查询ISL6410供应商

®

ISL6410, ISL6410A

Data Sheet September 17, 2004

Single Synchronous Buck Regulators

with Integrated FET

The ISL6410, ISL6410A are synchronous current-mode

PWM regulators designed to provide a total DC-DC solution

for microcontrollers, microprocessors, CPLDs, FPGAs, core

processors/BBP/MAC, and ASICs. The ISL6410 should be

selected for applications using 3.3V ±10% as an input

voltage and the ISL6410A in applications requiring 5.0V

±10%.

These synchronous current mode PWM regulators have

integrated N- and P-Channel power MOSFETs and provide

pre-set pin programmable outputs. Synchronous rectification

with internal MOSFETs is used to achieve higher efficiency

and a reduced external component count. The operating

frequency of 750kHz typical allows the use of small inductor

and capacitor values. The device can be synchronized to an

external clock signal in the range of 500kHz to 1MHz. A

power good signal “PG” is generated when the output

voltage falls outside the regulation limits. Other features

include overcurrent protection and thermal overload

shutdown. The ISL6410, ISL6410A are available in an

MSOP 10 lead package.

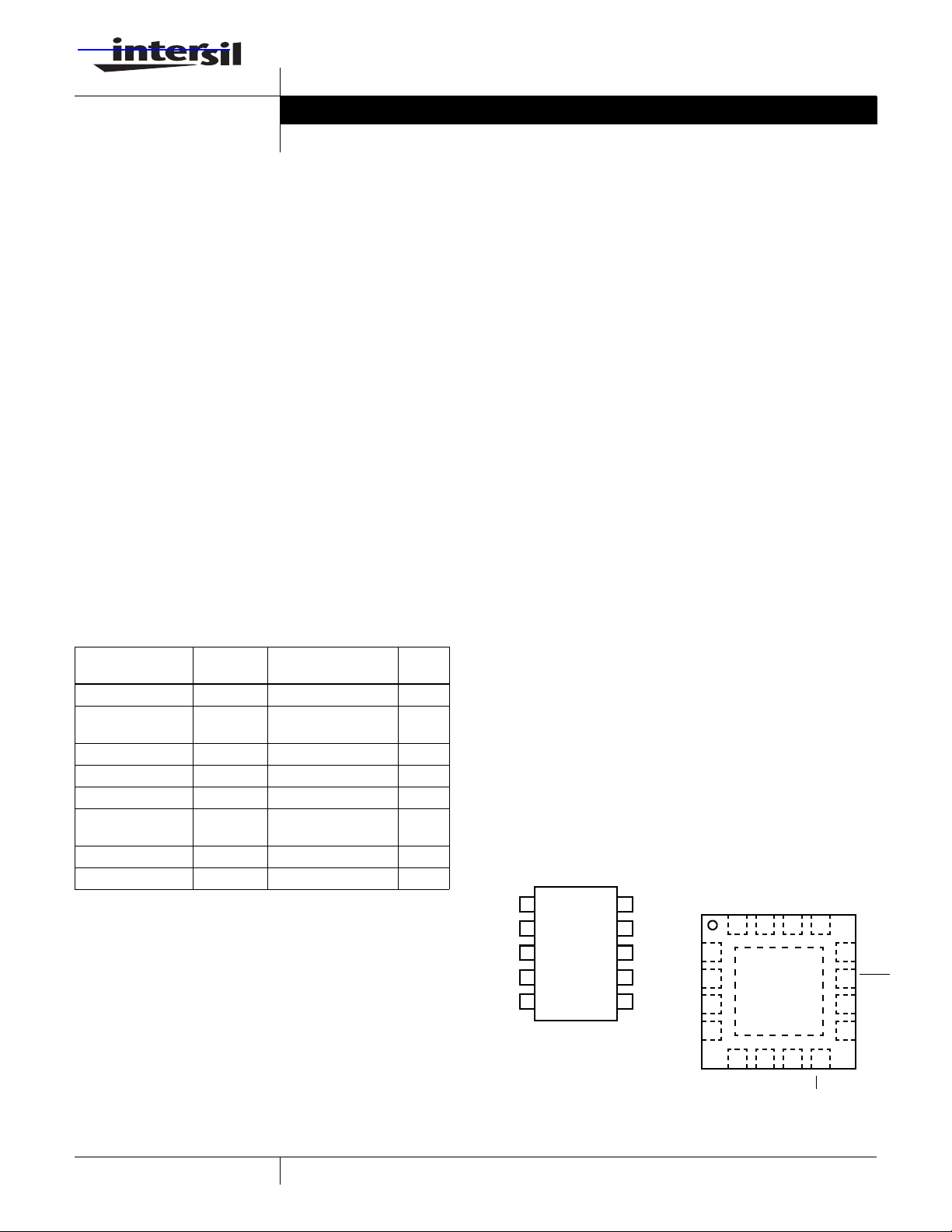

Ordering Information

TEMP.

PART NUMBER*

RANGE (°C) PACKAGE

ISL6410IR -40 to 85 16 Ld 4x4 QFN L16.4x4

ISL6410IRZ (Note) -40 to 85 16 Ld 4x4 QFN

(Pb-free)

ISL6410IU -40 to 85 10 Ld MSOP M10.118

ISL6410IUZ (Note) -40 to 85 10 Ld MSOP (Pb-free) M10.118

ISL6410AIR -40 to 85 16 Ld 4x4 QFN L16.4x4

ISL6410AIRZ (Note) -40 to 85 16 Ld 4x4 QFN

(Pb-free)

ISL6410AIU -40 to 85 10 Ld MSOP M10.118

ISL6410AIUZ (Note) -40 to 85 10 Ld MSOP (Pb-free) M10.118

*For tape and reel, add “-T”, “-TK” or “-T5K” suffix.

NOTE: Intersil Pb-free products employ special Pb-free material

sets; molding compounds/die attach materials and 100% matte tin

plate termination finish, which is compatible with both SnPb and

Pb-free soldering operations. Intersil Pb-free products are MSL

classified at Pb-free peak reflow temperatures that meet or exceed

the Pb-free requirements of IPC/JEDEC J Std-020B.

PKG.

DWG. #

L16.4x4

L16.4x4

FN9149.3

Features

• Fully Integrated Synchronous Buck Regulator

• PWM Fixed Output Voltage Options

- 1.8V, 1.5V or 1.2V with ISL6410 (VIN = 3.3V)

- 3.3V, 1.8V or 1.2V with ISL6410A (VIN = 5.0V)

• Continuous Output Current . . . . . . . . . . . . . . . . . . 600mA

• Ultra-Compact DC-DC Converter Design

• Stable with Small Ceramic Output Capacitors

• High Conversion Efficiency

• Extensive Circuit Protection and Monitoring features

- Overvoltage, UVLO

- Overcurrent

- Thermal Shutdown

• Available in MSOP and QFN packages

• QFN Package:

- Compliant to JEDEC PUB95 MO-220

QFN - Quad Flat No Leads - Package Outline

- Near Chip Scale Package footprint, which improves

PCB efficiency and has a thinner profile

• Pb-Free Packaging Available

Applications

• CPUs, DSP, CPLDs, FPGAs

• ASICs

• DVD and DSL applications

•WLAN Cards

• Generic 5V to 3.3V Conversion

Pinouts

ISL6410 (MSOP)

PVCC

1

VIN

2

GND

3

PG

4

FB

5

TOP VIEW

PGND

10

L

9

VIN

EN

8

SYNC

7

VSET

6

CT

GND

PG

ISL6410 (QFN)

TOP VIEW

VIN

PVCC

16 14 13

15

1

2

3

4

L

PGND

12

NC

RESET

11

10

EN

9

SYNC

6578

FB

NC

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright © Intersil Americas Inc. 2004. All Rights Reserved

PG

VSET

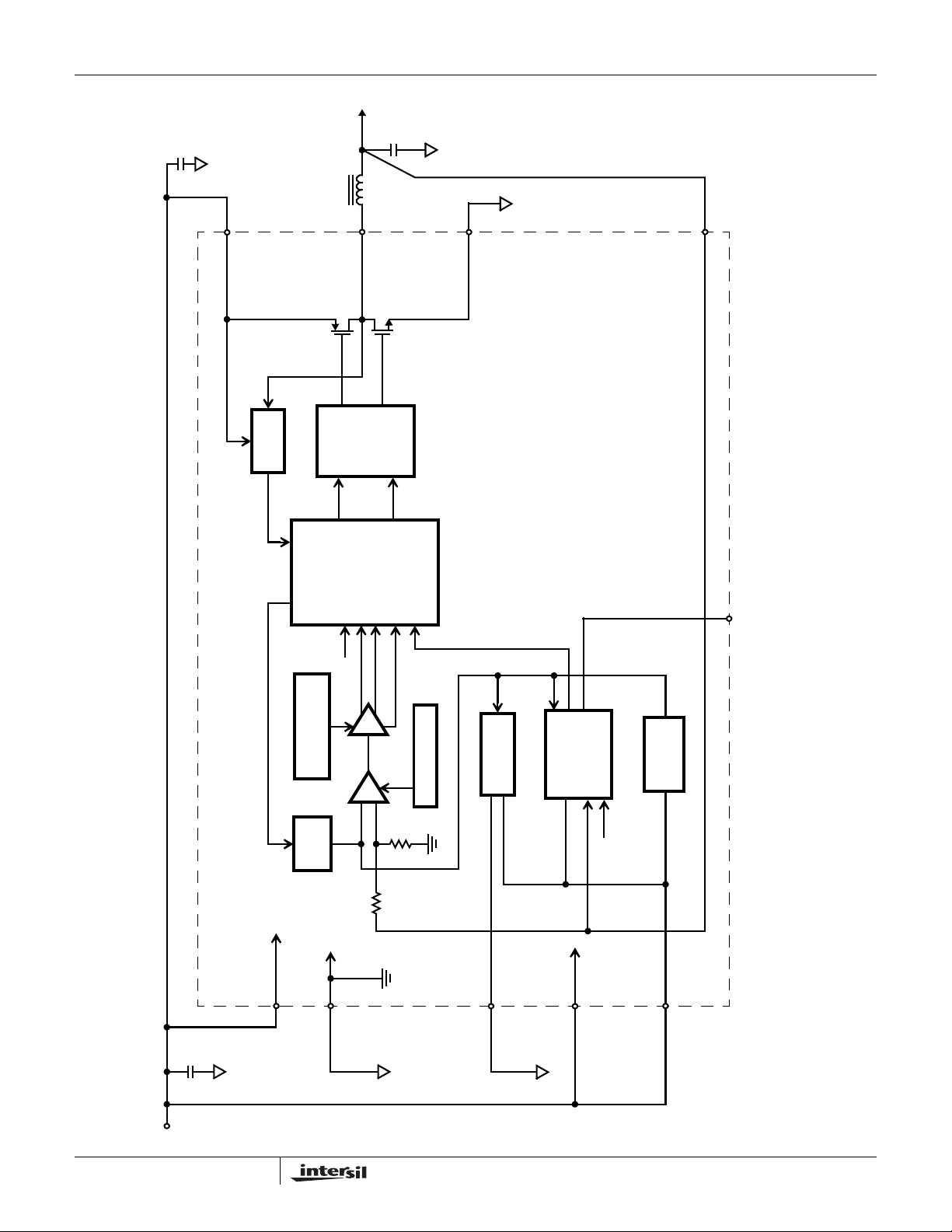

ISL6410, ISL6410A

0.1µF

VOUT

L1

8.2µH

1

PVCC

SENSE

CURRENT

10µF

9

L

GATE

DRIVE

10

PGND

5

FB

VIN

2

SLOPE

SOFT

COMPENSATION

START

GND

3

EN

PWM

OVERCURRENT,

OVERVOLTAGE

GM

EA

LOGIC

PG

4

POWER GOOD

PWM

OUT

UVLO

V

VSET

6

750kHz

COMPENSATION

OSCILLATOR

SYNC

7

PWM

0.45V

REFERENCE

EN

8

1. VIN is 3.3V for ISL6410 and 5.0V for ISL6410A.

NOTES:

2. VSET in the above schematic is connected to VIN, so the VOUT is 1.8V for ISL6410 and 3.3V for ISL6410A.

Functional Block Diagram for MSOP Version

10µF

VIN

2

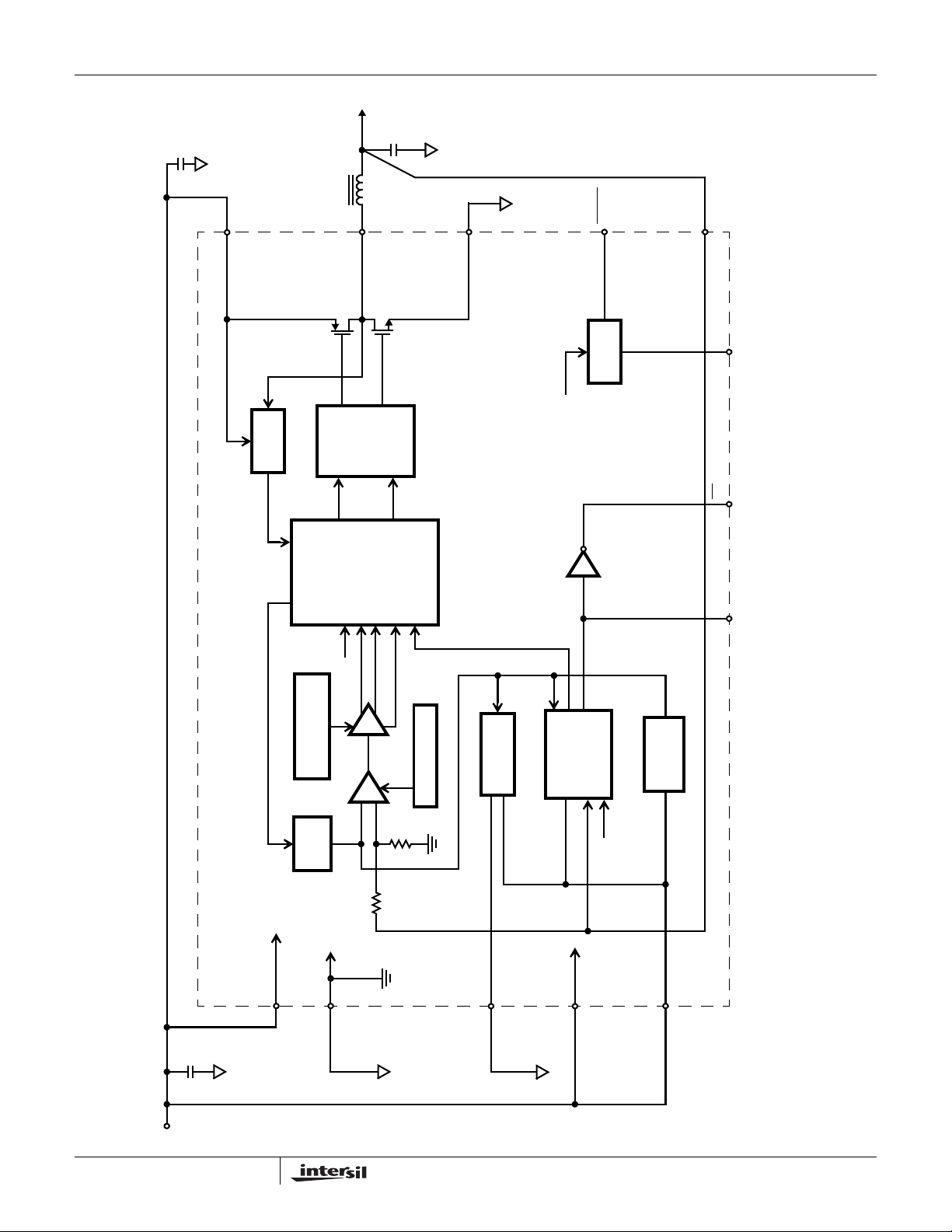

ISL6410, ISL6410A

0.1µF

VOUT

L1

8.2µH

15

PVCC

SENSE

CURRENT

10µF

14

L

GATE

DRIVE

13

PGND

RESET

11

RESET

BLOCK

IN

V

5

FB

T

C

2

PG

8

VIN

16

SLOPE

SOFT

COMPENSATION

START

GND

3

EN

PWM

OVERCURRENT,

OVERVOLTAGE

GM

EA

LOGIC

PG

4

POWER GOOD

PWM

OUT

UVLO

V

VSET

7

750kHz

COMPENSATION

OSCILLATOR

SYNC

9

PWM

0.45V

REFERENCE

EN

10

1. VIN is 3.3V for ISL6410 and 5.0V for ISL6410A.

NOTES:

2. VSET in the above schematic is connected to VIN, so the VOUT is 1.8V for ISL6410 and 3.3V for ISL6410A.

Functional Block Diagram for QFN Version

10µF

VIN

3

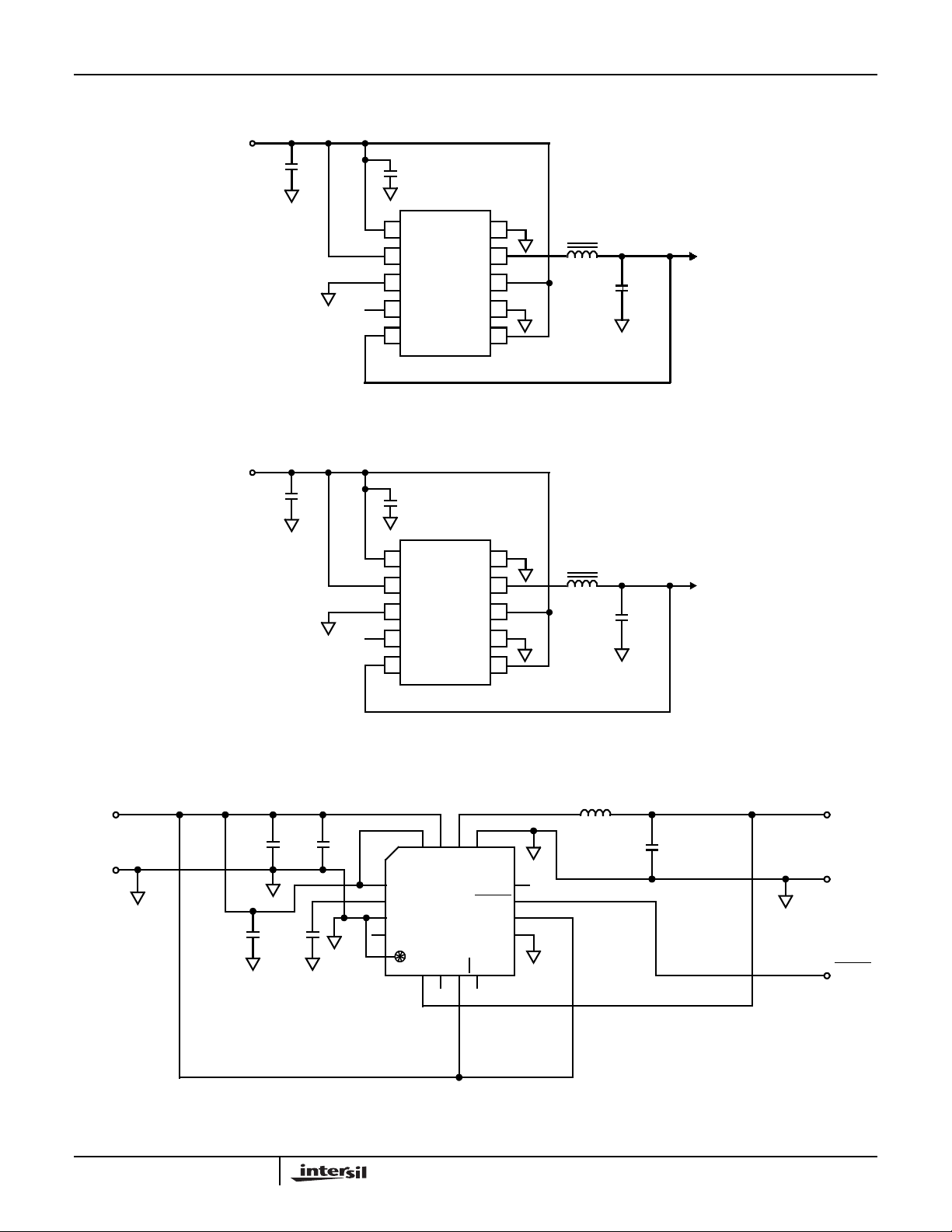

Typical Application Schematics

VIN

3.3V

±10%

C

IN

10µF

ISL6410, ISL6410A

0.1µF

VIN

5.0V

±10%

C

10µF

1

2

3

4

5

PVCC

VIN

GND

PG

FB

PGND

ISL6410

SYNC

VSET

EN

10

L

9

8

7

6

L1

8.2µH

C

OUT

10µF

V

OUT

1.8V

FIGURE 1. SCHEMATIC USING THE ISL6410 MSOP

IN

1

2

3

4

5

0.1µF

PVCC

VIN

GND

PG

FB

PGND

ISL6410A

SYNC

VSET

EN

10

L

9

8

7

L1

12µH

C

OUT

10µF

V

OUT

3.3V

6

+3.3V

VIN

GND

C7

0.1µF

C

10µF

IN

4

C

0.01µF

FIGURE 2. SCHEMATIC USING THE ISL6410A MSOP

1

VIN

2

CT

3

GND

4

PG

17

16 15 14 13

EP

567 8

L

VIN

PVCC

U1

ISL6410IR

NC

FB

VSET

PGND

NC

RESET

EN

SYNC

PG

12

11

10

9

1µF

T

FIGURE 3. SCHEMATIC USING THE ISL6410 QFN

L1

8.2µH

C

OUT

10µF

+1.2V

VOUT

GND

RESET

BAR

ISL6410, ISL6410A

Absolute Maximum Ratings Thermal Information

Supply Voltage, VCC . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to +6.0V

SYNC, FB, VSET & Enable Input (Note 3) . . . . -0.3V to VCC + 0.3V

ESD Classification (Human Body Model) . . . . . . . . . . . . . . . Class 2

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

3. All voltages are with respect to GND.

is measured in free air with the component mounted on a high effective thermal conductivity test board with “direct attach” features. See

4. θ

JA

Tech Brief TB379.

5. For θ

, the “case temp” location is the center of the exposed metal pad on the package underside.

JC

Thermal Resistance (Typical) θ

(°C/W) θJC (°C/W)

JA

MSOP Package (Note 4) . . . . . . . . . . . 128 NA

QFN Package (Notes 4, 5). . . . . . . . . . 45 7.5

Maximum Junction Temperature (Plastic Package) . . . . . . . . 150°C

Maximum Storage Temperature Range. . . . . . . . . . . -65°C to 150°C

Maximum Lead Temperature (10s, soldering . . . . . . . . . . . . . 260°C

Ambient Temperature Range. . . . . . . . . . . . . . . . . . . . -40°C to 85°C

Junction Temperature Range. . . . . . . . . . . . . . . . . . . -40°C to 125°C

Electrical Specifications Recommended operating conditions unless otherwise noted. V

(ISL6410A), T

= 25°C (Note 6).

A

= 3.3V ±10% (ISL6410) or 5V ±10%

IN

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

V

SUPPLY

CC

Supply Voltage Range VIN (ISL6410) 3.0 3.3 3.6 V

VIN (ISL6410A) 4.5 5.0 5.5 V

Input UVLO Threshold V

Quiescent Supply Current I

Shutdown Supply Current EN = GND, T

(ISL6410) Rising 2.62 2.68 2.73 V

TR

V

(ISL6410) Falling 2.53 2.59 2.64 V

TF

V

(ISL6410A) Rising 4.27 4.37 4.45 V

TR

V

(ISL6410A) Falling 4.1 4.22 4.32 V

TF

= 0mA - 2.3 - mA

OUT

= 25°C - 5 10 µA

A

EN = GND, T

= 85°C - 10 15 µA

A

Thermal Shutdown Temperature (Note 7) Rising Threshold - 150 - °C

Thermal Shutdown Hysteresis (Note 7) - 20 25 °C

SYNCHRONOUS BUCK PWM REGULATOR

Output Voltage ISL6410, VSET = L - 1.2 - V

ISL6410, VSET = H - 1.8 - V

ISL6410, VSET = OPEN - 1.5 - V

ISL6410A, VSET = L - 1.2 - V

ISL6410A, VSET = H - 3.3 - V

ISL6410A, VSET = OPEN - 1.8 - V

Output Voltage Accuracy I

Line Regulation I

Load Regulation I

= 3mA, TA = -40°C to 85°C -1.5 - +1.5 %

OUT

= 3mA -0.5 - +0.5 %

OUT

= 3mA to 600mA -1.5 - +1.5 %

OUT

Maximum Output Current - - 600 mA

Peak Output Current Limit 700 - 1300 mA

PMOS r

DS(ON)

NMOS r

DS(ON)

Efficiency I

I

= 200mA - 230 - mΩ

OUT

I

= 200mA - 230 - mΩ

OUT

= 200mA, VIN = 3.3V, VO = 1.8V (ISL6410) - 92 - %

OUT

5

ISL6410, ISL6410A

Electrical Specifications Recommended operating conditions unless otherwise noted. V

(ISL6410A), T

= 25°C (Note 6). (Continued)

A

= 3.3V ±10% (ISL6410) or 5V ±10%

IN

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Efficiency I

Efficiency I

= 200mA, VIN = 5.0V, VO = 3.3V (ISL6410A) - 93 - %

OUT

= 600mA, VIN = 5.0V, VO = 3.3V (ISL6410A) - 91 - %

OUT

Soft-Start Time 4096 Clock Cycles @ 750kHz - 5.5 - ms

OSCILLATOR

Oscillator Frequency 620 750 860 kHz

Frequency Synchronization Range (f

) Clock signal on SYNC pin 500 - 1000 kHz

SYNC

SYNC High Level Input Voltage As % of VIN 70 - - %

SYNC Low Level Input Voltage As % of VIN - - 30 %

Sync Input Leakage Current SYNC = GND or V

IN

-1 - 1 µA

Duty Cycle of External Clock Signal (Note 7) 20 - 60 %

PGOOD (ISL6410 interfaces to 3.3V Logic, ISL6410A interfaces to 5.0V Logic)

Rising Threshold 1mA minimum source/sink +5.0 8.0 +10.5 %

Falling Threshold -10.5 -8.0 -5.0 %

Rising/Falling Hysteresis -1 - %

ENABLE

EN High Level Input Voltage As % of VIN 70 - - %

EN Low Level Input Voltage As % of VIN - - 30 %

EN Input Leakage Current EN = GND or V

IN

-1 1 µA

OVERVOLTAGE

Overvoltage Threshold 27 30 33 %

RESET BLOCK SPECIFICATIONS

RESET (reset released) ISL6410, ISOURCE = 500µA, VIN = 2.90V 0.8V

IN

- - V

RESET (reset asserted) ISL6410, ISINK = 1.2mA, VIN = 2.50V - - 0.3 V

RESET Rising Threshold ISL6410 2.74 2.78 2.81 V

RESET Falling Threshold ISL6410 2.72 2.77 2.79 V

RESET (reset released) ISL6410A, ISOURCE = 800µA, VIN = 4.70V 0.8V

IN

-- V

RESET (reset asserted) ISL6410A, ISINK = 3.2mA, VIN = 4.10V - - 0.4 V

RESET Rising Threshold ISL6410A 4.5 4.58 4.64 V

RESET Falling Threshold ISL6410A 4.47 4.55 4.61 V

RESET Threshold Hysteresis ISL6410 - 20 - mV

RESET Threshold Hysteresis ISL6410A - 30 - mV

RESET Active Timeout Period (Note 8) CT = 0.01mF - 25 - ms

V

SET

V

High Level Input VIN-0.4V - - V

SET

V

Low Level Input --0.4V

SET

V

Open Level Input -VIN/2 - V

SET

NOTES:

6. Specifications at -40°C and +85°C are guaranteed by design, not production tested.

7. Guaranteed by design, not production tested.

8. The RESET Timeout period is linear with C

at a slope of 2.5ms/nF, thus a 10nF capacitor provides for 25ms.

T

6

ISL6410, ISL6410A

Pin Description

VIN - Supply voltage for the IC. It is recommended to place a

1µF decoupling capacitor as close as possible to the IC.

GND - Small signal ground for the PWM controller stage. All

internal control circuits are referenced to this pin.

PG - The Power good is an open-drain output. A pull-up

resistor should be connected between PG and VIN. It is

asserted active high when the output voltage reaches

94.5% of the nominal value.

FB - The Feedback pin is used to sense the output voltage,

and should be connected to VOUT for normal operation.

VSET - This pin is used to program the output voltages.

Refer to Table 1 below for details.

TAB L E 1 .

ISL6410

VSET

High 1.8V 3.3V

Open (NC) 1.5V 1.8V

Low 1.2V 1.2V

SYNC - This pin is used for synchronization. The converter

switching frequency can be synchronized to an external

CMOS clock signal in the range of (500kHz to 1MHz).

EN - A logic high enables the converter, logic low forces the

device into shutdown mode reducing the supply current to

less than 10

via a 10K resistor.

L - This pin is the drain junction of the internal power

MOSFETs and is to be connected to the external inductor.

PGND - Power ground. Connect all power grounds to this pin.

PVCC - This pin provides the Input supply for the internal

MOSFETs. It is recommended to place a 1µF decoupling

capacitor as close as possible to the IC.

CT - Timing capacitor connection to set the 25ms minimum

pulse width for the RESET

RESET - The outputs of the reset supervisory circuit, which

monitors VIN. The IC asserts these RESET

whenever the supply voltage drops below a preset threshold

and keeps it asserted for at least 25ms after VCC (VIN) has

risen above the reset threshold. These outputs are pushpull. RESET

The PWM will continue to operate until VIN drops below the

UVLO threshold.

µA at 25°C. This pin should be pulled up to VCC

is LOW when re-setting the microprocessor.

Vo

signal.

ISL6410A

Vo

signals

efficiency and reduced number of external components.

Operating frequency of 750kHz typical allows the use of

small inductor and capacitor values. The device can be

synchronized to an external clock signal in the range of

500kHz to 1MHz. The PG output indicates loss of regulation

on PWM output.

The PWM is based on the peak current mode control

topology with internal slope compensation. At the beginning

of each clock cycle, the high side P-channel MOSFET is

turned on. The current in the inductor ramps up and is

sensed via an internal circuit. On exceeding a preset limit the

high side switch is turned off causing the PWM comparator

to trip. This occurs whenever the output voltage is in

regulation or when the inductor current reaches the current

limit. After a minimum dead time to prevent shoot through

current, the low side N-channel MOSFET turns on and the

current ramps down. As the clock cycle is completed, the low

side switch turns off and the next clock cycle is initiated.

The control loop is internally compensated thus reducing the

amount of external components.

The switch current is internally sensed and the maximum

current limit is 1300mA peak.

Synchronization

The typical operating frequency for the converter is 750kHz.

It is possible to synchronize the converter to an external

clock frequency in the range of 500kHz to 1000kHz when an

external signal is applied to SYNC pin. The device will

automatically detect and synchronize to the rising edge of

the first clock pulse. If the clock signal is stopped, the

converter automatically switches back to the internal clock

and continues its operation without interruption. The switch

over will be initiated if no rising edge triggers are present on

the SYNC pin for a duration of four clock cycles.

Soft-Start

As the EN (Enable) pin goes high, the soft-start function will

generate an internal voltage ramp. This causes the start-up

current to slowly rise preventing output voltage overshoot

and high inrush currents. The soft-start duration is typically

5.5ms with 750kHz switching frequency. When the soft-start

is completed, the error amplifier will be connected directly to

the internal voltage reference.

Enable

Logic low on EN pin forces the PWM section into shutdown.

In the shutdown mode all the major blocks of the PWM

including power switches, drivers, voltage reference, and

oscillator are turned off.

Functional Description

The ISL6410, ISL6410A is a synchronous buck regulator

with integrated N- and P-channel power MOSFET and

provides pre-set pin programmable outputs. Synchronous

rectification with internal MOSFETs is used to achieve higher

7

Undervoltage Lockout

An undervoltage lockout circuit prevents the converter from

turning on when the voltage on VIN is less than the values

specified in the Input UVLO Threshold section of the

electrical specification.

ISL6410, ISL6410A

Power Good

This output is asserted high when the PWM is enabled, and

Vout is within 8.0% typical of its final value, and is active low

outside this range. When disabled, the output turns active

low. It is recommended to leave the PG pin unconnected

when not used.

PWM Overvoltage and Overcurrent Protection

The PWM output current is sampled at the end of each PWM

cycle, exceeding the overcurrent limit, causes a 4 bit

up/down counter to increment by one LSB. A normal current

state causes the counter to decrement by one LSB (the

counter will not however “rollover” or count below 0000).

When the PWM goes into overcurrent, the counter rapidly

reaches count 1111 and the PWM output is shut down and

the soft-start counter is reset. After 16 clocks the PWM

output is enabled and the soft-start cycle is started.

If Vout exceeds the overvoltage limit for 32 consecutive clock

cycles the PWM output is shut off and the soft-start cycle is

initiated.

No Load Operation

If there is no load connected to the output, the converter will

regulate the output voltage by allowing the inductor current

to reverse for a short period of time.

Output Capacitor Selection

For best performance, a low ESR output capacitor is

needed. Output voltages below 1.8V require a larger output

capacitor and ESR value to improve the performance and

stability of the converter. For 1.8V output applications, a

ceramic capacitor of 10µF or higher value with ESR ≤50mΩ

is recommended.

The RMS ripple current is calculated as:

Vo

1

---------–

I

RMS Co()

Vo

------------------ -

Lf×

Vin

L = the inductor value

f = the switching frequency

The overall output ripple voltage is the sum of the voltage spike

caused by the output capacitor ESR and the voltage ripple

caused by charge and discharge of the output capacitor:

Vo

1

---------–

Vin

Vo∆ Vo

------------------ -

Lf×

××=

Where the highest output voltage ripple occurs at the highest

input voltage VIN.

1

---------------- -

××=

23×

1

------------------------- ESR+

8Cof××

Input Capacitor Selection

The input current to the buck converter is pulsed, and

therefore a low ESR input capacitor is required. This results

in good input voltage filtering and minimizes the interference

it causes to other circuits. The input capacitor should have a

minimum value of 10µF and a higher value can be selected

for improving input voltage filtering. The input capacitor

should be rated for the maximum input ripple current

calculated as:

I

RMS

Io max()

Vo

---------

Vin

Vo

1

---------–

××=

Vin

The worst case RMS ripple current occurs at D = 0.5 and is

calculated as: Irms = Io/2.

D = Duty Cycle

Ceramic capacitors are preferred because of their low ESR

value. They are also less sensitive to voltage transients

when compared to tantalum capacitors. It is good practice to

place the input capacitor as close as possible to the input pin

of the IC for optimum performance.

Inductor Selection

The ISL6410 is an internally compensated device and hence

a minimum of 8.2

minimum of 12

must have a low DC resistance and a saturation current

greater than the maximum inductor current value can be

calculated from the equations below

dIL Vo

IL max Io max

×=

where

dIL = the peak to peak inductor current

L = the inductor value

f = the switching frequency

ILmax = the max inductor current

INDUCTOR VALUE DCR (mΩ)

8.2µH75Coilcraft

12µH 100 Coilcraft

µH must be used for the ISL6410 and a

µH for the ISL6410A. The selected inductor

Vo

1

---------–

Vin

------------------ -

Lf×

dIL

-------- -+=

2

TABLE 3. RECOMMENDED INDUCTORS

COMPONENT

SUPPLIER

MSS6122-822MX

MSS6122-123MX

TABLE 2. RECOMMENDED OUTPUT CAPACITORS

CAPACITOR

VAL UE

10µF <50 AVX 08056D106KAT2A Ceramic

ESR

(mΩ)

COMPONENT

SUPPLIER COMMENTS

8

ISL6410, ISL6410A

Layout Considerations

As in all switching power supplies, the layout is an important

step in the design process, more so at high peak currents

and switching frequencies. Improper layout practice will give

rise to Stability and EMI issues. It is recommended that wide

and short traces are used for the main current paths. The

Performance Curves and Waveforms

100

VOUT = 1.8V

90

80

VOUT = 1.5V

VOUT = 1.2V

input capacitor should be placed as close as possible to the

IC pins. This applies to the output inductor and capacitor as

well. The analog ground, GND, and the power ground,

PGND, need to be separated. Use a common ground node

to minimize the effects of ground noise.

100

IOUT = 200mA

90

IOUT = 600mA

80

70

EFFICIENCY (%)

60

50

IOUT LOAD CURRENT (mA)

100010050

70

EFFICIENCY (%)

60

50

3.1 3.5

VIN INPUT VOLTAGE (V)

3.32.9

FIGURE 4. ISL6410 EFFICIENCY vs LOAD CURRENT FIGURE 5. ISL6410 VIN vs EFFICIENCY

100

VOUT = 3.3V

90

80

70

EFFICIENCY (%)

60

50

VOUT = 1.2V

IOUT LOAD CURRENT (mA)

VOUT = 1.8V

100010050

100

IOUT = 200mA

90

IOUT = 600mA

80

70

EFFICIENCY (%)

60

50

4.6

4.8 5.2

VIN (V)

FIGURE 6. ISL6410A EFFICIENCY vs LOAD CURRENT FIGURE 7. ISL6410A EFFICIENCY vs VIN

5.4

5.65.04.4

9

ISL6410, ISL6410A

Performance Curves and Waveforms (Continued)

800

780

790

780

770

760

SWITCHING FREQUENCY (kHz)

750

-15

10 60

TEMPERATURE (°C)

FIGURE 8. ISL6410 OSCILLATOR FREQUENCY vs

TEMPERATURE

CH1 = Top, CH2 = Middle, CH4 = Bottom, where applicable

VOUT

L PIN VOLTAGE

770

760

750

740

SWITCHING FREQUENCY (kHz)

8535-40

730

-15

10 60

TEMPERATURE (°C)

8535-40

FIGURE 9. ISL6410A OSCILLATOR FREQUENCY vs

TEMPERATURE

VOUT

L PIN VOLTAGE

L1 CURRENT

CH1 = 0.1V/DIV, CH2 = 2V/DIV CH4 = 200mA/DIV

0.5µs/DIV

L1 CURRENT

VIN = 5.0V, VOUT = 1.2V, IOUT = 0.5A

CH1 = 0.1V/DIV, CH2 = 2V/DIV CH4 = 200mA/DIV

0.5µs/DIV

FIGURE 10. SWITCHING WAVEFORM FOR ISL6410 FIGURE 11. SWITCHING WAVEFORM FOR ISL6410A

VOUT

IOUT

VIN = 3.3V, VOUT = 1.2V

0.5ms/DIV

CH1 = 0.2V/DIV, CH4 = 200mA/DIV

VOUT

IOUT

VIN = 5.0V, VOUT = 1.2V

0.5ms/DIV

CH1 = 0.1V/DIV, CH4 = 200mA/DIV

FIGURE 12. TRANSIENT LOAD WAVEFORM FOR ISL6410 FIGURE 13. TRANSIENT LOAD WAVEFORM FOR ISL6410A

10

ISL6410, ISL6410A

Performance Curves and Waveforms (Continued)

VOUT

VIN = 3.3V, VOUT = 1.2V

1µs/DIV

CH1 = 20mV/DIV

VOUT

VIN = 5.0V, VOUT = 1.2V

1µs/DIV

CH1 = 20mV/DIV

FIGURE 14. RIPPLE WAVEFORM FOR ISL6410 FIGURE 15. RIPPLE WAVEFORM FOR ISL6410A

-40

-50

-60

-70

-80

-90

-100

-110

-120

NOISE LEVEL 761kHz = -54.0dBm

CENTER 2.75MHz, SPAN = 4.5MHz

VIN = 3.3V, VOUT = 1.2V

FIGURE 16. SWITCHING HARMONICS AND NOISE FOR

ISL6410

-40

VIN = 5.0V, VOUT = 1.2V

-50

-60

-70

-80

-90

-100

-110

-120

NOISE LEVEL 732kHz = -65.3dBm

CENTER 2.75MHz, SPAN = 4.5MHz

FIGURE 17. SWITCHING HARMONICS AND NOISE FOR

ISL6410A

11

ISL6410, ISL6410A

Quad Flat No-Lead Plastic Package (QFN)

Micro Lead Frame Plastic Package (MLFP)

L16.4x4

16 LEAD QUAD FLAT NO-LEAD PLASTIC PACKAGE

(COMPLIANT TO JEDEC MO-220-VGGC ISSUE C)

MILLIMETERS

SYMBOL

A 0.80 0.90 1.00 A1 - - 0.05 A2 - - 1.00 9

A3 0.20 REF 9

b 0.23 0.28 0.35 5, 8

D 4.00 BSC D1 3.75 BSC 9

D2 1.95 2.10 2.25 7, 8

E 4.00 BSC E1 3.75 BSC 9

E2 1.95 2.10 2.25 7, 8

e 0.65 BSC -

k0.25 - - -

L 0.50 0.60 0.75 8

L1 - - 0.15 10

N162

Nd 4 3

Ne 4 3

P- -0.609

θ --129

NOTES:

1. Dimensioning and tolerancing conform to ASME Y14.5-1994.

2. N is the number of terminals.

3. Nd and Ne refer to the number of terminals on each D and E.

4. All dimensions are in millimeters. Angles are in degrees.

5. Dimension b applies to the metallized terminal and is measured

between 0.15mm and 0.30mm from the terminal tip.

6. The configuration of the pin #1 identifier is optional, but must be

located within the zone indicated. The pin #1 identifier may be

either a mold or mark feature.

7. Dimensions D2 and E2 are for the exposed pads which provide

improved electrical and thermal performance.

8. Nominal dimensions are provided to assist with PCB Land Pattern

Design efforts, see Intersil Technical Brief TB389.

9. Features and dimensions A2, A3, D1, E1, P & θ are present when

Anvil singulation method is used and not present for saw

singulation.

10. Depending on the method of lead termination at the edge of the

package, a maximum 0.15mm pull back (L1) maybe present. L

minus L1 to be equal to or greater than 0.3mm.

NOTESMIN NOMINAL MAX

Rev. 5 5/04

12

ISL6410, ISL6410A

Mini Small Outline Plastic Packages (MSOP)

N

EE1

INDEX

AREA

AA1A2

-H-

SIDE VIEW

12

TOP VIEW

b

e

D

NOTES:

1. These package dimensions are within allowable dimensions of

JEDEC MO-187BA.

2. Dimensioning and tolerancing per ANSI Y14.5M-1994.

3. Dimension “D” does not include mold flash, protrusions or gate

burrs and are measured at Datum Plane. Mold flash, protrusion

and gate burrs shall not exceed 0.15mm (0.006 inch) per side.

4. Dimension “E1” does not include interlead flash or protrusions

and are measured at Datum Plane. Interlead flash and

protrusions shall not exceed 0.15mm (0.006 inch) per side.

5. Formed leads shall be planar with respect to one another within

0.10mm (.004) at seating Plane.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. Dimension “b” does not include dambar protrusion. Allowable

dambar protrusion shall be 0.08mm (0.003 inch) total in excess

of “b” dimension at maximum material condition. Minimum space

between protrusion and adjacent lead is 0.07mm (0.0027 inch).

- H -

-A -

.

10. Datums and to be determined at Datum plane

11. Controlling dimension: MILLIMETER. Converted inch dimensions are for reference only

-B-

0.20 (0.008) A

GAUGE

PLANE

SEATING

PLANE

0.10 (0.004) C

-A-

0.20 (0.008) C

- B -

0.25

(0.010)

-C-

SEATING

PLANE

a

0.20 (0.008) C

- H -

B

4X θ

C

D

4X θ

L1

C

C

L

E

1

END VIEW

R1

R

L

-B-

M10.118 (JEDEC MO-187BA)

10 LEAD MINI SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.037 0.043 0.94 1.10 A1 0.002 0.006 0.05 0.15 A2 0.030 0.037 0.75 0.95 -

b 0.007 0.011 0.18 0.27 9

c 0.004 0.008 0.09 0.20 -

D 0.116 0.120 2.95 3.05 3

E1 0.116 0.120 2.95 3.05 4

e 0.020 BSC 0.50 BSC -

E 0.187 0.199 4.75 5.05 -

L 0.016 0.028 0.40 0.70 6

L1 0.037 REF 0.95 REF -

N10 107

R 0.003 - 0.07 - -

R1 0.003 - 0.07 - -

o

θ

α

5

o

0

15

o

o

6

o

5

o

0

15

o

o

6

Rev. 0 12/02

NOTESMIN MAX MIN MAX

-

-

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

13

Loading...

Loading...