®

www.BDTIC.com/Intersil

ISL5314

Data Sheet July 28, 2005

Direct Digital Synthesizer

The 14-bit ISL5314 provides a complete Direct Digital

Synthesizer (DDS) system in a single 48-pin LQFP package.

A 48-bit Programmable Carrier NCO (numerically controlled

oscillator) and a high speed 14-bit DAC (digital to analog

converter) are integrated into a stand alone DDS.

The DDS accepts 48-bit center and offset frequency control

information via a parallel processor interface. A 40-bit

frequency tuning word can also be loaded via an asynchronous

serial interface. Modulation control is provided by 3 external

pins. The PH0 and PH1 pins select phase offsets of 0, 90,

180 and 270 degrees, while the ENOFR pin enables or zeros

the offset frequency word to the phase accumulator.

The parallel processor interface has an 8-bit write-only data

input C(7:0), a 4-bit address A(3:0) bus, a Write Strobe

(WR), and a Write Enable (WE

). The processor can update

all registers simultaneously by loading a set of master

registers, then transfer all master registers to the slave

registers by asserting the UPDATE

pin.

Ordering Information

PART # TEMP. RANGE (°C) PACKAGE PKG. DW G . #

ISL5314IN -40 to 85 48 LQFP Q48.7x7A

ISL5314INZ

(See Note)

-40 to 85 48 LQFP

(Pb-free)

Q48.7x7A

ISL5314EVAL2 25 Evaluation Board

NOTE: Intersil Pb-free plus anneal products employ special Pb-free material

sets; molding compounds/die attach materials and 100% matte tin plate

termination finish, which are RoHS compliant and compatible with both SnPb

and Pb-free soldering operations. Intersil Pb-free products are MSL classified

at Pb-free peak reflow temperatures that meet or exceed the Pb-free

requirements of IPC/JEDEC J STD-020.

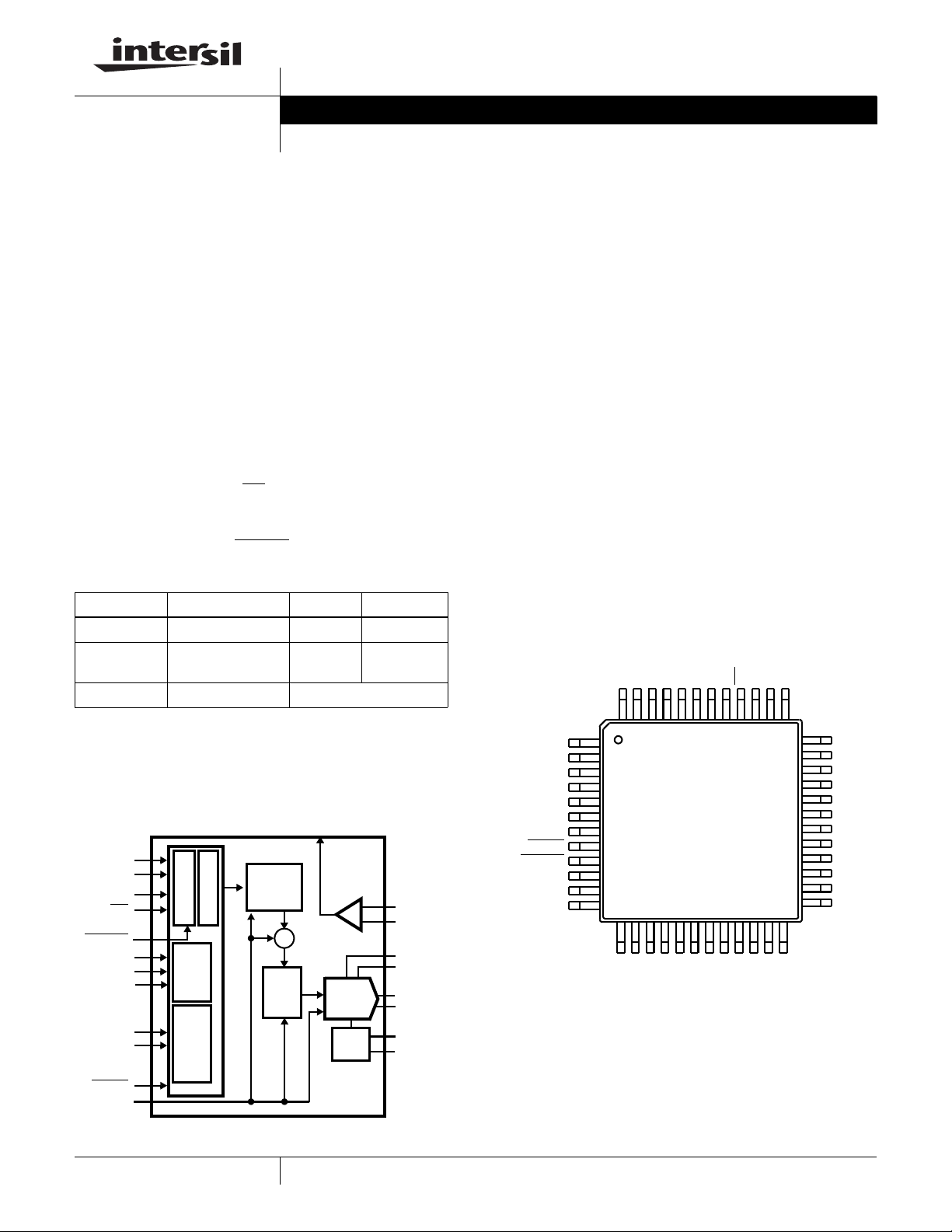

Block Diagram

C(7:0)

A(3:0)

WR

WE

UPDATE

SDATA

SSYNC

SCLK

ENOFR

PH(1:0)

MASTER

SLAVE

CONTROL

SERIAL

MODULATION

CONTROL

PHASE

ACCUM.

∑

SINE

WAVE

ROM

COMPOUT

+

14 BIT

DAC

INT

REF

ININ+

COMP1

COMP2

IOUTA

IOUTB

REFIO

REFLO

FN4901.2

Features

• 125MSPS output sample rate with 5V digital supply

• 100MSPS output sample rate with 3.3V digital supply

• 14-bit digital-to-analog (DAC) with internal reference

• Parallel control interface for fast tuning (50MSPS control

register write rate) and serial control interface

• 48-bit programmable frequency control

• Offset frequency register and enable pin for fast FSK

• Small 48-pin LQFP packaging

• Pb-Free plus anneal available (RoHS compliant)

Applications

• Programmable local oscillator

• FSK, PSK modulation

• Direct digital synthesis

• Clock generation

Pinout

48-PIN LQFP (Q48.7X7A)

TOP VIEW

WR

DGND

AVDD

COMP2

WE

AGND

NC

IN+

A0

IN-

A1

373839404142434445464748

36

35

34

33

32

31

30

29

28

27

26

25

2423222120191817

AGND

A2

A3

PH0

PH1

SSYNC

DVDD

SCLK

DGND

DGND

SDATA

DVDD

DGND

C2

C1

C0

ENOFR

DGND

CLK

DVDD

RESET

UPDATE

COMPOUT

REFLO

REFIO

C3

C4

1

2

3

4

5

6

7

8

9

10

11

12

13 14 15 16

FSADJ

COMP1

C6

C7

DVDD

C5

ISL5314

AGND

AGND

IOUTA

IOUTB

RESET

CLK

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright Intersil Americas Inc. 2000, 2005. All Rights Reserved

ISL5314

www.BDTIC.com/Intersil

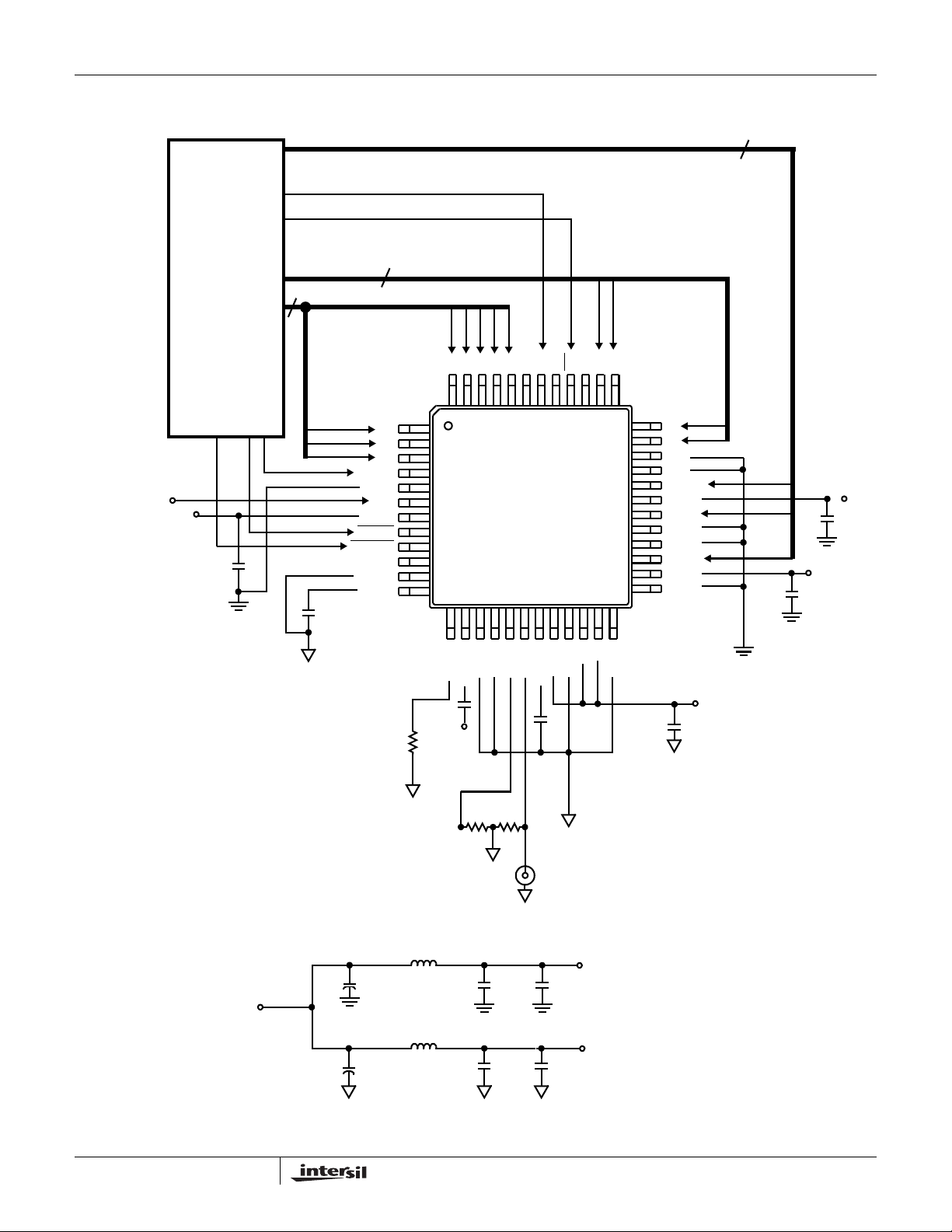

Typical Application Circuit (Parallel Control Mode, Sinewave Generation)

CLOCK

SOURCE

f

CLK

µPROCESSOR/

FPGA/CPLD

DV

PP

0.1µF

SDATA, SSYNC, SCLK (IN PARALLEL CONTROL MODE,

SERIAL CONTROL CAN ALSO BE USED IF DESIRED.)

WRITE CLOCK (WR)

WRITE ENABLE

C2

C1

C0

ENOFR

DGND

CLK

DVDD

RESET

UPDATE

REFLO

REFIO

4

C3

C6

C7

C5

DVDD

ISL5314

WR

1

2

3

4

5

6

7

8

9

10

11

12

13 14 15 16

C4

A3:A0 BUS

8

C7:C0 BUS

0.1µF

COMPOUT

DGND

WE

NC

A0

3

A1

373839404142434445464748

36

35

34

33

32

31

30

29

28

27

26

25

2423222120191817

A2

A3

PH0

PH1

SSYNC

DVDD

SCLK

DGND

DGND

SDATA

DVDD

DGND

DV

0.1µF

PP

DV

PP

0.1µF

+5V POWER SOURCE

+

+

10µF

10µF

R

SET

2kΩ

0.1µF

FERRITE

BEAD

10µH

FERRITE

BEAD

10µH

AV

FSADJ

PP

AGND

COMP1

50Ω

0.1µF

0.1µF

AGND

50Ω

DGND

AGND

AVDD

AGND

IOUTA

IOUTB

COMP2

0.1µF

(IOUTA) ANALOG OUTPUT

1µF

1µF

IN-

IN+

AGND

0.1µF

(DIGITAL POWER PLANE)

DVPP

AVPP

(ANALOG POWER PLANE)

AV

PP

2

ISL5314

www.BDTIC.com/Intersil

Functional Description

The ISL5314 is an NCO with an integrated 14-bit DAC

designed to run in excess of 125MSPS. The NCO is a 16-bit

output design, which is rounded to fourteen bits for input to the

DAC. The frequency control is the sum of a 48-bit center

frequency word, a 48-bit offset frequency word, and a 40-bit

serially loaded tuning word. The three components are added

modulo 48 bits with the alignment shown in T able 1. Each of the

three terms can be zeroed independently (via the

microprocessor interface for the center and serial frequency

registers and via the ENOFR pin for the offset frequency term).

Frequency Generation

The output frequency of the part is determined by the

summation of three registers:

f

= f

OUT

where CF is the center frequency register, OF is the offset

frequency register, SF is the serial frequency register and

f

CLK

With a 125MSPS clock rate, the center frequency can be

programmed to

(125 x 10

The addition of the frequency control words can be interpreted

as two’s complement if conv enient. F or example, if the center

frequency is set to 4000...00h and the offset frequency set to

C000..00h, the programmed center frequency would be f

and the programmed offset frequency -f

be 10000..00h, but because only the lower 48 bits are retained,

the effective frequency would be 0. In reality, frequencies above

8000...00h alias below f

the MSB is only provided as a convenience for two’s

complement calculations.

The frequency control of the NCO is the change in phase per

clock period or dφ/dt. This is integrated by the phase

accumulator to obtain frequency . The most significant 24 bits

of phase are then mapped to 16 bits of amplitude in a sine

look-up table function. The range of dφ/dt is 0–1 with 1

equaling 360 degrees or (2 x pi) per clock period. The phase

accumulator output is also 0–1 with 1 equaling 360 degrees.

The operations are modulo 48 bits because the MSB (bit 47)

aligns with the most significant address bit of the sine ROM

and the ROM contains one cycle of a sinusoid. The MSB is

weighted at 180 degrees. Full scale is 360 degrees minus

one LSB and the phase then rolls over to 0 degrees for the

next cycle of the sinusoid.

The DDS can be clocked with either a sinusoidal or a square

wave. Refer to the digital inputs V

electrical specifications table.

x ((CF + OF +SF) mod (248))/ (248),

CLK

is the DDS clock rate.

6

)/(248) = 0.4 µHz resolution.

/2 (the output of the part is real), so

CLK

/4. The sum would

CLK

and VIL values in the

IH

CLK

/4

four address pins (A3:A0), a write strobe (WR), and a write

enable (WE

processor interface loads a set of master registers. The

contents of the master set of registers is then transferred to a

slave set of registers by asserting a pin (UPDATE

allows all of the bits of the frequency control to be updated

simultaneously.

The rate which the user writes (WR) to these registers does not

have to be the same rate as the DDS clock rate (the rate of the

NCO and DAC; pin CLK). It is e x pected that most applications

will have a slower register write rate than the DDS clock rate. It

takes one WR cycle at the write rate for each register that is

written and another eleven CLK cycles at the DDS r ate to write

and obtain a new output, assuming that the UPDATE

always active . If the UPD ATE

word has been written, it takes fourteen CLK cycles, rather than

eleven. F or cases which require the output to be updated with

all of the new frequency information present, it is necessary that

the UPDATE

has been written to the device. See the Timing Diagrams for

more information. The parallel registers can be written at a rate

of CLK/2, such that updated control words can be pipelined. If

the application does not require all registers to be written, then

the output frequency can be changed more quickly . For

example, if only 32 bits of frequency information are needed

and it is desired that the output be updated all at once, then it

takes four WR cycles, then the ass ertion low of the UPD ATE

pin, plus another fourteen CLK cycles at the DDS rate to write

and update a new frequency.

The timing is the same whether writing to the center or offset

frequency registers. For f aster frequ ency update, consider the

ENOFR (Enable Offset Fr equency Register) option. Once the

values have been written to the center and offset frequency

registers, the user can enable and disab le the offset frequency

register, which is added to the center frequency value when

enabled. The ENOFR pin has a latency of fourteen CLK

cycles, but simplifies the interface because the only pin that

has to be toggled is the ENOFR pin. See the FSK explanation

for more information.

). The interface is a master/slave type. The

). This

pin is

pin is not active until after the new

be inactive until after all of the new frequency word

Serial Interface

A serial interface is provided for loading a tuning frequency .

This interface can be asynchronous to the master clock of the

part. When the tuning word has been shifted into the part, it is

loaded into a holding register by the serial interface clock,

SCLK. This loading triggers a synchronization circuit to transfer

the data to a slave register synchronous with the master clock.

A minimum of eleven serial clocks (at minimum serial word size

of eight) are necessary to complete the transfer to the slave

register. Another twelv e DDS CLK cycles are necessary before

the output of the DDS reflects the new frequency .

Parallel Interface

The processor interface is an 8-bit parallel write only

interface. The interface consists of eight data bits (C7:C0),

3

Serial loading latency = ((8 x N + 3) x SCLK)+ 12 x f

CLK

,

ISL5314

www.BDTIC.com/Intersil

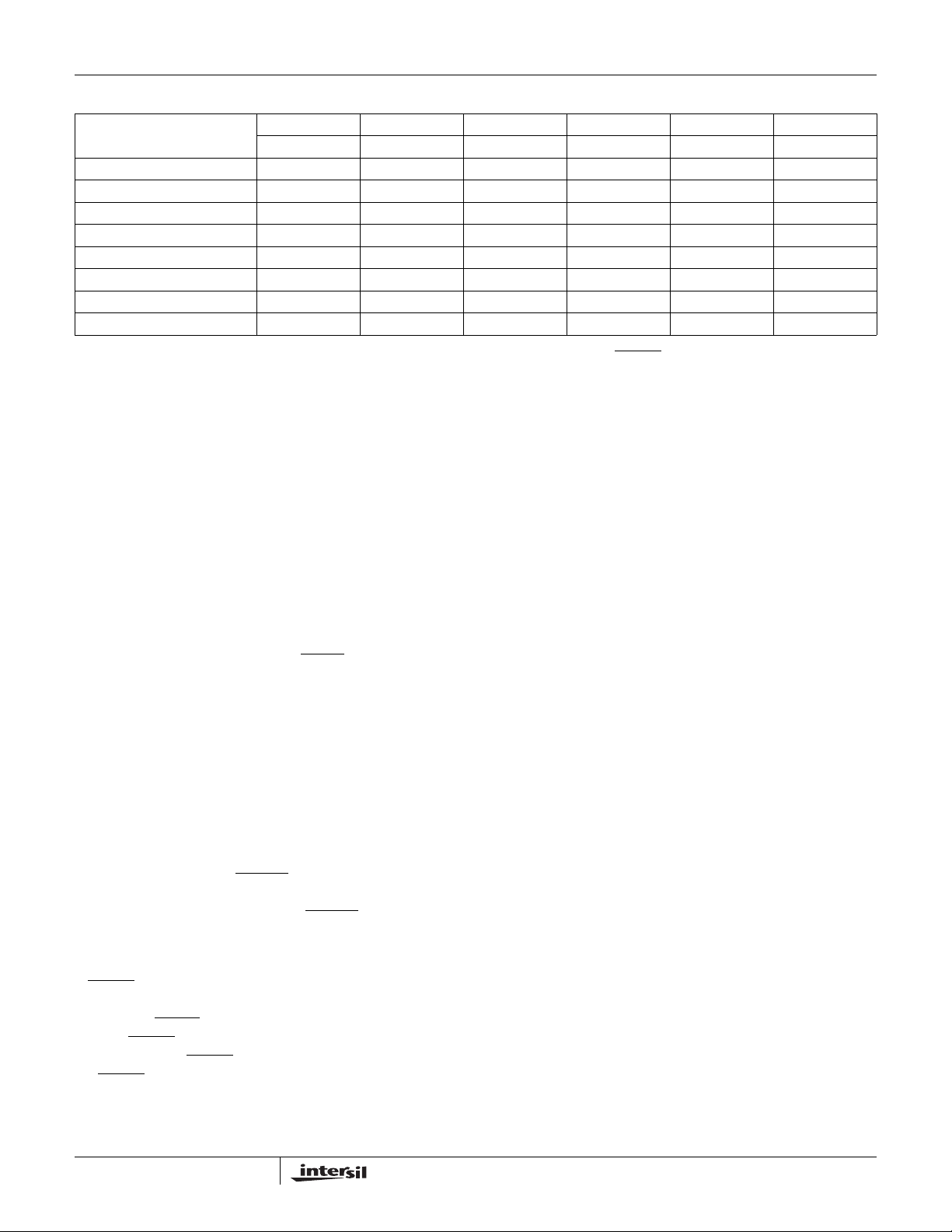

TABLE 1. FREQUENCY CONTROL BIT ALIGNMENTS

48 Bits

(Individual Bit Alignment)

Phase Accumulator xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx

Center Frequency xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx

Offset Frequency xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx

Serial Frequency, 8 Bits xxxx xxxx 0000 0000 0000 0000 0000 0000 0000 0000 0000 0000

Serial Frequency, 16 Bits xxxx xxxx xxxx xxxx 0000 0000 0000 0000 0000 0000 0000 0000

Serial Frequency, 24 Bits xxxx xxxx xxxx xxxx xxxx xxxx 0000 0000 0000 0000 0000 0000

Serial Frequency, 32 Bits xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx 0000 0000 0000 0000

Serial Frequency, 40 Bits xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx 0000 0000

4444 4444 3333 3333 3322 2222 2222 1111 1111 1100 0000 0000

7654 3210 9876 5432 1098 7654 3210 9876 5432 1098 7654 3210

where N = 1–5 (for 8–40 bit serial data) and f

clock rate. Three e xtr a SCLKs are required (one f or the SYNC

pulse plus two additional for register transfer). The latency in

seconds depends on how many bits of serial data are being

written and the speeds of both clocks. The center and offset

frequency registers cannot be written using the serial pins.

They must be programmed using the parallel interface.

In order to use the three wire serial interface in a mode that is

not the default mode, the parallel control bus must be used to

reprogram register 12. Register 12 can be set according to the

desired options of the serial interface that are described in the

register description table. Since the serial register defaults

enabled, it must be disabled in register 13 (bit 6) if it is not used.

is the DDS

CLK

Register 14

The parallel control bus must be used to program register 14

with 0x00h or 0x30h after assertion of RESET

Register table in the back of the datasheet for more information.

. See the Control

Control Pins

There are three control pins provided for phase and frequency

control. The PH0 and PH1 pins select phase offsets of 0, 90,

180, and 270 degrees and can be used for low speed,

unfiltered BPSK or QPSK modulation. These pins can also be

used for providing sine/cosine when using two ISL5314s

together as quadrature local oscillators. The ENOFR pin

enables or zeros the offset frequency word to the phase

accumulator and can be used for FSK or MSK modulation.

These control pins and the UPDATE

special cells to minimize the probability of metastability . Writing

anything to register 15 behaves like an UPDA TE

user can save one control pin if desired.

pin are passed through

so that the

Reset

A RESET pin is available which resets all registers to their

defaults. Register 14 must always be written with 0x00h or

0x30h after a RESET

take the RESET

and then take the RESET

the RESET

is eleven CLK cycles. See the register description table in

the back of the data sheet for the default states of all bits in

pin going high until the output reflects the reset

. In order to reset the part, the user must

pin low, allow at least one CLK rising edge,

pin high again. The latency from

all registers. After RESET

is required before the control registers can be written to

again. The center frequency register resets to f

offset frequency register resets to an unknown frequency but

is disabled. The serial frequency register resets to an

unknown frequency and is enabled. If the serial register is

not used, disable it in register 13 using the parallel interface.

goes high, one rising edge of CLK

/4. The

CLK

Comparator

A comparator is provided for square wave output generation.

The user can take the DDS analog output, filter it, and then

send it back into the comparator. A square wa ve will be

generated at the comparator output (COMPOUT pin) at an

amplitude level that is dependent on the digital power supply

(DV

). The comparator was designed to operate at speeds

DD

comparable to the DDS output frequency range (approximately

0–50MHz). It is not intended for low jitter applications (<0.5ns).

The comparator has a sleep mode that is activated by

connecting both inputs (IN- and IN+) to the analog power

supply plane. This will save appro ximately 4mA of current (as

shown in the Typical Application Circuit). If the comparator is

not used, leave the COMPOUT pin floating.

DAC Voltage Reference

The internal voltage reference for the DAC has a nominal

value of +1.2V with a ±60ppm/

full temperature range of the converter. It is recommended

that a 0.1µF capacitor be placed as close as possible to the

REFIO pin, connected to the analog ground. The REFLO pin

(11) selects the reference. The internal reference can be

selected if pin 11 is tied low (ground). If an external reference

is desired, then pin 11 should be tied high (the analog supply

voltage) and the external reference driven into REFIO, pin

12. The full-scale output current of the converter is a function

of the voltage reference used and the value of R

should be within the 2mA–20mA range, though operation

below 2mA is possible, with performance degradation.

If the internal reference is used, V

approximately 1.2V (pin 13). If an external reference is used,

V

I

will equal the external reference.

FSADJ

(Full Scale) = (V

OUT

FSADJ/RSET)

o

C drift coefficient over the

. I

SET

will equal

FSADJ

X 32.

OUT

4

ISL5314

www.BDTIC.com/Intersil

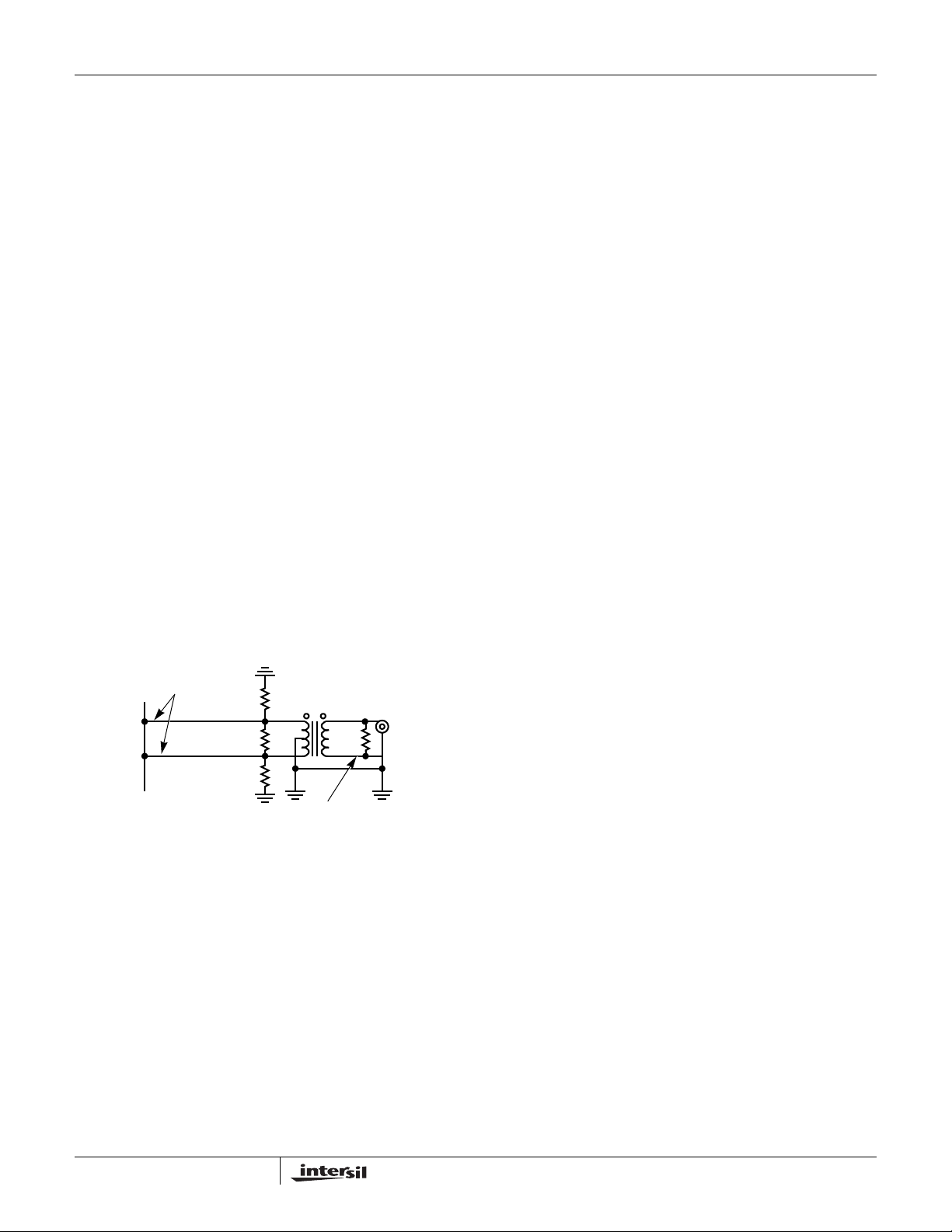

Analog Output

IOUT A and IOUTB are complementary current outputs. They

are generated by a 14-bit DA C that is capab le of running at the

full 125MSPS rate. The DDS clock also clocks the D A C. The

sum of the two output currents is always equal to the full scale

output current minus one LSB. If single-ended use is desired, a

load resistor can be used to convert the output current to a

voltage. It is recommended that the unused output be equally

terminated. The voltage developed at the output must not

violate the output voltage compliance range of -1.0V to +1.25V.

R

(the impedance loading each current output) should be

LOAD

chosen so that the desired output voltage is produced in

conjunction with the output full scale current. If a known line

impedance is to be driven, then the output load resistor should

be chosen to match this impedance. The output voltage

equation is:

V

= I

OUT

X R

OUT

These outputs can be used in a differential-to-single-ended

arrangement. This is typically done to achieve better harmonic

rejection. Because of a mismatch in IOUT A and IOUTB , the

transformer does not improve the harmonic rejection. Howev er ,

it can provide voltage gain without adding distortion. The SFDR

measurements in this data sheet were performed with a 1:1

transformer on the output of the DDS (see Figure 1). With the

center tap grounded, the output swing of pins 17 and 18 will be

biased at zero volts. The loading as shown in Figure 1 will result

in a 500mV

signal at the output of the transformer if the full

P-P

scale output current of the DAC is set to 20mA.

REQ IS THE IMPEDANCE

LOADING EACH OUTPUT

PIN 17

PIN 18

ISL5314

FIGURE 1. TRANSFORMER OUTPUT CIRCUIT OPTION

V

= 2 x I

OUT

OUT

center tap to float will result in identical transformer output,

howeve r the output pins of the DAC will have positive DC

offset, which could limit the voltage swing available due to

the output voltage compliance range. The 50Ω load on the

output of the transformer represents the load at the end of a

‘transmission line’, typically a spectrum analyzer,

oscilloscope, or the next function in the signal chain. The

necessity to have a 50Ω impedance looking back into the

transformer is negated if the DDS is only driving a short

trace. The output voltage compliance range does limit the

impedance that is loading the DDS output.

.

LOAD

IOUTB

IOUTA

50Ω

100Ω

50Ω

= (2 x I

V

OUT

50Ω REPRESENTS THE

SPECTRUM ANALYZER

50Ω

OUT

x REQ)V

x REQ, where REQ is 12.5Ω. Allowing the

PP

Application Considerations

Ground Plane

Separate digital and analog ground planes should be used. All

of the digital functions of the device and their corresponding

components should be located over the digital ground plane

and terminated to the digital ground plane. The same is true for

the analog components and the analog ground plane. Pins 11

through 24 are analog pins, while all the others are digital.

Noise Reduction

To minimize power supply noise, 0.1µF capacitors should be

placed as close as possible to the power supply pins, AV

and DV

. Also, the layout should be designed using

DD

separate digital and analog ground planes and these

capacitors should be terminated to the digital ground for

DV

and to the analog ground for A VDD. Additional filtering

DD

of the power supplies on the board is recommended.

Power Supplies

The DDS will provide the best SFDR (spurious free dynamic

range) when using +5V analog and +5V digital power supply .

The analog supply must always be +5V (±10%). The digital

supply can be either a +3.3V (±10%), a +5V (±10%) supply,

or anything in between. The DDS is rated to 125MSPS when

using a +5V digital supply and 100MSPS when using a

+3.3V digital supply.

Improving SFDR

+5V power supplies provides the best SFDR. Under some

clock and output frequency combinations, particularly when

the f

CLK/fOUT

ratio is less than 4, the user can improve

SFDR even further by connecting the COMP2 pin (19) of the

DDS to the analog power supply. The digital supply must be

+5V if this option is explored. Improvements as much as

6dBc in the SFDR-to-Nyquist measurement were seen in the

lab.

FSK Modulation

Binary frequency shift keying (BFSK) can be done by using

the offset frequency register and the ENOFR pin. M-ary FSK

or GFSK (Gaussian) can be done by continuously loading in

new frequency words. The maximum FSK data rate of the

ISL5314 depends on the way the user programs the device

to do FSK, and the form of FSK.

For example, simple BFSK is efficiently performed with the

ISL5314 by loading the center frequency register with one frequency, the offset frequency register with another frequency ,

and toggling the ENOFR (enable offset frequency register)

pin. The latency is fourteen CLK cycles between assertion of

the ENOFR pin and the change occurring at the analog output. However, the change in frequency can be pipelined such

that the ENOFR can be toggled at a rate up to

ENOFR

where f

= f

MAX

is the frequency of the master CLK.

CLK

CLK

/2,

DD

5

ISL5314

www.BDTIC.com/Intersil

If M-ary FSK is required (more than two frequencies), the user

will have to continually reprogram the center frequency register.

The maximum write rate to the same parallel register is the

lesser of 50MSPS or f

/2. One WR clock cycle is required for

CLK

every register updated. The maximum possible rate occurs if

the user only needs to change eight bits (one register). For Mary FSK, the output frequency rate of change is

M-ary FSK Rate = WR

/ REG,

where REG = quantity of registers being written and WR =

write rate.

PSK Modulation

Binary or quadrature phase shift keying (PSK) can be done

by using the phase pins, PH0 and PH1. The change in

phase can be pipelined such that the PH pins can be toggled

at a rate up to

PH

= f

MAX

where f

/2,

CLK

is the frequency of the master CLK.

CLK

Quadrature Local Oscillators

Two ISL5314s can be used as sine/cosine generators for

quadrature local oscillator applications. It is important to note

that the phase accumulator feedback needs to be zeroed in

both devices if it is desired that both DDSs restart with a

known phase, which is determined by the use of the phase

control pins, PH1 and PH0. To zero the phase accumulator,

pull bit 5 of address 13 low and then high again at the same

time in both devices.

Squarewave Clock Source

The on-chip comparator can be used to generate a square

wave. The analog output is filtered and then fed into the

comparator input. Because the analog output is a sampledwavef orm, a high DA C output frequency (relative to the clock

rate) creates large amplitude steps in the sampled

wavef orm. These steps hav e to be smoothed with a lowpass

filter in order for the comparator to operate properly,

otherwise the zero-order hold nature of the sampled analog

output could possibly hold at the comparator’s trigger point

temporarily causing the comparator to toggle unexpectedly.

For this reason, it is very important that a lowpass filter be

used on the analog output prior to the input of the

comparator. The user can set one input to the comparator at

a DC reference point (typically the mid-point of the filtered

signal) and feed the filtered analog output into the other

input. See Figure 2 for an example of a square wave circuit

using this method. Since IOUTA and IOUTB are differential,

the mid-point between the 10k resistors will always be the

average value of each signal. The large resistors have to be

used so that the parallel resistance of the intended load and

the extra load of the averaging circuit yields a negligible

effect on the intended load. The average value is used as the

reference voltage for one input to the comparator, with a

capacitor to filter off any high frequency noise. The other

comparator input is connected to the lowpass filter output. It

is important that both IOUTA and IOUTB are equally loaded

so that each generates the same amplitude and therefore

has the same average value.

ISL5314

PIN 23

PIN 22

IN-

IN+

PIN 18

IOUTA

IOUTB

PIN 17

PIN 10

FIGURE 2. SQUAREWA VE GENERATION USING THE

COMPARATOR INPUTS

>1nF

100Ω

LPF (100Ω)

>10kΩ

>10kΩ

COMPOUT

ON-CHIP COMPARATOR

(TYP 20-40MHz)

50Ω

100Ω

The user can filter both IOUTA and IOUTB and feed them

differentially into the comparator. It is difficult to perfectly

match the differential option, so the single-ended option is

recommended. The jitter of the comparator is typically 500ps

peak to peak. The actual jitter achieved is partially

dependent on the quality of the signal at the comparator

input, which is dictated by the amount of oversampling of the

analog output and the quality of the lowpass filter.

The user also has the option to evaluate the comparator

circuit in Figure 2 with lower output current in order to save

power consumption in the ISL5314. The DAC output current

can be set to 5 or 10mA instead of 20mA and evaluated to

determine if the comparator performance is still suitable for

the application. Since the output current is derived from the

+5V analog supply , reducing the output from 20mA to 10mA

saves approximately 50mW of power. The recommended

minimum amplitude of the comparator input is 100mV, so

operation of the analog outputs with less than 20mA of

output current should be possible with appropriate resistive

loading (for example, 5mA into a 50Ω load provides 250mV

of amplitude).

If needed, series resistance on the comparator output can

be used to reduce overshoot and/or ringing. The comparator

can be used to drive a 50Ω load.

6

ISL5314

www.BDTIC.com/Intersil

Absolute Maximum Ratings Thermal Information

Digital Supply Voltage DVDD to DGND . . . . . . . . . . . . . . . . . . +5.5V

Analog Supply Voltage AV

Grounds, AGND To DGND. . . . . . . . . . . . . . . . . . . . . -0.3V To +0.3V

Digital Input Voltages . . . . . . . . . . . . . . . . . . . . . . . . . DV

Reference Input Voltage Range. . . . . . . . . . . . . . . . . . AV

Analog Output Current (I

to AGND. . . . . . . . . . . . . . . . . . +5.5V

DD

) . . . . . . . . . . . . . . . . . . . . . . . . . 24mA

OUT

DD

DD

+ 0.3V

+ 0.3V

Operating Conditions

Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . -40oC to 85oC

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

is measured with the component mounted on a low effective thermal conductivity test board in free air. See Tech Brief TB379 for details.

1. θ

JA

Thermal Resistance (Typical, Note 1) θ

LQFP Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Maximum Junction Temperature . . . . . . . . . . . . . . . . . . . . . . .150

Maximum Storage Temperature Range. . . . . . . . . . -65

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . .300

(oC/W)

JA

o

C to 150oC

o

o

C

C

Electrical Specifications AV

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

DAC CHARACTERISTICS

DAC Resolution 14 - - Bits

Integral Linearity Error, INL “Best Fit” Straight Line (Note 7) -5 +2.5 +6 LSB

Differential Linearity Error, DNL (Note 7) -2 +1.5 +4 LSB

Offset Error, I

Offset Drift Coefficient (Note 7) - 0.1 - ppm

Full Scale Gain Error With Internal Reference (Notes 2, 7) -10 ±1+10% FSR

Full Scale Gain Drift With Internal Reference (Note 7) - ±50 - ppm

Full Scale Output Current (Note 3) 2 - 20 mA

Output Voltage Compliance Range (Note 3, 7) -1.0 - 1.25 V

DAC DYNAMIC CHARACTERISTICS

Maximum Clock Rate, f

Maximum Clock Rate, f

Output Settling Time, (t

Output Rise Time Full Scale Step - 2.5 - ns

Output Fall Time Full Scale Step - 2.5 - ns

Output Capacitance -25- pF

Output Noise IOUTFS = 20mA - 50 - pA/√Hz

AC CHARACTERISTICS

Spurious Free Dynamic Range,

SFDR Within a Window (Notes 4, 7)

(Note 7) -0.025 +0.025 % FSR

OS

CLK

CLK

) ±0.05% (±8 LSB) (Note 7) - 35 - ns

SETT

= DVDD = +5V (unless otherwise noted), V

DD

all Min and Max Values. T

+5V DVDD, +5V AVDD (Note 3) 125 - - MSPS

+3.3V DVDD, +5V AVDD (Note 3) 100 - - MSPS

IOUTFS = 2mA - 30 - pA/√Hz

f

= 100MSPS, f

CLK

= 100MSPS, f

f

CLK

= 50MSPS, f

f

CLK

= 25oC for All Typical Values

A

= 20MHz, 5MHz Span - 93 - dBc

OUT

= 5MHz, 8MHz Span - 93 - dBc

OUT

= 5MHz, 8MHz Span - 93 - dBc

OUT

= Internal 1.2V , IOUTFS = 20mA, TA = -40oC to 85oC for

REF

FSR/

FSR/

o

C

o

C

7

ISL5314

www.BDTIC.com/Intersil

Electrical Specifications AV

= DVDD = +5V (unless otherwise noted), V

DD

all Min and Max Values. T

= 25oC for All Typical Values (Continued)

A

= Internal 1.2V , IOUTFS = 20mA, TA = -40oC to 85oC for

REF

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Spurious Free Dynamic Range,

SFDR to Nyquist (f

/2) (Notes 4,

CLK

Notes 4, 7)

= 125MSPS, f

f

CLK

= 125MSPS, f

f

CLK

= 125MSPS, f

f

CLK

= 100MSPS, f

f

CLK

= 100MSPS, f

f

CLK

= 100MSPS, f

f

CLK

f

= 100MSPS, f

CLK

= 50MSPS, f

f

CLK

= 50MSPS, f

f

CLK

= 50MSPS, f

f

CLK

= 50MSPS, f

f

CLK

= 25MSPS, f

f

CLK

= 40.4MHz - 40 - dBc

OUT

= 10.1MHz 57 63 - dBc

OUT

= 5.02MHz - 72 - dBc

OUT

= 40.4MHz - 40 - dBc

OUT

= 20.2MHz - 49 - dBc

OUT

= 5.04MHz - 72 - dBc

OUT

= 2.51MHz - 73 - dBc

OUT

= 20.2MHz - 45 - dBc

OUT

= 5.02MHz - 68 - dBc

OUT

= 2.51MHz - 72 - dBc

OUT

= 1.00MHz - 71 - dBc

OUT

= 1.0MHz - 72 - dBc

OUT

DAC REFERENCE VOLTAGE

Internal Reference Voltage, V

FSADJ

Internal Reference Voltage Drift - ±60 Internal Reference Output Current

Pin 13 Voltage with Internal Reference 1.13 1.2 1.28 V

ppm/

- ±0.1 - µA

Sink/Source Capability

Reference Input Impedance -1-MΩ

Reference Input Multiplying Bandwidth (NoteNotes 4, 7) - 1.4 - MHz

DIGITAL INPUTS

Input Logic High Voltage with

5V Digital Supply, V

IH

Input Logic High Voltage with

3V Digital Supply, V

IH

Input Logic Low Voltage with

5V Digital Supply, V

IL

Input Logic Low Voltage with

3V Digital Supply, V

Input Logic Current, I

Input Logic Current, I

IL

IH

IL

Digital Input Capacitance, C

IN

(Note 3) 3.5 5 - V

(Note 3) 2.0 3 - V

(Note 3) - 0 1.3 V

(Note 3) - 0 0.8 V

-10 - +10 µA

-10 - +10 µA

-4- pF

TIMING CHARACTERISTICS

Maximum Clock Rate, f

Maximum Clock Rate, f

CLK Pulse Width, t

CW

CLK

CLK

+5V DVDD, +5V AVDD (Note 3) 125 - - MSPS

+3.3V DVDD, +5V AVDD (Note 3) 100 - - MSPS

CLK pin (Note 3) 5 - - ns

Maximum Parallel Write Rate Rate of WR pin 50 - - MSPS

WR Pulse Width, t

Data Setup Time, t

Data Hold Time, t

WW

DS

DH

Address Setup Time, t

AS

(Note 3) 5 - - ns

Between DATA and WR (Note 3) 10 - - ns

Between DATA and WR (Note 3) 0 - - ns

Between ADDR and WR (Note 3) 12 - - ns

o

C

8

ISL5314

www.BDTIC.com/Intersil

Electrical Specifications AV

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Address Hold Time, t

UPDATE

UPDATE

UPDATE

UPDATE

UPDATE

Maximum PH Rate Rate of PH1 and PH0 pins (Note 3) f

Phase Pulse Width, t

Phase Setup Time, t

Phase Hold Time, t

Phase Latency, t

Maximum ENOFR Rate Rate of ENOFR (Note 3) f

ENOFR Pulse Width, t

ENOFR Setup Time, t

ENOFR Hold Time, t

ENOFR Latency, t

Write Enable Pulse Width, t

Write Enable Setup Time, t

Write Enable Hold Time, t

RESET

RESET

RESET

RESET

Maximum SCLK Rate See Figure 6 Timing Diagrams (Note 3) 50 - - MSPS

SCLK Pulse Width, t

SDATA Pulse Width, t

SDATA Setup Time, t

Pulse Width, t

Setup Time, t

Hold Time, t

Latency, t

Latency, t

Pulse Width, t

Setup Time, t

Latency to Output, t

Latency to Write, t

AH

UW

US

UH

UL

UL

PW

PS

PH

PL

EW

ES

EH

EL

WR

WS

WH

RW

RS

RL

RE

SCW

SDW

SDS

= DVDD = +5V (unless otherwise noted), V

DD

all Min and Max Values. T

Between ADDR and WR (Note 3) 0 - - ns

(Note 3) 5 - - ns

Between UPDATE and CLK (Note 3) 1 - - ns

Between UPDATE and CLK (Note 3) 3 - - ns

After UPDATE, before analog output change, if asserted after

writing to the control registers

After UPDATE, before analog output change, if asserted before

writing to the control registers

PH(1:0) (Note 3) 5 - - ns

Between PH(1:0) change and CLK (Note 3) 1 - - ns

Between PH(1:0) change and CLK (Note 3) 3 - - ns

Between PH(1:0) change and analog output change - 12 - Clock

ENOFR (Note 3) 5 - - ns

Between ENOFR and CLK (Note 3) 1 - - ns

Between ENOFR and CLK (Note 3) 3 - - ns

After ENOFR, before analog output change - 14 - Clock

WE (Note 3) 5 - - ns

Between WE and WR (Note 3) 2 - - ns

Between WE and WR (Note 3) 4 - - ns

RESET (Note 3) 5 - - ns

Between RESET and CLK 1 - - ns

After RESET, before analog output reflects reset values - 11 - Clock

After RESET, before the control registers can be written to - 1 - Clock

See Figure 6 Timing Diagrams (Note 3) 5 - - ns

See Figure 6 Timing Diagrams (Note 3) 5 - - ns

Between SDATA and SCLK. See Figure 6 Timing Diagrams. (Note 3)6- - ns

= 25oC for All Typical Values (Continued)

A

= Internal 1.2V , IOUTFS = 20mA, TA = -40oC to 85oC for

REF

-14-Clock

-11-Clock

/2 - - Hz

CLK

/2 - - Hz

CLK

Cycles

Cycles

Cycles

Cycles

Cycles

Cycles

SDATA Hold Time, t

SSYNC Pulse Width, t

SSYNC Setup Time, t

SSYNC Hold Time, t

SDH

SSW

SSS

SSH

Between SDATA and SCLK. See Figure 6 Timing Diagrams. (Note 3)1- - ns

See Figure 6 Timing Diagrams (Note 3) 5 - - ns

Between SSYNC and SCLK. See Figure 6 Timing Diagrams.

(Note 3)

Between SSYNC and SCLK. See Figure 6 Timing Diagrams.

(Note 3)

9

6- - ns

1- - ns

ISL5314

www.BDTIC.com/Intersil

Electrical Specifications AV

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

COMPARATOR CHARACTERISTICS

Input Capacitance -4- pF

Input Resistance ->1- MΩ

Input Current -1- µA

Maximum Input Voltage Allowed (Excluding Comparator Sleep Mode) - 4.0 3.75 V

Minimum Input Voltage, Peak-to-Peak (Dependent on Noise) - 0.1 - V

Propagation Delay, High to Low (Note 8) - 6 - ns

Propagation Delay, Low to High (Note 8) - 5 - ns

Output Rise Time (Note 8) - 1.5 - ns

Output Fall Time (Note 8) - 1.3 - ns

Output High Voltage, V

Output Low Voltage, V

Output Jitter -0.5- ns

Maximum Output Toggle Rate High Z Load (~1MΩ) - 100 - MHz

POWER SUPPLY CHARACTERISTICS

(Analog) Power Supply 4.5 5.0 5.5 V

AV

DD

(Digital) Power Supply 3.0 3.3 5.5 V

DV

DD

Analog Supply Current (I

Digital Supply Current (I

Power Dissipation AV

Power Supply Rejection Single 5V Supply (Note 7) -0.2 - +0.2 % FSR/V

NOTES:

2. Gain error for the DAC is measured as the error in the ratio between the full scale output current and the current through R

ideally the ratio should be 32.

3. Parameter guaranteed by design or characterization and not production tested.

4. Spectral measurements made with differential transformer coupled output and no external filtering.

5. Measured with the clock at 125MSPS and the output frequency at 10MHz.

6. Measured with the clock at 100MSPS and the output frequency at 10MHz.

7. See Definition of Specifications.

8. 50MHz, High Z Load (~1MΩ), 15pF capacitance, (IN- = 0.5V

9. For maximum value, 5.5V AV

10. For maximum value, 5.5V AV

OH

OL

) 5V, IOUTFS = 20mA (Note 10) - 25 30 mA

AVDD

) 5V (Notes 5, 10) - 90 100 mA

DVDD

= DVDD = +5V (unless otherwise noted), V

DD

all Min and Max Values. T

IOH = -4mA 2.6 - - V

I

= +4mA - - 0.4 V

OL

5V, IOUTFS = 2mA - 7 - mA

3.3V (Notes 6, 9) - 50 55 mA

= 5V, DVDD = 3.3V, IOUTFS = 20mA (Notes 6, 9) - 290 363 mW

DD

= 5V, DVDD = 5V, IOUTFS = 20mA (Notes 5, 10) - 625 715 mW

AV

DD

and 3.6V DV

DD

and 5.5V DV

DD

are used.

DD

are used.

DD

= 25oC for All Typical Values (Continued)

A

), (IN+ = 0.25VDC).

P-P

= Internal 1.2V , IOUTFS = 20mA, TA = -40oC to 85oC for

REF

SET

P-P

(typically 625µA);

Definition of Specifications

Differential Non-Linearity (DNL) is the measure of the step

size output deviation from code to code. Ideally the step size

should be one LSB. A DNL specification of one LSB or less

guarantees monotonicity.

Integral Non-Linearity (INL) is the measure of the worst

case point that deviates from a best fit straight line of data

values along the transfer curve.

Full Scale Gain Drift is measured by setting the DAC inputs

to be all logic high (all 1’s) and measuring the output voltage

through a known resistance as the temperature is varied

from T

MIN

to T

10

. It is defined as the maximum deviation

MAX

ISL5314

www.BDTIC.com/Intersil

from the value measured at room temperature to the value

measured at either T

(full scale range) per

MIN

o

C.

or T

. The units are ppm of FSR

MAX

Full Scale Gain Error is the error from an ideal ratio of 32

between the DAC output current and the full scale adjust

current (through R

SET

).

Internal Reference Voltage Drift is defined as the

maximum deviation from the value measured at room

temperature to the value measured at either T

The units are ppm per

o

C.

MIN

or T

MAX

Offset Drift is measured by setting the DAC inputs to all

logic low (all 0’s) and measuring the output voltage through a

known resistance as the temperature is varied from T

T

. It is defined as the maximum deviation from the value

MAX

MIN

to

measured at room temperature to the value measured at

either T

Range) per degree

MIN

or T

. The units are ppm of FSR (Full Scale

MAX

o

C.

Offset Error is measured by setting the DAC inputs to all

logic low (all 0’s) and measuring the output voltage through a

known resistance. Offset error is defined as the maximum

deviation of the output current from a value of 0mA.

Output Settling Time is the time required for the output

voltage to settle to within a specified error band measured

from the beginning of the output transition. The

measurement is done by switching quarter scale.

Termination impedance was 25Ω due to the parallel

resistance of the 50Ω loading on the output and the

oscilloscope’s 50Ω input. This also aids the ability to resolve

the specified error band without overdriving the oscilloscope.

Output Voltage Compliance Range is the voltage limit

imposed on the output. The output impedance should be

.

chosen such that the voltage developed at either IOUTA or

IOUTB does not violate the compliance range.

Power Supply Rejection is measured using a single power

supply. The nominal supply is varied

±10% and the change

in the DAC full scale output current is noted.

Reference Input Multiplying Bandwidth is defined as the

3dB bandwidth of the voltage reference input. It is measured

by using a sinusoidal waveform as the external reference

with the digital inputs to the DAC set to all 1’s . The frequency

is increased until the amplitude of the output waveform is

0.707 (-3dB) of its original value.

Spurious Free Dynamic Range (SFDR) is the amplitude

difference from the fundamental signal to the largest

harmonically or non-harmonically related spur within the

specified frequency window.

Timing Diagrams

WE

ADDR

ADDR

DAT A

WRITE

CLK (f

ANALOG OUT

CLK

UPDATE

)

t

WS

t

AS

t

DS

t

AH

A

0

W

A

1

W

0

t

DH

1 WRITE CYCLE FOR EVERY REGISTER

A

W

1

DON’T CARE

2

2

t

WH

A

N

W

N

t

US

t

UL

t

UD

DON’T CARE

DON’T CARE

DON’T CARE

= 14 CLK RISING EDGES

OLD FREQ

NEW FREQ

FIGURE 3. PARALLEL-LOAD METHOD 1, UPDATE ACTIVE AFTER LOADING REGISTERS (RESET = HIGH)

11

Timing Diagrams (Continued)

www.BDTIC.com/Intersil

ISL5314

WE

ADDR

DAT A

WRITE

CLK (f

CLK

UPDATE

ANALOG OUT

t

WS

t

t

AS

AH

A

0

W

t

DS

)

A

1

W

0

t

DH

1 WRITE CYCLE FOR EVERY REGISTER

A

2

W

1

DON’T CARE

2

PREVIOUS FREQ

t

WH

A

N

W

N

tUL= 11 CLK RISING EDGES

PARTIAL UPDATES

DON’T CARE

DON’T CARE

DON’T CARE

ENTIRE NEW FREQ

FIGURE 4. PARALLEL-LOAD METHOD 2, UPDATE ACTIVE WHILE LOADING REGISTERS (RESET = HIGH)

ONE CLK RISING EDGE

REQUIRED WHILE RESET LOW

CLK (f

ANALOG OUT

CLK (f

ENOFR

ANALOG OUT

CLK

RESET

)

CLK

)

t

RS

t

= 11 CLK RISING EDGES

RL

PREVIOUS REGISTER VALUES

FIGURE 5. RESET

t

ES

CENTER FREQUENCY ONLY CENTER + OFFSET

TIMING AND LATENCY

t

EH

RESET REGISTER VALUES

CENTER ONLY

CENTER

+ OFFSET

t

= 14 CLK RISING EDGES

EL

FIGURE 6. ENOFR (ENABLE OFFSET FREQUENCY REGISTER) TIMING AND LATENCY (RESET

12

= HIGH)

Timing Diagrams (Continued)

www.BDTIC.com/Intersil

ISL5314

RESET

SDATA

SCLK

SERIAL FREQ

REGISTER

SSYNC

CLK (f

ANALOG OUT

CLK

t

)

SSS

t

SDS

DON’T CARE (ASSUMED CONTINUOUSLY RUNNING)

t

SDH

SCLK EDGES = SERIAL BITS + 3

t

SSH

t

SCW

t

SSW

t

SDW

SERIAL DATA (8 BITS SHOWN; MAX IS 40)

OLD FREQ IN THE

SERIAL REGISTER

IN THE SERIAL REGISTER

t = 12 f

DON’T CARE

DON’T CARE (CAN FREE RUN)

NEW FREQ LOADED

RISING EDGES

CLK

DON’T CARE

OLD FREQ

NEW FREQ

FIGURE 7. SERIAL PROGRAMMING, SYNC EARLY MODE (REPRESENTS MINIMUM SCLKS REQUIRED . SCLK CAN FREE RUN.)

CONTROL REGISTER 12 IS SET TO 0001 00XX.

RESET

SERIAL DATA (8 BITS SHOWN; MAX IS 40)

SDATA

SCLK

SERIAL FREQ

REGISTER

SSYNC

CLK (f

ANALOG OUT

CLK

)

SCLK EDGES = SERIAL BITS + 3

OLD FREQ IN THE

SERIAL REGISTER

DON’T CARE (ASSUMED CONTINUOUSLY RUNNING)

DON’T CARE

DON’T CARE (CAN FREE RUN)

NEW FREQ LOADED

IN THE SERIAL REGISTER

t = 12 f

RISING EDGES

CLK

OLD FREQ

DON’T CARE

NEW FREQ

FIGURE 8. SERIAL PROGRAMMING, SYNC LATE BURST MODE (REPRESENTS MINIMUM SCLKS REQUIRED; SCLK CAN FREE RUN);

CONTROL REGISTER 12 IS SET TO 0000 00XX.

13

ISL5314

www.BDTIC.com/Intersil

Pin Descriptions

PIN NO. PIN NAME TYPE PIN DESCRIPTION

44-48, 1-3 C(7:0) Input 8-bit processor input data bus. C7 is the MSB. Data is written to the control register selected on

A(3:0) on the rising edge of WR when WE

42 WR Input Write clock for the processor interface. Parallel data is clocked into the chip on the rising edge of

WR.

40 WE

35-38 A(3:0) Input Processor interface address bus. These pins select the destination register for data on the C(7:0)

6 CLK Clock NCO and DAC clock. The phase accumulator and DAC output update on the rising edge of this

8 RESET

30 SCLK Input Serial clock. Polarity is programmable. See control word 12. May be asynchronous to CLK. If not

27 SDATA Input Serial data. See control word 12. If not used, connect to DGND.

32 SSYNC Input Serial sync. See control word 12. If not used, connect to DGND.

9 UPDATE

33, 34 PH(1:0) Input Phase offset bits. The phase of the output is shifted. If not used, these pins should be grounded.

4 ENOFR Input Enable offset frequency. Active high. When high, the offset frequency bus is enabled to the phase

10 COMPOUT Output Comparator output.

11 REFLO Input Connect to analog ground to enable the DAC’s internal 1.2V reference or connect to AV

12 REFIO Input Reference voltage input for the DAC if internal reference is disabled. Recommend the use of a

13 FSADJ Full scale current adjust for the DAC. Use a resistor to ground (R

14 COMP1 Noise reduction for the DAC. Connect a 0.1µF cap to AV

19 COMP2 Noise reduction for the DAC. Connect a 0.1µF cap to AGND plane.

18 IOUTA Output DAC current output.

17 IOUTB Output DAC complementary current output.

20 AV

15, 16, 21, 24 AGND GND Analog ground.

7, 26, 31, 43 DV

5, 25, 28, 29, 41 DGND GND Digital ground.

22, 23 IN+, IN- Input Comparator inputs. To power down the comparator, connect both of these pins to the analog

39 NC NC No connect.

DD

DD

Input Write enable. Active low. WE must be active when writing data to the chip.

bus. A3 is the MSB.

clock. CLK can be asynchronous to the WR clock.

Input Reset. Active low. Resets control registers to their default states (see register description table)

and zeroes the feedback in the phase accumulator. UPDATE

used, connect to DGND.

Input Active low. Updates the active control registers only. It has no effect on the ENOFR or PH(1:0)

pins. This pin is provided for updating an entire frequency word at once rather than byte by byte.

00 – 0 degrees reference

01 – 90 degrees shift

10 – 180 degrees shift

11 – 270 degrees shift

accumulator. When low, the offset frequency bus is zeroed. This pin does not affect the contents

of the offset frequency registers. If not used, the pin should be grounded.

disable the internal reference.

0.1µF cap to ground from the REFIO pin when a DC reference voltage is used.

output current. Full Scale Output Current = 32 x V

reference voltage.

Power Analog supply voltage.

Power Digital supply voltage.

power supply. This will conserve ~4mA of current.

is active.

FSADJ/RSET

plane.

DD

must be low for Reset to occur.

) to adjust the full scale

SET

, where V

FSADJ

equals the

DD

to

14

ISL5314

www.BDTIC.com/Intersil

Control Register Description

ADDRESS BITS DESCRIPTION

0 7:0 Center frequency bits CF(7:0) (LSB). 00h

1 7:0 Center frequency bits CF(15:8). 00h

2 7:0 Center frequency bits CF(23:16). 00h

3 7:0 Center frequency bits CF(31:24). 00h

4 7:0 Center frequency bits CF(39:32). 00h

f

5 7:0 Center frequency bits CF(47:40) (MSB). (Reset gives

6 7:0 Offset frequency bits OF(7:0) (LSB). 00h

7 7:0 Offset frequency bits OF(15:8). 00h

8 7:0 Offset frequency bits OF(23:16). 00h

9 7:0 Offset frequency bits OF(31:24). 00h

10 7:0 Offset frequency bits OF(39:32). 00h

11 7:0 Offset frequency bits OF(47:40) (MSB). 00h

12 7:0 Serial input control word. 01h

7:5 Select number of serial frequency input bits:

1xx = 40-bit word (weighting same as CF(47:8))

011 = 32-bit word (weighting same as CF(47:16))

010 = 24-bit word (weighting same as CF(47:24))

001 = 16-bit word (weighting same as CF(47:32))

000 = 8-bit word (weighting same as CF(47:40))

4 Serial input sync position select:

1 = sync early. Sync is expected one serial clock period before the first data bit.

0 = sync late. Sync is expected one serial clock after the last data bit.

3 Serial sync polarity: 1 = active low, 0 = active high. 0b

2 Serial clock polarity: 0 = rising edge, 1 = falling edge. 0b

1 Shift direction: 0 = MSB first, 1 = LSB first. 0b

0 Center frequency enable: 1 = enable, 0 = disable.

This bit can be used to zero the center frequency (CF(47:0)) to the phase accumulator. This does not zero

the processor interface registers—just the data path from the center frequency register to the phase

accumulator. The center frequency resets to f

13 7:0 NCO control word. F8h

7 Intersil reserved. Do not change. 1b

6 Serial output frequency register enable: 1 = enable, 0 = disable.

This bit enables/disables the data path from the serial frequency register to the phase accumulator,

without changing the value of the register. Should be disabled after RESET

5 Phase accumulator feedback: 0 = accumulator feedback disabled, 1 = accumulator enabled. 1b

4:0 Intersil reserved. Do not change. 11000b

14 7:0 Test and timing control register. User must write 00h or 30h to register 14 after RESET

5:4 NCO-to-DAC setup and hold timing control. Write either 11b or 00b to these bits. 01b

15 7:0 Register 15 does not actually exist. Any write to register 15 is an UPDATE

save one microprocessor control pin from being used for the UPDATE

* b=binary, h=hex

CLK

/4.

/4 output). 40h

CLK

if not used.

. 10h

. This function is provided to

pin, if the user chooses.

RESET

STATE*

000b

0b

1b

1b

N/A

15

ISL5314

www.BDTIC.com/Intersil

Thin Plastic Quad Flatpack Packages (LQFP)

D

D1

-D-

E

E1

GAGE

PLANE

0o-7

-A-

PIN 1

-H-

0.08

M

0.003

o

0.020

MIN

0.008

0o MIN

L

0.25

o

0.010

11o-13

11o-13

A2

A1

o

0.09/0.16

0.004/0.006

BASE METAL

WITH PLATING

-B-

e

SEATING

PLANE

A

0.08

0.003

-C-

D

A-B

C

S

b

b1

0.09/0.20

0.004/0.008

S

Q48.7x7A (JEDEC MS-026BBC ISSUE B)

48 LEAD THIN PLASTIC QUAD FLATPACK PACKAGE

INCHES MILLIMETERS

SYMBOL

A - 0.062 - 1.60 A1 0.002 0.005 0.05 0.15 A2 0.054 0.057 1.35 1.45 -

b 0.007 0.010 0.17 0.27 6

b1 0.007 0.009 0.17 0.23 -

D 0.350 0.358 8.90 9.10 3

D1 0.272 0.280 6.90 7.10 4, 5

E 0.350 0.358 8.90 9.10 3

E1 0.272 0.280 6.90 7.10 4, 5

L 0.018 0.029 0.45 0.75 -

N48 487

e 0.020 BSC 0.50 BSC -

NOTES:

1. Controlling dimension: MILLIMETER. Converted inch

dimensions are not necessarily exact.

2. All dimensions and tolerances per ANSI Y14.5M-1982.

3. Dimensions D and E to be determined at seating plane .

4. Dimensions D1 and E1 to be determined at datum plane

-H-

.

5. Dimensions D1 and E1 do not include mold protrusion.

Allowable protrusion is 0.25mm (0.010 inch) per side.

6. Dimension b does not include dambar protrusion. Allowable

dambar protrusion shall not cause the lead width to exceed

the maximum b dimension by more than 0.08mm (0.003

inch).

7. “N” is the number of terminal positions.

NOTESMIN MAX MIN MAX

Rev. 2 1/99

-C-

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

16

Loading...

Loading...