®

ISL21400

Data Sheet April 24, 2007

Programmable Temperature Slope

Voltage Reference

The ISL21400 features a precision voltage reference

combined with a temperature sensor whose output voltage

varies linearly with temperature. The precision 1.20V

reference has a very low temperature coefficient (tempco),

and its output voltage is scaled by an internal DAC (V

REF

) to

produce a temperature stable output voltage that is

programmable from 0V to 1.20V. The output voltage from the

temperature sensor (V

) is summed with V

TS

to produce

REF

a temperature dependent output voltage.

The slope of the V

portion of the output voltage can be

TS

programmed to be positive or negative in the range

-2.1mV/°C to +2.1mV/°C. A programmable gain amplifier

(PGA) sums the V

and the V

TS

voltages and provides

REF

gains of 1x, 2x, and 4x to scale the output up to 4.8V and the

slope to ±8.4mV/°C.

The V

resolution via an I

non-volatile registers. The PGA gain is also set via the I

REF

and V

terms are programmable with 8 bits of

TS

2

C bus and the values are stored in

2

C

bus and the value is stored in a non-volatile register.

Non-volatile memory storage assures the programmed

settings are retained on power-down, eliminating the need

for software initialization at device power-up.

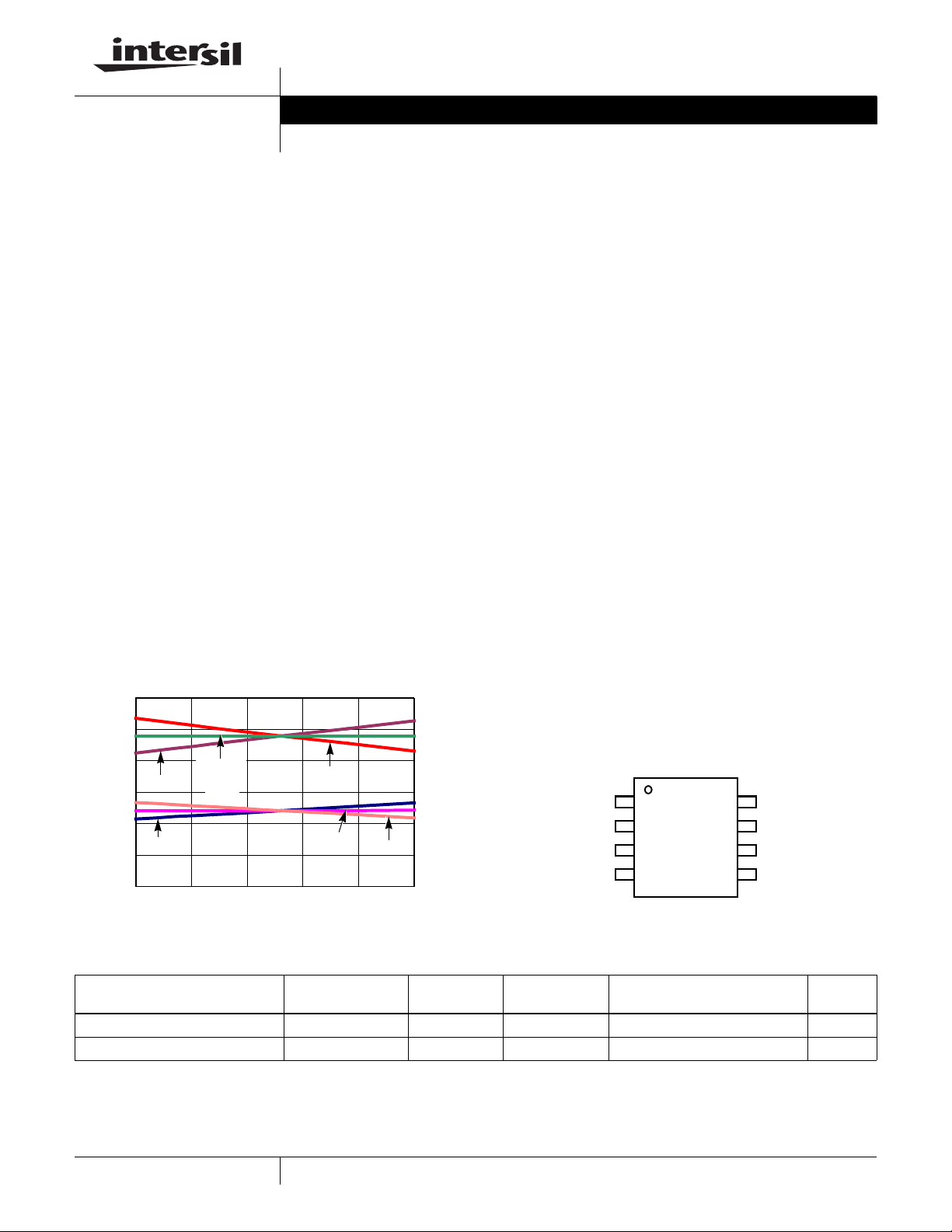

Temperature Characteristics Curve

3.0

2.5

2.0

TS = 0

1.5

VREF (V)

1.0

TS = 0

0.5

0.0

-40 -15 10 35 60 85

AV = 2

TS = 127

= 1

A

V

TEMPERATURE (°C)

TS = 255

TS = 255

TS = 127

FN8091.1

Features

• Programmable reference voltage

• Programmable temperature slope

• Programmable Gain Amplifier

• Non-volatile storage of programming registers

•I2C serial interface

• 2% total accuracy over temperature and V

CC

range

• 200µA typical active supply current

• Operating temperature range = -40°C to +85°C

• 8 Ld MSOP package

• Pb-free plus anneal available (RoHS compliant)

Applications

• RF power amplifier bias compensation

• LCD bias compensation

• Laser diode bias compensation

• Sensor bias and linearization

• Data acquisition systems

• Variable DAC reference

• Amplifier biasing

Pinout

ISL21400

(8 LD MSOP)

TOP VIEW

A2

V

A1

A0

SS

1

2

3

4

V

CC

8

V

7

OUT

6

SDA

SCL

5

Ordering Information

RANGE

V

DD

PART NUMBER (Note) PART MARKING

ISL21400IU8Z DEW 2.7 to 5.5 -40 to +85 8 Ld MSOP (3.0mm), green mtl M8.118

ISL21400IU8Z-TK DEW 2.7 to 5.5 -40 to +85 8 Ld MSOP (3.0mm), green mtl M8.118

NOTE: Intersil Pb-free products employ special Pb-free ma terial sets; molding compou nds/die att ach materials an d 100% matte tin plate termination

finish, which are RoHS compliant and compatible with both SnPb and Pb-free soldering operations. Intersil Pb-free products are MSL classified at

Pb-free peak reflow temperatures that meet or exceed the Pb-free requirements of IPC/JEDEC J STD-020.

1

(V)

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

TEMP RANGE

(°C)

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright Intersil Americas Inc. 2006, 2007. All Rights Reserved

All other trademarks mentioned are the property of their respective owners.

PACKAGE

(Pb-free)

PKG.

DWG. #

ISL21400

Pin Description

MSOP SYMBOL DESCRIPTION

1 A2 Hardwire slave address pin for I

2 A1 Hardwire slave address pin for I

3 A0 Hardwire slave address pin for I

4V

SS

Ground pin

2

C serial bus

2

C serial bus

2

C serial bus

5 SCL Serial bus clock input

6 SDA Serial bus data input/output

7 VOUT Output voltage

8V

CC

Device power supply

Block Diagram

VCC

TEMP

SENSE

V

BIAS

n = 0 to 255

m = 0 to 255

REF

V

V

REF

(n)

TS

DAC

(m)

DAC

EEPROM

5 BYTES

VSS

S

COMMUNICATIONS

A

AND

REGISTERS

A0 A1 A2

GAIN

SELECT

AV = 1, 2, 4

V

OUT

SCL

SDA

2

FN8091.1

April 24, 2007

ISL21400

Absolute Maximum Ratings Thermal Information

Supply Voltage Range. . . . . . . . . . . . . . . . . . . . . . . . . . .-1V to 6.5V

Storage Temperature Range . . . . . . . . . . . . . . . . . .-65°C to +150°C

Voltage on V

Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0V to V

OUT

CC

Voltage on All Other Pins . . . . . . . . . . . . . . . . . .-0.3V to VCC+0.3V

Lead Temperature (Soldering, 10s) . . . . . . . . . . . . . . . . . . . .+300°C

ESD Rating

Human Body Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2kV

Machine Model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200V

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

Thermal Resistance (Typical) θ

(°C/ W)

JA

8 Ld MSOP Package . . . . . . . . . . . . . . . . . . . . . . . . 130

Moisture Sensitivity for MSOP Package

(See Technical Brief TB363) . . . . . . . . . . . . . . . . . . . . . . . Level 2

Maximum Junction Temperature (Plastic Package). . . . . . . .+150°C

Pb-free reflow profile . . . . . . . . . . . . . . . . . . . . . . . . . .see link below

http://www.intersil.com/pbfree/Pb-FreeReflow.asp

Recommended Operating Conditions

Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to +85°C

Supply Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.7V to 5.5V

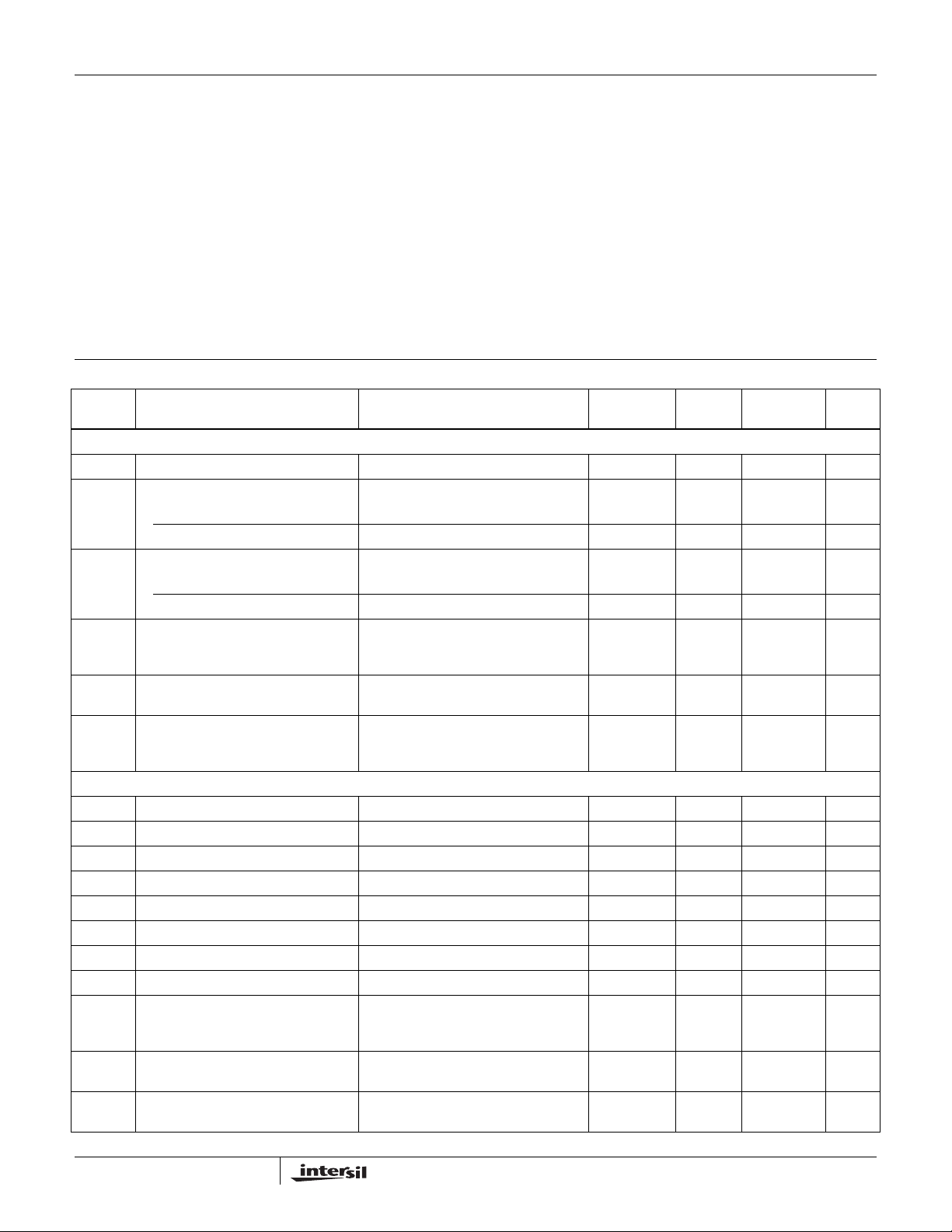

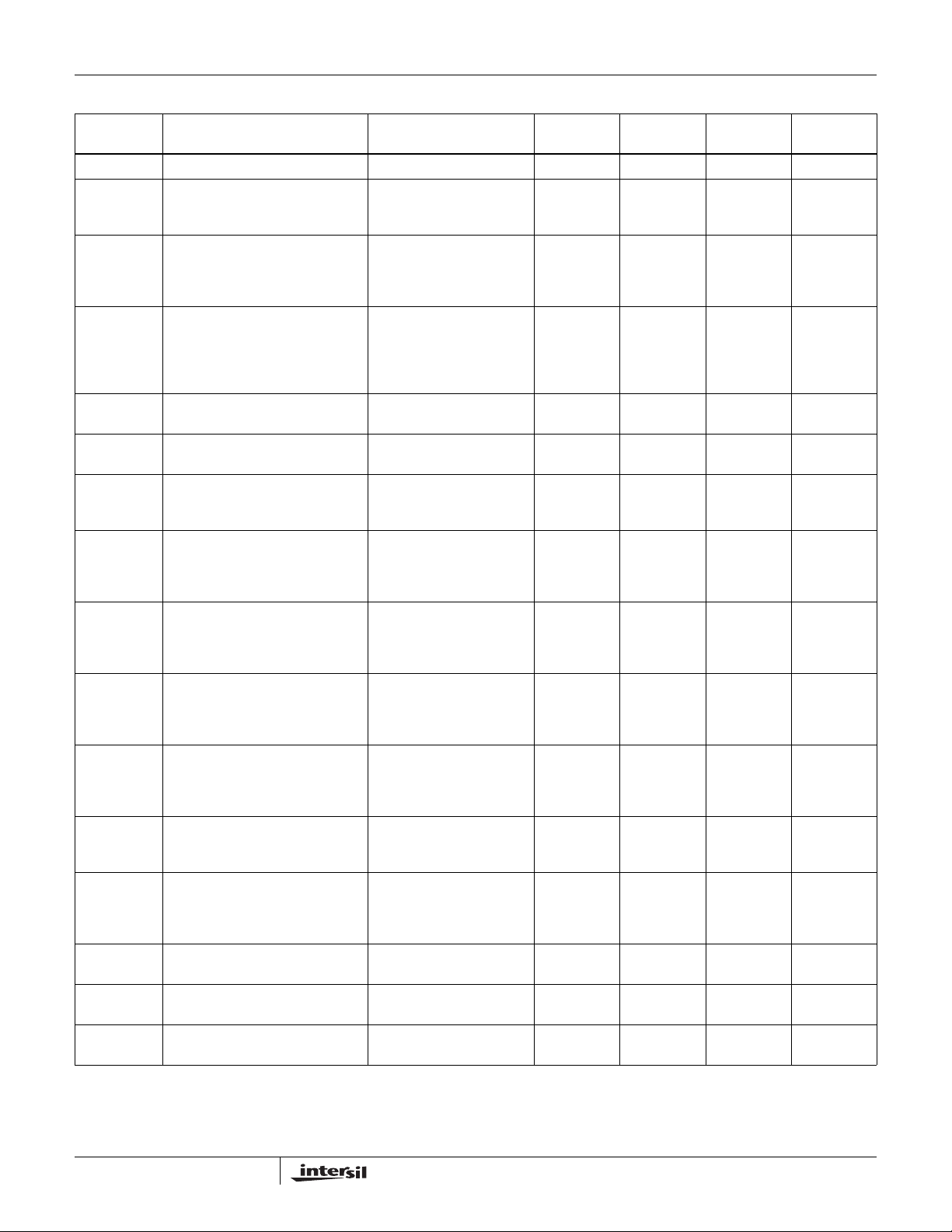

Analog Specifications V

= 5.5V, TA= +25°C to +85°C, Unless Otherwise Noted

CC

TYP

SYMBOL PARAMETER TEST CONDITIONS MIN

(Note 2) MAX UNITS

POWER SUPPLY

V

I

Q(NV)

Vpor Power-on Recall Voltage

V

Ramp

Supply Voltage Range 2.7 3.0 5.5 V

CC

I

Supply

Q

= 2.7V Standby, SDA = SCL = V

V

CC

V

= 5.5V Standby, SDA = SCL = V

CC

CC

CC

200 400 µA

235 500 µA

Non-Volatile Supply

= 2.7V Nonvolatile write 500 750 µA

V

CC

V

= 5.5V Nonvolatile write 1.3 1.6 mA

CC

2.0 2.6 V

CC

t

D

Minimum V

occurs

Ramp Rate 0.2 V/ms

V

CC

Power-Up Delay

V

above Vpor, time delay to Register

CC

recall, and I

at which memory recall

CC

2

C Interface in standby state

3ms

OUTPUT VOLTAGE PERFORMANCE SPECIFICATIONS

G

G

Gain Error AV = 2 (Notes 1, 3, 12) -1 +1 %

E1

Gain Error AV = 4 (Notes 1, 3, 12) -1 +1 %

E2

K Temperature Sensor Coefficient (Notes 1, 8) -2.2 -2.1 -2.0 mV/°C

Absolute Output Voltage (Swing) Range Unloaded, T

Absolute Output Voltage (Swing) Range Loaded, I

TS1 Temperature Sensor Slope A

TS2 Temperature Sensor Slope A

TS3 Temperature Sensor Slope A

TS4 Incremental Temperature Sensor Slope A

= 1, n = 255, m = 255 (Notes 1, 6) -2.1 mV/°C

V

= 2, n = 255, m = 255 (Notes 1, 6) -4.2 mV/°C

V

= 4, n = 255, m = 255 (Notes 1, 6) -8.4 mV/°C

V

= 1, n = 255, m = 0 to 255 (Notes 1,

V

= +25°C (Note 3) VCC - 0.100 GND + 0.100 V

A

= ±500µA (Note 3) VCC - 0.250 GND + 0.250 V

OUT

8.2 μV/°C

10)

TSNL Temperature Slope Non-Linearity n = 255, m = 0 to 255, T = -40°C to +85°C

±0.5 ±1.0 %

(Notes 1, 11)

DNL DAC Relative Linearity

(V

= 2.7 to 5.5V)

CC

and Temp Sense; AV = 1 (Note 13) -1.0 +1.0 LSB

V

REF

per

Code

3

FN8091.1

April 24, 2007

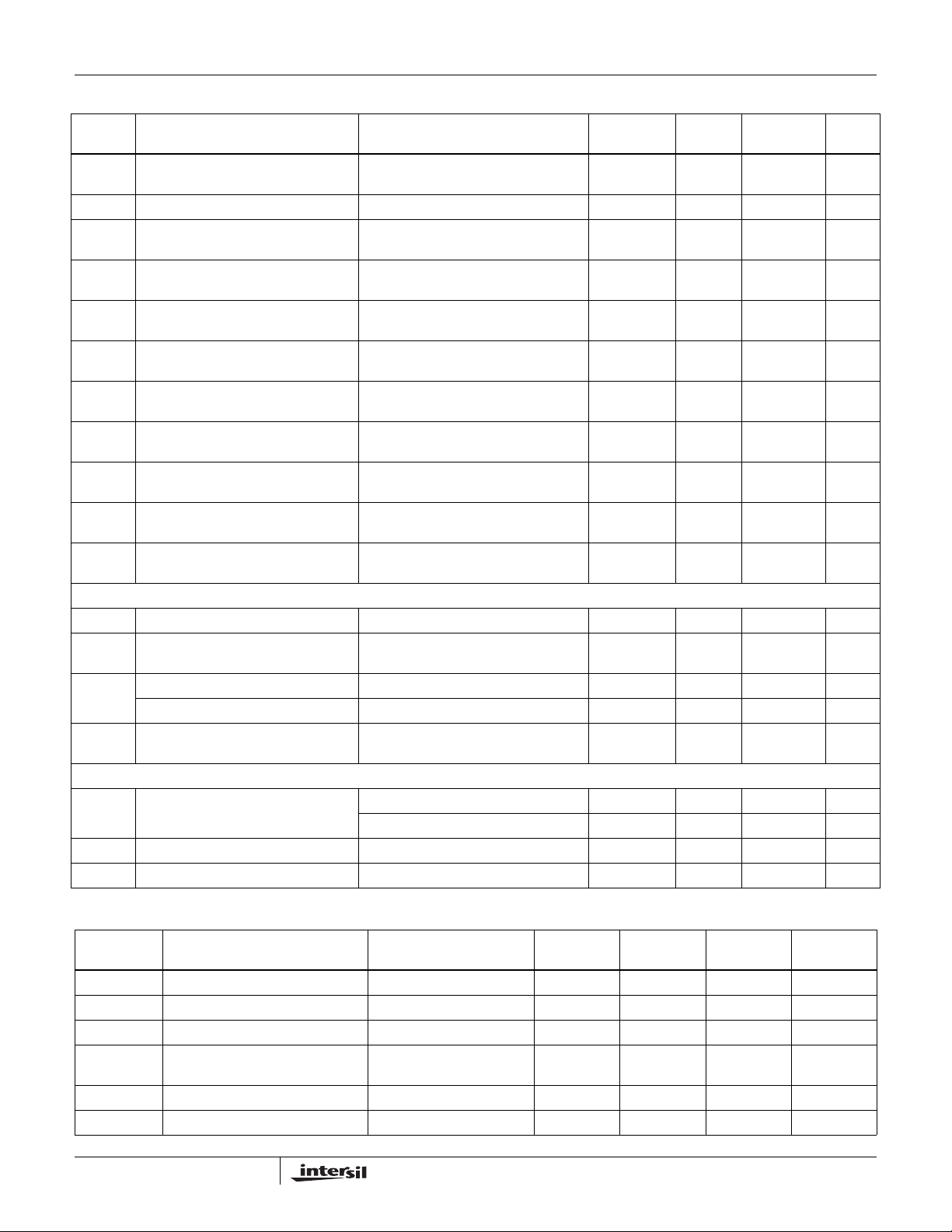

ISL21400

Analog Specifications V

= 5.5V, TA= +25°C to +85°C, Unless Otherwise Noted

CC

SYMBOL PARAMETER TEST CONDITIONS MIN

INL DAC Absolute Linearity (VCC = 2.7 to

V

and Temp Sense; AV = 1 (Note 13) -3.0 +3.0 LSB

REF

5.5V)

V

OUT(TE)

V

V

V

V

OUT1

OUT2

OUT3

OUT4

Total Error for V

Output Voltage V

Output Voltage V

Output Voltage V

Output Voltage V

OUT

, Gain = 1 AV = 1, n = 255, m = 128, TA=+25°C,

REF

, Gain = 2 AV = 2, n = 255, m = 128, TA=+25°C,

REF

, Gain = 4 AV = 4, n = 255, m = 128, TA=+25°C,

REF

+ TS AV = 1, n = 255, m = 0, TA = +85°C

REF

(Notes 1, 8, 9) ±1 ±2 %

V

=5.5V

CC

V

=5.5V

CC

V

=5.5V

CC

1.189 1.2 1.211 V

2.378 2.40 2.422 V

4.756 4.80 4.844 V

1.315 1.326 1.337 V

(Note 3)

V

V

V

OUT5

OUT6

OUT7

Output Voltage V

Output Voltage V

Output Voltage V

+ TS AV = 1, n = 255, m = 128, TA=+85°C

REF

+ TS AV = 1, n = 255, m = 255, TA=+85°C

REF

+ TS AV = 1, n = 255, m = 0, TA= -40°C,

REF

(Note 3)

(Note 3)

1.188 1.199 1.210 V

1.063 1.074 1.085 V

1.052 1.063 1.074 V

(Note 3)

V

V

OUT8

OUT9

Output Voltage V

Output Voltage V

+ TS AV = 1, n = 255, m = 128, TA= -40°C,

REF

+ TS AV = 1, n = 255, m = 255, TA= -40°C,

REF

(Note 3)

1.189 1.200 1.211 V

1.336 1.325 1.347 V

(Note 3)

OUTPUT VOLTAGE DC SPECIFICATIONS

PSRR Power Supply Rejection Ratio A

R

Output Impedance (load regulation) Given by R

OUT

I

Short Circuit, Sourcing V

SC

Short Circuit, Sinking V

C

Load Capacitance Reference output stable for all CL up to

L

= 1, n = 255, m = 128, (Note 7) 50 60 dB

V

T

= +25°C, I

A

= 5.5V, V

CC

= 5.5V, V

CC

OUT

= (ΔV

OUT

OUT

OUT

/ΔI

OUT

),

OUT

= ±500µA

= 0V 5 9 mA

= 5.5V 6 9 mA

specifications

OUTPUT VOLTAGE AC SPECIFICATIONS

Output Voltage Noise 0.1Hz to 10Hz, AV =1 90 µV

V

N

10Hz to 10kHz, CL = 0, AV = 1 TBD mV

Power On Response 1% Settling 500 µs

Line Ripple Rejection V

= 5V ±100mV, f = 120Hz 60 dB

CC

TYP

(Note 2) MAX UNITS

25Ω

5nF

P-P

RMS

Serial Interface Specification (for SCL, SDA, A0, A1, A2 unless specified otherwise)

SYMBOL PARAMETER TEST CONDITIONS MIN

I

LI

V

IL

V

IH

Hysteresis SDA and SCL Input Buffer

V

OL

C

pin

Input Leakage VIN = GND to V

CC

Input LOW Voltage -0.3 0.3 x V

Input HIGH Voltage 0.7 x V

0.05 x V

Hysteresis

SDA Output Buffer LOW Voltage IOL = 3mA 0 0.4 V

Pin Capacitance (Note 3) 10 pF

4

CC

CC

TYP

(Note 2) MAX UNITS

1V

CC

V

+ 0.3 V

CC

V

V

FN8091.1

April 24, 2007

ISL21400

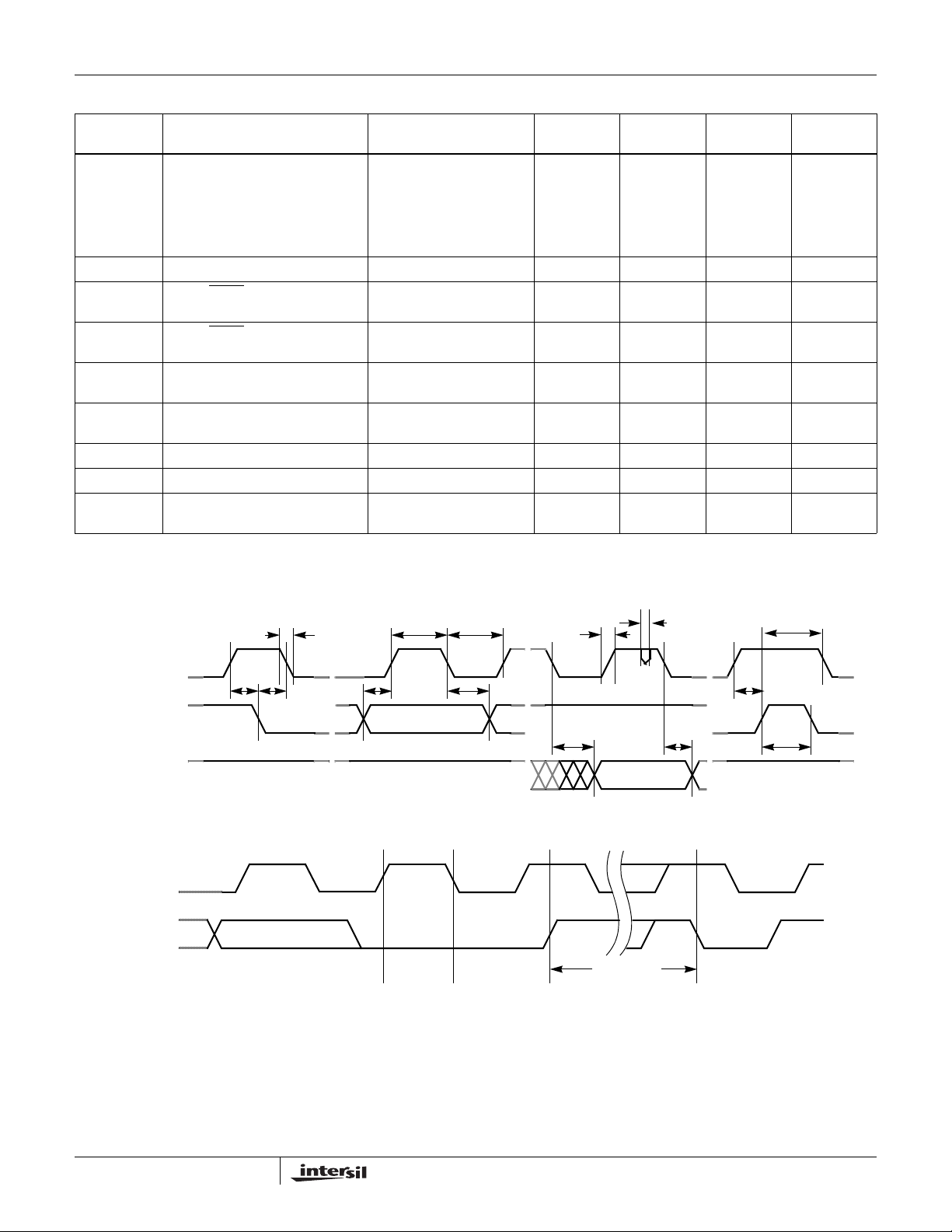

Serial Interface Specification (for SCL, SDA, A0, A1, A2 unless specified otherwise) (Continued)

SYMBOL PARAMETER TEST CONDITIONS MIN

f

SCL

t

sp

SCL Frequency (Note 3) 400 kHz

Pulse Width Suppression Time at

SDA and SCL Inputs

Any pulse narrower than the

max spec is suppressed

(Note 3)

t

AA

SCL Falling Edge to SDA Output

Data Valid

SCL falling edge crossing

30% of V

the 30% to 70% of V

, until SDA exits

CC

CC

window (Note 3)

t

BUF

Time the Bus Must be Free Before

the Start of a New Transmission

SDA crossing 70% of VCC

during a STOP condition, to

SDA crossing 70% of V

during the following START

CC

1300 ns

condition (Note 3)

t

LOW

t

HIGH

Clock LOW Time Measured at the 30% of VCC

crossing (Note 3)

Clock HIGH Time Measured at the 70% of VCC

1300 ns

600 ns

crossing (Note 3)

t

SU:STA

t

HD:STA

t

SU:DAT

START Condition Setup Time SCL rising edge to SDA

falling edge; both crossing

70% of V

(Note 3)

CC

START Condition Hold Time From SDA falling edge

crossing 30% of V

falling edge crossing 70% of

V

(Note 3)

CC

CC

to SCL

Input Data Setup Time From SDA exiting the 30% to

70% of V

window, to SCL

CC

600 ns

600 ns

100 ns

rising edge crossing 30% of

V

(Note 3)

CC

t

HD:DAT

t

SU:STO

t

HD:STO

t

DH

Input Data Hold Time From SCL rising edge

crossing 70% of V

entering the 30% to 70% of

V

window (Note 3)

CC

CC

STOP Condition Setup Time From SCL rising edge

STOP Condition Hold Time for

Read, or Volatile Only Write

crossing 70% of V

rising edge crossing 30% of

V

(Note 3)

CC

From SDA rising edge to SCL

falling edge; both crossing

70% of V

(Note 3)

CC

, to SDA

CC

Output Data Hold Time From SCL falling edge

crossing 30% of V

CC

to SDA

, until

0ns

600 ns

1300 ns

0ns

SDA enters the 30% to 70%

of V

window (Note 3)

CC

t

R

SDA and SCL Rise Time From 30% to 70% of VCC

20 + 0.1 x Cb 250 ns

(Note 3)

t

F

Cb Capacitive Loading of SDA or SCL Total on-chip and off-chip

SDA and SCL Fall Time From 70% to 30% of VCC

(Note 3)

20 + 0.1 x Cb 250 ns

10 400 pF

(Note 4)

(Note 2) MAX UNITS

TYP

50 ns

900 ns

5

FN8091.1

April 24, 2007

ISL21400

Serial Interface Specification (for SCL, SDA, A0, A1, A2 unless specified otherwise) (Continued)

SYMBOL PARAMETER TEST CONDITIONS MIN

1kΩ

Rpu SDA and SCL Bus Pull-up Resistor

Off-chip

Maximum is determined by t

and t

F

For Cb = 400pF , max is about

R

2~2.5kΩ

For Cb = 40pF, max is about

15~20kΩ

I

V

V

LO

IL

IH

Output Leakage Current (SDA only) V

A1, A0, SHDN, SDA, and SCL Input

Buffer LOW Voltage

A1, A0, SHDN, SDA, and SCL Input

= GND to V

OUT

CC

-0.3 VCC x 0.3 V

VCC x 0.7 V

Buffer HIGH Voltage

V

OL

C

SDA Output Buffer LOW Voltage IOL = 100µA (Note 3), at 3mA

sink

Capacitive Loading of SDA or SCL Total on-chip and off-chip

L

(Note 3)

00.4V

10 400 pF

EEPROM Endurance 1,000,000 Cycles

t

WC

(Note 14)

EEPROM Retention Temperature T

Non-Volatile Write Cycle Time 12 20 ms

≤ +55°C 50 Years

(Note 2) MAX UNITS

TYP

1µA

CC

V

Timing Diagrams

Bus Timing

t

F

SCL

(INPUT TIMING)

(OUTPUT TIMING)

SDA

SDA

t

SU:STA

t

HD:STA

t

SU:DAT

Write Cycle Timing

SCL

SDA

NOTES:

1. Equation 1 governs the output voltage and is stated as follows:

V

2. Typical values are for T

8th BIT OF LAST BYTE ACK

⎧⎫

• n = 0 to 255, m = 0 to 255, K = -2.1mV/C(typ), T0 = +25°C,=

OUTAVVREF

⎨⎬

⎩⎭

= +25°C and VCC = 5.5V.

A

n

--------- -

• KT T

+

255

t

HIGH

2m•()255–

--------------------------------

–()

0

255

t

LOW

t

HD:DAT

STOP

CONDITION

t

t

DH

sp

START

CONDITION

t

BUF

t

HD:STO

t

SU:STO

t

R

t

AA

t

WC

6

FN8091.1

April 24, 2007

ISL21400

3. This parameter is not 100% tested.

4. Cb = total capacitance of one bus line in pF.

is the time from a valid stop condition at the end of a write sequence to the end of the self-timed internal nonvolatile write cycle. It is the

5. t

WC

minimum cycle time to be allowed for any nonvolatile write by the user.

6. Over the specified temperature range. Temperature slope (TS) is measured by the box method whereby the change in V

temperature range; in this case, -40°C to +85°C = +125°C. TS

V

------------------------------------------------------------------------------- -

TS

=

OUT

, TS2, TS3 =.

1

Tmin()V

Tmin Tmax–

OUT

Tmax()–

OUT

is divided by the

7. Given by PSRR (dB) = 20 * log

(ΔVout/ΔVCC) at DC.

10

8. Test +25°C and +85°C only.

9. Total error of Equation 1 @ A

=1, K = -2.1mV/°C, V

V

TE()

V

OUT

10. Over the specified temperature range. Temperature slope (TS) is measured by the box method whereby the change in V

temperature range. Incremental TS is the temperature slope at m = 255 minus the temperature slope at m = 0 divided by 255 with A

Tmin()V

V

⎛⎞

OUT

TS4

------------------------------------------------------------------------------- -

⎜⎟

⎝⎠

Tmin Tmax–()

= 1.20V, m = 255, n = 255 to 0, VCC = 3.0V.

REF

measured()V

V

OUT

-------------------------------------------------------------------------------------------------------------

Tmax()–

OUT

m 255=

V

Equation1()

OUT

⎛⎞

– 255÷=

⎜⎟

⎝⎠

Equation1()–

OUT

V

Tmin()V

OUT

------------------------------------------------------------------------------- -

Tmin Tmax–()

OUT

x100%=

is divided by the

OUT

= 1, n = 255

V

Tmax()–

m0=

11. Temperature Slope Non- linearity is measured over the specified temperature range. The actual change in output voltage is subtracted from the

expected change in output voltage, and then divided by the expected change to normalize before converting to percent.

ΔT )()ΔVOUT–

T( S

y

TSNL

----------------------------------------------------------

TS

ΔT×

y

x100%; y 123,,==

12. For codes n = 8 to 255

13. Guaranteed monotonic

is the time from a valid STOP condition at the end of a Write sequence of I2C serial interface, to the end of the self-timed internal nonvolatile

14. t

WC

write cycle.

15. θ

is measured with the component mounted on a high effective thermal conductivity test board in free air. See Tech Brief TB379 for details.

JA

Typical Performance Curves

3.0

2.5

2.0

TS = 0

(V)

1.5

REF

V

1.0

TS = 0

0.5

0.0

-40 -15 10 35 60 85

FIGURE 1. V

AV = 2

TS = 127

= 1

A

V

TEMPERATURE (°C)

vs TEMPERATURE (AV = 1, 2) FIGURE 2. V

OUT

TS = 255

TS = 255

TS = 127

6.0

5.5

5.0

(V)

4.5

REF

V

4.0

3.5

3.0

-40 -15 10 35 60 85

AV = 4

TS = 127

TS = 0

TEMPERATURE (°C)

vs TEMPERATURE (AV = 4)

OUT

TS = 255

7

FN8091.1

April 24, 2007

Typical Performance Curves (Continued)

ISL21400

1.22

V

REGISTER = 255d

REF

TS REGISTER = 127d

1.21

1.20

VREF (V)

1.19

1.18

2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0

V

(V)

CC

FIGURE 3. V

NO LOAD

A

= 1

V

100µV/DIV (V

OUT

vs V

OUT

x 1000)

CC (VCC

= +2.7V to +5.5V) FIGURE 4. SUPPLY VOLTAGE vs SUPPLY CURRENT

0.40

0.35

0.30

0.25

0.20

(mA)

CC

I

0.15

0.10

0.05

NO LOAD

= 4

A

V

50µV/DIV (V

REGISTER = 255d

V

REF

TS REGISTER = 127d

0

2456

OUT

3

x 1000)

+85°C

+25°C

-40×C

-40°C

(V)

V

CC

7

FIGURE 5. V

1.22

1.21

(V)

1.20

REF

V

1.19

1.18

-40 -15 10 35 60 85

VOLTAGE NOISE (AV = 1, NO LOAD) FIGURE 6. V

OUT

V

REGISTER = 255d

REF

TS REGISTER = 127d

TEMPERATURE (°C)

VOLTAGE NOISE (AV = 4, NO LOAD)

OUT

FIGURE 7. ACCURACY vs TEMPERATURE (-40°C TO +85°C) FIGURE 8. POWER ON

8

CH1 = V

CH2 = V

CC

OUT

FN8091.1

April 24, 2007

Typical Performance Curves (Continued)

5

ISL21400

3

2

1

0

-1

INL IN LSB

-2

-3

0 15 30 45 60 75 90 105 120 135 150 165 180195210 225 240 255

FIGURE 9. INL, V

1.4

AT +25°C

TS REGISTER = 127d

1.2

1.0

0.8

(V)

REF

0.6

V

0.4

0.2

0.0

0 15 30 45 60 75 90 105120 135 150 165 180 195 210 225 240 25

FIGURE 11. V

REF

V

REGISTER CODE (m)

REF

OUT

AT +25°C

CODE

AND TEMP SLOPE DAC FIGURE 10. DNL, V

vs V

CODE (m) FIGURE 12. V

REF

1.0

0.8

0.6

0.4

0.2

0.0

-0.2

DNL IN LSB

-0.4

-0.6

-0.8

-1.0

1.40

1.35

1.30

1.25

(V)

1.20

REF

V

1.15

1.10

1.05

1.00

0 15 30 45 60 75 90 105120135 15 0165 180195 210 225240 255

AT +25° C

0 15 30 45 60 75 90 105120 135150 165180 195210225 240255

V

+85°C

vs TEMP SENSE CODE (n), TA = -40°C AND

OUT

+85°C

CODE

AND TEMP SLOPE DAC

REF

REGISTER = 255d

REF

-40°C

TS REGISTER CODE (n)

1.209

1.208

1.207

1.206

1.205

(V)

1.204

REF

V

1.203

1.202

1.201

9

V

REGISTER = 255d

REF

TS REGISTER = 127d

AT +25°C

1.2

-1 -0.5 0 0.5 1

FIGURE 13. V

OUT

I

OUT

vs I

(mA)

OUT

(±1mA)

FN8091.1

April 24, 2007

ISL21400

Pin Descriptions

V

OUT

Programmable voltage output pin. Absolute voltage is

determined by device temperature and Equation 1. Drive

capability is limited to ±500μA output current and 5000pF

output capacitance.

A2, A1, A0

Hardware slave address pins that can be used to provide

several ISL21400 with a unique physical address to allow for

multiple devices off one I

2

C bus.

GND

This is the circuit ground pin. It is common for the V

control signal inputs.

OUT

and

SDA

Serial Data Input/Output. Bidirectional pin used for serial

data transfer. As an output, it is open drain and may be

wire-ored with any number of open drain or open collector

outputs. A pullup resistor is required and the value is

dependent on the speed of the serial data bus and the

number of outputs tied together.

SCL

Serial Clock Input. Accepts a clock signal for clocking serial

data into and out of the device. The SCL line requires a

pull-up resistor whose value is dependent on the speed of

the serial clock bus and the number of inputs tied together.

V

CC

Positive Power Supply. Connect to a voltage supply in the

range of 2.7V<V

best performance, bypass with a 0.1µF capacitor to ground.

If the A

V

gain is set to 4 and V

V

must be set to >5.2V for best output performance.

CC

<5.5V, with minimum noise and ripple. For

CC

approaches 5.0V, then

OUT

Functional Description

Functional Overview

Refer to the Functional Block Diagram on page 2. The

ISL21400 provides a programmable output voltage which

combines both a temperature independent term and a

temperature dependent term. The temperature independent

term uses a bandgap voltage reference, and the

temperature dependent term uses a Proportional To

Absolute Temperature (PTA T) reference, or Temperature

Sensor. Each voltage source is scalable using two DACs via

2

the I

C serial bus. The resulting output voltage can vary from

0V to over 5V and has a variable, programmable

Temperature Slope (TS).

Reference Sections

Referring to the Block Diagram on page 2, the V

Temperature Sense (V

) outputs are summed together (Σ)

TS

and then passed through the output gain stage (A). The

voltage output is programmable and is determined by the

Equation 1:

V

OUTAVVREF

⎧⎫

•=

⎨⎬

⎩⎭

n

--------- -

• V

+

255

2m•()255–

--------------------------------

TS

255

where

•A

= 1, 2, 4

V

•V

= 1.200 (not temperature dependent)

REF

•0 ≤ n ≤ 255 (setting contained in Register 0, V

•V

= K(T - T0)

TS

•K = dV

/ dT = -2.1mV/C

TS

• T = device temperature

•T0 = +25°C

•0 ≤ m ≤ 255 (setting contained in Register 1, TS)

See “Applications Information” on page 14 for ways to use

Equation 1 and methods for output voltage calculations.

REF

REF

and

(EQ. 1)

)

DACs Section

The ISL21400 contains two 8-bit DACs whose registers can

be programmed via the I

are non-volatile such that the values are restored during the

V

power-up cycle of the device. One DAC (V

CC

dedicated to scale the bandgap voltage reference

(Temperature invariant) and the other DAC (V

dedicated to scale the Temperature Sensor. Both of these

DACs can determine the output voltage as defined by

Equation 1 (See “Register Descriptions” on page 11.).

2

C serial bus. The DAC registers

) is

REF

) is

TS

Output Gain Amplifier Section

The ISL21400 contains an output gain amplifier (A) that is

programmed via the I

last stage before the output and therefore controls the

overall gain for the device. The gain can be programmed for

1x, 2x, or 4x amplification. This gain factor is used to

program the output voltage as determined by Equation 1

(See “Register Descriptions” on page 11.).

There are 5 registers in the ISL21400 device, all nonvolatile

(see Table 2). All register s are accessible for reading or

writing through the I

2

C serial bus. The gain amplifier is the

2

C serial bus.

10

FN8091.1

April 24, 2007

ISL21400

Register Descriptions

TABLE 1. ISL21400 REGISTER BIT MAP

D7

Addr

0V

1 TS7 TS6 TS5 TS4 TS3 TS2 TS1 TS0

2 D7D6D5D4D3D2GAIN1GAIN0

3 D7D6D5D4D3D2D1D0

4 D7D6D5D4D3D2D1D0

(MSB)D6D5D4D3D2D1D0(LSB)

7V

REF

6V

REF

5V

REF

4V

REF

3V

REF

2V

REF

1V

REF

REF

0

TABLE 2. REGISTER DESCRIPTIONS

REG NONVOLATILE DESCRIPTION

0 Y Reference setting

1 Y Temperature Sensor setting

2 Y Gain and storage

3 Y Storage

4 Y Storage

Register 0: Bandgap Reference Gain (Nonvolatile)

Register 0 sets the output voltage of the bandgap reference

(V

). Referring to Equation 1, the number “n” is the setting

REF

from Register 0 as follows:

n

--------- -

V

• , for n = 0 to 255

REF

255

This term of Equation 1 can vary from 0V to 1.20V.

Register 1: Temperature Slope Gain (Nonvolatile)

Register 1 sets the Temperature Slope (TS) of the

temperature sensor. Referring to Equation 1, the number “m”

is the setting from Register 1 as follows:

2m•()255–

--------------------------------

V

TS

255

V

is the temperature dependent term and varies from

TS

+136mV at -40°C to -126mV at +85°C. The other term varies

from -1 to +1 and scales the temp erature t erm before add ing

to the V

REF

portion.

Register 2: Device Gain and Storage (nonvolatile)

TABLE 3. REGISTER 2 OUTPUT GAIN (NONVOLA TILE):

GAIN1 GAIN0 OUTPUT GAIN, A

Register 2 contains 2 bits (2 LSB’s) which control the output

gain of the device. Table 3 shows the state of these two bits

OUTPUT GAIN

V

00 x 1

01 x 2

10 x 2

11 x 4

and the resulting output gain. Note that two states produce

the same gain (Gain 1:0 set to 01b and 10b) of x2.

The other 6-bits in the register can be used for general

purpose memory (nonvolatile) or left alone.

Registers 3 and 4: general purpose data

(nonvolatile)

These two registers are one byte each and can be used for

general purpose nonvolatile memory.

I2C Serial Interface

The ISL21400 supports a bidirectional bus oriented protocol.

The protocol defines any device that sends data onto the

bus as a transmitter and the receiving device as the receiver.

The device controlling the transfer is the master and the

device being controlled is the slave. The master always

initiates data transfers and provides the clock for both

transmit and receive operations. Therefore, the ISL21400

operates as a slave device in all applications.

All communication over the I

sending the MSB of each byte of data first.

Protocol Conventions

Data states on the SDA line can change only during SCL

LOW periods. SDA state changes during SCL HIGH are

reserved for indicating START and STOP conditions (See

Figure 10). On power-up of the ISL21400 the SDA pin is in

the input mode.

2

All I

C interface operations must begin with a START

condition, which is a HIGH to LOW transition of SDA while

SCL is HIGH. The ISL21400 continuously monitors the SDA

and SCL lines for the START condition and does not

respond to any command until this condition is met (See

Figure 10). A START condition is ignored during the powerup sequence and during non-volatile write cycles for the

device.

2

All I

C interface operations must be terminated by a STOP

condition, which is a LOW to HIGH transition of SDA while

SCL is HIGH (See Figure 10) A STOP condition at the end of

a read operation, or at the end of a write operation places

the device in its standby mode. A STOP condition at the end

of a write operation to a non-volatile byte initiates an internal

2

C interface is conducted by

11

FN8091.1

April 24, 2007

ISL21400

non-volatile write cycle. The device enters its standby state

when the internal, non-volatile write cycle is completed.

An ACK, Acknowledge, is a software convention used to

indicate a successful data transfer. The transmitting device,

either master or slave, releases the SDA bus after

transmitting eight bits. During the ninth clock cycle, the

receiver pulls the SDA line LOW to acknowledge the

reception of the eight bits of data (See Figure 11).

The ISL21400 responds with an ACK after recognition of a

START condition followed by a valid Identification Byte, and

once again after successful receipt of an Address Byte. The

ISL21400 also responds with an ACK after receiving a Data

Byte of a write operation. The master must respond with an

ACK after receiving a Data Byte of a read operation.

A valid Identification Byte contains 0101 A2 A1 A0 as the

seven MSBs. The A2 A1 A0 bits must correspond to the

logic levels at those pins of the ISL21400 device. The LSB in

the Read/Write

bit. Its value is “1” for a Read operation, and

“0” for a Write operation (See Table 4).

Write Operation

TABLE 4. IDENTIFICATION BYTE FORMAT

0 1 0 1 A2 A1 A0 R/W

(MSB) (LSB)

A Write operation requires a START condition, followed by a

valid Identification Byte, a valid Address Byte, a Data Byte,

and a STOP condition. After each of the three bytes, the

ISL21400 responds with an ACK. The master will then send

a STOP and at this time the device begins its internal

non-volatile write cycle. During this time, the device ignores

transitions at the SDA and SCL pins, and the SDA output is

at a high impedance state. When the internal non-volatil e

write cycle is completed, the ISL21400 enters its standby

state (see Figure 12).

Read Operation

A Current Address Read operation is shown in Figure 13. It

consists of a minimum 2 bytes: a START followed by the ID

byte from the master with the R/W

followed by the data byte or bytes sent by the slave. The

master terminates the Read operation by not responding

with an ACK and then issuing a STOP condition. This

operation is useful if the master knows the current address

and desires to read one or more data bytes.

A Random Address Read operation consists of a three byte

“dummy write” instruction followed by a Current Address

Read operation (See Figure 14). The master initiates the

operation issuing the following sequence: a START, the

identification byte with the R/W

Byte, a second START, and a second Identification byte with

the R/W

bit set to "1". After each of the three bytes, the

ISL21400 responds with an ACK. The ISL21400 then

transmits Data Bytes as long as the master responds with an

ACK during the SCL cycle following the eighth bit of each

byte. The master terminates the Read operation (issuing a

STOP condition) following the last bit of the last Data Byte

(See Figure 13).

The Data Bytes are from the registers indicated by an

internal pointer. This pointer initial’s value is determined by

the Address Byte in the Read operation instruction, and

increments by one during transmission of each Data Byte.

Address 04h is the last valid data byte, higher addresses are

not available. Data from addresses higher than memory

location 04h will be invalid.

bit set to 1, then an ACK

bit set to "0", an Address

STOP conditions that terminate write operations must be

sent by the master after sending at least 1 full data byte and

its associated ACK signal. If a STOP byte is issued in the

middle of a data byte, or before 1 full data byte + ACK is

sent, then the ISL21400 resets itself without performing the

write. The contents of the array are not affected.

Data Protection

A valid Identification Byte, Address Byte, and total number of

SCL pulses act as a protection for the registers. A STOP

condition also acts as a protection for non-volatile memory.

During a Write sequence, the Data Byte is loaded into an

internal shift register as it is received. The presence of the

STOP condition after the rest of the bits are received then

triggers the non-volatile write.

12

FN8091.1

April 24, 2007

SCL

SDA

ISL21400

SCL FROM

MASTER

SDA OUTPUT FROM

TRANSMITTER

SDA OUTPUT

FROM RECEIVER

SIGNALS FROM THE

MASTER

START DATA DATA STOP

STABLE CHANGE

DATA

STABLE

FIGURE 14. VALID DATA CHANGES, START AND STOP CONDITIONS

81 9

HIGH

HIGH

START ACK

FIGURE 15. ACKNOWLEDGE RESPONSE FROM RECEIVERFIGURE 15. ACKNOWLEDGE RESPONSE FROM RECEIVER

WRITE

S

T

IDENTIFICATION

A

BYTE WITH R/W

R

T

= 0

ADDRESS

BYTE

DATA

BYTE

S

T

O

P

SIGNAL AT SDA

SIGNALS FROM THE

ISL21400

00011

A

C

K

000

A0A1A2

0

000

A

C

K

A

C

K

FIGURE 16. BYTE WRITE SEQUENCE

A1 A0

= 1

READ

A

C

FIRST READ DATA

K

BYTE

A

C

K

A

C

K

LAST READ DATA

BYTE

S

T

O

P

FN8091.1

April 24, 2007

SIGNALS

FROM THE

MASTER

SIGNAL AT SDA

SIGNALS FROM

THE SLAVE

S

T

IDENTIFICATION

A

BYTE WITH R/W

R

T

01011

A2

FIGURE 17. ADDRESS READ SEQUENCE

13

V

ISL21400

SIGNALS

FROM THE

MASTER

SIGNAL AT SDA

SIGNALS FROM

THE SLAVE

S

T

A

IDENTIFICATION

R

BYTE WITH R/W

T

00011

= 0

AAA0000 0

ADDRESS

BYTE

A

C

K

FIGURE 18. RANDOM ADDRESS READ SEQUENCE

A

C

K

Applications Information

Power-Up Considerations

The ISL21400 has on-chip EEPROM memory storage for

the DAC and gain settings of the device. These settings

must be recalled correctly on power-up for proper operation.

Normally there are no issues with recall, although it is always

best to provide a smooth, glitch-free power-up waveform on

V

. Adding a small 0.1μF capacitor at the device VCC will

CC

help with power-up as well as V

Noise Performance

The output noise voltage in a 0.1Hz to 10Hz bandwidth is

typically 90µV

. The noise measurement is made with a

P-P

bandpass filter made of a 1 pole high-pass filter with a corner

frequency at 0.1Hz and a 2-pole low-pass filter with a corner

frequency at 12.6Hz to create a filter with a 9.9Hz

bandwidth. Load capacitance up to 5000pF can be added

but will result in only marginal improvements in output noise

and transient response. The output stage of the ISL21400 is

not designed to drive heavily capacitive loads. For high

impedance loads, an R-C network can be added to filter high

frequency noise and preserve DC control.

Output Voltage Programming Considerations

Setting and controlling the output voltage of the ISL21400

can be done easily by breaking down the components into

temperature variant and invariant, and setting them

separately. Let’s use Equation 1 to derive separate

Reference Output and Output Temp Slope equations:

V

⎧⎫

AVV

•

⎨⎬

OUT

⎩⎭

• A

A

VVREF

Reference Term Temp Slope Term+

The first term controls the output DC value, and the second

term controls the Temp slope, where

n

A

A

--------- -

= (ranges from 0 to 1)

REF

255

2m•()255–

⎛⎞

----------------------------------

TS

⎝⎠

255

n

--------- -

•

REF

255

•{}= AVV•

REF

(ranges from -1 to +1)=

+=

load changes.

OUT

⎧⎫

A

⎨⎬

V

⎩⎭

2m•()255–

⎛⎞

----------------------------------

V•

•

⎝⎠

TS

TS

255

ATS•{}""+

S

T

A

IDENTIFICATION

R

BYTE WITH R/W

T

01011

S

T

O

P

AAA

= 1

A

C

FIRST READ

K

DATA BYTE

A

A

C

C

K

K

LAST READ

DATA BYTE

DC OUTPUT CONTROL DISCUSSION

The reference term yields Equation 2 for Reference Output:

V

OUT

(DC) A=

V

• A

REF

V

•

REF

(EQ. 2)

Note that the DC term is dependent on the 1.20V reference

voltage, which is constant, the overall gain, A

Reference gain, A

. Since the product AV * A

REF

, and the

V

REF

ranges

from 0 to 4, the total reference DC output can range from

0.0V to 4.8V. In order to get the 4.8V output, V

must be

CC

greater than 4.8V by the output dropout plus any overhead

for output loading (the specification for V

with V

changes with A

(A

V

A

V

= 5.5V). The Resolution of V

CC

, so that with a 4.80V full scale output

V

= 4), the resolution is 4.80/255 or 18.8mV/bit. With

= 1, the resolution is 4.7mV/bit.

= 5.0V is listed

OUT

(DC) control

OUT

TEMP SENSE CONTROL DISCUSSION

Equation 2 yields this expression, Equation 3, for Temp

Slope:

OUT

Since V

TS() AVVTS• ATS•=

= K(T - T0), the slope term is dependent on the

TS

(EQ. 3)

base temp slope of the device, K (-2.1mV/°C), and the gain

terms A

portion of V

V

OUT

The product A

and ATS. This gives a formula (Equation 4) for the

V

TS()AVK• ATS• TT0–()•=

at a specific temperature:

OUT

ranges from -4 to 4, so the T emperature

V*ATS

(EQ. 4)

Slope can range from -8.4 to +8.4mV/°C, which is

independent of the output DC voltage. The resolution of

Slope control is determined by this range (±8.4mV/°C) and

the gain terms, and will vary from 65.8μV/°C/bit (A

down to 16.2μV/°C/bit (A

At T = T0 = +25°C, V

cause a change in V

V

(DC) control. As temperature increases or decreases,

OUT

from T = +25°C, V

OUT

= 1).

V

(TS) = 0, no changes in ATS will

OUT

OUT

, and V

will only vary with the

OUT

will then change according to the

= 4)

V

programmed Temp Slope.

14

FN8091.1

April 24, 2007

ISL21400

In many cases a form of Equation 4 is needed which yields a

V

change with respect to temperature. By rearranging,

OUT

we get:

TS()

V

OUT

V

OUT

-----------------------------

T()

= A

TT

–()

0

K• ATS• ,(in mV/° C)=

V

(EQ. 5)

EXAMPLE 1: PROGRAMMED TEMPERATURE

COMPENSATION EXAMPLE

The ISL21400 can easily compensate for known

temperature drift by programming the device for the initial

V

setting and Tempco using standard equations and

OUT

some simple steps. The accuracy of the final programmed

output will be limited to the data sheet specs (typically 1%

accuracy for V

and Slope).

OUT

In this example, an N-Channel MOSFET gate has a

-2.8mV/°C Tempco from -10°C to +85°C. A constant bias

drain current is desired, with a target Vgs range derived from

the data sheet of 2.5V to 3.5V at +25°C.

Offset Setting: Using Equation 2 and targeting

V

= 3.0VDC:,

OUT

V

DC()AVV

OUT

Note that A

AREF()

n 159 decimal=

== =

9F hex=

• A

•()= 3.00V=

REF

REF

V

A

VAREF

REF

2.50

-----------

4

1.20V=

REF

• 2.50=

varies from 0 to 1, so to get 2.40, AV = 4.

n

0.625

--------- -

255

Temperature Slope Setting: Using Equation 5, which can

solve for Slope directly:

T() AVK• ATS•= 2.8mV °C⁄–=

V

OUT

2.8–

--------------------

A

=

TS

42.1–•

2m•()255–

0.333

A

==

TS

m 170 decimal=

A9 hex =

----------------------------------

255

The ISL21400 device can be programmed with these

calculated parameters and perform temperature

compensation or direct control in the target circuit. If

parameters change for some reason, then the device can be

reprogrammed with new values and the circuit retested.

EXAMPLE 2. CALCULATING THE V

TEMPERATURE

OUT

SLOPE

In some applications, it may be desirable to calculate what

the output voltage and temp slope are, given the

programmed register settings. Such an application could be

a closed loop system with internal calibration procedure. By

reading the registers of the ISL21400, then calculating the

V

parameters, the system characteristics can be

OUT

recorded.

For the example below, let’s determine the voltage output,

V

(DC) at +25°C, and also the change due to

OUT

temperature variation (ppm) from +25°C to +85°C.

Equations 2 and 5 will be used to calculate the answers.

Given, the contents of the registers:

A

= 1

V

n = 178 decimal

m = 74 decimal

Using Equation 2:

V

OUT

DC()AVV

=

• A

•()=

REF

REF

⎛⎞

11.20•

⎝⎠

178

--------- -

•

255

0.8376V=

Using Equation 5:

T() AVK• ATS•() mV °C⁄=

V

OUT

274•()255–

12.1

0.8812mV °C⁄=

------------------------------------

•–•=

255

Also, to solve for overall temp slope of the output:

0.8812mV °C⁄

---------------------------------------

872.5mV

6

• 1010ppm °C⁄=

10

Note that Equation 1 can be used directly to solve for output

voltage at a given temperature, in this case +85°C:

⎧⎫

V

OUTAVVREF

V

OUT

•=

⎨⎬

⎩⎭

+85°C()=

=

n

--------- -

• KT T

+

255

1

⎧⎫

178

--------- -

1.20

• 0.0021–()85 25–()

•

⎨⎬

⎩⎭

0.8905V=

255

+

2m•()255–

--------------------------------

–()

0

255

274•()255–

----------------------------------

255

Typical Applications Circuits

LDMOS RF Power Amplifier (RFPA). The ISL21400 is used

to set the gate bias for the LDMOS transistor in a single

stage of an RFPA. Normally this is done with a DAC or digital

potentiometer with some discrete temperature

compensation circuitry. The ISL21400 simplifies this control

and allows a full range of DC bias and tempco control.

A typical circuit can be calibrated for correct bias at room

temperature (+25°C) on power-up using a microcontroller or

2

direct I

increased to the highest operating range, and the

Temperature Slope setting can then be adjusted to bring the

amplifier back to correct bias. Since the Temp Slope setting

has a negligible effect on the room temperature setting, the

amplifier will be biased correctly over the operating

temperature of the unit.

C control. The temperature of the unit can then be

15

FN8091.1

April 24, 2007

ISL21400

2

I

C BUS

+28V

U2

1

IN OUT

2

GND

+5V REGULATOR

5

6

1

2

3

SCL

SDA

A0

A1

A2

A2

ISL21400

VCC

VOUT

GND

3

8

7

4

R1

1k

C1

100pF

RF INPUT

R2

100

C2

FIGURE 19. LDMOS RFPA BIAS CONTROL

+28V

L1

RF OUTPUT

Q1

LDMOS

16

FN8091.1

April 24, 2007

ISL21400

Mini Small Outline Plastic Packages (MSOP)

N

EE1

INDEX

AREA

AA1A2

-H-

SIDE VIEW

12

TOP VIEW

b

e

D

NOTES:

1. These package dimensions are within allowable dimensions of

JEDEC MO-187BA.

2. Dimensioning and tolerancing per ANSI Y14.5M-1994.

3. Dimension “D” does not include mold flash, protrusions or gate

burrs and are measured at Datum Plane. Mold flash, protrusion

and gate burrs shall not exceed 0.15mm (0.006 inch) per side.

4. Dimension “E1” does not include interlead flash or protrusions

and are measured at Datum Plane. Interlead flash and

protrusions shall not exceed 0.15mm (0.006 inch) per side.

5. Formed leads shall be planar with respect to one another within

0.10mm (0.004) at seating Plane.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. Dimension “b” does not include dambar protrusion. Allowable

dambar protrusion shall be 0.08mm (0.003 inch) total in excess

of “b” dimension at maximum material condition. Minimum space

between protrusion and adjacent lead is 0.07mm (0.0027 inch).

- H -

-A -

.

10. Datums and to be determined at Datum plane

11. Controlling dimension: MILLIMETER. Converted inch dimensions are for reference only.

-B-

0.20 (0.008) A

GAUGE

PLANE

SEATING

PLANE

0.10 (0.004) C

-A-

0.20 (0.008) C

- B -

0.25

(0.010)

-C-

SEATING

PLANE

a

0.20 (0.008) C

- H -

B

4X θ

C

D

4X θ

L1

C

C

L

E

1

END VIEW

R1

R

L

-B-

M8.118 (JEDEC MO-187AA)

8 LEAD MINI SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.037 0.043 0.94 1.10 -

A1 0.002 0.006 0.05 0.15 -

A2 0.030 0.037 0.75 0.95 -

b 0.010 0.014 0.25 0.36 9

c 0.004 0.008 0.09 0.20 -

D 0.116 0.120 2.95 3.05 3

E1 0.116 0.120 2.95 3.05 4

e 0.026 BSC 0.65 BSC -

E 0.187 0.199 4.75 5.05 -

L 0.016 0.028 0.40 0.70 6

L1 0.037 REF 0.95 REF -

N8 87

R 0.003 - 0.07 - -

R1 0.003 - 0.07 - -

05

α

o

o

0

15

o

o

6

o

5

o

0

15

o

o

6

Rev. 2 01/03

NOTESMIN MAX MIN MAX

-

-

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implicat ion or oth erwise u nde r any p a tent or p at ent r ights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

17

FN8091.1

April 24, 2007

Loading...

Loading...