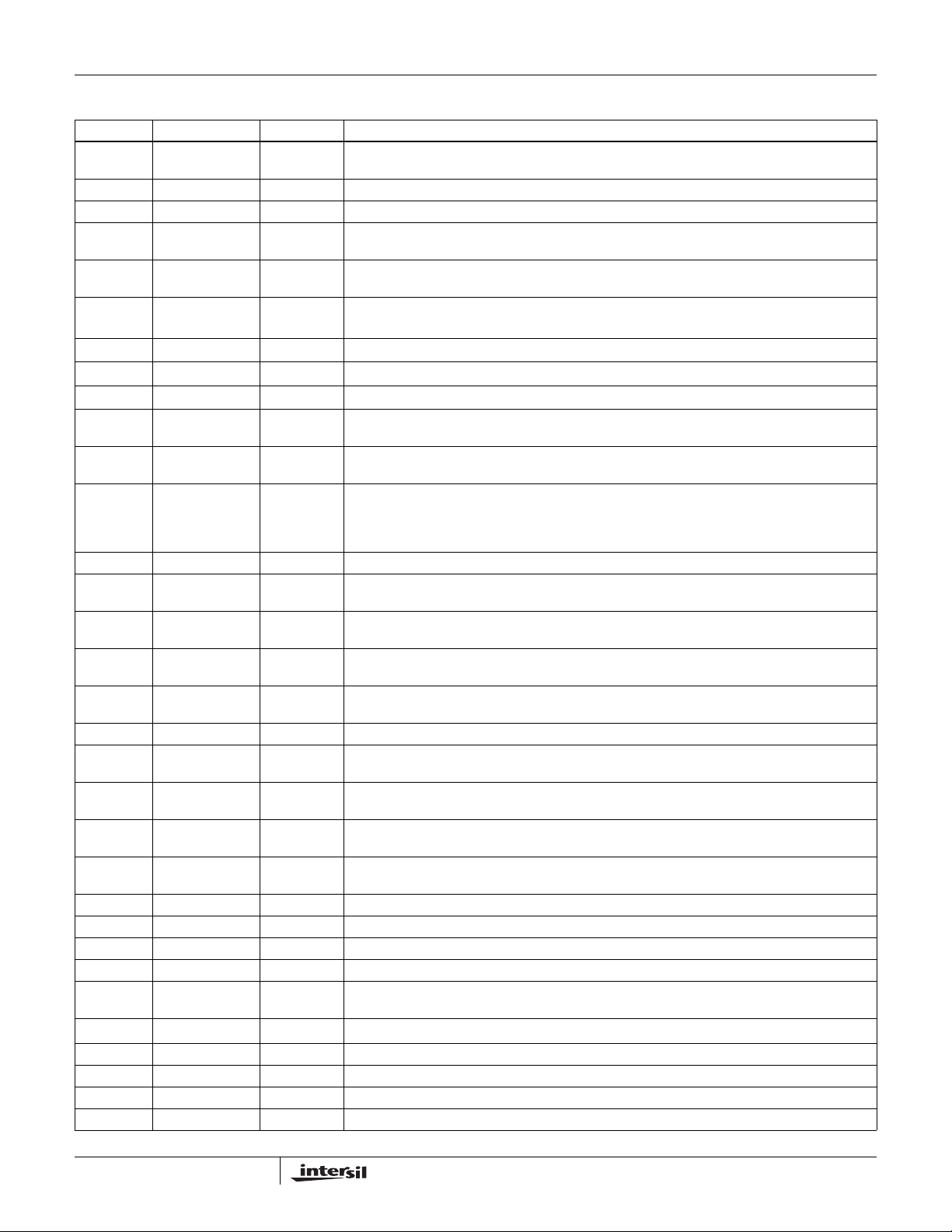

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

INPUTS

Outen, VID[0:5], V

Outen, VID[0:-5], V

IH

IL

MDI, IDIG[1-6], ATRL, ATRH, SOC,

ERR V

IH

MDI, IDIG[1-6], ATRL, ATRH, SOC,

ERR V

IL

EXT_RESETB, V

EXT_RESETB, V

ARX, V

IH

ARX, V

IL

OSC_IN, V

OSC_IN, V

IH

IL

IH

IL

3.3V no internal pull-up/down resistors 0.8 - - V

3.3V no internal pull-up/down resistors - - 0.4 V

3.3V internal pull-down resistor 2.0 - - V

3.3V internal pull-down resistor - - 0.8 V

3.3V internal pull-up resistor 2.0 - - V

3.3V internal pull-up resistor - - 0.8 V

3.3V internal pull-up resistor 2.0 - - V

3.3V internal pull-up resistor - - 0.8 V

No internal pull-up/down resistors 2.0 - - V

No internal pull-up/down resistors - - 0.8 V

OUTPUTS

MCLK, MDO, MCS, NDRIVE[0:5],

PWM[0:5], ATX, V

OH

MCLK, MDO, MCS, NDRIVE[0:5],

PWM[0:5], ATX, V

SYS_CLK, V

SYS_CLK, V

SCLK, V

SCLK, V

OH

OL

SDATA, V

SDATA, V

SDATA, V

SDATA, V

PWRGD, V

PWRGD, V

OSC_OUT, V

OSC_OUT, V

OL

OH

OL

OH

OL

IH

IL

OH

OL

OH

OL

No internal pull-up/down resistors, 8mA drive 2.4 - - V

No internal pull-up/down resistors, 8mA drive - - 0.4 V

No internal pull-up/down resistors, 20mA drive 2.4 - - V

No internal pull-up/down resistors, 20mA drive - - 0.4 V

No internal pull-up/down resistors, 16mA drive 2.4 - - V

No internal pull-up/down resistors, 16mA drive - - 0.4 V

3.3V pull-up resistor, 16mA drive 2.4 - - V

3.3V pull-up resistor, 16mA drive - - 0.4 V

3.3V pull-up resistor 2.0 - - V

3.3V pull-up resistor - - 0.8 V

Open drain, 6mA drive 2.4 - - V

Open drain, 6mA drive - - 0.4 V

No internal pull-up/down resistors, 10mA drive 2.4 - - V

No internal pull-up/down resistors, 10mA drive - - 0.4 V

C

C

C

3

Page 4

ISL6590

Electrical Specifications Operating Conditions: V

DDIO

= 3.3V, V

DDCORE

= 1.8V, TA = 25oC, Unless Otherwise Specified (Continued)

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

POWER-ON RESET AND ENABLE

POR Threshold V

Rising 1.4 - - V

ddio

V

Falling - - 2.55 V

ddio

V

ddcore Rising

V

ddcore Falling

0.7 - - V

--1.4V

OUTEN Threshold OUTEN Rising -0.71- V

OUTEN Falling -0.64- V

OSCILLATOR

Adjustment Range 0.250 - 1 MHz

Max Duty Cycle 24 TBD - %

NOTE:

1. Reserved for note.

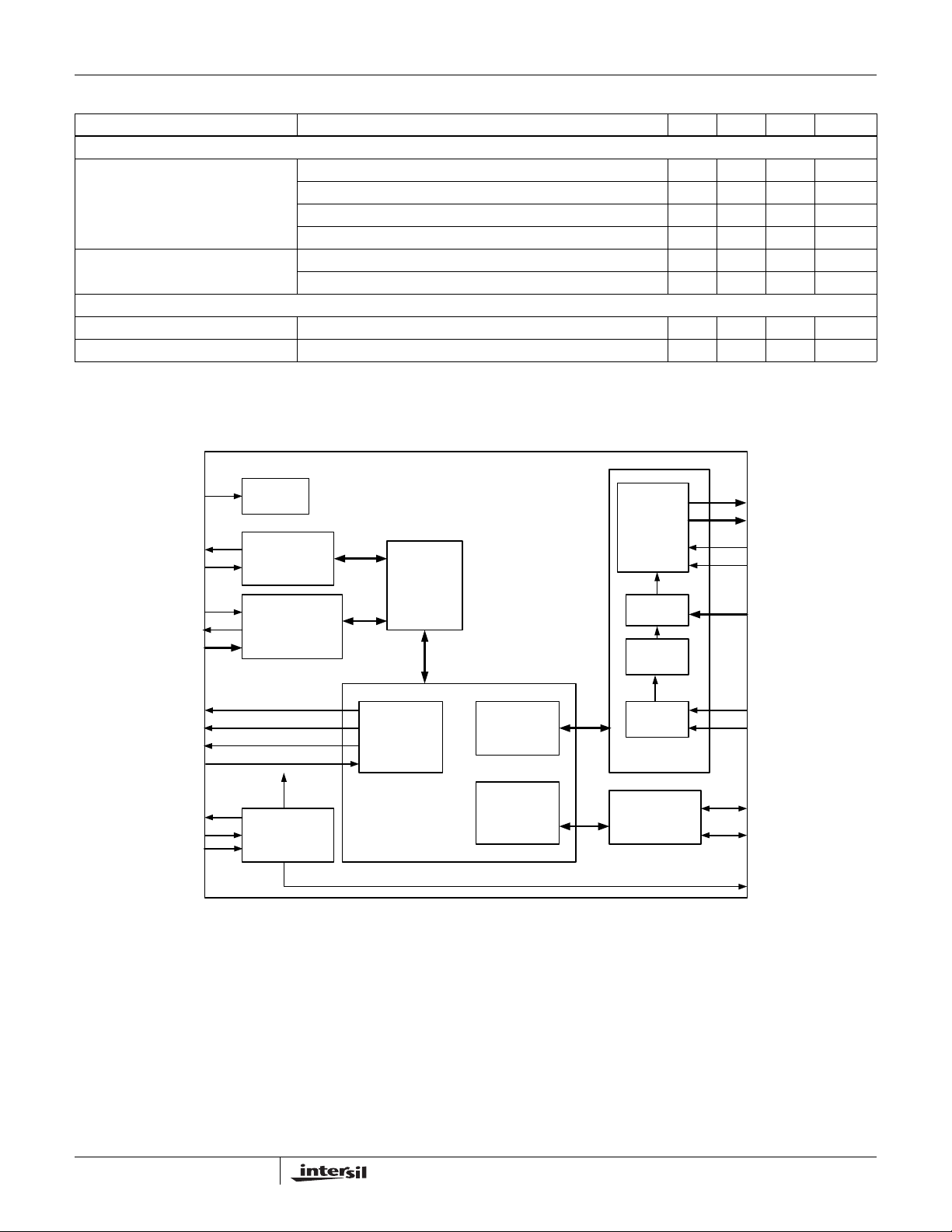

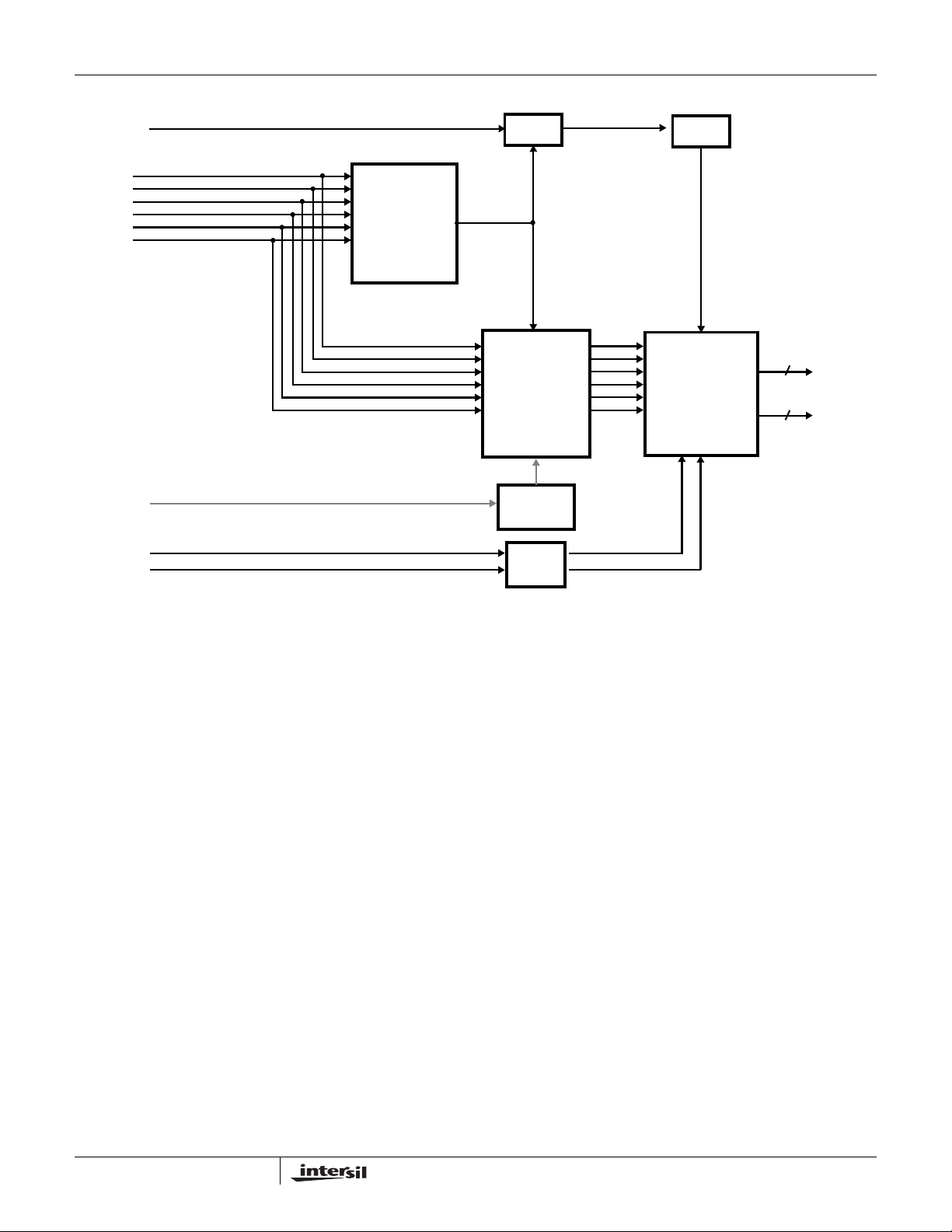

Block Diagram

Ext_Reset

ATX

ARX

OUTEN

PWRGD

VID[5:0]

POR

Asynchronous

Serial Interface

State

Control and

Fault

Moni tor

Memory Bus

MUX

Feedback

Control

PWM Driver

Current

Loop

Voltage

Loop

PWM [6:1]

NDRIVE [6: 1]

ATRH

ATRL

IDIG[6:1]

MDI

MCLK

MCS

MDO

OSC_OUT

OSC_IN

PLL_FILTER

Clock

Distribution

Non-Volatile

SPI EEPOM

Interface

State

Machine

Control/

Status

Registers

MHz Memory

Mapped

Registers

FIGURE 1. ISL6590 BLOCK DIAGRAM

AVP

Backside Serial

Bus

SOC

ERR

SCLK

SDATA

SYS_CLK

4

Page 5

ISL6590

Pin Descriptions

PIN NO. PIN NAME TYPE PIN DESCRIPTION

1 OUTEN Input Output enable high input signal used to command the regulator on and a low input signal turns

the regulator off.

2-7 VID[0:5] Input Voltage identification (6 bit). Programs Vout regulation voltage.

8, 21, 39, 57 VDD_CORE Power IC internal core supply voltage (1.8 VDC logic).

9 PWRGD Output Power Good high output signal to indicate the regulator output voltage is within the specified

10, 25, 42,

44, 54

11 MCLK Output

12 MDO Output

13 MDI Input

14 MCS Output

15, 18, 22,

26, 30, 34

16, 19, 23,

27, 31, 35

17, 20, 24,

28, 32, 36

29 EXT_Reset Input Voltage identification (6 bit). Programs Vout regulation voltage.

33, 48, 50,

51

37, 38, 40,

41

43 SYSCLK Input/Output System clock which runs at a 133.3MHz rate used to clock the ISL6580. This is generated by the

45 ERR Input Serial data transmitted at a 66MHz (or SYSCLK/2) rate. This 6 bit voltage error is feedback into

46 SOC Input Start of Conversion signal initiated by the ISL6580’s Voltage A/D to create the ERR signal.

47 ATRL Input Active Transient Response Low input signal from the ISL6580 indicating a voltage overshoot on

49 ATRH Input Active Transient Response High input signal from the ISL6580 indicating a voltage droop on the

52 SDATA Input/Output Controller serial interface for communication, monitoring, and configuration data between the

53 SCLK Output Serial digital bus clock supplied for the 16.67MHz clocking that accompanies SDATA via the

55 ATX Output Asynchronous Serial Interface Transmit

56 ARX Input Asynchronous Serial Interface Receive

58 OSC_OUT Output Only used if part is using a crystal to generate the system clock.

59 OSC_IN Input Requires a 33.33MHz oscillator or crystal which is used to generate system clock.

60 PLL_DIG_VSS

61 PLL_DIG_VDD Power

62 PLL_ANA_VSS Ground Analog Ground for the 4X clock multiplier PLL.

63 PLL_ANA_VDD Power 1.8V power supply for the 4X clock multiplier PLL (1.8 VDC logic).

64 PLL_Filter Analog Input Filter cap for PLL.

65 GND Ground Paddle IC Ground

VDD_IO Power IC I/O input supply voltage (3.3 VDC logic).

NDRIVE[1:6] Output Low side drive signal used to initiate the ISL6580 to turn on the LSFET.

PWM[1:6] Output PWM performs pulse width modulation which is used to turn on the ISL6580’s power devices.

IDIG[1:6]

TEST[1:4] Output Test pins for part evaluation

NC N/A These pins have not been bonded out.

PLL Bypass

Input Current A/D data serial 7-bit digital word (MSB first). The first bit is a start bit (Start = 1). The

Ground

Input

range. A low signal indicates the voltage is not within range.

EEPROM external memory clock, data is clocked out of the IC on the rising edge and data is

clocked into the ISL6580 IC on the falling edge. Compliant with SPI™ EEPROMs.

EEPROM external memory data output. Compliant with SPI EEPROMs

EEPROM external memory data input. Compliant with SPI EEPROMs.

EEPROM external memory chip select (Active low). Compliant with SPI EEPROMs.

remaining 6 bits represent the sampled peak current in the drain of the particular ISL6580

P-Channel HSFET. (IDIG word transmission is triggered by the falling edge of the PWM signal.)

IDIG is an input that is received at SYSCLK/2, normally 66.6MHz.

internal PLL circuit to create a 4x frequency multiply of the OSC_IN frequency.

the control loop and used to regulate the output voltage.

the converter output.

converter output.

ISL6580 and ISL6590 controller.

Backside serial bus.

Digital Ground

Test mode to bypass PLL input to core.

1.8V power supply for the 4X clock multiplier PLL clock tree driver

for the 4X clock multiplier PLL.

.

(1.8 VDC logic).

5

Page 6

ISL6590

General Description

The ISL6590 is a multiphase digital controller optimized for

microprocessor core voltage generation in the 0.8375Vdc -

1.600Vdc output range and high current loading up to 150A

with a 12Vdc input. It is intended to be used as a chipset with

multiple ISL6580 power stages. The current per stage is up

to 25A and the switching frequency can operate from

250kHz to 1MHz. The adaptability of having a digital

controller with a serial data bus to the power stages means

that the control algorithms can be adjusted with software

instead of having to make hardware or board changes. All of

the features of the ISL6590 are available in applications that

require 3-6 phases of PWM (Pulse-Width Modulation) core

voltage regulation. For more information on the power stage,

consult the ISL6580 data sheet.

Block Diagram Overview

The ISL6590 contains functionality to control up to 6 power

stages with PWM core voltage regulation. The blocks

described follow the block diagram shown in Figure 1. For

additional help it would be useful to reference the block

diagram of the ISL6580, which is located in the ISL6580 data

sheet.

Asynchronous Serial Interface (ASI) (ATX, ARX)

This 2-wire serial data host interface is designed to transfer

command information from the designers PC to the

controller, such as adjustments to register settings. The ASI

is used during the design process to configure and test your

power supply settings. It allows the designer to change loop

coefficients to achieve the best response for their system

design. This serial bus runs at 115K baud rate to interface

with a host computer during testing.

Backside Serial Bus (BSB) (SDATA, SCLK)

The backside serial bus is a 2-wire communication between

the ISL6590 controller and the ISL6580 power ICs used for

transfer of control and status information. This bus is critical

for proper operation of the system, any miscommunications

will cause a bus error between the controller and power

stages and shutdown the power supply. A bus error can be

caused by poor routing of those lines or by a failed ISL6580.

Feedback (PWM, NDRIVE, ATR, IDIG, SOC, ERR)

The feedback control block implements the loop

compensation, hysteretic control, and switch driver. Defaults

for the loop compensation coefficients are retained in the

memory block. If the default values need to be optimized,

they can be adjusted using the ASI.

The PWM generator that drives NDRIVE and PWM derives

its waveform from a current balancing circuit that balances

the current to each phase. The current balancing circuit

requires information about the amount of current each phase

is supporting. This information is obtained using the 6-bit

current ADC in each ISL6580.

Each of the ISL6580s contains a 6-bit voltage ADC that can

be used to measure the difference between the core voltage

at the output and a reference voltage that is set by the VID

information. Even though each ISL6580 has the voltage

ADC, only one of them is required to use it.

When a large change in current occurs at the output load, a

large voltage transient also occurs. The ATRH and ATRL

levels are designed to trigger a temporary mode in which the

PWM generator aligns all phases or removes all phases in

order to quickly raise or lower the output voltage.

Controller Memory

The internal volatile memory provides control and status

registers which are reset to default states on each power up.

These registers can be altered with commands from the ASI,

the State Control and Fault Monitors, or the Serial Interface

with the ISL6580 Power ICs.

EEPROM Interface (MCS, MCLK, MDI, MDO)

An external EEPROM (non-volatile memory) can be used to

write custom information to the volatile memory. The nonvolatile memory can be modified via the ASI. The EEPROM

contains configuration values for a given design. The

ISL6590 uses the standard Serial Peripheral Interface

(SPI™) serial protocol for this memory.

be at least a 2K byte memory. Larger memory can be used

without problems, however the ISL6590 will utilize only 2K

bytes.

The EEPROM must

Clock Distribution (OSC_IN, OSC_OUT)

The clock distribution block creates the internal system clock

from an external clock source such as a crystal oscillator. It

performs a 4x frequency multiplication of the external clock

frequency. The maximum clock input is 33.33MHz for an IC

sample rate of 133.3MHz. It generates the read/write clock

for the ASI. The system clock is provided to the ISL6580s via

the SYS_CLK pin.

State Control and Fault Monitoring (OUTEN,

VID[5:0], PWRGD)

Implements control of the power system state and processes

fault information from the ISL6580 Power IC. All fault

detection within the system is accomplished within each

individual ISL6580 and is communicated to the ISL6590 via

the Backside Serial Interface. ISL6590 detects the fault

through constant polling of the ISL6580 fault registers and

responds by tristating the outputs or shutting down the

system which then requires a power cycle and initiates a

softstart sequence.

Memory Bus Multiplexer

Controls the priority of data transfer to the volatile memory

(control registers) from both the ASI and the state control

and fault monitoring. The state control and fault monitoring is

given priority over the ASI.

6

Page 7

6-BIT OFFSET BINARY

V

ERR

(FROM ERR SIGNAL - ISL6580 VOLTAGE ADC)

1

2

3

4

5

6

6-BIT SERIAL

IDIG

IDIG

IDIG

IDIG

IDIG

IDIG

CURRENT

AVERAGING

ISL6590

I

AVG

AVP

AVP

0

PID

PID

OUT

PWM[6:1]

ISHARE

ATRH

ATRL

(FROM ISL6580 ATRH AND ATRL SIGNALS)

FIGURE 2. FEEDBACK CONTROL DIAGRAM

Block Diagram Details

Feedback Control

At a minimum, there must be three ISL6580s available to

implement the following modes.

1. Regulation Mode (Voltage ADC)

2. Voltage Transient Mode (ATR Window Comparator)

3. Over/Under Voltage Mode (O/U Voltage Comparator)

Additional phases 4-6 are in normal conversion mode.

Located in the Feedback Control section of the ISL6590 is

an interface to the feedback information collected and

delivered by the analog ISL6580 power stages. To

understand the functionality of the ISL6590 feedback

algorithms, key blocks of the ISL6580 must be understood,

such as the ADC converters and the window comparator.

6-bit Current ADC (ISL6580)

A current ADC (Analog-to-Digital Converter) located in each

ISL6580 measures, converts, and transmits that driver’s

current back to the ISL6590 serially via the IDIG[6:1] bus.

The start of conversion is initiated on the falling edge of the

PWM input signal at the ISL6580 and the conversion takes

about 8 SYSCLK cycles. The SYSCLK signal is provided by

the ISL6590 to the ISL6580 and is equal to 4x the crystal

CURRENT

BALANCING

I

ERR

CURRENT

SHARE

FLASH

LOGIC

ATRH

ATRL

PWM

GENERATOR

PARALLEL LINES

NDRIVE[6:1]

(TO ISL6580s)

oscillator rate. The 6-bit current ADC is a successive

approximation converter, requiring one clock per bit, for a

total of 6 clocks. Another clock cycle is for transferring data

to the serial register. Since the PWM and SYSCLK may not

be phase related, one extra clock cycle may be required

depending on the alignment.

It is not possible to predict when the serial data will begin to

transfer on the IDIG bus, so a start bit is used to notify the

ISL6590 that data is coming. The start bit is followed by the

six data bits in descending order from the MSB. A bit is

transferred every two SYSCLK cycles. Since the PWM

signal is used as the start of conversion signal, a significant

glitch on the PWM signal during the conversion or data

transfer will initiate a new conversion and abort the present

conversion. The ISL6590 uses the serial current information

on the IDIG bus to calculate the average of all the phases,

compare it to the current of each phase, and balance the

phases by adjusting each PWM and NDRIVE signal as

necessary.

Because the start of conversion is dictated by the falling

edge of the PWM signal, the effective sample rate of the

current information is the PWM rate (typ<1MHz), even

though each bit is converted and transferred at SYSCLK/2 =

66.6MHz. All ISL6580s will return IDIG information,

regardless of their mode.

7

Page 8

ISL6590

6-bit Voltage ADC (ISL6580)

Each of the ISL6580s contain a 6-bit voltage ADC that can

be used to measure the difference between the core voltage

at the output and a reference voltage that is set by the VID

information. The VID is sent to the designated ISL6580 via

the backside serial bus from the ISL6590 prior to soft start.

The voltage difference measured is sent via the ERR signal

serially to the ISL6590. Even though each ISL6580 has the

voltage ADC, only one of them is required to use it. This

mode is called the Regulation Mode. The conversion is

initiated with the SOC (Start Of Conversion) signal from the

ISL6580 pulsing high for two SYSCLK cycles. After another

two SYSCLK cycles, the 6 bits of data are shifted out of the

ISL6580 on the ERR signal, one bit every two SYSCLK

cycles, starting with the MSB.

Because the ADC uses a successive approximation

architecture, every two SYSCLK cycles converts one bit, for

a total of 12 SYSCLK cycles to make the 6-bit conversion.

With a 133.3MHz SYSCLK, 66.6MHz is the sample rate per

bit of the ADC and is also the serial data rate of the ERR0

signal. However, since the SOC signal initiates the sampling

process, the effective overall sample rate of the voltage

measuring system is equal to the SOC rate.

Window Comparator (ISL6580)

Each ISL6580 contains a window comparator. At least two

ISL6580s must be configured to use it. One is configured

with comparator trip levels for Transient Voltage Mode (ATR

described below) and the other for Over/Under Voltage

Mode which responds via the fault registers and is described

in detail under Fault Processing.

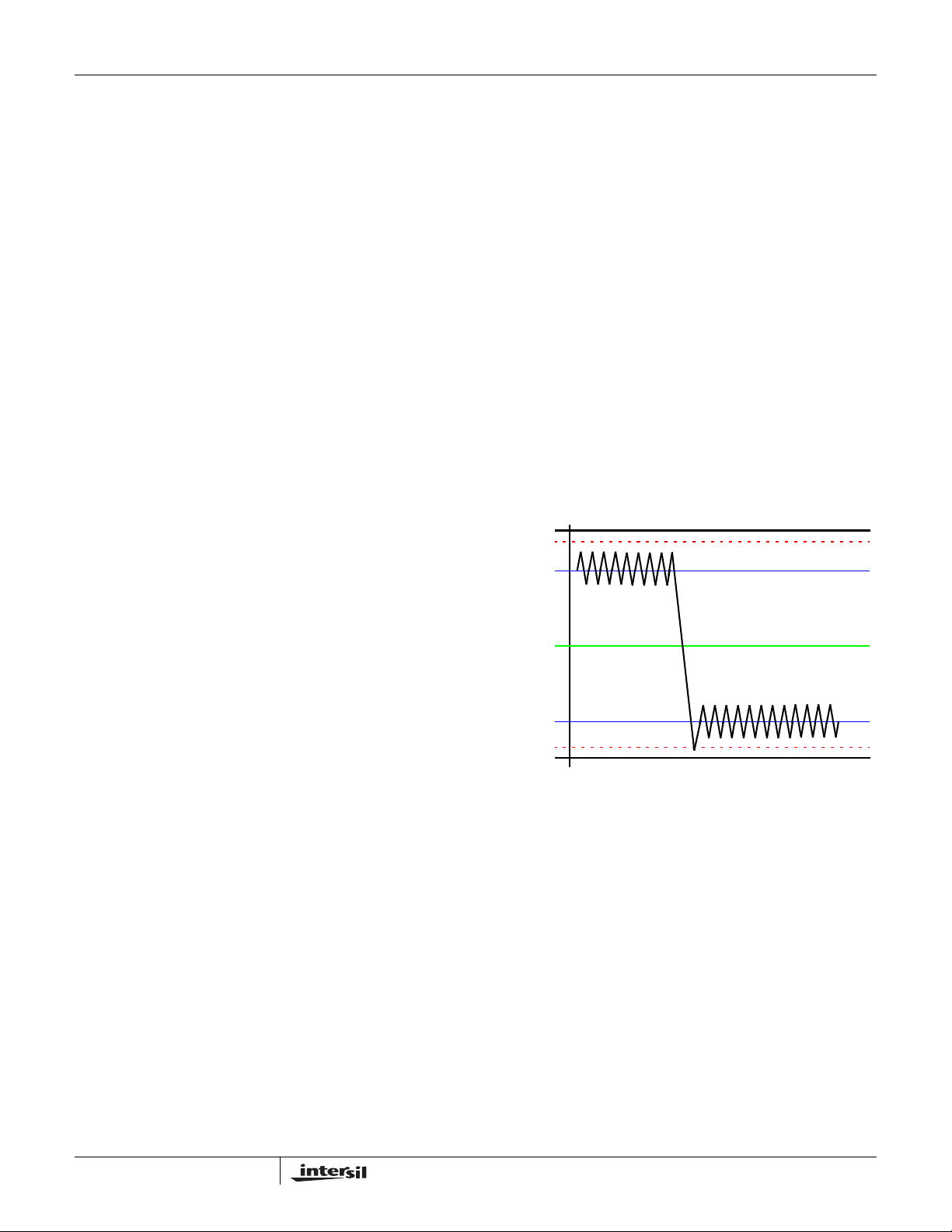

Adaptive Voltage Positioning (AVP)

The Adaptive Voltage Positioning section of the ISL6590

takes the average current of all the active ISL6580 channels

and passes it through an AVP gain factor and a low pass

filter. The AVP gain factor sets the slope of the load line so

that the voltage at high current loading is intentionally less

than the voltage at small current loading. The output of the

low pass filter is subtracted from the ADC voltage error (ERR

signal) to adjust the operating voltage position. The AVP

value is modified in the digital compensation block with the

coefficients stored in the ISL6590 memory. The resulting

modified output is sent to the PWM generator to adjust the

target output voltage for all phases with a voltage offset from

the nominal VID so that current and voltage transients can

better be accommodated.

removes all phases in order to quickly raise or lower the

output voltage. The event is short-lived and the controller

quickly returns to normal operation, but the result is an

instantaneous boost or reduction in output voltage to keep

the transient event within the required regulation window. An

ATR window comparator located in the designated ISL6580

generates the ATRH or ATRL indicator signals when the

event occurs. The ATRH and ATRL trip levels are offsets

from the VID voltage and are set in ISL6590 register 0883h,

each with a 4-bit word. The ATRH, ATRL, and VID values

from the ISL6590 memory are sent to the designated

ISL6580’s registers via the BSB prior to soft start. In the

ISL6580, these are added or subtracted from the VID target

value with 7.5mV LSB resolution to set the trip levels.

Whereas AVP is performed with slight, tightly controlled

modifications to the PWM duty cycle in the ISL6590 using

sampled current data from each phase, ATR is performed

with preset values and trips a comparator in a single

ISL6580. The ISL6580 ATRH or ATRL signals immediately

tell the PWM generator in the ISL6590 to enter the ATR

mode. For this reason, the ATR mode is able to react much

quicker than the sample rate derived AVP.

MAX=VID

ATRL

PAVP

I

=MIN

LOAD

PVID

=MAX

I

LOAD

NAVP

ATRH

MIN

FIGURE 3. ADAPTIVE VOLTAGE POSITIONING AND ACTIVE

TRANSIENT RESPONSE TRIP LEVELS

Active Transient Response (ATR)

Voltage Transient Mode must be performed by one

ISL6580 in the system (but not one already processing

another mode). It is done by using the ATR signals between

the ISL6580 and ISL6590. When a large change in current

occurs at the load, a large voltage transient also occurs. The

ATRH and ATRL levels are designed to trigger a temporary

mode in which the PWM generator aligns all phases or

8

Page 9

ISL6590

VID Map

TABLE 1. VOLTAGE IDENTIFICATION (VID)

V

(V) VID5 VID4 VID3 VID2 VID1 VID0

OUT

0.8375 0 0 1 0 1 0

0.8500 1 0 1 0 0 1

0.8625 0 0 1 0 0 1

0.8750 1 0 1 0 0 0

0.8875 0 0 1 0 0 0

0.9000 1 0 0 1 1 1

0.9125 0 0 0 1 1 1

0.9250 1 0 0 1 1 0

0.9375 0 0 0 1 1 0

0.9500 1 0 0 1 0 1

0.9625 0 0 0 1 0 1

0.9750 1 0 0 1 0 0

0.9875 0 0 0 1 0 0

1.0000 1 0 0 0 1 1

1.0125 0 0 0 0 1 1

1.0250 1 0 0 0 1 0

1.0375 0 0 0 0 1 0

1.0500 1 0 0 0 0 1

1.0625 0 0 0 0 0 1

1.0750 1 0 0 0 0 0

1.0875 0 0 0 0 0 0

OFF 111111

OFF 011111

1.1000 1 1 1 1 1 0

1.1125 0 1 1 1 1 0

1.1250 1 1 1 1 0 1

1.1375 0 1 1 1 0 1

1.1500 1 1 1 1 0 0

1.1625 0 1 1 1 0 0

1.1750 1 1 1 0 1 1

1.1875 0 1 1 0 1 1

1.2000 1 1 1 0 1 0

VID

Control of the output voltage of the regulator is set from the

external six bit VID [5:0] input pins. After power-up, the VID

inputs are sampled and this value is used as the final output

voltage for the Soft Start process. After Soft Start is

complete, the internal VID setting may be changed by

modifying the external six bit VID [5:0] input pins or via the

host interface write to the internal VID register. To allow for

host interface control of VID requires that a separate register

is needed for the value of the external VID input pins. This is

needed to separately track changes to the VID set by the

host interface and the VID set from the external pins. The

same method of output voltage stepping that is used in the

Soft Start process is also applied to dynamic VID changes.

Custom VID

The ISL6590 has additional registers for a custom VID table

to be created and stored in memory locations 0940-097F.

V

(V) VID5 VID4 VID3 VID2 VID1 VID0

OUT

1.2125011010

1.2250111001

1.2375011001

1.2500111000

1.2625011100

1.2750110111

1.2875010111

1.3000110110

1.3125010110

1.3250110101

1.3375010101

1.3500110100

1.3625010000

1.3750110011

1.3875010011

1.4000110010

1.4125010010

1.4250110001

1.4375010001

1.4500110000

1.4625010100

1.4750101111

1.4875001111

1.5000101110

1.5125001110

1.5250101101

1.5375001101

1.5500101100

1.5625001000

1.5750101011

1.5875001011

1.6000101010

9

Page 10

ISL6590

PID

Feedback Control PID block not only performs each of the

basic Proportional, Integral, and Differential compensation

components, it also includes a Low Pass Filter (LPF) to help

reduce high frequency noise and a transient recovery path to

help transient event. The coefficients used in the PID portion

are Kp, Kd, and Ki. The coefficients used in the LPF are Kfp

and Kfd.

The calculations in the transient path take the differential

AVP output (DAVPout), gained up by Kdf, and then added to

the integral path accumulator. The input to the Low pass

filter is the adjusted Verr by AVP output. The coefficients for

the PID block are stored in modifiable registers in the

Controller Memory Map. In order to put a cap on PID output,

the Duty_limit term from the memory map is used to saturate

the output of the PID block.

Current Balancing

This block adjusts each individual channel current, I

comparing it with the average current, I

, of all the active

AV

channels. The difference between each channel current and

the average current passes through a low pass filter and a

shift operation to suppress it before it is added to PID output.

I

is an input from the Current Sharing block (not

ERR

implemented) and represents a difference between the local

module’s average current and the average currents of all

other modules in the system.

1-6

, by

PWM Generator

The PWM generator delivers 1-6 complementary high side

(PWM) and low side (NDRIVE) outputs to each of the

ISL6580 power stage’s inputs. A high state on the PWM

signal enables the high side integrated P-channel MOSFET

of each ISL6580. The low side drive signal is a

complementary, non-overlapped version of the PWM signal.

The rising edge of each PWM phase is evenly distributed

over the switching period. Prior to each PWM output, the

generator samples the PID output value and generates a

pulse that is proportional to the sampled value.

A high level on the OUTEN input signal enables the PWM

generator. The PWRGD output signal denotes that the

output is regulated within the specified limits. If OUTEN is

low or a major fault occurs, PWRGD will be low.

Asynchronous Serial Interface Details

Writes to the control registers from the ASI are second

priority to the fault and state monitoring writes to the control

registers. The priority is handled by the Memory Bus

Multiplexer. The ASI functions at 115.2 kbits/second with a

50ms inter-byte time-out and reset. The ASI waits for

command bytes after reset. The serial data is constructed

with a start bit, eight data bits, and a stop bit. Parity is not

supported.

Controller specific serial interface commands are restricted

to reads and writes of the controller memory map. Details

are provided in Tables 2-5.

TABLE 2. ASYNCHRONOUS SERIAL INTERFACE

COMMAND

NAME

Read_Byte 00h Reads 1 byte at starting address

Write_Byte 01h Writes 1 byte at starting address

TABLE 3. ASYNCHRONOUS SERIAL INTERFACE ERROR

COMMAND

NAME

No Error 00h No Error

Bus Error 01h Bus Error

TABLE 4. ASYNCHRONOUS SERIAL INTERFACE

Address (LSB) 1 In

Address (MSB) 1 In

Error 1 Out

Read data (0 bytes if error) 1 Out

TABLE 5. ASYNCHRONOUS SERIAL INTERFACE

Address (LSB) 1 In

Address (MSB) 1 In

Write data 1 In

Error 1 Out

CONTROLLER SPECIFIC COMMANDS

CODE

(8 BITS) DESCRIPTION

02h-FFh Reserved

CODES

CODE

(8 BITS) DESCRIPTION

02h-FFh Reserved

READ_BYTE COMMAND FORMAT

DATA BYTE DESCRIPTION

(FIRST TO LAST)

WRITE_BYTE COMMAND FORMAT

DATA BYTE DESCRIPTION

(FIRST TO LAST)

LENGTH

(BYTES) DIRECTION

LENGTH

(BYTES) DIRECTION

EEPROM Operation

After the Controller powers up, the SPI Serial EEPROM

interface is polled to see if a memory device is connected.

This polling is performed by doing a SPI Memory Write

Enable (WREN) command and then doing a Read Status

Register (RDSR) to see if the Write Enabl e bi t is set

correctly. If an external SPI Serial EEPROM is connected to

the controller, the Non-Volatile Memory block asserts an

EXTMEM bit in the Memory Status Register. If the

NVMEMCODE check passes, all non-volatile memory

locations in the Controller Memory Map are read from the

serial memory and loaded into the local register copies in the

Controller. Once the startup checks and configuration

loading (if possible) are complete, SPI_READY bit is set in

10

Page 11

ISL6590

the status register which then allows accesses to the NonVolatile Memory map.

FIGURE 4. EEPROM DATA READ TIMING

TABLE 6. EEPROM DATA READ TIMING

TIMING NAME PARAMETER MIN UNITS

Data Setup t

Data Hold t

DSU

DH

20 ns

20 ns

ISL6590 Data Write Timing

Tp

SCLK

t

DSU

t

DH

t

KH

SDATA

FIGURE 6. ISL6590 DATA WRITE TIMING

TABLE 8. DATA WRITE TIMING

TIMING NAME PARAMETER TYPICAL UNITS

Data Setup t

Data Hold t

Kick Hold t

Stop Hold t

SCLK Period t

DSU

DH

KH

SPH

p

45 ns

15 ns

15 ns

15 ns

62.5 ns

ISL6590 Data Read Timing

t

SPH

FIGURE 5. EEPROM DATA WRITE TIMING

TABLE 7. EEPROM TIMING

TIMING NAME PARAMETER TYPICAL UNITS

CS to MCLK delay t

Data Setup t

Data Hold t

Clock Period t

MCLK to CS delay t

CSSU

DSU

DH

P

CSH

480 ns

240 ns

240 ns

480 ns

720 ns

Write-Through Cycles

During startup and local register loading, any incoming

writecycles to the Non-Volatile Memory will be held off until

start up and configuration is complete. During normal

operation, writes to the Non-Volatile Memory shall be

extended until such time that the data is both written to and

read back from the external EEPROM.

FIGURE 7. DATA READ TIMING

TABLE 9. DATA READ TIMING

TIMING NAME PARAMETER TYPICAL UNITS

Data Setup t

Data Hold t

DSU

DH

52 ns

14 ns

11

Page 12

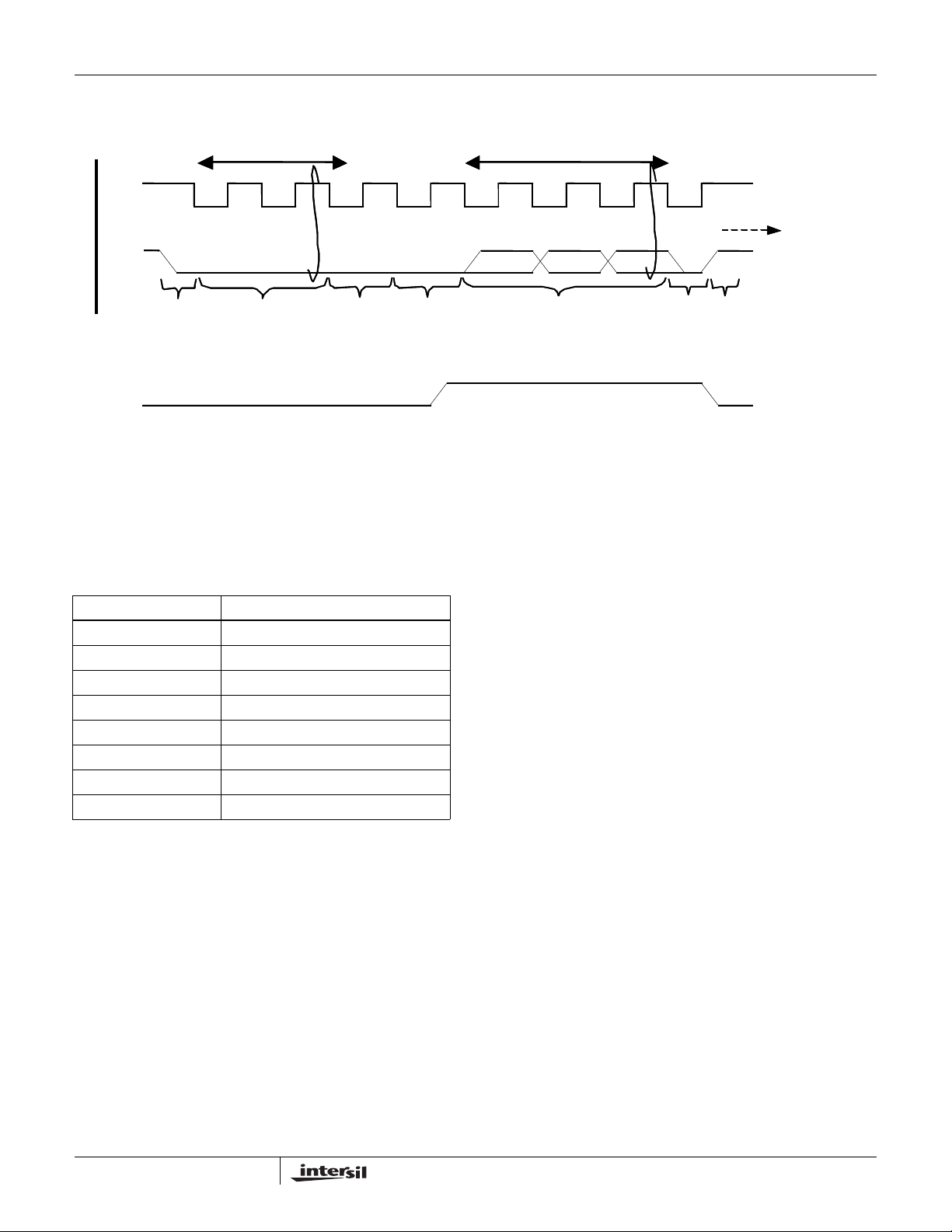

ISL6590 Data Write Protocol

5 cl oc k s 5 clocks 8 Clock s

CLK

DATA

ISL6590

Start Addre s s:

Device ID

Addre s s :

Regi s ter

ISL6590 Data Read Protocol

5 clo cks 5 c locks 8 Clocks

SCLK

SDATA

Star t Address: De viceID Address: Regist er R/W

R/W Dea d

Cycle

FIGURE 8. ISL6590 WRITE PROTOCOL

Dead

Cycle

(from

ISL6580

(from

ISL6580

Dead

Cycle

Dead

Cyc le

Ack

(from

ISL6580

Ack

(from

ISL6580

Stop Data Byte (to ISL6580)Ack

Stop Data Byte (from ISL6580)Ack

12

FIGURE 9. ISL6590 READ PROTOCOL

Page 13

ISL6590

ATX

ARX

ASYNCHRONOUS

SERIAL

INTERFACE

(ASI)

WRITE

READ

ADDR[15:0]

DATA[7:0]

DONE OPEN LOOP

MEMORY

BUS

MUX

READ

WRITE

ADDR[15:0]

WRITE

READ

ADDR[15:0]

DATA[7:0]

DATA[7:0]

CONTROL

AND

STATUS

REGISTERS

EEPROM

INTERFACE

ISL6580

MAPPED

REGISTERS

STATUS

COEFFICIENTS

CONTROL

STATE

CONTROL/

FAULT

MONITOR

MDI

/MCS

MCLK

MDO

STATUS

DONE

WRITE

DEVICE[4:0]

DATA[7:0]

ADDR[4:0]

VID[5:0]

OUTEN

PWRGD

FEEDBACK

CONTROL

EEPROM

INTERFACE

BACKSIDE

SERIAL

BUS

MEMORY

(REGISTERS)

FIGURE 10. MEMORY INTERFACE DIAGRAM

Backside Serial Bus (BSB)

The transfer of data on the BSB consists of a start bit, 5 ID

bits, 5 memory address bits, a read/write bit, an address

acknowledge bit, 8 data bits, a data acknowledge bit, and a

stop bit. The rate of transfer is set by the serial clock divider

register.

Background polling of ISL6580 fault registers is performed

using the BSB. The fault information is written to the

ISL6590 local copies of the ISL6580 fault registers. ISL6580

control registers can be written to or read back from the

ISL6590 memory via the BSB.

Startup Process

ISL6580 Enumeration

After power-up of the system, each installed ISL6580 is

polled for its existence. This procedure involves the

Controller to assert the PWM signal for a specific Power IC.

If the specified Power IC is present, it will assert its signal to

acknowledge seeing its PWM asserted. This sequence is

repeated for each Power IC that may be in the system. This

process is known as Device Polling.

After this initial PWM polling is complete, the serial interface

of each Power IC has to be configured with a device ID to be

able to respond to serial commands later. This procedure

involves issuing a “config call” which is to send a serial write

command to global device ID ‘0’. During the data portion of

the cycle, the Power IC to be configured has its PWM signal

asserted by the Controller. This action allows the data bits

that are sent from the Controller to be shifted into a device ID

register within the Power IC. This process is known as

Enumeration.

During enumeration, the address on the serial bus for each

ISL6580 is uniquely defined according to Table 6. If an

address acknowledge bit is not returned, the device is not

used because it is either not present or not functional. The

PWM signals are used to enable address writing to each

ISL6580. Fault processing is disabled during enumeration.

13

Page 14

SCLK

SCLK

SDATA

SDATA

ISL6590

Address Cycle Data Cycle

Address Cycle Data Cycle

10 clocks 8 Clocks

10 clocks 8 Clocks

Repeat for N-1 devices

Repeat for N-1 devices

Start

Start

"0000000000"

"0000000000"

PWM1 MHz Power IC 1 ID register enable

PWM1 MHz Power IC 1 ID register enable

("ID" register enable)

("ID" register enable)

MHz Power IC Configuration Process

First the master will initiate “config call” by sending a “10’h00” address

All of the slaves should “ACK” because every MHz Power IC register contains 0” after reset

The ID is then sent out during the data cycle.

The process is repeated until all (N) of the devices are configured.

TABLE 10. SERIAL BUS ID MAPPING

BSB ID DESCRIPTION

00h “config call”

01h Power IC 1

02h Power IC 2

03h Power IC 3

04h Power IC 4

05h Power IC 5

06h Power IC 6

09-1Fh Reserved

ISL6580 Calibration

Prior to calibration, the status of each ISL6580 is checked.

The input supply voltage is checked by polling the status of

the under-voltage lockout in the status registers of the

ISL6580s. Other faults are also checked. If a fault is

detected during or after calibration, the system state may be

frozen while fault processing takes over to resolve the error.

To calibrate the voltage ADC, the VID is set to the same

voltage as the external VID setting. Voltage ADC calibration

is initiated by setting the device that is hard wired for

Ack R/W

Ack R/W

Directio

Directio

FIGURE 11. ENUMERATION TIMING DIAGRAM

ID for Power IC 1

ID for Power IC 1

n

n

ISL6580 Softstart

The system is slowly brought out of the no output voltage

open loop state by sending a small PWM pulse width to the

ISl6580s. A fixed time period and step size is used to bring

the output voltage into the lower range of the voltage ADC.

Once the voltage ADC begins readin g vo lt ag e , a fi xed V

step size is used (25mV). After each V

performed, the output voltage must settle within a +/(V

/2) mV window of the specified VID voltage before

step

stepping to the next output voltage setting. The stepping

continues until the final voltage is reached.

Power On Reset

The ISL6590 controller performs a Power On Reset function

internally. It holds all internal logic in a reset state until the

Vdd (3.3V) exceeds a threshold. While in the reset state all

PWM and NDRIVE signals are held at ground and all

MOSFETs are OFF.

Duty Cycle Limit

The ISL6590 limits the on time of the upper FETs. The

system designer can set the maximum ON time with

PowerCode software The value is put in as a percentage. If

the duty cycle reaches this percentage, the top side FET

turns off until the next cycle.

Regulation mode into calibration mode. This should be

device #1. During calibration, any offset voltage internal to

the ADC is output on the ERR serial line. The error is stored

in the non-volatile memory. Then the ISL6590 changes

themode of the ISL6580 to normal operation and calibration

is complete.

Ack Stop Configcall

Ack Stop Configcall

step

step

step is

14

Page 15

Loop Compensation

Any closed loop system must be designed to insure stability

(prevent oscillation) and provide correct response to external

events such as load transients. The output of a buck

regulator has an inherent, low pass filter formed by the

output inductor(s), output capacitance and their ESRs

(Equivalent Series Resistance). Figure 12 shows a typical

gain and phase plot of output inductors, capacitors and ESR.

ISL6590

0

-10

-20

-30

-40

-50

-60

Plant Gain (in DB)

-70

-80

-90

1 10 100 1000 10000

Frequency (in KHz)

FIGURE 12. FREQUENCY RESPONSE OF THE OUTPUT

INDUCTORS AND CAPACITORS

Plant Gain

Phase

0

-20

-40

-60

-80

-100

Phase (in Degrees)

-120

-140

Above the resonant frequency of the output LC filter (10kHz

in this case) the gain falls at a rate of 40dB/decade and the

phase shift approaches –180 degrees. At a frequency

above the F = 1/(2πC*ESR) = 500kHz in this case) the gain

slope changes to –20dB/decade and the phase shift

approaches –90 degrees In a closed loop control system,

the output is subtracted from a reference voltage to produce

an error voltage. The error voltage is amplified and fed to

the output stage. In a buck regulator the output stage

consists of a Pulse Width Modulator (PWM), switching

transistors (typically MOSFETs), series inductor(s) and

output capacitors. High gain feedback reduces variation in

the output due to changes in input voltage, load current and

component values. However, high gain at high frequencies

can cause excessive over shoot in response to transients ( if

phase shift > 120 degrees and gain > 0dB ) or oscillation ( if

phase shift > 180 degrees and gain > 0dB ). The trade off in

designing the loop compensation is to achieve fast response

to transients without excessive overshoot or oscillation.

FIGURE 13. TYPICAL ANALOG VOLTAGE LOOP BLOCK

FIGURE 14. DIGITAL CONTROL LOOP BLOCK DIAGRAM

DIAGRAM

The ISL6580 subtracts a reference from the output voltage

to produce an error voltage. It converts the error voltage to a

6 bit digital number and sends it to the ISL6590 controller.

The controller processes the error number numerically to

provide gain (P

phase lead (D

roportional), phase lag (Integration) and

erivative) functions. This forms the digital PID

control.

15

FIGURE 15. TYPICAL ANALOG ERROR AMPLIFIER AND

COMPENSATION

Page 16

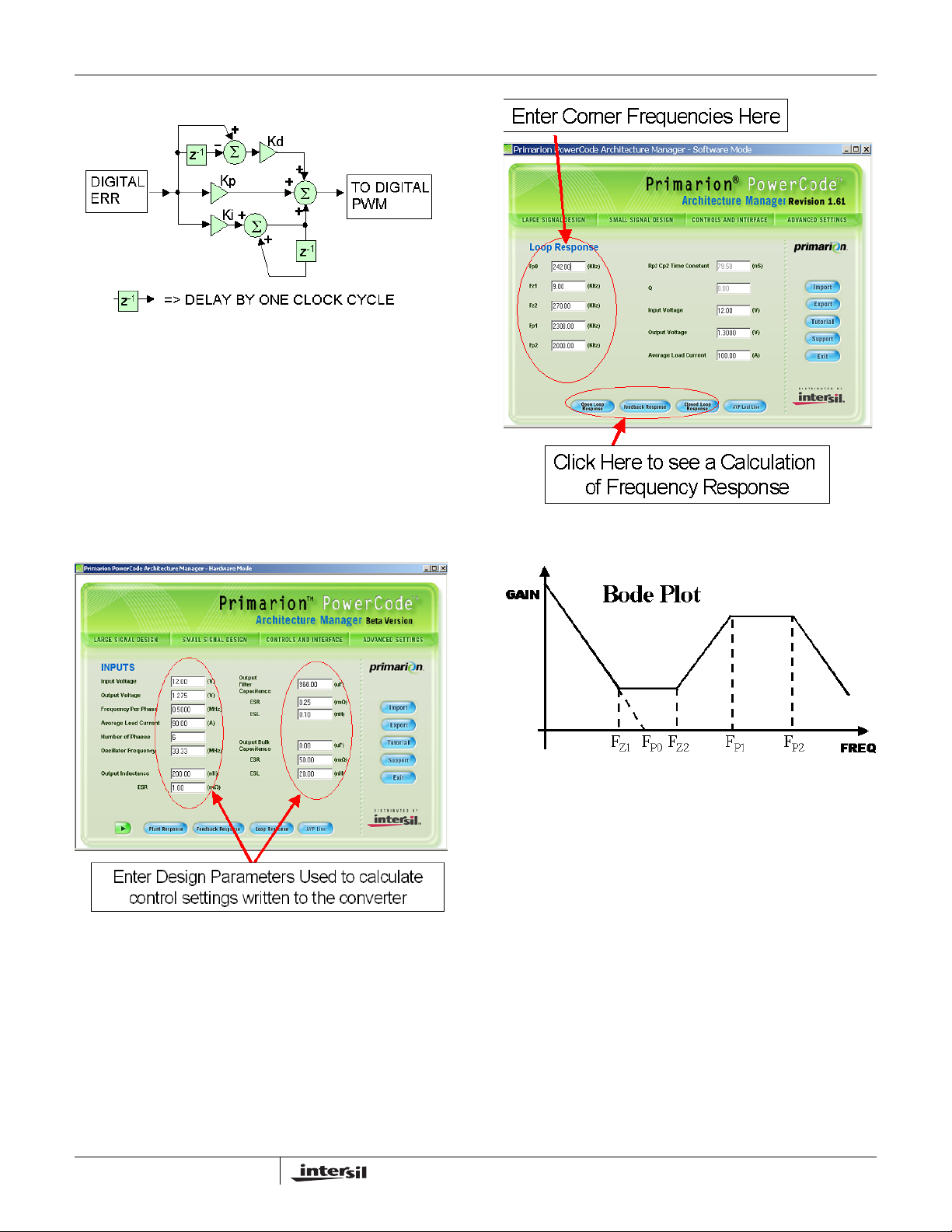

Adjusting The Digital PID

FIGURE 16. DIGITAL PID COMPENSATOR

Frequency response of the digital PID compensator is

determined by the Kp, Ki, Kd factors. These factors are

stored in nonvolatile memory and are loaded in the controller

at power on reset. The system designer sets the PID

compensators frequency response using user interface

software. The designer enters the frequencies of the

desired poles and zeros and user interface software

calculates the Kp, Ki and Kd factors. the software will

calculate and display the frequency response of the

feedback and the closed loop system.

ISL6590

FIGURE 18. SMALL SIGNAL DESIGN WINDOW

FIGURE 17. DESIGN PARAMETER INPUT WINDOW

16

FIGURE 19. BODE PLOT

F

= Frequency of first zero

Z1

= Frequency of second zero

F

Z2

FP0 = Gain * frequency of first pole (A

DC*F P0

)

FP1 = Frequency of second pole

RP2 = External Resistor used for third pole

CP2 = External Capacitor used for third pole

FP2 = 1 / (2 * π* RP2 * CP2 )

The software will calculate the frequency response of the

PID controller and the closed loop system as in figures 20

and 21 below.

Primarion is a registered trademark of Primarion, Inc. Primarion PowerCode is a trademark of Primarion, Inc

Page 17

ISL6590

60

50

40

30

20

Feedback Gain (in DB)

10

0

1 10 100 1000 10000

Frequency (in KHz)

Compensation

Phase

0

-10

-20

-30

-40

-50

-60

-70

-80

-90

FIGURE 20. PID COMPENSATOR FREQUENCY RESPONSE

60

40

20

0

-20

-40

-60

Loop Gain (in DB)

-80

-100

-120

1 10 100 1000 10000

Loop

Phase

Frequency (in KHz)

400

350

300

250

200

150

100

50

0

-50

Phase (in Degrees)

Phase (in Degrees)

slightly below 180 degrees at the cross over frequency, the

loop will respond to transients with overshoot and ringing.

Loop phase shift between 90 and 120 degrees at the cross

over frequency (Phase margin = 60 to 90 degrees) results in

little or no over shoot and ringing. Large phase margins

(>90 degrees) result in slower transient response.

Time Domain

It is recommended to place the first zero (FZ1) at the

resonant frequency of the output inductors and capacitors (F

= 1/(2π√LC = 10kHz in this case). Then increase F

F

to minimize response time over (under) shoot and

P0

ringing. The first microseconds of transient response are

primarily dependant on the ESR and ESL of the output

capacitors. After the affects of ESL and ESR pass the loop

must control the response.

Z2

and

FIGURE 21. FREQUENCY RESPONSE OF THE CLOSED LOOP

Compensation Methodology

Due to the user interface software interface, it is very easy to

change the frequency compensation and see the resulting

performance on a scope or network analyzer. Transient

response is viewed by applying a transient load and

monitoring the output voltage with a scope. Frequency

response is viewed by placing a small resistor between the

output and the feed back network, applying a small sine

wave at the input to the feed back network and measuring

the amplitude and phase shift of the resulting sine wave on

the output. Sweeping the frequency produces plots similar

to those above.

Frequency Domain

It is recommended to place the first zero (FZ1) at the

resonant frequency of the output inductors and capacitors (F

= 1/(2π√LC) = 10kHz in this case). Then increase F

F

to maximize DC gain and the frequency at which gain

P0

drops below 0dB while keeping the phase margin above 60

degrees. Phase Margin is the difference between 180

degrees and the phase shift of the loop at the frequency

where the gain drops below 0dB (cross over frequency). If

the loops phase shift reaches 180 degrees and has gain

equal to or greater than 0dB, it acts as positive feed back

and the loop will oscillate. Even if the loops phase shift is

Z2

and

FIGURE 22. TYPICAL RESPONSE TO A LOAD TRANSIENT

User Interface Software

The ISL6590 controller and the ISL6580 intelligent power

stage have programmable values that can be changed using

the User Interface Software. The loop configuration and

system performance is adjusted using the software. The use

of the software allows the engineer to evaluate the system

performance without having to physically change

components on the board. Primarion PowerCode user

interface software (provided by Intersil and our partner

Primarion).

Below are screen shots showing data entry points, pull down

menus, buttons for help and a tutorial. The user interface

software allows the designer to adjust the load line,

frequency response, ATR and protection modes.

17

Page 18

ISL6590

FIGURE 23. PRIMARION POWERCODE LOADLINE AND ATR

SETTINGS

FIGURE 24. PRIMARION POWERCODE LOOP RESPONSE

SETTINGS

FIGURE 25. PRIMARION POWERCODE MONITOR WINDOW

FIGURE 26. PRIMARION POWERCODE DESIGN INPUTS

18

FIGURE 27. PRIMARION POWERCODE DUTY CYCLE LIMIT

SELECTION

Page 19

ISL6590

Register Description Tables

TABLE 11. ISL6590 MEMORY MAP

R/W/S

ADDRESS RANGE NAME

VOLATILE MEMORY

0000 - 01FF General Control Registers R/W/Ws

0000 Part Number (ASCII character #1) R 8

0001 Part Number (ASCII character #2) R 8

0002 Part Number (ASCII character #3) R 8

0003 Part Number (ASCII character #4) R 8

0004 Version Number (ASCII) R8

0005 Vendor Name (ASCII character #1) R 8

0006 Vendor Name (ASCII character #2) R 8

0007 Vendor Name (ASCII character #3) R 8

0008 Vendor Name (ASCII character #4) R 8

0009 Reserved

000A SPI Memory Status Register R3

000B Reserved

000C Serial Polling Enable R/W 1

000D Reserved

000E System Status (LSB) R/Ws 8

000F System Status (MSB) R/Ws 8

0010 Oscillator-In Frequency (LSB) R 8

0011 Oscillator-In Frequency (MSB) R 8

0012 State Control Status (LSB) R/Ws 8

0013 State Control Status (MSB) R/Ws 8

0014 Reserved

0015 Reserved

0016 – 00EF Reserved

00F0 Scratchpad R/W 8

00F1 – 00FF Reserved

0100 - 01FF Reserved

0200 - 02FF Control/Status Registers R/W/Ws

0200 Reserved

0201 Feedback Loop Control R/W 6

0202 Open Loop PID (LSB) R/W 8

0203 Open Loop PID (MSB) R/W 7

0204 – 0205 Reserved

0206 ATR Control

0207 Phases Used

0208 Phase Enables

209 Reserved

(NOTE 1)

R/W 4

R4

R/W 8

(BITS)

1

SIZE (bits)

1

Size (bits)

SIZE

19

Page 20

ISL6590

TABLE 11. ISL6590 MEMORY MAP (Continued)

R/W/S

ADDRESS RANGE NAME

020A VID_IN_SOFT R/W 6

020B Alive Found R8

020D Reserved

020E VCODE_IN R8

020F VCODE_OUT R/W 8

0210 Enumeration Control R/W 3

0211 Enumeration Done R4

0212 VID_IN (from VID pins) R6

0213 OUTEN (from OUTEN pin) R1

0214 PWRGD R1

0215 VID_OUT R7

0216 Voltage Error R6

0217 Average Peak Channel Current R 6

0218 Overload R8

0219 AVP Offset R8

021A Voltage Calibration Offset R/W 5

021B Regulated R1

021C – 21F Reserved

0220 Peak Channel Current – Phase 1 R 6

0221 Peak Channel Current – Phase 2 R 6

0222 Peak Channel Current – Phase 3 R 6

0223 Peak Channel Current – Phase 4 R 6

0224 Peak Channel Current – Phase 5 R 6

0225 Peak Channel Current – Phase 6 R 6

0226 Peak Channel Current – Phase 7 R 6

0227 Peak Channel Current – Phase 8 R 6

0228 – 022F Reserved

0230 On Time – Phase 1 (upper 8 bits) R 8

0231 On Time – Phase 2 (upper 8 bits) R 8

0232 On Time – Phase 3 (upper 8 bits) R 8

0233 On Time – Phase 4 (upper 8 bits) R 8

0234 On Time – Phase 5 (upper 8 bits) R 8

0235 On Time – Phase 6 (upper 8 bits) R 8

0236 On Time – Phase 7 (upper 8 bits) R 8

0237 On Time – Phase 8 (upper 8 bits) R 8

0238 – 02FF Reserved

0300 - 03FF Reserved

0400 – 07FF Broadcast Write Memory Map R/W/Ws

0400 Reserved

(NOTE 1)

1

Size (bits)

SIZE

(BITS)

20

Page 21

ISL6590

TABLE 11. ISL6590 MEMORY MAP (Continued)

R/W/S

ADDRESS RANGE NAME

0401 Reserved

0402 HFWND (High ATR Window) W 4

0403 LFWND (Low ATR Window) W4

0404 VID (7 bit Voltage Identification) W 7

0405 ILIM (Current Limit) W2

0406 TSD (Thermal Shutdown) W3

0407 Reserved

0408 TEST W8

0409 ENABLE1 (Block Enables LSB) W 8

040A ENABLE2 (Block Enables MSB) W 3

040B SPARE1 W8

040C SPARE2 W8

040D – 041F Reserved

Device 1 Memory Map R/W/Ws

0420 Reserved

0421 Bus ID R4

0422 HFWND (High ATR Window) R/W 4

0423 LFWND (Low ATR Window) R/W 4

0424 VID (7 bit Voltage Identification) R/W 7

0425 ILIM (Current Limit) R/W 2

0426 TSD (Thermal Shutdown) R/W 3

0427 FAULT (Fault Status) R6

0428 TEST R/W 8

0429 ENABLE1 (Block Enables LSB) R/W 8

042A ENABLE2 (Block Enables MSB) R/W 3

042B SPARE1 R/W 8

042C SPARE2 R/W 8

0440 – 07FF Device n to 31 Memory Map (structure as Device 1)

NON-VOLATILE MEMORY

0800 – 09FF General Settings R/W/Ws

0800 NVMEMCODE R/W 8

0801 Serial Clock Divider R/W 3

0802 VID_IN Table Select R/W 2

0803 VID_OUT Table Select R/W 2

0804 OffOn Non-Overlap Driver Control R/W 4

0805 OnOff Non-Overlap Driver Control R/W 4

0806 Duty Limit R/W 8

0807 System Configuration R/W 3

0808 Reserved R/W 5

(NOTE 1)

(BITS)

1

SIZE (bits)

1

Size (bits)

SIZE

21

Page 22

ISL6590

TABLE 11. ISL6590 MEMORY MAP (Continued)

R/W/S

ADDRESS RANGE NAME

0809 A/D ID R/W 5

080A WCOMP ID R/W 5

080B OUVP ID R/W 5

080C MG Poll Priority R/W 7

080D State Control R/W 6

080E Reserved R/W 2

080F Phases to be Used R/W 8

0810 POR Wait R/W 5

0811 Regulation Window R/W 6

0812 Regulation Time R/W 8

0813 Voltage Calibration Maximum R/W 6

0814 Reserved R/W 8

0815 Startup Fault Mask R/W 7

0816 Startup Enables 1 R/W 8

0817 Startup Enables 2 R/W 5

0818 Active Fault Mask R/W 7

0819 Active Enables 1 R/W 8

081A Active Enables 2 R/W 5

081B Active Feature Mask R/W 1

081C Reserved

081D Current Limit R/W 6

081E – 083F Reserved

0840 ATR Exit Delay R/W 5

0841 ATR Count Max (LSB) R/W 8

0842 ATR Count Max (MSB) R/W 1

0843 PVID Offset R/W 4

0844 – 086F Reserved

0870 – 08FF Reserved

Address Range General Control Registers R/W/Ws1 Size (bits)

Phase # Independent Compensation Parameters

0900 Kp AVP R/W 8

0901 Kd AVP R/W 8

0902 Kp PID R/W 6

0903 Ki PID R/W 8

0904 Kd Transient Recovery R/W 8

0905 Vos AVP R/W 6

0906 Ios AVP R/W 8

0907 Kfp PID R/W 6

0908 Kfd PID R/W 6

(NOTE 1)

SIZE

(BITS)

22

Page 23

ISL6590

TABLE 11. ISL6590 MEMORY MAP (Continued)

R/W/S

ADDRESS RANGE NAME

Phase # Dependent Compensation Parameters

0909 K Current Balancing R/W 8

090A Kd PID R/W 8

090B HFWND R/W 4

090C LFWND R/W 4

090D OUVPLF R/W 4

090E OOVPHF R/W 4

090F ILIM (not phase # dependent) R/W 2

0910 Reserved

0911 Reserved

0912 Switching Frequency Phases=1 (LSB) R/W 8

0913 Switching Frequency Phases=1 (MSB) R/W 4

0914 Switching Frequency Phases=2 (LSB) R/W 8

0915 Switching Frequency Phases=2 (MSB) R/W 4

0916 Switching Frequency Phases=3 (LSB) R/W 8

0917 Switching Frequency Phases=3 (MSB) R/W 4

0918 Switching Frequency Phases=4 (LSB) R/W 8

0919 Switching Frequency Phases=4 (MSB) R/W 4

091A Switching Frequency Phases=5 (LSB) R/W 8

091B Switching Frequency Phases=5 (MSB) R/W 4

091C Switching Frequency Phases=6 (LSB) R/W 8

091D Switching Frequency Phases=6 (MSB) R/W 4

091E Switching Frequency Phases=7 (LSB) R/W 8

091F Switching Frequency Phases=7 (MSB) R/W 4

0920 Switching Frequency Phases=7 (LSB) R/W 8

0921 Switching Frequency Phases=7 (MSB) R/W 4

0922 – 093F Reserved

0940 Custom VID2VCODE0 LUT Entry

0941 – 097F Custom VID2VCODE1 to VID2VCODE63 LUT Entries

0980 – 09FF Reserved for User R/W/Ws1SIZE (bits)

0A00 – FFFF Reserved

TABLE 12. SECOND SOURCE INFORMATION

o

PART NUMBER TEMP. (

Primarion PX3530 0 to 85 64 Ld QFN L64.9x9

C) PACKAGE PKG. NO

(NOTE 1)

R/W 8

R/W 8

SIZE

(BITS)

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data she ets are current before placin g orders. Information furn ished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or othe rwise under any patent or patent righ ts of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

23

Page 24

ISL6590

Quad Flat No-Lead Plastic Package (QFN)

Micro Lead Frame Plastic Package (MLFP)

0.10

2X

2X

SEATING

PLANE

(DATUM B)

(DATUM A)

NX L

INDEX

AREA

C

4X P

6

INDEX

AREA

B

4X

4X P

2X

A

N

6

1

2

3

C0.10

A

0

C

4X b

3

2

1

N

D

9

TOP VIEW

SIDE VIEW

5

0.10 BAMC

D2

e

(Nd-1)Xe

REF.

BOTTOM VIEW

NX b

5

SECTION "C-C"

SCALE: NONE

D1

78

D2

2

D/2

D1/2

NX k

N

A1

E1/2

A3

E2/2

A0.10

C

2X

0.10

C

E/2

E

E1

9

B

A2

A

/

0.10

C

/

0.08 C

A1

(Ne-1)Xe

E2

REF.

7

8

L64.9x9-S

64 LEAD QUAD FLAT NO-LEAD PLASTIC PACKAGE

MILLIMETERS

SYMBOL

A 0.70 0.75 0.80 A1 - - 0.05 A2 - 0.50 - -

B

A3 0.25 REF -

b 0.18 0.20 0.30 5, 8

D 9.00 BSC D1 8.75 BSC D2 3.64 3.74 3.84 7, 8

E 9.00 BSC E1 8.75 BSC E2 3.64 3.74 3.84 7, 8

e 0.50 BSC -

k0.25 - - -

L 0.30 0.40 0.50 8

L1 - - 0.15 9

N642

Nd 16 3

Ne 16 3

P- -0.50-

θ --8-

NOTES:

1. Dimensioning and tolerancing conform to ASME Y14.5-1994.

2. N is the number of terminals.

3. Nd and Ne refer to the number of terminals on each D and E.

4. All dimensions are in millimeters. Angles are in degrees.

5. Dimension b applies to the metallized terminal and is measured

between 0.15mm and 0.30mm from the terminal tip.

6. The configuration of the pin #1 identifier is optional, but must be

located within the zone indicated. The pin #1 identifier may be

either a mold or mark feature.

7. Dimensions D2 and E2 are for the exposed pads which provide

improved electrical and thermal performance.

8. Nominal dimensions are provided to assist with PCB Land Pattern

Design efforts, see Intersil Technical Brief TB389.

9. Depending on the method of lead termination at the edge of the

package, a maximum 0.15mm pull back (L1) maybe present. L

minus L1 to be equal to or greater than 0.3mm.

NOTESMIN NOMINAL MAX

Rev. 0 04/03

TERMINAL TIP

C

L

e

FOR EVEN TERMINAL/SIDE

24

9

L

L1

Loading...

Loading...