Page 1

®

www.BDTIC.com/Intersil

ISL5239

Data Sheet September 2, 2005 FN8039.2

Pre-Distortion Linearizer

The ISL5239 Pre-Distortion Linearizer (PDL) is a full featured

component for P o wer Amplifier (PA) linearization to improve PA

power efficiency and reduce PA cost.

The Radio Frequency (RF) PA is one of the most expensive and

power-consuming devices in any wireless communication

system. The ideal RF P A would hav e an entirely linear

relationship between input and output, expressed as a simple

gain which applies at all power levels. Unf ortunately, realizable

RF amplifiers are not completely linear and the use of predistortion techniques allows the substitution of lower cost/power

PA’s for higher cost/power PA’s.

The ISL5239 pre-distortion linearizer enables the linearization of

less expensive PA’s to provide more efficient operation closer to

saturation. This provides the benefit of improved linearity and

efficiency , while reducing PA cost and operational expense.

The ISL5239 features a 125MHz pre-distortion bandwidth

capable of full 5th order intermodulation correction for signal

bandwidths up to 20MHz. This bandwidth is particularly well

suited for 3G cellular deployments of UMTS and CDMA2000.

The device also corrects for PA memory effects that limit predistortion performance including self heating.

The ISL5239 combines an input formatter and interpolator, predistortion linearizer, an IF converter, correction filter ,

gain/phase/offset adjustment, output formatter, and input and

feedback capture memories into a single chip controlled by a 16bit linearizer interface.

The ISL5239 supports log of power, linear magnitude, and linear

power based pre-distortion, utilizing two Look-Up T ab le (LUT)

based algorithms for the pre-distortion correction. The device

provides progr ammable scaling and offset corre ction, a nd

provides for phase imbalance adjustment.

Features

• Output Sample Rates Up to 125MSPS

• Full 20MHz Signal Bandwidth

• Dynamic Memory Effects Compensation

• Input and Feedback Capture Memories

• LUT-based Digital Pre-distortion

• Two 18-bit Output Busses with Programmable Bit-Width

• 16-Bit Parallel µProcessor Interface

• Input Interpolator x2, x4, x8

• Programmable Frequency Response Correction

• Low Power Architecture

• Threshold Comparator for Internal Triggering

• Quadrature or Digital IF Architecture

• Lowest-Cost Full-Featured Part Available

• Pb-Free Plus Anneal Available (RoHS Compliant)

Applications

• Base Station Power Amplifier Linearization

• Operates with ISL5217 in Software Radio Solutions

• Compatible with the ISL5961 or ISL5929 D/A Converters

Ordering Information

PART

NUMBER

ISL5239KI ISL5239KI -40 to 85 196 Ld BGA V196.15x15

ISL5239KIZ

(Note)

ISL5239EVAL1 25 Evaluation Kit

NOTE: Intersil Pb-free plus anneal products employ special Pb-free

material sets; molding compounds/die attach materials and 100%

matte tin plate termination finish, which are RoHS compliant and

compatible with both SnPb and Pb-free soldering operations. Intersil

Pb-free products are MSL classified at Pb-free peak reflow

temperatures that meet or exceed the Pb-free requirements of

IPC/JEDEC J STD-020.

PART

MARKING

ISL5239KIZ -40 to 85 196 Ld BGA

TEMP

RANGE

o

C) PACKAGE

(

(Pb-free)

PKG. DWG.

#

V196.15x15

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright Intersil Americas Inc. 2002, 2005. All Rights Reserved

Page 2

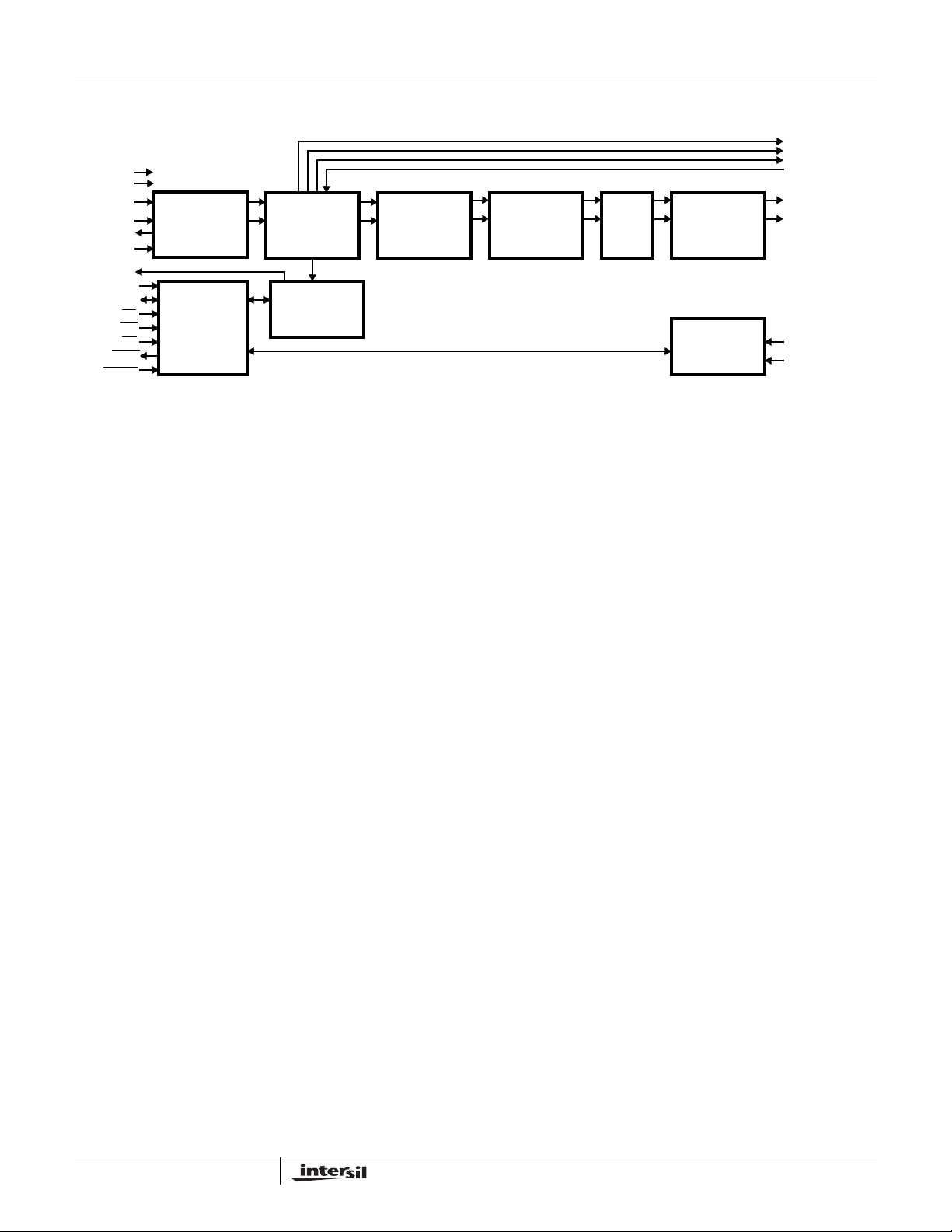

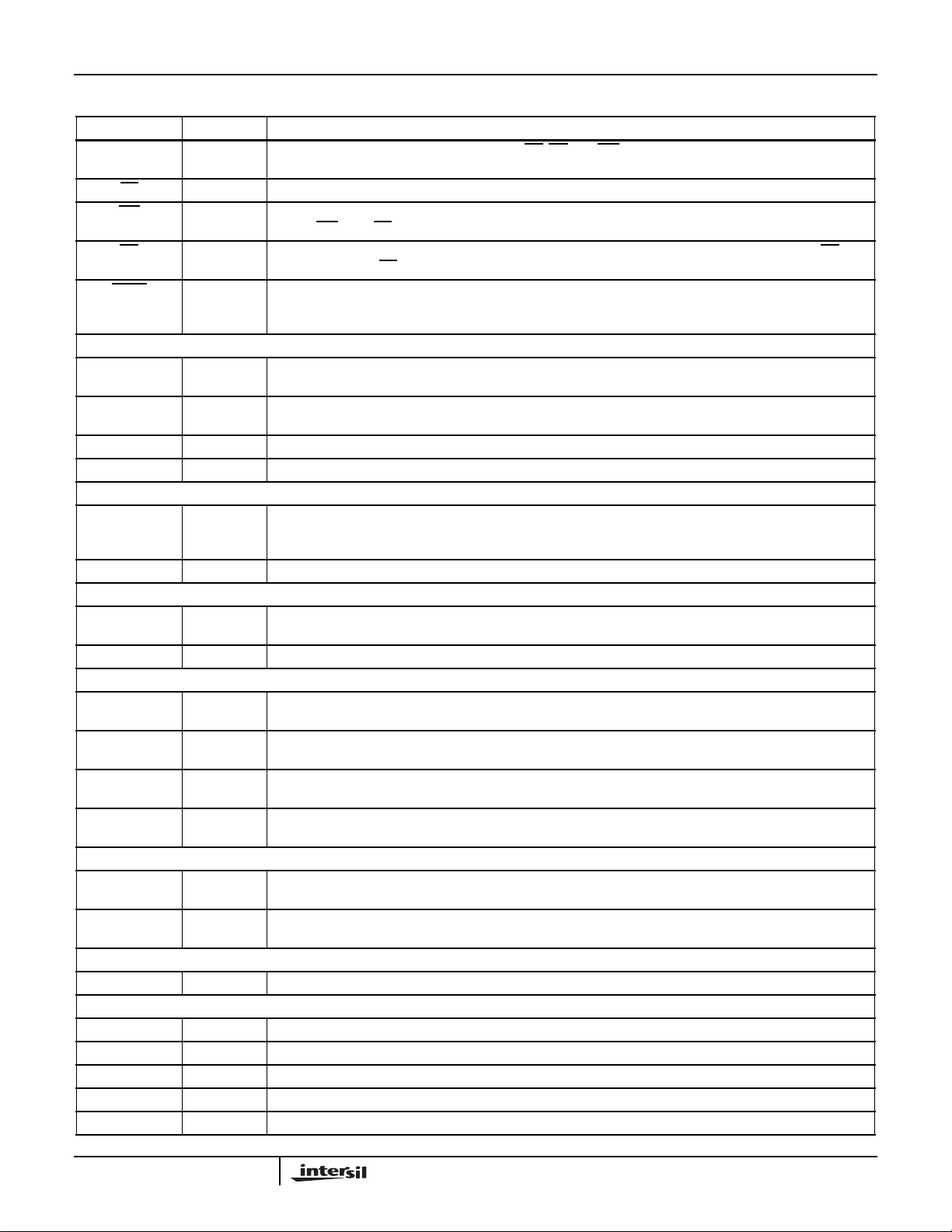

Block Diagram

www.BDTIC.com/Intersil

CLK

TRIGIN

IIN<17:0>

QIN<17:0>

CLKOUT

ISTRB

TRIGOUT

A<5:0>

P<15:0>

CS

WR

RD

BUSY

RESET

INPUT

FORMATTER

AND

INTERPOLATOR

X1, X2, X4, X8

uP INTERFACE

PRE-DISTORTER

WITH

TWO 1K x 60

LUTs

INPUT

MEMORY

(2k x 32)

ISL5239

IF CONVERTER

REAL 1X

REAL 2X

COMPLEX

CORRECTION

FILTER

REAL 1X

REAL 2X

COMPLEX

GAIN /

PHASE

OFFSET

ADJUST

OUTPUT

DAT A

FORMATTER

8-18 BIT-WIDTH

FEEDBACK

MEMORY

(1k x 20)

SERCLK

SERSYNC

SEROUT

SERIN

IOUT<17:0>

QOUT<17:0>

FBCLK

FB<19:0>

2

Page 3

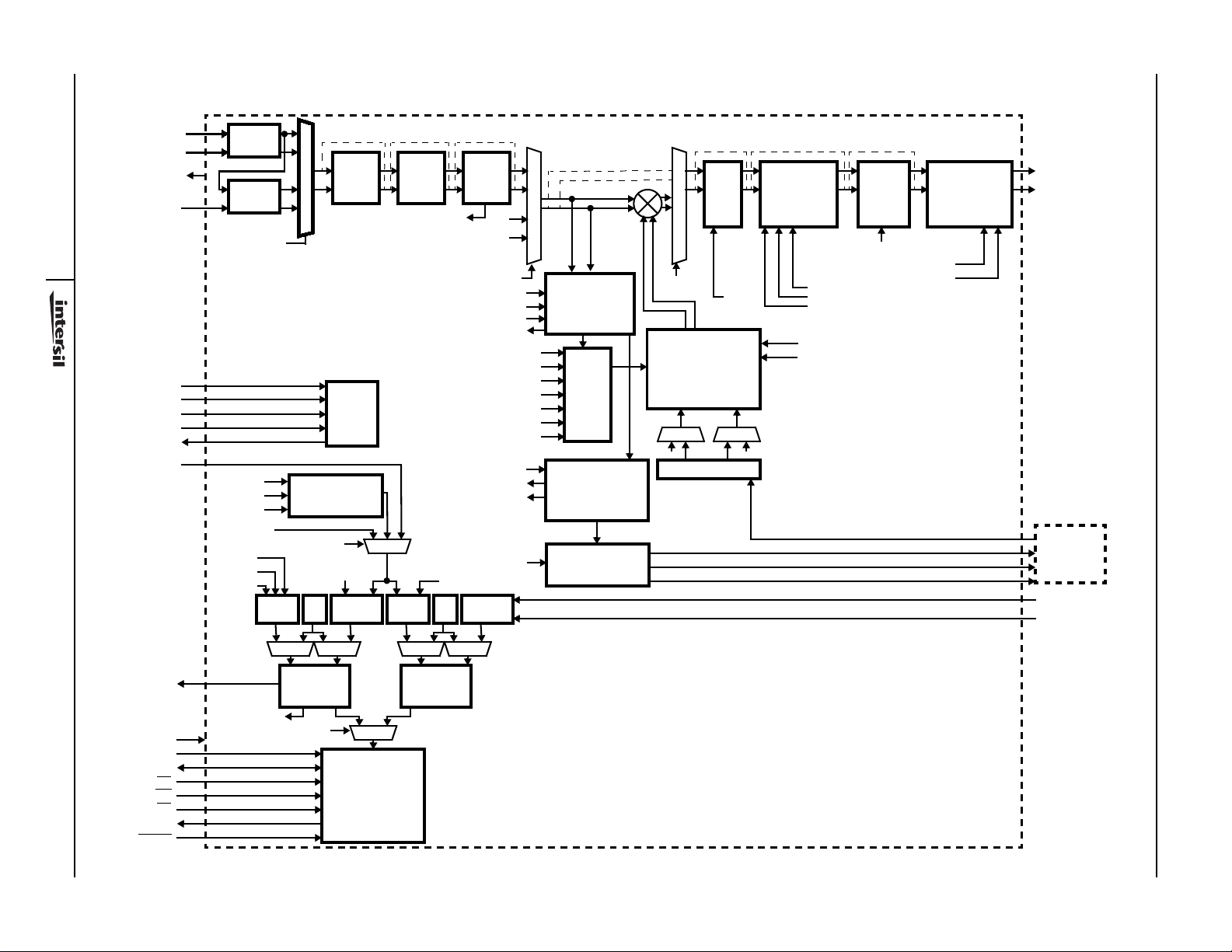

Functional Block Diagram

www.BDTIC.com/Intersil

ISL5239 Pre-Distortion Linearizer

IIN<17:0>

QIN<17:0>

CLKOUT

ISTRB

3

TMS

TDI

TCK

TRST

TDO

TRIGIN

OFFSET

BINARY

DE-MUX

INPUT TYPE

(PAR/SERIAL)

PD MAG.

MAX

IFIP I,Q

PD I,Q

PD MAG.

THRESHOLD

MIN

uP

TRIG SEL

INPUT

SEL STATE

BYPASS BYPASS BYPASS

HALF

BAND

FILTER

MUX

/

1

18

JTAG

COMPARE

INPUT DELAY

COUNT

INPUT

uP

HALF

BAND

FILTER

/ /

/

2

20

IFIP I,Q

LUT DELTA DATA Q

LUT ADDR AUTO INCR.

PWR INTGR PER.

TRIG

FB

STATE

SER. OUTPUT EN.

HALF

I

BAND

FILTER

/

20

CM TEST

FUNC. SEL.

LUT DELTA DATA I

PWR HIGH

FB DELAY COUNT

FORMAT

uP

/

Q

3

I

Q

TEST

OFFSET

SCALE

PD MAG.

LUT DATA I

LUT DATA Q

ACTIVE LUT

LUT ADDR

PWR LOW

INPUT OR TEST

LUT

ADDRESS

CALCULATION

ADDR

DATA

LUT

POWER

INTEGRATOR

PAR. TO SERIAL

BYPASS BYPASS BYPASS

IF

CONV.

PD I,Q

PRE-D OR BYPASS

BYPASS

CHANNEL 3

MEMORY EFFECT

COMPENSATION

POWER

COEF. A COEF. B

SERIAL TO PAR.

MODE

CORRECTION

FILTER

REAL 1X

REAL 2X

COMPLEX

HM, KM, LM, GM, DC OFFSETS

OUTPUT WORD WIDTH SEL.

COEF. DATA

REAL PIPELINE SEL.

COEF. ADDR.

SERIAL INPUT EN.

COEF . B SELECT

GAIN /

PHASE

OFFSET

ADJUST.

OUTPUT VALUE TYPE

OUTPUT

DATA

FORMATTER

8-18 BIT-WIDTH

SERIN

SERCLK

SERSYNC

SEROUT

IOUT<17:0>

QOUT<17:0>

EXTERNAL

MEMORY

EFFECTS

FPGA

FBCLK

FB<19:0>

ISL5239

ADDR DATA

FEEDBACK

CAPTURE

MEMORY 1K

TRIGOUT

CLK

A<5:0>

P<15:0>

CS

WR

RD

BUSY

RESET

DATA ADDR

CM TEST I,Q

MEMORY SELECT

INPUT

CAPTURE

MEMORY 2K

uP INTERFACE

Page 4

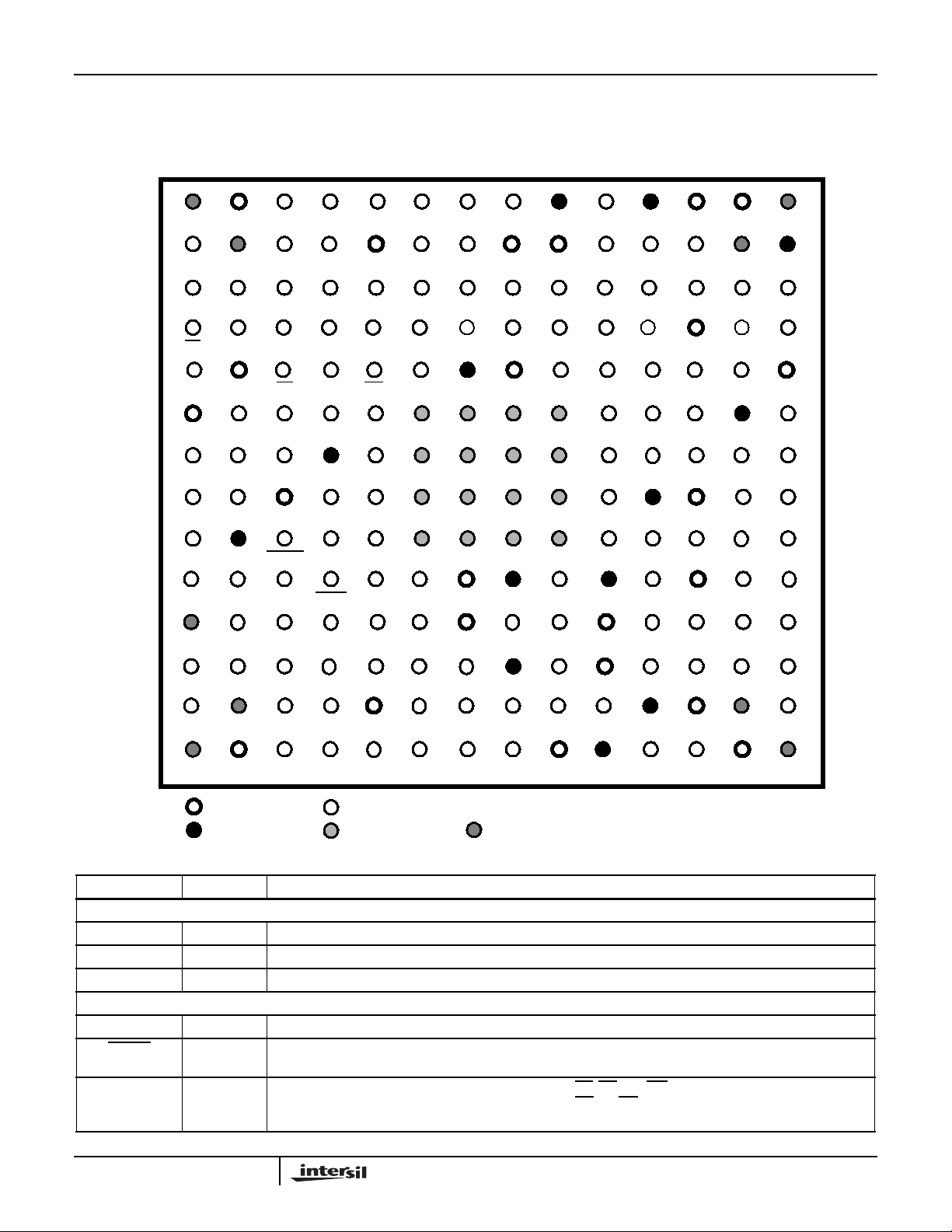

Pinout

www.BDTIC.com/Intersil

ISL5239

196 CABGA

TOP VIEW

123456789 1110

A

NC

B

NCISTRB IIN3

C

A3

A0

D

E

F

G

H

J

K

P13

L

M

N

TRST NC IOUT1

P

A1 A5 IIN13 IIN1 QOUT2 QOUT5

CS

P0

VCCC RD

P7 FB11 SERINP6

GND

TDO VCCC

NC QIN10 VCCC IOUT17

A2

QOUT17 FB17IIN10 IIN6

P1 GND

P2

P5

GND FB9

VCCIO

RESET

BUSY

TCK FB3 FB4

TMS

QIN11 IOUT16QIN4 IOUT0 IOUT2

P4

P11

P9

P15

QIN6

QIN9

QIN5 GND

QOUT11 GNDGNDQOUT15 VCCIO VCCC NCVCCC IIN16 IIN12 IIN9 IIN4 IIN0

QOUT9VCCIOVCCIOIIN17 IIN14 IIN7VCCC

VCCCQOUT12QOUT16 QOUT1 QOUT3IIN15 IIN11 IIN8 IIN2

QOUT8

QOUT13

QOUT14VCCCWR IIN5 GND QOUT10

FB13

SEROUT

SERSYNC

TRIGOUT

IOUT11GNDQIN0 VCCC

GND

VCCCIOUT9DCTEST FB2QIN2 VCCIO

VCCIO IOUT3IOUT7QIN16 GND

IOUT8QIN14 QIN3 IOUT10

QOUT6 QOUT4 NC GND

QOUT7

FB14 VCCCA4

FB16VCCIO FB15 FB10P3

GNDP10 VCCIO CLKOUTP12 P8

FB7CLK FB8P14

FB0

GNDIIOUT12

IOUT6VCCIONC IOUT14 IOUT5 VCCC NCVCCC QIN12 QIN8 QIN1 IOUT15

12

VCCIO

FB12

FB6

FB1IOUT4IOUT13QIN17TDI

VCCIO

13 14

QOUT0

FB18FB19

SERCLK

FB5

TRIGIN

FBCLKQIN15 QIN13 QIN7

POWER PIN

GROUND PIN

SIGNAL PIN

THERMAL BALL

NC (Do not connect)

Pin Descriptions

NAME TYPE DESCRIPTION

POWER SUPPLY

VCCC - Positive Device Core Power Supply Voltage, 1.8V ±0.18V.

VCCIO - Positive Device Input/Output Power Supply Voltage, 3.3V ±0.165V.

GND - Common Ground, 0V

MICROPROCESSOR INTERFACE AND CONTROL

CLK I Input Clock. Rising edge drives all of the devices synchronous operations, except feedback capture.

RESET

I Reset. (Active Low). Asserting reset will clear all configuration registers to their default values, reset all internal

states, and halt all processing.

P<15:0> I/O 16-bit bi-directional data bus that operates with A<5:0>, CS

internal control registers. When the host system asserts CS

under all other conditions, it is an input bus. Bit 15 is the MSB.

4

, RD, and WR to write to and read from the devices

and RD simultaneously, P<15:0> is an output bus,

Page 5

ISL5239

www.BDTIC.com/Intersil

Pin Descriptions (Continued)

NAME TYPE DESCRIPTION

A<5:0> I 6-bit address bus that operates with P<15:0>, CS, RD, and WR to write to and read from the devices internal

control registers. Bit 5 is the MSB.

CS

WR

RD

BUSY

EXTERNAL SERIAL INTERFACE

SERCLK O Serial Clock. Clock signal provided to external device for serial input and output, derived from rising edge of

SERSYNC O Serial Sync. Active high single-cycle pulse that is time coincident with the first sample of the 32-bit serial data

SEROUT O Serial Output. Output data bit for the serial interface. Derived from the rising edge of CLK.

SERIN I Serial Input .In put d at a bi t for se ria l int erfa ce. Derived from rising ed ge of C LK.

FEEDBACK INTERFACE

FB<19:0> I Feedback Input Data. Parallel or serial data to be stored in the feedback memory. In parallel mode, all 20-

FBCLK I Input clock used for sampling the FB<19:0> pins.

TRIGGER INTERFACE

TRIGIN I Trigger input. Hardwired trigger source to be used to trigger an input/feedback capture. Sampled internally

TRIGOUT O Trigger output. Indicated that the capture system has been triggered, either internally or externally.

DATA INPUT

IIN<17:0> I I input data. Real component of the complex input sample when input format is parallel. Alternating real and

QIN<17:0> I Q input data. Imaginary component of the complex input sample when input format is parallel. Unused in serial

ISTRB I I data strobe. (active high). Used in the muxed input format. When asserted, the input data buses contains valid

CLKOUT O Input data clock. Output clock for the data source driving the IIN<17:0> and QIN<17:0> inputs. Input data

DATA OUTPUT

IOUT<17:0> I I output data. Real component of the complex output sample driven by the rising edge of CLK. Selectable as

QOUT<17:0> I Q output data. IMaginary component of the complex output sample driven by the rising edge of CLK. Selectable

TEST ACCESS

DCTEST O DC tree output. NAND tree output for DC threshold test. Do not connect for normal operation.

JTAG TEST ACCESS PORT

TMS I JTAG Test Mode Select. Internally pulled up.

TDI I JTAG Test Data In. Internally pulled up.

TCK I JTAG Test Clock.

TRST I JTAG Test Reset (Active Low). Internally pulled-up.

TDO O JTAG Test Data Out.

I Chip Select. (active low). Enables device to respond to µP access by enabling read or write operations.

I Write Strobe, (active low). The data on P<15:0> is written to the destination selected by A<5:0> on the rising

edge of WR

I Read Strobe (Active Low). The d a t a at the ad d r e s s selected by A(5:0) i s placed on P < 1 5:0> when R D is

asserted (low) and CS

O µP Busy. (Active Low) Indicates that the µP interface is busy. The device asserts BUSY during a read operation

to indicate that the output data on P<15:0> is not ready, and it asserts this signal during a write operation to

indicate that it is not available for another read or write operation yet.

CLK.

frame. Derived from by rising edge of CLK.

bits are stored on the rising edge of FBCLK. In serial mode, bit 0 is serial input data and bit 1 is serial sync,

sampled at the rising edge of FBCLK.

with rising edge of CLK.

imaginary when input format is muxed. Selectable as 2’s complement or offset binary.

input format.

I data.

busses sampled on the rising edge of CLK that generates the rising edge of CLKOUT.

2’s complement or offset binary.

as 2’s complement or offset binary.

when CS is asserted (low).

is asserted (low).

5

Page 6

ISL5239

www.BDTIC.com/Intersil

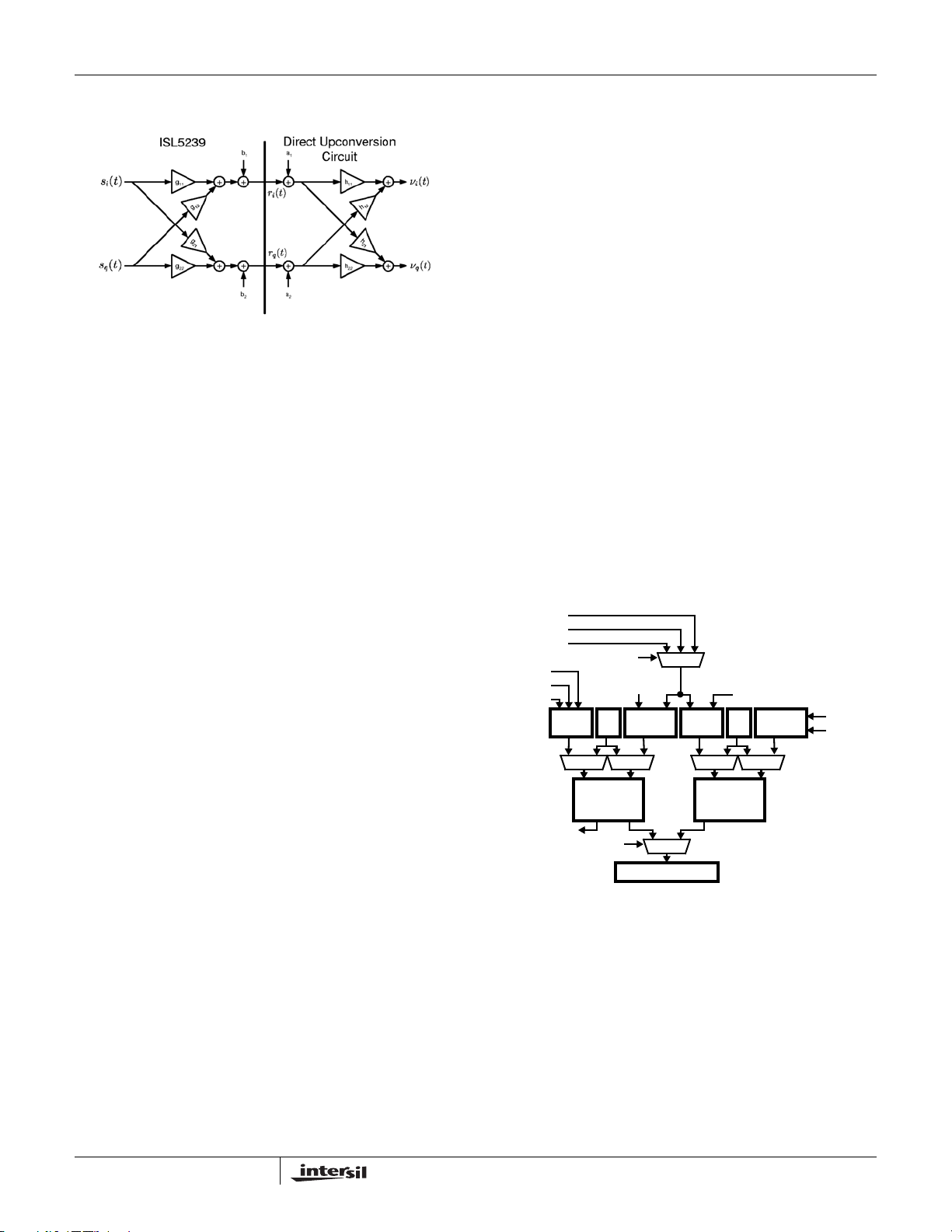

Functional Description

The ISL5239 is a full-featured digital pre-distortion part

featuring a high-performance lookup-table based predistortion (PD) processing unit. It includes an interpolator for

upsampling and supports all varieties of upconversion

architectures with a programmable correction filter for

equalization including both sin(x)/x correction and removal of

frequency response imbalance between quadrature paths. It

also features gain, phase, and offset compensation for direct

upconversion, digital IF output for heterodyning, and

input/output capture memories with internal/external

triggering capabilities to facilitate closedloop feedback

processing. System implementation is typically as shown in

Figure 1. Although the power detect feedback is shown with

one Analog to Digital Converter (ADC), coherently

demodulated feedback signalsLO configurations with 1 or 2

ADC’s are also supported.

The block diagram on page 1 shows the internal functional

units within the ISL5239. In the following sections each

functional unit is described. The operation of the ISL5239 is

controlled by the register map listed in Table 3. Detailed

descriptions for each control/status register are given in

Tables 4 through 48. The control/status registers are ref erred

to in the discussion below.

The clock divider generates the CLKOUT signal which is

used to clock data from the input signal source. Typical input

sources include the ISL5217 quad programmable

upconverter, which is designed to operate seamlessly with

the ISL5239.

The interpolation factor is selectable in control word 0x02,

bits 6:4 as x1, x2, x4, and x8. The x1 mode bypasses all

three half-band filters. The x2 mode utilized HB1 and

bypasses HB2 and HB3. The x4 mode utilized HB1 and HB2

and bypasses HB3. Finally, the x8 mode utilizes all three

HBFs. Saturation status bits are provided for each of the

three HBFs in the status register 0x03.

Input data rates up to the CLK rate are supported, based on

the requirement CLK >= Fs * IP, where Fs is the input rate of

the incoming data and IP is the interpolation factor selected

in control word 0x02.

/

1

20

BYPASS BYPASS

HALF

BAND

FILTER

2

20

/

HALF

BAND

FILTER

3

I

Q

/

20

BYPASS

IIN<17:0>

QIN<17:0>

FIGURE 2. INPUT FORMATTER AND INTERPOLAT OR

BLOCK DIAGRAM

HALF

BAND

FILTER

/

INPUT

18

FORMATTER

FIGURE 1. SYSTEM OVERVIEW

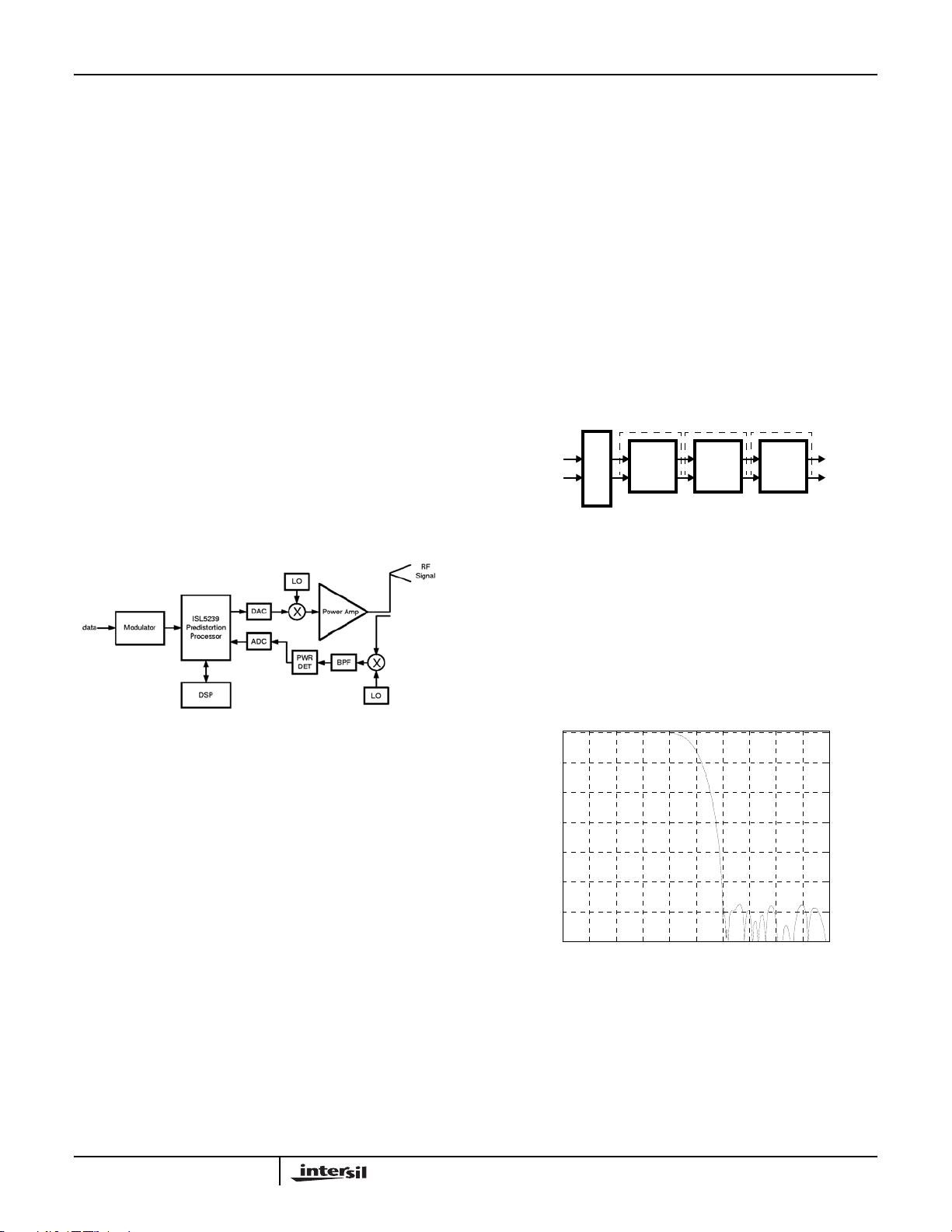

Input Formatter and Interpolator (IFIP)

The Input Formatter and Interpolator interfaces to the data

source to provide for parallel data input via the IIN<17:0>,

QIN<17:0> busses, or serial input via the IIN<17:0> input

bus. In parallel input mode, both 18-bit input busses are

used to allow for parallel I and Q sample loading. In serial

mode, the data is input via the IIN<17:0> bus only, as the I

sample followed by the Q sample with the ISTRB input

asserted with each I sample. In this mode, the QIN<17:0>

bus is not utilized. The input data format is selectable as

either two’s complement or offset binary.

The Interpolator function is necessary because predistorting a signal results in a much wider bandwidth signal

(typically 5x to 7x wider). The Input Formatter and

Interpolator is depicted in Figure 2.

Each half-band filter performs a x2 interpolation by inserting

one zero between each input data sample, causing the

sampling frequency to double. The resulting zero-stuffed

data is then low pass filtered to reject the upsampling image.

The half-band filter frequency responses are as shown in

Figure 3.

0

-20

-40

-60

-80

MAGNITUDE (dB)

-100

-120

-140

FIGURE 3. x2, HB1 ENABLED FREQUENCY RESPONSE

HALFBAND FILTER 1 RESPONSE

0 0.1 0.2 0.3 0.4 0. 5 0.6 0.7 0.8 0.9 1

NORMALIZED FREQUENCY (NYQUIST=1)

Three interpolation rates (x2, x4, and x8) are supported by

the cascade of three Half-Band (HB) Filters. The ISL5239

includes an on-chip clock divider to facilitate input clocking.

6

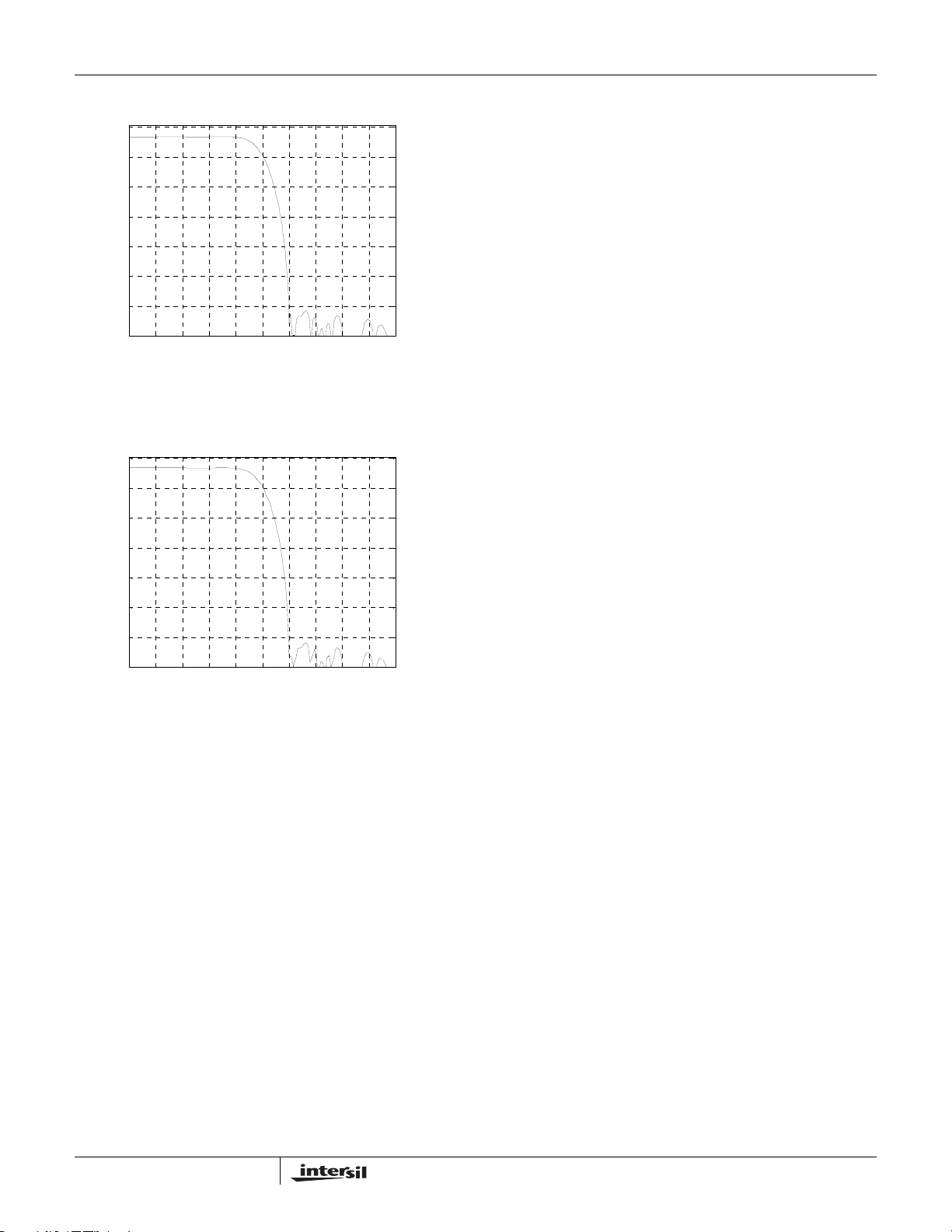

Page 7

ISL5239

www.BDTIC.com/Intersil

0

-20

-40

-60

-80

MAGNITUDE (dB)

-100

-120

-140

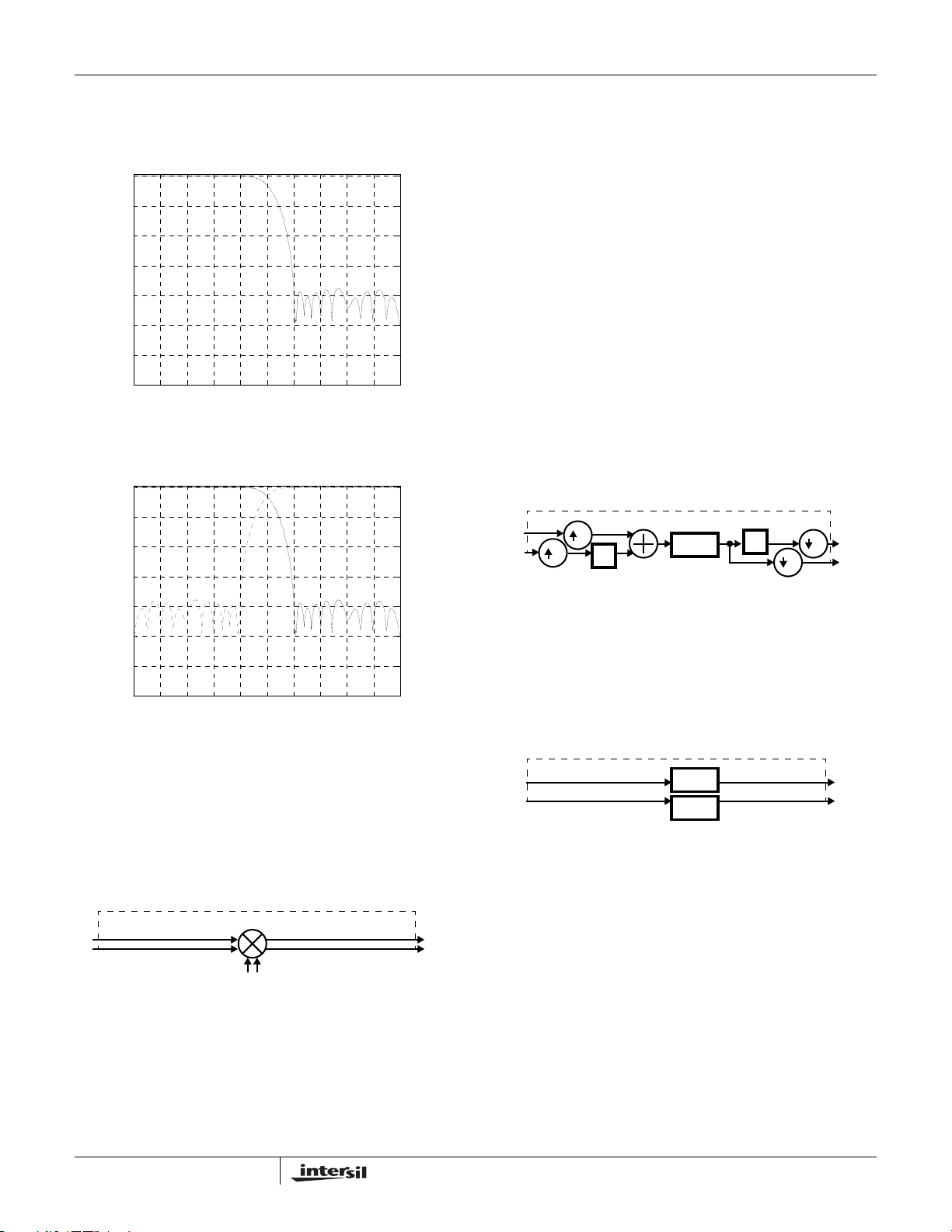

FIGURE 3A. X4, HB1 AND HB2 ENABLED FREQUENCY

0

-20

-40

-60

-80

MAGNITUDE (dB)

-100

-120

-140

FIGURE 3B. X8, HB1-HB3 ENABLED FREQUENCY RESPONSE

HALFBAND FILTER 2 RESPONSE

0 0.1 0.2 0.3 0.4 0. 5 0.6 0.7 0.8 0.9 1

NORMALIZED FREQUENCY (NYQUIST=1)

RESPONSE

HALFBAND FILTER 3 RESPONSE

0 0.1 0.2 0.3 0.4 0. 5 0.6 0.7 0.8 0.9 1

NORMALIZED FREQUENCY (NYQUIST=1)

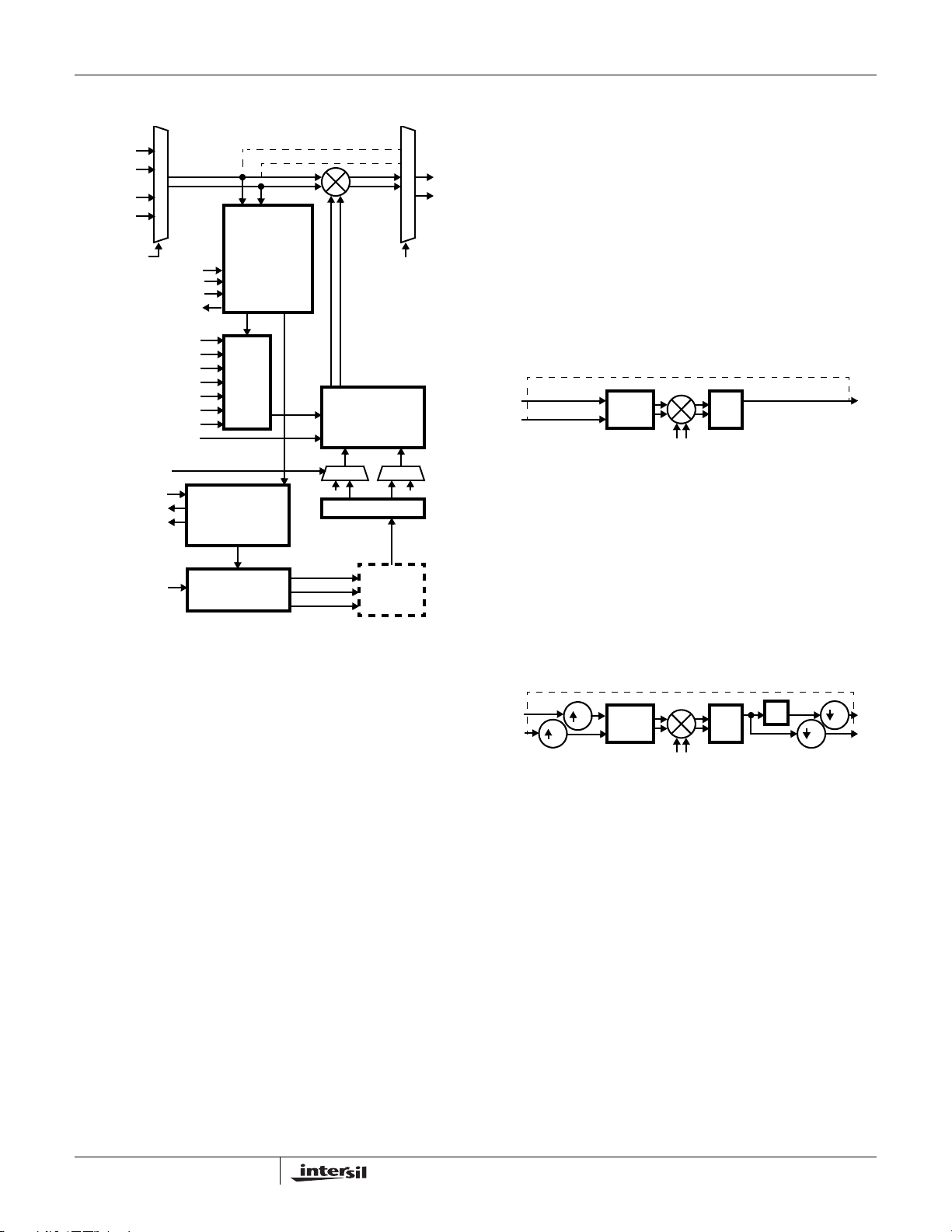

Pre-Distorter (PD)

The function of the Pre-distorter is to compute the

magnitude of the input signal, look up a complex distortion

vector based on the magnitude, and apply that distortion to

the input signal.

The signal magnitude may be computed by any of three

different methods: log of power, linear magnitude or linear

power. The result is scaled and offset by programmable

amounts and becomes the address into a Look-up Table

(LUT).

Two LUTs are available, one of which is ‘live’ in the circuit

and the other is offline and can be loaded via the processor

interface. This configuration allo ws instantaneou s s witching

of pre-distortion characteristics without unpredictable

effects on the processed signal.

The LUTs contain a complex distortion vector, as well as

complex delta values which interact with an external

Thermal/Memory calculation circuit to predict the effects of

temperature changes on the RF amplifier’s behavior and

compensate. The average power into the amplifier is

computed and transmitted serially off chip. The external

circuits compute one or two memory effect coefficients

which are combined with the complex delta values in the

LUT to derive the final distortion vector. The distortion

vector is a rectangular complex value which is multiplied

with the input signal resulting in a magnitude based nonlinearity. Access to the LUT is optimized by the use of an

auto incrementing address register which allows the tables

to be updated with only one address register write

operation. Control words 0x10 through 0x1d apply to the

7

Page 8

ISL5239

www.BDTIC.com/Intersil

pre-distorter. The pre-distorter block diagram is shown in

Figure 4.

FROM

I

IFIP

Q

CM TEST

LUT ADDR AUTO INCR.

SERIAL INPUT EN.

PWR INTGR PER.

SER. OUTPUT EN.

I

Q

INPUT OR TEST

TEST

FUNC. SEL.

OFFSET

SCALE

PD MAG.

LUT DATA I

LUT DATA Q

LUT DELTA DATA I

LUT DELTA DATA Q

ACTIVE LUT

LUT ADDR

COEF. B SELECT

PWR LOW

PWR HIGH

LUT

ADDRESS

CALCULATION

POWER

ADDR

LUT

DATA

POWER

INTEGRATOR

PAR. TO SERIAL

BYPASS

MEMORY EFFECT

COMPENSATION

COEF. A COEF. B

SERIAL TO PAR.

SERCLK

SERSYNC

SEROUT

EXTERNAL

MEMORY

EFFECTS

FPGA

I

Q

PRE-D OR BYPASS

SERIN

FIGURE 4. PRE-DISTORTER BLOCK DIAGRAM

Serial Interface

The serial interface for the external memory effects

calculation consists of outputs SERCLK, SERSYNC, and

SEROUT and input SERIN. The serial output sends the 32bit unsigned average power off-chip for further processing.

The data is transmitted via the SEROUT pin MSB first, with

the first bit marked by a high pulse on the SERSYNC pin.

The SERCLK rate is scaled such that 32 bits are transmitted

in one period of the power integrator as controlled by register

0x18 bits 5:4. SEROUT is enabled by register 0x18 bit 12.

IF Converter (IFC)

The output of the pre-distorter is a complex baseband signal

sampled at the system CLK rate. To provide greater system

flexibility, the IF Converter function can change this in one of

three different ways, providing frequency shifts, sample rate

changes and complex to real conversions.

Real 1X

The real 1x operating mode shifts the signal up by Fs/4 and

performs a complex to real conversion without changing the

base sample rate. This mode has 1/2 the bandwidth of the

original input signal, with the I output channel active and the

Q output channel set to 0. The operation of the IF converter

in this mode is shown in Figure 5.

BYPASS

I

Q

FROM

PD

FIGURE 5. IF CONVERTER IN REAL 1X MODE OPERATION

Real 2X

The real 2x operating mode converts complex to real at 2x

the sample rate and shifts the signal up to Fs/2 (Fs/4 of the

output rate). This mode has the same bandwidth as the

original signal with the I channel carrying the first of twwo

samples/clock and the Q channel carrying the second

sample. The operation of the IF Converter in this mode is

shown in Figure 6.

I

Q

FROM

2

PD

FIGURE 6. IF CONVERTER IN REAL 2X MODE OPERATION

HALF

BAND

FILTER

j(pi/2)(n)

e

BYPASS

HALF

2

BAND

FILTER

j(pi/2)(n)

e

Re{*}

Re{*}

-1

Z

2

I

I

2

Q

The SERIN receives the thermal compensation parameters

from external processing using the same SERCLK and

SERSYNC used by the SEROUT. The chip expects to

receive 32 bits of data sequentially on the SERIN pin: the

MSB of A, followed by the rest of A, then the MSB of B,

followed by the rest of B. The SERIN is enabled by register

0x18 bit 8. When SERIN is disabled, registers 0x19 and

0x1a supply the A and B parameters for the thermal

compensation calculations. See Figure 16 for a detailed

timing diagram of the serial interface.

8

Page 9

ISL5239

www.BDTIC.com/Intersil

The IF converter frequency response is as shown in

Figure 7, with the folding effect shown in Figure 7A for the

x2, Fs/4 upconverter case.

0

-20

-40

-60

-80

MAGNITUDE (dB)

-100

-120

-140

0

-20

-40

-60

IFC FILTER RESPONSE (x2 MODE)

0 0.1 0.2 0.3 0.4 0. 5 0.6 0.7 0.8 0.9 1

NORMALIZED FREQUENCY (NYQUIST=1)

FIGURE 7. x2, IFC FREQUENCY RESPONSE

IFC FILTER RESPONSE (x2 MODE, WITH FOLDING)

Correction Filter (CF)

To compensate for imperfections in the analog filtering which

takes place after D/A conversion, the correction filter

provides an independent 13-tap FIR filter on each channel.

These filters may be programmed to remove differential

group delay and ripple characteristics of external analog

circuits including sin(x)/x correction and frequency response

imbalance between the I and Q channels using either

amplitude or group delay. This allows for correction of the

two physically separate I and Q analog response paths from

the DAC’s through the quadrature up-converter. It also

provides correction of the bandpass response when

operating in a complex frequency shifted IF mode. There are

two possible correction fi lter modes.

Real 2X

When the IF Converter is set to generate 2x sampled real

data, the Correction Filter must be reconfigured to process

this data correctly. In this mode it effectively pro vides one 13tap block-mode filter when the coefficients for the two filters

are programmed identically.

BYPASS

I

Q

FROM

IFC

2

2

-1

Z

I/Q FIRs

-1

Z

2

I

2

Q

-80

MAGNITUDE (dB)

-100

-120

-140

0 0.1 0.2 0.3 0.4 0. 5 0.6 0.7 0.8 0.9 1

NORMALIZED FREQUENCY (NYQUIST=1)

FIGURE 7A. x2, IFC FREQUENCY RESP. WITH FOLDING

Complex

The complex operating mode simply shifts the complex

baseband signal up by Fs/4 without any filtering or real

conversion. The operation of the IF converter in this mode is

shown in Figure 8.

BYPASS

I

Q

FROM

PD

j(pi/2)(n)

e

FIGURE 8. IF CONVERTER IN COMPLEX MODE OPERATION

I

Q

FIGURE 9. CORRECTION FILTER IN REAL 2X MODE

Complex or Real 1x

When configured for operation in the complex mode, one 13tap filter is provided for each the I and Q channels. In Real 1x

mode, the Q channel is not used.

BYPASS

I

Q

FROM

IFC

I-CHAN

FIR

Q-CHAN

FIR

FIGURE 10. CORRECTION FILTER IN COMPLEX MODE

I

Q

Output Data Conditioner (ODC)

The Output Data Conditioner can apply I/Q balance

corrections, DC offset corrections and output format

conversions.

To compensate for gain/phase imperfections in external

analog modulation circuits which can result in poor image

rejection and reduced dynamic range, the ODC provides an

I/Q balance corrector. The I/Q balance corrector provides

four coefficients to control the magnitude of the direct and

9

Page 10

ISL5239

www.BDTIC.com/Intersil

cross-coupled term on both the I and Q channels. Typical

implementation is as shown in Figure 10.

FIGURE 11. IMBALANCE CORRECTION

The Output formatter also provides DC offset correction to

1/4 LSB for 18-bit outputs to reduce analog DC offsets

introduced in external D/A conversion and modulation

circuits which can degrade system performance by causing

carrier feed through in complex baseband systems, or spurs

at DC for IF systems.

The ODC also provides programmable output precision 8 to

18-bits, with unbiased (convergent) rounding, since practical

system designs will require D/A converters with fewer than

18-bits. Internal accuracy is in excess of 18-bits, and utilizes

20-bit data paths in critical areas. Additionally, both two’s

complement and offset binary formats are supported.

Capture Memory (CM)

The Capture Memory allows the capture and viewing of data

from various points in the chip. The primary function is to

capture the digital signals coming into the pre-distorter. The

CM also provides a secondary mode, as it can provide

stimulus directly to the pre-Distorter. The CM is comprised of

both the Input and the Feedback Memories. The processor

interface provides the access to view, input, and alter the

memory data. Synchronized (triggered) capture of both input

and feedback signals is a typical requirement of adaptive

digital pre-distortion systems.

Input Memory

The input capture memory observes the signals going into

the amplifier. The 2K deep memory grabs complex samples

of data at one of three possible locations, either at the input

to the pre-distorter, the output of the pre-distorter, or from its

magnitude calculation. In addition to capturing input data,

this memory may also be configured as a data source. The

input capture memory may be pre-loaded with user defined

data and ‘played’ into the pre-distorter to stimulate the

system with signals that will elicit a desired response.

Feedback Memory

The feedback memory allows the user to capture data from

an external system and to view the memory through the

processor interface. The feedback memory is used to

observe the signals coming out of the amplifier. The 1K deep

memory grabs 20-bit data, either in parallel or serial format.

The feedback capture memory has its own clock input,

FBCLK, which must be synchronously derived from CLK and

meet the timing requirements.

Capture operations may be triggered by an external signal

(TRIGIN), by magnitude threshold crossings detection

programmed in the magnitude threshold maximum and

minimum values, or by system software writing to the

processor trigger bit in control word 0x04, bit 6. Separate

programmable delays of up to 32k samples are provided for

both input memory and feedback capture, allowing system

delays to be calibrated out for optimum alignment prior to

analysis. A TRIGOUT output is provided to indicates when a

capture operation has begun.

The processor interface to the capture memories is designed

to minimize the time required for loading/unloading. Although

access to the memories takes place through indirect address

and data registers, auto incrementing of the address is

supported so the address only needs to be written once to

access the entire memory. The capture memory is as shown

in Figure 13.

TRIGIN

MAG COMP

uP

IFC I,Q

PD I,Q

PD MAG

CM TEST I,Q

MEMORY SELECT

TRIG SEL

INPUT DELAY

COUNT

INPUT

uP

SEL STATE

DATA ADDR

INPUT

CAPTURE

MEMORY 2K

FIGURE 12. CAPTURE MEMORY BLOCK DIAGRAM

TRIG

INPUT

uP INTERFACE

STATE

FB DELAY COUNT

FB

uP

ADDR DATA

FEEDBACK

CAPTURE

MEMORY 1K

FORMAT

FBCLK

FB<19:0>

Memory Modes and Programming Instructions

Unless noted, the following discussion applies to both the

input memory and feedback memory operations. Prior to

invoking the memory to capture or send data, the control

word 0x06, bits 14:0 input trigger delay counter, 0x08 bits

14:0 feedback trigger delay count, 0x05, bits 10:0 input

length, 0x04, bits 2:1 input memory datain source or 0x04,

bit 8 feedback input format, and 0x04, bits 5:4 trigger select

registers must be loaded.

10

Page 11

ISL5239

www.BDTIC.com/Intersil

For the input data, the 0x04, bit 3 input data round bit must

also be selected and the feedback memory length count is

always set to 1024. To invoke memory operation, the 0x07,

bit 4 feedback memory mode or bits 1:0 input memory mode

and 0x04, bit 6 processor trigger must be controlled.

There are three modes of operation — capture, loop, and

single-shot. The feedback memory does not have a loop

mode. A synopsis of the three modes is described below.

Capture Mode

There are two types of capture mode — advanced trigger

and single/capture. The advanced trigger mode allows data

to be captured around a trigger point, and the quantity of the

data captured after the trigger point is set by 0x06, bits 14:0.

When input memory capture mode = DELAY, the delay

register acts as a delay count prior to the capture or sending

of data. The max delay in this case is 32768 counts or

system clock ticks. The advanced trigger mode is used in

capture mode only. With the feedback capture operations

being analogous to the input memory , one feedbac k memory

exception is its control register 0x08, bits 14:0. It has 10

LSBs of available capture space.

Advanced Trigger Capture Mode Sequence

The control register 0x0e, bit 13:12 input capture status,

should be in IDLE. Set 0x06, bit 15, input memory capture

mode to ADVANCE to signify an advanced trigger capture.

0x06, bits 14:0 set the input trigger delay counter to = 0x56

signifies there are 86 points captured after the occurrence of

the trigger point, 0x0e, bit 10:0, input trigger position and all

other points are captured prior to trigger point. Note: only the

11 lsbs are valid for the delay capture in this mode. The input

trigger position is a read-only register and adding to it the 11

lsbs of the input trigger delay counter determines the

position of the final data point captured after the trigger. If the

input trigger position is 0x1ff, the final point captured

occurred at address: 0x1ff + 0x56 = 0x255 or 597 (decimal).

The user must set the input trigger delay counter prior to

invoking the transaction of the capture.

The user invokes the capture mode register by writing

CAPTURE to 0x07, bit 1:0 input memory mode. The system

is in the advanced trigger capture mode and 0x0e, bits

13:12, input capture status is ARMED. The system waits for

a trigger as the memory is continuously being written into.

When a trigger occurs, the trigger causes the memory to

load the data till the memory address is equal to input trigger

position + 11 lsbs of the input trigger delay counter. The

memory address that is time coincident with the trigger

occurrence latches to the input trigger position. During this

period, the input capture status is LOADING. When the final

capture point loads, the input capture status returns to IDLE

and a new capture transaction can be initiated by writing

CAPTURE to the input memory mode.

Single/Capture Mode

The sequence for the single shot stimulus mode, input

memory mode = SINGLE, and input memory capture mode

= CAPTURE with input capture mode = DELAY are the

identical. The function of the memory reading or writing

provides the difference between the two modes. In the single

shot case, the capture memories read data to the output bus,

and in the capture mode, they write data to the memories.

The sequence of operation in the Single/Capture mode is

described below.

The input capture status should be in IDLE and the input

memory capture mode in DELAY with the input memory

delay counter set to 0x0056. Note: The 15 LSBs of the input

memory delay counter are valid for the delay count in this

mode. After the trigger, Ox56 signifies there are 86 counts of

delay before the start of the capture/send of data to/from the

memory.

The user invokes the capture mode by writing the input

memory mode to CAPTURE. The system is in the capture

mode and the input memory status is ARMED. The system

waits for a trigger and the memory is idle at this point. When

a trigger occurs, the trigger causes the delay counters to

count 86 clocks of delay. At the end of the delay, the

memories begin their writing sequence until input memory

length data points are written. During the writing of data, the

input memory status is LOADING. When the final input

memory length point is written, the input memory status

returns to IDLE and a new capture transaction can be

initiated by writing CAPTURE to the input memory mode.

For the Single Capture mode, the deviations from the

sequence are the writing of the input memory mode to

SINGLE, and the input memory status to SEND when

reading of the data from memory. All other operations are

analogous.

Loop Mode

This is a continuous play mode from the memories;

therefore, the memories should contain valid data before

invoking transactions. The length of each repeatable output

stream is controlled by the input memory length. Upon

outputting the final input memory length point, the hardware

resets to play another set of input memory length points from

the memory.

The user invokes the loop mode by writing input memory

mode to LOOP. The system is in the loop mode and the input

memory status = SEND. The memory starts reading data

continuously and a stop can be initiated by setting input

memory mode to IDLE during the transaction. The input

memory status returns to IDLE and a new loop transaction

can be initiated by writing the input memory mode to LOOP.

This is the only mode where immediate mode changes are

acknowledged during its transaction cycle.

11

Page 12

ISL5239

www.BDTIC.com/Intersil

General Comments About Modes

Once a trigger is detected in the ARMED condition, all

following triggers are ignored during the sequence. The

system does not acknowledge new triggers until a new

transaction is invoked and re-armed. When a new mode is

invoked, all subsequent inv ocations of new modes during the

duration of its sequence is ignored, except in the loop mode.

In the loop mode, an input memory mode change to IDLE is

processed immediately.

When in the IDLE, all controls, addresses, and data, default

to the processor interface values.

Triggers

When a capture memory is ARMED, i.e. waiting for a trigger

to happen, the activation of the trigger occurs in three ways

— external, data dependent, and user invoked. The trigger

select, 0x04, bits 5:4, provides the selection of the trigger

source. When the pre-distorter magnitude bus values fall

between the range of 0x09 minimum and 0x0a maximum,

the data dependent trigger activates. The first of these

transitions causes a trigger to be detected and the remaining

triggers during the capture sequence is ignored.

To invoke the user invoked trigger, 0x04, 5:4, set to

processor, the programmer writes a TRIGGER to the 0x04,

bit 6 processor trigger register. After a TRIGGER is in the

field, the user initiates the trigger by just writing to that

register. The user does not have to reset the trigger back to

IDLE. By setting the processor trigger bit to IDLE when not in

use, it keeps the circuit quiet and allows the user to write to

other values at that address without causing a trigger to

occur during operation. To disable the processor trigger, the

user should change trigger select to something other than

PROCESSOR and then change values in processor trigger.

If trigger select is not set to PROCESSOR, the system

ignores the trigger generated by processor trigger.

The feedback and input memory circuit uses the same

trigger; both circuits trigger at the same point with its

operation registers causing different operations to occur. The

user should monitor input memory status and feedback

memory status simultaneously before activating triggers.

Make sure both status registers are in ARMED before

activating triggers or the results from the capture can be

erroneous and data can be overwritten. Selecting processor

trigger (register 0x04, bits 5:4 = 00) while arming the input

and feedback memory circuits is a convenient way to ensure

no unexpected triggers occur before confirming ARMED

status of both circuits.

Input Data to Input Memory

There are three sources of input data to the input memory —

interpolator, pre-distorter’s data outputs, and the predistorter’s magnitude. Data from the interpolator and the

predistort output are the upper 16 bits with or without

rounding. Only 16 of the original 20 bits of I or Q is loaded

into the memory. The I data is read from the memory on the

DataHigh register and the Q data, DataLow register.

In the predistort magnitude input, the data is unsigned 16

bits and the software has to reshuffle the data to extract the

original magnitude. The DataHigh contains only the predistorter magnitude bit 15, and the DataLow contains the

pre-distorter magnitude 14:0.

Writing/Reading the Memories from the Proc essor

Interface

In the auto-increment mode, the data is loaded in 16-bit

increments. The low word is written or read first followed by

the high word. The high word increments the address

counter and generates the actual write to the memory. For

reading, it just increments the counter. The input memory

select 0x04, bit 12, selects the memory to be written to or

read from.

When writing or reading a specific address, the 0x0b

address register must be loaded before the 0x0c and 0x0d

memory data registers. In the write, the high word

transaction will trigger the actual write to the memory and a

low word must be written first. For additional details, see the

uP interface section.

Microprocessor Interface

The microprocessor interface allows the ISL5239 to appear

as a memory mapped peripheral to the µP. All registers can

be accessed through this interface. The interface consists of

a 16 bit bidirectional data bus, P<15:0>, six bit address bus,

A<5:0>, a write strobe (WR

enable (CE

and write strobe inputs.

The processor interface provides a simple parallel

Data/Control/Address bus for monitoring and controlling its

operation. The processor interface is asynchronous to the

CLK, and BUSY signal is included to indicate when read and

write operations are complete.

The register configuration is master/slave, where the slave

registers are updated from the masters and all reads access

the slaves.

The master registers are clocked by the µP WR

writable and cleared by a hard reset. The slave registers are

clocked by CLK, and are readable and cleared by either a

hard or soft reset. The transfer of configuration data from the

master register to the slave register occurs synchronously

after an event and requires a four clock synchronization

period.

The µP can perform back-to-back accesses to the register,

but must maintain four f

the same address. This limits the maximum µP access rate

for the RAM to 125MHz/4 = 31.25MHz.

). The interface is configured for separate read

), a read strobe (RD) and a chip

strobe, are

periods between accesses to

CLK

12

Page 13

ISL5239

www.BDTIC.com/Intersil

The address map and bit field details for the microprocessor

interface is shown in the Tables 2-48. The procedures for

reading and writing to this interface are provided below.

Microprocessor Read/Write Procedure

The ISL5239 offers the user microprocessor read/write

access to all of the configuration registers and the capture

memory.

Configuration Read/Write Procedure

Write Access to the Configuration Master

Registers

Perform a direct write to the configurati on master registers

by setting up the address A<5:0>, data P<15:0>, enabling the

CS

input, and generating WR strobe. The rising edge of the

WR

initiates the transfer to the master register. Registers may

be written in any order.

1. Write the global control register 0x00.

2. Write all remaining registers sequentially .

3. Load all IFIP, PD, IFC, CM and ODC coefficients and

control words.

RD

WR

A<5:0> 0x00

P<15:0>

FIGURE 13. CONFIGURATION WRITE TRANSFER

0x01 0x02 0x03

xxxx

0x04 0x05

Read Access to the Configuration Slave Registers

1. Perf orm a direct read of a configuration register by

dropping the RD line low to transfer data from the register

selected by A<5:0> onto the data bus P<15:0>.

RD

WR

A<5:0>

P<15:0>

FIGURE 14. CONFIGURATION READ TRANSFER

0X00 0X01 0X02 0X03 0X04 0X05

HI-Z

DATA VALID

LUT Read/Write Procedure

Write Access to the LUT Memory

1. Perf orm a direct write to control word 0x13 by setting up

the address on A<5:0>, data on P<15:0>, and generating

a rising edge on WR.

mode and the LUT address as specified in bit 9:0.

2. Perf orm a direct write to any/all control words 0x14, 0x15,

or 0x16, in any order, by setting up the address on A<5:0>,

data on P<15:0>, and generating a rising edge on WR.

0x13 selects the auto increment

3. Perf orm a direct write to control word 0x17 by settin g u p

the address on A<5:0>, data on P<15:0>, and generating

a rising edge on WR. The WR updates the contents of

0x014-0x017 and performs the auto increment, if

enabled.

Read Access to the LUT

1. Perf orm a direct write to control word 0x13 by settin g u p

the address on A<5:0>, data on P<15:0>, and generating

a rising edge on WR.

mode and the LUT address as specified in bit 9:0.

2. Perf orm a direct read of any/all control words 0x14, 0x15,

0x16, in any order, by dropping the RD line low to transfe r

data from the slave register selected by A<5:0> onto the

data bus P<15:0>.

3. Perf orm a direct read of control word 0x17 by dropping the

line low to transfer data from the slave register

RD

selected by A<5:0> onto the data bus P<15:0> . Reading

from this control word performs the auto increment, if

enabled.

0x13 selects the auto increment

Capture Memory Read/Write Procedure

Indirect addressing is used to access the Capture Memory.

The control word 0x04, bit 12 selects whether the input or

feedback memory is accessed and bit 13 selects the auto

address increment or manual modes. Control word 0x0b is

the memory address, and words 0x0c and 0x0d combine to

form the 32-bit word which is written or read from the

memory. The write to 0x0d triggers the write to the memory

and the auto increment of the address, if enabled. When

reading feedback capture memory , 0x0c bits 3:0 will contain

the upper four bits, and 0x0d, bits 15:0 will be the remaining

15-bits.

Write Access to the Capture Memory

1. Perf orm a direct write to control word 0x04 by settin g u p

the address on A<5:0>, data on P<15:0>, and generating

a rising edge on WR.

mode and the input or feedback memories.

2. Perf orm a direct write to control word 0x0b by settin g u p

the address on A<5:0>, data on P<15:0>, and generating

a rising edge on WR. 0x0b selects the starting memory

address.

3. Perform a direct write to 0x0c by setting up the address on

A<5:0>, data on P<15:0>, and generating a rising edge on

WR.

4. Perf orm a direct write to control word 0x0d by settin g u p

the address on A<5:0>, data on P<15:0>, and generating

a rising edge on WR.

0x0c and 0x0d and performs the auto increment, if

enabled.

0x04 selects the auto increment

The WR updates the contents of

13

Page 14

ISL5239

www.BDTIC.com/Intersil

Read Access to the Capture Memory

1. Perf orm a direct write to control word 0x04 by setting up

the address on A<5:0>, data on P<15:0>, and generating

a rising edge on WR. 0x04 selects the auto increment

mode and the input or feedback memories.

2. Perf orm a direct read of 0x0c by dropping the RD line low

to transfer data from the slave register selected by

A<5:0> onto the data bus P<15:0>.

3. Perf orm a direct read of control word 0x0d by dropping the

line low to transfer data from the slave register

RD

selected by A<5:0> onto the data bus P<15:0>. Reading

from this control word performs the auto increment, if

enabled.

Correction Filter Read/Write Procedure

Write Access to the Correction Filter Coefficients

1. Perf orm a direct write to control word 0x28 by setting up

the address on A<5:0>, data on P<15:0>, and generating

a rising edge on WR.

mode.

2. Perf orm a direct write to control word 0x29 by setting up

the address on A<5:0>, data on P<15:0>, and generating

a rising edge on WR. 0x29 selects the coefficient address

for I or Q.

3. Perf orm a direct write to control word 0x2a by setting up

the address on A<5:0>, data on P<15:0>, and generating

a rising edge on WR.

4. Repeat step 3 until all 13 coefficients for I and for Q hav e

been loaded as the master registers are transferred to the

slaves when the last Q coefficient is written.

0x28 selects the auto increment

Read Access to the Correction Filter Coefficients

1. Perf orm a direct write to control word 0x028 by settin g up

the address on A<5:0>, data on P<15:0>, and generating

a rising edge on WR.

mode.

2. Perf orm a direct write to control word 0x029 by settin g up

the address on A<5:0>, data on P<15:0>, and generating

a rising edge on WR.

3. Perf orm a direct read of 0x2a by dropping the RD line low

to transfer data from the slave register selected by

A<5:0> onto the data bus P<15:0>.

0x28 selects the auto increment

Latency

To be provided later.

Reset

There are three types of chip resets.

RESET pin

A hard reset can occur by asserting the input pin RESET

which resets all chip registers to their default condition, and

resets the uP interface.

Software Hard Reset

The µP can issue a reset command through the global

control register 0x00, bit 4. This reset is identical to asserting

the RESET

not affected, and the uP interface is not reset.

pin, except the control fields 0x00 and 0x01 are

Software Soft Reset

The uP can issue a reset command through the global

control register 0x00, bit 0, which is identical to a Software

hard reset, but none of the control registers are reset. A soft

reset leaves the device in an idle state.

JTAG Test

The IEEE 1149.1 Joint Test Action Group boundary scan

standard operational codes shown in Table 9 are supported.

A separate application note is available with implementation

details and the BSDL file is available.

TABLE 1. JTAG OP CODES SUPPORTED

INSTRUCTION OP CODE

EXTEST 0000

IDCODE 0001

SAMPLE/PRELOAD 0010

INTEST 0011

BYPASS 1111

Power-up Sequencing

The ISL5239 core and I/O blocks are isolated by structures

which may become forward biased if the supply voltages are

not at specified levels. During the power-up and power-down

operations, differences in the starting point and ramp rates of

the two supplies may cause current to flow in the isolation

structures which, when prolonged and excessive, can

reduce the usable life of the device. In general, the most

preferred case would be to power-up or down the core and

I/O structures simultaneously. However, it is also safe to

power-up the core prior to the I/O block if simultaneous

application of the supplies is not possible. In this case, the

I/O voltage should be applied within 10 ms to 100 ms

nominally to preserve component reliability. Bringing the

core and I/O supplies to their respective regulation levels in

a maximum time frame of a 100 ms, moderates the stresses

placed on both, the power supply and the ISL5239. When

powering down, simultaneous removal is preferred, but It is

also safe to remove the I/O supply prior to the core supply. If

the core power is removed first, the I/O supply should also

be removed within 10-100mS.

Application Notes and Evaluation Boards

The ISL5239 operation can be demonstrated via the

ISL5239EVAL1 board. All required hardware and Windows

GUI software are supplied with both a user’s manual and

accompanying applications notes.

14

Page 15

ISL5239

www.BDTIC.com/Intersil

Absolute Maximum Ratings Thermal Information

Supply Voltage. . . . . . . . . . . . . . . . . . . . . . +2.5VCCC, 4.6V VCCIO

Input, Output or I/O Voltage. . . . . . . . . . . . . . . . .GND -0.5V to 5.5V

ESD Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Class 2

Operating Conditions

Voltage Range Core, V

Voltage Range I/O, V

Temperature Range

Industrial. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -40

Input Low Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0V to +0.8V

Input High Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2V to V

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

is measured in free air with the component mounted on a high effective thermal conductivity test board. See Tech Brief TB379.

1. θ

JA

2. With “direct attach” features (i.e., vias in the PCB), the thermal resistance is 36 without airflow, w/200 it is 33, w/400 it is 31

package pins F6-9, G6-9, H6-9, J6-9 to heat sink or ground with vias to ensure maximum device heat dissipation.

3. Single supply operation of both the core VCCC and I/O VCCIO at 1.8V is not allowed.

. . . . . . . . . . . . . . . . . .+1.71V to +1.89V

CCC

CCCIO (Note 3)

. . . . . . . . .+3.135V to +3.465V

o

C to 85oC

CC

Thermal Resistance (Typical, Notes 1, 2) θ

JA

(oC/W)

196 BGA Package . . . . . . . . . . . . . . . . . . . . . . . . . . 42

w/200 LFM Air Flow . . . . . . . . . . . . . . . . . . . . . . . . . 38

w/400 LFM Air Flow . . . . . . . . . . . . . . . . . . . . . . . . . 36

Maximum Storage Temperature Range. . . . . . . . . . -65

o

C to 150oC

Maximum Junction Temperature . . . . . . . . . . . . . . . . . . . . . . 125

For Recommended Soldering Conditions, See Tech Brief TB334.

o

C/W. Tie 196 BGA

o

C

DC Electrical Specifications V

= 1.8± 5%, V

CCC

= 3.3 ±5%, TA = -40oC to 85oC

CCIO

PARAMETER SYMBOL TEST CONDITIONS MIN Typ MAX UNITS

Logical One Input Voltage V

Logical Zero Input Voltage V

Clock Input High V

Clock Input Low V

Output High Voltage V

Output Low Voltage V

Input Leakage Current I

Output Leakage Current I

Input Pull-up Leakage Current Low I

Input Pull-up Leakage Current High I

Standby Power Supply Current I

Operating Power Supply Current I

CCSB

CCOP

Input Capacitance C

Output Capacitance C

IH

IL

IHC

ILC

OH

OL

L

H

SL

SH

IN

OUT

= 1.89V, V

CCC

V

= 1.71V, V

CCC

V

= 1.89V, V

CCC

V

= 1.71V, V

CCC

IOH = -2mA, V

IOL = 2mA, V

VIN = V

V

CCIO

VIN = V

V

CCIO

VIN = V

V

CCIO

VIN = V

V

CCIO

V

CCC

Loaded

CCC

or GND, V

CCIO

= 3.465V

or GND, V

CCIO

= 3.465V

or GND, V

CCIO

= 3.465V, TMS, TRST, T DI

or GND, V

CCIO

= 3.465V, TMS, TRST, T DI

= 1.89V, V

f = 125MHz, VIN = V

V

= 3.465V, V

CCIO

Freq = 1MHz, V

Are Referenced to Device Ground

Freq = 1MHz, V

= 3.465V 2.0 - V

CCIO

= 3.135V - 0.8 V

CCIO

= 3.465V 2.0 - V

CCIO

= 3.135V - 0.8 V

CCIO

= 1.71V, V

CCC

= 1.71V, V

CCC

CCC

CCC

CCC

= 3.465V, Outputs Not

CCIO

CCIO

= 1.89V,

CCC

Open, All Measurements

CCIO

Open, All Measurements

CCIO

V

are Referenced to Device Ground

NOTES:

4. Power Supply current is proportional to operation frequency. Typical rating for I

5. Capacitance T

process or design changes.

= 25oC, controlled via design or process parameters and not directly tested. Characterized upon initial design and at major

A

CCIO

CCIO

= 1.89V,

= 1.89V,

= 1.89V,

= 1.89V,

or GND,

CCOP

= 3.135V 2.6 VCC-0.2 - V

= 3.135V 0.2 0.4 V

-10 1 10 µA

-10 1 10 µA

-100 -50 - µA

-110µA

-1

100

- 300

3

500

100

mA(core)

uA(I/O)

mA (Core)

mA(I/O),

(Note 4)

- 5 pF (Note 5)

- 5 pF (Note 5)

is 2.0 mA/MHz (core) and 0.5mA/MHz(I/O),

15

Page 16

ISL5239

www.BDTIC.com/Intersil

AC Electrical Specifications V

PARAMETER SYMBOL MIN MAX UNITS

CLK Frequency f

CLK Period t

CLK High, FBCLK High t

CLK Low, FBCLK Low t

Setup Time RESET High to CLK (Note 8) t

Hold RESET

RESET

Setup Time P<15:0> to WR t

Hold Time P<15:0> from WR

Setup Time A<5:0> to WR

Hold Time A<5:0> from WR t

Setup Time CS

Hold Time CS

Delay Time from WR to BUSY t

Setup Time WR

Hold Time WR

Pulse Width High t

WR

WR Pulse Width Low t

Setup Time from RD

Hold Time RD

Setup Time from CS to CLK t

Hold Time CS

Setup Time from A<5:0> to CS

Setup Time from A<5:0> to CLK t

Delay Time from CS

Delay Time from CS

Delay Time from CLK to P<15:0> valid t

Setup Time IIN<17:0>, QIN<17:0>, or ISTRB to CLK t

Hold Time IIN<17:0>, QIN<17:0>, or ISTRB from CLK t

Delay Time from CLK to CLKOUT in x1 Mode t

Delay Time from CLK to CLKOUT in x2, x4, x8 Mode t

Delay Time from CLK to IOUT<17:0>, QOUT<17:0> valid t

Time Skew from CLK to FBCLK (Note 7) t

Setup Time from FB<19:0> to FBCLK t

Hold Time FB<19:0> from FBCLK t

Delay Time from CLK to SERSYNC t

Delay Time from CLK to SEROUT t

Delay Time from CLK to SERCLK in Period_32 Mode t

Delay Time from CLK to SERCLK in Period_64 or Period_128 Modes t

Setup Time from SERIN to CLK (Note 7) t

High from CLK t

Low Pulse Width (Note 7) t

to WR t

from WR t

to CLK (Note 9) t

from CLK t

to CLK t

from CLK t

from CLK t

and RD (Note 7) t

and RD to P<15:0> Enable (Note 7) t

and RD to P<15:0> Disable (Note 7) t

= 1.8± 5%, V

CCC

= 3.3 ± 5%, TA = -40oC to 85oC (Note 6)

CCIO

CLK

CLK

CH

CL

RS

RH

RPW

PSW

t

PHW

t

ASW

AHW

CSW

CHW

BDW

WSC

WHC

WPWH

WPWL

RSR

RHR

CSR

CHR

ASR

ASC

RE

RD

DR1

DS

DH

CC01

CC0N

PDC1

CFBD

FS

FH

SD1

SD2

SC1

SCN

DSS

- 125 MHz

8.0 - ns

3- ns

3- ns

2- ns

2- ns

2 - CLK Cycles

1- ns

4- ns

0- ns

4- ns

0- ns

3- ns

-8 ns

3- ns

0- ns

3- ns

3- ns

1- ns

2- ns

1- ns

2- ns

-2 - CLK Cycles

3- ns

-8 ns

-6 ns

-7 ns

2- ns

2- ns

7ns

8ns

2 (Note 7) 8 ns

-0.1 t

2ns

1ns

2 (Note 7) 7 ns

2 (Note 7) 8 ns

2 (Note 7) 9 ns

2 (Note 7) 8 ns

1ns

- 2 ns

CLK

16

Page 17

ISL5239

www.BDTIC.com/Intersil

AC Electrical Specifications V

= 1.8± 5%, V

CCC

= 3.3 ± 5%, TA = -40oC to 85oC (Note 6) (Continued)

CCIO

PARAMETER SYMBOL MIN MAX UNITS

Hold Time SERIN from CLK (Note 7) t

Delay Time from CLK to TRIGOUT t

Setup Time from TRIGIN to CLK t

Hold Time TRIGIN from CLK t

Setup Time from TMS and TDI to TCK t

Hold Time TMS and TDI from TCK t

Delay Time from TCK to TDO valid t

Test Clock Frequency f

Output Rise/Fall Time (Note 7) t

DHS

PDC

DS1

DH1

TS

TH

TD

T

RF

1ns

2 (Note 7) 7 ns

2ns

2ns

3ns

3ns

8ns

50 MHz

-3 ns

NOTES:

6. AC tests performed with C

Test V

= 3.0V, V

IH

IHC

= 70pF. Input reference level for CLK is 1.5V, all other inputs 1.5V.

L

= 3.0V, VIL = 0V, VOL = 1.5V, VOH = 1.5V.

7. Controlled via design or process parameters and not directly tested. Characterized upon initial design and at major process or design changes.

8. Can be asynchronous to CLK, specification guarantying which CLK edge the device comes out of reset on.

9. Can be asynchronous to CLK, specification guarantying which CLK edge the device begins the read cycle on.

AC Test Load Circuit

Waveforms

CLK

RESET

t

CLK

tCHt

SWITCH S1 OPEN FOR I

† TEST HEAD CAPACITANCE

t

= 1 / F

CL

t

RH

CLK

t

RPW

CLK

DUT

CCSB

t

RS

C

L

AND I

S

1

†

CCOP

I

EQUIVALENT CIRCUIT

CLK

SERCLK

SERSYNC

SEROUT

SERIN

OH

±

1.5V I

t

DSS

t

SD2

t

DHS

OL

t

SC1,tSCN

t

SD1

FIGURE 15. CLOCK AND RESET TIMING

FIGURE 16. SERIAL INTERFACE RELATIVE TIMING

17

Page 18

Waveforms (Continued)

www.BDTIC.com/Intersil

ISL5239

CLK

IN<17:0>,

QIN<17:0>,

ISTRB

CLKOUT

IOUT<19:0>,

QOUT<19:0>

CLK

FBCLK

FB<19:0>

t

DS

VALID

t

, t

CCO1

CCON

t

PDC1

VALID

VALID VALID

FIGURE 17. INPUT/OUTPUT TIMING

t

CFBD

t

FS

t

FH

t

DH

VALID

CLK

TRIGIN

TRIGOUT

TCK

TMS, TDI

TDO

t

PDC

t

t

DS1

DH1

FIGURE 18. TRIGGER PORT TIMING

t

TS

t

TH

t

TD

VALID

CLK

RD

WR

BUSY

CS

A<5:0>

P<15:0>

FIGURE 19. FEEDBACK TIMING

t

WSC

t

WPWL

VALID

VALID

t

WHC

t

WPWH

t

BDW

4 CLK CYCLES

t

CSW

t

t

ASW

t

t

PSW

t

CHW

AHW

PHW

CLK

RD

WR

BUSY

CS

A<5:0>

P<15:0>

FIGURE 20. JTAG TIMING

t

RSR

t

CSR

t

ASC

VALID

t

ASR

t

RE

VALID

t

t

DR1

CHR

t

t

RD

RHR

FIGURE 21. MICROPROCESSOR WRITE TIMING FIGURE 22. MICROPROCESSOR READ TIMING

18

Page 19

ISL5239

www.BDTIC.com/Intersil

Programming Information and Device Control Registers

TABLE 2. CONTROL REGISTER MAP

ADDRESS

(5:0) TYPE FUNCTION DESCRIPTION RESET DEFAULT

00 R/W Global Chip Control 0x0000

01 R Chip ID 0x0000

02 R/W Input Formatter and Interpolator Control 0x0000

03 R Status 0x0000

04 R/W Capture Memory Control 0x0000

05 R/W Length of Input Memory Loops 0x0000

06 R/W Input Memory Capture Mode and Trigger Delay 0x0000

07 R/W Operating Modes 0x0000

08 R/W Feedback Memory Capture Mode and Trigger

Delay

09 R/W Magnitude Threshold Minimum Value 0x0000

0a R/W Magnitude Threshold Maximum Value 0x0000

0b R/W Memory Address 0x0000

0c R/W Memory Data LSW 0x0000

0d R/W Memory Data MSW 0x0000

0e R Input Memory Status 0x0000

0f R Feedback Memory Status 0x0000

10 R/W Pre-Distorter Control 0x0000

11 R/W Magnitude Function Control 0x0000

12 R/W Magnitude Function Scale Factor 0x0000

13 R/W Look-Up Table Control 0x0000

14 R/W Look-Up Table Delta Imaginary Data 0x0000

15 R/W Look-Up Table Delta Real Data 0x0000

16 R/W Look-Up Table Imaginary Data 0x0000

17 R/W Look-Up Table Real Data 0x0000

18 R/W Memory Effect Control 0x0000

19 R/W Memory Effect Coefficient A 0x0000

1a R/W Memory Effect Coefficient B 0x0000

1b R/W Memory Effect Power Integrator LSW 0x0000

1c R/W Memory Effect Power Integrator MSW 0x0000

1d R Status 0x0000

20 R/W IF Converter Control 0x0002

21 R Status 0x0000

28 R/W Correction Filter Control 0x0000

29 R/W Coefficient Index 0x0000

2a R/W Coefficient Value 0x0000

2b R Status 0x0000

0x0000

19

Page 20

ISL5239

www.BDTIC.com/Intersil

TABLE 2. CONTROL REGISTER MAP (Continued)

ADDRESS

(5:0) TYPE FUNCTION DESCRIPTION RESET DEFAULT

30 R/W Output Data Conditioner Control 0x0000

31 R/W I-to-I (hm) Coefficient 0x0000

32 R/W Q-to-I (km) Coefficient 0x0000

33 R/W I-to-Q(Im) Coefficient 0x0000

34 R/W Q-to-Q (gm) Coefficient 0x0000

35 R/W I-Channel DC Offset MSW 0x0000

36 R/W I-Channel DC Offset LSW 0x0000

37 R/W Q-Channel DC Offset MSW 0x0000

38 R/W Q-Channel DC Offset LSW 0x0000

39 R Status 0x0000

TABLE 3. CHIP CONTROL

TYPE: GLOBAL: ADDRESS: 0x00

BIT FUNCTION DESCRIPTION

15:11 Reserved Not Used

10:8 ID Index Pointer that selects a pair of characters from the Chip Identification, where the Chip Identification is a

string of 16 ASCII characters. The ChipID field provides access to the selected character pair. For

example, if the Chip Identification is the first 16 letters of the alphabet,—“ABCD…P”—then setting

ID_Index = PAIR_0, selects the left-most pair, AB, which can be accessed by reading the ChipID field.

Setting ID_Index = PAIR_1, selects the pair, CD.

000 - Pair 0

001 - Pair 1

010 - Pair 2

011 - Pair 3

100 - Pair 4

101 - Pair 5

110 - Pair 6

111 - Pair 7

7:5 Reserved Not Used

4 Hard Reset Control bit that resets the entire chip except the Processor Interface (PI) block. Identical to asserting

3:1 Reserved Not Used.

0 Soft Reset Control bit that is identical to Hard Reset except that it does not reset any control registers.

, except:

RESET

(1) it does not reset the control fields, ID Index, Hard Reset, Soft Reset, and Chip ID.

(2) it does not reset the PI Controller in the PI block.

0 - Reset not active (default).

1 - Reset is active for the entire chip except the PI block.

0 - Reset not active (default).

1 - Reset is active for the entire chip except the PI block and all control registers.

TABLE 4. CHIP ID

TYPE: GLOBAL: ADDRESS: 0x01

BIT FUNCTION DESCRIPTION

15:0 Chip ID Pair of ASCII character codes for the Chip Identification, where the Chip Identification is a string of 16

ASCII characters. The ChipID field provides access to the characters selected by ID_Index. From the

example in the ID_Index description, reading ChipID with ID_Index = PAIR_0 returns the ASCII code for

“AB”. The ASCII code for “A” is 0x41, and the ASCII code for “B” is 0x42; therefore, ChipID would have

the value 0x4142.

20

Page 21

ISL5239

www.BDTIC.com/Intersil

TABLE 5. CONTROL

TYPE: INPUT FORMATTER AND INTERPOLATOR, ADDRESS: 0x02

BIT FUNCTION DESCRIPTION

15 Reserved Not used.

14 Clear Status Set high to clear all status bits, set low (default) to allow the status bits to update.

13:8 Reserved Internal use only.

7 Reserved Not used.

6:4 Interpolation Factor The chip upsamples its input data by x1, x2, x4, or x8, and it performs the appropriate filtering to reject

3 Reserved Not used.

2 Input Sequence Type The type of sample sequence of the Input Formatter and Interpolator input data IIN<17:0>, QIN<17:0>.

1 Input Value Type Allows selection of the input type as 2’s complement or offset binary.

0 Soft Reset Soft reset that, when high, resets all input formatter and interpolator circuitry except the control fields.

the images created by the upsampling operation. Interpolation by 1 bypasses all the interpolation filters.

000 - x1 (default)

001 - x2

011 - x4

111 - x8

010, 100, 101, 110 Internal Use Only.

0 - PARALLEL. (default) The chip receives I and Q data in parallel through IIN<17:0>, QIN<17:0>The chip

ignores the input signal, ISTRB, in this mode.

1 - SERIAL. The chip receives I and Q data in a serial stream through IIN<17:0>. The serial stream

alternates between I and Q samples, and the chip uses the input signal, ISTRB, to detect which samples

are I and which samples are Q. The chip ignores the input signal QIN<17:0> in this mode.

0 - 2’s complement (default) Input data.

1 - Offset Binary Input data.

TABLE 6. STATUS

TYPE: INPUT FORMATTER AND INTERPOLATOR, ADDRESS: 0x03

BIT FUNCTION DESCRIPTION

15:14 Reserved Not used.

13 Reserved Internal use only.

12:8 Reserved Internal use only.

7 HB 3 Q Saturation When high, bit indicates HB 3 saturated at least one sample in the Q channel since the last clear status

command. Invalid when Interpolation factor < x8.

6 HB 3 I Saturation When high, bit indicates HB 3 saturated at least one sample in the I channel since the last clear status

command. Invalid when Interpolation factor < x8.

5 HB 2 Q Saturation When high, bit indicates HB 2 saturated at least one sample in the Q channel since the last clear status

4 HB 2 I Saturation When high, bit indicates HB 2 saturated at least one sample in the I channel since the last clear status

3 HB 1Q Saturation When high, bit indicates HB 1 saturated at least one sample in the Q channel since the last clear status

2 HB 1I Saturation When high, bit indicates HB 1 saturated at least one sample in the I channel since the last clear status

1 Serial Mode Error When high, indicated the input formatter and interpolator block performed an illegal operation since the

0 Serial Mode Error Active When high, indicates the input formatter and interpolator block is performing an illegal operation. Not

command. Invalid when Interpolation factor < x8.

command. Invalid when Interpolation factor < x8.

command. Invalid when Interpolation factor < x2.

command. Invalid when Interpolation factor < x2.

last clear status command.

impacted by the clear status command.

21

Page 22

ISL5239

www.BDTIC.com/Intersil

TABLE 7. CONTROL

TYPE: CAPTURE MEMORY, ADDRESS: 0x04

BIT FUNCTION DESCRIPTION

15:14 Reserved Not used.

13 Address Auto Increment When set high, automatically increments the memory address after any access operation (read or write).

12 Memory Select Selects the memory for access.

0 - Input memory (default).

1 - Feedback memory.

11:9 Reserved Not used.

8 Feedback Input Format Selects the feedback input format.

0 - Parallel (default) uses FB<19:0> as a 20-bit parallel input.

1 - Serial uses FB<0> as the input data bit and FB<1> as the serial sync, sampled at the rising edge of

FBCLK.

7 Reserved Not used.

6 Processor Trigger When high, enables the trigger. Low (default) is trigger disabled.

5:4 Trigger Select Selects the trigger mode.

00 - Processor trigger used (default).

01 - Magnitude trigger when min threshold <= magnitude <= maximum threshold.

10 - External trigger.

3 Reserved Not used.

2:1 Input Memory Data in

Source

0 CM Soft Reset When high, resets all the configuration memory circuitry except the control fields. Low is default.

Select the input memory dataIn Source.

00 - Interpolator output (default).

01 - Pre-distortion Output.

10 - Pre-distortion Magnitude.

TABLE 8. LENGTH OF INPUT MEMORY LOOP

TYPE: CAPTURE MEMORY, ADDRESS: 0x05

BIT FUNCTION DESCRIPTION

15:11 Reserved Not Used

0

10:0 Input Length Length of the input memory loop. Specified from 2

BIT FUNCTION DESCRIPTION

15 Input Memory Capture

Mode

14:0 Input Trigger Delay

Counter

memory address to 0 when input length reached. Actual loop length is this value + 2.

TABLE 9. INPUT MEMORY CAPTURE MODE AND TRIGGER DELAY

TYPE: CAPTURE MEMORY, ADDRESS: 0x06

Selects the active capture mode when the input capture memory is running. Identical to feedback capture

mode except applies to the input memory.

0 - Delay. (default) Defines the beginning of the 2k sample capture window as the trigger point plus the

input trigger delay counter samples.

1 - Advance. Defines the end of the 2k-sample capture window as the trigger point plus the input trigger

delay counter samples.

See control word 0x07, bit 1:0 for mode selection.

Offset delay that defines the input memory capture window when control word 0x07, bits 1:0 = 01

(Capture mode).

When control word 0x06, bit 15 is set to 0, delay mode, values selectable from 2

When control word 0x06, bit 15 is set to 1, advance mode, value selectable from 2

(1) to 211 (2047). Default = 0. Resets the input

0

to 215 (0...32768).

0

to 211 (0...2047).

22

Page 23

ISL5239

www.BDTIC.com/Intersil

TABLE 10. OPERATING MODES

TYPE: CAPTURE MEMORY, ADDRESS: 0x07

BIT FUNCTION DESCRIPTION

15:5 Reserved Not used.

4 Feedback Memory Mode Selects the feedback memory operating mode as

0 - Idle. (default) Memory not operating.

1 - Capture. Memory is capturing data in accordance with the mode and trigger settings specified in

control word 0x08.

3:2 Reserved Not used.

1:0 Input Memory Mode Selects the capture memory operating mode as

BIT FUNCTION DESCRIPTION

15 Feedback Memory

Capture Mode

14:0 Feedback Trigger Delay

Counter

00 - Idle. (default) Memory not operating.

01 - Capture. Memory is capturing data in accordance with the mode and trigger settings specified in

control word 0x06.

10 - Loop. Input memory plays back data in a continuous loop to provide stimulus.

11 - Single. Input memory plays back data in a one pass through its contents to provide stimulus.

TABLE 11. FEEDBACK MEMORY CATPURE MODE AND TRIGGER DELAY

TYPE: CAPTURE MEMORY, ADDRESS: 0x08

Selects the active capture mode when the feedback capture memory is running. Identical to input capture

mode except applies to the feedback memory.

0 - Delay. (default) Defines the beginning of the 1k sample capture window as the trigger point plus the

feedback trigger delay counter samples.

1 - Advance. Defines the end of the 1k-sample capture window as the trigger point plus the feedback

trigger delay counter samples.

See control word 0x07, bit 4 for mode selection

Offset delay that defines the feedback memory capture window when control word 0x07, bits 4 = 1

(Capture mode)

When control word 0x08, bit 15 is set to 0, delay mode, values selectable from 2

When control word 0x08, bit 15 is set to 1, advance mode, value selectable from 2

0

15

to 2

(0...32767)

0

to 210 (0...1023)

TABLE 12. MAGNITUDE THRESHOLD MINIMUM VALUE

TYPE: CAPTURE MEMORY, ADDRESS: 0x09

BIT FUNCTION DESCRIPTION

0

15:0 Magnitude Threshold

Minimum

BIT FUNCTION DESCRIPTION

15:0 Magnitude Threshold

Maximum

BIT FUNCTION DESCRIPTION

15:11 Reserved Not used.

10:0 Memory Address Index into memory value. Default = 0. Selectable from 2

Default = 0. Value selectable from 2