®

ISL6559

Data Sheet December 29, 2004

Multi-Phase PWM Controller

The ISL6559 provides core-voltage regulation by driving 2 to

4 interleaved synchronous-rectified buck-conv erter channels

in parallel. Interleaving the channel timing results in

increased ripple frequency which reduces input and output

ripple currents. The reduction in ripple results in lower

component cost, reduced dissipation, and a smaller

implementation area.

The ISL6559 uses cost and space-saving r

for channel current balance, active voltage positioning, and

over-current protection. Output voltage is monitored by an

internal differential remote sense amplifier. A high-bandwidth

error amplifier drives the output voltage to match the

programmed 5-bit DAC reference voltage. The resulting

compensation signal guides the creation of pulse width

modulated (PWM) signals to control companion Intersil

MOSFET drivers. The OFS pin allows direct offset of the

DAC voltage from 0V to 50mV using a single external

resistor. The entire system is trimmed to ensure a system

accuracy of ±

1% over temperature.

Outstanding features of this controller IC include

Dynamic VID

TM

technology allowing seamless on-the-fly VID

changing without the need of any external components.

Output voltage “droop” or active voltage positioning is

optional. When employed, it allows the reduction in size and

cost of the output capacitors required to support load

transients. A threshold-sensitive enable input allows the use

of an external resistor divider for start-up coordination with

Intersil MOSFET drivers or any other devices powered from

a separate supply.

Superior over-voltage protection is achiev ed by gating on the

lower MOSFET of all phases to crowbar the output voltage.

An optional second crowbar on V

, formed with an external

IN

MOSFET or SCR gated by the OVP pin, is triggered when

an over-voltage condition is detected. Under-voltage

conditions are detected, but PWM operation is not disrupted.

Over-current conditions cause a hiccup-mode response as

the controller repeatedly tries to restart. After a set number

of failed startup attempts, the controller latches off. A power

good logic signal indicates when the converter output is

between the UV and OV thresholds.

DS(ON)

sensing

FN9084.8

Features

• Multi-Phase Power Conversion

- 2, 3 or 4 Phase Operation

• Active Channel Current Balancing

• Precision r

Current Sharing

DS(ON)

- Lossless

-Low Cost

• Input Voltage: 12V or 5V Bias

• Precision CORE Voltage Regulation

-±

1% S y s t e m A c c u r a c y Over Temperature

- Differential Remote Output Voltage Sensing

- Programmable Reference Offset

• Microprocessor Voltage Identification Input

- 5-Bit VID Input

- 0.800V to 1.550V in 25mV Steps

- Dynamic VID Technology

• Programmable Droop Voltage

• Fast Transient Recovery Time

• Over Current Protection

• Digital Soft Start

• Threshold Sensitive Enable Input

• High Ripple Frequency (160kHz to 4MHz)

• QFN Package:

- Compliant to JEDEC PUB95 MO-220 QFN - Quad Flat

No Leads - Pac kage Outline

- Near Chip Scale Package f ootprint, which impro v es PC B

efficiency and has a thinner profile

• Pb-Free Available (RoHS Compliant)

Applications

• AMD Hammer F am ily Processor V ol t ag e Regu l a to r

• Low Output Vo ltage, High Current DC-DC Converters

• Voltage Regulator Modules

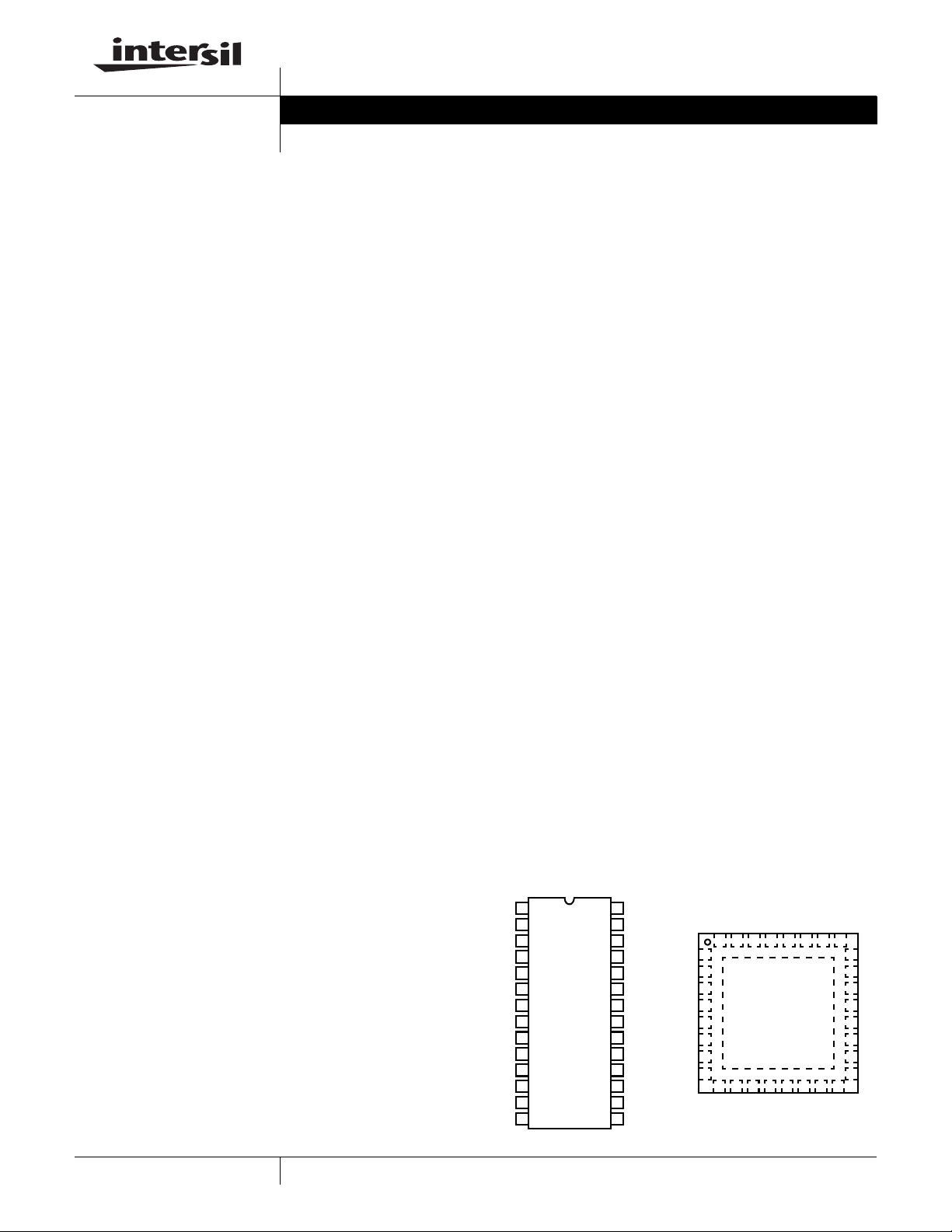

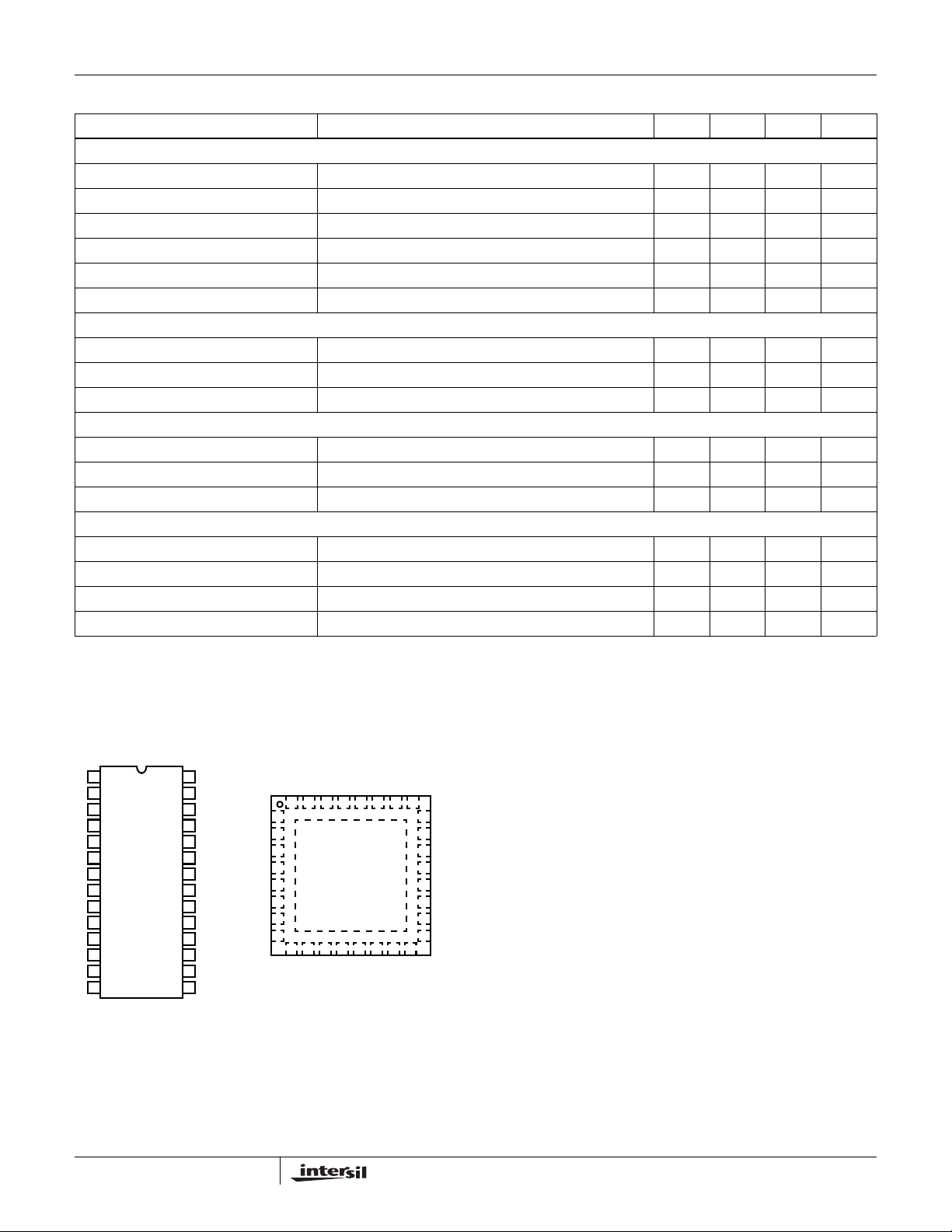

Pinouts

ISL6559CB (28 LEAD SOIC)

TOP VIEW TOP VIEW

28

27

26

25

24

23

22

21

20

19

18

17

16

15

EN

FS/DIS

PGOOD

PWM4

ISEN4

ISEN1

PWM1

PWM2

GND

ISEN2

ISEN3

PWM3

VCC

GND

GND

OVP

VID4

VID3

VID2

VID1

VID0

OFS

COMP

FB

IOUT

VDIFF

VSEN

RGND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

ISL6559CR (32 LEAD QFN)

VID3NCVID4

32 31 30 29 28 27 26 25

VID2

1

VID1

2

VID0

3

NC

4

OFS

5

6

COMP

FB

7

NC

8

910111213141516

IOUT

VSEN

VDIFF

NC = NO CONNECT

OVP

GNDENFS/DIS

GND

RGND

GND

VCC

PGOOD

24

PWM4

23

ISEN4

22

ISEN1

21

PWM1

20

PWM2

19

GND

18

ISEN2

17

ISEN3

PWM3

1

Dynamic VID is a trademark of Intersil Americas Inc. All other trademarks mentioned are the property of their respective owners.

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright © Intersil Americas Inc. 2002-2004. All Rights Reserved.

ISL6559

Ordering Information

PART # TEMP. (°C) PACKAGE PKG. DWG. #

ISL6559CB 0 to 70 28 Ld SOIC M28.3

ISL6559CBZ* 0 to 70 28 Ld SOIC (Pb-free) M28.3

ISL6559CB-T 28 Ld SOIC Tape and Reel

ISL6559CBZ-T* 28 Ld SOIC Tape and Reel (Pb-free)

ISL6559CR 0 to 70 32 Ld 5x5 QFN L32.5x5

ISL6559CRZ* 0 to 70 32 Ld 5x5 QFN (Pb-free) L32.5x5

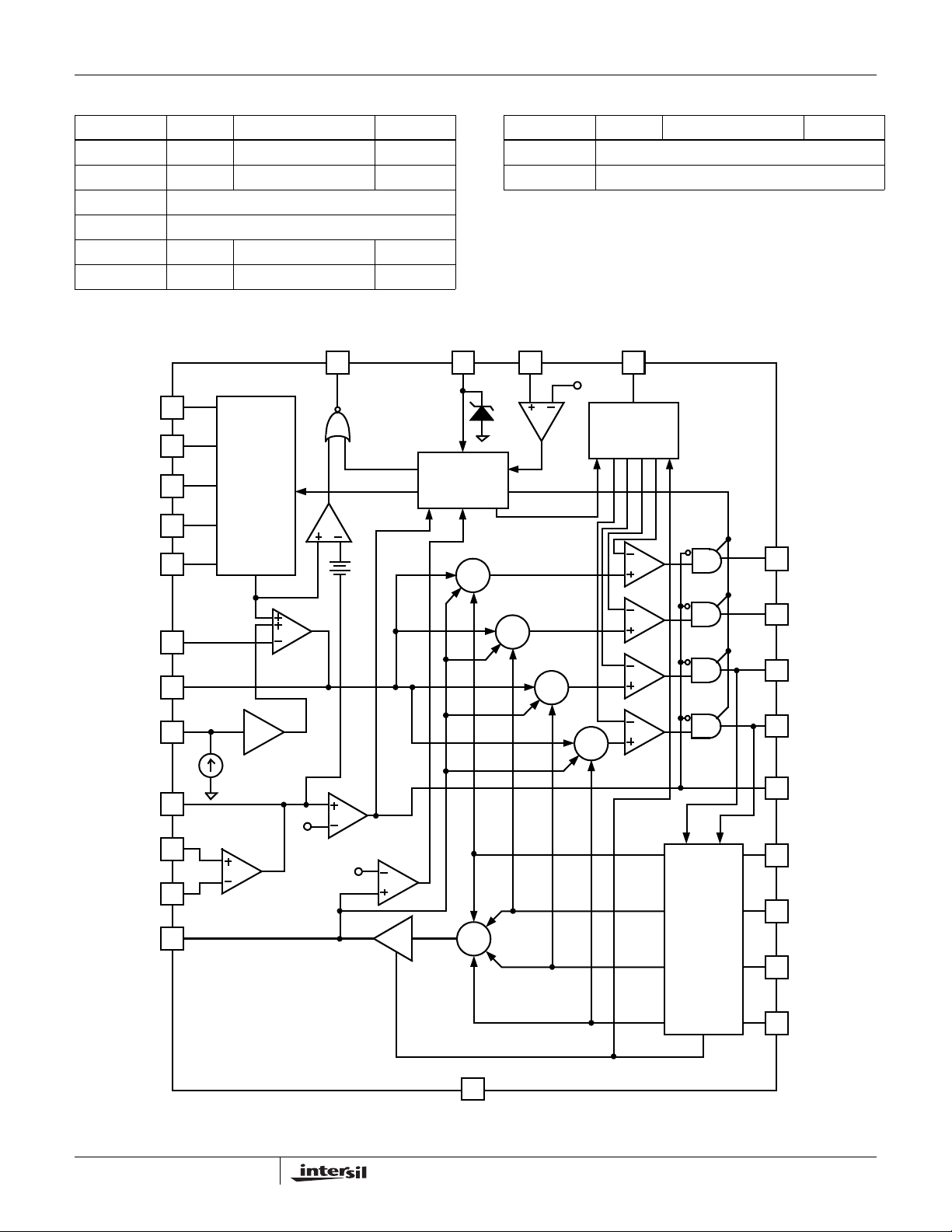

Block Diagram

PGOOD VCC

VID4

VID3

VID2

VID1

VID0

FB

COMP

OFS

DYNAMIC

VID

DAC

x 0.1

E/A

UV

-

+

350mV

POR

AND

SOFT START

+

+

+

Ordering Information (Continued)

PART # TEMP. (°C ) PACKAGE PKG. DW G. #

ISL6559CR-T 32 Ld 5x5 QFN Tape and Reel

ISL6559CRZ-T* 32 Ld 5x5 QFN Tape and Reel (Pb-free)

NOTE: * Intersil Pb-free products employ special Pb-free material sets;

molding compounds/die attach materials and 100% matte tin plate

termination finish, which are RoHS compliant and compatible with both

SnPb and Pb-free soldering operations. Intersil Pb-free products are

MSL classified at Pb-free peak reflow temperatures that meet or

exceed the Pb-free requirements of IPC/JEDEC J STD-020.

EN

1.23V

6V

-

+

+

-

+

+

FS/DIS

OSCILLATOR

AND

SAWTOOTH

PWM1

PWM2

PWM3

PWM4

VDIFF

VSEN

RGND

IOUT

100µA

DIFF

AVERAGE

2

2.2V

OV

90µA

OC

1/N

GND

-

+

OVP

I1

+

+

+

+

I2

I3

I4

N PHASES

CURRENT

SENSE

&

PHASE

DETECT

ISEN1

ISEN2

ISEN3

ISEN4

FN9084.8

December 29, 2004

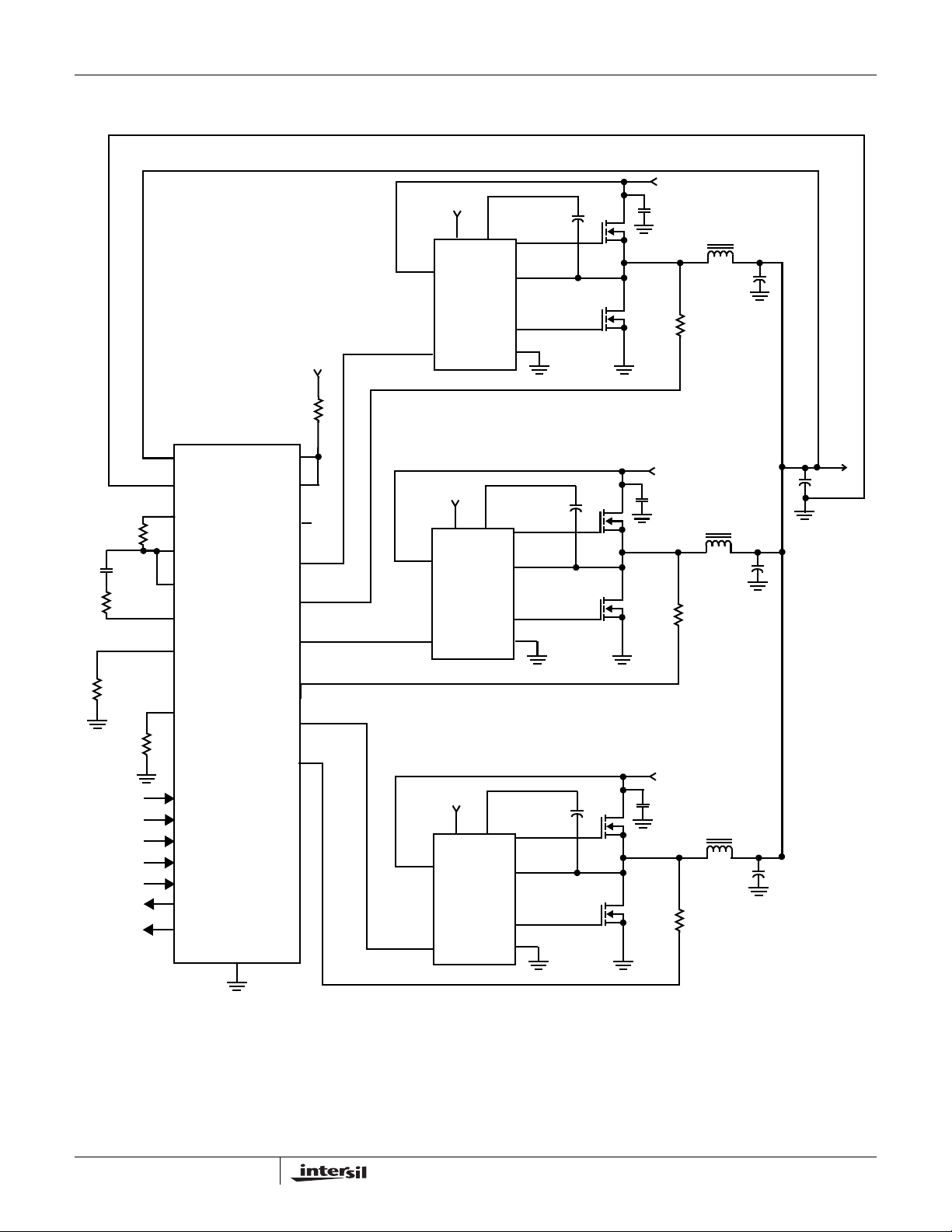

Typical Application - 3 Phase Converter

ISL6559

+12V

PVCC

+12V

BOOT

UGATE

VCC

DRIVER

HIP6601B

PWM

+12V

300Ω

ISL6559

VSEN

RGND

R

FB

C

C

R

C

R

OFS

R

T

VDIFF

FB

IOUT

COMP

OFS

FS/DIS

VID4

VID3

VID2

VID1

VID0

PGOOD

OVP

GND

VCC

PWM4

ISEN4

PWM1

ISEN1

PWM2

ISEN2

PWM3

ISEN3

NC

VCC

PWM

VCC

PWM

PVCC

PVCC

+12V

DRIVER

HIP6601B

+12V

DRIVER

HIP6601B

BOOT

BOOT

PHASE

LGATE

GND

UGATE

PHASE

LGATE

GND

UGATE

PHASE

LGATE

GND

+12V

+12V

R

R

R

ISEN1

ISEN2

ISEN3

V

OUT

3

FN9084.8

December 29, 2004

ISL6559

Absolute Maximum Ratings

Supply Voltage, VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +7V

Input, Output, or I/O Voltage. . . . . . . . . . .GND -0.3V to V

ESD Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Class TBD

CC

+ 0.3V

Thermal Information

Thermal Resistance θJA (°C/W) θJC (°C/W)

SOIC Package (Note 1) . . . . . . . . . . . . 60 N/A

QFN Package (Note 2). . . . . . . . . . . . . 33 4

Maximum Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . 150°C

Operating Conditions

Supply Voltage, VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +5V ±5%

Ambient Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . 0°C to 70°C

Maximum Storage Temperature Range. . . . . . . . . . . -65°C to 150°C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . . 300°C

(SOIC - Lead Tips Only)

Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . . .0°C to 125°C

CAUTION: Stress above those listed in “Absolute Maximum Ratings” may cause permanent damage to the de vice. This is a stress only rating and operation of the device

at these or any other conditions above those indicated in the operational section of this specification is not implied.

NOTES:

is measured with the component mounted on a high effective thermal conductivity test board in free air. See Tech Brief TB379 for details.

1. θ

JA

2. θ

is measured in free air with the component mounted on a high effective thermal conductivity test board with “direct attach” features. θ

JA

JC,

the

“case temp” is measured at the center of the exposed metal pad on the package underside. See Tech Brief TB379.

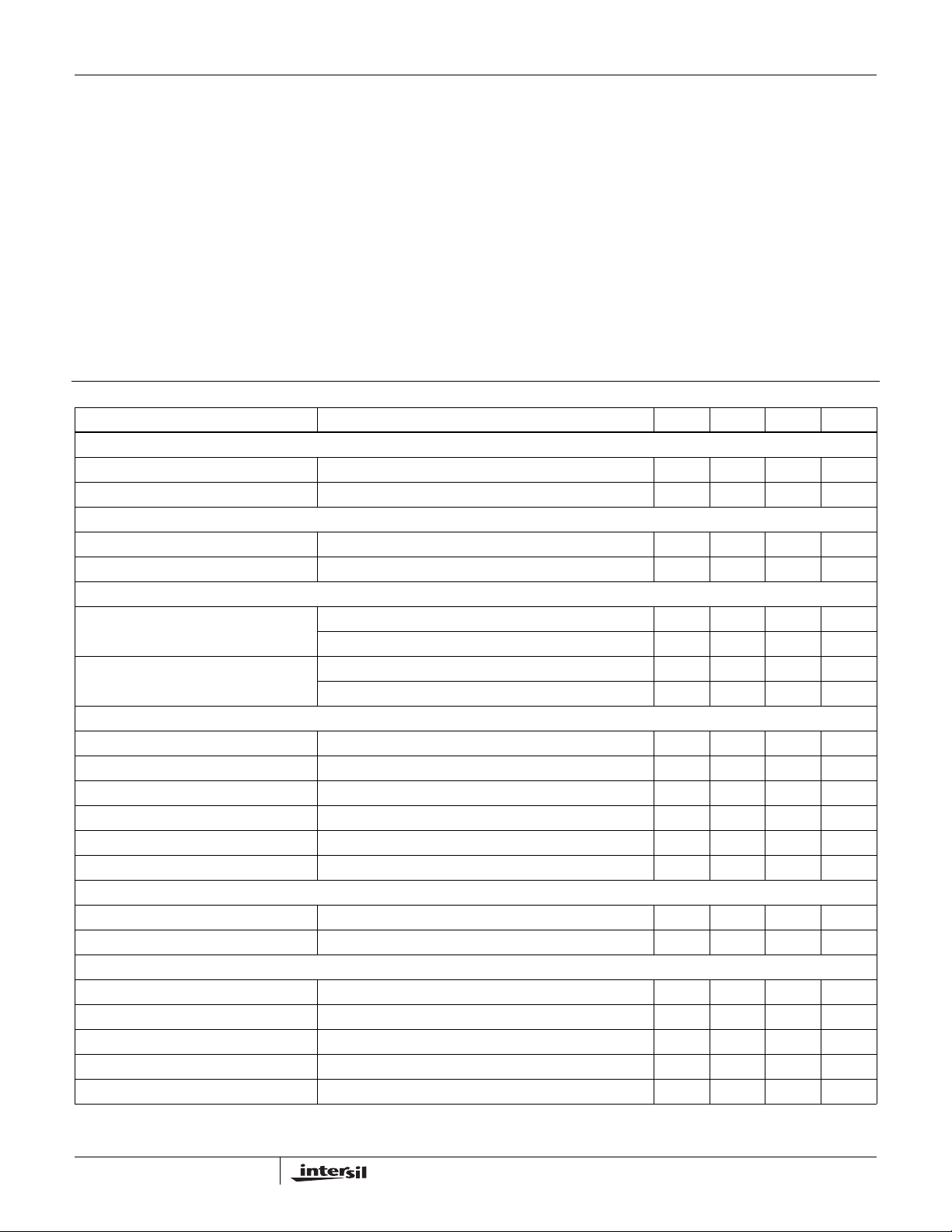

Electrical Specifications Operating Conditions: VCC = 5V, T

= 0°C to 70°C. Unless Otherwise Specified.

A

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

VCC SUPPLY CURRENT

Nominal Supply VCC = 5VDC; EN = 5VDC; R

Shutdown Supply VCC = 5VDC; EN = 0VDC; R

= 100 kΩ ±1% 8.0 10.8 14.0 mA

T

= 100 kΩ ±1% 8.0 10.3 13.0 mA

T

SHUNT REGULATOR

VCC Voltage VCC tied to 12VDC thru 300Ω resistor, R

VCC Sink Current VCC tied to 12VDC thru 300Ω resistor, R

= 100kΩ 5.63 5.8 5.97 V

T

= 100kΩ 15 20 25 mA

T

POWER-ON RESET AND ENABLE

POR Threshold VCC Rising 4.25 4.35 4.50 V

VCC Falling 3.75 3.85 4.00 V

ENABLE Threshold EN Rising 1.205 1.23 1.255 V

Hysteresis 86 92 98 mV

REFERENCE VOLTAGE AND DAC

Reference Voltage 0.792 0.8 0.808 V

System Accuracy (Note 3) -1 - 1 %VID

VID on Fly Step Size R

= 100kΩ -25-mV

T

VID Pull Up --20-µA

VID Input Low Level --1V

VID Input High Level - 1.36 1.60 V

PIN-ADJUSTABLE OFFSET

OFS Current -100- µA

Offset Accuracy ROFS = 5.00kΩ ±1% 47.0 50.0 53.0 mV

OSCILLATOR

Accuracy -10 - 10 %

Adjustment Range 0.08 - 1.0 MHz

Disable Voltage I

= 1mA 0.8 1.0 1.2 V

FS/DIS

Sawtooth Amplitude -1.37- V

Max Duty Cycle -75-%

4

FN9084.8

December 29, 2004

ISL6559

Electrical Specifications Operating Conditions: VCC = 5V, T

= 0°C to 70°C. Unless Otherwise Specified. (Continued)

A

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

ERROR AMPLIFIER

Open-Loop Gain R

Open-Loop Bandwidth C

Slew Rate C

Maximum Output Voltage R

= 10kΩ to ground - 72 - dB

L

= 100pF, RL = 10kΩ to ground - 18 - MHz

L

= 100pF, Load = ±400mA - 7.1 11 V/µs

L

= 10kΩ to ground 3.6 4.5 - V

L

Source Current 3.0 7.0 9.5 mA

Sink Current 1.6 3.0 5.4 mA

REMOTE-SENSE AMPLIFIER

Input Impedance -80-kΩ

Bandwidth -20-MHz

Slew Rate -6-V/µs

SENSE CURRENT

IOUT Accuracy ISEN1 = ISEN2 = ISEN3 = ISEN4 = 50µA -5 - 5 %

ISEN Offset Voltage -6-mV

Over-Current Trip Level 72 90 108 µA

POWER GOOD AND PROTECTION MONITORS

PGOOD Low Voltage I

= 4mA - - 0.4 V

PGOOD

Under-Voltage Offset From VID VSEN Falling 320 350 420 mV

Over-Voltage Threshold VSEN Rising 2.08 2.13 2.20 V

OVP Voltage I

= 100mA, VCC = 5V 2.2 3.28 4.0 V

OVP

NOTE:

3. These parts are designed and adjusted for accuracy within the system tolerance

Functional Pin Description

VID2

VID1

VID0

NC

OFS

COMP

FB

NC

ISL6559CR (32 LEAD QFN)ISL6559CB (28 LEAD SOIC)

TOP VIEW

VID3NCVID4

32 31 30 29 28 27 26 25

1

2

3

4

5

6

7

8

9 10111213141516

IOUT

NC = NO CONNECT

OVP

GNDENFS/DIS

GND

VSEN

VDIFF

RGND

GND

VCC

TOP VIEW

28

27

26

25

24

23

22

21

20

19

18

17

16

15

EN

FS/DIS

PGOOD

PWM4

ISEN4

ISEN1

PWM1

PWM2

GND

ISEN2

ISEN3

PWM3

VCC

GND

GND

OVP

VID4

VID3

VID2

VID1

VID0

OFS

COMP

FB

IOUT

VDIFF

VSEN

RGND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

GND

Bias and reference ground for the IC.

OVP

Over-voltage protection pin. This pin pulls to VCC and is

latched when an over-voltage condition is detected. Connect

PGOOD

PWM4

24

ISEN4

23

ISEN1

22

PWM1

21

PWM2

20

GND

19

ISEN2

18

ISEN3

17

PWM3

this pin to the gate of an SCR or MOSFET tied across V

IN

and ground to prevent damage to a load device.

VID4, VID3, VID2, VID1, VID0

The state of these five inputs program the internal DAC,

which provides the reference voltage for output regulation.

Connect these pins to either open-drain or active pull-up

type outputs. Pulling these pins above 2.9V can cause a

reference offset inaccuracy.

OFS

Connecting a resistor between this pin and ground creates a

positive offset voltage which is added to the DAC voltage,

allowing easy implementation of load-line regulation. For no

offset, simply tie this pin to ground.

FB and COMP

The internal error amplifier inverting input and output

respectively. Connect the external R-C feedback

compensation network of the regulator to these pins.

IOUT

The current carried out of this pin is proportional to output

current and can be used to incorporate output voltage droop

5

FN9084.8

December 29, 2004

ISL6559

and/or load sharing. The scale f actor is set b y the r atio of th e

ISEN resistors and the lower MOSFET r

DS(ON)

. If droop is

desired, connect this pin to FB. When not used for droop or

load sharing, simply leave this pin open.

VSEN, RGND, VDIFF

VSEN and RGND are the inputs to the differential remotesense amplifier. Connect these pins to the sense points of

the remote load. Connect an appropriately sized feedback

resistor, R

, between VDIFF and FB.

FB

VCC

Supplies all the power necessary to operate the chip. The IC

starts to operate when the voltage on this pin exceeds the

rising POR threshold and shuts down when the voltage on

this pin drops below the falling POR threshold. Connect this

pin directly to a +5V supply or through a series 300Ω resistor

to a +12V supply.

ISEN1, ISEN2, ISEN3, ISEN4

Current sense inputs. A resistor connected between these

pins and their respective phase node sets a current

proportional to the current in the lower MOSFET during it’s

conduction interval. This current is used as a reference for

channel balancing, load sharing, protection, and load-line

regulation. Inactive channels should have their respective

sense inputs left open.

PWM1, PWM2, PWM3, PWM4

Pulse-width modulating outputs. Connect these pins to the

individual HIP660x driver PWM input pins. These logic

outputs command the driver IC(s) in switching the halfbridge configuration of MOSFETs.The number of active

channels is determined by the state of PWM3 and PWM4. If

PWM3 is tied to VCC, this indicates to the controller that two

channel operation is desired. In this case, PWM 4 should be

left open or tied to VCC. Shorting PWM4 to VCC indicates

that three channel operation is desired.

PGOOD

Power good is an open-drain logic output that changes to a

logic low when the voltage at VDIFF is 350mV below the VID

setting or above 2.2V.

FS/DIS

A dual function pin for setting the switching frequency and

disabling the controller. Place a resistor from this pin to

ground to set the switching frequency between 80kHz and

1MHz. Pulling this pin below 0.8V disables the controller.

EN

Threshold sensitive enable input of the controller. Transition

this pin above 1.23V (typical enable threshold) to initiate a

soft-start cycle. Pull this pin below 1.14V , taking into account

the enable hysteresis, to disable the controller once in

operation. Connect a resistor divider to this pin to set the

power-on voltage level for proper coordination with Intersil

MOSFET drivers. If this function is not required, simply tie

this pin to VCC.

Multi-Phase Power Conversi on

Microprocessor load current profiles have changed to the

point where the multi-phase power conversion advantage is

pronounced. The technical challenges associated with

producing a single-phase converter which is both costeffective and thermally viable have forced a change to the

cost-saving approach of multi-phase. The ISL6559 controller

helps reduce the complexity of implementation by integrating

vital functions and requiring minimal output components.

The block diagram in Figure 1 provides a top level view of

multi-phase power conversion using the ISL6559 controller.

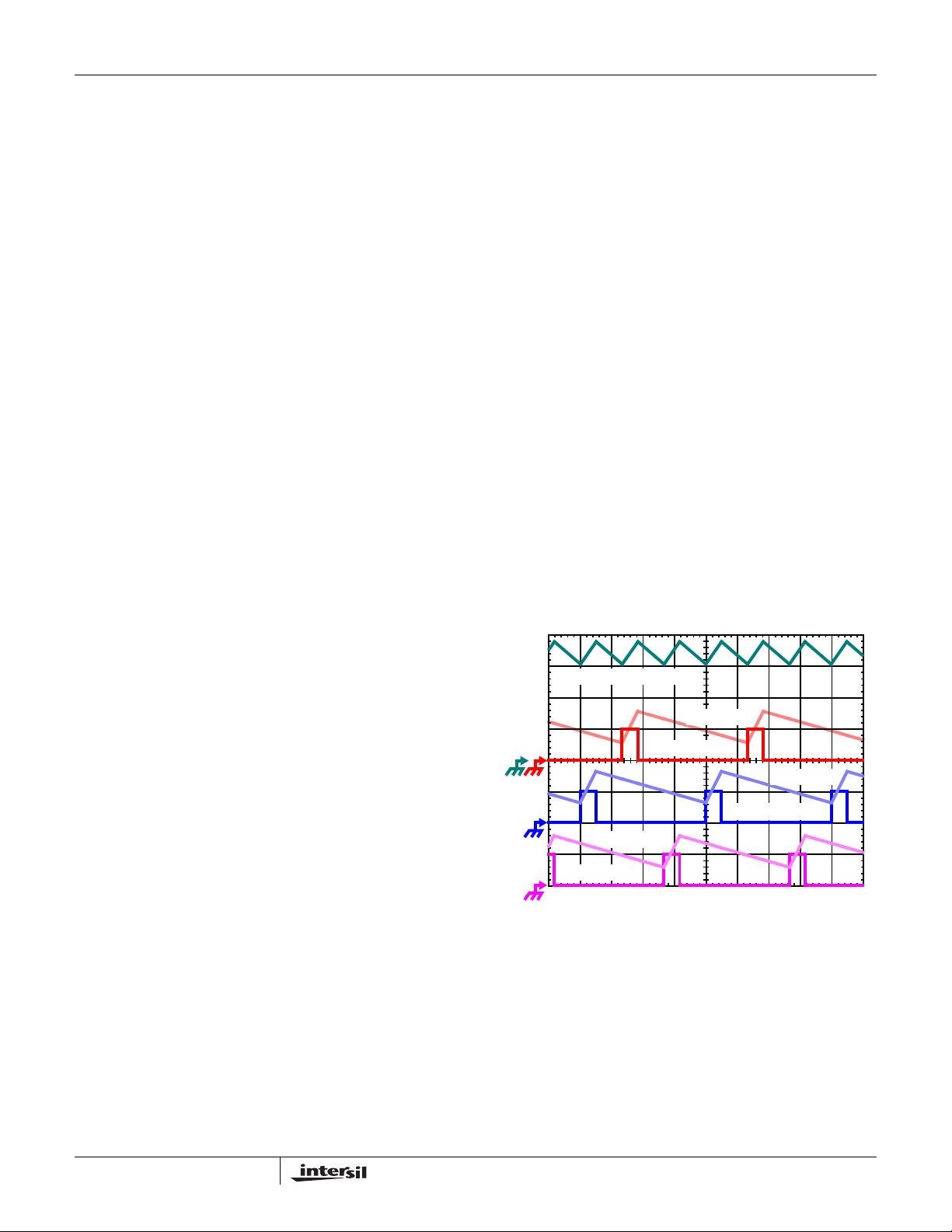

Interleaving

The switching of each channel in a multi-phase converter is

timed to be symmetrically out of phase with each of the other

channels. In a 3-phase converter, each channel switches 1/3

cycle after the previous channel and 1/3 cycle before the

following channel. As a result, the three-phase converter has

a combined ripple frequency three times greater than the

ripple frequency of any one phase. In addition, the peak-topeak amplitude of the combined inductor currents is reduced

in proportion to the number of phases (Equations 1 and 2).

Increased ripple frequency and lower ripple amplitude mean

that the designer can use less per-channel inductance and

lower total output capacitance for any performance

specification.

IL1 + IL2 + IL3, 7A/DIV

IL3, 7A/DIV

PWM3, 5V/DIV

IL2, 7A/DIV

PWM2, 5V/DIV

IL1, 7A/DIV

PWM1, 5V/DIV

1µs/DIV

FIGURE 1. PWM AND INDUCTOR-CURRENT WA VEFORMS

FOR 3-PHASE CONVERTER

Figure 1 illustrates the multiplicative effect on output ripple

frequency. The three channel currents (IL1, IL2, and IL3),

combine to form the AC ripple current and the DC load

current. The ripple component has three times the ripple

frequency of each individual channel current. Each PWM

pulse is terminated 1/3 of a cycle, or 1.33µs, after the PWM

pulse of the previous phase. The peak-to-peak current

waveforms for each phase is about 7A, and the dc

components of the inductor currents combine to feed the load.

6

FN9084.8

December 29, 2004

ISL6559

To understand the reduction of ripple current amplitude in

the multi-phase circuit, examine the equation representing

an individual channel’s peak-to-peak inductor current.

VINV

–()V

OUT

I

------------------------------------------------------=

PP

LfSV

In Equation 1, V

IN

and V

IN

OUT

are the input and output

OUT

(EQ. 1)

voltages respectively, L is the single-channel inductor value,

and f

is the switching frequency.

S

The output capacitors conduct the ripple component of the

inductor current. In the case of multi-phase converters, the

capacitor current is the sum of the ripple currents from each

of the individual channels. Compare Equation 1 to the

expression for the peak-to-peak current after the summation

of N symmetrically phase-shifted inductor currents in

Equation 2. Peak-to-peak ripple current decreases by an

amount proportional to the number of channels. Outputvoltage ripple is a function of capacitance, capacitor

equivalent series resistance (ESR), and inductor ripple

current. Reducing the inductor ripple current allows the

designer to use fewer or less costly output capacitors.

VINNV

–()V

OUT

I

------------------------------------------------------------=

CPP,

LfSV

OUT

IN

(EQ. 2)

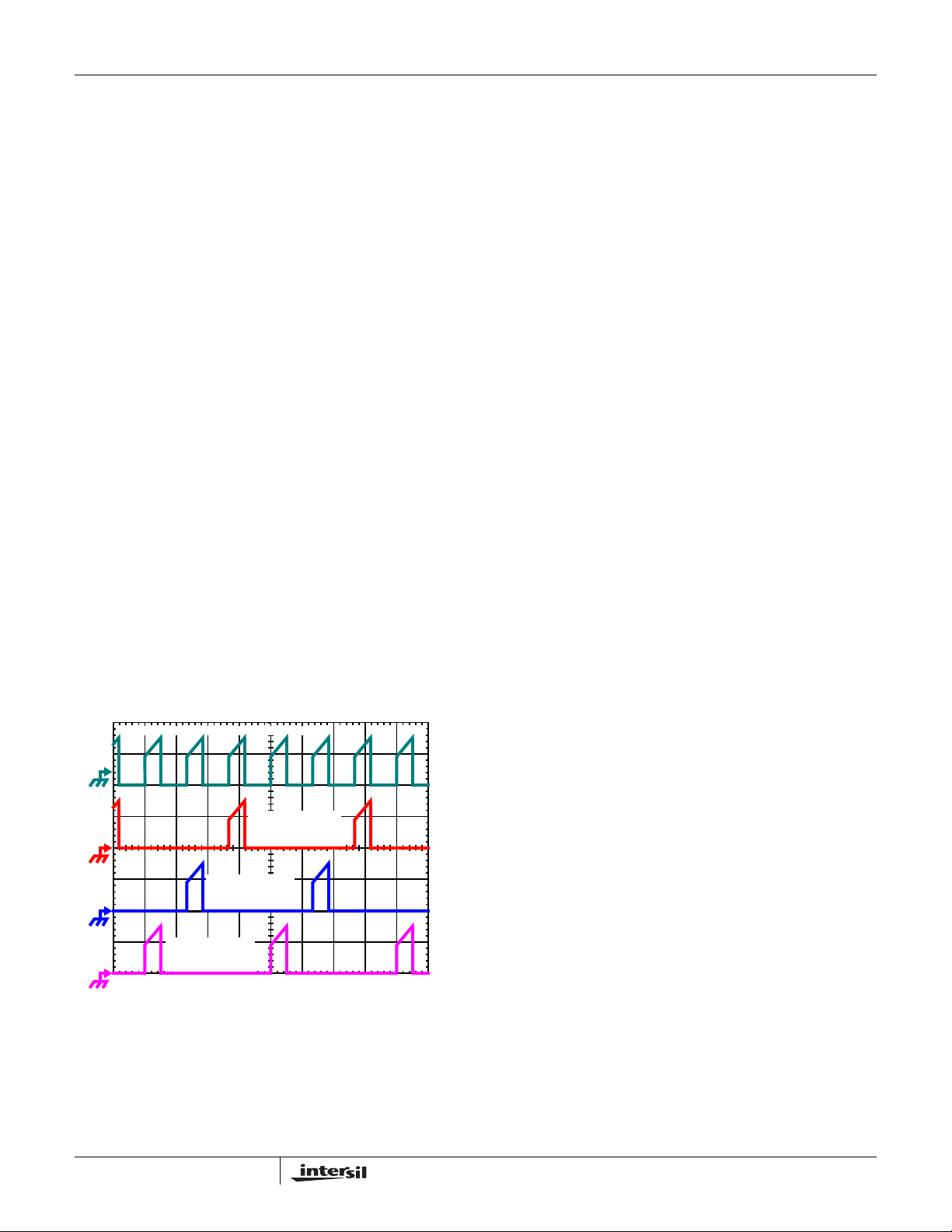

Another benefit of interleaving is to reduce input ripple

current. Input capacitance is determined in part by the

maximum input ripple current. Multi-phase topologies can

improve overall system cost and size b y lowe ring input ripple

current and allowing the designer to reduce the cost of input

capacitance. The example in Figure 2 illustrates input

currents from a three-phase converter combining to reduce

the total input ripple current.

INPUT-CAPACITOR CURRENT, 10A/DIV

CHANNEL 3

INPUT CURRENT

10A/DIV

CHANNEL 2

INPUT CURRENT

10A/DIV

CHANNEL 1

INPUT CURRENT

10A/DIV

1µs/DIV

FIGURE 2. CHANNEL INPUT CURRENTS AND INPUT-

CAPACITOR RMS CURRENT FOR 3-PHASE

CONVERTER

The converter depicted in Figure 2 delivers 36A to a 1.5V

load from a 12V input. The RMS input capacitor current is

5.9A. Compare this to a single-phase converter also

stepping down 12V to 1.5V at 36A. The single-phase

converter has 11.9A RMS input capacitor current. The

single-phase converter must use an input capacitor bank

with twice the RMS current capacity as the equivalent threephase converter.

Figures 15, 16 and 17 in the section entitled Input Capacitor

Selection can be used to determine the input-capacitor RMS

current based on load current, duty cycle, and the number of

channels. They are provided as aids in determining the

optimal input capacitor solution. Figure 18 shows the single

phase input-capacitor RMS current for comparison.

PWM Operation

The timing of each converter leg is set by the number of

active channels. The default channel setting for the ISL6559

is four. One switching cycle is defined as the time between

PWM1 pulse termination signals. The pulse termination

signal is an internally generated clock signal which triggers

the falling edge of PWM1. The cycle time of the pulse

termination signal is the inverse of the switching frequency

set by the resistor between the FS/DIS pin and ground. Each

cycle begins when the clock signal commands the channel-1

PWM output to go low. The PWM1 transition signals the

channel-1 MOSFET driver to turn off the channel-1 upper

MOSFET and turn on the channel-1 synchronous MOSFET.

In the default channel configuration, the PWM2 pulse

terminates 1/4 of a cycle after PWM1. The PWM 3 output

follows another 1/4 of a cycle after PWM2. PWM4 terminates

another 1/4 of a cycle after PWM3.

If PWM3 is connected to VCC, then two channel operation is

selected and the PWM2 pulse terminates 1/2 of a cycle later.

Connecting PWM4 to VCC selects three channel operation

and the pulse-termination times are spaced in 1/3 cycle

increments.

Once a PWM signal transitions low, it is held low for a

minimum of 1/4 cycle. This forced off time is required to

ensure an accurate current sample. Current sensing is

described in the next section. After the forced off time

expires, the PWM output is enabled. The PWM output state

is driven by the position of the error amplifier output signal,

V

, minus the current correction signal relative to the

COMP

sawtooth ramp as illustrated in Figure 1. When the modified

V

voltage crosses the sawtooth ramp, the PWM output

COMP

transitions high. The MOSFET driver detects the change in

state of the PWM signal and turns off the synchronous

MOSFET and turns on the upper MOSFET. The PWM signal

will remain high until the pulse termination signal marks the

beginning of the next cycle by triggering the PWM signal low.

Current Sensing

During the forced off time following a PWM transition low , the

controller senses channel load current by sampling the

voltage across the lower MOSFET r

ground-referenced amplifier, internal to the ISL6559,

connects to the PHASE node through a resistor, R

voltage across R

is equivalent to the voltage drop

ISEN

, see Figure 3. A

DS(ON)

ISEN

. The

7

FN9084.8

December 29, 2004

Loading...

Loading...