intersil ISL6324A DATA SHEET

®

Hybrid SVI/PVI with I

ISL6324A

2

C

Data Sheet

Monolithic Dual PWM Hybrid Controller

Powering AMD SVI Split-Plane and PVI

Uniplane Processors

The ISL6324A dual PWM controller delivers high efficiency

and tight regulation from two synchronous buck DC/DC

converters. The ISL6324A supports hybrid power control of

AMD processors which operate from either a 6-bit parallel

VID interface (PVI) or a serial VID interface (SVI). The dual

output ISL6324A features a multi-phase controller to support

uniplane VDD core voltage and a single phase controller to

power the Northbridge (VDDNB) in SVI mode. Only the

multi-phase controller is active in PVI mode to support

uniplane VDD only processors.

A precision uniplane core voltage regulation system is provided

by a 2-to-4-phase PWM voltage regulator (VR) controller. The

integration of two power MOSFET drivers, adding flexibility in

layout, reduce the number of external components in the multiphase section. A single phase PWM controller with integrated

driver provides a second precision voltage regulation system

for the North Bridge portion of the processor. This monolithic,

dual controller with integrated driver solution provides a cost

and space saving power management solution.

For applications which benefit from load line programming to

reduce bulk output capacitors, the ISL6324A features output

voltage droop. The multi-phase portion also includes

advanced control loop features for optimal transient response

to load application and removal. One of these features is

highly accurate, fully differential, continuous DCR current

sensing for load line programming and channel current

balance. Dual edge modulation is another unique feature,

allowing for quicker initial response to high di/dt load

transients.

The ISL6324A supports Power Savings Mode by dropping

phases when the PSI_L bit is set. The number of phases

that the ISL6324A will drop to is programmable through an

2

I

C interface. The number of PWM cycles between both

dropping phases when entering Power Savings Mode and

adding phases when exiting Power Savings Mode is also

programmable through the I

The ISL6324A I2C interface also allows independent

programmable output voltage offset for both the Core and

North Bridge regulators. The I

to set the PGOOD and OVP trip levels for both regulators as

well.

2

C interface.

2

C interface can also be used

March 23, 2009

FN6880.0

Features

Processor Core Voltage Regulator Features

• Configuration Flexibility

- 2-Phase Operation with Internal Drivers

- 3- or 4-Phase Operation with External PWM Drivers

• Parallel VID (6-bit) Interface Inputs for PVI Mode

• PSI_L Support via Phase Shedding

• Differential Remote Voltage Sensing

• Optimal Processor Core Voltage Transient Response

- Adaptive Phase Alignment (APA)

- Active Pulse Positioning Modulation

Processor Core Voltage Regulator and North Bridge

Voltage Regulator Shared Features

• Precision Voltage Regulation: ±0.5% System Accuracy

Over-Temperature

• Two Wire, AMD Compliant Serial VID Interface Inputs for

SVI Mode

2

C Interface

•I

- Voltage Margining, OVP and PGOOD Trip Levels

- Enhanced PSI_L State Control

• Fully Differential, Continuous DCR Current Sensing

- Accurate Load Line Programming

- Precision Channel Current Balancing for Core

• Overcurrent Protection

• Multi-tiered Overvoltage Protection

• Variable Gate Drive Bias: 5V to 12V

• Simultaneous Digital Soft-Start of Both Outputs

• Selectable Switching Frequency up to 1MHz

• Pb-Free (RoHS Compliant)

Ordering Information

PART

NUMBER

(Note)

ISL6324ACRZ* ISL6324A CRZ 0 to +70 48 Ld 7x7 QFN L48.7x7

ISL6324AIRZ* ISL6324A IRZ -40 to +85 48 Ld 7x7 QFN L48.7x7

*Add “-T” suffix for tape and reel. Please refer to TB347 for details on

reel specifications.

NOTE: These Intersil Pb-free plastic packaged products employ

special Pb-free material sets, molding compounds/die attach materials,

and 100% matte tin plate plus anneal (e3 termination finish, which is

RoHS compliant and compatible with both SnPb and Pb-free soldering

operations). Intersil Pb-free products are MSL classified at Pb-free peak

reflow temperatures that meet or exceed the Pb-free requirements of

IPC/JEDEC J STD-020.

PART

MARKING

TEMP.

RANGE

(°C)

PACKAGE

(Pb-free)

PKG.

DWG . #

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright Intersil Americas Inc. 2009. All Rights Reserved

Pinout

ISL6324AISL6324A

ISL6324A HYBRID SVI AND PVI

(48 LD QFN)

TOP VIEW

COMP_NB

ISEN_NB-

ISEN4+

ISEN4-

ISEN3+

ISEN3-

PVCC_NB

LGATE_NB

BOOT_NB

UGATE_NB

PHASE_NB

48 47 46 45 44 43 42 41 40 39 38 37

VDDPWRGD

SDA

VID4

VID5

VCC

FS

RGND

1

2

3

4

5

6

7

8

9

10

11

12

13 14 15 16 17 18 19 20 21 22 23 24

VSEN

FB_NB

ISEN_NB+

VID0/VFIXEN

VID1/SEL

VID2/SVD

VID3/SVC

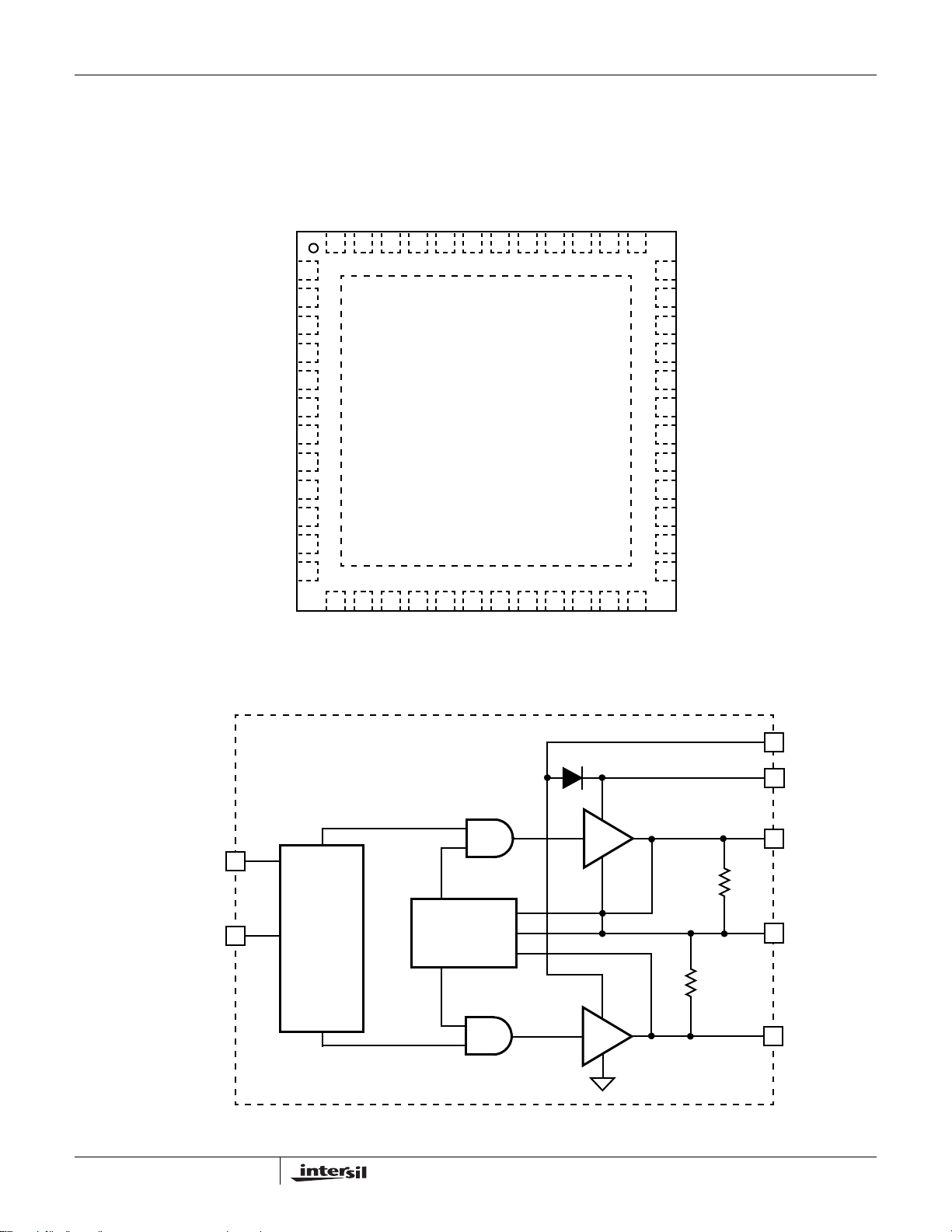

Integrated Driver Block Diagram

SCL

RSET

RCOMP

FB

49

GND

COMP

36

PWM4

35

PWM3

34

PWROK

33

PHASE1

UGATE1

32

31

BOOT1

30

LGATE1

29

PVCCI_2

LGATE2

28

BOOT2

27

UGATE2

26

PHASE2

25

APA

ISEN1+

ISEN1-

ISEN2+

EN

ISEN2-

PWM

SOFT-START

AND

FAULT LOGIC

2

GATE

CONTROL

LOGIC

SHOOT-

THROUGH

PROTECTION

10kΩ

20kΩ

PVCC

BOOT

UGATE

PHASE

LGATE

March 23, 2009

FN6880.0

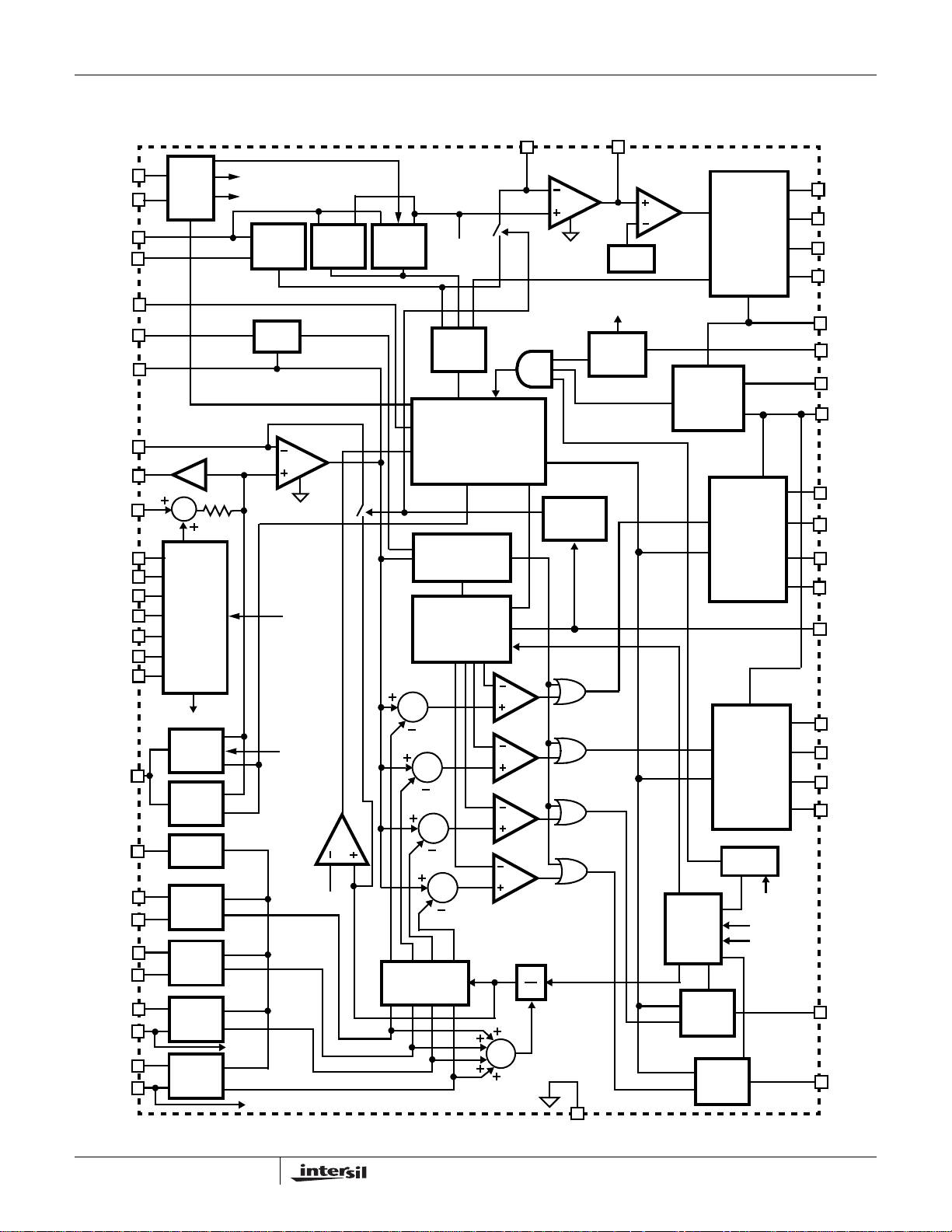

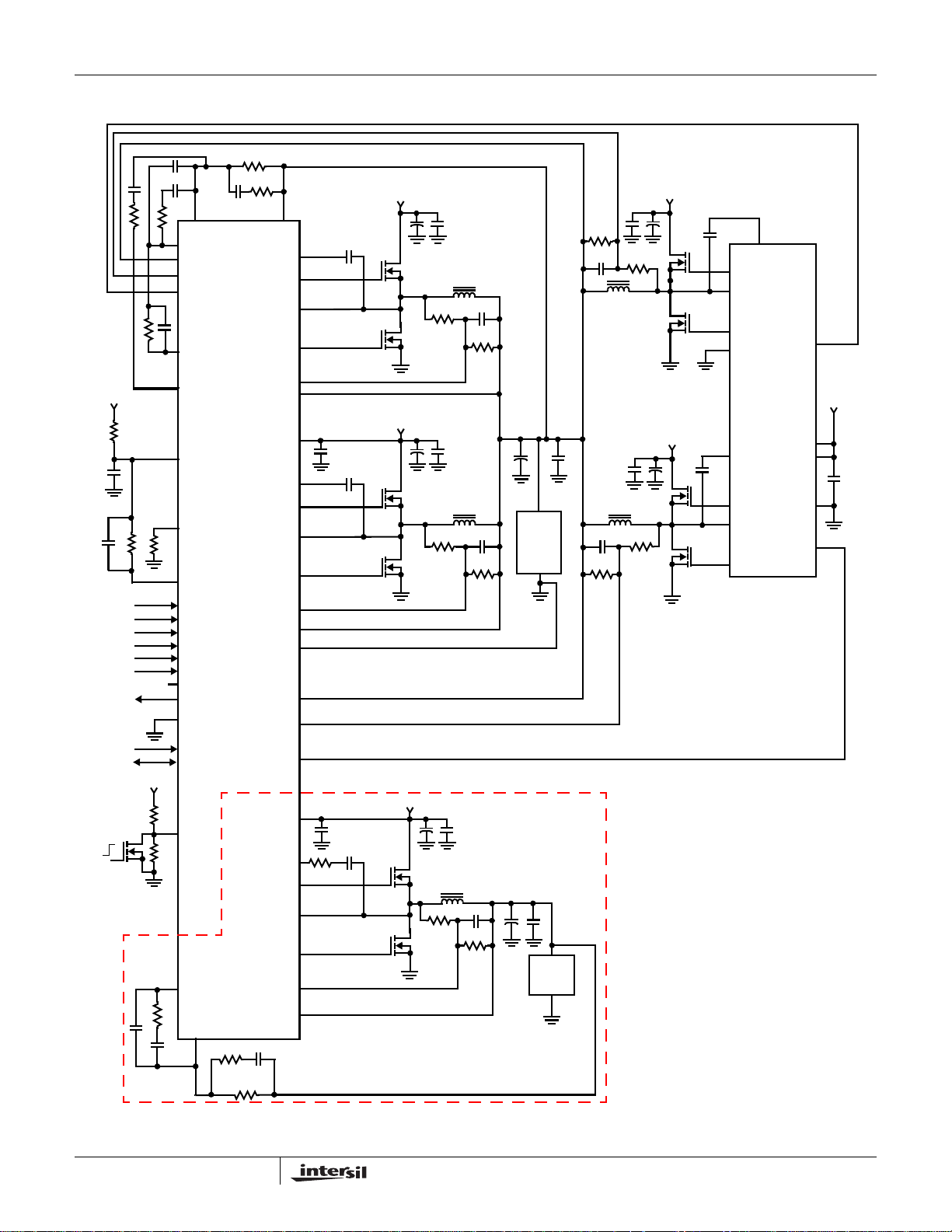

Controller Block Diagram

ISL6324AISL6324A

SCL

SDA

ISEN_NB+

ISEN_NB-

VDDPWRGD

APA

COMP

FB

DVC

RGND

PWROK

VID0/VFIXEN

VID1/SEL

VID2/SVD

VID3/SVC

VID4

VID5

VSEN

RSET

ISEN1+

ISEN1-

ISEN2+

ISEN2-

ISEN3+

ISEN3-

ISEN4+

ISEN4-

I2C

VDDPWRGD_MOD

2X

∑

SVI

SLAVE

BUS

AND

PVI

DAC

NB_REF

OV

LOGIC

UV

LOGIC

RESISTOR

MATCHING

CH1

CURRENT

SENSE

CH2

CURRENT

SENSE

CH3

CURRENT

SENSE

CH4

CURRENT

SENSE

CORE_OVP

DAC_OFS

CURRENT

ISEN3-

ISEN4-

SENSE

APA

DAC_OFS

CORE_OVP

E/A

LOGIC

I_TRIP

UV

OC

I_AVG

NB_OVP

OV

LOGIC

TRIANGLE WAVE

∑

CHANNEL

CURRENT

BALANCE

NB_REF

NB

FAULT

LOGIC

SOFT-START

AND

FAULT LOGIC

LOAD APPL Y

TRANSIENT

ENHANCEMENT

CLOCK AND

GENERATOR

∑

∑

∑

I_AVG

∑

FB_NB

1

N

E/A

DROOP

CONTROL

PWM1

PWM2

GND

COMP_NB

RAMP

EN_12V

ENABLE

LOGIC

PWM3

PWM4

POWER-ON

RESET

CHANNEL

DETECT

PWM3

SIGNAL

LOGIC

PWM4

SIGNAL

LOGIC

MOSFET

DRIVER

MOSFET

DRIVER

MOSFET

DRIVER

PH3/PH4

POR

EN_12V

ISEN3ISEN4-

LGATE_NB

BOOT_NB

UGATE_NB

PHASE_NB

PVCC_NB

EN

VCC

PVCC1_2

BOOT1

UGATE1

PHASE1

LGATE1

FS

BOOT2

UGATE2

PHASE2

LGATE2

PWM3

PWM4

3

FN6880.0

March 23, 2009

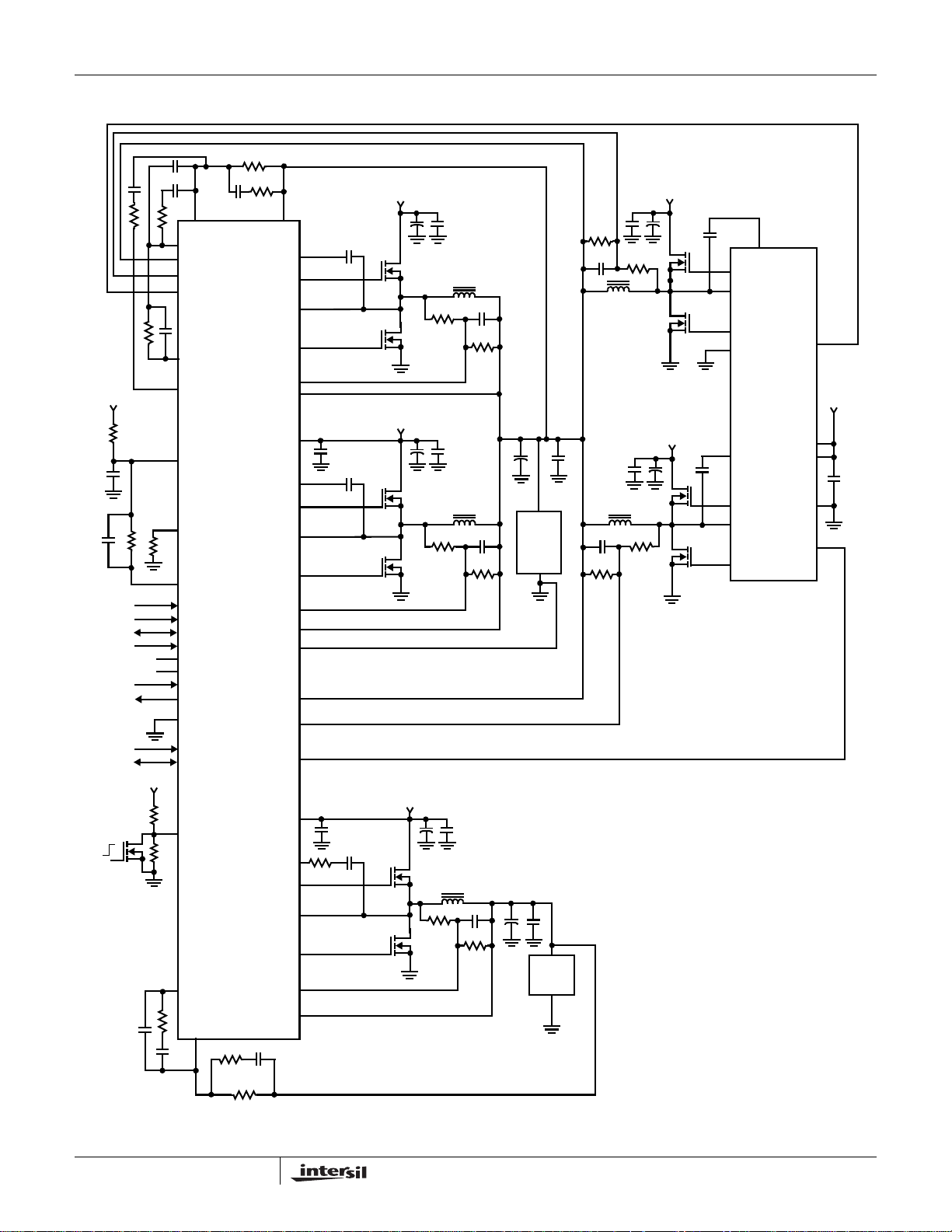

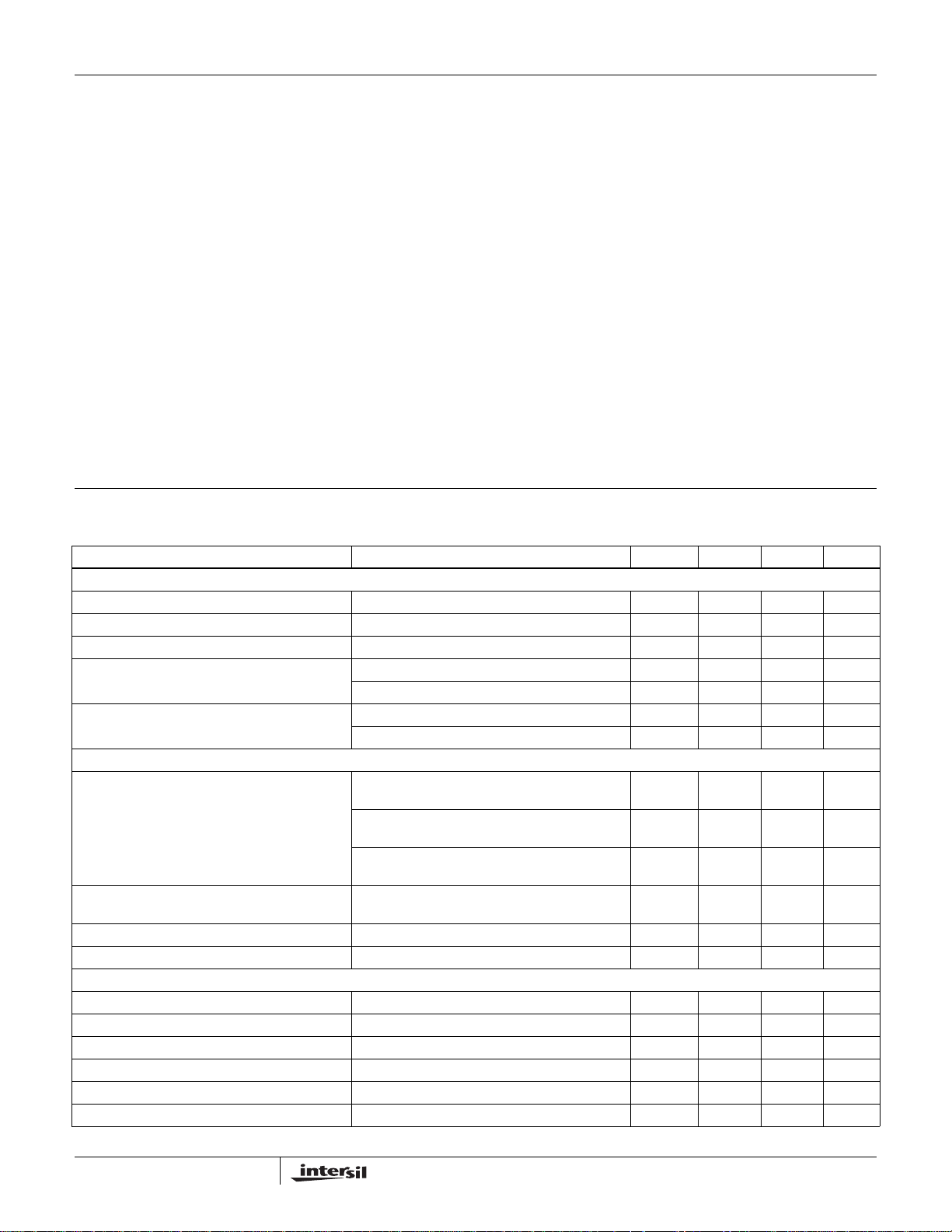

Typical Application - SVI Mode

ISL6324AISL6324A

OFF

ON

+5V

NC

NC

+12V

FB

COMP

ISEN3+

ISEN3PWM3

APA

DVC

VCC

FS

RSET

VFIXEN

SEL

SVD

SVC

VID4

VID5

PWROK

VDDPWRGD

GND

SCL

SDA

ISL6324A

EN

UGATE_NB

VSEN

BOOT1

UGATE1

PHASE1

LGATE1

ISEN1-

ISEN1+

PVCC1_2

BOOT2

UGATE2

PHASE2

LGATE2

ISEN2-

ISEN2+

RGND

ISEN4+

ISEN4-

PWM4

PVCC_NB

BOOT_NB

+12V

+12V

+12V

VDD

CPU

LOAD

+12V

+12V

BOOT1

UGATE1

PHASE1

LGATE1

PGND

ISL6614

BOOT2

UGATE2

PHASE2

LGATE2

PWM1

VCC

PVCC

GND

PWM2

+12V

COMP_NB

FB_NB

PHASE_NB

LGATE_NB

ISEN_NB-

ISEN_NB+

4

NB

LOAD

VDDNB

FN6880.0

March 23, 2009

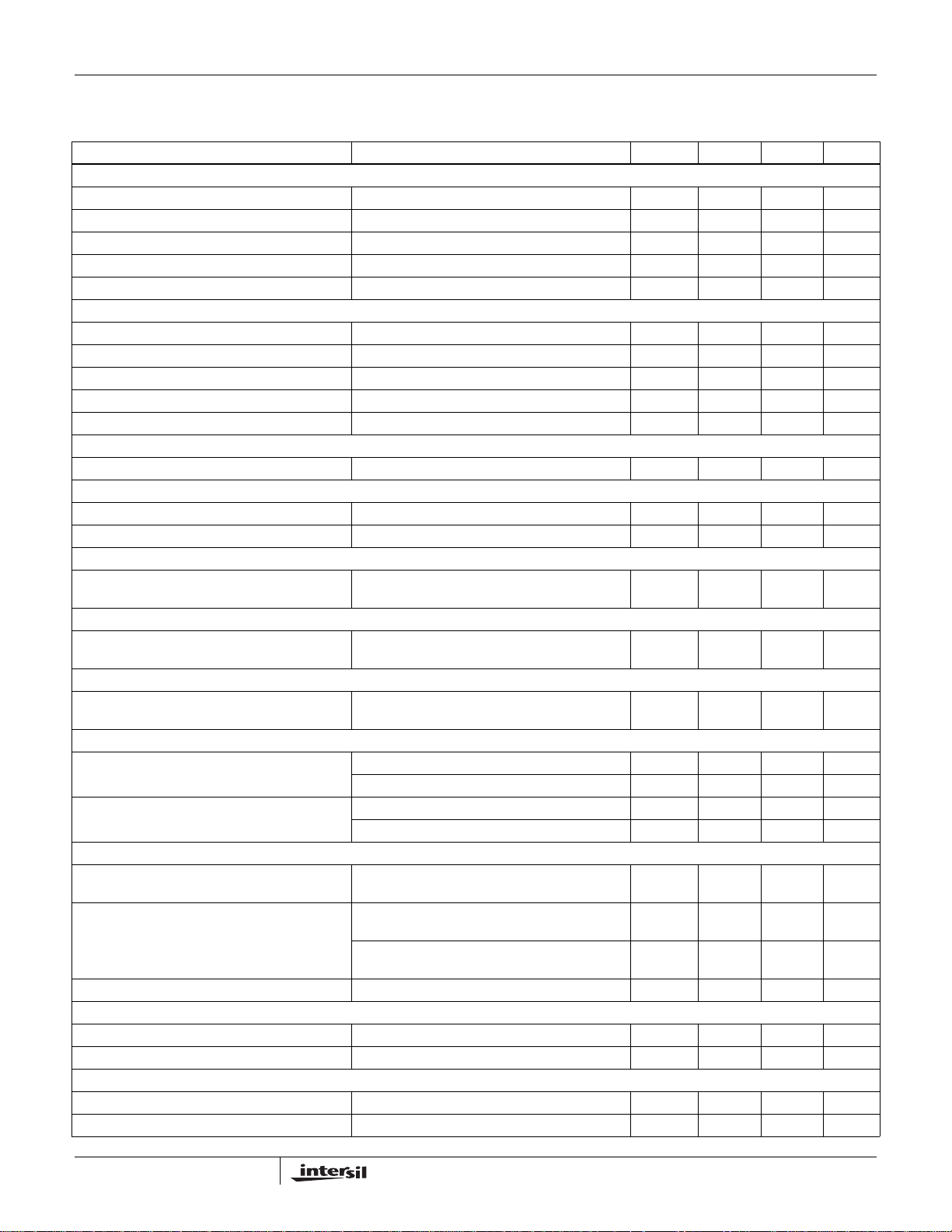

Typical Application - PVI Mode

ISL6324AISL6324A

OFF

ON

+5V

NC

+12V

FB

COMP

ISEN3+

ISEN3PWM3

APA

DVC

VCC

FS

RSET

VID0

VID1/SEL

VID2

VID3

VID4

VID5

PWROK

VDDPWRGD

GND

SCL

SDA

ISL6324A

EN

VSEN

BOOT1

UGATE1

PHASE1

LGATE1

ISEN1-

ISEN1+

PVCC1_2

BOOT2

UGATE2

PHASE2

LGATE2

ISEN2-

ISEN2+

RGND

ISEN4+

ISEN4-

PWM4

PVCC_NB

BOOT_NB

UGATE_NB

+12V

+12V

+12V

VDD

CPU

LOAD

+12V

BOOT1

UGATE1

PHASE1

LGATE1

PGND

ISL6614

+12V

BOOT2

UGATE2

PHASE2

LGATE2

NORTH BRIDGE REGULATOR

DISABLED IN PVI MODE

PWM1

VCC

PVCC

GND

PWM2

+12V

COMP_NB

FB_NB

PHASE_NB

LGATE_NB

ISEN_NB-

ISEN_NB+

5

VDDNB

NB

LOAD

FN6880.0

March 23, 2009

ISL6324AISL6324A

Absolute Maximum Ratings Thermal Information

Supply Voltage (VCC) . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to +6.2V

Supply Voltage (PVCC) . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to +15V

Absolute Boot Voltage (V

Phase Voltage (V

GND - 8V (<400ns, 20µJ) to 24V (<200ns, V

PHASE

Upper Gate Voltage (V

V

- 3.5V (<100ns Pulse Width, 2µJ) to V

Lower Gate Voltage (V

PHASE

). . . . . . . .GND - 0.3V to GND + 36V

BOOT

). . . . . . . . GND - 0.3V to 15V (PVCC = 12)

BOOT

BOOT

= 12V)

+ 0.3V

+ 0.3V

). . . .V

UGATE

LGATE

PHASE

). . . . . . . GND - 0.3V to PVCC + 0.3V

BOOT-PHASE

- 0.3V to V

GND - 5V (<100ns Pulse Width, 2µJ) to PVCC+ 0.3V

Input, Output, or I/O Voltage . . . . . . . . . GND - 0.3V to VCC + 0.3V

CAUTION: Do not operate at or near the maximum ratings listed for extended periods of time. Exposure to such conditions may adversely impact product reliability and

result in failures not covered by warranty.

NOTES:

is measured in free air with the component mounted on a high effective thermal conductivity test board with “direct attach” features. See

1. θ

JA

Tech Brief TB379.

2. For θ

, the “case temp” location is the center of the exposed metal pad on the package underside.

JC

3. Limits should be considered typical and are not production tested.

Electrical Specifications Recommended Operating Conditions (0°C to +70°C), Unless Otherwise Specified. Parameters with MIN and/or

MAX limits are 100% tested at +25°C, unless otherwise specified. Temperature limits established by

characterization and are not production tested.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

BIAS SUPPLIES

Input Bias Supply Current I

Gate Drive Bias Current - PVCC1_2 Pin I

Gate Drive Bias Current - PVCC_NB Pin I

VCC POR (Power-On Reset) Threshold VCC Rising 4.20 4.35 4.50 V

PVCC POR (Power-On Reset) Threshold PVCC Rising 4.20 4.35 4.50 V

PWM MODULATOR

Oscillator Frequency Accuracy, f

SW

Typical Adjustment Range of Switching

Frequency

Oscillator Ramp Amplitude, V

P-P

Maximum Duty Cycle (Note 3) 99.5 %

CONTROL THRESHOLDS

EN Rising Threshold 0.80 0.88 0.92 V

EN Hysteresis 70 130 190 mV

PWROK Input HIGH Threshold 1.1 V

PWROK Input LOW Threshold 0.95 V

VDDPWRGD Sink Current Open drain, V_VDDPWRGD = 400mV 4 mA

PWM Channel Disable Threshold V

; EN = high 15 22 25 mA

VCC

PVCC1_2

PVCC_NB

; EN = high 1 1.8 3 mA

; EN = high 0.3 0.9 2 mA

VCC Falling 3.70 3.85 4.05 V

PVCC Falling 3.70 3.85 4.05 V

RT = 100kΩ (±0.1%) to Ground, (All Temps)

(Droop Enabled)

= 100kΩ (±0.1%) to VCC, TA = 0°C to +70°C

R

T

(Droop Disabled)

= 100kΩ (±0.1%) to VCC, TA = -40°C to +85°C

R

T

(Droop Disabled)

(Note 3) 0.08 1.0 MHz

(Note 3) 1.50 V

, V

ISEN3-

ISEN4-, VISEN2-

Thermal Resistance θ

(°C/W) θJC (°C/W)

JA

QFN Package (Notes 1, 2). . . . . . . . . . 30 2

Maximum Junction Temperature . . . . . . . . . . . . . . . . . . . . . .+150°C

Maximum Storage Temperature Range. . . . . . . . . .-65°C to +150°C

Pb-free Reflow Profile . . . . . . . . . . . . . . . . . . . . . . . . .see link below

http://www.intersil.com/pbfree/Pb-FreeReflow.asp

Recommended Operating Conditions

VCC Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+5V ±5%

PVCC Supply Voltage . . . . . . . . . . . . . . . . . . . . . . .+5V to 12V ±5%

Ambient Temperature

ISL6324ACRZ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0°C to +70°C

ISL6324AIRZ . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to +85°C

225 250 265 kHz

245 275 310 kHz

240 275 310 kHz

4.4 V

6

FN6880.0

March 23, 2009

ISL6324AISL6324A

Electrical Specifications Recommended Operating Conditions (0°C to +70°C), Unless Otherwise Specified. Parameters with MIN and/or

MAX limits are 100% tested at +25°C, unless otherwise specified. Temperature limits established by

characterization and are not production tested. (Continued)

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

REFERENCE AND DAC

System Accuracy (VDAC > 1.000V) -0.6 0.6 %

System Accuracy (0.600V < VDAC < 1.000V) -1.0 1.0 %

System Accuracy (VDAC < 0.600V) -2.0 2.0 %

DVC Voltage Gain VDAC = 1V 2.0 V

APA Current Tolerance V

ERROR AMPLIFIER

DC Gain R

Gain-Bandwidth Product (Note 3) C

Slew Rate (Note 3) C

Maximum Output Voltage Load = 1mA 3.80 4.20 V

Minimum Output Voltage Load = -1mA 1.3 1.6 V

SOFT-START RAMP

Soft-Start Ramp Rate 2.2 3.0 4.0 mV/µs

PWM OUTPUTS

PWM Output Voltage LOW Threshold I

PWM Output Voltage HIGH Threshold I

CURRENT SENSING - CORE CONTROLLER

Sensed Current Tolerance V

CURRENT SENSING - NB CONTROLLER

Sensed Current Tolerance V

DROOP CURRENT

Tolerance V

OVERCURRENT PROTECTION

Overcurrent Trip Level - Average Channel Normal Operation, R

Overcurrent Limiting- Individual Channel Normal Operation, R

POWER-GOOD

Core Overvoltage Threshold VSEN Rising

Undervoltage Threshold VSEN Falling (Core)

Power Good Hysteresis 50 mV

OVERVOLTAGE PROTECTION

OVP Trip Level Bit 7 of I

OVP Lower Gate Release Threshold 350 400 mV

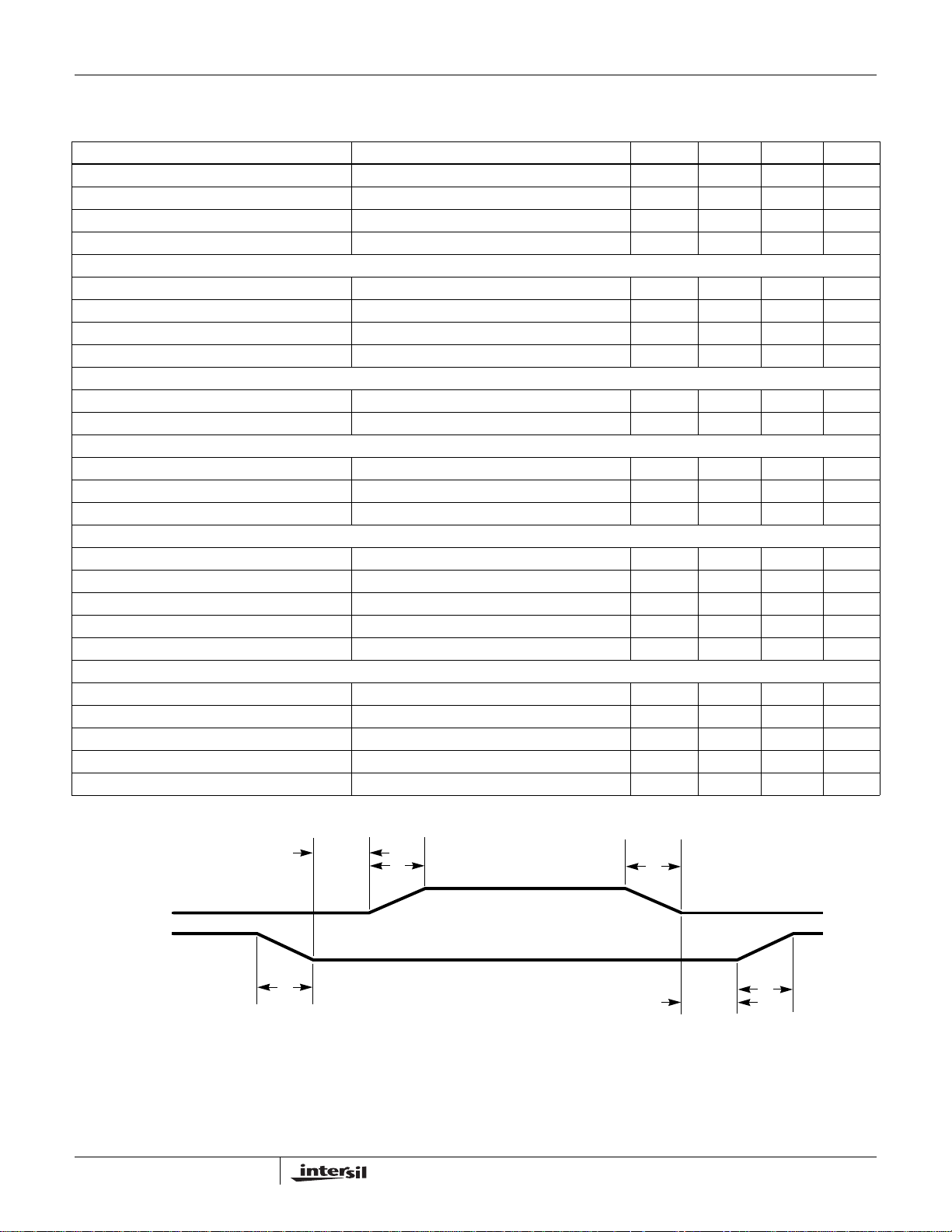

SWITCHING TIME (Note 3) [See “Timing Diagram” on page 8]

UGATE Rise Time t

LGATE Rise Time t

= 1V 90 100 108 µA

APA

= 10k to ground, (Note 3) 96 dB

L

= 100pF, RL = 10k to ground, (Note 3) 20 MHz

L

= 100pF, Load = ±400µA, (Note 3) 8 V/µs

L

= ±500µA 0.5 V

LOAD

= ±500µA 4.5 V

LOAD

- V

ISENn-

4 Phases, T

ISEN_NB-

R

= 37.6kΩ, 4 Phases, TA = +25°C

SET

- V

ISENn-

4 Phases, T

ISENn+

= +25°C

A

- V

ISEN_NB+

ISENn+

= +25°C

A

= 23.2mV, R

= 23.2mV,

= 23.2mV, R

= 28.2kΩ 87 100 120 µA

SET

SET

SET

= 37.6kΩ,

= 37.6kΩ,

68 88 µA

68 89 µA

68 88 µA

Dynamic VID Change (Note 3) 130 µA

= 28.2kΩ 142 µA

SET

Dynamic VID Change (Note 3) 190 µA

2

Bit 6 of I

Bit 6 of I

ISEN_NB+ Falling (North Bridge)

Bit 6 of I

RUGATE; VPVCC

RLGATE; VPVCC

C data = 0

2

C data = 0

2

C data = 0

2

C data = 0, VDAC ≤ 1.55V 1.73 1.80 1.84 V

= 12V, 3nF Load, 10% to 90% 26 ns

= 12V, 3nF Load, 10% to 90% 18 ns

VDAC +

225mV

VDAC -

325mV

VDAC -

310mV

VDAC +

250mV

VDAC -

300mV

VDAC -

275mV

VDAC +

275mV

VDAC -

270mV

VDAC -

235mV

mV

mV

V

7

FN6880.0

March 23, 2009

ISL6324AISL6324A

Electrical Specifications Recommended Operating Conditions (0°C to +70°C), Unless Otherwise Specified. Parameters with MIN and/or

MAX limits are 100% tested at +25°C, unless otherwise specified. Temperature limits established by

characterization and are not production tested. (Continued)

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

UGATE Fall Time t

LGATE Fall Time t

UGATE Turn-On Non-overlap t

LGATE Turn-On Non-overlap t

FUGATE; VPVCC

FLGATE; VPVCC

PDHUGATE

PDHLGATE

GATE DRIVE RESISTANCE (Note 3)

Upper Drive Source Resistance V

Upper Drive Sink Resistance V

Lower Drive Source Resistance V

Lower Drive Sink Resistance V

= 12V, 15mA Source Current 2.0 Ω

PVCC

= 12V, 15mA Sink Current 1.65 Ω

PVCC

= 12V, 15mA Source Current 1.25 Ω

PVCC

= 12V, 15mA Sink Current 0.80 Ω

PVCC

MODE SELECTION

VID1/SEL Input Low EN taken from HI to LO, VDDIO = 1.5V 0.6 V

VID1/SEL Input High EN taken from LO to HI, VDDIO = 1.5V 1.00 V

PVI INTERFACE

VIDx Pull-down VDDIO = 1.5V 30 40 µA

VIDx Input Low VDDIO = 1.5V 0.6 V

VIDx Input High VDDIO = 1.5V 1.00 V

SVI INTERFACE

SVC, SVD Input LOW (VIL) 0.4 V

SVC, SVD Input HIGH (VIH) 0.95 V

Schmitt Trigger Input Hysteresis 0.14 0.35 0.45 V

SVD Low Level Output Voltage 3mA Sink Current 0.285 V

Maximum SVC, SVD Leakage (Note 3) ±5 µA

2

I

C INTERFACE

SCL, SDA Input LOW (VIL) 1.10 V

SCL, SDA Input HIGH (VIH) 1.75 V

Schmitt Trigger Input Hysteresis 0.18 0.35 0.50 V

SDA Low Level Output Voltage 3mA Sink Current 0.2 V

Maximum SCL, SDA Leakage (Note 3) ±5 µA

= 12V, 3nF Load, 90% to 10% 18 ns

= 12V, 3nF Load, 90% to 10% 12 ns

; V

= 12V , 3nF Load, Adaptive 10 ns

PVCC

; V

= 12V, 3nF Load, Adaptive 10 ns

PVCC

Timing Diagram

UGATE

LGATE

t

PDHUGATE

t

8

FLGATE

t

RUGATE

t

t

PDHLGATE

FUGATE

t

RLGATE

FN6880.0

March 23, 2009

ISL6324AISL6324A

Functional Pin Description

VID1/SEL

This pin selects SVI or PVI mode operation based on the state

of the pin prior to enabling the ISL6324A. If the pin is LO prior

to enable, the ISL6324A is in SVI mode and the dual purpose

pins [VID0/VFIXEN, VID2/SVC, VID3/SVD] use their SVI

mode related functions. If the pin held HI prior to enable, the

ISL6324A is in PVI mode and dual purpose pins use their

VIDx related functions to decode the correct DAC code.

VID0/VFIXEN

If VID1 is LO prior to enable [SVI Mode], the pin is functions

as the VFIXEN selection input from the AMD processor for

determining SVI mode versus VFIX mode of operation.

If VID1 is HI prior to enable [PVI Mode], the pin is used as

DAC input VID0. This pin has an internal 30µA pull-down

current applied to it at all times.

VID2/SVD

If VID1 is LO prior to enable [SVI Mode], this pin is the serial

VID data bi-directional signal to and from the master device on

AMD processor. If VID1 is HI prior to enable [PVI Mode], this

pin is used to decode the programmed DAC code for the

processor. In PVI mode, this pin has an internal 30µA pull-down

current applied to it. There is no pull-down current in SVI mode.

VID3/SVC

If VID1 is LO prior to enable [SVI Mode], this pin is the serial

VID clock input from the AMD processor . If VID1 is HI prior to

enable [PVI Mode], the ISL6324A is in PVI mode and this pin

is used to decode the programmed DAC code for the

processor. In PVI mode, this pin has an internal 30µ A

pull-down current applied to it. There is no pull-down current in

SVI mode.

VID4

This pin is active only when the ISL6324A is in PVI mode.

When VID1 is HI prior to enable, the ISL6324A decodes the

programmed DAC voltage required by the AMD processor.

This pin has an internal 30µA pull-down current applied to it at

all times.

VID5

This pin is active only when the ISL6324A is in PVI mode.

When VID1 is HI prior to enable, the ISL6324A decodes the

programmed DAC voltage required by the AMD processor.

This pin has an internal 30µA pull-down current applied to it at

all times.

VCC

VCC is the bias supply for the ICs small-signal circuitry.

Connect this pin to a +5V supply and decouple using a

quality 0.1µF ceramic capacitor.

PVCC1_2

The power supply pin for the multi-phase internal MOSFET

drivers. Connect this pin to any voltage from +5V to +12V

depending on the desired MOSFET gate-drive level.

Decouple this pin with a quality 1.0µF ceramic capacitor.

PVCC_NB

The power supply pin for the internal MOSFET driver for the

Northbridge controller. Connect this pin to any voltage from

+5V to +12V depending on the desired MOSFET gate-drive

level. Decouple this pin with a quality 1.0µF ceramic capacitor .

GND

GND is the bias and reference ground for the IC. The GND

connection for the ISL6324A is through the thermal pad on

the bottom of the package.

EN

This pin is a threshold-sensitive (approximately 0.85V) system

enable input for the controller. Held low, this pin disables both

CORE and NB controller operation. Pulled high, the pin

enables both controllers for operation.

When the EN pin is pulled high, the ISL6324A will be placed

in either SVI or PVI mode. The mode is determined by the

latched value of VID1 on the rising edge of the EN signal.

A third function of this pin is to provide driver bias monitor for

external drivers. A resistor divider with the center tap

connected to this pin from the drive bias supply prevents

enabling the controller before insufficient bias is provided to

external driver. The resistors should be selected such th at

when the POR-trip point of the external driver is reached, the

voltage at this pin meets the above mentioned threshold level .

FS

A resistor, placed from FS to Ground or from FS to VCC,

sets the switching frequency of both controllers. Refer to

Equation 1 for proper resistor calculation.

10.61 1.035 fs()log–[]

10

=

R

T

With the resistor tied from FS to Ground, Droop is enabled.

With the resistor tied from FS to VCC, Droop is disabled.

(EQ. 1)

VSEN and RGND

VSEN and RGND are inputs to the core voltage regulator

(VR) controller precision differential remote-sense amplifier

and should be connected to the sense pins of the remote

processor core(s), VDDFB[H,L].

FB and COMP

These pins are the internal error amplifier inverting input and

output respectively of the core VR controller. FB, VSEN and

COMP are tied together through external R-C networks to

compensate the regulator.

APA

Adaptive Phase Alignment (APA) pin for setting trip level and

adjusting time constant. A 100µA current flows into the APA

pin and by tying a resistor from this pin to COMP the trip

level for the Adaptive Phase Alignment circuitry can be set.

9

FN6880.0

March 23, 2009

ISL6324AISL6324A

ISEN1-, ISEN1+, ISEN2-, ISEN2+, ISEN3-, ISEN3+,

ISEN4-, and ISEN4+

These pins are used for differentially sensing the corresponding

channel output currents. The sensed currents are used for

channel balancing, protection, and core load line regulation.

Connect ISEN1-, ISEN2-, ISEN3-, and ISEN4- to the node

between the RC sense elements surrounding the inductor of

their respective channel. Tie the ISEN+ pins to the VCORE

side of their corresponding channel’s sense capacitor.

UGATE1 and UGATE2

Connect these pins to the corresponding upper MOSFET

gates. These pins are used to control the upper MOSFETs

and are monitored for shoot-through prevention purposes.

Maximum individual channel duty cycle is limited to 93.3%.

BOOT1 and BOOT2

These pins provide the bias voltage for the corresponding

upper MOSFET drives. Connect these pins to appropriately

chosen external bootstrap capacitors. Internal bootstrap

diodes connected to the PVCC1_2 pin provide the

necessary bootstrap charge.

PHASE1 and PHASE2

Connect these pins to the sources of the corresponding

upper MOSFETs. These pins are the return path for the

upper MOSFET drives.

LGATE1 and LGATE2

These pins are used to control the lower MOSFET s. Connect

these pins to the corresponding lower MOSFETs’ gates.

PWM3 and PWM4

Pulse-width modulation outputs. Connect these pins to the

PWM input pins of an Intersil driver IC if 3- or 4-phase

operation is desired. Connect the ISEN- pins of the channels

not desired to +5V to disable them and configure the core

VR controller for 2-phase or 3-phase operation.

PWROK

System wide Power Good signal. If this pin is low, the two

SVI bits are decoded to determine the “metal VID”. When the

pin is high, the SVI is actively running its protocol.

RSET

Connect this pin to the VCC pin through a resistor (R

set the effective value of the internal R

resistors. The values of the R

than 20kΩ and no more than 80kΩ. A 0.1µF capacitor

should be placed in parallel to the R

resistor should be no less

SET

current sense

ISEN

resistor.

SET

SET

) to

VDDPWRGD

During normal operation this pin indicates wh ether both output

voltages are within specified overvoltage and undervolt age

limits. If either output voltage exceeds these limits or a re set

event occurs (such as an overcurrent event), the pin is pulled

low. This pin is always low prior to the end of sof t-start.

DVC

The DVC pin is a buffered version of the reference to the error

amplifier. A series resistor and capaci tor between the DVC pin

and FB pin smooth the voltage transition d uring VID-on-the-fly

operations.

FB_NB and COMP_NB

These pins are the internal error amplifier inverting input and

output respectively of the NB VR controller. FB_NB,

VDIFF_NB, and COMP_NB are tied together through

external R-C networks to compensate the re gu l at o r.

ISEN_NB-, ISEN_NB+

These pins are used for differentially sensing the North

Bridge output current. The sensed current is used for

protection and load line regulation if droop is enabled.

Connect ISEN_NB- to the node between the RC sense

element surrounding the inductor. Tie the ISEN_NB+ pin to

the VNB side of the sense capacitor.

UGATE_NB

Connect this pin to the corresponding upper MOSFET gate.

This pin provides the PWM-controlled gate drive for the

upper MOSFET and is monitored for shoot-through

prevention purposes.

BOOT_NB

This pin provides the bias voltage for the corresponding

upper MOSFET drive. Connect this pin to appropriately

chosen external bootstrap capacitor. The internal bootstrap

diode connected to the PVCC_NB pin provides the

necessary bootstrap charge.

PHASE_NB

Connect this pin to the source of the corresponding upper

MOSFET. This pin is the return path for the upper MOSFET

drive. This pin is used to monitor the voltage drop across the

upper MOSFET for overcurrent protection.

LGATE_NB

Connect this pin to the corresponding MOSFET’s gate. This

pin provides the PWM-controlled gate drive for the lower

MOSFET. This pin is also monitored by the adaptive

shoot-through protection circuitry to determine when the

lower MOSFET has turned off.

SCL

Connect this pin to the clock signal for the I2C bus, which is

a logic level input signal. The clock signal tells the controller

when data is available on th e I

2

C bus.

SDA

Connect this pin to the bidirectional data line of the I2C bus,

which is a logic level input/output signal. All I

over this line, including the address of the device the bus is

trying to communicate with, and what functions the device

should perform.

2

C data is sent

10

FN6880.0

March 23, 2009

ISL6324A

Operation

The ISL6324A utilizes a multi-phase architecture to provide

a low cost, space saving power conversion solution for the

processor core voltage. The controller also implements a

simple single phase architecture to provide the Northbridge

voltage on the same chip.

Multi-phase Power Conversion

Microprocessor load current profiles have changed to the

point that the advantages of multi-phase power conversion

are impossible to ignore. The technical challenges

associated with producing a single-phase converter that is

both cost-effective and thermally viable have forced a

change to the cost-saving approach of multi-phase. The

ISL6324A controller helps simplify implementation by

integrating vital functions and requiring minimal external

components. The “Controller Block Diagram” on page 3

provides a top level view of the multi-phase power

conversion using the ISL6324A controller.

Interleaving

The switching of each channel in a multi-phase converter is

timed to be symmetrically out-of-phase with each of the other

channels. In a 3-phase converter, each channel switches 1/3

cycle after the previous channel and 1/3 cycle before the

following channel. As a result, the three-phase converter has a

combined ripple frequency three times greater than the ripple

frequency of any one phase. In addition, the peak-to-peak

amplitude of the combined inductor currents is reduced in

proportion to the number of phases (Equations 2 and 3).

Increased ripple frequency and lower ripple amplitude mean

that the designer can use less per-channel inductance and

lower total output capacitance for any performance

specification.

Figure 1 illustrates the multiplicative effect on output ripple

frequency. The three channel currents (IL1, IL2, and IL3)

combine to form the AC ripple current and the DC load

current. The ripple component has three times the ripple

frequency of each individual channel current. Each PWM

pulse is terminated 1/3 of a cycle after the PWM pulse of the

previous phase. The peak-to-peak current for each phase is

about 7A, and the DC components of the inductor currents

combine to feed the load.

T o understand the reduction of ripple current amplitude in the

multi-phase circuit, examine Equation 2, which represents

an individual channel peak-to-peak inductor current.

VINV

–()V

OUT

IN

and V

IN

OUT

are the input and output

OUT

I

------------------------------------------------------=

PP–

LfSV

In Equation 2, V

voltages respectively, L is the single-channel inductor value,

and f

is the switching frequency.

S

(EQ. 2)

The output capacitors conduct the ripple component of the

inductor current. In the case of multi-phase converters, the

capacitor current is the sum of the ripple currents from each

of the individual channels. Compare Equation 2 to the

expression for the peak-to-peak current after the summation

of N symmetrically phase-shifted inductor currents in

Equation 3. Peak-to-peak ripple current decreases by an

amount proportional to the number of channels. Output

voltage ripple is a function of capacitance, capacitor

equivalent series resistance (ESR), and inductor ripple

current. Reducing the inductor ripple current allows the

designer to use fewer or less costly output capacitors.

I

CP P–()

------------------------------------------------------------=

LfSV

OUT

IN

(EQ. 3)

VINNV

–()V

OUT

Another benefit of interleaving is to reduce input ripple

current. Input capacitance is determined in part by the

maximum input ripple current. Multi-phase topologies can

improve overall system cost and size by lowering input ripple

current and allowing the designer to reduce the cost of input

capacitance. The example in Figure 2 illustrates input

currents from a three-phase converter combining to reduce

the total input ripple current.

The converter depicted in Figure 2 delivers 1.5V to a 36A load

from a 12V input. The RMS input capacitor current is 5.9A.

Compare this to a single-phase conve rter also step ping down

12V to 1.5V at 36A. The single-phase converter has

11.9A

input capacitor current. The single-phase converter

RMS

must use an input capacitor bank with twice the RMS current

capacity as the equivalent three-phase converter .

Figures 26, 27 and 28 in the section entitled “Input Capacitor

Selection” on page 35 can be used to determine the input

capacitor RMS current based on load current, duty cycle,

and the number of channels. They are provided as aids in

determining the optimal input capacitor solution.

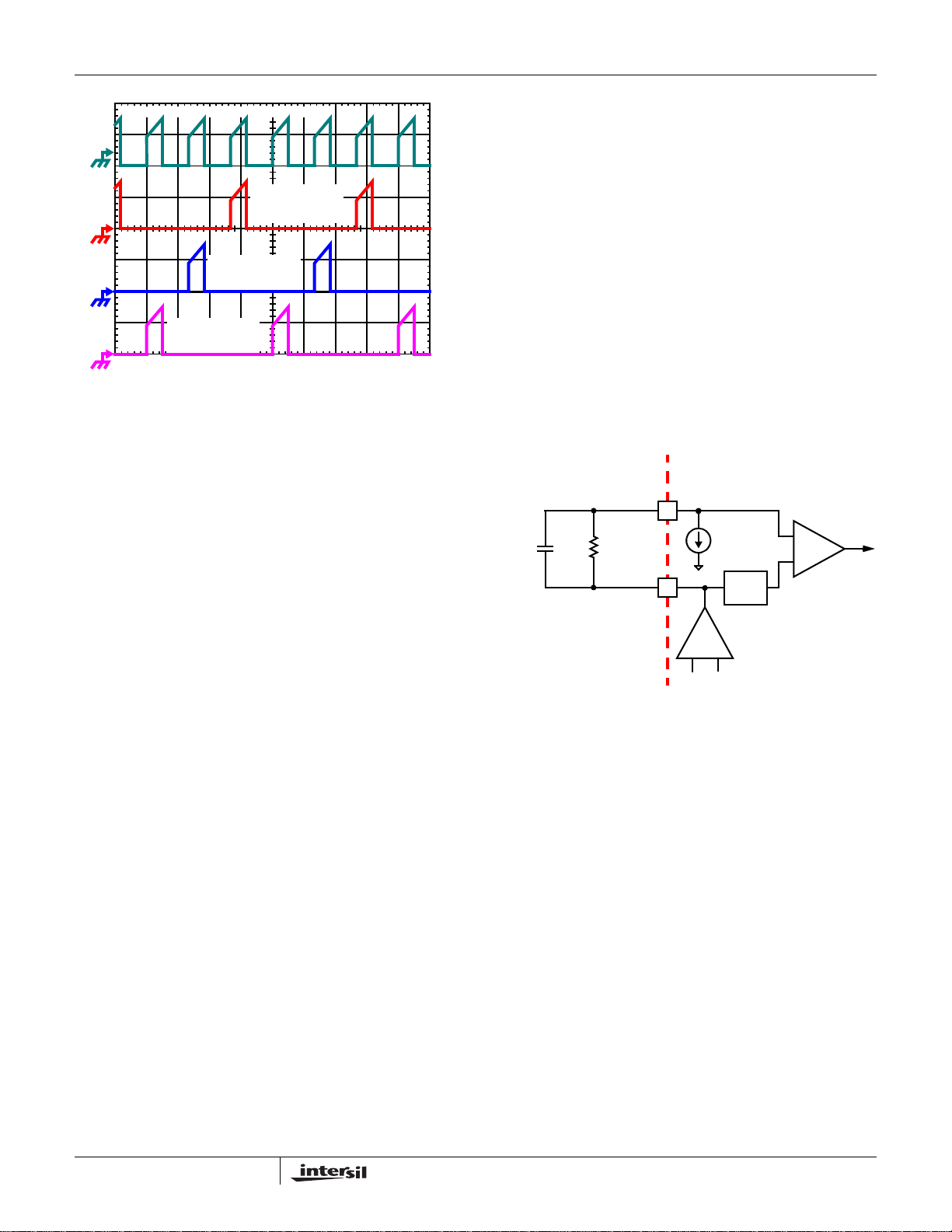

IL1 + IL2 + IL3, 7A/DIV

IL3, 7A/DIV

PWM3, 5V/DIV

IL2, 7A/DIV

PWM2, 5V/DIV

IL1, 7A/DIV

PWM1, 5V/DIV

1µs/DIV

FIGURE 1. PWM AND INDUCTOR-CURRENT WA VEFORMS

FOR 3-PHASE CONVERTER

11

FN6880.0

March 23, 2009

ISL6324A

INPUT-CAPACITOR CURRENT, 10A/DIV

CHANNEL 3

INPUT CURRENT

10A/DIV

CHANNEL 2

INPUT CURRENT

10A/DIV

CHANNEL 1

INPUT CURRENT

10A/DIV

1μs/DIV

FIGURE 2. CHANNEL INPUT CURRENTS AND INPUT

CAPACITOR RMS CURRENT FOR 3-PHASE

CONVERTER

Active Pulse Positioning Modulated PWM Operation

The ISL6324A uses a proprietary Active Pulse Positioning

(APP) modulation scheme to control the internal PWM signals

that command each channel’s driver to turn their upper and

lower MOSFETs on and off. The time interval in which a PWM

signal can occur is generated by an internal clock, whose cycle

time is the inverse of the switching frequency set by the resistor

between the FS pin and ground. The advantage of Intersil’s

proprietary Active Pulse Positioning (APP) modulator is that the

PWM signal has the ability to turn on at any point during this

PWM time interval, and turn off immediately after the PWM

signal has transitioned high. This is important because it allows

the controller to quickly respond to output voltage drops

associated with current load spikes, while avoiding the ring

back affects associated with other modulation schemes.

To further improve the transient response, ISL6324A also

implements Intersil’s proprietary Adaptive Phase Alignment

(APA) technique, which turns on all phases together under

transient events with large step current. With both APP and

APA control, ISL6324A can achieve excellent transient

performance and reduce the demand on the output capacitors.

Adaptive Phase Alignment (APA)

To further improve the transient response, the ISL6324A

also implements Intersil’s proprietary Adaptive Phase

Alignment (APA) technique, which turns on all of the

channels together at the same time during large current step

transient events. As Figure 3 shows, the APA circuitry works

by monitoring the voltage on the APA pin and comparing it to

a filtered copy of the voltage on the COMP pin. The voltage

on the APA pin is a copy of the COMP pin voltage that has

been negatively offset. If the APA pin exceeds the filtered

COMP pin voltage an APA event occurs and all of the

channels are forced on.

EXTERNAL CIRCUIT

APA

-

C

R

APA

FIGURE 3. ADAPTIVE PHASE ALIGNMENT DETECTION

APA

V

APA,TRIP

+

COMP

ISL6324A INTERNAL CIRCUIT

100µA

+

APA

-

-

LOW

PASS

FILTER

ERROR

AMPLIFIER

+

CIRCUITRY

TO APA

The PWM output state is driven by the position of the error

amplifier output signal, V

, minus the current correction

COMP

signal relative to the proprietary modulator ramp waveform as

illustrated in Figure 3. At the beginning of each PWM time

interval, this modified V

internal modulator waveform. As long as the modified V

signal is compared to the

COMP

COMP

voltage is lower then the modulator waveform voltage, the

PWM signal is commanded low. The internal MOSFET driver

detects the low state of the PWM signal and turns off the

upper MOSFET and turns on the lower synchronous

MOSFET. When the modified V

voltage crosses the

COMP

modulator ramp, the PWM output transitions high, turning off

the synchronous MOSFET and turning on the upper

MOSFET. The PWM signal will remain high until the modified

V

voltage crosses the modulator ramp again. When this

COMP

occurs the PWM signal will transition low again.

During each PWM time interval the PWM signal can only

transition high once. Once PWM transitions high it can not

transition high again until the beginning of the next PWM

time interval. This prevents the occurrence of double PWM

pulses occurring during a single period.

12

The APA trip level is the amount of DC offset between the

COMP pin and the APA pin. This is the voltage excursion

that the APA and COMP pins must have during a transient

event to activate the Adaptive Phase Alignment circuitry.

This APA trip level is set through a resistor, R

connects from the APA pin to the COMP pin. A 100µA

current flows across R

into the APA pin to set the APA

APA

APA

, that

trip level as described in Equation 4. An APA trip level of

500mV is recommended for most applications. A 0.1µF

capacitor, C

, should also be placed across the R

APA

APA

resistor to help with noise immunity.

V

APA TRIP,

R

APA

100 106–×⋅=

(EQ. 4)

PWM Operation

The timing of each core channel is set by the number of

active channels. Channel detection on the ISEN3- and

ISEN4- pins selects 2-Channel to 4-Channel operation for

the ISL6324A. The switching cycle is defined as the time

between PWM pulse termination signals of each channel.

The cycle time of the pulse signal is the inverse of the

FN6880.0

March 23, 2009

Loading...

Loading...