查询ISL3159EIBZ供应商

®

ISL3159E

Data Sheet July 26, 2007

±15kV ESD Protected, +125°C, 40Mbps,

5V, PROFIBUS®, Full Fail-safe,

RS-485/RS-422 Transceivers

Intersil’s ISL3159E is a ±15kV IEC61000 ESD Protected, 5V

powered, single transceiver that meets both the RS-485 and

RS-422 standards for balanced communication. It also

features the larger output voltage and higher data rate - up to

40Mbps - required by high speed PROFIBUS applications,

and is offered in Industrial and Extended Industrial (-40°C to

+125°C) temperature ranges. The low bus currents

(+220μA/-150μA) present a “1/5 unit load” to the RS-485 bus,

thus allowing up to 160 transceivers on the network without

violating the RS-485 specification’s load limit, and without

using repeaters.

This transceiver requires a 5V ±10% tolerance supply, and

delivers at least a 2.1V differential output voltage over this

supply range. This translates into b etter noise i mmunity

(data integrity), longer reach, or the ability to drive up to six

120Ω terminations in “star” or other non-standard bus

topologies, at the exceptional 40Mbps data rate.

SCSI applications benefit from the ISL3159’s low receiver

and transmitter part-to-part skews, which make it perfect for

high speed parallel applications where large numbers of bits

must be simultaneously captured. The low bit-to-bit skew

eases the timing constraints on the data latching signal.

Receiver (Rx) inputs feature a “Full Fail-Safe” design, which

ensures a logic high Rx output if Rx inputs are floating,

shorted, or terminated but undriven. Rx outputs feature high

drive levels (typically >30mA @ V

of optically isolated interfaces.

Hot Plug circuitry ensures that the Tx and Rx outputs remain

in a high impedance state while the power supply stabilizes.

Driver (Tx) outputs are short circuit protected, even for

voltages exceeding the power supply voltage. Additionally,

on-chip thermal shutdown circuitry disables the Tx outputs to

prevent damage if power dissipation becomes excessive.

= 1V) to ease the design

OL

FN6364.0

Features

• IEC61000 ESD Protection on RS-485 I/O Pins . . . ±15kV

- Class 3 HBM ESD Level on all Other Pins. . . . . . >9kV

• Large Differential V

Better Noise Immunity, or drive up to 6 Terminations

• High Data Rates. . . . . . . . . . . . . . . . . . . . . up to 40Mbps

• Specified for +125°C Operation

• 11/13ns (Max) Tx/Rx Propagation Delays; 1.5ns (Max)

Skew

• 1/5 Unit Load Allows up to 160 Devices on the Bus

• Full Fail-Safe (Open, Shorted, Terminated/Undriven)

Receiver

• High Rx I

Applications

• Hot Plug - Tx and Rx Outputs Remain Three-State During

Power-Up

• Low Quiescent Supply Current . . . . . . . . . . . . . . . . . 4mA

• Low Current Shutdown Mode. . . . . . . . . . . . . . . . . . . 1μA

• -7V to +12V Common Mode Input Voltage Range

• Three-State Rx and Tx Outputs

• Operates from a Single +5V Supply (10% Tolerance)

• Current Limiting and Thermal Shutdown for driver

Overload Protection

• Pb-Free Plus Anneal Available (RoHS Compliant)

to Drive Opto-Couplers for Isolated

OL

. . . . . . . . . . . . . . . 2.8V into 54Ω

OUT

Applications

•PROFIBUS® DP and FMS Networks

• SCSI “Fast 40” Drivers and Receivers

• Motor Controller/Position Encoder Systems

• Factory Automation

• Field Bus Networks

• Security Networks

• Building Environmental Control Systems

• Industrial/Process Control Networks

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright Intersil Americas Inc. 2007. All Rights Reserved

ISL3159E

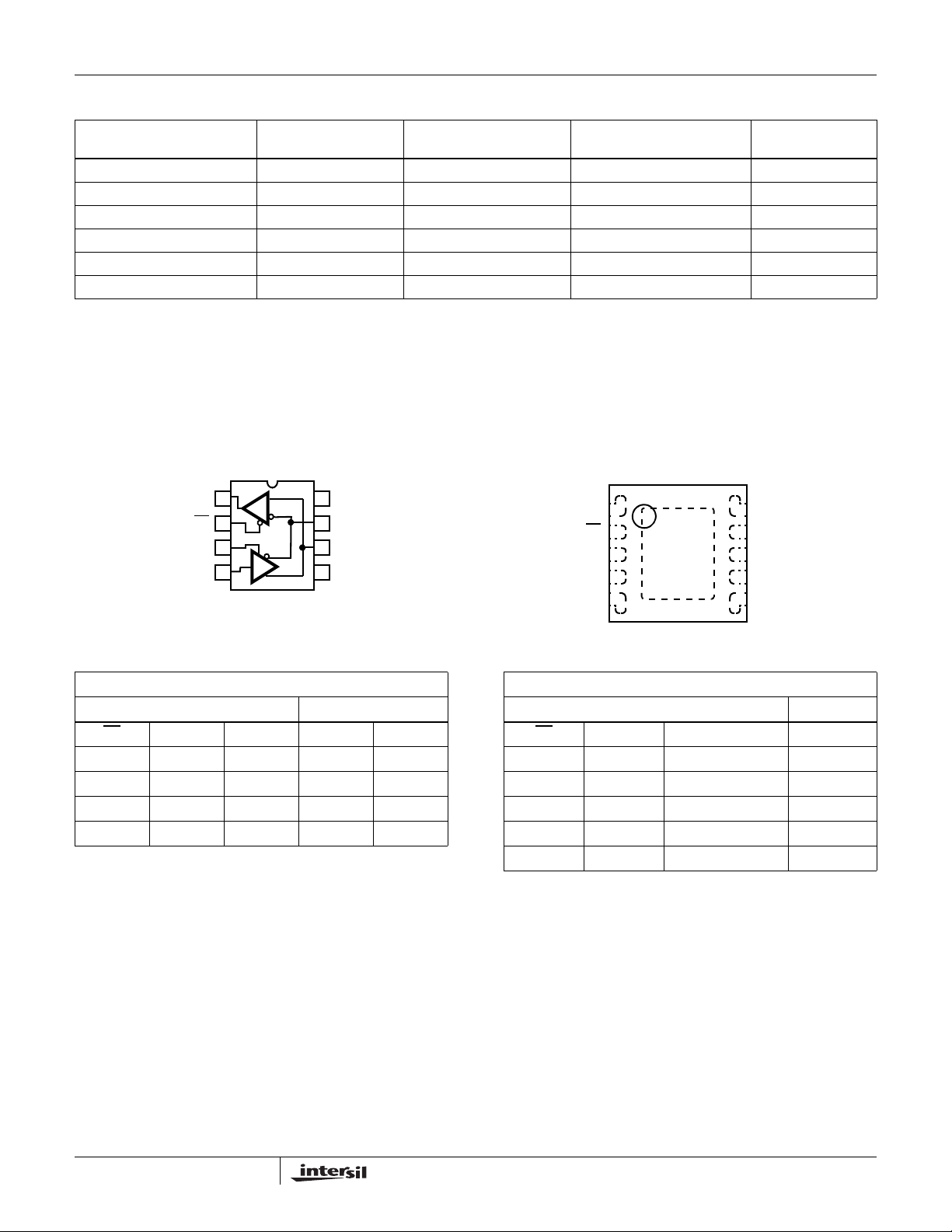

Ordering Information

PART NUMBER

(Notes 1, 2) PART MARKING

ISL3159EIBZ 3159 EIBZ -40 to +85 8 Ld SOIC M8.15

ISL3159EIUZ 3159Z -40 to +85 8 Ld MSOP M8.118

ISL3159EIRZ 159Z -40 to +85 10 Ld DFN L10.3x3C

ISL3159EFBZ 3159 EFBZ -40 to +125 8 Ld SOIC M8.15

ISL3159EFUZ 159FZ -40 to +125 8 Ld MSOP M8.118

ISL3159EFRZ 59FZ -40 to +125 10 Ld DFN L10.3x3C

NOTES:

1. Add “-T” suffix for tape and reel. Please refer to TB347 for details on reel specifications.

2. Intersil Pb-free plus anneal products employ special Pb-free material sets; molding compounds/die attach materials and 100% matte tin plate

termination finish, which are RoHS compliant and compatible with both SnPb and Pb-free soldering operations. Intersil Pb-free products are

MSL classified at Pb-free peak reflow temperatures that meet or exceed the Pb-free requirements of IPC/JEDEC J STD-020.

TEMP. RANGE

(°C)

PACKAGE

(Pb-Free) PKG. DWG. #

Pinouts

(10 LD DFN)

TOP VIEW

1

2

3

4

5

ISL3159E

V

10

CC

NC

9

B/Z

8

A/Y

7

GND

6

ISL3159E

(8 LD SOIC, MSOP)

TOP VIEW

RO

1

R

2

RE

DE

3

D

4

DI

8

V

CC

7

B/Z

6

A/Y

5

GND

RO

RE

DE

DI

NC

Truth T able

TRANSMITTING

INPUTS OUTPUTS

RE

X1101

X1010

0 0 X High-Z High-Z

1 0 X High-Z * High-Z *

NOTE: *Shutdown Mode

DE DI B/Z A/Y

Truth Table

RECEIVING

INPUTS OUTPUT

RE

00 ≥-0.05V 1

00 ≤-0.2V 0

0 0 Inputs Open/Shorted 1

1 1 X High-Z

10 X High-Z *

NOTE: *Shutdown Mode

DE A-B RO

2

FN6364.0

July 26, 2007

ISL3159E

Pin Descriptions

PIN FUNCTION

RO Receiver output: If A-B ≥ -50mV, RO is high; If A-B ≤ -200mV, RO is low; RO = High if A and B ar e unconnected (floating) o r shorted, or

connected to a terminated bus that is undriven.

RE

Receiver output enable. RO is enabled when RE is low; RO is high impedance when RE is high. If the Rx enable function isn’t

required, connect RE

directly to GND.

DE Driver output enable. The driver outputs, Y and Z, are enabled by bringing DE high. They are high impedance when DE is low . If the

Tx enable function isn’t required, connect DE to V

through a 1kΩ or greater resistor.

CC

DI Driver input. A low on DI forces output Y low and output Z high. Similarly, a high on DI forces output Y high and output Z low.

GND Ground connection. This is also the potential of the DFN thermal pad.

A/Y ±15kV

IEC61000 ESD Protected RS-485/422 level, noninverting receiver input and noninverting driver output. Pin is an input (A) if

DE = 0; pin is an output (Y) if DE = 1.

B/Z ±15kV

IEC61000 ESD Protected RS-485/422 level, inverting receiver input and inverting driver output. Pin is an input (B) if DE = 0;

pin is an output (Z) if DE = 1.

V

System power supply input (4.5V to 5.5V).

CC

NC No Connection.

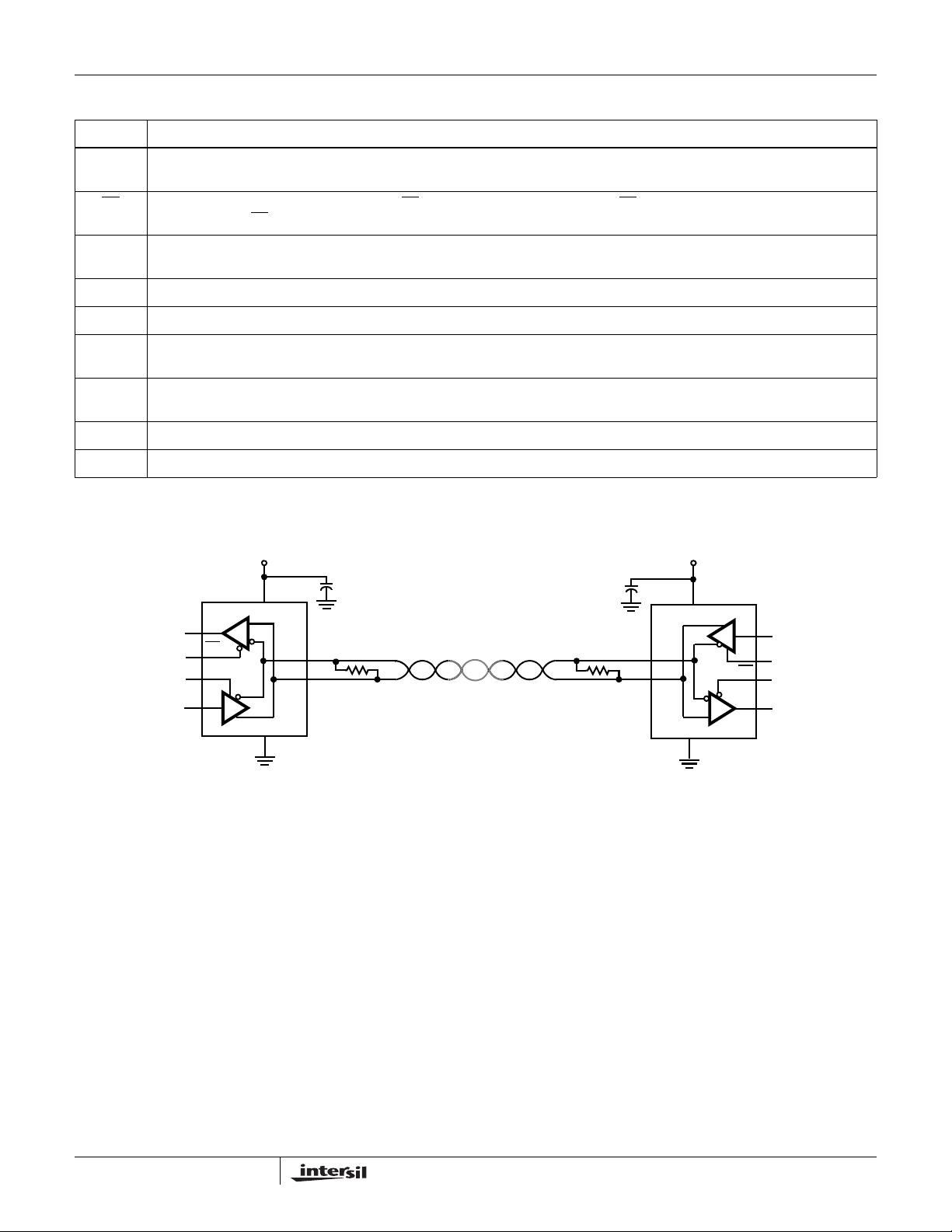

Typical Operating Circuit

ISL3159E

+5V

+

8

V

RO

1

2

RE

3

DE

CC

R

7

B/Z

A/Y

6

SOIC AND MSOP PIN NUMBERS SHOWN

0.1μF

R

T

0.1μF

R

T

+

7

6

B/Z

A/Y

V

+5V

CC

8

4

DI

D

3

DE

2

RE

DI

4

D

GND

5

R

GND

5

RO

1

3

FN6364.0

July 26, 2007

ISL3159E

Absolute Maximum Ratings Thermal Information

VCC to GND. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7V

Input Voltages

DI, DE, RE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to 7V

Input/Output Voltages

A/Y, B/Z . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -9V to +13V

RO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to (V

CC

+0.3V)

Short Circuit Duration

Y, Z. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Continuous

ESD Rating . . . . . . . . . . . . . . . . . . . . . . . . . See Specification Table

Operating Conditions

Temperature Range

ISL3159EF . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to +125°C

ISL3159EI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to +85°C

CAUTION: Do not operate at or near the maximum ratings listed for extended periods of time. Exposure to such conditions may adversely impact product reliability and

result in failures not covered by warranty.

NOTE:

is measured with the component mounted on a high effective thermal conductivity test board in free air. See Tech Brief TB379 for details.

3. θ

JA

is measured in free air with the component mounted on a high effective thermal conductivity test board with “direct attach” features. See

4. θ

JA

Tech Brief TB379.

Thermal Resistance (Typical)

θ

JA

(°C/W)

8 Ld SOIC Package (Note 3) . . . . . . . . . . . . . . . . . . 105

8 Ld MSOP Package (Note 3) . . . . . . . . . . . . . . . . . 140

10 Ld DFN Package (Note 4). . . . . . . . . . . . . . . . . . 75

Maximum Junction Temperature (Plastic Package) . . . . . . +150°C

Maximum Storage Temperature Range. . . . . . . . . .-65°C to +150°C

Pb-free reflow profile . . . . . . . . . . . . . . . . . . . . . . . . . .see link below

http://www.intersil.com/pbfree/Pb-FreeReflow.asp

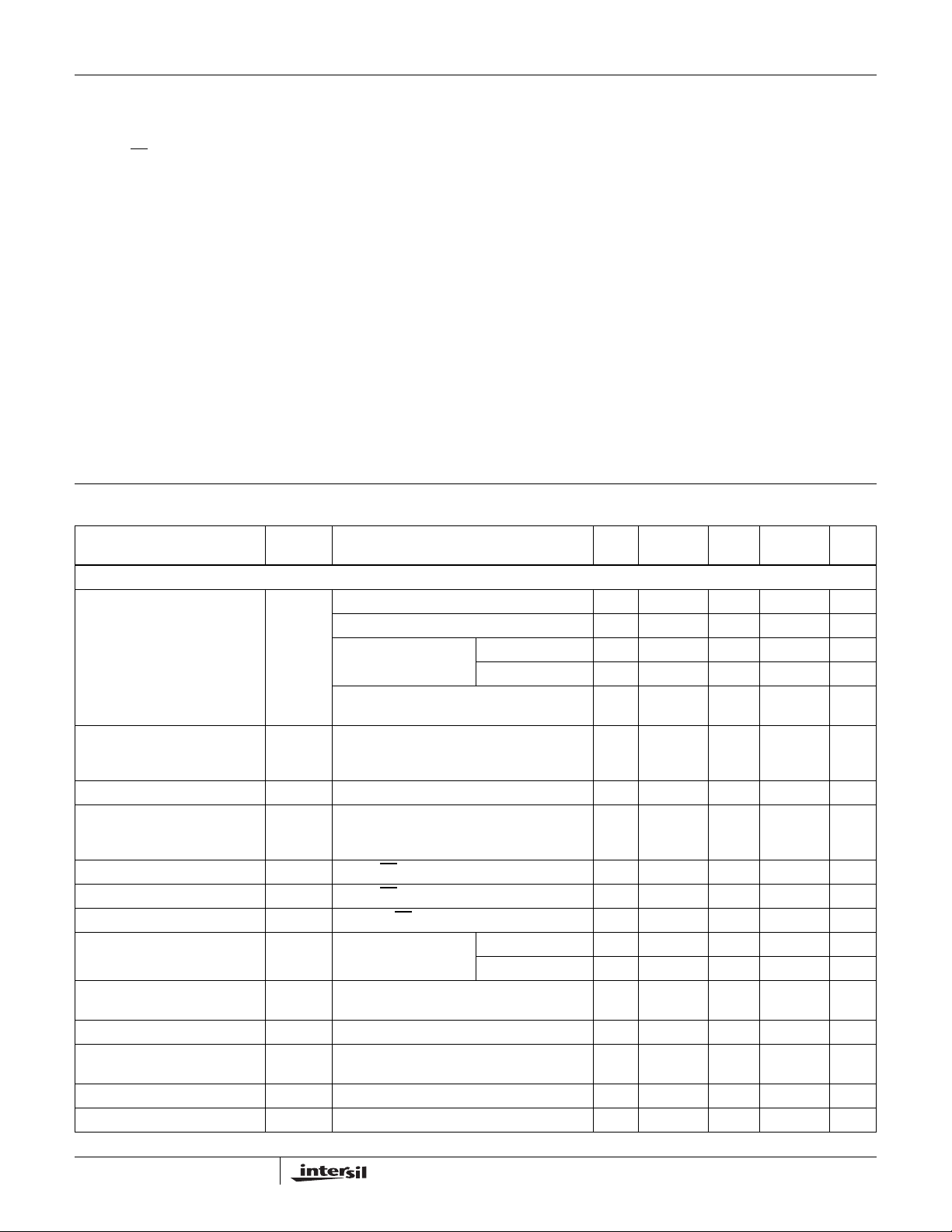

Electrical Specifications Test Conditions: V

(Note 5)

PARAMETER SYMBOL TEST CONDITIONS

DC CHARACTERISTICS

Driver Differential V

OUT

Change in Magnitude of Driver

Differential V

Complementary Output States

Driver Common-Mode V

OUT

for

OUT

Change in Magnitude of Driver

Common-Mode V

Complementary Output States

OUT

for

Logic Input High Voltage V

Logic Input Low Voltage V

Logic Input Current I

Input Current (A/Y, B/Z) I

Driver Short-Circuit Current,

= High or Low

V

O

Differential Capacitance C

Receiver Differential Threshold

Voltage

Receiver Input Hysteresis ΔV

Receiver Output High Voltage V

V

OD

ΔV

ODRL

V

OC

ΔV

OCRL

IH

IL

IN1

IN2

I

OSD1

D

V

TH

TH

OHIO

No Load Full - - V

RL = 100Ω (RS-422) (Figure 1A) Full 2.6 3.4 - V

R

= 54Ω (RS-485)

L

(Figure 1A)

R

= 60Ω, -7V ≤ VCM ≤ 12V (Figure 1B),

L

(Note 14)

= 54Ω or 100Ω (Figure 1A) Full - 0.01 0.2 V

RL = 54Ω or 100Ω (Figure 1A), (Note 14) Full - 2 3 V

= 54Ω or 100Ω (Figure 1A) Full - 0.01 0.2 V

DI, DE, RE Full 2 - - V

DI, DE, RE Full - - 0.8 V

DI = DE = RE = 0V or V

DE = 0V, VCC = 0V or

5.5V

DE = VCC, -7V ≤ VY or VZ ≤ 12V (Note 7) Full - - ±250 mA

A/Y to B/Z 25 - 9 - pF

-7V ≤ VCM ≤ 12V Full -200 - -50 mV

VCM = 0V 25 - 28 - mV

= -8mA, VID = -50mV Full VCC - 0.5 - - V

= 4.5V to 5.5V; Unless Otherwise Specified. Typicals are at VCC = 5V, TA = +25°C,

CC

TEMP

(°C)

I Suffix Fu ll 2.1 2.8 V

F Suffix, (Note 14) Full 2.1 2.8 V

MIN

(NOTE 15) TYP

MAX

(NOTE 15) UNITS

CC

CC

CC

Full 1.9 2.7 - V

CC

Full -2 - 2 μA

VIN = 12V Full - - 220 μA

= -7V Full -160 - - μA

V

IN

V

V

4

FN6364.0

July 26, 2007

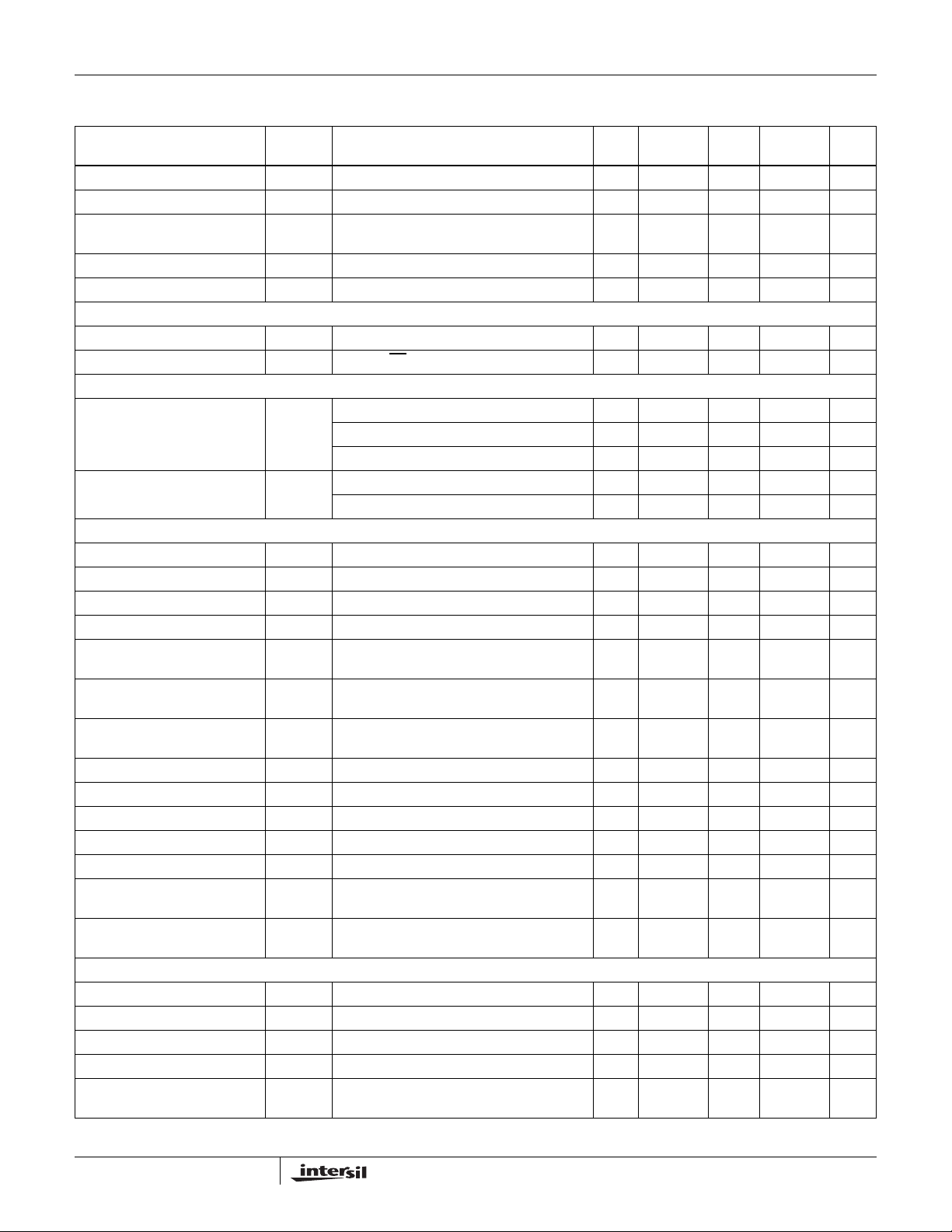

ISL3159E

Electrical Specifications Test Conditions: V

(Note 5) (Continued)

PARAMETER SYMBOL TEST CONDITIONS

Receiver Output Low Voltage V

Receiver Output Low Current I

Three-State (high impedance)

Receiver Output Current

Receiver Input Resistance R

Receiver Short-Circuit Current I

OLIO

OL

I

OZR

IN

OSR

VOL = 1V, VID = -200mV Fu ll 25 40 - mA

0.4V ≤ VO ≤ 2.4V Full -1 0.015 1 μA

-7V ≤ VCM ≤ 12V Full 54 80 - kΩ

0V ≤ VO ≤ V

= 4.5V to 5.5V; Unless Otherwise Specified. Typicals are at VCC = 5V, TA = +25°C,

CC

TEMP

(°C)

MIN

(NOTE 15) TYP

MAX

(NOTE 15) UNITS

= +10mA, VID = -200mV Full - - 0.4 V

CC

Full ±20 - ±110 mA

SUPPLY CURRENT

No-Load Supply Current (Note 6) I

Shutdown Supply Current I

CC

SHDN

DI = DE = 0V or V

CC

DE = 0V, RE = VCC, DI = 0V or V

CC

Full - 2.6 4 mA

Full - 0.05 1 μA

ESD PERFORMANCE

RS-485 Pins (A/Y, B/Z) IEC61000-4-2, Air-Gap Discharge Method 25 - ±15 - kV

IEC61000-4-2, Contact Discharge Method 25 - ±8-kV

Human Body Model, From Bus Pins to GND 25 - ±16.5 - kV

All Pins HBM, per MIL-STD-883 Method 3015 25 - > ±9-kV

Machine Model 25 - > ±400 - V

DRIVER SWITCHING CHARACTERISTICS

Maximum Data Rate f

Driver Differential Output Delay t

Driver Differential Output Skew t

Prop Delay Part-to-Part Skew t

Driver Differential Rise or Fall

MAX

SKEWRD

SKP-PRD

t

R

VOD ≥ ±1.5V, RD = 54Ω, CL = 100pF (Figure 4) Full 40 - - Mbps

RD = 54Ω, CD = 50pF (Figure 2) Full - 8 12 ns

DD

= 54Ω, CD = 50pF (Figure 2) Full - 0.5 1.5 ns

= 54Ω, CD = 50pF (Figure 2), (Note 13) Full - - 4 ns

, tFRD = 54Ω, CD = 50pF (Figure 2) Full 2 5 8 ns

Time

Driver Enable to Output High t

RL = 110Ω, CL = 50pF, SW = GND (Figure 3),

ZH

Full - 13 20 ns

(Note 8)

Driver Enable to Output Low t

RL = 110Ω, CL = 50pF, SW = VCC (Figure 3),

ZL

Full - 11 20 ns

(Note 8)

Driver Enable Time Skew t

ENSKEW|tZH

Driver Disable from Output High t

Driver Disable from Output Low t

Driver Disable Time Skew t

DISSKEW|tHZ

Time to Shutdown t

Driver Enable from Shutdown to

Output High

Driver Enable from Shutdown to

t

ZH(SHDN)RL

t

ZL(SHDN)RL

Output Low

HZ

LZ

SHDN

(Y or Z) - tZL (Z or Y)| Full - 2.5 - ns

RL = 110Ω, CL = 50pF, SW = GND (Figure 3), Full - 14 20 ns

RL = 110Ω, CL = 50pF, SW = VCC (Figure 3), Full - 12 20 ns

(Y or Z) - tLZ (Z or Y)| Full - 3 - ns

(Note 10) Full 60 - 600 ns

= 110Ω, CL = 50pF, SW = GND (Figure 3),

Full - - 1000 ns

(Notes 10, 11)

= 110Ω, CL = 50pF, SW = VCC (Figure 3),

Full - - 1000 ns

(Notes 10, 11)

RECEIVER SWITCHING CHARACTERISTICS

Maximum Data Rate f

Receiver Input to Output Delay t

Receiver Skew | t

PLH

- t

PHL

PLH

|t

Prop Delay Part-to-Part Skew t

Receiver Enable to Output High t

MAX

SKD

SKP-P

VID = ±1.5V Full 40 - - Mbps

, t

(Figure 5) Full - 9 13 ns

PHL

(Figure 5) Full - 0 1.5 ns

(Figure 5), (Note 13) Full - - 4 ns

RL = 1kΩ, CL = 15pF, SW = GND (Figure 6),

ZH

(Note 9)

Full - - 12 ns

5

FN6364.0

July 26, 2007

ISL3159E

Electrical Specifications Test Conditions: V

(Note 5) (Continued)

PARAMETER SYMBOL TEST CONDITIONS

Receiver Enable to Output Low t

RL = 1kΩ, CL = 15pF, SW = VCC (Figure 6),

ZL

= 4.5V to 5.5V; Unless Otherwise Specified. Typicals are at VCC = 5V, TA = +25°C,

CC

TEMP

(°C)

MIN

(NOTE 15) TYP

MAX

(NOTE 15) UNITS

Full - - 12 ns

(Note 9)

Receiver Disable from Output

t

RL = 1kΩ, CL = 15pF, SW = GND (Figure 6) Full - - 12 ns

HZ

High

Receiver Disable from Output

RL = 1kΩ, CL = 15pF, SW = VCC (Figure 6) Full - - 12 ns

t

LZ

Low

Time to Shutdown t

Receiver Enable from Shutdown

t

to Output High

Receiver Enable from Shutdown

t

to Output Low

SHDN

ZH(SHDN)RL

ZL(SHDN)RL

(Note 10) Full 60 - 600 ns

= 1kΩ, CL = 15pF, SW = GND (Figure 6),

Full - - 1000 ns

(Notes 10, 12)

= 1kΩ, CL = 15pF, SW = VCC (Figure 6),

Full - - 1000 ns

(Notes 10, 12)

NOTES:

5. All currents into device pins are positive; all currents out of device pins are negative. All voltages are referenced to device ground unless

otherwise specified.

6. Supply current specification is valid for loaded drivers when DE = 0V.

7. Applies to peak current. See “Typical Performance Curves” for more information.

8. Because of the shutdown feature, keep RE

9. Because of the shutdown feature, the RE

10. These IC’s are put into shutdown by bringing RE

= 0 to prevent the device from entering SHDN.

signal high time must be short enough (typically <100ns) to prevent the device from entering SHDN.

high and DE low. If the inputs are in this state for less than 60ns, the p arts are guaranteed not

to enter shutdown. If the inputs are in this state for at least 700ns, the parts are guaranteed to have entered shutdown. See “Low-Power

Shutdown Mode” section.

11. Keep RE

12. Set the RE

13. This is the part-to-part skew between any two units tested with identical test conditions (Temperature, V

14. V

= VCC, and set the DE signal low time >700ns to ensure that the device enters SHDN.

signal high time >700ns to ensure that the device enters SHDN.

= 5V ±5%

CC

CC

, etc.).

15. Parts are 100% tested at +25°C. Over temperature limits established by characterization and are not production tested.

Test Circuits and Waveforms

DE

V

CC

DI

Z

D

Y

V

OD

FIGURE 1A. VOD AND V

RL/2

V

V

R

/2

OC

L

OC

FIGURE 1. DC DRIVER TEST CIRCUITS

DE

CC

DI

Z

D

Y

V

OD

RL = 60Ω

FIGURE 1B. VOD WITH COMMON MODE LOAD

375Ω

VCM

-7V TO +12V

375Ω

6

FN6364.0

July 26, 2007

Test Circuits and Waveforms (Continued)

ISL3159E

3V

DI

1.5V1.5V

0V

DE

V

CC

SIGNAL

GENERATOR

DI

Z

D

Y

R

D

C

D

FIGURE 2A. TEST CIRCUIT

FIGURE 2. DRIVER PROPAGATION DELAY AND DIFFERENTIAL TRANSITION TIMES

DE

SIGNAL

GENERATOR

DI

Z

D

Y

110Ω

SW

50pF

PARAMETER OUTPUT RE DI SW

t

HZ

t

LZ

t

ZH

t

ZL

t

HZ(SHDN)

t

LZ(SHDN)

Y/Z X 1/0 GND

Y/Z X 0/1 V

Y/Z 0 (Note 8) 1/0 GND

Y/Z 0 (Note 8) 0/1 V

Y/Z 1 (Note 11) 1/0 GND

Y/Z 1 (Note 11) 0/1 V

V

CC

GND

CC

CC

CC

OUT (Z)

OUT (Y)

DIFF OUT (Y - Z)

FIGURE 2B. MEASUREMENT POINTS

DE

(NOTE 10)

tZH, t

ZH(SHDN)

(NOTE 10)

OUT (Y, Z)

, t

t

ZL

ZL(SHDN)

(NOTE 10)

OUT (Y, Z)

PLH

- t

t

PHL

t

t

PHL

|

1.5V1.5V

HZ

VOH - 0.5V

LZ

VOL + 0.5V

t

PLH

90% 90%

10% 10%

t

R

SKEW = |t

OUTPUT HIGH

50%

50%

OUTPUT LOW

V

OH

V

OL

+V

OD

-V

OD

t

F

3V

0V

V

OH

0V

V

CC

V

OL

V

CC

SIGNAL

GENERATOR

FIGURE 3A. TEST CIRCUIT

DE

DI

Z

D

Y

54Ω

FIGURE 4A. TEST CIRCUIT

7

FIGURE 3B. MEASUREMENT POINTS

FIGURE 3. DRIVER ENABLE AND DISABLE TIMES

+

C

L

V

OD

-

C

L

DI

DIFF OUT (Y - Z)

FIGURE 4B. MEASUREMENT POINTS

3V

0V

+V

OD

-V

OD

0V

FN6364.0

July 26, 2007

Test Circuits and Waveforms (Continued)

FIGURE 4. DRIVER DATA RATE

ISL3159E

RE

B

+1.5V

SIGNAL

GENERATOR

A

RO

R

FIGURE 5A. TEST CIRCUIT FIGURE 5B. MEASUREMENT POINTS

RE

B

A

RO

R

15pF

SIGNAL

GENERATOR

GND

PARAMETER DE A SW

t

HZ

t

LZ

t

(Note 9) 0 +1.5V GND

ZH

t

(Note 9) 0 -1.5V V

ZL

t

HZ(SHDN)

t

LZ(SHDN)

(Note 12) 0 +1.5V GND

(Note 12) 0 -1.5V V

0 +1.5V GND

0-1.5VV

15pF

A

RO

FIGURE 5. RECEIVER PROPAGATION DELAY

1kΩ

SW

CC

CC

CC

V

CC

GND

RE

tZH, t

ZH(SHDN)

(NOTE 10)

RO

, t

t

ZL

ZL(SHDN)

(NOTE 10)

RO

(NOTE 10)

t

PLH

1.7V 1.7V

OUTPUT HIGH

1.5V

1.5V

OUTPUT LOW

t

1.5V1.5V

PHL

t

t

1.5V1.5V

HZ

LZ

+3V

0V

3V

0V

VOH - 0.5V

VOL + 0.5V

V

CC

0V

V

OH

0V

V

CC

V

OL

FIGURE 6A. TEST CIRCUIT

FIGURE 6. RECEIVER ENABLE AND DISABLE TIMES

8

FIGURE 6B. MEASUREMENT POINTS

FN6364.0

July 26, 2007

ISL3159E

Application Information

RS-485 and RS-422 are differential (balanced) data

transmission standards for use in long haul or noisy

environments. RS-422 is a subset of RS-485, so RS-485

transceivers are also RS-422 compliant. RS-422 is a

point-to-multipoint (multidrop) standard, which allows only

one driver and up to 10 (assuming one unit load devices)

receivers on each bus. RS-485 is a true multipoint standard,

which allows up to 32 one unit load devices (any mix of

drivers and receivers) on each bus. To allow for multipoint

operation, the RS-485 spec requires that drivers must

handle bus contention without sustaining any damage.

Another important advantage of RS-485 is the extended

common mode range (CMR), which specifies that the driver

outputs and receiver inputs withstand signals that range from

+12V to -7V. RS-422 and RS-485 are intended for runs as

long as 4000’ (~1200m), so the wide CMR is necessary to

handle ground potential differences, as well as voltages

induced in the cable by external fields.

Receiver (Rx) Features

This transceiver utilizes a differential input receiver for

maximum noise immunity and common mode rejection. Input

sensitivity is ±200mV, as required by the RS422 and RS-485

specifications. Receiver inputs function with common mode

voltages as great as 7V outside the power supplies (i.e.,

+12V and -7V), making them ideal for long networks, or

industrial environments, where induced voltages are a

realistic concern.

The receiver input resistance of 50kΩ surpasses the RS-422

spec of 4kΩ, and is five times the RS-485 “Unit Load” (UL)

requirement of 12kΩ minimum. Thus, the ISL3159E is

known as a “one-fifth UL” transceiver, and there can be up to

160 devices on the RS-485 bus while still complying with the

RS-485 loading specification.

The receiver is a “full fail-safe” version that guarantees a

high level receiver output if the receiver inputs are

unconnected (floating), shorted together, or connected to a

terminated bus with all the transmitters disabled

(terminated/undriven).

Rx outputs deliver large low state currents (typically >30mA)

at V

= 1V (to ease the design of optically coupled isolated

OL

networks).

Receivers easily meet the 40Mbps data rate supported by

the driver, and the receiver output is tri-statable via the active

low RE

input.

Driver (Tx) Features

The RS-485/RS-422 driver is a differential output device that

delivers at least 2.1V across a 54Ω load (RS-485/

PROFIBUS), and at least 2.6V across a 100Ω load (RS-422)

even with V

delay skew to maximize bit width, and to minimize EMI.

= 4.5V. The drivers feature low propagation

CC

Outputs of the drivers are not slew rate limited, so faster

output transition times allow data rates of at least 40Mbps.

Driver outputs are tri-statable via the active high DE input.

For parallel applications, bit-to-bit skews between any two

ISL3159E transmitter and receiver pairs are guaranteed to

be no worse than 8ns (4ns max for any two Tx, 4ns max for

any two Rx).

High V

Improves Noise Immunity and Flexibilit y

OD

The ISL3159E driver design delivers larger differential output

voltages (VOD) than the RS-485 standard requires, or than

most RS-485 transmitters can deliver. The minimum ±2.1V

V

guarantees at least ±600mV more noise immunity than

OD

networks built using standard 1.5V V

transmitters.

OD

Another advantage of the large VOD is the ability to drive

more than two bus terminations, which allows for utilizing the

ISL3159E in “star” and other multi-terminated,

“non-standard” network topologies. Figure 8, details the

transmitter’s V

OD

vs I

characteristic, and includes load

OUT

lines for four (30Ω) and six (20Ω) 120Ω terminations. The

figure shows that the driver typically delivers 1.9/1.5V into

4/6 terminations, even at +85

requires a minimum 1.5V V

°C. The RS-485 standard

into two terminations, but the

OD

ISL3159E typically delivers RS-485 voltage levels with 2x to

3x the number of terminations.

ESD Protection

All pins on the ISL3159E include class 3 (>9kV) Human

Body Model (HBM) ESD protection structures, but the

RS-485 pins (driver outputs and receiver inputs)

incorporate advanced structures allowing them to survive

ESD events in excess of ±16.5kV HBM and ±15kV

IEC61000-4-2. The RS-485 pins are particularly vulnerable

to ESD strikes because they typically connect to an

exposed port on the exterior of the finished product. Simply

touching the port pins, or connecting a cable, can cause an

ESD event that might destroy unprotected ICs. These new

ESD structures protect the device whether or not it is

powered up, and without degrading the RS-485 common

mode range of -7V to +12V. This built-in ESD protection

eliminates the need for board level protection structures

(e.g., transient suppression diodes), and the associated,

undesirable capacitive load they present.

IEC61000-4-2 Testing

The IEC61000 test method applies to finished equipment,

rather than to an individual IC. Therefore, the pins most likely

to suffer an ESD event are those that are exposed to the

outside world (the RS-485 pins in this case), and the IC is

tested in its typical application configuration (power applied)

rather than testing each pin-to-pin combination. The

IEC61000 standard’s lower current limiting resistor coupled

with the larger charge storage capacitor yields a test that is

much more severe than the HBM test. The extra ESD

protection built into this device’s RS-485 pins allows the

9

FN6364.0

July 26, 2007

ISL3159E

design of equipment meeting level 4 criteria without the need

for additional board level protection on the RS-485 port.

AIR-GAP DISCHARGE TEST METHOD

For this test method, a charged probe tip moves toward the

IC pin until the voltage arcs to it. The current waveform

delivered to the IC pin depends on approach speed,

humidity, temperature, etc., so it is more difficult to obtain

repeatable results. The ISL3159E RS-485 pins withstand

±15kV air-gap discharges.

CONTACT DISCHARGE TEST METHOD

During the contact discharge test, the probe contacts the

tested pin before the probe tip is energized, thereby

eliminating the variables associated with the air-gap

discharge. The result is a more repeatable and predictable

test, but equipment limits prevent testing devices at voltages

higher than ±9kV. The RS-485 pins of the ISL 3159E survive

±8kV contact discharges.

Hot Plug Function

When a piece of equipment powers up, there is a period of

time where the processor or ASIC driving the RS-485 control

lines (DE, RE

) is unable to ensure that the RS-485 Tx and

Rx outputs are kept disabled. If the equipment is connected

to the bus, a driver activating prematurely during power up

may crash the bus. To avoid this scenario, the ISL3159E

incorporates a “Hot Plug” function. Circuitry monitoring V

CC

ensures that, during power up and power down, the Tx and Rx

outputs remain disabled, regardless of the state of DE and RE

if V

is less than ~3.2V . This gives the processor/ASIC a

CC

chance to stabilize and drive the RS-485 control lines to the

proper states.

DE, DI = V

3.3V

V

CC

5.0

2.5

A/Y

0

DRIVER Y OUTPUT (V)

RO

FIGURE 7. HOT PLUG PERFORMANCE (ISL3159E) vs

ISL83088E WITHOUT HOT PLUG CIRCUITRY

ISL3159E

ISL3159E

TIME (40μs/DIV)

3.1V

RE = GND

CC

RL = 1kΩ

RL = 1kΩ

5.0

2.5

0

5.0

2.5

0

Data Rate, Cables, and Terminations

Twisted pair is the cable of choice for RS-485, RS-422, and

PROFIBUS networks. Twisted pair cables tend to pick up

noise and other electromagnetically induced voltages as

common mode signals, which are effectively rejected by the

differential receivers in these ICs.

According to guidelines in the RS-422 and PROFIBUS

specifications, networks operating at data rates in excess of

3Mbps should be limited to cable lengths of 100m (328 ft) or

less, and the PROFIBUS specification recommends that the

more expensive “Type A” (22AWG) cable be used. The

ISL3159E’s large differential output swing, fast transition

times, and high drive-current output stages allow operation

even at 40Mbps over standard “CAT5” cables in excess of

100m (328 ft). Figure 17 details the ISL3159E performance

at this condition, with a 120Ω termination resistor at both the

driver and the receiver ends. Note that the differential signal

delivered to the receiver at the end of the cable (A-B) still

exceeds 1V, so even longer cables could be driven if lower

noise margins are acceptable. Of course, jitter or some other

criteria may limit the network to shorter cable lengths than

those discussed here. If more noise margin is desired,

shorter cables produce a larger receiver input signal as

illustrated in Figure 16. Performance should be even better if

the “Type A” cable is utilized.

The ISL3159E may also be used at slower data rates over

longer cables, but there are some limitations. The Rx is

optimized for high speed operation, so its output may glitch if

the Rx input differential transition times are too slow.

Keeping the transition times below 500ns, (which equates to

the Tx driving a 1000’ (305m) CAT 5 cable) yields excellent

performance over the full operating temperature range.

,

T o minimize refle ctions, proper terminat ion is imperative when

using this high data rate transceiver. In point-to-point, or pointto-multipoint (single driver on bus) networks, the main cable

should be terminated in its characteristic impe dance (typically

120Ω for “CAT5”, and 220Ω for “Type A”) at the end farthest

from the driver. In multi-receiver applications, stubs

(V)

CC

V

connecting receivers to the main cable should be kept as

short as possible. Multipoint (multi-driver) systems require that

the main cable be terminated in its characteristic impedance

at both ends. Stubs connecting a tra nsceiver to the main cable

should be kept as short as possible.

Built-In Driver Overload Protection

As stated previously, the RS-485 specification requires that

drivers survive worst case bus contentions undamaged.

These transmitters meet this requirement via driver output

short circuit current limits, and on-chip thermal shutdown

circuitry.

RECEIVER OUTPUT (V)

The driver output stages incorporate short circuit current

limiting circuitry which ensures that the output current never

exceeds the RS-485 specification, even at the common

mode voltage range extremes. In the event of a major short

circuit condition, the device also includes a thermal

shutdown feature that disables the drivers whenever the die

temperature becomes excessive. This eliminates the power

dissipation, allowing the die to cool. The drivers

automatically reenable after the die temperature drops about

10

FN6364.0

July 26, 2007

ISL3159E

15 degrees. If the contention persists, the thermal

shutdown/reenable cycle repeats until the fault is cleared.

Receivers stay operational during thermal shutdown.

Low Power Shutdown Mode

This BiCMOS transceiver uses a fraction of the power

required by their bipolar counterparts, but it also includes a

shutdown feature that reduces the already low quiescent I

to a 50nA trickle. It enters shutdown whenever the receiver

Typical Performance Curves V

110

100

90

80

70

60

50

40

30

20

DRIVER OUTPUT CURRENT (mA)

10

0

+25°C

+85°C

+125°C

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

DIFFERENTIAL OUTPUT VOLTAGE (V)

FIGURE 8. DRIVER OUTPUT CURRENT vs DIFFERENTIAL

OUTPUT VOLTAGE

RD = 20Ω

RD = 30Ω

= 5V, TA = +25°C; Unless Otherwise Specified

CC

RD = 54Ω

RD = 100Ω

CC

and driver are simultaneously disabled (RE

=VCC and

DE = GND) for a period of at least 600ns. Disabling both the

driver and the receiver for less than 60ns guarantees that

the transceiver will not enter shutdown.

Note that receiver and driver enable times increase when

the transceiver enables from shutdown. Refer to Notes 8, 9,

10, 11 and 12, at the end of the Electrical S pecification table

on page 6, for more information.

3.5

3.4

3.3

3.2

3.1

3.0

2.9

2.8

2.7

2.6

DIFFERENTIAL OUTPUT VOLTAGE (V)

2.5

-40 -15 10 35 60 85 110

FIGURE 9. DRIVER DIFFERENTIAL OUTPUT VOLTAGE vs

RD = 100Ω

RD = 54Ω

125

TEMPERATURE (°C)

TEMPERATURE

200

150

Y OR Z = LOW

100

50

0

-50

OUTPUT CURRENT (mA)

-100

-150

-7 -6 -4 -2 0 2 4 6 8 10 12

OUTPUT VOLTAGE (V)

Y OR Z = HIGH

FIGURE 10. DRIVER OUTPUT CURRENT vs SHORT CIRCUIT

VOLTAGE

2.55

2.50

2.45

(mA)

CC

I

2.40

2.35

2.30

-40 -15 10 35 60 85 110 125

DE = VCC, RE = X OR DE = GND, RE = GND

TEMPERATURE (°C)

FIGURE 11. SUPPLY CURRENT vs TEMPERATURE

11

FN6364.0

July 26, 2007

ISL3159E

Typical Performance Curves V

9.0

8.8

8.6

8.4

8.2

8.0

7.8

7.6

PROPAGATION DELAY (ns)

7.4

7.2

7.0

-40 -15 10 35 60 85 110

TEMPERATURE (°C)

= 5V, TA = +25°C; Unless Otherwise Specified (Continued)

CC

t

PHL

t

PLH

FIGURE 12. DRIVER DIFFERENTIAL PROPAGATION DELAY

vs TEMPERATURE

R

= 54Ω, CD = 50pF

DIFF

DI

5

0

RECEIVER OUTPUT (V)

RO

125

5

0

DRIVER INPUT (V)

0.9

|t

- t

PHL

|

TEMPERATURE (°C)

PLH

0.8

0.7

0.6

SKEW (ns)

0.5

0.4

0.3

-40 -15 10 35 60 85 110 125

FIGURE 13. DRIVER DIFFERENTIAL SKEW vs

TEMPERATURE

R

= 54Ω, CD = 50pF

DIFF

DI

5

0

RECEIVER OUTPUT (V)

RO

5

0

DRIVER INPUT (V)

3

2

1

0

Y-Z

-1

-2

DRIVER OUTPUT (V)

-3

TIME (5ns/DIV)

3

2

1

0

Y-Z

-1

-2

-3

DRIVER OUTPUT (V)

TIME (5ns/DIV)

FIGURE 14. DRIVER AND RECEIVER WAVEFORMS FIGURE 15. DRIVER AND RECEIVER WAVEFORMS

DI = 40Mbps

RO

DRIVER+CABLE DELAY (~480ns)

A - B

TIME (10ns/DIV)

350 FEET (107 METERS) OF CAT5 CABLE

(DOUBLE TERMINATED WITH 120Ω)

RECEIVER OUTPUT (V)

RECEIVER INPUT (V)

5.0

3.0

1.5

-1.5

-3.0

DI = 40Mbps

0

0

RO

DRIVER+CABLE DELAY (~156ns)

A - B

TIME (10ns/DIV)

5

0

FIGURE 16. DRIVER AND RECEIVER WAVEFORMS DRIVING

100 FEET (31 METERS) OF CAT5 CABLE

(DOUBLE TERMINATED WITH 120Ω)

DRIVER INPUT (V)

5.0

0

RECEIVER OUTPUT (V)

3.0

1.5

0

-1.5

RECEIVER INPUT (V)

-3.0

FIGURE 17. DRIVER AND RECEIVER WAVEFORMS DRIVING

5

0

DRIVER INPUT (V)

12

FN6364.0

July 26, 2007

ISL3159E

Typical Performance Curves V

70

60

VOH, +25°C

50

40

30

20

10

RECEIVER OUTPUT CURRENT (mA)

0

012 3 45

VOH, +85°C

VOH, +125°C

RECEIVER OUTPUT VOLTAGE (V)

= 5V, TA = +25°C; Unless Otherwise Specified (Continued)

CC

VOL, +25°C

VOL, +85°C

VOL, +125°C

FIGURE 18. RECEIVER OUTPUT CURRENT vs RECEIVER

OUTPUT VOLTAGE

Die Characteristics

SUBSTRATE AND DFN THERMAL PAD POTENTIAL

(POWERED UP):

GND

TRANSISTOR COUNT:

768

PROCESS:

Si Gate BiCMOS

13

FN6364.0

July 26, 2007

ISL3159E

Mini Small Outline Plastic Packages (MSOP)

N

EE1

INDEX

AREA

AA1A2

-H-

SIDE VIEW

12

TOP VIEW

b

e

D

NOTES:

1. These package dimensions are within allowable dimensions of

JEDEC MO-187BA.

2. Dimensioning and tolerancing per ANSI Y14.5M-1994.

3. Dimension “D” does not include mold flash, protrusions or gate

burrs and are measured at Datum Plane. Mold flash, protrusion

and gate burrs shall not exceed 0.15mm (0.006 inch) per side.

4. Dimension “E1” does not include interlead flash or protrusions

and are measured at Datum Plane. Interlead flash and

protrusions shall not exceed 0.15mm (0.006 inch) per side.

5. Formed leads shall be planar with respect to one another within

0.10mm (0.004) at seating Plane.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. Dimension “b” does not include dambar protrusion. Allowable

dambar protrusion shall be 0.08mm (0.003 inch) total in excess

of “b” dimension at maximum material condition. Minimum space

between protrusion and adjacent lead is 0.07mm (0.0027 inch).

- H -

-A -

.

10. Datums and to be determined at Datum plane

11. Controlling dimension: MILLIMETER. Converted inch dimensions are for reference only.

-B-

0.20 (0.008) A

GAUGE

PLANE

SEATING

PLANE

0.10 (0.004) C

-A-

0.20 (0.008) C

- B -

0.25

(0.010)

-C-

SEATING

PLANE

a

0.20 (0.008) C

- H -

B

4X θ

C

D

4X θ

L1

C

L

E

1

END VIEW

R1

R

L

C

-B-

M8.118 (JEDEC MO-187AA)

8 LEAD MINI SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.037 0.043 0.94 1.10 A1 0.002 0.006 0.05 0.15 A2 0.030 0.037 0.75 0.95 -

b 0.010 0.014 0.25 0.36 9

c 0.004 0.008 0.09 0.20 -

D 0.116 0.120 2.95 3.05 3

E1 0.116 0.120 2.95 3.05 4

e 0.026 BSC 0.65 BSC -

E 0.187 0.199 4.75 5.05 -

L 0.016 0.028 0.40 0.70 6

L1 0.037 REF 0.95 REF -

N8 87

R 0.003 - 0.07 - R1 0.003 - 0.07 - -

0 5

α

o

o

0

15

o

o

6

o

5

o

0

15

o

o

6

Rev. 2 01/03

NOTESMIN MAX MIN MAX

-

-

14

FN6364.0

July 26, 2007

Dual Flat No-Lead Plastic Package (DFN)

ISL3159E

(DAT UM B )

6

INDEX

AREA

(DATUM A)

NX (b)

5

SECTION "C-C"

6

INDEX

AREA

SEATING

PLANE

NX L

8

A

C

D

TOP

VIEW

SIDE VIEW

D2

D2/2

12

N

N-1

e

(Nd-1)Xe

REF .

BOTTOM VIEW

(A1)

2X

A3

E2/2

NX b

5

C

L

e

CC

FOR ODD TERMINAL/SIDE

87

0.10

ABC0.10

2X

0.10

E

//

A

NX k

E2

M

9

TERMINAL TIP

0.10

0.08

L

CB

BAC

L10.3x3C

10 LEAD DUAL FLAT NO-LEAD PLASTIC PACKAGE

MILLIMETERS

SYMBOL

A 0.85 0.90 0.95 A1 - - 0.05 A3 0.20 REF -

b 0.20 0.25 0.30 5, 8

D 3.00 BSC -

D2 2.33 2.38 2.43 7, 8

C

E 3.00 BSC E2 1.59 1.64 1.69 7, 8

C

e 0.50 BSC k0.20- - L 0.35 0.40 0.45 8

N102

Nd 5 3

NOTES:

1. Dimensioning and tolerancing conform to ASME Y14.5-1994.

2. N is the number of terminals.

3. Nd refers to the number of terminals on D.

4. All dimensions are in millimeters. Angles are in degrees.

5. Dimension b applies to the metallized terminal and is measured

between 0.15mm and 0.30mm from the terminal tip.

6. The configuration of the pin #1 identifier is optional, but must be

located within the zone indicated. The pin #1 identi fier may be

either a mold or mark feature.

7. Dimensions D2 and E2 are for the exposed pads which provide

improved electrical and thermal performance.

8. Nominal dimensions are provided to assist with PCB Land

Pattern Design efforts, see Intersil Technical Brief TB389.

9. COMPLIANT TO JEDEC MO-229-WEED-3 except for

dimensions E2 & D2.

NOTESMIN NOMINAL MAX

Rev. 1 4/06

15

FN6364.0

July 26, 2007

Small Outline Plastic Packages (SOIC)

ISL3159E

N

INDEX

AREA

123

-A-

E

-B-

SEATING PLANE

D

A

-C-

0.25(0.010) BM M

H

L

h x 45°

α

e

B

0.25(0.010) C AM BS

M

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of

Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm (0.006

inch) per side.

4. Dimension “E” does not include interlead flash or protrusions. Interlead flash and protrusions shall not exceed 0.25mm (0.010 inch) per

side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width “B”, as measured 0.36mm (0.014 inch) or greater

above the seating plane, shall not exceed a maximum value of

0.61mm (0.024 inch).

10. Controlling dimension: MILLIMETER. Converted inch dimensions

are not necessarily exact.

A1

C

0.10(0.004)

M8.15 (JEDEC MS-012-AA ISSUE C)

8 LEAD NARROW BODY SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.0532 0.0688 1.35 1.75 -

A1 0.0040 0.0098 0.10 0.25 -

B 0.013 0.020 0.33 0.51 9

C 0.0075 0.0098 0.19 0.25 -

D 0.1890 0.1968 4.80 5.00 3

E 0.1497 0.1574 3.80 4.00 4

e 0.050 BSC 1.27 BSC -

H 0.2284 0.2440 5.80 6.20 -

h 0.0099 0.0196 0.25 0.50 5

L 0.016 0.050 0.40 1.27 6

N8 87

α

0° 8° 0° 8° -

NOTESMIN MAX MIN MAX

Rev. 1 6/05

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implicat ion or oth erwise u nde r any p a tent or p at ent r ights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

16

FN6364.0

July 26, 2007

Loading...

Loading...