Page 1

查询ISL6431供应商

TM

ISL6431

Data Sh eet June 200 1

Advanced Pulse-Width Modulation (PWM)

Controller for Home Gateways

The ISL6431 is a high efficiency, fixed frequency,

synchronousbuck PWM controller. Itis designed for use in

applicationsthat convert5V to lower distributed voltages

required for set-top box, cable modem, DSL modem and

residential home gateway core processor, memory and

peripheral power supplies.

This device makes simple work out of implementing a

complete control and protection scheme for a D C-DC

stepdownconverter.Designed to drive N-channel MOSFETs

in a synchronous buck topology,the ISL6431 integrates the

control, output adjustment, monitoring and protection

functions into a single 8-pin package.

The ISL6431 provides simple, single feedback loop, voltagemode control with fast transient response. The output

voltagecan be precisely regulated to as low as 0.8V,with a

maximum t olerance of ±1.5% over temperatureand l ine

voltagevariations. A fixed frequency oscillator reduces

design complexity,while balancing typical application cost

and efficiency.

The error amplifier features a 15MHz gain-bandwidth

product and 6V/µs slew rate which enables high converter

bandwidthfor fast transient performance. The resulting

PWM duty cycles range from 0% to 100%.

Protection from overcurrent conditions is provided by

monitoringthe r

DS(ON)

operation appropriately. This approach simplifies the

implementation and improves efficiency by eliminating the

need for a current sense r esistor.

of the upper MOSFET toinhibit PWM

File Number 9018

Features

• Operates from +5V Input

•0.8VtoV

Output Range

IN

- 0.8V Internal Reference

- ±1.5% Over Line Voltage and Temperature

• Drives N-Channel MOSFETs

• Simple Single-Loop Control Design

- Voltage-Mode PWM Control

• Fast Transient Response

• Lossless, Programmable Overcurrent Protection

- Uses Upper MOSFET’s r

DS(ON)

• Small Converter Size

- 300kHz Fixed Frequency Oscillator

- InternalSoft Start

- 8 Lead SOIC Package

• High Conversion Efficiency

• Synchronous/Standard Buck Configuration

Applications

• Cable Modems, Set TopBoxes, and DSL Modems

• DSP and Core CommunicationsProcessor Supplies

• Power Supplies for Microprocessors and Embedded

Controllers

• Memory Supplies

• Personal Computer Per ipherals

• Industrial Power Supplies

Ordering Information

TEMP.RANGE

PART NUMBER

ISL6431CB 0 to 70 8 Ld SOIC M8.15

ISL6431IB -40 to 85 8 Ld SOIC M8.15

ISL6431EVAL1 Evaluation Board

(oC) PACKAGE

1

PKG.

• 5V-Input DC-DC Regulators

• Low-Voltage Distributed Power Supplies

NO.

Pinout

1

BOOT

2

UGATE

3

GND

LGATE

4

CAUTION: These devices aresensitiveto electrostatic discharge;followproperIC Handling Procedures.

1-888-INTERSIL or 321-724-7143 | Intersil andDesign is a trademark of Intersil AmericasInc.

Copyright © Intersil Americas Inc. 2001, All Rights Reserved

8

PHASE

COMP/OCSET

7

6

FB

5

VCC

Page 2

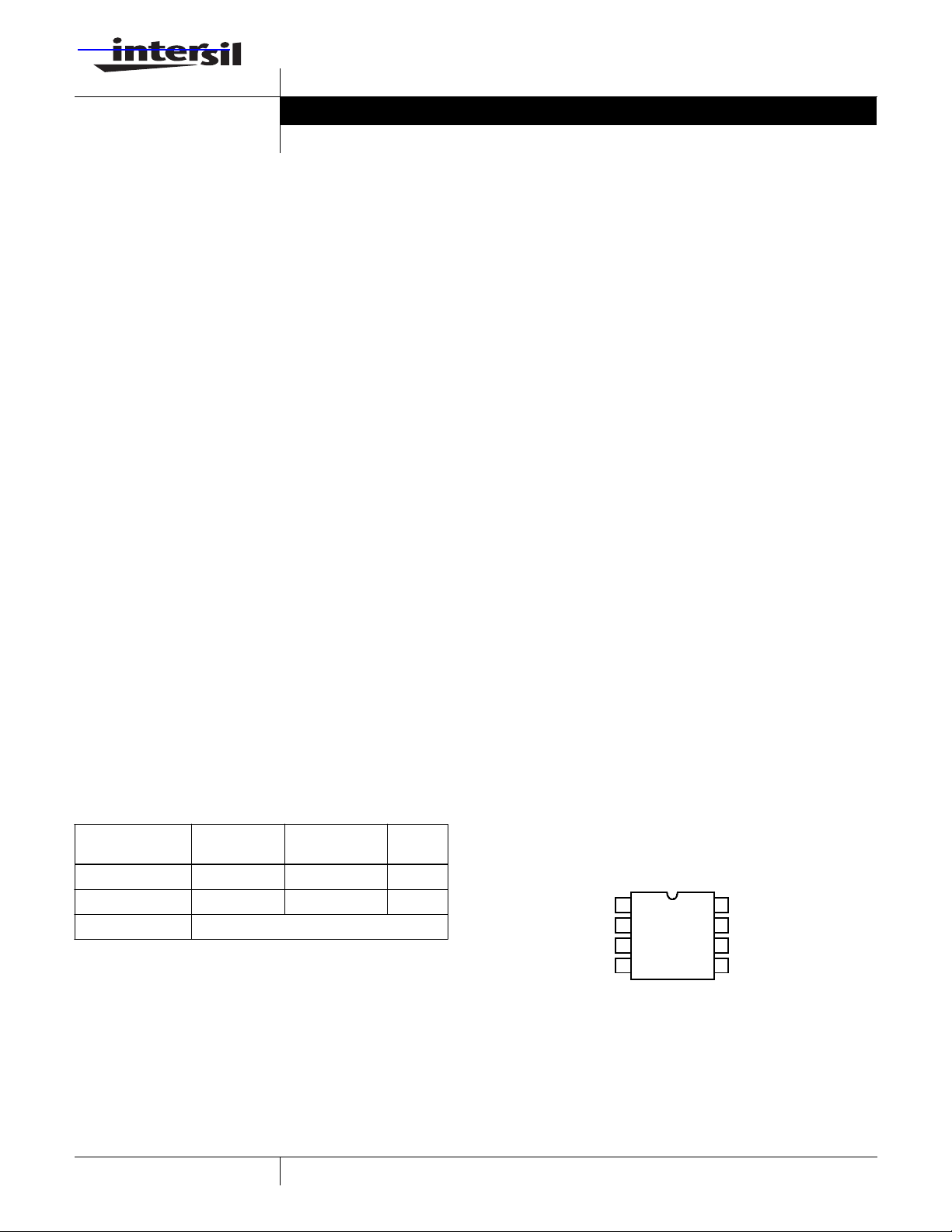

Block Diagram

ISL6431

V

CC

0.8V

FB

COMP/OCSET

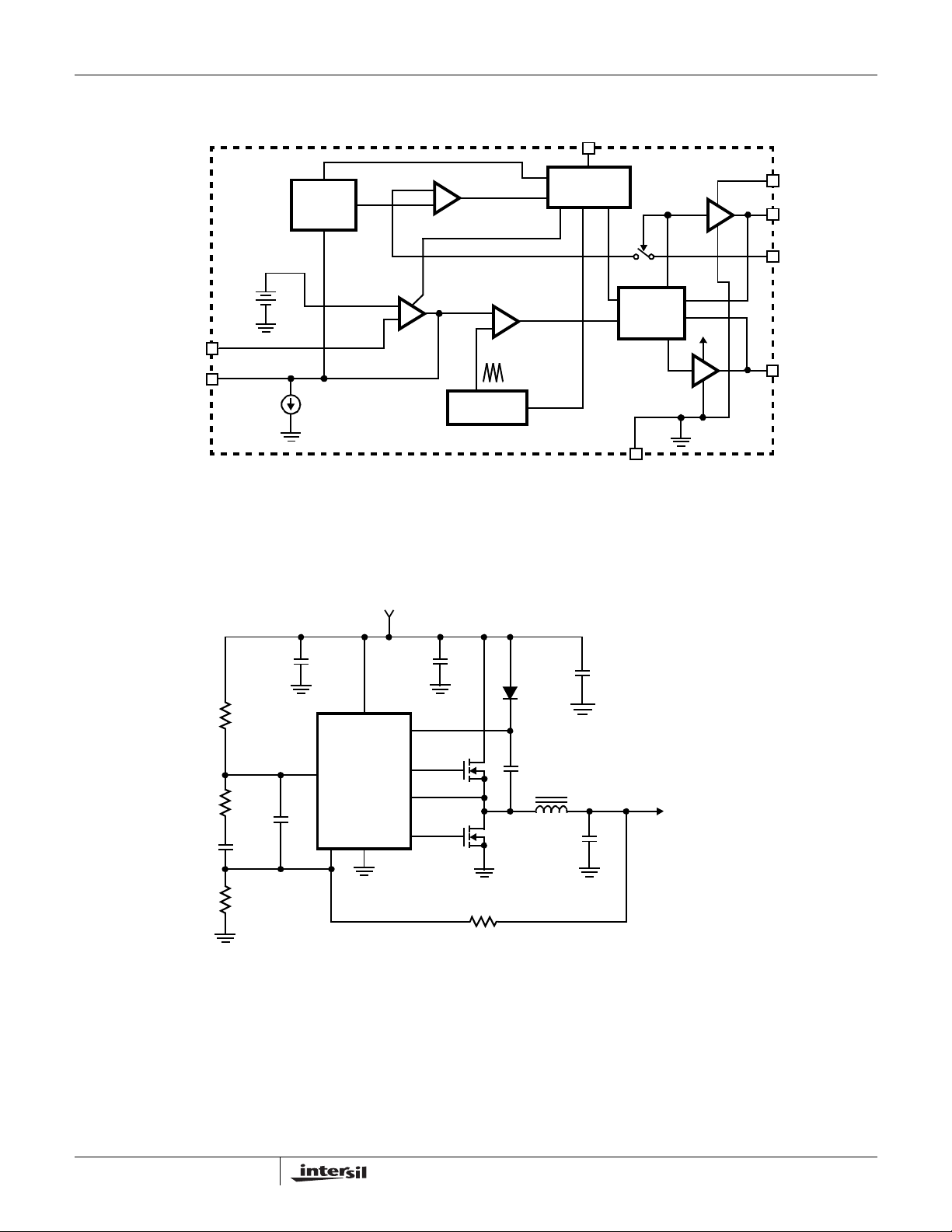

Typical Application

+

-

20µA

SAMPLE

AND

HOLD

ERROR

AMP

V

CC

+

-

COMPARATOR

+

-

OC

PWM

COMPARATOR

+

-

OSCILLATOR

FIXED 300kHz

POR AND

SOFTSTART

PWM

INHIBIT

GATE

CONTROL

LOGIC

GND

BOOT

UGATE

PHASE

VCC

LGATE

R

1

R

2

C

1

R

3

C

3

COMP/OCSET

C

2

ISL6431

7

63

FB

5

VCC

GND

1

2

8

4

C

4

BOOT

UGATE

PHASE

LGATE

C

D

BOOT

C

6

L

OUT

R

4

5

+VO=0.8toV

C

7

IN

2

Page 3

ISL6431

Absolute M aximum Ratings Thermal Information

Supply Voltage, VCC................................+6.0V

Absolute Boot Voltage, V

Upper Driver Supply Voltage, V

Input, Output or I/O Voltage. . . . . . . . . . . GND -0.3V to VCC +0.3V

.......................+15.0V

BOOT

BOOT-VPHASE

...........+6.0V

ESDClassification.................................Class2

Operating Conditions

SupplyVoltage,VCC............................+5V±10%

AmbientTemperatureRange...................-40

JunctionTemperatureRange.................. -40

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operationofthe

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

is measured with the component mountedon a low effective thermal conductivity test board in free air. See Tech Brief TB379 for details.

1. θ

JA

o

Cto85oC

o

Cto125oC

Thermal Resistance (Typical, Note 1) θ

JA

(oC/W)

SOICPackage............................. 100

MaximumJunctionTemperature...................... 150

MaximumStorageTemperatureRange..........-65

o

Cto150oC

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . 300

(SOIC - Lead Tips Only)

o

C

o

C

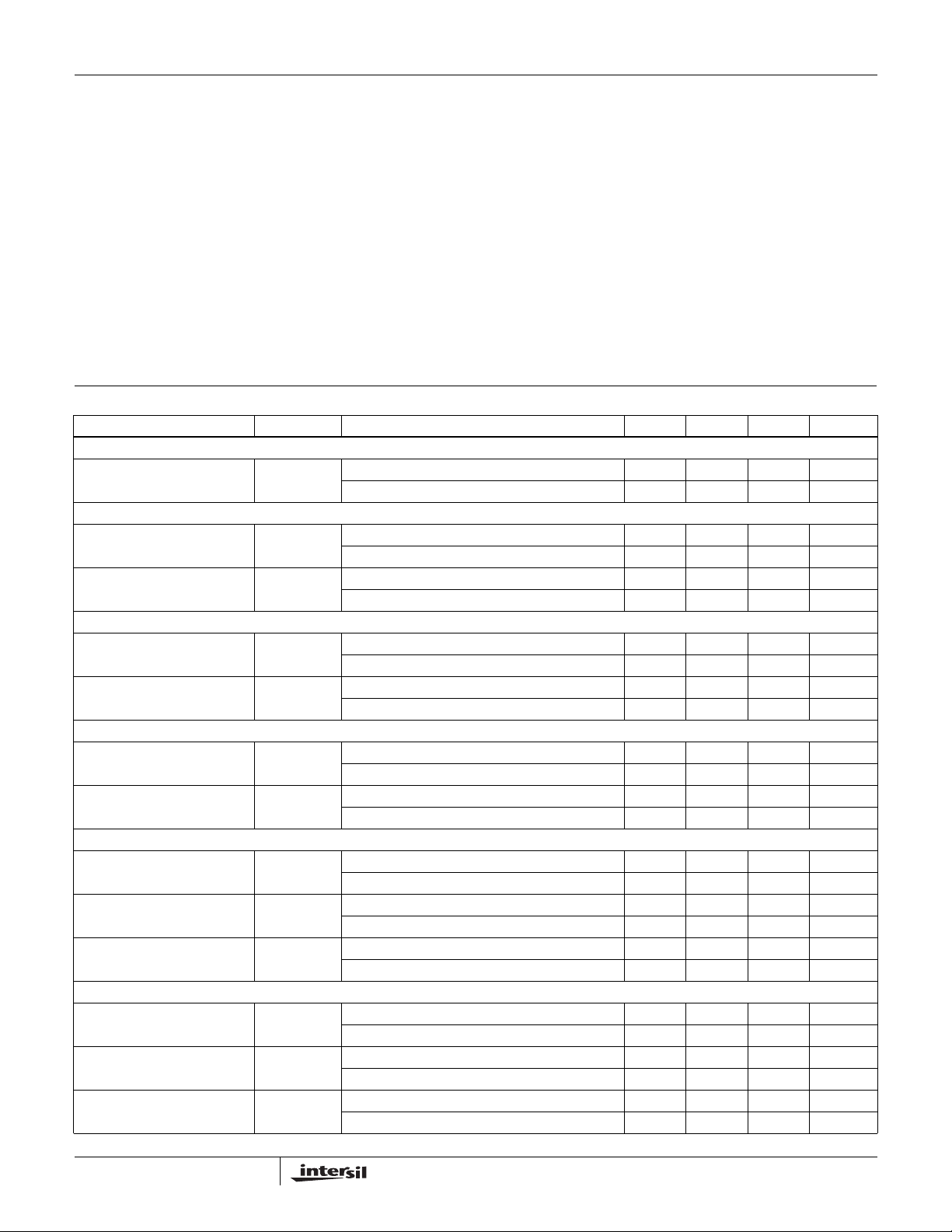

Electrical Specifications Recommended OperatingConditions, Unless Otherwise Noted V

=5.0V±5% and TA=25oC

CC

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

VCC SUPPLY CURRENT

NominalSupply I

VCC

ISL6431CB; UGATE and LGATE Open - 3.2 - mA

ISL6431IB; UGATE and LGATE Open 2.5 3.2 3.8 mA

POWER-ON RESET

Rising VCC POR Threshold POR ISL6431CB - 4.30 - V

ISL6431IB 4.17 4.30 4.50 V

VCC POR Threshold

Hysteresis

ISL6431CB - 0.20 - V

ISL6431IB 0.01 0.20 0.85 V

OSCILLATOR

Frequency f

OSC

ISL6431CB; VCC = 5V - 300 - kHz

ISL6431IB; VCC = 5V 230 300 340 kHz

Ramp Amplitude ∆V

OSC

ISL6431CB - 1.5 - V

ISL6431IB - 1.5 - V

REFERENCE

Reference Voltage Tolerance ISL6431CB - - 1.5 %

ISL6431IB - - 1.5 %

NominalReferenceVoltage V

REF

ISL6431CB - 0.800 - V

ISL6431IB - 0.800 - V

ERROR AMPLIFIER

DC Gain ISL6431CB - 82 - dB

ISL6431IB - 82 - dB

Gain-BandwidthProduct GBWP ISL6431CB 14 - - MHz

ISL6431IB 14 - - MHz

Slew Rate SR ISL6431CB; COMP = 10pF - 8.0 - V/µs

ISL6431IB; COMP = 10pF 4.5 8.0 9.2 V/µs

GATE DRIVERS

UpperGate Source Current I

UpperGate Sink Current I

UGATE-SRC

UGATE-SNK

ISL6431CB;V

ISL6431IB; V

BOOT-VPHASE

BOOT-VPHASE

ISL6431CB - 1.0 - A

=5V,V

=5V,V

=4V - 1.0 - A

UGATE

=4V - 1.0 - A

UGATE

ISL6431IB - 1.0 - A

LowerGate Source Current I

LGATE-SRC

ISL6431CB; VCC=5V,V

ISL6431IB; V

CC

=5V,V

=4V - 1.0 - A

LGATE

=4V - 1.0 - A

LGATE

P-P

P-P

3

Page 4

ISL6431

Electrical Specifications Recommended OperatingConditions, Unless Otherwise Noted V

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

LowerGate Sink Current I

PROTECTION / DISABLE

OCSET Current Source I

DisableThreshold V

LGATE-SNK

OCSET

DISABLE

Functional Pin Descriptions

VCC (Pin 5 )

This is the main bias supply for the ISL6431, as well as the

lower MOSFET’s gate. Connect a well-decoupled 5V supply

to this pin.

FB (Pin 6)

This pin is the inverting input of the internal error amplifier.

Use this pin, in combination with the COMP/OCSET pin, to

compensate the voltage-control feedback loop of the

converter.

GND (Pin 3)

This pin represents the signal and power ground for the IC.

Tie this pin to the ground island/plane through the lowest

impedance connection available.

PHASE (Pin 8)

Connect this pin to the upper MOSFET source. This pin is

used to monitor the voltage drop across the upper MOSFET

for overcurrent protection. This pin i s also monitored by the

continuously adaptive shoot-through protection circuitry to

determine when the upper MOSFET has turned off.

UGATE (Pin 2)

Connect this pin to the upper MOSFET’s gate. This pin

provides the PWM-controlledgate drive for the upper

MOSFET. This pin is also monitored by the adaptive shootthrough protection circuitry to determine when the upper

MOSFET has turned off. Do not insert any circuitry between

this pin and the gate of the upper MOSFET, a s it may

interfere with the internal adaptive shoot-through protection

circuitryand render it ineffective.

BOOT (Pin 1)

This pin provides ground referenced bias voltage to the

upper MOSFET driver. A bootstrap circuitis used to create a

voltagesuitable to drive a logic-level N-channel MOSFET.

COMP/OCSET (P in 7)

This is a multiplexedpin. During a short period of time

followingpower-onreset (POR), this pin is usedto determine

the overcurrent threshold of the converter. Connect a

resistor (R

MOSFET (V

) from this pin to the drain of the upper

OCSET

CC

). R

, an internal 20µA current source

OCSET

ISL6431CB - 2.0 - A

ISL6431IB - 2.0 - A

ISL6431CB 17 20 22 µA

ISL6431IB 14 20 24 µA

ISL6431CB - - 0.8 V

ISL6431IB - - 0.8 V

(I

), and the upper MOSFET on-resistance (r

OCSET

set the converter overcurrent(OC) trip pointaccording to the

following equation:

I

OCSETxROCSE T

----- ----------- ----------- ----------- ---------- -

=

I

PEAK

r

DS O N()

Internal circuitry of the ISL6431 will not recognize a voltage

drop across R

across R

OCSET

OCSET

that is greater than 0.5V will set the

overcurrent trip point to:

PEAK

r

DS ON()

0.5V

----- ----------- ------

=

I

An overcurrent trip cycles the soft-start function.

Pulling OCSET to a level below 0.8V will di sable the

controller. Disabling the ISL6431 causes the oscillator to

stop,the LGATEand UGATE outputs to be held low,and the

softstart circuitry to re-arm.

During soft-start, and all the time during normal converter

operation, this pin represents the output of the error

amplifier. Use this pin, in combination with t he FB pin, to

compensate the voltage-control feedback loop of the

converter.

LGATE (Pin 4)

Connect this pin to the lower MOSFET’s gate. This pin

provides the PWM-controlled gate drive for the lower

MOSFET. This pin is also monitored by the adaptive shootthrough protection circuitry to determine when the lower

MOSFET has turned off. Do not insert any circuitry between

this pin and the gate of the lower MOSFET, as it may

interfere with the internal adaptive shoot-through protection

circuitryand r ender it ineffective.

Functional Descriptions

Initialization

The ISL6431 automatically initializes upon receipt of power.

The Power-On Reset (POR) function continually monitors the

bias voltage at the VCC pin. The POR function initiates the

Overcurrent Protection (OCP) sampling and hold operation

after the supply voltage exceeds its POR threshold. Upon

=5.0V±5% and TA=25oC (Continued)

CC

DS(ON)

larger than 0.5V. Any voltage drop

)

4

Page 5

ISL6431

completion of the OCP sampling and hold operation, the POR

function initiates the Soft Startoperation.

Over Current Protection

Theovercurrentfunctionprotects the converterfrom a shorted

output by using the upper MOSFET’s on-resistance, r

to monitor the current. This method enhances the converter’s

efficiency and reduces cost by eliminating a current sensing

resistor.

14A

12A

10A

8A

6A

4A

OUTPUT INDUCTOR

2A

0A

TIME (50µs/DIV.)

FIGURE 1. OVERCURRENT OPERATION

The overcurrent function cycles the soft-start function in a

hiccup m ode to provide fault protection. A resistor

(R

) progr ams the overcurrent trip level (see Typical

OCSET

Application diagram).

DS(ON)

in the normal operating load range, find the R

OCSET

resistor

from the equation above with:

1. Themaximumr

2. The minimum I

,

3. Determine I

DS(ON)

OCSET

PEAK

atthe highestjunctiontemperature.

from the specification table.

I

for ,

PEAKIOUT MAX()

∆I()

------ ----+>

2

where ∆I is the output inductor ripple current.

For an equation for the ripple current see the section under

component guidelines titled ‘Output Inductor Selection’.

Soft Start

The POR function initiates the soft start sequence after the

overcurrent set point has been sampled. Soft start clamps the

error amplifier output (COMP pin) and reference input (noninverting terminal of the error amp) to the internally generated

Soft Startvoltage. Figure 2 shows a typical soft start interval.

Initially the clamp on the error amplifier (COMP/OCSET pin)

controls the converter’s output voltage. The oscillator’s

triangular waveform is compared to the ramping error amplifier

voltage. This generates PHASE pulses of increasing width that

charge the output capacitor(s). With sufficient output voltage,

the clamp on the reference input controls the output voltage.

When the internally generated Soft Start voltage exceeds the

feedback (FB pin) voltage, the output voltage is in regulation.

This method provides a rapid and controlled output voltage rise.

Immediately following POR, the ISL6431 initiates the

Overcurrent Protection sampling and hold operation. First,

the internal error amplifieris disabled. This allows an internal

20µA current sink to develop a voltage across R

OCSET

.The

ISL6431 then samples this voltage at the COMP pin. This

sampled voltage, which is referenced to the VCC pin, is held

internallyas the Overcurrent Set Point.

Whenthe voltage across the upper MOSFET, which is also

referenced to the VCC pin, exceeds the Overcurrent Set

Point, the overcurrent function initiates a soft-start sequence.

Figure 1 shows this operationwith an overload condition.This

current is repeated with a 21ms period. Note that the inductor

current increases to over 14A during the Soft Start interval and

causes an overcurrent trip. The converter dissipates very little

power with this method. The measured input power for the

conditionsof Figure 1 is only 0.25W.

The overcurrent function will trip at a peak inductor current

(I

I

where I

PEAK)

PEAK

determined by:

I

OCSETxROCSET

----- ----------- ----------- ----------- ----------- --- -

=

r

DS ON()

is the internal OCSET current source (20µA

OCSET

typical).The OC trip point varies mainly due t o the

MOSFET’s r

DS(ON)

variations.Toavoid overcurrent tripping

V

OUT

500mV/DIV.

0V

TIME (1ms/DIV.)

FIGURE 2. SOFT START INTERVAL

Application Guidelines

Layout Considerations

As in any high frequency switching converter,layout is very

important. Switching current from one power device to another

can generate voltage transients across the impedances of the

interconnecting bond wires and circuit traces. These

interconnecting impedances should be minimized by using

wide, short printed circuit traces. The critical components

should be located as close together as possible, using ground

plane construction or single point grounding.

5

Page 6

ISL6431

V

IN

ISL6431

UGATE

PHASE

LGATE

Q

1

Q

2

RETURN

L

O

V

OUT

C

IN

C

O

LOAD

FIGURE 3. PRINTED CIRCUIT BOARD POWER AND

GROUND PLANES OR ISLANDS

Figure 3 shows the critical power components of the converter.

To minimize the voltage overshoot, the interconnecting wires

indicated by heavy lines should be part of a ground or power

plane in a printed circuit board. The components shown in

Figure 3 should be located as close together as possible.

Please note that the capacitors C

and COmay each

IN

represent numerous physical capacitors. Locate the ISL6431

within 3 inches of the MOSFETs,Q

and Q2. The circuit traces

1

for the MOSFETs’ gate and source connections from the

ISL6431 must be sized to handle up to 1A peak current.

Figure 4 shows the circuit traces that require additional layout

consideration.Usesinglepointandgroundplaneconstruction

for the circuits shown. Minimize any leakage current paths on

the COMP/OCSET pin and locate the resistor, R

OSCET

close

to the COMP/OCSET pin because the internal current source

isonly 20µA. ProvidelocalV

GND pins. Locate the capacitor, C

decoupling between VCC and

CC

as closeas practical

BOOT

to the BOOT and PHASE pins. All components used for

feedback compensation should be located as close to the IC a

practical.

+V

IN

Q

L

1

O

C

Q

2

V

OUT

O

+5V

OCSET

R

ISL6431

COMP/OCSET

GND

BOOT

C

BOOT

PHASE

VCC

+5V

D

1

C

VCC

FIGURE 4. PRINTED CIRCUIT BOARD SMALL SIGNAL

LAYOUT GUIDELINES

Feedback Compensation

Figure 5 highli ghts the voltage-mode control l oop fo r a

synchronous-rectified buck converter. The output voltage

(V

) is regulated to the R ef er ence voltage level. The

OUT

error a mpli f ier (Error Amp) output (V

the oscillator (OSC) triangul ar wave to provide a pulse-

) is compared with

E/A

width modulated (PWM) w ave with an amplitude of V

IN

at

the PHASE node. The PWM waveis smoothedby the output

filter (L

∆V

and CO).

O

V

FB

Z

FB

IN

L

O

PHASE

ESR

(PARASITIC)

Z

IN

C

R

3

R

1

OSC

OSC

PWM

COMPARATOR

-

+

Z

FB

V

E/A

-

+

ERROR

AMP

DETAILED COMPENSATION COMPONENTS

COMP

ISL6431

DRIVER

DRIVER

Z

REFERENCE

C

2

C

R

1

2

-

+

REFERENCE

IN

FIGURE 5. VOLTAGE-MODEBUCK CONVERTER

COMPENSATION DESIGN

V

OUT

C

O

V

OUT

3

The modulator transfer function is the small-signal transfer

function of V

OUT/VE/A

Gain and the output filter (L

break frequency at F

the modulator is simply the input voltage(V

peak-to-peakoscillator voltage ∆V

. This function is dominated by a DC

and CO), with a double pole

O

andazeroatF

LC

OSC

. The DC Gain of

ESR

) divided by the

IN

.

Modulator Break Frequency Equations

F

LC

=

2π xL

OxCO

F

ESR

=

1

------ ----------- ----------- ----------- -- -

The compensation network consists of the error amplifier

LOAD

(internalto the ISL6431) and the i mpedance networks Z

and ZFB. The goal of the compensation network is to provide

a closed l oop transfer function with the highest 0dB crossing

frequency(f

) and adequatephase margin. Phase margin

0dB

is the difference between the closed loop phase at f

180 degrees. The equations below relate the compensation

network’spoles, zeros and gain to the components(R

R

3,C1,C2

,andC3) in Figure 7. Use these guidelines for

locating the poles and zeros of the compensation network:

1. Pick Gain (R

2. Place1

3. Place 2

4. Place 1

5. Place 2

ST

ND

ST

ND

) for desired converter bandwidth.

2/R1

Zero Below Filter’s Double Pole (~75% FLC).

Zero at Filter’s Double Pole.

Pole at the ESR Zero.

Pole at Half t he Switching Frequency.

1

------ ----------- ----------- ----------- ----

2π xESRxC

O

IN

and

0dB

,

1,R2

6

Page 7

ISL6431

6. Check Gain against Error Ampl ifier’s Open-Loop Gain.

7. Estimate Phase Margin - Repeat if Necessary.

Compensation Break Frequency Equations

1

----- ----------- ----------- -------- -

=

F

Z1

2π xR

----- ----------- ----------- ----------- ----------- ----- -

F

=

Z2

2π xR

2xC1

1

+()xC

1R3

3

------ ----------- ----------- ----------- ----------- ------ -

=

F

P1

2π xR

------ ----------- ----------- ------- -

F

=

P2

2π xR

Figure 6 shows an asymptotic plot of the DC-DC converter’s

gain vs frequency. The actual Modulator Gain has a high gain

peakdue to the high Q factor of the output filter and is not

shown in Figure 6. Using the above guidelines should give a

Compensation Gain similar to the curve plotted. The open

looperror amplifier gain bounds the compensation gain.

Check the compensation gain at F

with the capabilities of

P2

the error amplifier. The Closed Loop Gain is constructedon

the graph of Figure 6 by adding the Modulator Gain (in dB) to

the Compensation Gain (in dB). This is equivalent to

multiplying the modulator transfer function to the

compensationtransfer function and plottingthe gain.

The compensation gain uses external impedance networks

and ZINto provide a stable,highbandwidth (BW) overall

Z

FB

loop. A stable control loop has a gain crossing with

-20dB/decadeslope and a phase margin greater than 45

degrees. Include worst case component variations when

determiningphase margin.

Refer to the evaluation board application note (available

soon) for a complete reference design schematic and bill of

materials for a typical Residential Gateway application.

100

80

60

40

20LOG

(R

)

2/R1

20

GAIN (dB)

0

MODULATOR

-20

-40

-60

FIGURE 6. ASYMPTOTIC BODE PLOT OF CONVERTER GAIN

GAIN

F

F

F

P1

Z2

Z1

F

LC

F

FREQUENCY (Hz)

(V

ESR

F

P2

20LOG

/DV

IN

1

C

1xC2

------ ----------- ---- -

x

2

C1C2+

1

3xC3

OPEN LOOP

ERROR AMP GAIN

)

OSC

COMPENSATION

GAIN

CLOSEDLOOP

GAIN

10M1M100K10K1K10010

Component Selection Guidelines

Output Capacitor Selection

An output capacitor is required to f ilter the output and supply

the load transient current. The filtering requirements are a

function of the switching frequency and the ripple current.

The load transient requirementsare a function of the slew

rate (di/dt) and the magnitude of the transient load current.

These requirements are generally met with a mix of

capacitors and careful layout.

Highfrequency capacitorsinitially supply the transientand

slow the current load rate seen by the bulk capacitors. The

bulk filter capacitor values are generally determined by the

ESR (Effective Series Resistance) and voltage rating

requirements rather thanactual capacitance requirements.

High frequency decoupling capacitors should be placed as

closeto the power pins of the load as physicallypossible. Be

careful not to add inductance in the circuit board wiring that

could cancel the usefulness of these low inductance

components.

Use only specialized low-ESR capacitors intended for

switching-regulator applications for the bulk capacitors. The

bulk capacitor’s ESR will determine the output ripple voltage

and the initial voltage drop after a high slew-rate transient. An

aluminum electrolytic capacitor’s ESR value is related to the

casesize with lower ESR available in largercase sizes.

However,the EquivalentSeries Inductance (ESL)of these

capacitors increases with case size and can reduce the

usefulness of the capacitor to high slew-rate transient loading.

Unfortunately, ESL is not a specified parameter. Work with

your capacitor supplier and measure the capacitor’s

impedance with frequency to select a suitable component. In

mostcases, multiple electrolytic capacitors of smallcase size

perform betterthan a single largecase capacitor.

Output Inductor Selection

The output inductor is selected to meet the output voltage

ripple requirements and minimize the converter’s response

time to t he load transient. The inductor value determines the

converter’s ripple current and the ripple voltage is a function

of the ripple current. The ripple voltage and current are

approximatedby the following equations:

V

IN-VOUT

∆I =

FsxL

Increasingthe valueof inductancereduces the ripple current

and voltage. However, the large inductance values reduce

the converter’s response time to a load transient.

One o f the parameters limiting the converter’s response to

a load transient is the ti me required to change the inductor

current. Given a sufficiently fast control loop design, the

ISL6431 will provi de either 0% or 100% d ut y cycle in

response to a loa d transient. The response time i s the time

required to slew the inductor current from an ini tial current

value to the transient current level. During thi s interval the

difference between the inductor current and the transient

current level must be supplied by the o utput capacitor.

Minimizing the response time can minimize the output

capacitance r equir ed.

V

OUT

x

V

IN

∆V

OUT

= ∆IxESR

7

Page 8

ISL6431

The response time to a transient i s different for the

applicationof load and the removal of load. The following

equations give the approximate response time interval for

applicationand removal of a transient load:

LxI

t

=

RISE

where: I

TRAN

VIN-V

OUT

is the transient load current step, t

TRAN

t

FALL

response time t o the application of load, and t

LxI

TRAN

=

V

OUT

is the

RISE

is the

FALL

response time t o the removal of load. The worst case

response time can be either at the application or removal of

load. Be sure to check both of these equationsat the

minimum and maximum output levels for the worst case

response time.

Input C apacitor Selection

Use a mix of input bypass capacitorsto control the voltage

overshoot across the MOSFETs.Use small ceramic

capacitors for high frequency decoupling and bulk capacitors

to supply the current needed each time Q

turnson. Placethe

1

small ceramic capacitors physically close to the MOSFETs

and between the drain of Q

and the source of Q2.

1

The important parameters for the bulk inputcapacitorare the

voltagerating and the RMS current rating. For reliable

operation, select the bulk capacitorwith voltage and current

ratings above the maximum input voltage and largest RMS

current requiredby the circuit. The capacitor voltage rating

should be at least 1.25 times greater than the maximum

input voltage and a voltage rating of 1.5 times is a

conservative guideline. The RMS current rating requirement

for the input capacitor of a buck regulator i s approximately

1/2 the DC load current.

For a through hole design, several electrolytic capacitors may

be needed. For surface mount designs, solid tantalum

capacitors can be used, but caution must be exercised with

regard to the capacitor surge current rating. These capacitors

must be capable of handling the surge-current at power-up.

Some capacitor series available from reputable manufacturers

are surge current tested.

MOSFET Selection/Considerations

The ISL6431 requires two N-Channel power MOSFETsfor use

in a synchronous buck configuration.These should be selected

based upon r

management requirements.

, gate supply requirements, and thermal

DS(ON)

across the lowe r MOSFET clamps the switching node

before the synchronous rectifier turns on.

These e quat i ons

assume linear voltage-current tr ansi tio ns and do not

adequately model power loss due the reverse-reco v ery of

the lower MOSFET’s bod y diode. The gate-charge losses

are dissi pated by the ISL6431 and don' t heat the

MOSFETs. However, large gate-charge increases the

switching interval, t

which increases the

SW

upper MOSFET

switching l osses. Ensure that both M O SFETs are within

their maxi mum juncti on temper atur e at high ambient

temperature by calculating the temper atur e rise according

to package thermal-resi stance specificat i ons. A separate

heatsink may be necessary depending upon MOSFE T

power, package type, ambient t em per atur e and air flow.

1

P

P

UPPER

LOWER

=Io2xr

=Io2xr

DS(ON)

DS(ON)

xD+

x(1-D)

Where: D is the duty cycle = V

is the switch ON time, and

t

SW

is the switching frequency.

F

S

Io x V

2

OUT/VIN

INxtSWxFS

,

Given the reduced available gate bias voltage (5V), logiclevel or sub-logic-level transistors have to be used for both

N-MOSFETs. Caution should be exercised with devices

exhibitingvery low V

GS(ON)

characteristics, as the low gate

thresholdcould be conducive to some shoot-through(due to

the Miller effect),in spite of the counteracting circuitry

present aboard the ISL6431.

+5V

VCC

ISL6431

-

+

FIGURE 7. UPPER GATE DRIVE BOOTSTRAP

D

BOOT

+VD-

BOOT

UGATE

PHASE

LGATE

GND

C

BOOT

Q1

Q2

+5V

NOTE:

V

G-S

NOTE:

V

G-S

≈ VCC-V

≈ V

CC

D

In hig h-cur r ent applicat io ns, the MOSFET power

dissipation, package selec tion and heatsink are the

dominant design factors. The pow er dissipation includes

two loss components; conduc tion loss and switching loss.

The condu ct ion losses are the largest component of power

dissipation for both the upper and the lower MOSFETs.

These losses ar e distributed between the two MOSFETs

according t o duty factor (see the equations b elo w). Only

the upper MOS FET has switching losses, since the lower

MOSFETs body diod e or an external Schottky r ect ifier

8

Figure 7 shows the upper gate drive (BOOT pin) supplied by a

bootstrap circuit from V

. The boot capacitor, C

CC

BOOT

,

develops a floating supply voltage referenced to the PHASE

pin. The supply is refreshed to a voltage of V

diode drop (V

) each time the lower MOSFET, Q2, turnson.

D

less the boot

CC

Page 9

ISL6431

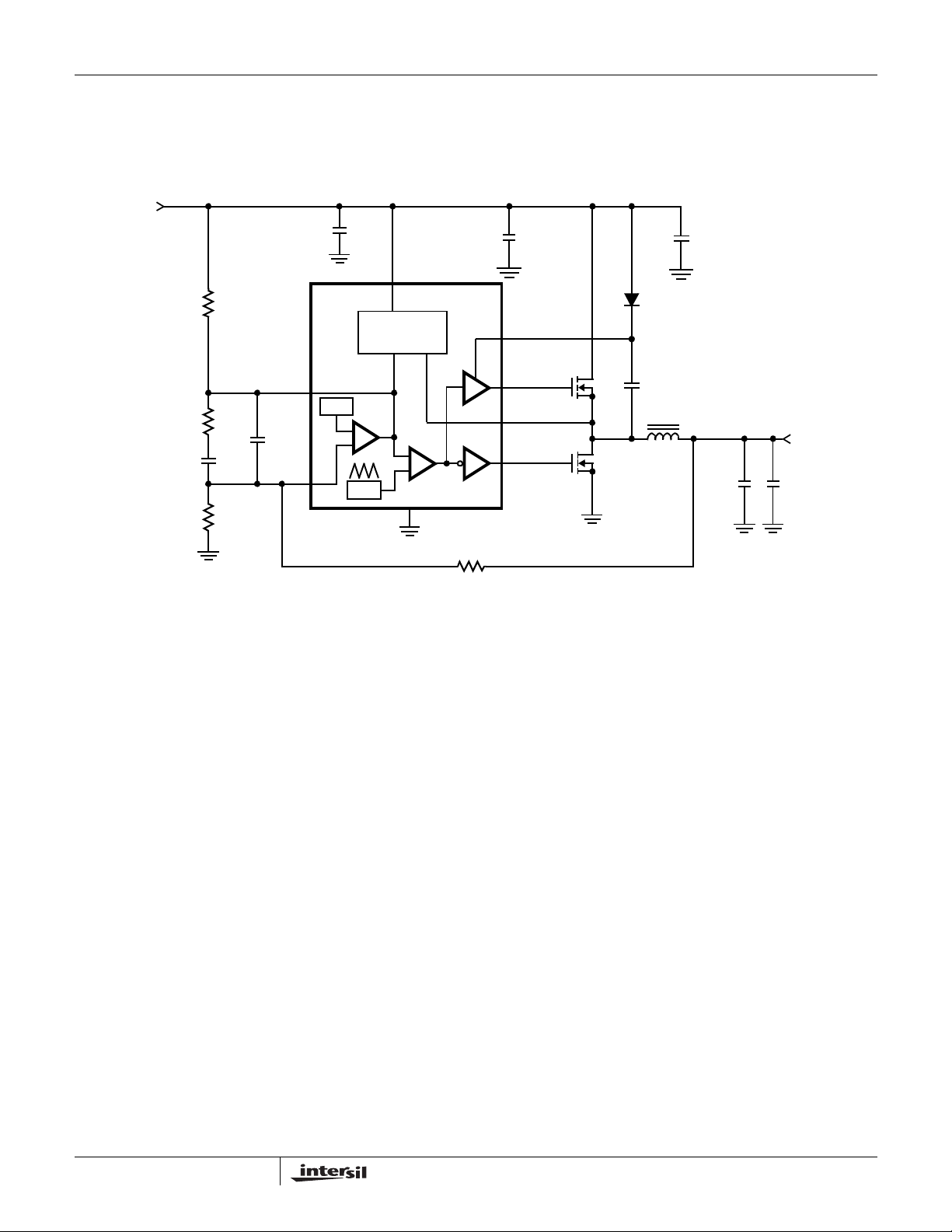

ISL6431 DC-DC Converter Application Circuit

Figure 8 shows an application circuit of a DC-DC Converter.

Detailed information on the circuit, including a complete Billof-Materials and circuit board description is available.

+5V

VCC

MONITOR

AND

PROTECTION

+

-

OSC

5

+

-

3

GND

COMP/OCSET

FB

ISL6431

7

REF

6

U

1

+

C

IN

D

1

1

BOOT

UGATE

2

Q

8

4

PHASE

LGATE

1

Q

2

L

1

V

OUT

+

C

OUT

FIGURE 8. DC-DC CONVERTER

9

Page 10

Small Outline Plastic Packages (SOIC)

ISL6431

N

INDEX

AREA

123

-AD

e

B

0.25(0.010) C AM BS

E

-B-

SEATING PLANE

A

-C-

M

0.25(0.010) BM M

H

α

µ

A1

0.10(0.004)

L

hx45

o

C

NOTES:

1. Symbolsaredefinedin the “MO SeriesSymbol List” in Section2.2 of

Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension“D” does not includemoldflash,protrusionsor gate burrs.

Moldflash,protrusionandgate burrsshallnot exceed 0.15mm(0.006

inch) per side.

4. Dimension“E” does not include interlead flash or protrusions. Interlead flash and protrusions shall not exceed 0.25mm (0.010 inch) per

side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminalnumbersare shown for reference only.

9. The lead width “B”, as measured 0.36mm (0.014 inch) or greater

above the seating plane, shall not exceed a maximum value of

0.61mm (0.024 inch).

10. Controllingdimension: MILLIMETER.Converted inch dimensions

are not necessarilyexact.

M8.15 (JEDEC MS-012-AA ISSUE C)

8 LEAD NARROW BODY SMALL OUTLINE PLASTIC

PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.0532 0.0688 1.35 1.75 -

A1 0.0040 0.0098 0.10 0.25 -

B 0.013 0.020 0.33 0.51 9

C 0.0075 0.0098 0.19 0.25 D 0.1890 0.1968 4.80 5.00 3

E 0.1497 0.1574 3.80 4.00 4

e 0.050 BSC 1.27 BSC H 0.2284 0.2440 5.80 6.20 h 0.0099 0.0196 0.25 0.50 5

L 0.016 0.050 0.40 1.27 6

N8 87

o

α

0

o

8

o

0

o

8

Rev. 0 12/93

NOTESMIN MAX MIN MAX

-

All Intersil products are manufactured, assembled and tested utilizingISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at website www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without notice.

Accordingly, the reader is cautionedto verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and reliable. However,no responsibilityis assumed by Intersil or its subsidiaries for its use; nor for any infringementsof patents or other rights of third partieswhich may result from its use. No

license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information r egarding Intersil Corporation and its products, see web site www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

2401 Palm Bay Road

Palm Bay, FL 32905

TEL: (321) 724-7000

FAX: (321) 724-7240

EUROPE

Intersil SA

MercureCenter

100,RuedelaFusee

1130 Brussels,Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

10

ASIA

Intersil Ltd.

8F-2,96, Sec. 1, Chien-kuo North,

Taipei, Taiwan 104

Republic of China

TEL: 886-2-2515-8508

FAX: 886-2-2515-8369

Loading...

Loading...