查询ISL4089IBZ供应商

®

ISL4089

Data Sheet June 28, 2006

DC-Restored Video Amplifier

The ISL4089 is complete DC-restored monolithic video

amplifier sub-system. It contains a high performance video

amplifier and a nulling, sample-and-hold amplifier designed

to establish a programmable DC output level.

When the HOLD logic input “0” is applied the DC restore

function is active. The sample-and-hold amplifier loop is

closed and used to null the DC offset of the video amplifier.

This can occur during sync, or, at any time that a black level

is expected. When the HOLD input “1” is applied, the

correcting voltage is stored on the video amplifier’s input

coupling capacitor. This condition must be true during active

video. The restored DC voltage level can be adjusted using

an external reference voltage applied to the V

The device operates from a single +5V supply and is ideal

for +5V only systems when used with a sync separator, such

as the EL1883.

The ISL4089 is intended to directly replace the EL4089 only

in certain applications. This direct replacement requires that

the single positive supply is no higher than +5.5V and that no

part of the clamped output goes below ground. The NC on

pin 6 is not internally connected, so it can be connected to

the -5V pin in existing EL4089 applications.

REF

pin.

FN6192.1

Features

• Complete video level DC-restoration system

• 0.03% differential gain and 0.05° differential phase

accuracy

• 300MHz -3dB small signal bandwidth at AV = 1

• 150MHz -3dB small signal bandwidth at A

V

= 2

• 300V/µs Slew Rate

• 0.1dB flatness to 80MHz

• +5V single supply operation

• TTL/CMOS compatible hold signal

• Pb-free plus anneal available (RoHS compliant)

Applications

• Input amplifier in video equipment

• DC-restoration amplifier in video mixers

Related Documents

• AN1261: ISL4089EVAL1 User’s Guide

• AN1089: EL4089 and EL4390 DC-Restored Video

Amplifier

The ISL4089 is specified for operation over -40°C to +85°C

temperature range.

Pinout

ISL4089

(8 Ld SOIC)

TOP VIEW

V+

IN-

IN-

IN+

IN+

V

V

REF

REF

HOLD

HOLD

-

-

-

+

+

+

-

-

-

+

+

+

V+

V

V

OUT

OUT

N/C

N/C

GND

GND

Ordering Information

PART

PART NUMBER

ISL4089IBZ

(See Note)

ISL4089IBZ-T7

(See Note)

NOTE: Intersil Pb-free plus anneal products employ special Pb-free

material sets; molding compounds/die attach materials and 100%

matte tin plate termination finish, which are RoHS compliant and

compatible with both SnPb and Pb-free soldering operations. Intersil

Pb-free products are MSL classified at Pb-free peak reflow

temperatures that meet or exceed the Pb-free requirements of

IPC/JEDEC J STD-020.

MARKING

4089IBZ - 8 Ld SO

4089IBZ 7” 8 Ld SO

TAPE &

REEL PACKAGE

(Pb-free)

(Pb-free)

PKG.

DWG. #

MDP0027

MDP0027

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright © Intersil Americas Inc. 2006. All Rights Reserved.

ISL4089

Absolute Maximum Ratings (T

Voltage between V+ and GND. . . . . . . . . . . . . . . . . . . . . . . . . . 5.5V

Voltage between IN+, IN-, HOLD, V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GND -0.5;V+ +0.5V

Supply Turn-on Slew Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . 1V/µs

REF

= 25°C)

A

and GND

Storage Temperature Range . . . . . . . . . . . . . . . . . .-65°C to +150°C

Ambient Operating Temperature . . . . . . . . . . . . . . . .-40°C to +85°C

Operating Junction Temperature . . . . . . . . . . . . . . .-40°C to +125°C

Power Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Curves

Digital and Analog Input Current (Note 1) . . . . . . . . . . . . . . . . 50mA

Output Current (Continuous) . . . . . . . . . . . . . . . . . . . . . . . . . . 60mA

ESD Rating

Human Body Model (Per MIL-STD-883 Method 3015.7). . . .3000V

Machine Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .250V

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

IMPORTANT NOTE: All parameters having Min/Max specifications are guaranteed. Typical values are for information purposes only. Unless otherwise noted, all tests

are at the specified temperature and are pulsed tests, therefore: TJ = TC = T

DC Electrical Specifications V+ = +5V, Load = 1kΩ; T

A

= +25°C

A

PARAMETER DESCRIPTION CONDITION MIN TYP MAX UNIT

AMPLIFIER SECTION (HOLD = 5V)

Ib+ IN+ Input Bias Current V

Ib- IN- Input Bias Current V

A

VOL

V

OUT+

V

OUT-

I

SC

Open Loop Gain 60 dB

High Output Level RL = 1k 3.5 V

Low Output Level IL = 0mA 5 mV

Short Circuit Current 100 mA

= 2.5V -7 20 µA

IN+

= 1.3V -30 -1 µA

IN-

RESTORE SECTION

V

, Comp Composite Input Offset Voltage V

OS

I

OUT

Restoring Current Available 300 µA

= 0V to +2.5V 10 15 mV

REF

PSRR Power Supply Rejection Ratio V+ = 5V to 6V 70 90 dB

Ib V

REF

V

Input Bias Current V

REF

= +2.5V -0.8 -0.5 -0.2 µA

REF

VH HOLD HOLD Logic Input Low 0.8 V

V

HOLD HOLD Logic Input High 2.0 V

L

I

, Hold HOLD Input Current @ Logic High V

IH

, Hold HOLD Input Current @ Logic Low V

I

IL

I

S

Supply Current V

= 5V -15 30 µA

HOLD

= 0V -5 5 µA

HOLD

= 0V 17 20 23 mA

HOLD

AC Electrical Specifications V

= +5V, V

S

= 0VDC, RL = 150Ω, RF and RG = 475Ω; AV = 2, TA= +25°C.

REF

PARAMETER DESCRIPTION CONDITION MIN TYP MAX UNITS

AMPLIFIER SECTION

SR Slew Rate; 2V

tr, tf Output Rise and Fall Times V

tpd Propagation Delay, IN+ to Output V

-3dB BW Small Signal; Unity Gain R

Large Signal; Unity Gain R

Small Signal; A

Large Signal; A

, 20% to 80% 300 V/µs

P-P

= 0.2Vp-p; 10% to 90% 3.2 ns

OUT

= 0.2V; 10% to 10% 0.3 ns

OUT

= 0; RG = inf.; CL = 0.6pF,

F

V

= 0.2V

OUT

= 0; RG = inf.; CL = 0.6pF,

F

V

= 2V

OUT

= +2 CL = 0.6pF, V

V

= +2 CL = 0.6pF, V

V

P-P

P-P

OUT

OUT

= 0.2V

= 2V

P-P

P-P

300 MHz

95 MHz

150 MHz

85 MHz

2

FN6192.1

June 28, 2006

ISL4089

AC Electrical Specifications V

= +5V, V

S

= 0VDC, RL = 150Ω, RF and RG = 475Ω; AV = 2, TA= +25°C. (Continued)

REF

PARAMETER DESCRIPTION CONDITION MIN TYP MAX UNITS

0.1dB BW 0.1dB Gain Flatness; Unity Gain RF = 0; RG = inf.; CL = 0.6pF

V

= 0.2V

0.1dB Gain Flatness; A

OUT

R

= 0; RG = inf.; CL = 0.6pF

F

V

OUT

= +2 CL = 0.6pF, V

V

CL = 0.6pF, V

= 2V

P-P

P-P

OUT

OUT

= 0.2V

= 2V

P-P

P-P

70 MHz

60 MHz

80 MHz

50 MHz

dG Differential Gain Error NTC-7, Restore on sync tip 0.03 %

dP Differential Phase Error NTC-7, Restore on sync tip 0.05 °

RESTORE SECTION

T

HE

T

HD

Time to Enable Hold; 50% to 50% HOLD input 0V to +5V 40 ns

Time to Disable Hold; 50% to 50% HOLD input 5V to 0V 20 ns

NOTE:

1. If an input signal is applied before the supplies are powered up, the input current must be limited to these maximum values

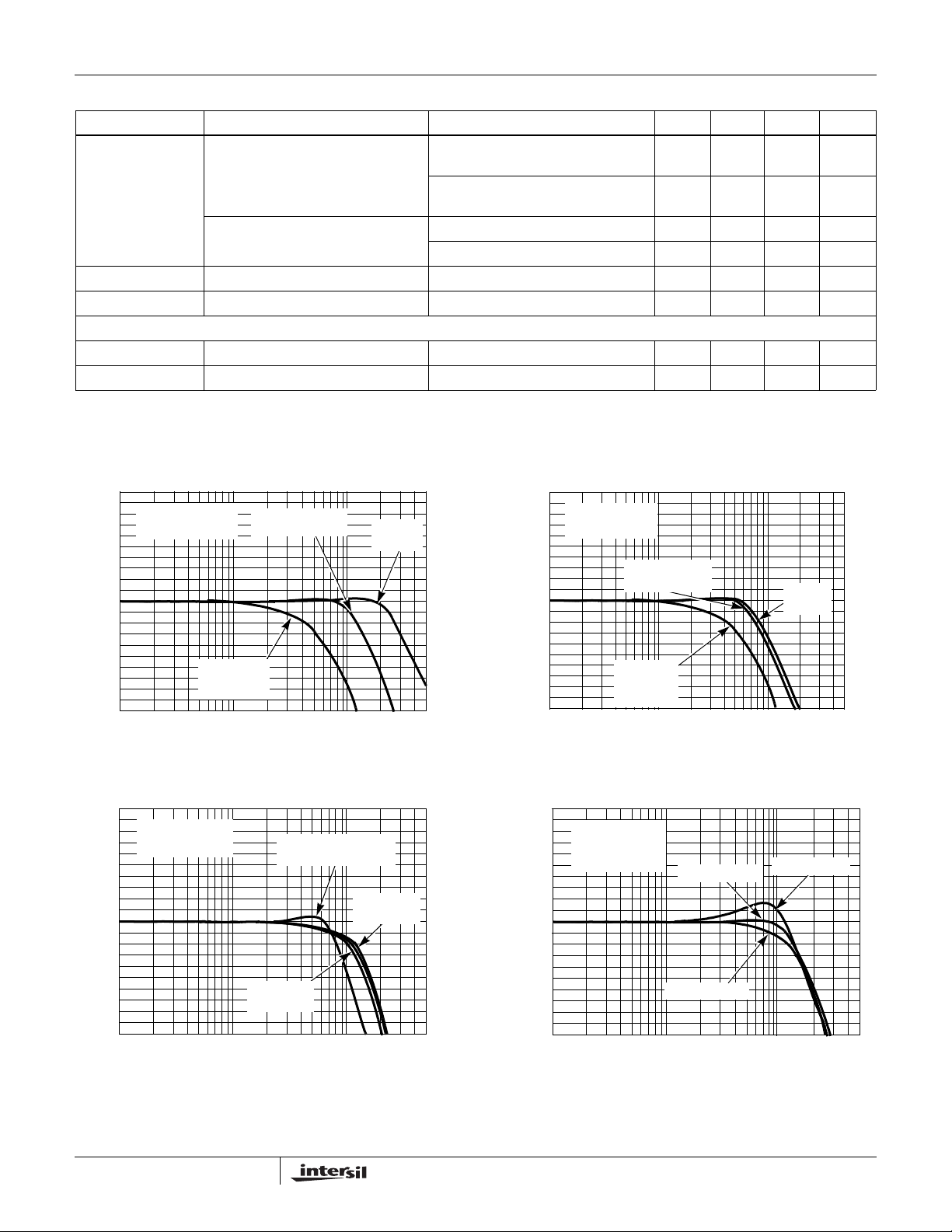

Typical Performance Curves V

10

V

8

6

4

2

0

-2

-4

NORMALIZED GAIN (dB)

-6

-8

-10

1M 10M 100M 500M

= 0.2V

OUT

RL = 150Ω

P-P

AV=4

R

R

FIGURE 1. SMALL SIGNAL GAIN vs FREQUENCY for

VARIOUS GAINS

AV = 2

R

= RG = 475Ω

F

= 475Ω

F

= 158Ω

G

FREQUENCY (Hz)

= +5V, RL = 150Ω to GND, CL = 0.6pF, TA = 25°C, unless otherwise specified.

S

10

V

= 2V

OUT

RL = 150Ω

P-P

AV = 2

= RG = 475Ω

R

F

AV = 4

= 475Ω

R

F

= 158Ω

R

G

FREQUENCY (Hz)

A

= 1

V

RF = 0Ω

8

6

4

2

0

-2

-4

NORMALIZED GAIN (dB)

-6

-8

-10

1M 10M 100M 500M

FIGURE 2. LARGE SIGNAL GAIN vs FREQUENCY for

VARIOUS GAINS

AV = 1

= 0Ω

R

F

10

V

8

6

4

2

0

-2

-4

NORMALIZED GAIN (dB)

-6

-8

-10

1M 10M 100M 500M

= 2V

OUT

RL = 150Ω

P-P

FREQUENCY (Hz)

AV = 2

C

= 0.6pF

L

AV = 1

= 0.6pF to 22pF

C

L

AV = 2

= 22pF

C

L

FIGURE 3. LARGE SIGNAL GAIN vs FREQUENCY vs C

3

10

V

8

6

4

2

0

-2

-4

NORMALIZED GAIN (dB)

-6

-8

-10

1M 10M 100M 500M

L

FIGURE 4. SMALL SIGNAL GAIN vs RF, RG

= 0.2V

OUT

RL = 150Ω

AV = 2

P-P

RF = RG = 475Ω

RF = RG = 301Ω

FREQUENCY (Hz)

RF = RG = 1kΩ

FN6192.1

June 28, 2006

ISL4089

Typical Performance Curves V

0.2

AV = 2

= RG = 475

R

F

0.1

R

= 150

L

0

-0.1

-0.2

-0.3

-0.4

-0.5

NORMALIZED GAIN (dB)

-0.6

-0.7

-0.8

1M 10M 100M 1G

V

= 2V

OUT

FREQUENCY (Hz)

P-P

FIGURE 5. 0.1dB GAIN FLATNESS

1.05

1.0

0.95

0.9

V

= +5V, RL = 150Ω to GND, CL = 0.6pF, TA = 25°C, unless otherwise specified. (Continued)

S

0.025

0.02

OUT

= 0.2V

P-P

0.015

0.01

0.005

0

-0.005

-0.01

ERROR(%)

-0.015

NORMALIZED GAIN

-0.02

-0.025

0.01

0.08

0.06

0.04

0.02

0

-0.02

-0.04

-0.06

-0.08

-0.10

NORMALIZED PHASE (°)

05.0

V

= 0.6V

OUT

= 150

R

L

= 2

A

V

f = 3.58MHz

RF = RG = 475Ω

V

OUT

V

OUT

V

OUT

P-P

V

OUT

= 0.6V

= 0.3V

2.5 3.0 3.5 4.0 4.50.5 1.0 1.5 2.0

DC (V)

= 0.3V

P-P

P-P

P-P

FIGURE 6. DIFFERENTIAL GAIN - PHASE

4.0

V

V

= 0.2V

OUT

RF = RG = 475Ω

CG = 0.5pF

P-P

3.5

3.0

2.5

= 2V

OUT

= RG = 475Ω

R

F

CG = 0.5pF

P-P

0.85

0.8

0.75

OUTPUT VOLTAGE (V)

0.7

0.65

TIME (20ns/DIV)

FIGURE 7. SMALL SIGNAL TRANSIENT RESPONSE; A

60

50

40

30

20

VOLTAGE NOISE (nV/√Hz)

10

V

= 2

2.0

1.5

OUTPUT VOLTAGE (V)

1.0

0.5

0

TIME (20ns/DIV)

FIGURE 8. LARGE SIGNAL TRANSIENT RESPONSE; A

V

= 2

0

100 1k 10k 100k

FREQUENCY (Hz)

FIGURE 9. INPUT NOISE vs FREQUENCY

4

FN6192.1

June 28, 2006

V

ISL4089

Typical Performance Curves V

JEDEC JESD51-7 HIGH EFFECTIVE THERMAL

CONDUCTIVITY TEST BOARD

1

909mW

0.8

0.6

0.4

0.2

POWER DISSIPATION (W)

0

0 100 125 150

FIGURE 10. PACKAGE POWER DISSIP A TION vs AMBIENT

ISL4089

(8 LD SOIC) PIN NAME

θ

S

J

O

A

=

8

1

1

0

°

C

/

W

5025 75 85

AMBIENT TEMPERATURE (°C)

TEMPERATURE

EQUIVALENT

CIRCUIT DESCRIPTION

= +5V, RL = 150Ω to GND, CL = 0.6pF, TA = 25°C, unless otherwise specified. (Continued)

S

JEDEC JESD51-3 LOW EFFECTIVE THERMAL

CONDUCTIVITY TEST BOARD

0.7

0.6

625mW

θ

S

J

O

0.5

0.4

0.3

0.2

POWER DISSIPATION (W)

0.1

0

0 100 125 150

A

=

8

1

6

0

°

C

/

W

5025 75 85

AMBIENT TEMPERATURE (°C)

FIGURE 11. P ACKAGE POWER DISSIP ATION vs AMBIENT

TEMPERATURE

1 IN- Circuit 1 Video amplifier inverting input

2 N+ Circuit 1 Video amplifier non-inverting input

3V

REF

Circuit 1 Restore amplifier V

REF

input

4 HOLD Circuit 2 Hold/restore logic input. Logic “0” selects the restore state; logic “1” selects the hold state

5 GND Circuit 4 Ground

6 NIC Circuit 1 No internal connection

7V

OUT

Circuit 3 Video amplifier output

8 V+ Circuit 4 Positive power supply

+

V+

21k

IN

V-

LOGIC PIN

GND

CIRCUIT 1 CIRCUIT 2

V+

V+

CAPACITIVELY

COUPLED

ESD CLAMP

FN6192.1

June 28, 2006

CIRCUIT 3

OUT

GND

5

GND

CIRCUIT 4

ISL4089

AC Test Circuits

R

GRF

R

-

V

IN

50Ω

FIGURE 12A. VIDEO AMPLIFIER AC TEST CIRCUIT FOR 50Ω

V

IN

75Ω

FIGURE 12B. BACKTERMINATED TEST CIRCUIT FOR VIDEO

+

R

GRF

+

CABLE APPLICATION.

S

118Ω

C

L

1. HOLD INPUT = 1

R

75Ω

C

L

1. HOLD INPUT = 1

86.6Ω

S

TEST

EQUIPMENT

50Ω

TEST

EQUIPMENT

75Ω

Figure 12A illustrates the AC test circuit used to operate the

video amplifier into a 150Ω load while providing a 50Ω

matched impedance. Figure 12B illustrates the test circuit for

impedance matching to 75Ω test equipment.

Application Information

General

The ISL4089 implements the video DC-restore function

using a high performance gain adjustable video amplifier

and a nulling, sample-hold amplifier to establish a user

defined DC reference voltage at the video amplifier output. A

detailed description of the DC-restore function implemented

in the ISL4089 can be found in application note AN1089,

EL4089 and EL4390 DC-Restored Video Amplifier. The

ISL4089 performs the same function with the exception that

it is designed for single supply operation.

Video Amplifier Operation (Figure 13)

The ISL4089 video amplifier (A1) is voltage-feed, high

performance video amplifier designed for +5V operation.

The output stage is capable of swinging to within 10mV of

the negative rail. The differential input stage contains an

internal voltage reference that positions the non-inverting

input DC level (V1) to ~1.2V higher than the negative supply

rail. This offset ensures that the amplifier input DC level is

maintained within the common mode input voltage range.

The amplifier non-inverting gain is given in Equation 1.

R

⎛⎞

V

OUT

V

IN+

1.2V–()1

F

--------+

•=

⎜⎟

R

⎝⎠

G

(EQ. 1)

DC-Restore Amplifier (Figure 13)

The DC-restore circuit contains a voltage reference amplifier

and an analog switch function that closes the DC-restore

loop under control of the HOLD logic input. The reference

amplifier uses an internal 10mV offset voltage (V2) to enable

the V

amplifier output stage operates in a current-feed mode with a

source/sink capability of ±300µA (Typ).

A logic “0” at the HOLD input closes switch S1 which closes

the DC-restore loop. The video input AC coupling capacitor,

CX1, acts as a DC hold capacitor (through the 75Ω

termination resistor RX1) to average the current-source

output of amplifier A2. When the DC-restore loop has

reached equilibrium, the DC voltage stored on CX1 will the

value required to force the output voltages at A1 (V

A2 (V

V

OUT

and; the DC voltage at the non-inverting input of the video

amplifier A1 is given in Equation 3:

V

IN+VOUT

Therefore, if V

the DC voltage stored on CX1 is ~1.2V.

The CX1 capacitor value is chosen from the system

requirements. A typical DC-restore application using the

horizontal sync to drive the HOLD pin will result in a 62µs

hold time. The typical input bias current to the video amplifier

is 1.2µA, so for a 62µs hold time, and a 0.01µF capacitor, the

output voltage drift is 7.5mV in one line. The restore amplifier

can provide a typical current of 300µA to charge capacitor

CX1, so with a 1.2µs sampling time, the output can be

corrected by 36mV in each line.

Using a smaller value of CX1 increases both the voltage that

can be corrected, as well as the droop while being held.

Likewise, using a larger value of CX1, reduces the correction

and droop voltages. A sample of charging and droop rates

are shown on the following table.

CAP VALUE

NOTE: Basic formulae are: V (droop) = Ib+ * (Line time - Sample

time)/Capacitor and V (charge) = I

input to sense down to the negative supply. The A2

REF

) and

) according to the following:

IN+

(DC) V

TABLE OF CHARGE STORAGE CAPACITOR VS DROOP

(if)

10 7.5 36 120

33 2.3 11 36

100 0.75 3.6 12

10mV+=

REF

(DC) 1.2V+=

is set to 0V (GND); V

REF

CHARGING RATES (NOTE)

DROOP IN

62µs

(mV)

CHARGE IN

OUT

OUT

1.2µs

(mV)

* Sample time/Capacitor

OUT

(EQ. 2)

(EQ. 3)

= 10mV, and

CHARGE IN

4µs

(mV)

6

FN6192.1

June 28, 2006

ISL4089

VIDEO

INPUT

RX1

75Ω

R

G

475Ω

CX1

-

V

Ref

0V to +4.5V

R

F

475Ω

V

IN-

V

IN+

V

REF

10mV

-

+

+

V2

FIGURE 13. BASIC +5V APPLICATION CIRCUIT

S1

+

A2

1.2V

+

-

V1

-

TTL

INPUT

A1

+

HOLD

ISL4089

4k

40pF

GND

V+

V

OUT

0.1µF

RXT

75Ω

4.7µF

VIDEO

OUT

+5V

GND

Using the Reference Voltage Input (V

REF

)

Implementing DC-restore and amplifying composite video

using a single +5V supply amplifier, requires attention to the

performance of the amplifier over the minimum to maximum

range of output voltage swing. The differential gain - phase

plot in Figure 6 shows the amplifier accuracy operating from

a single +5V supply, driving a 300mV

and a 600mV

P-P

P-P

signal into a 150Ω load. Over the output DC voltage range of

0.5V to 3.25V, differential gain and phase are less than

0.05% and 0.05° respectively and defines the optimum

output voltage range of the ISL4089. Figure 6 also shows

that as the signal level increases, a corresponding decrease

in the output DC level (min/max voltage swing) can be

expected. The V

input enables the output DC voltage

REF

level to be optimally programmed within the min/max voltage

range, according to Equation 2. The values in Figure 6 take

into account the additional amplifier overhead (300mV

and 600mV

) needed by the video signal. Although the

P-P

P-P

AC performance degrades below ~0.5V, the ISL4089

maintains DC accuracy down to 10mV .

Limiting the Output Current

No output short circuit current limit exists on these parts. All

applications need to limit the output current to less than

60mA. Adequate thermal heat sinking of the parts is also

required.

Application Information

A typical single supply application circuit using the EL1883

sync separator to generate the DC-restore hold command, is

shown in Figure 13. The ISL4089 is configured for a gain of

2, and 75

driving; providing an end to end gain of 1. DC-restore is

performed during sync tip using the composite sync output

of the EL1883, which clamps the -300mV input sync tip level

to 0VDC at the ISL4089 output (Figure 15 - lower trace).

Clamping sync tip to 0VDC forces the black level, color burst

and active video to the +300mV level at the 75Ω load in the

terminal equipment, and to +600mV at the ISL4089 output

pin. The +600mV DC offset is safely within the lower linear

range of the ISL4089 output (Figure 6 - Differential Gain Phase) and the 2V maximum video amplitude at the output

is safely within the upper limit. In applications where the sync

tip level can’t be guaranteed, positioning the active video

within the linear range can be accomplished using the back

porch clamp output of the EL1883 and supplying +1V to the

V

REF

the +1V V

sync tip level to pass through to the output.

Ω

input and output terminations are used for cable

input. This has the effect of clamping the back porch to

level at the output while enabling the negative

REF

7

FN6192.1

June 28, 2006

VIDEO

VIDEO

INPUT

INPUT

Composite Sync

Composite Sync

Out

Out

Vertical Sync

Vertical Sync

Out

Out

475 ohms

475 ohms

R3

R3

75 ohms

75 ohms

C5

C5

0.1uF

0.1uF

R4

R4

0.01uF

0.01uF

ISL4089

R5

R5

475 ohms

475 ohms

+5V

4.7uF

4.7uF

Out

Out

Out

Out

C1

C1

+5V

Ground

Ground

Out

Out

ISL4089

1

1

1

IN-

IN-

C4

C4

IN-

2

2

2

IN+

IN+

IN+

3

3

3

Vref

Vref

Vref

4

4

4

Hold

Hold

Hold

EL1883

1

1

1

2

2

2

3

3

3

4

4

4

EL1883

ISL4089

-

-

+

+

C2, C3

R6

R6

75 ohms

75 ohms

C6

C6

0.056 uF

0.056 uF

C2, C3

0.1uF

0.1uF

Back-porch Clamp

Back-porch Clamp

Horizontal Sync

Horizontal Sync

V+

V+

V+

-

-

+

+

Vout

Vout

Vout

NC

NC

NC

GND

GND

GND

8

8

8

7

7

7

6

6

6

5

5

5

R7

R7

681K

681K

FIGURE 14. APPLICATION CIRCUIT USING THE EL1883 SYNC SEPARATOR TO GENERATE DC-RESTORE HOLD CONTROL

COMPOSITE VIDEO INPUT

0VDC

COMPOSITE SYNC INPUT

0VDC

DC-RESTORED VIDEO OUTPUT

0VDC

FIGURE 15. DC-RESTORE USING COMPOSITE SYNC AND V

REF

= 0VDC

8

FN6192.1

June 28, 2006

Small Outline Package Family (SO)

A

D

NN

(N/2)+1

ISL4089

h X 45°

PIN #1

E

C

SEATING

PLANE

0.004 C

E1

B

0.010 BM CA

I.D. MARK

1

e

0.010 BM CA

(N/2)

c

SEE DETAIL “X”

L1

H

A2

GAUGE

PLANE

A1

b

DETAIL X

L

4° ±4°

MDP0027

SMALL OUTLINE PACKAGE FAMILY (SO)

SYMBOL SO-8 SO-14

(0.150”)

A 0.068 0.068 0.068 0.104 0.104 0.104 0.104 MAX -

A1 0.006 0.006 0.006 0.007 0.007 0.007 0.007 ±0.003 A2 0.057 0.057 0.057 0.092 0.092 0.092 0.092 ±0.002 -

b 0.017 0.017 0.017 0.017 0.017 0.017 0.017 ±0.003 -

c 0.009 0.009 0.009 0.011 0.011 0.011 0.011 ±0.001 D 0.193 0.341 0.390 0.406 0.504 0.606 0.704 ±0.004 1, 3

E 0.236 0.236 0.236 0.406 0.406 0.406 0.406 ±0.008 -

E1 0.154 0.154 0.154 0.295 0.295 0.295 0.295 ±0.004 2, 3

e 0.050 0.050 0.050 0.050 0.050 0.050 0.050 Basic L 0.025 0.025 0.025 0.030 0.030 0.030 0.030 ±0.009 -

L1 0.041 0.041 0.041 0.056 0.056 0.056 0.056 Basic -

h 0.013 0.013 0.013 0.020 0.020 0.020 0.020 Reference -

N 8 14 16 16 20 24 28 Reference -

NOTES:

1. Plastic or metal protrusions of 0.006” maximum per side are not included.

2. Plastic interlead protrusions of 0.010” maximum per side are not included.

3. Dimensions “D” and “E1” are measured at Datum Plane “H”.

4. Dimensioning and tolerancing per ASME Y14.5M-1994

SO16

SO16 (0.300”)

(SOL-16)

SO20

(SOL-20)

SO24

(SOL-24)

SO28

(SOL-28) TOLERANCE NOTES

A

0.010

Rev. L 2/01

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implicat ion or oth erwise u nde r any p a tent or p at ent r ights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

9

FN6192.1

June 28, 2006

Loading...

Loading...