®

www.BDTIC.com/Intersil

Dual Digitally Controlled Potentiometer (XDCP™)

ISL22429

Data Sheet September 26, 2006

Low Noise, Low Power, SPI® Bus, 128 T aps,

Wiper Only

The ISL22429 integrates two digitally controlled

potentiometers (DCP) and non-volatile memory on a

monolithic CMOS integrated circuit.

The digitally controlled potentiometers are implemented with

a combination of resistor elements and CMOS switches. The

position of the wipers are controlled by the user through the

SPI serial interface. Each potentiometer has an associated

volatile Wiper Register (WR) and a non-volatile Initial Value

Register (IVR) that can be directly written to and read by the

user. The contents of the WR controls the position of the

wiper. At power-up the device recalls the contents of the

DCP’s IVR to the corresponding WR.

The DCP can be used as a voltage divider in a wide variety

of applications including control, parameter adjustments, AC

measurement and signal processing.

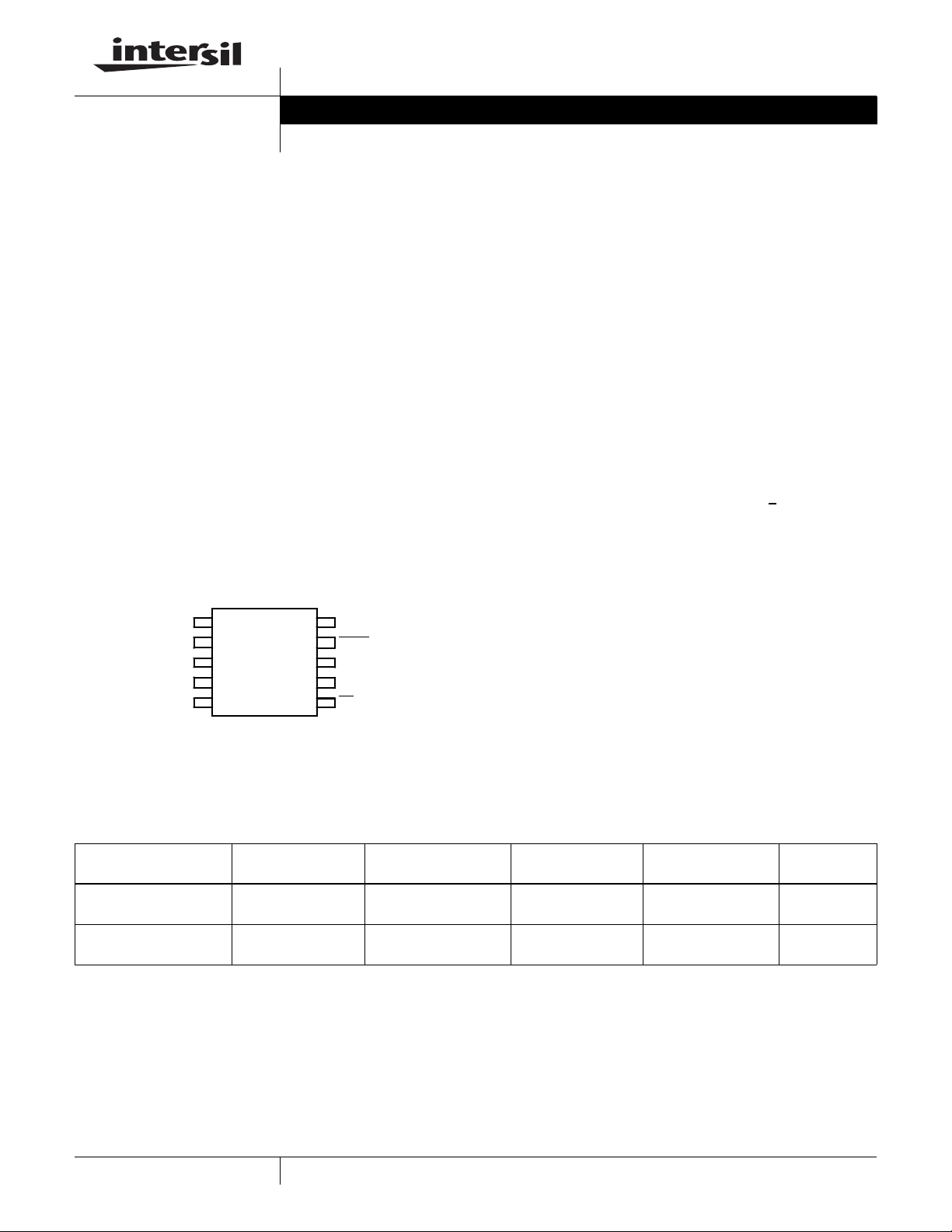

Pinout

ISL22429

(10 LD MSOP)

TOP VIEW

FN6332.1

Features

• Two potentiometers in one package

• 128 resistor taps

• SPI serial interface

• Non-volatile storage of wiper position

• Wiper resistance: 70Ω typical @ 3.3V

• Shutdown mode

• Shutdown current 5µA max

• Power supply: 2.7V to 5.5V

•50kΩ or 10kΩ total resistance

• High reliability

- Endurance: 1,000,000 data changes per bit per register

- Register data retention: 50 years @ T <

• 10 Lead MSOP

• Pb-free plus anneal product (RoHS compliant)

+55°C

RW0NC

10

SHDN

9

V

8

CC

SDI

7

CS

SCK

SDO

GND

RW1

1

2

3

4

56

Ordering Information

RESISTANCE OPTION

PART NUMBER PART MARKING

ISL22429UFU10Z

(Notes 1, 2)

ISL22429WFU10Z

(Notes 1, 2)

NOTES:

1. Intersil Pb-free plus anneal products employ special Pb-free material sets; molding compounds/die attach materials and 100% matte tin plate

termination finish, which are RoHS compliant and compatible with both SnPb and Pb-free soldering operations. Intersil Pb-free products are

MSL classified at Pb-free peak reflow temperatures that meet or exceed the Pb-free requirements of IPC/JEDEC J STD-020.

2. Add “-TK” suffix for 1,000 Tape and Reel option

429UZ 50 -40 to +125 10 Ld MSOP

429WZ 10 -40 to +125 10 Ld MSOP

(kΩ)

TEMP. RANGE

(°C) PACKAGE PKG. DWG. #

M10.118

(Pb-free)

M10.118

(Pb-free)

1

1-888-INTERSIL or 1-888-468-3774

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

| Intersil (and design) and XDCP are registered trademarks of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright Intersil Americas Inc. 2006. All Rights Reserved

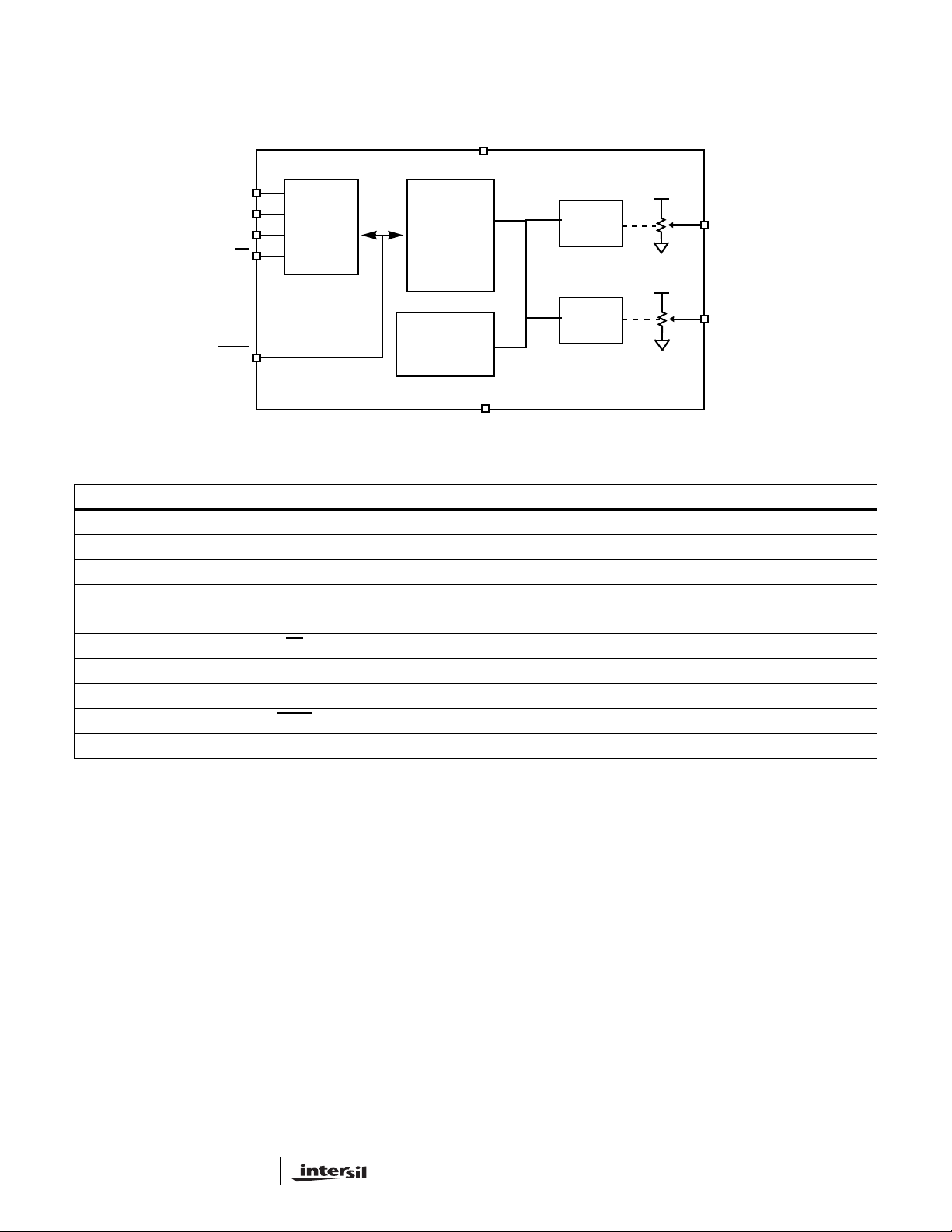

Block Diagram

www.BDTIC.com/Intersil

SCK

SDI

SDO

CS

SPI

INTERFACE

ISL22429

POWER-UP

INTERFACE,

CONTROL

AND STA TUS

LOGIC

V

CC

V

CC

WR1

V

CC

RW1

NON-

VOLATILE

SHDN

REGISTERS

GND

Pin Descriptions

MSOP PIN SYMBOL DESCRIPTION

1NC

2 SCK SPI interface clock input

3 SDO Open drain SPI interface data output

4 GND Device ground pin

5 RW1 “Wiper” terminal of DCP1

6CS

7 SDI SPI interface data input

8V

9SHDN

10 RW0 “Wiper” terminal of DCP0

CC

Chip Select active low input

Power supply pin

Shutdown active low input

WR0

RW0

2

FN6332.1

September 26, 2006

ISL22429

www.BDTIC.com/Intersil

Absolute Maximum Ratings Thermal Information

Storage Temperature. . . . . . . . . . . . . . . . . . . . . . . .-65°C to +150°C

Voltage at any Digital Interface Pin

with Respect to GND . . . . . . . . . . . . . . . . . . . . -0.3V to V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to +6V

V

CC

Voltage at any DCP pin with Respect to GND. . . . . . . -0.3V to V

Lead Temperature (Soldering, 10s) . . . . . . . . . . . . . . . . . . . .+300°C

(10s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±6mA

I

W

Latchup (Note 4) . . . . . . . . . . . . . . . . . .Class II, Level B @ +125°C

ESD (HBM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5kV

(CDM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1kV

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

θ

is measured with the component mounted on a high effective thermal conductivity test board in free air. See Tech Brief TB379 for details.

3.

JA

4. Jedec Class II pulse conditions and failure criterion used. Level B exceptions are: using a max positive pulse of 6.5V on the SHDN pin, and using

a max negative pulse of -0.8V for all pins.

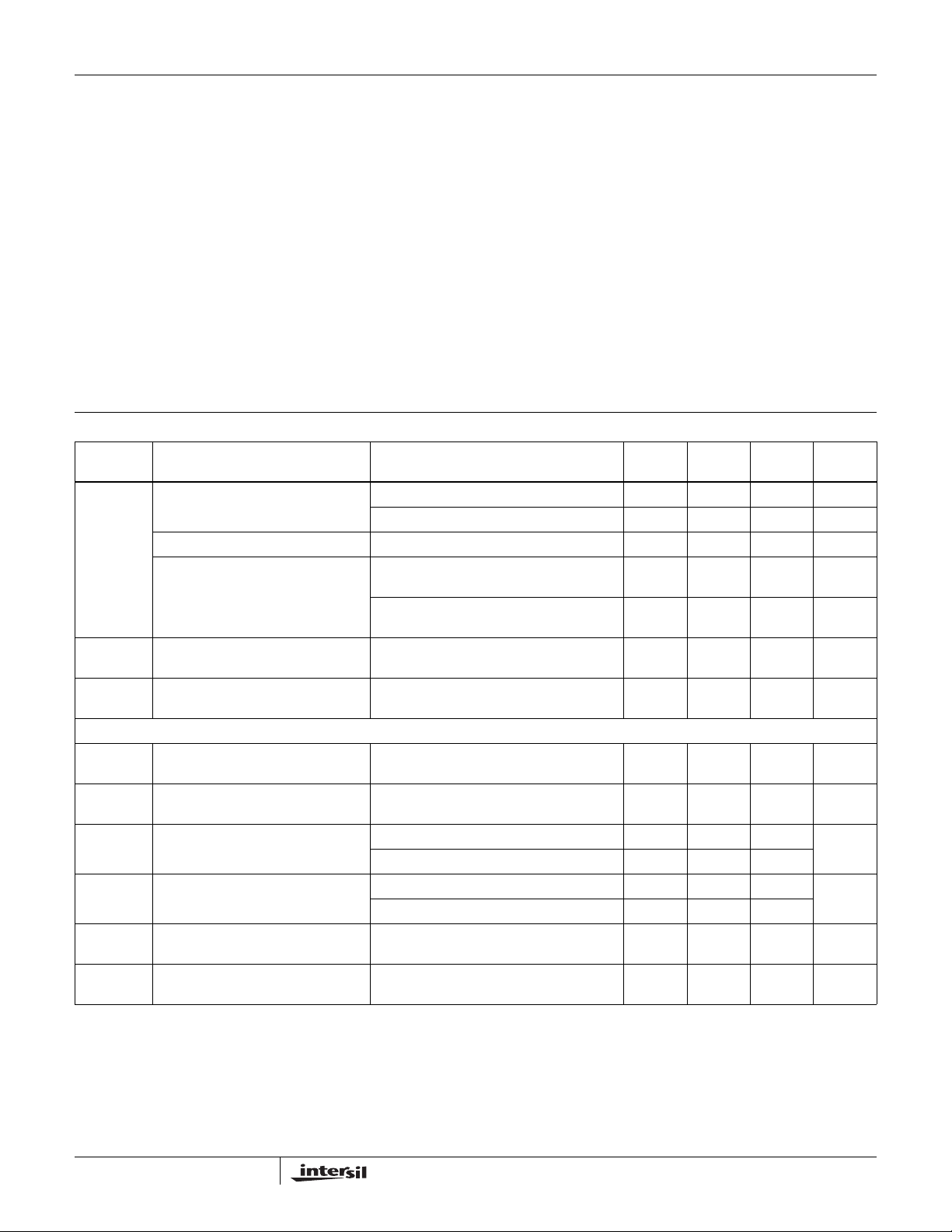

Analog Specifications Over recommended operating conditions unless otherwise stated.

SYMBOL PARAMETER TEST CONDITIONS MIN

R

TOTAL

R

(Note 15)

C

(Note 15)

VOLTAGE DIVIDER MODE (measured at R

INL

(Note 10)

DNL

(Note 9)

ZSerror

(Note 7)

FSerror

(Note 8)

V

MATCH

(Note 11)

TC

(Note 12)

End-to-End Resistance W option 10 kΩ

End-to-End Resistance Tolerance W and U option -20 +20 %

End-to-End Temperature Coefficient W option ±50 ppm/°C

Wiper Resistance V

W

Wiper Capacitance

W

Integral Non-linearity Monotonic over all tap positions -1 1 LSB

Differential Non-linearity Monotonic over all tap positions -0.5 0.5 LSB

Zero-scale Error W option 0 1 5 LSB

Full-scale Error W option -5 -1 0 LSB

DCP to DCP Matching Any two DCPs at the same tap position -2 2 LSB

Ratiometric Temperature Coefficient DCP register set to 40 hex ±4 ppm/°C

V

i, unloaded; i = 0 or 1)

W

+ 0.3

CC

CC

U option 50 kΩ

U option ±80 ppm/°C

= 3.3V @ +25°C,

CC

wiper current = V

U option 0 0.5 2

U option -2 -1 0

Thermal Resistance (Typical, Note 3)

10 Lead MSOP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Maximum Junction Temperature (Plastic Package). . . . . . . .+150°C

Recommended Operating Conditions

Ambient Temperature . . . . . . . . . . . . . . . . . . . . . . .-40°C to +125°C

Voltage for DCP Operation . . . . . . . . . . . . . . . . . . 2.7V to 5.5V

V

CC

Wiper Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -3mA to 3mA

Power Rating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5mW

TYP

(NOTE 5) MAX UNIT

70 Ω

CC/RTOTAL

25 pF

θ

(°C/W)

JA

(Note 15)

(Note 15)

(Note 6)

(Note 6)

(Note 6)

(Note 6)

(Note 6)

3

FN6332.1

September 26, 2006

ISL22429

www.BDTIC.com/Intersil

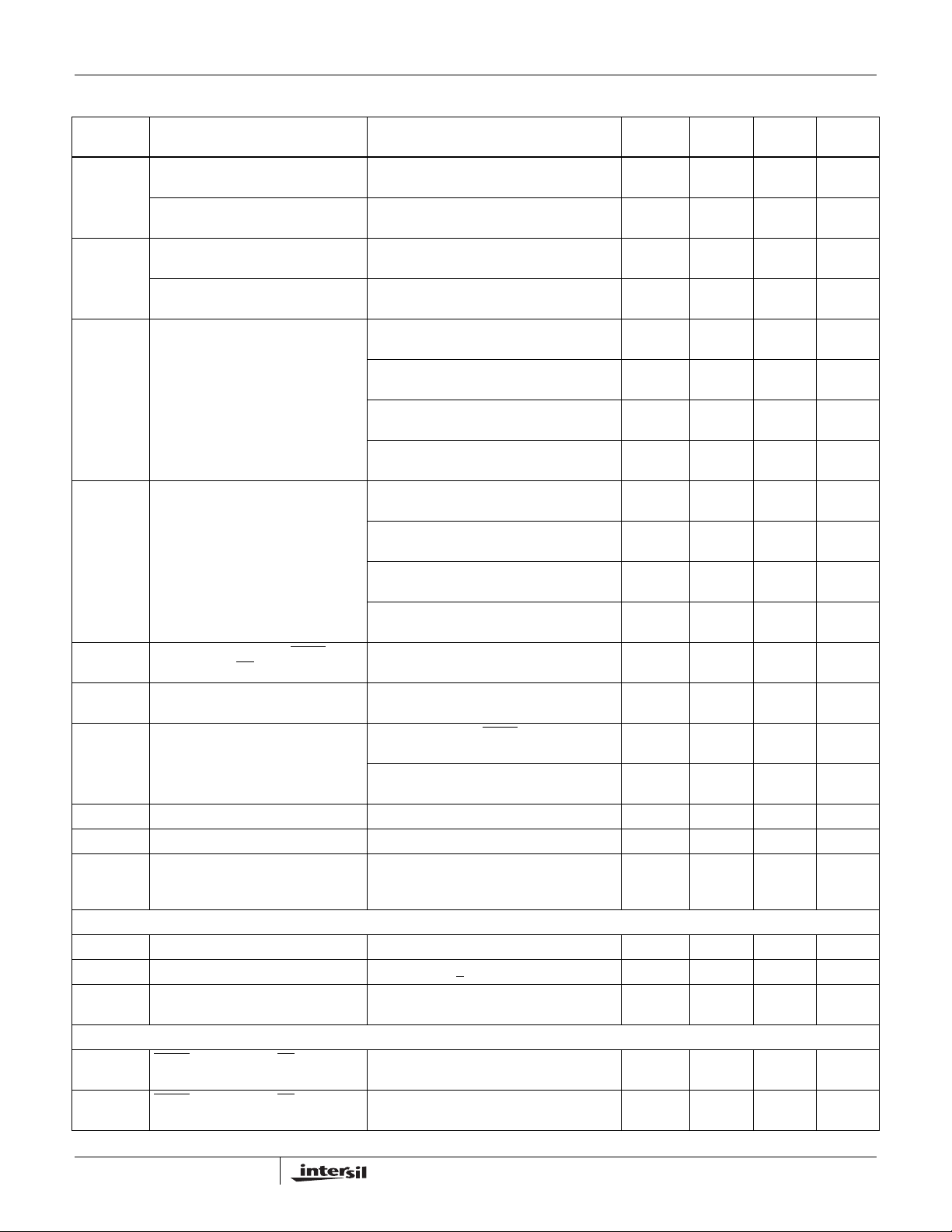

Operating Specifications Over the recommended operating conditions unless otherwise specified.

SYMBOL PARAMETER TEST CONDITIONS MIN

I

CC1

I

CC2

I

SB

I

SD

I

LkgDig

t

WRT

(Note 15)

t

ShdnRec

(Note 15)

Vpor Power-on Recall Voltage Minimum V

VccRamp V

t

EEPROM SPECIFICATION

t

WC

(Note 13)

SERIAL INTERFACE SPECIFICATIONS

V

V

VCC Supply Current (volatile

write/read)

V

Supply Current (volatile

CC

write/read)

VCC Supply Current (non-volatile

write/read)

Supply Current (non-volatile

V

CC

write/read)

VCC Current (standby) V

VCC Current (shutdown) V

Leakage Current, at Pins SHDN, SCK,

SDI, SDO and CS

Wiper Response Time after SPI Write

to WR Register

DCP Recall Time from Shutdown

Mode

Ramp Rate 0.2 V/ms

CC

Power-up delay VCC above Vpor, to DCP Initial Value

D

EEPROM Endurance 1,000,000 Cycles

EEPROM Retention Temperature T <

Non-volatile Write Cycle Time 12 20 ms

SHDN, SCK, SDI, and CS Input Buffer

IL

LOW Voltage

SHDN, SCK, SDI, and CS Input Buffer

IH

HIGH Voltage

10k DCP, f

and write states)

50k DCP, f

and write states)

10k DCP, f

and write states)

50k DCP, f

and write states)

= +5.5V, 10k DCP, SPI interface in

CC

standby state

= +5.5V, 50k DCP, SPI interface in

V

CC

standby state

= +3.6V, 10k DCP, SPI interface in

V

CC

standby state

V

= +3.6V, 50k DCP, SPI interface in

CC

standby state

= +5.5V @ +85°C, SPI interface in

CC

standby state

V

= +5.5V@ +125°C, SPI interface in

CC

standby state

= +3.6V @ +85°C, SPI interface in

V

CC

standby state

= +3.6V @ +125°C, SPI interface in

V

CC

standby state

Voltage at pin from GND to V

From rising edge of SHDN

stored position and RH connection

SCK rising edge of last bit of ACR data byte

to wiper stored position and RH connection

Register recall completed, and SPI Interface

in standby state

= 5MHz; (for SPI active, read

SPI

= 5MHz; (for SPI active, read

SPI

= 5MHz; (for SPI active, read

SPI

= 5MHz; (for SPI active, read

SPI

CC

signal to wiper

at which memory recall occurs 2.0 2.6 V

CC

+55°C 50 Years

-1 1 µA

-0.3 0.3*V

0.7*V

TYP

(NOTE 5) MAX UNIT

1.4 mA

450 µA

3.5 mA

2.0 mA

1.22 mA

320 µA

800 µA

250 µA

3µA

5µA

2µA

4µA

1.5 µs

1.5 µs

1.5 µs

3ms

CC

VCC+0.3 V

CC

V

4

FN6332.1

September 26, 2006

ISL22429

www.BDTIC.com/Intersil

Operating Specifications Over the recommended operating conditions unless otherwise specified. (Continued)

SYMBOL PARAMETER TEST CONDITIONS MIN

Hysteresis SHDN, SCK, SDI, and CS Input Buffer

Hysteresis

V

R

SDO Output Buffer LOW Voltage IOL = 4mA 0 0.4 V

OL

SDO Pull-up Resistor Off-chip Maximum is determined by t

pu

(Note 14)

Cpin

(Note 15)

f

SCK

t

CYC

t

WH

t

WL

t

LEAD

t

LAG

t

SU

t

t

t

t

DIS

t

t

HO

t

RO

t

FO

t

CS

SHDN

, SCK, SDI, SDO and CS Pin

Capacitance

SPI Frequency 5MHz

SPI Clock Cycle Time 200 ns

SPI Clock High Time 100 ns

SPI Clock Low Time 100 ns

Lead Time 250 ns

Lag Time 250 ns

SDI, SCK and CS Input Setup Time 50 ns

SDI, SCK and CS Input Hold Time 50 ns

H

SDI, SCK and CS Input Rise Time 10 ns

RI

SDI, SCK and CS Input Fall Time 10 20 ns

FI

SDO Output Disable Time 0 100 ns

SDO Output Valid Time 350 ns

V

SDO Output Hold Time 0 ns

SDO Output Rise Time Rpu = 2k, Cbus = 30pF 60 ns

SDO Output Fall Time Rpu = 2k, Cbus = 30pF 60 ns

CS Deselect Time 2µs

and tFO with

RO

maximum bus load Cbus = 30pF, f

5MHz

SCK

=

0.05*

V

CC

NOTES:

5. Typical values are for T

6. LSB: [V(R

incremental voltage when changing from one tap to an adjacent tap.

– V(RW)0]/127. V(RW)

W)127

7. ZS error = V(RW)

8. FS error = [V(RW)

9. DNL = [V(RW)

10. INL = [V(RW)

11. V

MATCH

12. for i = 16 to 112 decimal, T = -40°C to +125°C. Max( ) is the maximum value of the wiper

TC

V

is the time from the end of a Write sequence of SPI serial interface, to the end of the self-timed internal non-volatile write cycle.

13. t

WC

– V(RW)

i

– i • LSB – V(RW)]/LSB for i = 1 to 127

i

= [V(RWx)i – V(RWy)i]/LSB, for i = 1 to 127, x = 0 to 3 and y = 0 to 3.

Max V RW()

()Min V RW()

----------------------------------------------------------------------------------------------

Max V RW()

()Min V RW()

= +25°C and 3.3V supply voltage.

A

and V(RW)0 are V(RW) for the DCP register set to 7F hex and 00 hex respectively. LSB is the

127

/LSB.

0

– VCC]/LSB.

127

]/LSB-1, for i = 1 to 127. i is the DCP register setting.

i-1

()–

i

i

()+[]2⁄

i

i

---------------- -

×=

165°C

6

10

voltage and Min ( ) is the minimum value of the wiper voltage over the temperature range.

14. Rpu is specified for the highest data rate transfer for the device. Higher value pull-up can be used at lower data rates.

15. This parameter is not 100% tested.

TYP

(NOTE 5) MAX UNIT

V

2kΩ

10 pF

5

FN6332.1

September 26, 2006

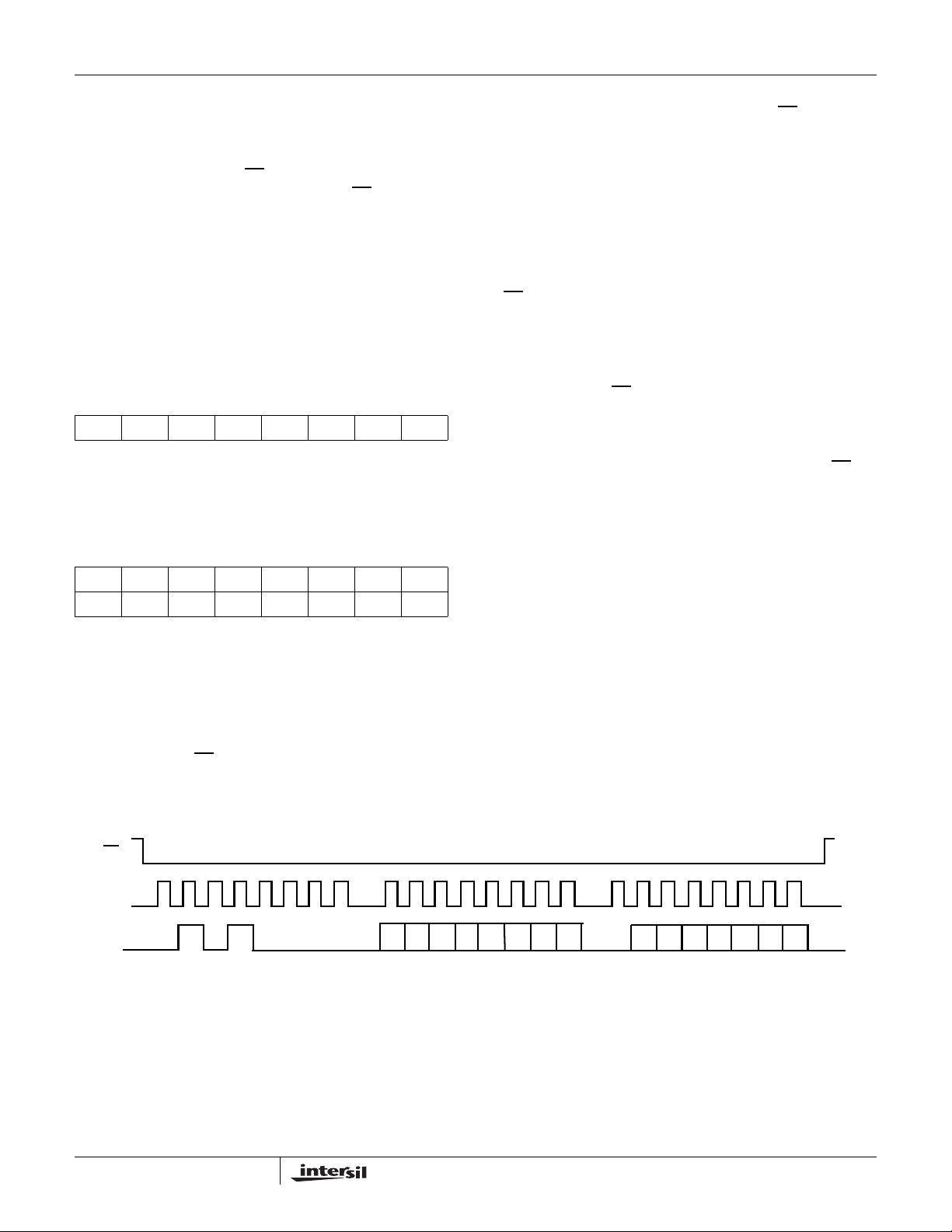

Timing Diagrams

www.BDTIC.com/Intersil

Input Timing

CS

t

LEAD

ISL22429

t

CYC

t

CS

t

LAG

SCK

SDI

SDO

Output Timing

CS

SCK

SDO

SDI

t

SU

MSB LSB

HIGH IMPEDANCE

ADDR

t

H

t

WL

t

WH

...

t

FI

t

RI

...

...

t

V

MSB LSB

t

HO

...

t

DIS

XDCP Timing (for All Load Instructions)

CS

SCK

SDI

V

SDO

W

HIGH IMPEDANCE

MSB LSB

6

...

...

t

WRT

FN6332.1

September 26, 2006

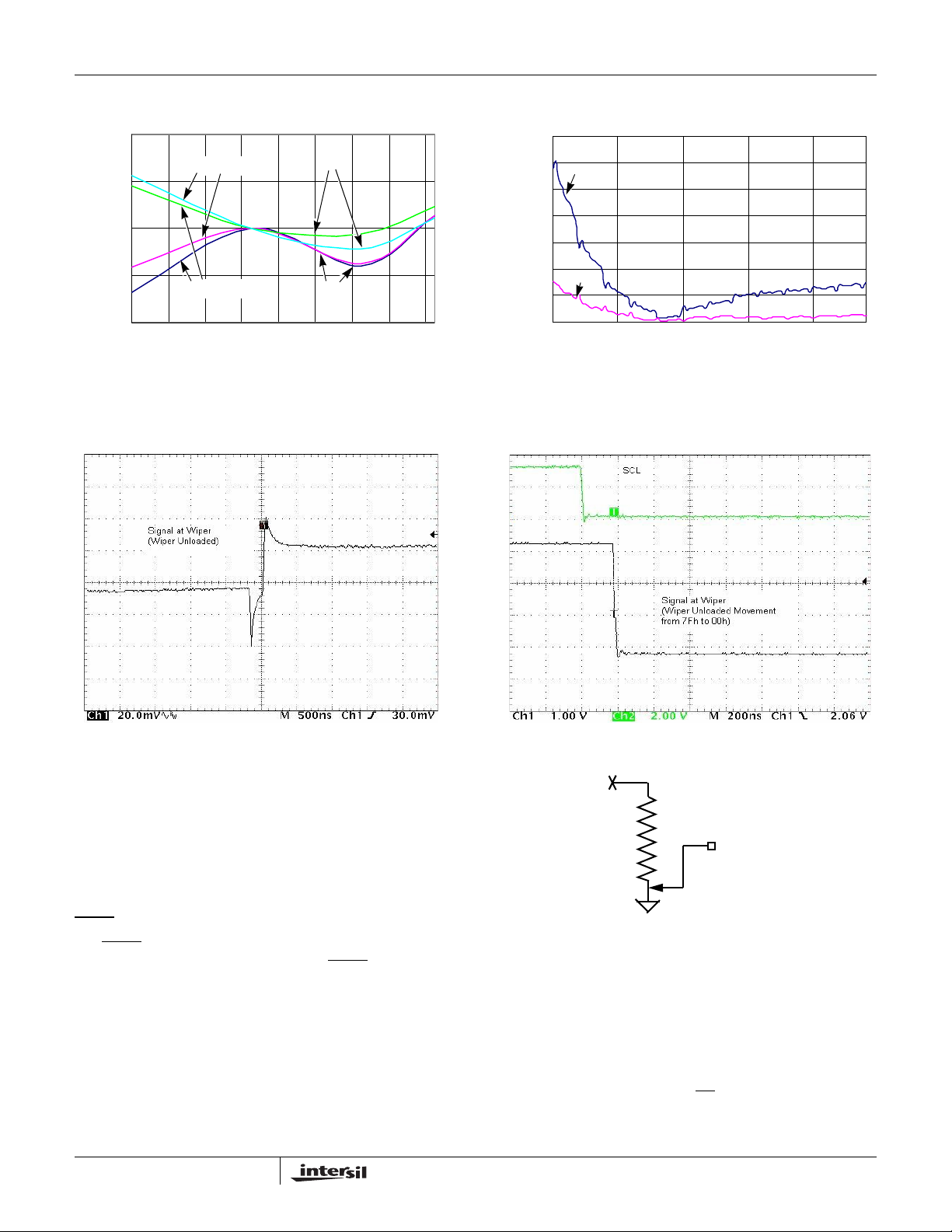

Typical Performance Curves

www.BDTIC.com/Intersil

VCC

100

Vcc = 3.3V, T = 125ºC

90

80

70

60

50

40

30

Vcc = 3.3V, T = 20ºC

WIPER RESISITANCE (Ω)

20

10

0

0 20406080100120

TAP PO SITI ON ( D E C I MAL )

Vcc = 3.3V, T = -40ºC

ISL22429

1.4

1.2

1

VCC

0.8

0.6

Isb (µA)

0.4

0.2

0

2.73.23.74.24.75.2

T = 1 25

T = 25

ºC

ºC

Vcc, V

FIGURE 1. WIPER RESISTANCE vs T AP POSITION

[ I(RW) = V

CC/RTOTAL

] FOR 10kΩ (W)

0.2

Vcc = 2.7V

T = 25ºC

0.1

0

DNL (LSB)

-0. 1

Vcc = 5.5V

-0. 2

0 20 40 60 80 100 120

TAP PO S ITI O N ( DE C I MAL )

FIGURE 3. DNL vs TAP POSITION IN VOLTAGE DIVIDER

1.30

MODE FOR 10kΩ (W)

10k

1.10

0.90

0.70

0.50

0.30

ZSerror (LSB)

Vcc = 5.5V

Vcc = 2.7V

0.10

-0.10

50k

-0.30

-40 -20 0 20 40 60 80 100 120

TEMPERATURE (ºC)

FIGURE 2. STANDBY I

CC

vs V

CC

0.2

T = 25º C

0.1

Vcc = 2.7V

0

INL (LSB)

-0.1

Vcc = 5.5V

-0.2

0 20406080100120

TAP PO SI TIO N (D ECI MAL )

FIGURE 4. INL vs TAP POSITION IN VOL TAGE DIVIDER

MODE FOR 10kΩ (W)

0.00

-0. 30

Vcc = 2.7V Vcc = 5.5V

50k

-0. 60

-0. 90

FSerror (LSB)

10k

-1. 20

-1. 50

-40-200 20406080100120

TEMPERATURE (ºC)

FIGURE 5. ZSerror vs TEMPERATURE

FIGURE 6. FSerror vs TEMPERATURE

7

FN6332.1

September 26, 2006

Typical Performance Curves (Continued)

www.BDTIC.com/Intersil

ISL22429

1.00

Vcc = 2.7V

0.50

CHANGE (%)

0.00

TOTAL

-0.50

END TO END R

-1.00

-40 -20 0 20 40 60 80 100 120

FIGURE 7. END TO END R

Vcc = 5.5V

TEMPERATURE (º C)

TOTAL

TEMPERATURE

50k

10k

% CHANGE vs

105

90

10k

75

60

45

TCv (ppm/°C)

30

50k

15

0

16 36 56 76 96

TAP PO SI T IO N ( D ECIMAL)

FIGURE 8. TC FOR VOLTAGE DIVIDER MODE IN ppm

FIGURE 9. MIDSCALE GLITCH, CODE 80h TO 7Fh

Pin Description

Potentiometer Pins

RWi (i = 0, 1)

RWi is the wiper terminal and is equivalent to the movable

terminal of a mechanical potentiometer. The position of the

wiper within the array is determined by the WRi register.

SHDN

The SHDN pin forces the resistors to end-to-end open circuit

condition and shorts RWi to GND. When SHDN

to logic high, the previous latch settings put RWi at the same

resistance setting prior to shutdown. This pin is logically

OR’d with SHDN bit in ACR register. SPI interface is still

available in shutdown mode and all registers are accessible.

This pin must remain HIGH for normal operation.

8

is returned

FIGURE 10. LARGE SIGNAL SETTLING TIME

RW

FIGURE 11. DCP CONNECTION IN SHUTDOWN MODE

Bus Interface Pins

Serial Clock (SCK)

This is the serial clock input of the SPI serial interface.

Serial Data Output (SDO)

The SDO is an open drain serial data output pin. During a

read cycle, the data bits are shifted out at the falling edge of

the serial clock SCK, while the CS

input is low.

FN6332.1

September 26, 2006

ISL22429

www.BDTIC.com/Intersil

SDO requires an external pull-up resistor for proper

operation.

Serial Data Input (SDI)

The SDI is the serial data input pin for the SPI interface. It

receives device address, operation code, wiper address and

data from the SPI external host device. The data bits are

shifted in at the rising edge of the serial clock SCK, while the

CS

input is low.

Chip Select (CS)

LOW enables the ISL22429, placing it in the active

CS

power mode. A HIGH to LOW transition on CS is required

prior to the start of any operation after power up. When CS

is

HIGH, the ISL22429 is deselected and the SDO pin is at

high impedance, and (unless an internal write cycle is

underway) the device will be in the standby state.

Principles of Operation

The ISL22429 is an integrated circuit incorporating two DCPs

with its associated registers, non-volatile memory and the SPI

serial interface providing direct communication between host

and potentiometers and memory. The resistor array is

comprised of individual resistors connected in se ries. At either

end of the array and between each resistor is an electronic

switch that transfers the potential at that point to the wiper.

The electronic switches on the device operate in a “make

before break” mode when the wiper changes tap positions.

memory reading, all WRs will be reload with the value stored

in corresponding non-volatile Initial Value Registers (IVRs).

The SPI interface register address bits have to be set to

0000b or 0001b to access the WR of DCP0 or DCP1

respectively. The WRi and IVRi can be read or written to

directly using the SPI serial interface as described in the

following sections.

Memory Description

The ISL22429 contains seven non-volatile and three volatile

8-bit registers. The memory map of ISL22429 is on Table 1.

The two non-volatile registers (IVRi) at address 0 and 1,

contain initial wiper value and volatile registers (WRi) contain

current wiper position. In addition, five non-volatile General

Purpose registers from address 2 to address 6 are available.

TABLE 1. MEMORY MAP

ADDRESS NON-VOLATILE VOLATILE

8— ACR

7 Reserved

6

5

4

3

2

1

0

General Purpose

General Purpose

General Purpose

General Purpose

General Purpose

IVR1

IVR0

Not Available

Not Available

Not Available

Not Available

Not Available

WR1

WR0

When the device is powered down, the last value stored in

IVRi will be maintained in the non-volatile memory. When

power is restored, the contents of the IVRi is recalled and

loaded into the corresponding WRi to set the wiper to the

initial value.

DCP Description

Each DCP is implemented with a combination of resistor

elements and CMOS switches. The physical ends of each

DCP are equivalent to the fixed terminals of a mechanical

potentiometer and internally connected to Vcc and GND.

The RW pin of each DCP is connected to intermediate

nodes, and is equivalent to the wiper terminal of a

mechanical potentiometer. The position of the wiper terminal

within the DCP is controlled by volatile Wiper Register (WR).

Each DCP has its own WR. When the WR of a DCP contains

all zeroes (WR[6:0] = 00h), its wiper terminal (RW) is closest

to GND. When the WR register of a DCP contains all ones

(WR[6:0] = 7Fh), its wiper terminal (RW) is closest to V

As the value of the WR increases from all zeroes (0) to all

ones (127 decimal), the wiper moves monotonically from the

position closest to GND to the closest to V

CC

.

While the ISL22429 is being powered up, all two WRs are

reset to 40h (64 decimal), which locates RW roughly at the

center between GND and Vcc. After the power supply

voltage becomes large enough for reliable non-volatile

CC

.

The non-volatile IVRi and volatile WRi registers are

accessible with the same address.

The Access Control Register (ACR) contains information

and control bits described below in Table 2.

The VOL bit (ACR[7]) determines whether the access is to

wiper registers WRi or initial value registers IVRi.

TABLE 2. ACCESS CONTROL REGISTER (ACR)

BIT #76543210

Bit Name VOL SHDN WIP

00000

If VOL bit is 0, the non-volatile IVRi register is accessible. If

VOL bit is 1, only the volatile WRi is accessible. Note, value

is written to IVRi register also is written to the WRi. The

default value of this bit is 0.

The SHDN bit (ACR[6]) disables or enables Shutdown

mode. This bit is logically OR’d with SHDN

pin. When this bit

is 0, DCPs are in Shutdown mode. The default value of

SHDN bit is 1.

The WIP bit (ACR[5]) is read only bit. It indicates that

non-volatile write operation is in progress. The WIP bit can

be read repeatedly after a non-volatile write to determine if

the write has been completed. It is impossible to write to the

IVRi, WRi or ACR while WIP bit is 1.

9

FN6332.1

September 26, 2006

ISL22429

www.BDTIC.com/Intersil

SPI Serial Interface

The ISL22429 supports an SPI serial protocol, mode 0. The

device is accessed via the SDI input and SDO output with

data clocked in on the rising edge of SCK, and clocked out

on the falling edge of SCK. CS

communication with the ISL22429. SCK and CS

controlled by the host or master. The ISL22429 operates

only as a slave device.

All communication over the SPI interface is conducted by

sending the MSB of each byte of data first.

must be LOW during

lines are

Protocol Conventions

The first byte sent to the ISL22429 from the SPI host is the

Identification Byte. A valid Identification Byte contains 0101

as the four MSBs, with the following four bits set to 0.

TABLE 3. IDENTIFICATION BYTE FORMAT

01010000

(MSB) (LSB)

The next byte sent to the ISL22429 contains the instruction

and register pointer information. The four MSBs are the

instruction and four LSBs are register address (see Table 4).

TABLE 4. IDENTIFICATION BYTE FORMAT

76543210

I3 I2 I1 I0 R3 R2 R1 R0

There are only two valid instruction sets:

1011(binary) - is a Read operation

11 00(binary) - is a Write operation

Write Operation

A Write operation to the ISL22429 is a three-byte operation.

It requires first, the CS transition from HIGH to LOW, then a

valid Identification Byte, then a valid instruction byte

following by Data Byte is sent to SDI pin. The host

terminates the write operation by pulling the CS

LOW to HIGH. For a write to addresses 0000b or 0001b, the

MSB at address 8 (ACR[7]) determines if the Data Byte is to

be written to volatile or both volatile and non-volatile

registers. Refer to “Memory Description” and Figure 12.

Device can receive more than one byte of data by auto

incrementing the address after each received byte. Note

after reaching the address 0110b, the internal pointer “rolls

over” to address 0000b.

The internal non-volatile write cycle starts after rising edge of

and takes up to 20ms. Thus, non-volatile registers must

CS

be written individually.

pin from

Read Operation

A read operation to the ISL22429 is a three-byte operation. It

requires first, the CS

valid Identification Byte, then a valid instruction byte

following by “dummy” Data Byte is sent to SDI pin. The SPI

host reads the data from SDO pin on falling edge of SCK.

The host terminates the read operation by pulling the CS

from LOW to HIGH (see Figure 13).

The ISL22429 will provide the Data Bytes to the SDO pin as

long as SCK is provided by the host from the registers

indicated by an internal pointer. This pointer initial value is

determined by the register address in the Read operation

instruction, and increments by one during transmission of

each Data Byte. After reaching the memory location 0110b,

the pointer “rolls over” to 0000b, and the device continues to

output the data for each received SCK clock.

In order to read back the non-volatile IVR, it is recommended

that the application reads the ACR first to verify the WIP bit

is 0. If the WIP bit (ACR[5]) is not 0, the host should repeat

its reading sequence again.

transition from HIGH to LOW, then a

pin

CS

SCK

SDI

0 1 0 1 0 0 I3 I2 I1 I0 R3 R2 R1 R0

00

10

0

FIGURE 12. THREE BYTE WRITE SEQUENCE

0 D6D5D4 D3D2 D1D0

September 26, 2006

FN6332.1

CS

y

xxxxxxx

x

A

T

www.BDTIC.com/Intersil

SCK

ISL22429

SDI

0 101 00 I3 I2 I1 I0 R3 R2 R1 R0

SDO

Applications Information

00

0

FIGURE 13. THREE BYTE READ SEQUENCE

any non-volatile memory changes. This is done by setting

MSB bit at address 1000b to 1.

Communicating with ISL22429

Communication with ISL22429 proceeds using SPI interface

through the ACR (address 1000b), IVRi (addresses 0000b,

0001b) and WRi (addresses 0000b, 0001b) registers.

The wiper of the potentiometer is controlled by the WRi

register. Writes and reads can be made directly to these

registers to control and monitor the wiper position without

The non-volatile IVRi stores the power up value of the wiper.

IVRs are accessible when MSB bit at address 1000b is set

to 0. Writing a new value to the IVRi register will set a new

power up position for the wiper. Also, writing to this register

will load the same value into the corresponding WRi as the

IVRi. Reading from the IVRi will not change the WRi, if its

contents are different.

Examples:

B. Reading from the WR:

This sequence will read the value from the WR1 (volatile):

Write to ACR first to access the volatile WRs

Send the ID byte, Instruction Byte, then the Data byte

0 1 0 1 0 0 0 0 1 1 0 0 1 0 0 0 1 1 0 0 0 0 0 0

(Sent to SDI)

Read the data from WR1 (Addr 0001b)

Send the ID b

0 1 0 1 0 0 0 0 1 0 1 1 0 0 0 1

te, Instruction Byte, then Read the Data byte

(Out on SDO)

Don’t Care

0 D6D5D4 D3 D2 D1D0

. Writing to the IVR:

his sequence will write a new value (77h) to the IVR0(non-volatile):

Set the ACR (Addr 1000b) for NV write (40h)

Send the ID byte, Instruction Byte, then the Data byte

0 1 0 1 0 0 0 0 1 1 0 0 1 00001000000

(Sent to SDI)

Set the IVR0 (Addr 0000b) to 77h

Send the ID byte, Instruction Byte, then the Data byte

0 1 0 1 0 0 0 0 1 1 0 0 0 00001110111

(Sent to SDI)

11

FN6332.1

September 26, 2006

ISL22429

www.BDTIC.com/Intersil

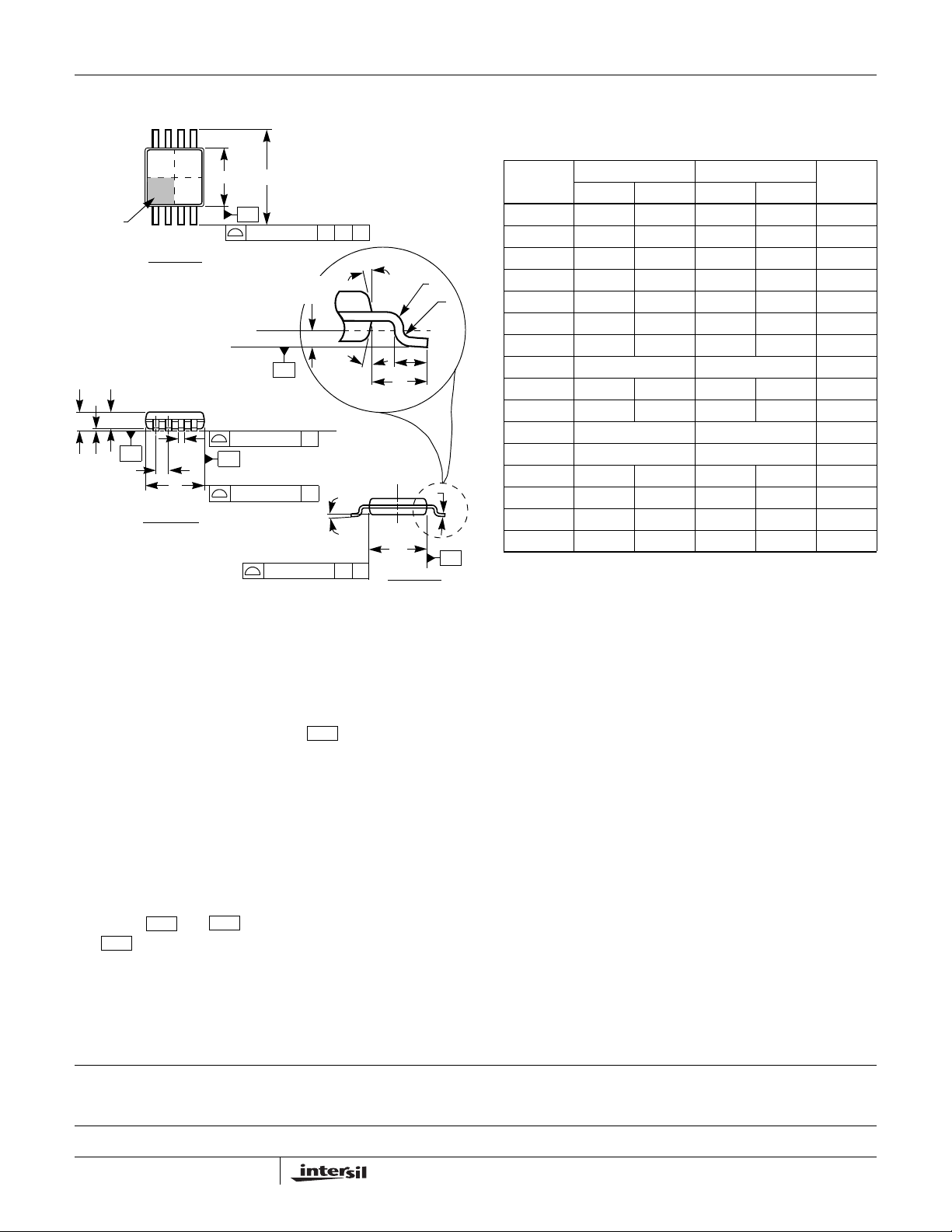

Mini Small Outline Plastic Packages (MSOP)

N

EE1

INDEX

AREA

AA1A2

-H-

SIDE VIEW

12

TOP VIEW

b

e

D

NOTES:

1. These package dimensions are within allowable dimensions of

JEDEC MO-187BA.

2. Dimensioning and tolerancing per ANSI Y14.5M-1994.

3. Dimension “D” does not include mold flash, protrusions or gate

burrs and are measured at Datum Plane. Mold flash, protrusion

and gate burrs shall not exceed 0.15mm (0.006 inch) per side.

4. Dimension “E1” does not include interlead flash or protrusions

and are measured at Datum Plane. Interlead flash and

protrusions shall not exceed 0.15mm (0.006 inch) per side.

5. Formed leads shall be planar with respect to one another within

0.10mm (.004) at seating Plane.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. Dimension “b” does not include dambar protrusion. Allowable

dambar protrusion shall be 0.08mm (0.003 inch) total in excess

of “b” dimension at maximum material condition. Minimum space

between protrusion and adjacent lead is 0.07mm (0.0027 inch).

- H -

-A -

.

10. Datums and to be determined at Datum plane

11. Controlling dimension: MILLIMETER. Converted inch dimensions are for reference only

-B-

0.20 (0.008) A

GAUGE

PLANE

SEATING

PLANE

0.10 (0.004) C

-A-

0.20 (0.008) C

- B -

0.25

(0.010)

-C-

SEATING

PLANE

a

0.20 (0.008) C

- H -

B

4X θ

C

D

4X θ

L1

C

C

L

E

1

END VIEW

R1

R

L

-B-

M10.118 (JEDEC MO-187BA)

10 LEAD MINI SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.037 0.043 0.94 1.10 -

A1 0.002 0.006 0.05 0.15 -

A2 0.030 0.037 0.75 0.95 -

b 0.007 0.011 0.18 0.27 9

c 0.004 0.008 0.09 0.20 -

D 0.116 0.120 2.95 3.05 3

E1 0.116 0.120 2.95 3.05 4

e 0.020 BSC 0.50 BSC -

E 0.187 0.199 4.75 5.05 -

L 0.016 0.028 0.40 0.70 6

L1 0.037 REF 0.95 REF -

N10 107

R 0.003 - 0.07 - -

R1 0.003 - 0.07 - -

o

θ

α

5

o

0

15

o

o

6

o

5

o

0

15

o

o

6

Rev. 0 12/02

NOTESMIN MAX MIN MAX

-

-

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implic atio n or other wise u nde r any p a tent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

12

FN6332.1

September 26, 2006

Loading...

Loading...