®

www.BDTIC.com/Intersil

O

F

D

E

D

N

E

M

T

O

N

IB

Data Sheet August 2004

S

S

O

P

D

O

R

P

M

O

C

E

R

B

U

S

E

L

I

:

T

C

U

W

E

N

R

T

U

T

I

T

S

2

1

4

6

L

S

D

E

G

I

S

E

S

N

ISL6414

FN9128.1

Triple Output, Low-Noise LDO Regulator

with Integrated Reset Circuit

The ISL6414 is an ultra low noise triple output LDO regulator

with microprocessor reset circuit and is optimized for

powering wireless chip sets. The IC accepts an input voltage

range of 3.0V to 3.6V and provides three regulated output

voltages: 1.8V (LDO1), 2.84V (LDO2), and another ultra

clean 2.84V (LDO3). On chip logic provides sequencing

between LDO1 and LDO2 for BBP/MAC and I/O supply

voltage outputs. LDO3 features ultra low noise that does not

typically exceed 30µV RMS to aid VCO stability. High

integration and the thin Quad Flat No-lead (QFN) package

makes ISL6414 an ideal choice to power many of today’s

small form factor industry standard wireless cards, such as

PCMCIA, mini-PCI and Cardbus-32.

The ISL6414 uses an internal PMOS transistor as the pass

device. The SHDN pin controls LDO1 and LDO2 outputs

whereas SHDN3 controls LDO3 output. Internal voltage

sequencing insures that LDO1 output (1.8V supply) is

always stabilized before LDO2 is turned on. When powering

down, power to the LDO2 is removed before the LDO1

output goes off. The ISL6414 also integrates RESET

function, which eliminates the need for additional RESET IC

required in WLAN applications. The IC asserts a RESET

signal whenever the V

threshold, keeping it asserted for at least 25ms after V

risen above the reset threshold. An output fault detection

circuit indicates loss of regulation on LDO1. Other features

include an overcurrent protection, thermal shutdown and

reverse battery protection.

supply voltage drops below a preset

IN

IN

has

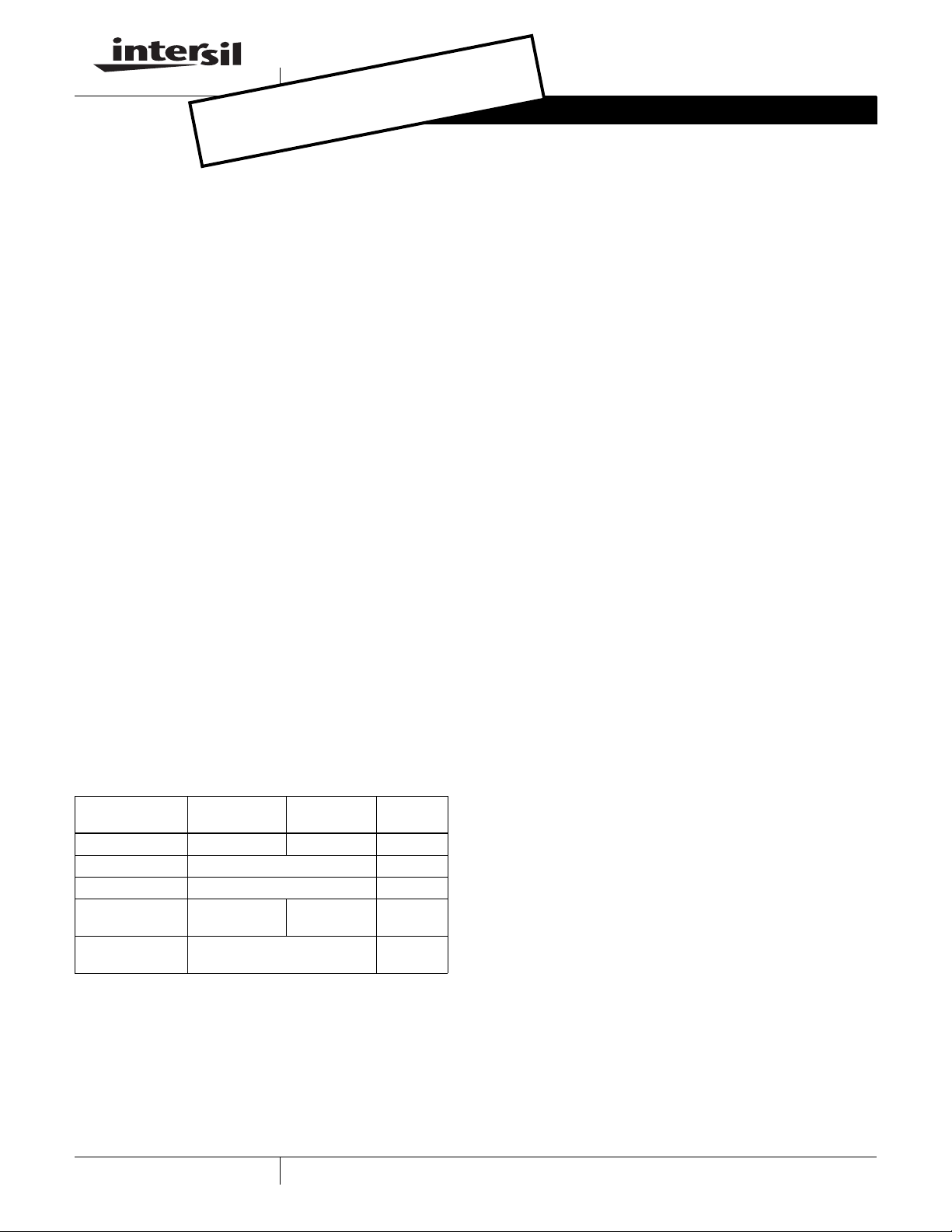

Ordering Information

TEMP.

PART NUMBER

ISL6414IR -40 to +85 16 Ld QFN L16.4x4

ISL6414IR-T5K 16 Ld QFN Tape and Reel L16.4x4

ISL6414IR-TK 16 Ld QFN Tape and Reel L16.4x4

ISL6414IRZ (Note) -40 to +85 16 Ld QFN

ISL6414IRZ-TK

(Note)

NOTE: Intersil Pb-free plus anneal products employ special Pb-free

material sets; molding compounds/die attach materials and 100%

matte tin plate termination finish, which are RoHS compliant and

compatible with both SnPb and Pb-free soldering operations. Intersil

Pb-free products are MSL classified at Pb-free peak reflow

temperatures that meet or exceed the Pb-free requirements of

IPC/JEDEC J STD-020.

RANGE (°C) PACKAGE

(Pb-free)

16 Ld QFN Tape and Reel

(Pb-free)

PKG.

DWG. #

L16.4x4

L16.4x4

Features

• Small DC/DC Converter Size

- Three LDOs and RESET Circuitry in a Low-Profile

4x4mm QFN Package

• High Output Current

- LDO1, 1.8V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500mA

- LDO2, 2.84V. . . . . . . . . . . . . . . . . . . . . . . . . . . . 300mA

- LDO3, 2.84V. . . . . . . . . . . . . . . . . . . . . . . . . . . . 200mA

• Ultra-Low Dropout Voltage

- LDO2, 2.84V. . . . . . . . . . . . . . . 125mV (typ.) at 300mA

- LDO3, 2.84V. . . . . . . . . . . . . . . 100mV (typ.) at 200mA

• Ultra-Low Output Voltage Noise

-<30µV

• Stable with Smaller Ceramic Output Capacitors

• Voltage Sequencing for BBP/MAC and Analog Supplies

• Extensive Protection and Monitoring Features

- Overcurrent and short circuit protection

- Thermal shutdown

- Reverse battery protection

- FAULT indicator

• Logic-Controlled Dual Shutdown Pins

• Integrated Microprocessor Reset Circuit

- Programmable Reset Delay

- Complimentary Reset Outputs

• Proven Reference Design for Total WLAN System

Solution

• QFN Package Option

- Compliant to JEDEC PUB95 MO-220 QFN - Quad Flat

No Leads - Product Outline

- Near Chip-Scale Package Footprint Improves PCB

Efficiency and Is Thinner in Profile

• Pb-Free Plus Anneal Available (RoHS Compliant)

(typ.) for LDO3 (VCO Supply)

RMS

Applications

• PRISM® 3, PRISM GT™, and PRISM WWR Chipsets

•WLAN Cards

- PCMCIA, Cardbus32, MiniPCI Cards

- Compact Flash Cards

• Hand-Held Instruments

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright © Intersil Americas Inc. 2003-2005. All Rights Reserved.

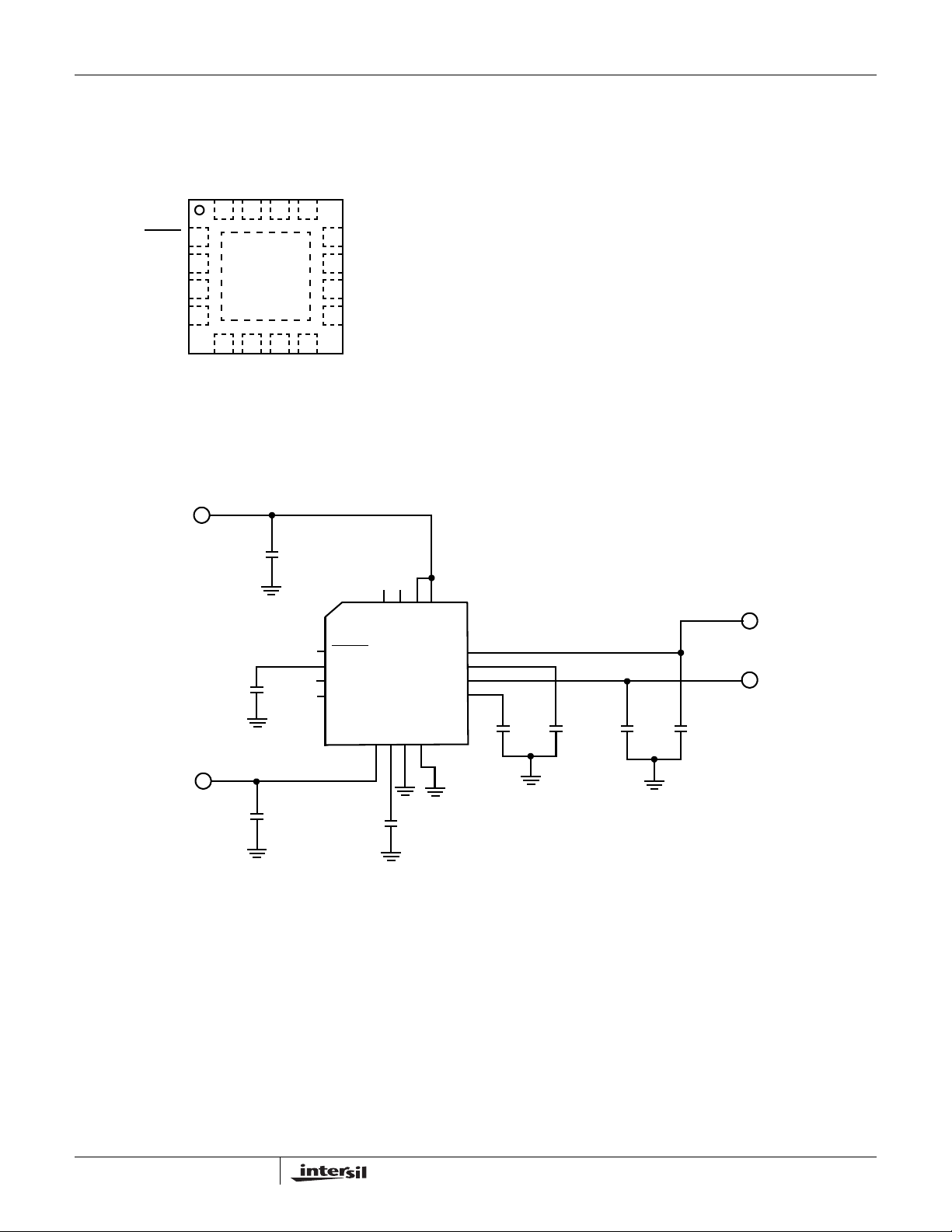

Pinout

www.BDTIC.com/Intersil

ISL6414 (QFN)

TOP VIEW

RESET

FAULT

VIN

1516 14 13

ISL6414

VIN

RESET

CT

SHDN

SHDN3

1

2

3

4

6578

CC3

OUT3

GND3

12

11

10

9

GND

Typical Application Schematic

+3.3V

V

IN

+

C8

3.3µF

1

RESET

2

CT

3

4

SHDN

SHDN3

V

OUT3

+2.84V

C7

0.01µF

C5

3.3µF

OUT1

CC1

OUT2

CC2

16

RESET

ISL6414

CC3

OUT3

5

6

14

15

FAULT

GND3

7

E

C6

0.033µF

VIN

GND

8

13

VIN

OUT1

OUT2

CC1

CC2

E

+1.8V

V

OUT1

12

11

10

9

C4

0.033µF

C3

0.033µF

C2

3.3µF

C1

3.3µF

+2.84V

V

OUT2

2

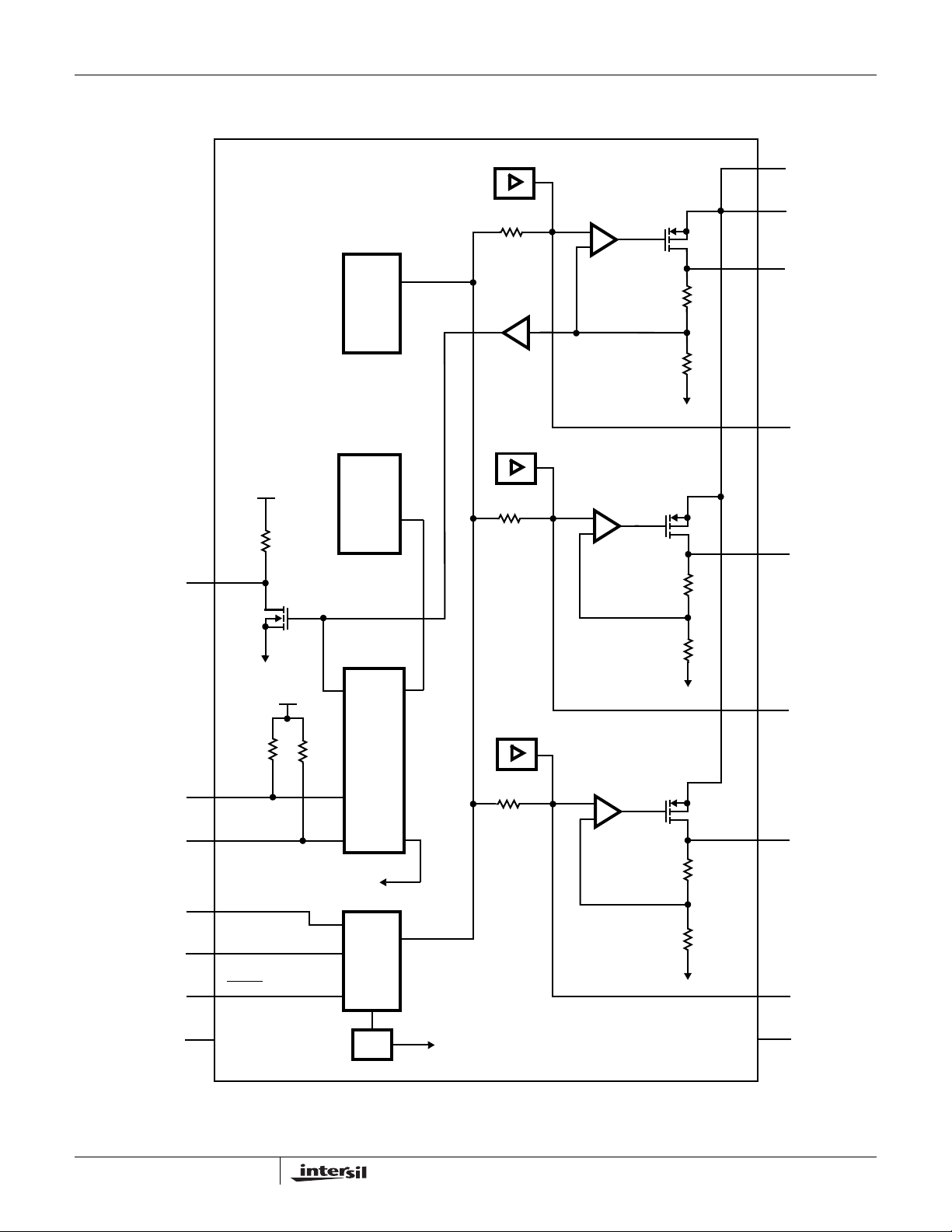

Functional Block Diagram

www.BDTIC.com/Intersil

VIN

15

FAU LT

BAND

GAP

REF.

1.2V

THERMAL

SHUT

DOWN

150°C

ISL6414

WINDOW

COMP

Gm

Gm

13

VIN

14

VIN

+

-

LDO1

+

-

LDO2

OUT1

OUT2

12

11CC1

10

VIN

CONTROL

LOGIC

3

SHDN

4

SHDN3

ENABLES

2

CT

16

RESET

1

RESET

8

GND

RESET

POR

POR

Gm

+

-

LDO3

CC2

OUT3 5

CC3

GND3

9

6

7

3

ISL6414

www.BDTIC.com/Intersil

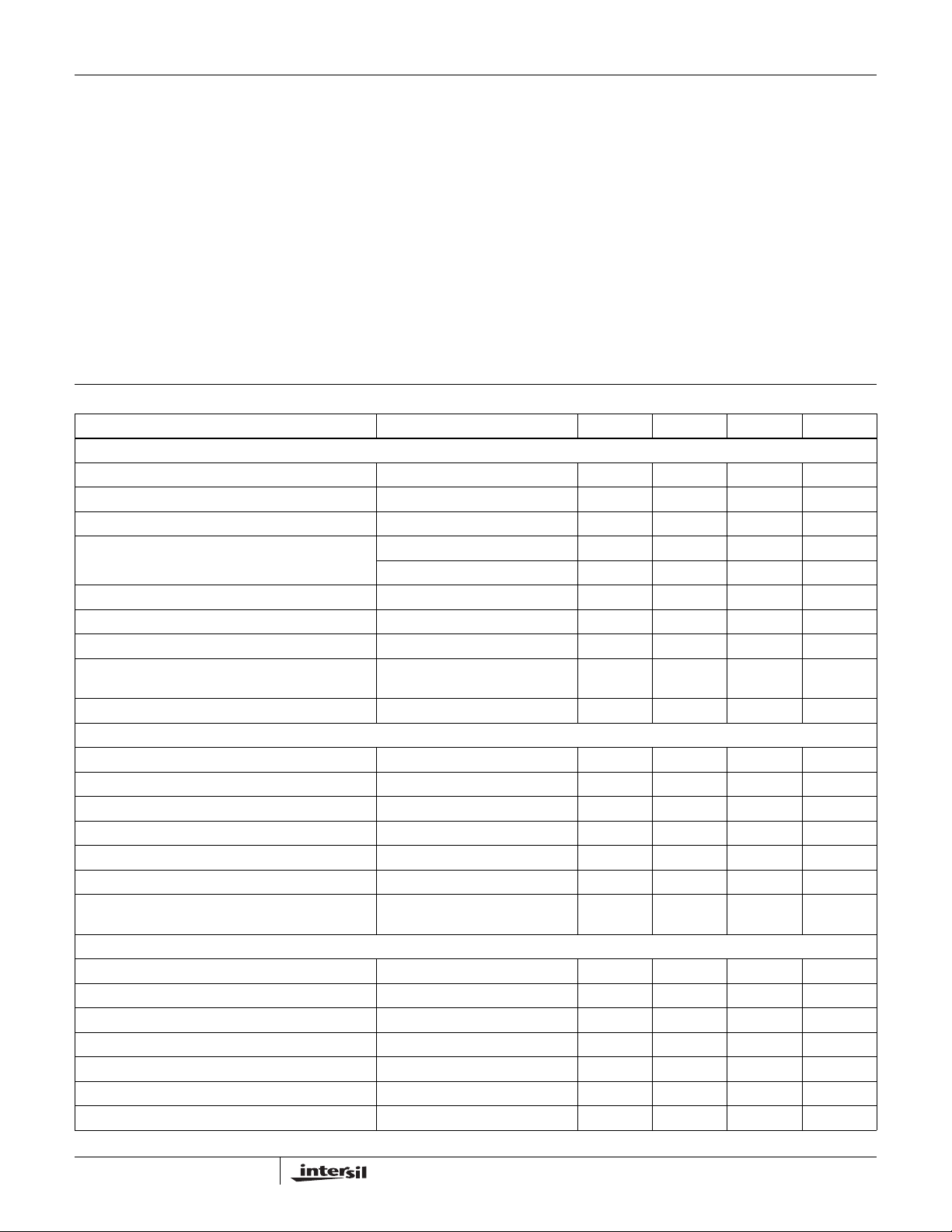

Absolute Maximum Ratings (Note 1) Thermal Information

VIN, SHDN/SHDN3 to GND/GND3 . . . . . . . . . . . . . . . -7.0V to 7.0V

SET, CC, FAULT to GND/GND3 . . . . . . . . . . . . . . . . . -0.3V to 7.0V

Output Current (Continuous)

LDO1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500mA

LDO2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300mA

LDO3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200mA

ESD Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Class 1

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

1. All voltages are with respect to GND.

is measured in free air with the component mounted on a high effective thermal conductivity test board with “direct attach” features. See

2. θ

JA

Tech Brief TB379.

3. For θ

, the “case temp” location is the center of the exposed metal pad on the package underside. See Tech Brief TB379.

JC

Thermal Resistance (Typical Notes 2, 3) θ

QFN Package. . . . . . . . . . . . . . . . . . . . 46 8.0

Maximum Junction Temperature (Plastic Package) . -55°C to 150°C

Maximum Storage Temperature Range. . . . . . . . . . . -65°C to 150°C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . . 300°C

Operating Temperature Range . . . . . . . . . . . . . . . . . . -40°C to 85°C

(°C/W) θJC (°C/W)

JA

Electrical Specifications V

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

GENERAL SPECIFICATIONS

V

Voltage Range (Note 7) 3.0 3.3 3.6 V

IN

Operating Supply Current I

Shutdown Supply Current SHDN/SHDN3 = GND - 5 15 µA

SHDN/SHDN3 Input Threshold V

FAULT Output Low Voltage I

Thermal Shutdown Temperature (Note 6) 145 150 160 °C

Thermal Shutdown Hysteresis - 20 - °C

Start-up Time C

Input Undervoltage Lockout (Note 6) Rising 75mV Hysteresis 2.2 2.45 2.65 V

LDO1 SPECIFICATIONS

Output Voltage (V

Output Voltage Accuracy I

Line Regulation V

Load Regulation I

Maximum Output Current (I

Output Current Limit (Note 6) 0.55 0.6 1.0 A

Output Voltage Noise 10Hz < f < 100kHz, C

LDO2 SPECIFICATIONS

Output Voltage (V

Output Voltage Accuracy I

Maximum Output Current (I

Output Current Limit (Note 6) 330 770 - mA

Dropout Voltage (Note 4) I

Line Regulation V

Load Regulation I

) -1.8- V

OUT1

OUT1

) -2.84- V

OUT2

OUT2

= +3.3V, Compensation Capacitor = 33nF, TA = 25°C, Unless Otherwise Noted.

IN

= 0mA - 600 850 µA

OUT

, VIN = 3V to 3.6V 2.0 - - V

IH

V

, VIN = 3V to 3.6V - - 0.4 V

IL

= 2mA - - 0.25 V

SINK

= 10µF, V

OUT

value

= 10mA -1.5 - 1.5 %

OUT

= 3.0V to 3.6V, I

IN

= 10mA to 500mA -1.5 - 1.5 %

OUT

) (Note 6) 500 - - mA

= 50mA

I

OUT

= 10mA -1.5 - 1.5 %

OUT

) (Note 6) VIN = 3.6V 300 - - mA

= 300mA - 125 220 mV

OUT

= 3.0V to 3.6V, I

IN

= 10mA to 300mA - 0.2 1.0 %

OUT

= 90% of final

OUT

OUT

OUT

OUT

- 120 - µs

= 10mA -0.15 0.0 0.15 %/V

= 4.7µF,

= 10mA -0.15 0.0 0.15 %/V

-115-µV

RMS

4

ISL6414

www.BDTIC.com/Intersil

Electrical Specifications V

= +3.3V, Compensation Capacitor = 33nF, TA = 25°C, Unless Otherwise Noted. (Continued)

IN

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Output Voltage Noise 10Hz < f < 100kHz, I

C

= 2.2µF-65-µV

OUT

C

= 10µF-60-µV

OUT

OUT

= 10mA

RMS

RMS

LDO3 SPECIFICATIONS

Output Voltage (V

Output Voltage Accuracy I

Maximum Output Current (I

) -2.84- V

OUT3

= 10mA -1.5 - 1.5 %

OUT

) (Note 6) VIN = 3.6V 200 - - mA

OUT3

Output Current Limit (Note 6) 250 400 - mA

Dropout Voltage (Note 4) I

Line Regulation V

Load Regulation I

Output Voltage Noise 10Hz < f < 100kHz, I

= 200mA - 100 200 mV

OUT

= 3.0V to 3.6V, I

IN

= 10mA to 200mA - 0.2 1.0 %

OUT

= 2.2µF-30-µV

C

OUT

C

= 10µF-20-µV

OUT

= 10mA -0.15 0.0 0.15 %/V

OUT

= 10mA

OUT

RMS

RMS

RESET BLOCK SPECIFICATIONS

RESET Threshold 2.564 2.630 2.696 V

RESET Threshold Hysteresis (Note 6) 6.3 - - mV

V

to RESET Delay VCC = VTH to VTH - 100mV - 20 - µs

IN

RESET/RESET

Active Timeout Period (Notes 5,6) 25 - - ms

FAULT

Rising Threshold % of VOUT 5.0 5.5 6.0 %

Falling Threshold % of VOUT -5.0 -5.5 -5.0 %

NOTES:

4. Specifications at -40°C are guaranteed by design/characterization, not production tested.

5. The dropout voltage is defines as V

- V

OUT,

when V

IN

is 50mV below the value of V

OUT

OUT

for VIN = V

OUT

+ 0.5V.

6. The RESET time is linear with CT at a slope of 2.5ms/nF. Thus, at 10nF (0.01µF) the RESET time is 25ms; at 100nF (0.1µF) the RESET time

would be 250ms.

7. Guaranteed by design, not production tested.

8. LDO1 is guaranteed by design to be within regulation at 2.7V minimum input voltage.

Typical Performance Curves

0.140

0.120

0.100

0.080

(V)

D

V

0.060

0.040

0.020

0.000

0.00 0.05 0.10 0.15 0.20 0.25 0.30

I

(Amps)

O

FIGURE 1. LD02 DROPOUT VOLTAGE FIGURE 2. LD03 DROPOUT VOLTAGE

5

0.100

0.090

0.080

0.070

0.060

(V)

D

0.050

V

0.040

0.030

0.020

0.010

0.000

0.00 0.05 0.10 0.15

(Amps)

I

O

0.30

Typical Performance Curves (Continued)

www.BDTIC.com/Intersil

V

= 1.8V

20

0

OUTPUT

VO LTAGE ( mV)

4

OUT

LOAD = 50mA

ISL6414

V

= 2.84V

20

0

OUTPUT

VOLTAGE (mV)

4

OUT

LOAD = 50mA

3

INPUT

VOLTAGE (V)

TIME (1ms/DIV)

FIGURE 3. LINE TRANSIENT RESPONSE (V

V

20

0

OUTPUT

VOLTAGE (mV)

4

3

INPUT

VOLTAGE (V)

TIME (1ms/DIV)

OUT

LOAD = 50mA

FIGURE 5. LINE TRANSIENT RESPONSE (V

3

INPUT

VOLTAGE (V)

TIME (1ms/DIV)

1) FIGURE 4. LINE TRANSIENT RESPONSE (V

OUT

= 2.84V

3) FIGURE 6. LOAD TRANSIENT RESPONSE (V

OUT

10

5

0

DEVIATION (mV)

OUTPUT VOLTAGE

100

LOAD

0

CURRENT (mA)

TIME (2ms/DIV)

V

V

OUT

= 3.3V

IN

OUT

= 1.8V

OUT

2)

1)

V

= 2.84V

10

5

0

DEVIATION (mV)

OU TPU T VOLTA GE

100

LOAD

0

CURRENT (mA)

TIME (2ms/DIV)

FIGURE 7. LOAD TRANSIENT RESPONSE (V

V

OUT

= 3.3V

IN

10

5

0

DEVIATION (mV)

OU TPU T VOLTA GE

100

LOAD

0

CURRENT (mA)

2) FIGURE 8. LOAD TRANSIENT RESPONSE (V

OUT

6

TIME (2ms/DIV)

V

V

OUT

= 3.3V

IN

= 2.84V

OUT

3)

Typical Performance Curves (Continued)

www.BDTIC.com/Intersil

ISL6414

1.2

1.1

1

0.9

LOAD REGULATION (%)

0.8

-40 -15 10 35 60 85

TEMPERATURE (°C)

1.6

1.5

1.4

1.3

1.2

LOAD REGULATION (%)

1.1

1

-40 -15 10 35 60 85

TEMPERATURE (°C)

FIGURE 9. LD01 LOAD REGULATION vs TEMPERATURE FIGURE 10. LD02 LOAD REGULATION vs TEMPERATURE

1.4

1.3

1.2

1.1

1

LOAD REGULATION (%)

0.9

0.8

-40 -15 10 35 60 85

TEMPERATURE (°C)

0.04

0.03

0.02

0.01

0

-0.01

-0.02

-0.03

LINE REGULATION (%/V)

-0.04

-0.05

-40 -15 10 35 60 85

TEMPERATURE (°C)

FIGURE 11. LD03 LOAD REGULATION vs TEMPERATURE FIGURE 12. LD01 LINE REGULATION vs TEMPERATURE

0

-0.01

-0.02

-0.03

-0.04

LINE REGULATION (%/V)

-0.05

-0.06

-40 -15 10 35 60 85

TEMPERATURE (°C)

0

-0.002

-0.004

-0.006

-0.008

-0.001

-0.012

LINE REGULATION (%/V)

-0.014

-0.016

-40 -15 10 35 60 85

TEMPERATURE (°C)

FIGURE 13. LD02 LINE REGULATION vs TEMPERATURE FIGURE 14. LD03 LINE REGULATION vs TEMPERATURE

7

Typical Performance Curves (Continued)

www.BDTIC.com/Intersil

ISL6414

8.3

8.25

8.2

8.15

8.1

8.05

OPERATING CURRENT (µA)

8

-40 -15 10 35 60 85

TEMPERATURE (°C)

720

710

700

690

680

670

660

650

640

630

OPERATING CURRENT (µA)

620

610

-40 -15 10 35 60 85

TEMPERATURE (°C)

FIGURE 15. SHUTDOWN CURRENT vs TEMPERATURE FIGURE 16. OPERATING CURRENT vs TEMPERATURE

180

160

140

120

100

80

60

40

DROPOUT VOLTAGE (mV)

20

0

-40 -15 10 35 60 85

TEMPERATURE (°C)

100

90

80

70

(mV)

60

50

40

DROPOUT

30

20

10

0

-40 -10 25 85

TEMPERATURE (°C)

FIGURE 17. LD02 DROPOUT VOLTAGE vs TEMPERATURE FIGURE 18. LD03 DROPOUT VOLTAGE vs TEMPERATURE

0

-10

-20

-30

-40

PSRR (dB)

-50

VOLTAGE (V)

TIME (µs)

FIGURE 19. SHUTDOWN vs RESET and FAULT

-60

-70

-80

0.01 0.1 1 10 100 1000

FREQUENCY (kHz)

FIGURE 20. POWER SUPPLY REJECTION RATIO vs

FREQUENCY

8

ISL6414

www.BDTIC.com/Intersil

Pin Descriptions

OUT1 - This pin is the output for LDO1. Bypass with a

minimum of 2.2µF, low ESR capacitor to GND for stable

operation.

V

- Supply input pins. Connect to input power source.

IN

Bypass with 2.2µF capacitor to GND. Both V

tied together on the PC board, close to the IC.

GND - Ground pin for LDO1 and LDO2.

CC1 - Compensation Capacitor for LDO1. Connect a

0.033µF capacitor from CC1 to GND.

SHDN - Shutdown input for LDO1 and LDO2. Connect to IN

for normal operation. Drive SHDN pin LOW to turn off LDO1

and LDO2.

OUT2 - This pin is the output for LDO2. Bypass with a

minimum of 2.2µF, low ESR capacitor to GND for stable

operation.

CT - Timing pin for the RESET circuit pulse width.

CC2 - Compensation capacitor for LDO2. Connect a

0.033µF capacitor from CC2 to GND.

OUT3 - This pin is output for LDO3. Bypass with a minimum

of 2.2µF, low ESR capacitor to GND3 for stable operation.

pins must be

IN

Functional Description

The ISL6414 is a 3-in-1 multi-output, low dropout, regulator

designed for wireless chipset power applications. It supplies

three fixed output voltages 1.8V, 2.84V and 2.84V. The 1.8V

output from LDO1 remains active down to a V

(min.), ensuring proper BBP/MAC operation. Each LDO

consists of a 1.2V reference, error amplifier, MOSFET driver,

P-Channel pass transistor, dual-mode comparator and

internal feedback voltage divider.

The 1.2V band gap reference is connected to the error

amplifier’s inverting input. The error amplifier compares this

reference to the selected feedback voltage and amplifies the

difference. The MOSFET driver reads the error signal and

applies the appropriate drive to the P-Channel pass

transistor. If the feedback voltage is lower then the reference

voltage, the pass transistor gate is pulled lower, allowing

more current to pass and increasing the output voltage. If the

feedback voltage is higher then the reference voltage, the

pass transistor gate is driven higher, allowing less current to

pass to the output. The output voltage is fed back through an

internal resistor divider connected to OUT1/2/3 pins.

Additional blocks include an output overcurrent protection,

reverse battery protection, thermal sensor, fault detector,

RESET function and shutdown logic.

= 2.7V

IN

GND3 - Ground pin for LDO3.

CC3 - Compensation capacitor for LDO3. Connect a

0.033µF capacitor from CC3 to GND3.

SHDN3 - Shutdown input for LDO3. Connect to V

normal operation. Drive SHDN3 pin LOW to turn off LDO3.

FAULT - This is the power good indicator for LDO1. When

the 1.8V output is out of regulation (>±5%, typ.), this pin

goes LOW. This pin also goes LOW during thermal

shutdown and any overcurrent event on LDO1. Connect this

pin to GND, if unused. This pin remains HIGH in the

shutdown mode, as controlled by the SHDN pin (refer to

Figure 19).

RESET

- This pin is the active-LOW output of the push-pull

output stage of the integrated reset supervisory circuit. The

reset circuit monitors V

pin, if V

output remains LOW, while the V

reset threshold, and for at least 25ms, after V

the RESET threshold.

RESET - This pin is the active-HIGH output of the push-pull

output stage of the integrated reset supervisory circuit. The

reset circuit monitors V

pin, if V

output remains HIGH, while the V

RESET threshold, and for at least 25ms, after V

above the RESET threshold.

falls below the RESET threshold. The RESET

IN

falls below the RESET threshold. The RESET

IN

and asserts a RESET output at this

IN

pin voltage is below the

IN

and asserts a RESET output at this

IN

pin voltage is below the

IN

for

IN

rises above

IN

rises

IN

Internal P-Channel Pass Transistors

The ISL6414 features a typical 0.5Ω r

MOSFET pass transistors. This provides several advantages

over similar designs using PNP bipolar pass transistors. The

P-Channel MOSFET requires no base drive, which reduces

quiescent current considerably. PNP based regulators waste

considerable current in dropout when the pass transistor

saturates. They also use high base drive currents under

large loads. The ISL6414 does not suffer from these

problems.

DS(ON)

P-channel

Integrated RESET for MAC/ Baseband Processors

The ISL6414 includes a microprocessor supervisory block.

This block eliminates the extra RESET IC and external

components needed in wireless chipset applications. This

block performs a single function; it asserts a RESET signal

whenever the V

threshold, keeping it asserted for a programmable time (set

by external capacitor CT) after the V

above the RESET threshold.

The push pull output stage of the reset circuit provides both

an active-Low and an active-HIGH output. This function is

guaranteed to be in the correct state for V

reset comparator is designed to ignore transients on the V

pin. The RESET threshold for ISL6414 is 2.63V typical.

In addition to issuing a reset to the microprocessor during

power-up, power down and brownout conditions, this block

is relatively immune to short duration, negative-going V

transients/glitches.

supply voltage decreases below a preset

IN

pin voltage has risen

IN

down to 1V. The

IN

IN

IN

9

ISL6414

www.BDTIC.com/Intersil

Output Voltages

The ISL6414 provides fixed output voltages for use in

Wireless Chipset applications. Internal trimmed resistor

networks set the typical output voltages as shown here:

V

OUT1

= 1.8V; V

OUT2

= 2.84V; V

OUT3

= 2.84V.

Shutdown

Driving the SHDN input LOW puts both LDO1 and LDO2 in

shutdown mode. Driving the SHDN3 input LOW puts LDO3

in shutdown mode. Pulling the SHDN and SHDN3 pins LOW

simultaneously, puts the complete chip into shutdown mode,

and supply current drops to 5µA typical. Both SHDN and

SHDN3 inputs have internal pull-up resistors, so that in

normal operation the outputs are always enabled; external

pull-up resistors are not required. During shutdown mode

using the SHDN pin, the FAULT output will remain HIGH

(refer to Figure 19).

Current Limit

The ISL6414 monitors and controls the pass transistor’s

gate voltage to limit the output current. The current limit for

LDO1 is 550mA, LDO2 is 330mA and LDO3 is 250mA. The

output can be shorted to ground without damaging the part

due to the current limit and thermal protection features.

Thermal Overload Protection

Thermal overload protection limits total power dissipation in

the ISL6414. When the junction temperature (T

+150°C, the thermal sensor sends a signal to the shutdown

logic, turning off the pass transistor and allowing the IC to

cool. The pass transistor turns on again after the IC’s

junction temperature typically cools by 20°C, resulting in a

pulsed output during continuous thermal overload

conditions. Thermal overload protection protects the

ISL6414 against fault conditions. For continuous operation,

do not exceed the absolute maximum junction temperature

rating of +150°C.

) exceeds

J

Operating Region and Power Dissipation

The maximum power dissipation of ISL6414 depends on the

thermal resistance of the IC package and circuit board, the

temperature difference between the die junction and ambient

air, and the rate of air flow. The power dissipated in the

device is:

PT = P1 + P2 + P3, where

P1 = I

P2 = I

P3 = I

The maximum power dissipation is:

Pmax = (T

Where T

is the thermal resistance from the junction to the surrounding

environment.

OUT1

OUT2

OUT3

JMAX

(VIN – V

(VIN – V

(VIN- V

– TA)/θ

JMAX

= 150°C, TA = ambient temperature, and θJA

OUT1

OUT2

OUT3

)

)

)

JA

The ISL6414 package features an exposed thermal pad on

its underside. This pad lowers the thermal resistance of the

package by providing a direct heat conduction path from the

die to the PC board. Additionally, the ISL6414’s ground

(GND/GND3) performs the dual function of providing an

electrical connection to system ground and channeling heat

away. Connect the exposed backside pad and GND to the

system ground using a large pad or ground plane, or through

multiple vias to the ground plane layer.

Reverse Input Protection

The ISL6414 has a unique protection scheme that limits the

reverse supply current to less than 1mA when V

below GND. The circuitry monitors the polarity of these two

pins, disconnecting the internal circuitry and parasitic diodes

when the applied voltage is reversed. This feature prevents

the device from overheating and damaging an improperly

installed input supply.

IN

falls

Integrator Circuitry

The ISL6414 uses an external 33nF compensation capacitor

for minimizing load and line regulation errors and for

lowering output noise. When the output voltage shifts due to

varying load current or input voltage, the integrator capacitor

voltage is raised or lowered to compensate for the

systematic offset at the error amplifier. Compensation is

limited to ±5% to minimize transient overshoot when the

device goes out of dropout, current limit, or thermal

shutdown.

Fault-Detection Circuitry

The FAULT pin monitors LDO1 output regulation, as well as

fault conditions such as current limit and thermal shutdown.

The FAULT output goes LOW, if the LDO1 output is out of

regulation by ±5.5% (typ.). During shutdown mode using the

SHDN pin, the FAULT output will remain HIGH (refer to

Figure 19).

Applications Information

Capacitor Selection and Regulator Stability

Capacitors are required at the ISL6414’s input and output for

stable operation over the entire load range and the full

temperature range. Use >1µF capacitor at the input of

ISL6414. The input capacitor lowers the source impedance

of the input supply. Larger capacitor values and lower ESR

provides better PSRR and line transient response. The input

capacitor must be located at a distance of not more then 0.5

inches from the V

analog ground. Any good quality ceramic or tantalum can be

used as an input capacitor.

The output capacitor must meet the requirements of minimum

amount of capacitance and ESR for all three LDO’s. The

ISL6414 is specifically designed to work with small ceramic

output capacitors. The output capacitor’s ESR affects stability

and output noise. Use an output capacitor with an ESR of

pins of the IC and returned to a clean

IN

10

ISL6414

www.BDTIC.com/Intersil

50mΩ or less to insure stability and optimum transient

response. For stable operation, a ceramic capacitor whose

value is minimum 3.3µF is recommended for V

300mA output current and 2.2µF is recommended for V

and V

limit to the output capacitor value. Larger capacitor can

reduce noise and improve load transient response, stability

and PSRR. The output capacitor should be located very close

to V

should be returned to a clean analog ground.

each at 200mA load current. There is no upper

OUT3

pins to minimize impact of PC board inductances and

OUT

OUT1

for

OUT2

Input-Output (Dropout) Voltage

A regulator’s minimum input-output voltage differential (or

dropout voltage) determines the lowest usable supply voltage.

In battery-powered systems, this determines the useful endof-life battery voltage. Because the ISL6414 uses a P-channel

MOSFET pass transistor, its dropout voltage is a function of

r

(typically 0.5) multiplied by the load current.

DS(ON)

Noise, PSSR and Transient Response

The ISL6414 is designed to operate with low dropout

voltages and low quiescent current while still maintaining

good noise, transient response, and AC rejection. When

operating from noisy sources, improved supply-noise

rejection and transient response can be achieved by

increasing the values of the input and output bypass

capacitors and through passive filtering techniques.

The ISL6414 load transient response graph is presented in

application note AN1080. Increasing the output capacitor

value and decreasing the ESR attenuates the overshoot.

11

ISL6414

www.BDTIC.com/Intersil

Quad Flat No-Lead Plastic Package (QFN)

Micro Lead Frame Plastic Package (MLFP)

L16.4x4

16 LEAD QUAD FLAT NO-LEAD PLASTIC PACKAGE

(COMPLIANT TO JEDEC MO-220-VGGC ISSUE C)

MILLIMETERS

SYMBOL

A 0.80 0.90 1.00 A1 - - 0.05 A2 - - 1.00 9

A3 0.20 REF 9

b 0.23 0.28 0.35 5, 8

D 4.00 BSC D1 3.75 BSC 9

D2 1.95 2.10 2.25 7, 8

E 4.00 BSC -

E1 3.75 BSC 9

E2 1.95 2.10 2.25 7, 8

e 0.65 BSC -

k0.25 - - -

L 0.50 0.60 0.75 8

L1 - - 0.15 10

N162

Nd 4 3

Ne 4 3

P- -0.609

θ --129

NOTES:

1. Dimensioning and tolerancing conform to ASME Y14.5-1994.

2. N is the number of terminals.

3. Nd and Ne refer to the number of terminals on each D and E.

4. All dimensions are in millimeters. Angles are in degrees.

5. Dimension b applies to the metallized terminal and is measured

between 0.15mm and 0.30mm from the terminal tip.

6. The configuration of the pin #1 identifier is optional, but must be

located within the zone indicated. The pin #1 identifier may be

either a mold or mark feature.

7. Dimensions D2 and E2 are for the exposed pads which provide

improved electrical and thermal performance.

8. Nominal dimensions are provided to assist with PCB Land Pattern

Design efforts, see Intersil Technical Brief TB389.

9. Features and dimensions A2, A3, D1, E1, P & θ are present when

Anvil singulation method is used and not present for saw

singulation.

10. Depending on the method of lead termination at the edge of the

package, a maximum 0.15mm pull back (L1) maybe present. L

minus L1 to be equal to or greater than 0.3mm.

NOTESMIN NOMINAL MAX

Rev. 5 5/04

All Intersil products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without notice.

Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and reliable.

However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result from its

use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

12

Loading...

Loading...