®

ISL24010

Octal Voltage Level Shifter for TFT/LCD Panels

Data Sheet November 4, 2005

High Voltage TFT-LCD Logic Driver

The ISL24010 is a high voltage TFT-LCD logic driver with a

+40V and -20V (momentary absolute max) output voltage

swing capability. It is manufactured using the Intersil’s

proprietary monolithic high voltage bipolar process and is

capable of driving a 3000pF load in 500ns.

The ISL24010 will level shift a digital input signal to an output

voltage nearly equal to its output supply voltages. The

ISL24010 has 3 supplies. V

ON1

and V

are positive

ON2

supplies with a voltage range between +10V and +40V

(absolute max). V

is the negative supply with a voltage

OFF

range between -5V and -20V (absolute max). Outputs 1

through 6 are connected to V

are connected to V

ON2

and V

and V

ON1

OFF

OFF

. This configuration

. Outputs 7 and 8

enables outputs 1 through 6 to provide slicing to the row

drivers to reduce flicker, and outputs 7 and 8 to control

possible supply lines. V

possible to tie V

ON1

should remain constant. It is

ON2

and V

supplies together, if

ON2

independent control as described above is not desired.

V

is required to be greater than or equal to V

ON2

ON1

at all

times.

The ISL24010 is available in TSSOP-20 pin package. It is

specified for operation over the -40°C to +85°C industrial

temperature range.

Ordering Information

TEMP.

PART

NUMBER

ISL24010IVZ

(See Note)

ISL24010IVZ-T

(See Note)

NOTE: Intersil Pb-free plus anneal products employ special Pb-free

material sets; molding compounds/die attach materials and 100%

matte tin plate termination finish, which are RoHS compliant and

compatible with both SnPb and Pb-free soldering operations. Intersil

Pb-free products are MSL classified at Pb-free peak reflow

temperatures that meet or exceed the Pb-free requirements of

IPC/JEDEC J STD-020.

PART

MARKING

24010IVZ -40 to +85 20 Ld TSSOP

24010IVZ -40 to +85 20 Ld TSSOP

RANGE

(°C) PACKAGE

(Pb-free)

Tape and Reel

(Pb-free)

PKG.

DWG. #

M20.173

M20.173

FN6124.0

Features

• 0V to 5.5V (absolute max) Input Voltage Range

• +40V and -20V (momentary absolute max) Output Voltage

Range

• 10mA Output Continuous Current (all 8 channels)

• 25mA Output Peak Current (all 8 channels)

• Rise/Fall Times 150ns/210ns

• Propagation Delay 250ns

• 50kHz Input Logic Frequency

• 20 Ld TSSOP Pb-Free Plus Anneal (RoHS Compliant)

Applications

• TFT-LCD panels

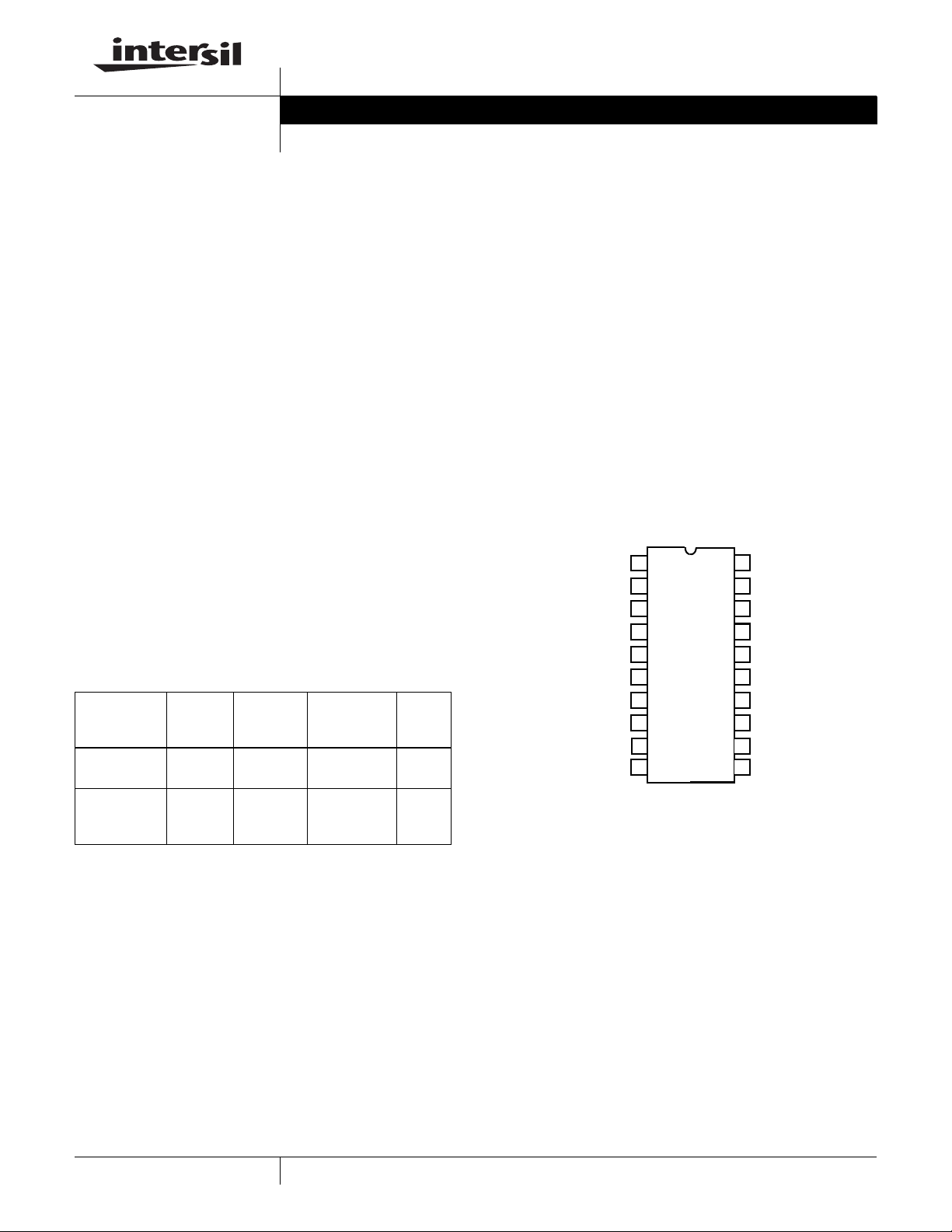

Pinout

20 Ld TSSOP

TOP VIEW

V

GND

IN1

IN2

IN3

IN4

IN5

IN6

IN7

OFF

1

2

3

4

5

6

7

8

9IN8

10V

20

ON1

OUT1

19

18

OUT2

17

OUT3

16

OUT4

15

OUT5

OUT6

14

OUT7

13

OUT8

12

11

V

ON2

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright © Intersil Americas Inc. 2005. All Rights Reserved.

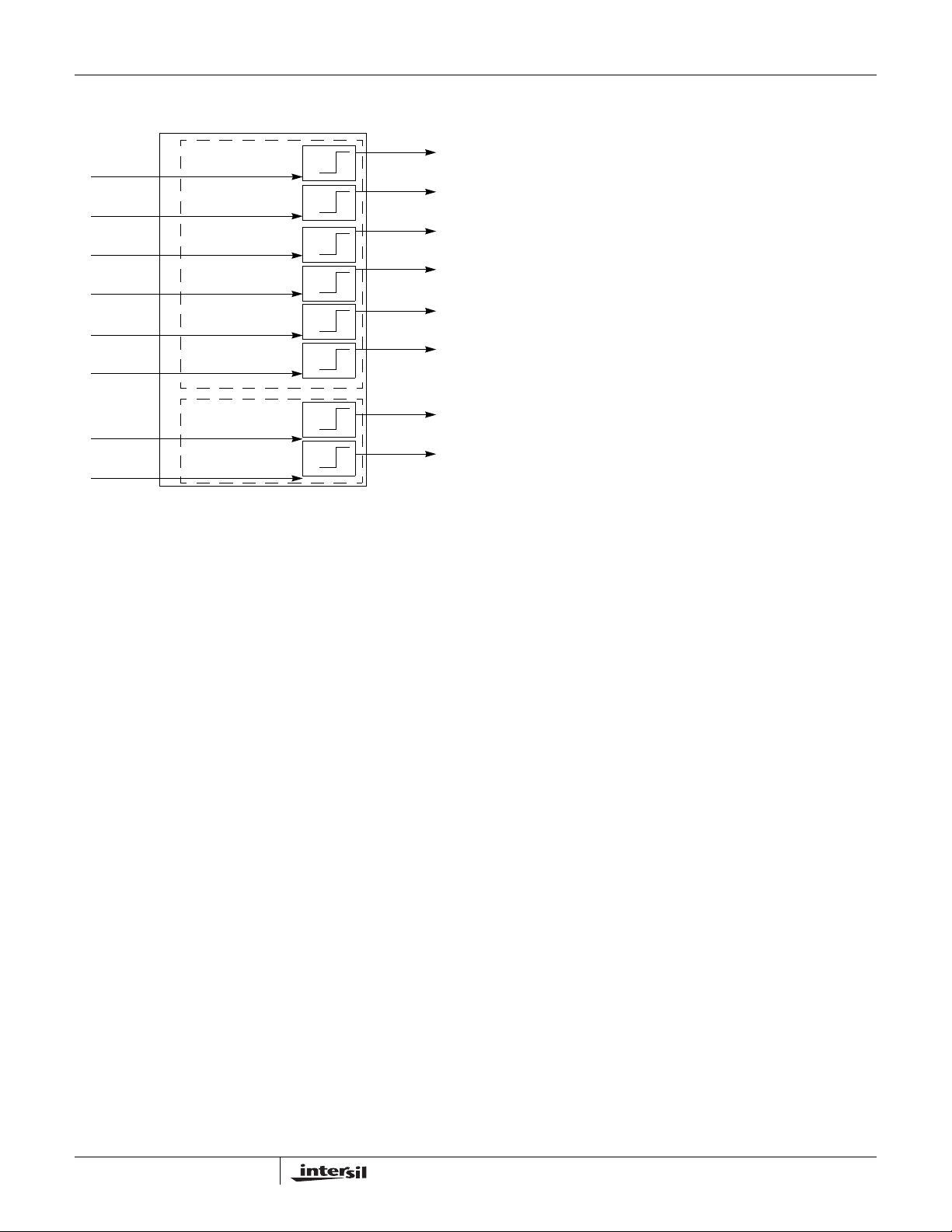

Functional Diagram

ISL24010

IN1

IN2

IN3

IN4

IN5

IN6

IN7

IN8

Connected to V

and V

OFF

Connected to V

and V

OFF

ON1

ON2

CH1

CH2

CH3

CH4

CH5

CH6

CH7

CH8

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

OUT8

2

ISL24010

Absolute Maximum Ratings (T

Driver Positive Supply Voltage Range, (VON) . . . . . . . .+5V to +40V

Power Supply Voltage Range, (V

Negative Supply Voltage Range, (V

Supply Turn-on Slew Rate . . . . . . . . . . . . . . . . . . . . . . . . . . 10V/µs

Input Voltage Range, All Inputs . . . . . . . . . . . . . . . . . . -0.5V to 5.5V

Output Voltage Range, All Outputs . . . . . V

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

ON

= 25°C) Thermal Information

A

Thermal Resistance (Typical, Note 1)

to V

OFF

) . . . . . .+10V to +60V

OFF

). . . . . . . . . . . . .-20V to -5V

-0.5V to VON +0.5V

OFF

20 Ld TSSOP Package . . . . . . . . . . . . . . . . . . . . . . 140

(continuous, all 8 channels) . . . . . . . . . . . . . . . . . . . . . . 80mA

I

OUT

T

AMBIENT

T

JUNCTION

T

STORAGE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -40°C to +85°C

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -40°C to +150°C

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -65°C to +150°C

θ

JA

(°C/W)

NOTE:

is measured with the component mounted on a HIGH effective thermal conductivity test board in free air. See Tech Brief TB379 for details.

1. θ

JA

IMPORTANT NOTE: All parameters having Min/Max specifications are guaranteed. Typical values are for information purposes only. Unless otherwise noted, all tests

are at the specified temperature and are pulsed tests, therefore: T

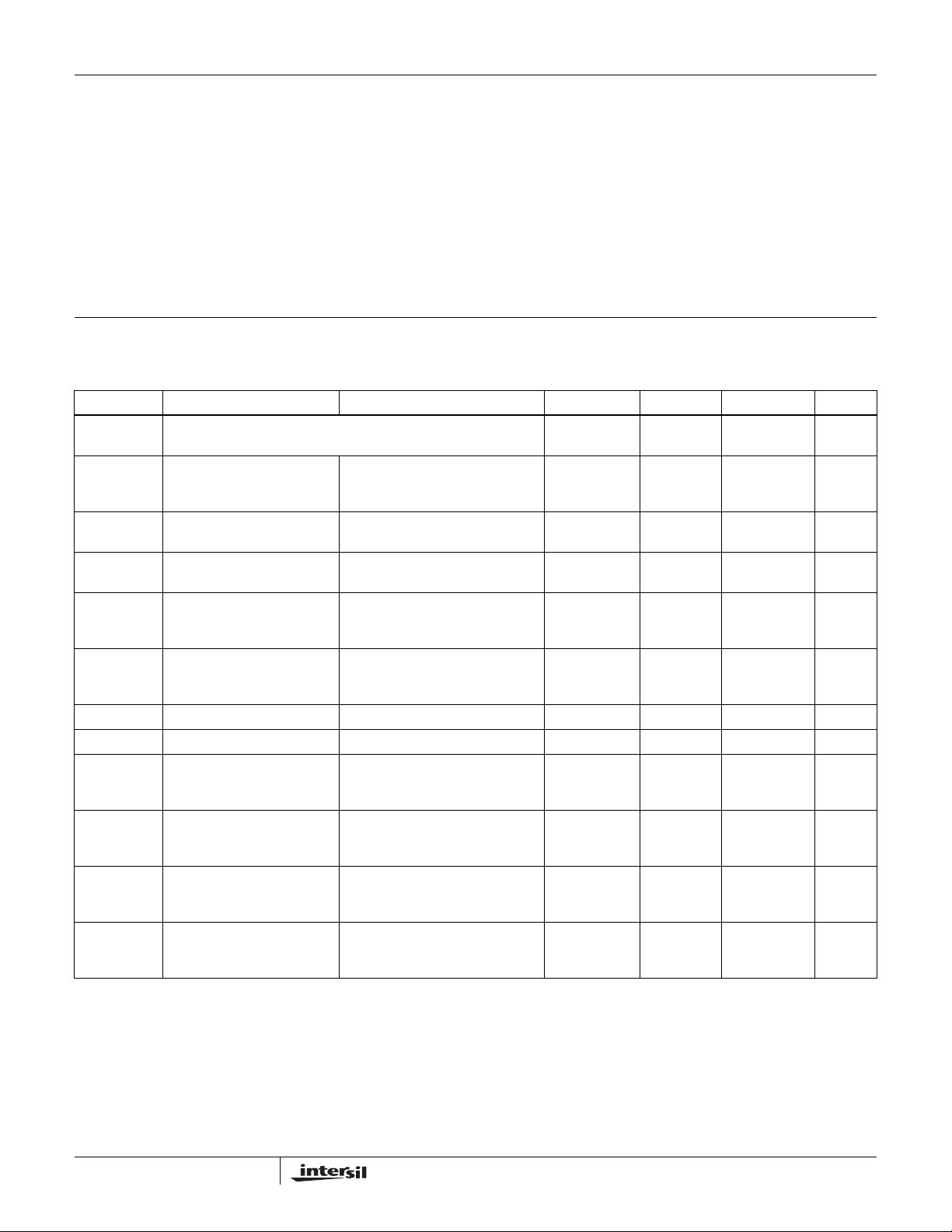

Electrical Specifications V

ON

= 22V, V

OFF

= TC = T

J

A

= -5V, TA = -40°C to +85°C Unless Otherwise Specified. Typical values tested at 25°C

PARAMETER DESCRIPTION CONDITION MIN TYP MAX UNIT

Power

Supplies

I(VON) Supply Current All Inputs low or high

Recommended Operating Voltages -5

(V

OFF

22

)

(VON)

V

1.8 4.0 mA

No load

V

= V

ON1

+ V

ON2

-4.0 -1.8 mA

-8.0 ± 2.0 8.0 µA

ON

) Supply Current All Inputs low or high

I(V

OFF

I

IN

Input Leakage Each Input low or high

No load

High = 1.8V, Low = 0.8V

VOH High Level Output Voltage IOH = -100µA

V

= 22V

ON

(V

- 1.5V) 21.2 V

ON

RL = 100pF in parallel with 5kΩ

VOL Low Level Output Voltage IOH = +100µA

V

= -5V

OFF

-4.3 (V

+ 1.5V) V

OFF

RL = 100pF in parallel with 5kΩ

VIH High Level Input Voltage 1.8 V

VIL Low Level Input Voltage 0.8 V

tplh Low to High Prop Delay 50% to 50%, Tested with

300 500 ns

RL = 100pF in parallel with 5kΩ,

f = 50kHz

tphl High to Low Prop Delay Measured at 50% to 50%

250 500 ns

f = 50kHz

RL = 100pF in parallel with 5kΩ,

ttlh Rise Time Measured at 10% to 90%

150 500 ns

f = 50kHz

RL = 100pF in parallel with 5kΩ

tthl Fall Time Measured at 10% to 90%

210 500 ns

f = 50kHz

RL = 100pF in parallel with 5kΩ

3

Pin Descriptions

ISL24010

PIN NUMBER

TSSOP-20 PIN NAME

EQUIVALENT

CIRCUIT DESCRIPTION

1 GND 4 Ground pin

2 IN1 1 Level shifter input 1

3 IN2 1 Level shifter input 2

4 IN3 1 Level shifter input 3

5 IN4 1 Level shifter input 4

6 IN5 1 Level shifter input 5

7 IN6 1 Level shifter input 6

8 IN7 1 Level shifter input 7

9 IN8 1 Level shifter input 8

10 VOFF 4 Negative output supply for all channels

11 VON2 4 Positive output supply for channels 7 and 8. V

V

.

ON1

12 OUT8 3 Lever shifter output 8

13 OUT7 3 Lever shifter output 7

14 OUT6 2 Lever shifter output 6

15 OUT5 2 Lever shifter output 5

16 OUT4 2 Lever shifter output 4

17 OUT3 2 Lever shifter output 3

18 OUT2 2 Lever shifter output 2

19 OUT1 2 Lever shifter output 1

20 VON1 4 Positive output supply for channels 1 through 6. V

V

.

ON2

V

V

ON2

OFF

Outputs 1-6 Outputs 7-8

IN

CIRCUIT 1.

V

OUT

V

CIRCUIT 2.

ON1

OFF

is required to be greater than or equal to

ON2

is required to be less than or equal to

ON1

V

ON2

OUT

V

OFF

CIRCUIT 3.

V

ON2

V

V

ON1

OFF

ESD CLAMP

CIRCUIT 4.

GND

4

ISL24010

Typical Performance Curves T

10.0

9.0

8.0

7.0

V

& 2 = 22V

ON1

V

= -5V

OFF

Input 50% Duty Cycle

10 15 20 25 30 35 40 45 50 55 60 65 70 75 80

FREQUENCY (kHz)

mA

6.0

5.0

4.0

3.0

2.0

1.0

0.0

= 25°C, Output load parallel RC (RL = 5kΩ, CL = 100pF) unless otherwise specified.

A

V

OFF

V

ON1

V

ON2

FIGURE 1. SUPPLY CURRENT vs FREQUENCY 1 CHANNEL

TOGGELING

15.0

13.5

12.0

V

& 2 = 22V

ON1

10.5

V

= -5V

OFF

9.0

mA

Input 50% Duty Cycle

7.5

6.0

4.5

3.0

1.5

0.0

10 15 20 25 30 35 40 45 50 55 60 65 70 75 80

FREQUENCY (kHz)

V

OFF

V

ON1

V

ON2

12.0

10.8

9.6

8.4

7.2

mA

6.0

V

& 2 = 22V

ON1

4.8

V

= -5V

OFF

3.6

Input 50% Duty Cycle

2.4

1.2

0.0

10 15 20 25 30 35 40 45 50 55 60 65 70 75 80

FREQUENCY (kHz)

V

ON1

V

OFF

FIGURE 2. SUPPLY CURRENT vs FREQUENCY

4 CHANNELS TOGGELING

15.0

13.5

12.0

V

& 2 = 22V

ON1

10.5

V

= -5V

OFF

9.0

Input 50% Duty Cycle

7.5

mA

6.0

4.5

3.0

1.5

0.0

10 15 20 25 30 35 40 45 50 55 60 65 70 75 80

FREQUENCY (kHz)

V

ON1

V

OFF

V

V

ON2

ON2

FIGURE 3. SUPPLY CURRENT vs FREQUENCY

6 CHANNELS TOGGLING

350

315

280

245

210

175

ns

140

V

& 2 = 20-40V

ON1

105

V

= -5V

OFF

70

Frequency 50kHz

35

100pF load

0

20 22 24 26 28 30 32 34 36 38 40

V

ON1

Prop Delay

& V

ON2

Fall Time

Rise Time

(V D.C.)

FIGURE 5. RISE TIME, FALL TIME AND PROP DELAY vs

V

ON1

& V

VOLTAGE WITH V

ON2

OFF

= -5V

FIGURE 4. SUPPLY CURRENT vs FREQUENCY

8 CHANNELS TOGGLING

ns

350

315

280

245

210

175

140

105

70

35

0

Prop Delay

Fall Time

Rise Time

V

= 20-40V

ON1 & 2

V

= -20V

OFF

Frequency 50kHz

100pF load

20 22 24 26 28 30 32 34 36 38 40

V

& V

ON2

(V D.C.)

ON1

FIGURE 6. RISE TIME, FALL TIME AND PROP DELAY vs

V

ON1

& V

VOLTAGE WITH V

ON2

OFF

= -20V

5

ISL24010

Typical Performance Curves T

2000

V

= 20-40V

ON1 & 2

1800

V

= -5V

OFF

1600

50kHz 50% Duty Cycle

1400

1200

1000

ns

800

600

400

200

0

20 22 24 26 28 30 32 34 36 38 40

V

& V

ON1

ON2

= 25°C, Output load parallel RC (RL = 5kΩ, CL = 100pF) unless otherwise specified. (Continued)

A

3300pF

1800pF

(V D.C.)

FIGURE 7. RISE TIME vs CAPACITANCE vs SUPPLY

VOLTAGE WITH V

2000

V

& 2 = 20-40V

ON1

1800

V

= -5V

OFF

50kHz 50% Duty Cycle

1600

1400

1200

1000

ns

800

600

400

200

0

20 22 24 26 28 30 32 34 36 38 40

V

ON1

OFF

& V

= -5V

ON2

3300pF

1800pF

(V D.C.)

100pF

100pF

2100

1890

ON1

& V

3300pF

(V D.C.)

ON2

1800pF

1680

1470

1260

1050

ns

840

V

& 2 = 20-40V

ON1

630

V

= -20V

OFF

420

50kHz 50% Duty Cycle

210

0

20 22 24 26 28 30 32 34 36 38 40

V

FIGURE 8. RISE TIME vs CAPACITANCE vs SUPPLY

VOLTAGE WITH V

2200

1980

1760

1540

1320

1100

ns

880

V

& 2 = 20-40V

ON1

660

V

= -20V

OFF

50kHz 50% Duty Cycle

440

220

0

20 22 24 26 28 30 32 34 36 38 40

V

ON1

OFF

& V

= -20V

3300pF

(V D.C.)

ON2

1800pF

100pF

100pF

FIGURE 9. FALL TIME vs CAPACITANCE vs SUPPLY

VOLTAGE WITH V

1500

1350

V

& 2 = 20-40V

ON1

V

= -5V

OFF

50kHz 50% Duty Cycle

20 22 24 26 28 30 32 34 36 38 40

V

ns

1200

1050

900

750

600

450

300

150

0

ON1

OFF

& V

= -5V

ON2

3300pF

1800pF

100pF

(V D.C.)

FIGURE 11. PROP DELAY vs CAPACITANCE vs SUPPLY

VOLTAGE WITH V

OFF

= -5V

6

FIGURE 10. FALL TIME vs CAPACITANCE vs SUPPLY

VOLTAGE WITH V

1500

V

& 2 = 20-40V

ON1

1350

V

= -5V

OFF

50kHz 50% Duty Cycle

1200

1050

900

750

ns

600

450

300

150

0

20 22 24 26 28 30 32 34 36 38 40

V

ON1

OFF

& V

= -20V

(V D.C.)

ON2

3300pF

1800pF

100pF

FIGURE 12. PROP DELAY vs CAPACITANCE vs SUPPLY

VOLTAGE WITH V

OFF

= -20V

ISL24010

Typical Performance Curves T

FIGURE 13. TRANSIENT RESPONSE vs LOAD CAPACITANCE

= 25°C, Output load parallel RC (RL = 5kΩ, CL = 100pF) unless otherwise specified. (Continued)

A

2V/DIV

0

100pF

5V/DIV

0

Pulse Input

1500pF

V

& 2 = 22V

ON1

V

= -5V

OFF

50kHz 50% Duty Cycle

Application Information

General

The ISL24010 is an Octal voltage level shifter. The part was

designed to level shifts a digital input signal to +22V and -5V

for TFT-LCD displays. The device is capable of level shifting

a CMOS logic signal between +40V and -20V.

Power Supply Decoupling

The ISL24010 requires a 0.1µF decoupling capacitor as

close to the V

large load equal to 5kΩ in parallel with 100pF (Figure 16).

This will deduce any dv/dt between the different supplies and

prevent the internal ESD clamp from turning on and

damaging the part.

ON1

, V

ON2

and V

power supply pins for a

OFF

2µs/DIV

Input Pin Connections

Unused inputs must be tied to ground. Failure to tie unused

input pins to ground will result in a rail to rail oscillations on

the respective output pins and higher unwanted power

dissipation in the part. Under these conditions, the

temperature of the part could get very hot.

Limiting the Output Current

No output short circuit current limit exists on this part. All

applications need to limit the output current to less than

80mA. Adequate thermal heat sinking of the parts is also

required.

Application Diagram (TV)

Power Supply Sequence

The ISL24010 requires that V

V

at all times. Therefore, if V

ON1

supplies, then V

needs to be turned on before V

ON2

The reason for this requirement is shown in Circuit 4 in the

Pin Description Table. The ESD protection diode between

V

and Von 1 will forward bias if V

ON2

drop greater than V

sequence: V

ON2

. Recommended power supply

ON2

, V

, V

ON1

The ESD protection scheme is based on diodes from the

pins to the V

supply and a dV/dt- triggered clamp. This

ON2

dV/dt triggered clamp imposes a maximum supply turn-on

slew rate of 10V/µs. This clamp will trigger if the supply

powers up too fast, causing amps of current to flow. Ground

and V

are treated as I/O pins with this protection

ON1

scheme. In applications where the dV/dt supply ramp could

exceed 10V/µs, such as hot plugging, additional methods

should be employed to ensure the rate of rise is not

exceeded.

be greater than or equal to

ON2

OFF

and Von 2 are different

ON1

becomes a diode

ON1

then input logic signals.

ON1

.

Latch-up Proof

The ISL24010 is manufactured in a high voltage DI process

that isolates every transistor in it’s own tub making the part

latch-up proof.

DC/DC

CONVERTER

1.0µF

1.0µF

TIMING

CON-

TROLLER

FIGURE 14. TYPICAL TV APPLICATION CIRCUIT

V

ON1

ISL24010

LEVEL

SHIFTER

V

ON2

V

OFF

1.0µF

LCD PANEL

7

Application Diagram (Monitor)

ISL24010

V

OFF

ISL24010

LEVEL

SHIFTER

VON SLICER

CIRCUIT

V

ON1

V

ON2

1.0µF

LCD PANEL

DC/DC

CONVERTER

V

OFF

1.0µF

TIMING

CON-

TROLLER

1.0µF

V

ON1VON1

V

ON2

FIGURE 15. TYPICAL MONITOR APPLICATION CIRCUIT WITH

SLICER TO REDUCE FLICKER

Test Circuit

V

ON1

V

ON2

OUT8

C

3

C

2

5kΩ 100pF

1.0µF

IN1

IN8

V

C

OFF

1

ISL24010

1.0µF

OUT1

1.0µF

If the output load is a series 200Ω resistor and a 3300pF

then C1, C2 and C3 can be reduced to 0.47pF.

INx

t

PHL

t

F

OUTx

t

PLH

t

R

FIGURE 16. TEST LOAD AND TIMING DEFINITIONS

8

ISL24010

Thin Shrink Small Outline Plastic Packages (TSSOP)

N

INDEX

AREA

123

-A-

0.05(0.002)

D

SEATING PLANE

e

b

0.10(0.004) C AM BS

M

E1

-B-

A

-C-

0.25(0.010) BM M

E

α

A1

0.10(0.004)

GAUGE

PLANE

0.25

0.010

A2

L

c

NOTES:

1. These package dimensions are within allowable dimensions of

JEDEC MO-153-AC, Issue E.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm

(0.006 inch) per side.

4. Dimension “E1” does not include interlead flash or protrusions. Interlead flash and protrusions shall not exceed 0.15mm (0.006 inch) per

side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. Dimension “b” does not include dambar protrusion. Allowable dambar

protrusion shall be 0.08mm (0.003 inch) total in excess of “b” dimension at maximum material condition. Minimum space between protrusion and adjacent lead is 0.07mm (0.0027 inch).

10. Controlling dimension: MILLIMETER. Converted inch dimensions

are not necessarily exact. (Angles in degrees)

M20.173

20 LEAD THIN SHRINK SMALL OUTLINE PLASTIC

PACKAGE

INCHES MILLIMETERS

SYMBOL

A - 0.047 - 1.20 A1 0.002 0.006 0.05 0.15 A2 0.031 0.051 0.80 1.05 -

b 0.0075 0.0118 0.19 0.30 9

c 0.0035 0.0079 0.09 0.20 -

D 0.252 0.260 6.40 6.60 3

E1 0.169 0.177 4.30 4.50 4

e 0.026 BSC 0.65 BSC -

E 0.246 0.256 6.25 6.50 -

L 0.0177 0.0295 0.45 0.75 6

N20 207

o

α

0

o

8

o

0

o

8

Rev. 1 6/98

NOTESMIN MAX MIN MAX

-

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

9

Loading...

Loading...