Intersil IRF620 Datasheet

IRF620

Data Sheet June 1999

5.0A, 200V, 0.800 Ohm, N-Channel

Power MOSFET

This N-Channel enhancementmode silicon gate power field

effect transistor is an advanced power MOSFET designed,

tested, and guaranteed to withstand a specified level of

energy in the breakdownavalanchemodeof operation. All of

these power MOSFETs are designed for applications such

as switching regulators, switching convertors, motor drivers,

relay drivers, and drivers for high power bipolar switching

transistors requiring high speed and low gate drive power.

These types can be operated directly from integrated

circuits.

Formerly developmental type TA9600.

Ordering Information

PART NUMBER PACKAGE BRAND

IRF620 TO-220AB IRF620

NOTE: When ordering, use the entire part number.

File Number

Features

• 5.0A, 200V

•r

• Single Pulse Avalanche Energy Rated

• SOA is Power Dissipation Limited

• Nanosecond Switching Speeds

• Linear Transfer Characteristics

• High Input Impedance

• Related Literature

- TB334 “Guidelines for Soldering Surface Mount

= 0.800Ω

DS(ON)

Components to PC Boards”

Symbol

D

G

1577.3

Packaging

S

JEDEC TO-220AB

SOURCE

DRAIN

GATE

DRAIN (FLANGE)

4-196

CAUTION: These devices are sensitive to electrostatic discharge; follow proper ESD Handling Procedures.

http://www.intersil.com or 407-727-9207

| Copyright © Intersil Corporation 1999

IRF620

Absolute Maximum Ratings T

= 25oC, Unless Otherwise Specified

C

IRF620 UNITS

Drain to Source Voltage (Note 1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

Drain to Gate Voltage (RGS = 20kΩ) (Note 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

DGR

Continuous Drain Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I

TC= 100oC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I

Pulsed Drain Current (Note 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I

Gate to Source Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

Maximum Power Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P

DS

D

D

DM

GS

D

200 V

200 V

5.0

3.0

20 A

±20 V

40 W

A

A

Linear Derating Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.32 W/oC

Single Pulse Avalanche Energy Rating (Note 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E

Operating and Storage Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TJ,T

AS

STG

Maximum Temperature for Soldering

Leads at 0.063in (1.6mm) from Case for 10s. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . T

Package Body for 10s, See TB334. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . T

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operationofthe

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

L

pkg

85 mJ

-55 to 150

300

260

o

C

o

C

o

C

NOTE:

1. TJ= 25oC to 125oC

Electrical Specifications T

= 25oC, Unless Otherwise Specified

C

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

Drain to Source Breakdown Voltage BV

Gate Threshold Voltage V

GS(TH)VDS

Zero Gate Voltage Drain Current I

On-State Drain Current (Note 2) I

D(ON)VDS

Gate to Source Leakage Current I

Drain to Source On Resistance (Note 2) r

DS(ON)VGS

Forward Transconductance (Note 2) g

Turn-On Delay Time t

d(ON)

Rise Time t

Turn-Off Delay Time t

d(OFF)

Fall Time t

Total Gate Charge

Q

g(TOT)VGS

(Gate to Source + Gate to Drain)

Gate to Source Charge Q

Gate to Drain “Miller” Charge Q

Input Capacitance C

Output Capacitance C

Reverse Transfer Capacitance C

Internal Drain Inductance L

Internal Source Inductance L

Thermal Resistance Junction to Case R

Thermal Resistance Junction to Ambient R

DSSVGS

DSS

GSS

fs

r

f

gs

gd

ISS

OSS

RSS

D

S

θJC

θJA

= 0V, ID = 250µA, (Figure 10) 200 - - V

= VGS, ID = 250µA 2.0 - 4.0 V

VDS = Rated BV

VDS = 0.8 x Rated BV

> I

D(ON)

, VGS = 0V - - 25 µA

DSS

, VGS = 0V, TJ = 125oC - - 250 µA

DSS

x r

DS(ON)MAX

, VGS = 10V 5.0 - - A

VGS = ±20V - - ±100 nA

= 10V, ID = 2.5A, (Figures 8, 9) - 0.8 1.2 Ω

VDS > I

VDD = 100V, ID≈ 5.0A, RG = 9.1Ω, RL = 20Ω,

MOSFET Switching Times are

Essentially Independent of Operating

Temperature

D(ON)

x r

DS(ON)MAX

, ID = 2.5A (Figure 12) 1.3 2.5 - S

-2040ns

-3060ns

- 50 100 ns

-3060ns

= 10V, ID = 5.0A, VDS = 0.8 x Rated BV

I

= 1.5mA, (Figure 14)

G(REF)

Gate Charge is Essentially Independent of

Operating Temperature

DSS,

-1115nC

- 5.0 - nC

- 6.0 - nC

VDS = 25V, VGS = 0V, f = 1MHz, (Figure 11) - 450 - pF

- 150 - pF

-40-pF

Measured from the Contact

Screw on Tab to Center of

Die

Measured from the Drain

Lead, 6mm (0.25in) from

Package to Center of Die

Measured from the Source

Lead, 6mm (0.25in) from

Header to Source Bonding

Pad

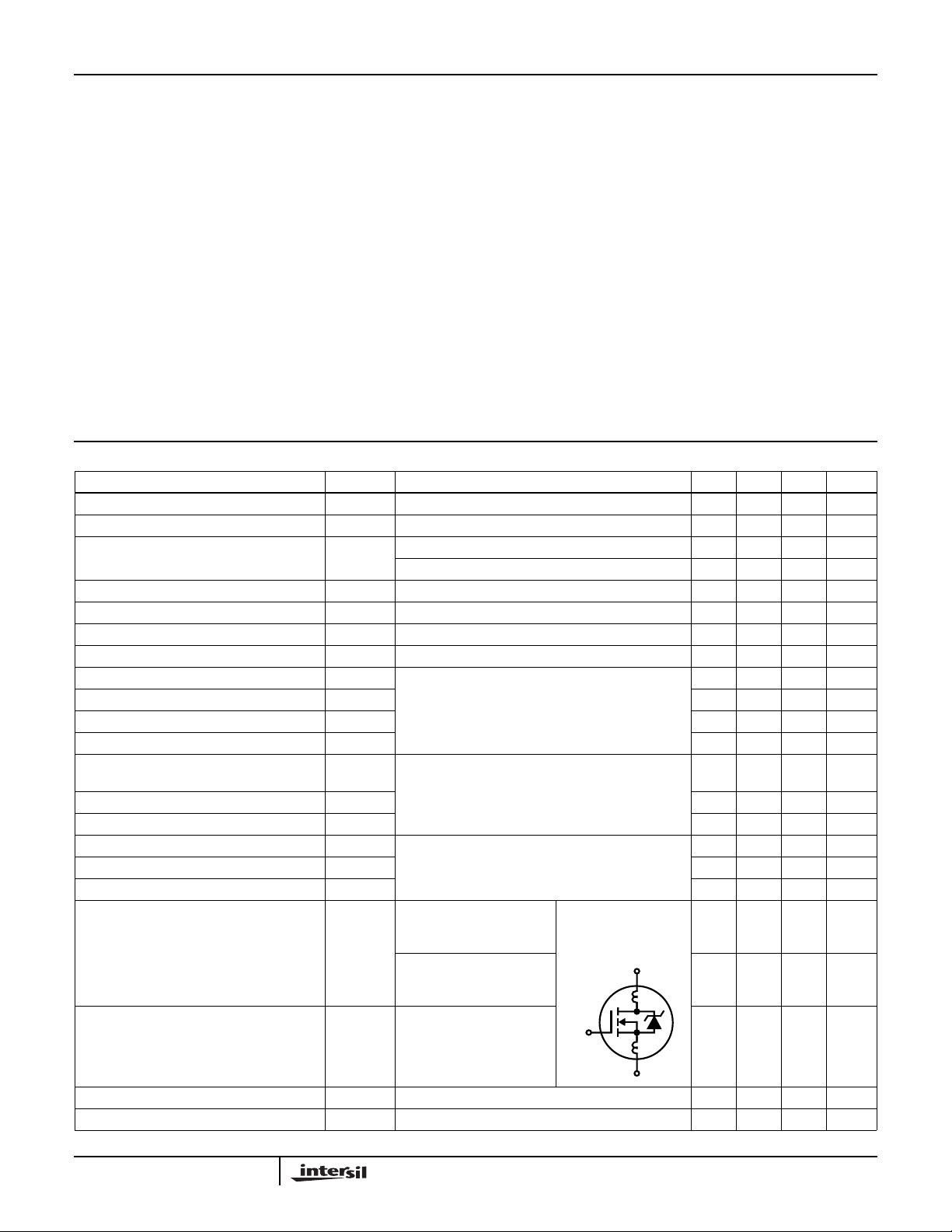

Modified MOSFET

Symbol Showing the

Internal Devices

Inductances

D

L

D

G

L

S

S

- 3.5 - nH

- 4.5 - nH

- 7.5 - nH

- - 3.12oC/W

Free Air Operation - - 62.5oC/W

4-197

IRF620

Source to Drain Diode Specifications

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

Continuous Source to Drain Current I

Pulse Source to Drain Current

SD

I

SDM

(Note 3)

Source to Drain Diode Voltage (Note 2) V

Reverse Recovery Time t

Reverse Recovery Charge Q

NOTES:

2. Pulse test: pulse width ≤ 300µs, duty cycle ≤ 2%.

3. Repetitive rating: pulse width limited by maximum junction temperature. See Transient Thermal Impedance curve (Figure 3).

4. VDD= 10V, starting TJ= 25oC, L = 6.18mH, RG= 50Ω, peak IAS = 5A.

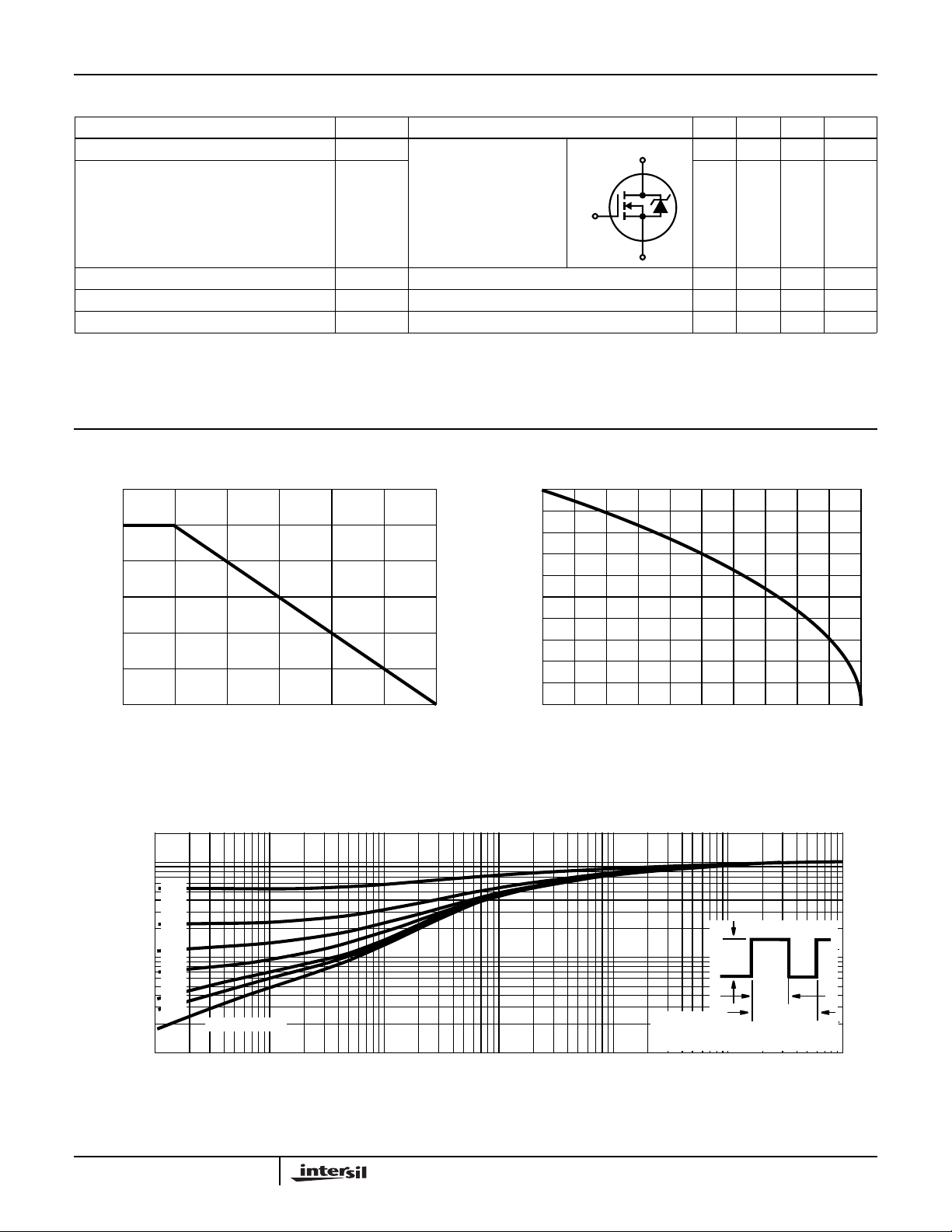

Modified MOSFET Symbol

Showing the Integral

Reverse P-N Junction

D

- - 5.0 A

- - 20 A

Rectifier

G

S

TJ = 25oC, ISD = 5.0A, VGS = 0V, (Figure 13) - - 1.8 V

SD

TJ = 150oC, ISD = 5.0A, dISD/dt = 100A/µs - 350 - ns

rr

TJ = 150oC, ISD = 5.0A, dISD/dt = 100A/µs - 2.3 - µC

RR

Typical Performance Curves

1.2

1.0

0.8

0.6

0.4

0.2

POWER DISSIPATION MULTIPLIER

0

0 50 100 150

, CASE TEMPERATURE (oC)

T

C

Unless Otherwise Specified

FIGURE 1. NORMALIZED POWER DISSIPATION vs CASE

TEMPERATURE

1.0

0.5

5

4

3

2

, DRAIN CURRENT (A)

D

I

1

0

25 50 75 100

TC, CASE TEMPERATURE (oC)

125

FIGURE 2. MAXIMUM CONTINUOUS DRAIN CURRENT vs

CASE TEMPERATURE

150

0.2

0.1

0.1

0.05

, NORMALIZED TRANSIENT

θJC

Z

0.02

THERMAL IMPEDENCE

0.01

SINGLE PULSE

0.01

-5

10

4-198

NOTES:

DUTY FACTOR: D = t

PEAK TJ = PDM x Z

-4

10

-3

10

t1, RECTANGULAR PULSE DURATION (s)

-2

10

-1

10

FIGURE 3. NORMALIZED MAXIMUM TRANSIENT THERMAL IMPEDANCE

P

DM

t

1

t

2

1/t2

x R

θJC

+ T

C

10

θJC

1

Loading...

Loading...