查询ISL6571供应商

®

ISL6571

Data Sheet April 18, 2005

Complementary MOSFET Driver and

Synchronous Half-Bridge Switch

The Intersil ISL6571 provides a new approach for

implementing a synchronous rectified buck switching

regulator. The ISL6571 replaces two power MOSFETs, a

Schottky diode, two gate drivers and synchronous control

circuitry. Its main applications address high-density power

conversion circuits including multiphase-topology computer

microprocessor core power regulators, ASIC and memory

array regulators, etc. Another useful feature of the ISL6571

is the compatibility with three-state input control: left open,

the PWM input turns off both output drives. The ISL6571

operates in continuous conduction mode reducing EMI

constraints and enabling high bandwidth operation.

Ordering Information

TEMP.

PART NUMBER

ISL6571CR* 0 to 70 68 Ld 10x10 QFN L68.10x10A

ISL6571CRZ*

(See Note)

ISL6571EVAL1 Evaluation Board

*Add “-T” suffix for tape and reel.

NOTE: Intersil Pb-free products employ special Pb-free material

sets; molding compounds/die attach materials and 100% matte tin

plate termination finish, which are RoHS compliant and compatible

with both SnPb and Pb-free soldering operations. Intersil Pb-free

products are MSL classified at Pb-free peak reflow temperatures that

meet or exceed the Pb-free requirements of IPC/JEDEC J STD-020.

RANGE (°C) PACKAGE

0 to 70 68 Ld 10x10 QFN

(Pb-free)

PKG.

DWG. #

L68.10x10A

FN9082.4

Features

• Improved Performance over Conventional Synchronous

Buck Converter using Discrete Components

• Optimal Deadtime Provided by Adaptive Shoot-Through

• Switching Frequency up to 1MHz

- High-Bandwidth, Fast Transient Response

- Small, Low Profile Converters

• Reduced Connection Parasitics between Discrete

Components

- Low Electromagnetic Emissions

• Low Profile, Low Thermal Impedance Packaging

- High Power Density Applications

• QFN Package:

- Compliant to JEDEC PUB95 MO-220

QFN - Quad Flat No Leads - Package Outline

- Near Chip Scale Package footprint, which improves

PCB efficiency and has a thinner profile

• Pb-Free Available (RoHS Compliant)

Applications

•

Multiphase Power Regulators

•

Low-Voltage Switchmode Power Conversion

• High-Density Power Converters

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-352-6832

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright Intersil Americas Inc. 2003-2005. All Rights Reserved

ISL6571

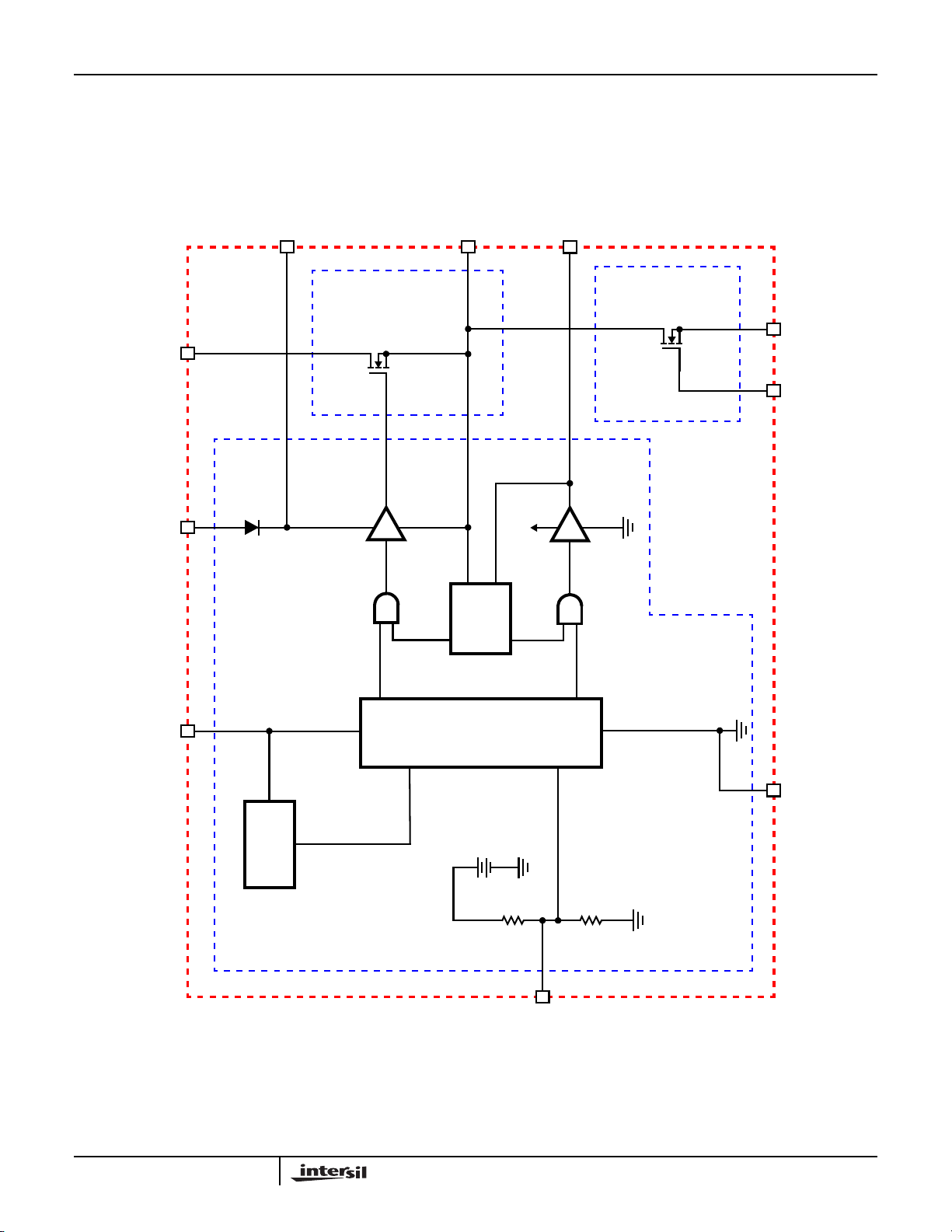

Pinout

PHASE

PHASE

PHASE

PHASE

PHASE

PHASE

PHASE

PHASE

PHASE

PHASE

PHASE

PHASE

PHASE

PHASE

PHASE

PHASE

PHASE

PGND

PGND

PGND

PGND

67666564636261

68

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19202122232425

ISL6571 (QFN) TOP VIEW

PGND

PGND

PGND

PGND

PGND

LGATE1

PHASEPHASE

58

59

60

69

PHASE

28

27

26

PVCC

56

NC

55

71

GND

70

VIN

VCC

54

GND

57

2930313233

LGATE

NC

52

53

NC51

50

GND

49

NC

48

PWM

47

BOOT

GND

46

45

PHASE

44

VIN

43

VIN

42

VIN

41

VIN

VIN

40

VIN

39

38

VIN

VIN

37

36

VIN

VIN

35

34

NC

NC

NCNCNC

NC

NC

NC

NC

NC

VIN

VIN

VIN

VIN

VIN

VIN

2

FN9082.4

ISL6571

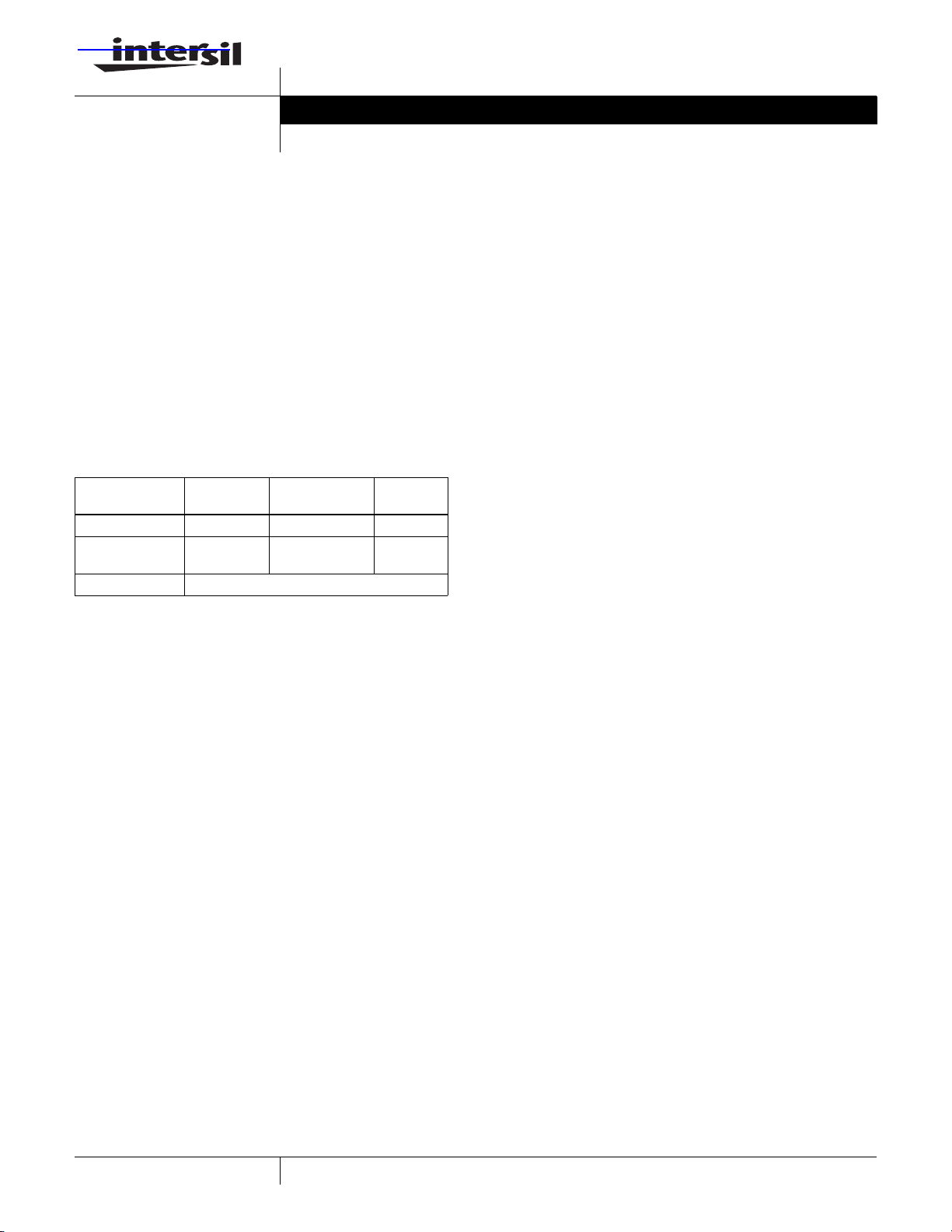

BOOT

UFET

VIN

DRIVE1

PVCC

PHASE

GATE

PVCC

CONTROL

LGATE

LFET

PGND

LGATE1

DRIVE2

VCC

FIGURE 1. BLOCK DIAGRAM

LOGIC

CONTROL

GND

5V

+

-

POWER-ON

RESET (POR)

10K

PWM

10K

3

FN9082.4

+12VIN

+12VIN

+5VIN

PWM

ISL6571

CONTROL

AND

DRIVERS

ISL6571

FIGURE 2. SIMPLIFIED POWER SYSTEM DIAGRAM

L

IN

C

BOOT

L

OUT

C

OUT

V

OUT

+5VIN

POWER

GOOD

C

+

VCC

PWM

PVCC

BOOT

VIN

U2

ISL6571

GND

PVCC

U3

PHASE

PGND

BOOT

VIN

PHASE

18

17

19

PWM4

ISEN4

PGOOD

20

VCC

PWM1

ISEN1

PWM2

ISEN2

LGATE1

LGATE

15

16

14

13

VCC

PWM

ISL6571

LGATE1

U1

HIP6301

8

FS/DIS

R

FS

PWM3

ISEN3

11

12

LGATE

GND

PGND

IN1

C

BOOT1

L

OUT1

R

SNS1

C

+

IN2

C

BOOT2

L

OUT2

V

OUT

R

SNS2

C

OUT

+

R

OFFSET

COMP

VSEN

10

FB

6

7

C2

C1

R2

VCC

PWM

PVCC

U4

BOOT

VIN

ISL6571

GND

PHASE

PGND

LGATE1

LGATE

R1

5

VID0

4

VID1

3

VID2

2

VID3

1

VID4

GND

9

C

+

IN3

C

BOOT3

L

OUT3

R

SNS3

FIGURE 3. TYPICAL APPLICATION

4

FN9082.4

ISL6571

Absolute Maximum Ratings Thermal Information

Bias Supply Voltage, VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+15V

Driver Supply, PVCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +10.5V

Conversion Voltage, VIN . . . . . . . . . . . . . . . . . . . . . . . . . VCC+0.3V

DRIVE1 Voltage, V

Input Voltage, PWM . . . . . . . . . . . . . . . . . . . . . . . . GND -0.3V to 7V

BOOT

- V

. . . . . . . . . . . . . . . . . . . . . .+15V

PHASE

ESD Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Class 2

Recommended Operating Conditions

Control and Conversion Voltage, VCC, VIN. . . . . . . . . . +12V ±10%

MOSFET Bias Supply, PVCC . . . . . . . . . . . . . . . . . . . +5V to +10V

Ambient Temperature Range . . . . . . . . . . . . . . . . . . . . . 0°C to 70°C

Junction Temperature Range . . . . . . . . . . . . . . . . . . . . 0°C to 125°C

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

is measured with the component mounted on a typical application PCB. A separate θ

1. θ

JC

pads (#69, 70, 71). Each value should be used in combination with the power dissipated by only the individual die mounted on that pad.

Electrical Specifications Recommended Operating Conditions, Unless Otherwise Noted. Refer to Figures 1, 2 and 3

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

SUPPLY CURRENT

Nominal Bias Supply Current I

VCC

POWER-ON RESET

Rising VCC Threshold 9.70 9.95 10.40 V

VCC Threshold Hysteresis -2.40- V

MOSFET DRIVER

Input Impedance Z

IN

PWM Rising Threshold - - 3.80 V

PWM Falling Threshold 1.30 - - V

PWM-to-PHASE Low-to-High Propagation

Delay

PWM-to-PHASE High-to-Low Propagation

t

PLH

t

PHL

Delay

Shutdown Window 1.60 - 3.40 V

Shutdown Holdoff Time t

SH

UPPER MOSFET (UFET)

Drain-to-Source ON-State Resistance r

DS(ON)

ON-State Drain Current V

LOWER MOSFET (LFET)

Drain-to-Source ON-State Resistance r

DS(ON)

ON-State Drain Current V

PWM Open - 2.5 3.6 mA

V

- V

BOOT

V

- V

BOOT

- V

BOOT

V

= 5V 4.10 4.80 5.55 mΩ

PVCC

V

= 10V 3.40 4.05 4.70 mΩ

PVCC

= 5V 25 - - A

PVCC

Thermal Resistance (Typical, Note 1)

Pad 69 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

Pad 70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.0

Pad 71 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.0

Maximum Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . 125°C

Maximum Storage Temperature Range . . . . . . . . . . . -40°C to 125°C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . . 300°C

value is provided for each of the three exposed die

JC

-5- kΩ

-80- ns

-56- ns

- 230 - ns

= 5V 12.8 13.5 18.2 mΩ

PHASE

= 10V 7.70 9.20 12.7 mΩ

PHASE

= 5V 25 - - A

PHASE

θ

JC

(°C/W)

5

FN9082.4

Typical Performance Curves/Setup

∆I

(p-p)

+12V

+5V

+12V

C

PVCC

C

VCC

VCC

PVCC

BOOT

VIN

LOUT

C

VIN

C

BOOT

ISL6571

V

R

OUT

OUT

(DS)ON

1.8

1.6

1.4

1.2

VGS = 10V

ID = 12A

1.0

NORMALIZED r

0.8

0.6

-25 0 25 50 100 125 150

75

Tj (°C)

FIGURE 5. UPPER MOSFET ON RESISTANCE vs

PWM

CONTROL

DRIVERS

ISL6571

GND

AND

PGND

PHASE

FIGURE 4. TYPICAL TEST CIRCUIT

C

L

OUT

OUT

V

OUT

R

OUT

TEMPERATURE

126

V

= 5V

PVCC

108

V

= 10V

PVCC

I

= 0A

PHASE

90

72

(mA)

54

PVCC

I

36

18

0

100 200 300 400 500 600 700 800 900 1000

SWITCHING FREQUENCY (kHz)

1.26

1.08

0.90

0.72

0.54

0.36

0.18

0

(W)

PVCC

P

1.6

VGS = 10V

1.4

(DS)ON

1.2

1.0

NORMALIZED r

0.8

0.6

ID = 20A

-25 0 25 50 100 125 150

Tj (°C)

75

FIGURE 6. BIAS SUPPLY CURRENT/POWER vs FREQUENCY FIGURE 7. LOWER MOSFET ON RESISTANCE vs

TEMPERATURE

4.00

V

= 5V

PVCC

I

= 12A

LOUT

3.50

L

= 1µH

OUT

3.00

2.50

DISSIPATED POWER (W)

2.00

1.50

200 500 700 900 1000

SWITCHING FREQUENCY (kHz)

600

800300 400

FIGURE 8. ISL6571 POWER DISSIPATION vs FREQUENCY

AT 12A

6

4.00

V

= 5V

PVCC

L

3.50

3.00

2.50

2.00

1.50

1.00

DISSIPATED POWER (W)

0.50

0

= 1µH

OUT

12Vin/1.5Vout

0 4.5 7.5 10.5 12.0

6.0

OUTPUT CURRENT (A)

9.01.5 3.0

750kHz

13.5

500kHz

300kHz

200kHz

15.0 16.5

FIGURE 9. ISL6571 POWER DISSIPATION vs CURRENT AT

200kHz, 300kHz, 500kHz, 750kHz

FN9082.4

ISL6571

Typical Performance Curves/Setup (Continued)

93

91

89

87

85

83

81

EFFICIENCY (%)

79

77

75

73

0 4.5 7.5 10.5 12.0

1.5 3.0

FIGURE 10. ISL6571 EFFICIENCY AT 200kHz, 300kHz, 500kHz, 750kHz

OUTPUT CURRENT (A)

Functional Pin Descriptions

VCC (Pin 54)

Provide a 12V bias supply for the driver IC to this pin. The

voltage at this pin is monitored for Power-On Reset (POR)

purposes.

PVCC (Pin 56)

Provide a well decoupled 5V to 10V bias supply at this pin.

The voltage at this pin is used to bias the gates of the

MOSFET switches.

GND (Pins 46, 50, 57, 71)

Ground pins for the driver IC. Connect these pins to the

circuit ground (plane) and to the PGND pins using the

shortest available paths.

PGND (Pins 60-68)

This is the source ground connection for the lower MOSFET

switches. Connect these pins to the circuit ground (plane)

and to the GND pins using the shortest available paths.

VIN (Pins 29-44, 70)

Connect these pins to the input voltage to be converted

down. Provide bulk and high-frequency decoupling

capacitors as close to these pins as feasible.

PHASE (Pins 1-17, 27, 45, 59, 69)

As a minimum, connect pin 69 to the output inductor. The

remainder of the PHASE pins may be tied to pin 69, left

open, or used for other connections. It is recommended pin

45 is connected to the bootstrap capacitor, C

BOOT (Pin 47)

This pin is connected to the PVCC pin through an internal

quasi-diode. Connect a bootstrap capacitor from this pin to

PHASE pin 45 (0.1µF recommended). This capacitor

BOOT

.

6.0

200kHz

300kHz

500kHz

750kHz

9.0

13.5

15.0 16.5

provides the bias for the upper MOSFET drive and the gate

charge for the upper MOSFET.

LGATE (Pin 53)

This pin is the output of the lower MOSFET drive. Connect

this pin to LGATE1 pin using the shortest available path.

LGATE1 (Pin 58)

This pin is connected to the gate of the lower MOSFET

switch. Connect this pin to LGATE pin using the shortest

available path.

PWM (Pin 48)

Connect this pin to the regulating controller’s PWM output.

Left open, this input will float to approximately 2.5V and

cause both MOSFET switches to be turned off. Applying 5V

to this input causes the upper MOSFET switch to be turned

on. A 0V applied to this input causes the lower MOSFET

switch to be turned on. The approximate input impedance of

this pin is 5kΩ.

NC (Pins 18-26, 28, 49, 51, 52, 55)

These pins are not internally connected.

Description

Bias Requirements

The on-board driver includes a Power-On Reset (POR)

function, which continually monitors the input bias supply.

The POR monitors the bias voltage (+12V

and enables the ISL6571 for operation immediately after it

exceeds the rising threshold. Upon the bias voltage’s drop

below the falling threshold, the IC is disabled and both

internal MOSFETs are turned off.

The output drivers are powered from the PVCC pin. For

proper functionality and driving capability, connect PVCC to

) at the VCC pin,

IN

7

FN9082.4

ISL6571

a suitable supply, 5V to 10V, no higher than the voltage

applied at the VCC pin. The higher the voltage applied at the

PVCC pin, the better the channel enhancement of the onboard power MOSFETs, but also the higher the power

dissipated inside the driver.

The down-conversion voltage applied at VIN cannot exceed

the bias voltage applied at VCC, but can be as low as

practically possible.

Operation

The ISL6571 combines two MOSFET transistors in a

synchronous buck power train configuration, along with a halfbridge MOSFET driver designed to control these two

MOSFETs. When reviewing the operational details, refer to

Figure 5 test setup.

With all requirements for operation met, a logic high signal

on the PWM pin causes the UFET to turn on, while a logic

low signal applied to the PWM pin causes LFET to turn on. If

the PWM input is driven within the shutdown window and

remains there for the minimum holdoff time specified (See

‘Electrical Specifications’), both MOSFETs are turned off.

PWM

GND

PHASE

GND

SH

PLH

t

FIGURE 11. PHASE RESPONSE TO PWM INPUT

PHL

t

t

At the transition between the on intervals of the two

MOSFETs, the internal driver acts in a ‘break-before-make’

fashion. Thus, the driver monitors the on device and turns on

the (previously) off device, following a short time delay after

the on MOSFET has turned off. This behavior is necessary

to insure the absence of cross-conduction (shoot-through)

amongst the two MOSFETs.

Application and Component Selection

Guidelines

Layout Considerations

MOSFETs switch very fast and efficiently. The speed with

which the current transitions from one device to another

causes voltage spikes across the interconnecting

impedances and parasitic circuit elements. The voltage

spikes can degrade efficiency, radiate noise into the circuit,

and lead to device overvoltage stress. Careful component

layout and printed circuit design minimizes the voltage

spikes in the converter. Consider, as an example, the turn-off

transition of the upper MOSFET. Prior to turn-off, the upper

MOSFET was carrying the full load current. During the turnoff, current stops flowing in the upper MOSFET and is picked

up by the lower MOSFET or Schottky diode. Any inductance

in the switched current path generates a large voltage spike

during the switching interval. Careful component selection,

tight layout of the critical components, and short, wide circuit

traces minimize the magnitude of voltage spikes.

The ISL6571 is the first step in such an efficient design. By

bringing the driver and switching transistors in close

proximity, most of the interconnect/layout parasitic

inductances are greatly reduced. However, these benefits

are nulled if the associated decoupling elements and other

circuit components are not carefully positioned and laid out

to help the ISL6571 realize its full potential. Figure 12 shows

one possible layout pattern, detailing preferred positioning of

components, land size/pattern, and via count. Figure 12 is

one of many possible layouts yielding good results; use it for

general illustration and guidance.

Locate the decoupling capacitors, especially the highfrequency ceramic capacitors, close to the ISL6571. To fully

exploit ceramic capacitors’ low equivalent series inductance

(ESL), insure their ground connection is made as close to

their grounded terminal as physically feasible. Figure 12

details via-in-pad (VIP) practices, where the via is placed on

the component’s landing pad, thus yielding the shortestpath, lowest ESL connection to the desired plane/island.

Via-in-pad design is very important to the layout of the

ISL6571, since it is an integral part of the thermal design

consideration. VIP not only provides the lowest ESL circuit

connections, but it is essential to the propagation of heat

from the internal dies to the ambient. The vias placed directly

underneath the bottom pads of the package provide a low

thermal impedance path for the heat generated inside the IC

to diffuse through the internal planes, as well as through

islands on the back side of the board. Layout with landing

pads for the bottom pads of the package devoid of vias is

possible (rather, with vias placed outside of the package

outline), but the thermal performance of such a layout would

be significantly reduced. Use the smallest diameter vias

available and avoid the use of thermal relief on the contacts

with internal planes; if thermal relief is mandatory on all vias,

design the thermal relief so that it voids the smallest possible

copper area around the vias (thus preserving thermal

conductivity and reducing electrical contact resistance).

A multi-layer printed circuit board is recommended. Dedicate

one solid layer for a ground plane and make all critical

component ground connections with vias to this layer.

Dedicate another solid layer as a power plane and break this

plane into smaller islands of common voltage levels. The

power plane should support the input power and output

power nodes.

8

FN9082.4

TO +12V

TO +5V

C

PVCC

C

VCC

TO PWM

C

BULK

C

PHASE

BOOT

VINGND

TO V

CHF (x2)

IN

ISL6571

Use the remaining printed circuit layers for small signal

wiring. The wiring traces from the surrounding application to

the ISL6571 should be sized according to their task. Thus,

small-signal traces, like the PWM signal or the ISEN

feedback (if used in conjunction with another Intersil

controller), only need be as wide as 5-10mils. Traces

carrying bias current should be larger, proportionately with

the current flowing through them; for example, traces

carrying PVCC current around 50-100mA would require

30-50mils. Generally, the best connections are the shortest,

enclosing the least amount of area possible. Similarly, from a

conduction requirement perspective, where vias are required

to carry current, use a via for each 2-3A of RMS current.

Bootstrap Requirements

The ISL6571 features an integrated boot element connected

between the PVCC and BOOT pins. A 0.1µF external

bootstrap capacitor is recommended.

TO L

OUT

KEY

ISLAND ON POWER PLANE LAYER

CONNECTING TRACES ON TOP/BOTTOM LAYERS

VIA CONNECTION TO OTHER PLANEs

FIGURE 12. PRINTED CIRCUIT BOARD POWER PLANES AND

ISLANDS

Use copper-filled polygons on the top and bottom circuit

layers for the PHASE node, but do not unnecessarily

oversize these particular islands. Since the PHASE node is

subject to very high dV/dt voltages, the stray capacitors

formed between these islands and the surrounding circuitry

or internal planes will tend to couple switching noise. On the

other hand, these islands have to be sufficiently large to offer

a good path to surrounding environment for the heat

produced inside the ISL6571.

Capacitor (Decoupling) Selection

To fully extract the benefits of a highly performant power

integrated circuit, the circuit elements surrounding it must

conform to the same high standards as the active power

element. As such, the capacitors used for high-frequency

decoupling of the ISL6571 should be good quality ceramic,

with a low ESR and ESL (X7R, X5R dielectric, and 0805 or

smaller footprints recommended); a minimum of two 1µF

capacitors are recommended. Bulk decoupling capacitor

technology is not restricted to ceramic, as electrolytic

capacitors are also suitable. For best results, select

capacitors based on the input RMS current draw of the

circuit, with a low ESL; distribute evenly amongst and place

them as close to the ISL6571 as possible.

ISL6571 DC-DC Converter Application

Circuit

Figure 13 shows an application circuit of a power supply for

a microprocessor computer system. For detailed information

on the circuit, including a Bill-of-Materials and circuit board

description, contact Intersil to order the evaluation kit

ISL6571EVAL1. Also see Intersil web page

(http://www.intersil.com).

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

9

FN9082.4

+12VIN

+5VIN

POWER

GOOD

>

R

FS

ISL6571

L

IN

>

>

VCC

PWM

LGATE1

ISL6571

LGATE2

C

VCC1

20

VCC

R

PG

19

PGOOD

U1

PWM1

ISEN1

PWM2

ISEN2

PWM3

ISEN3

15

16

14

13

11

12

HIP6301

8

5

4

3

2

1

FS/DIS

VID0

VID1

VID2

VID3

VID4

GND

9

PWM4

ISEN4

COMP

VSEN

10

FB

18

17

6

C2

C1

7

R2

LGATE

VCC

PWM

LGATE1

ISL6571

LGATE2

LGATE

VCC

PWM

LGATE1

ISL6571

LGATE2

PVCC

U2

GND

PVCC

U3

GND

PVCC

U4

BOOT

VIN

PHASE

PGND

BOOT

VIN

PHASE

PGND

BOOT

VIN

PHASE

+

C

IN1

C

BOOT1

L

OUT1

R

SNS1

+

C

IN2

C

BOOT2

L

OUT2

+

C

C

BOOT3

OUT

L

OUT3

V

OUT

R

SNS2

C

+

IN3

ADDITIONAL

HIGH-FREQUENCY

DECOUPLING

C

VCC2-5

C

PVCC2-5

C

VIN2-5

C

OUT_HF

C

OUT_BULK

R

OFFSET

1 to each of VCC2-5

1 to each of PVCC2-5

2 to each of VIN2-5

varied HF mix to V

varied bulk mix to V

OUT

10

OUT

R3

C3

LGATE

R1

VCC

PWM

LGATE1

LGATE2

LGATE

GND

PVCC

U5

ISL6571

GND

PGND

BOOT

VIN

PHASE

PGND

FIGURE 13. TYPICAL ISL6571 APPLICATION CIRCUIT

R

SNS3

C

+

IN4

C

BOOT4

L

OUT4

R

SNS3

FN9082.4

ISL6571

Quad Flat No-Lead Plastic Package (QFN)

Micro Lead Frame Plastic Package (MLFP)

2X

C

A

5

0.10 C A B

7

A1

E1/2

M

8

NX k

E2/2

0.15

E1

A3 A1

(Ne–1)Xe

E2

8

A2

REF.

7

CC

E/2

C

2X

E

B

A

NX

E4

E3

L

e

0.15

2X

2X

SEATING

PLANE

INDEX

AREA

C

0.15

C

INDEX

AREA

NX L

8

6

4X P

4X P

6

A

N

1

2

3

B

C

A

θ

b

NX

3

2

1

N

C

L

D

D1

TOP VIEW

SIDE VIEW

D2

D4

69

e

(Nd–1)Xe

REF.

BOTTOM VIEW

NX b

D/2

D1/2

D2/2

D3

70

71

5

SECTION "C-C"

e

TERMINAL TIP

FOR ODD TERMINAL/SIDE FOR EVEN TERMINAL/SIDE

0.15

0.05

L68.10x10A

68 LEAD MICRO LEAD FRAME PLASTIC PACKAGE

(CUSTOMIZED WITH THREE EXPOSED PADS)

MILLIMETERS

SYMBOL

C

B

A- -0.90A1 - - 0.05 A2 - - 0.70 A3 0.20 REF -

b 0.18 0.23 0.30 5, 8

D 10.00 BSC D1 9.75 BSC D2 7.55 7.70 7.85 7, 8

D3 2.44 2.59 2.74 7, 8

D4 4.48 4.63 4.78 7, 8

E 10.00 BSC E1 9.75 BSC E2 7.55 7.70 7.85 7, 8

C

E3 2.44 2.59 2.74 7, 8

E4 4.48 4.63 4.78 7, 8

e 0.50 BSC -

k0.25 - - L 0.50 0.60 0.75 8

N682

Nd 17 3

Ne 17 3

P- -0.60-

θ --12-

NOTES:

1. Dimensioning and tolerancing per ASME Y14.5-1994.

2. N is the number of peripheral terminals. Exposed pads are

terminals 69, 70 and 71, as shown.

3. Nd is the number of terminals in the X direction, and Ne is the

number of terminals in the Y direction.

4. Controlling dimension: Millimeters. Angles are in degrees.

5. Dimension b applies to the plated terminal and is measured

between 0.20mm and 0.25mm from the terminal tip.

6. The configuration of the pin #1 identifier is optional, but must be

located within the zone indicated. The pin #1 identifier may be

either a molded or marked feature.

7. Dimensions D2/3/4 and E2/3/4 are for the three exposed pads

which provide improved electrical and thermal performance.

8. Nominal dimensions provided to assist with PCB Land Pattern

Design efforts, see Technical Brief TB389.

NOTESMIN NOMINAL MAX

Rev. 0 2/02

11

FN9082.4

Loading...

Loading...