Page 1

查询ICL7112供应商

January 1998

®

D

W

E

N

R

O

F

D

E

D

N

E

M

M

O

C

E

R

T

O

N

S

N

G

I

S

E

ICL7112

12-Bit, High-Speed,

CMOS µP-Compatible A/D Converter

Features

• 12-Bit Resolution and Accuracy

• No Missing Codes

• Microprocessor Compatible Byte-Organized Buffered

Outputs

• Auto-Zeroed Comparator for Low Offset Voltage

• Low Linearity and Gain Errors

• Low Power Consumption (60mW)

• No Gain or Offset Adjustment Necessary

• Provides 3% Usable Overrange

• Fast Conversion (40µs)

Description

The ICL7112 is a monolithic 12-bit resolution, fast

successive approximation A/D converter. It uses thin film

resistors and CMOS circuitry combined with an on-chip

PROM calibration table to achieve 12-bit linearity without

laser trimming. Special design techniques used in the DAC

and comparator result in high speed operation, while the

fully static silicon-gate CMOS circuitry keeps the power

dissipation very low.

Microprocessor bus interfacing is eased by the use of

standard memory WRite

signals, combined with Chip

digital output pins are byte-organized and three-state gated

for bus interface to 8-bit and 16-bit systems.

The lCL7112 provides separate Analog and Digital grounds

for increased system accuracy. Operating with ±5V supplies,

the lCL7112 accepts 0V to +10V input with a -10V reference

or 0V to -10V input with a +10V reference.

and ReaD cycle timing and control

Select and Address pins. The

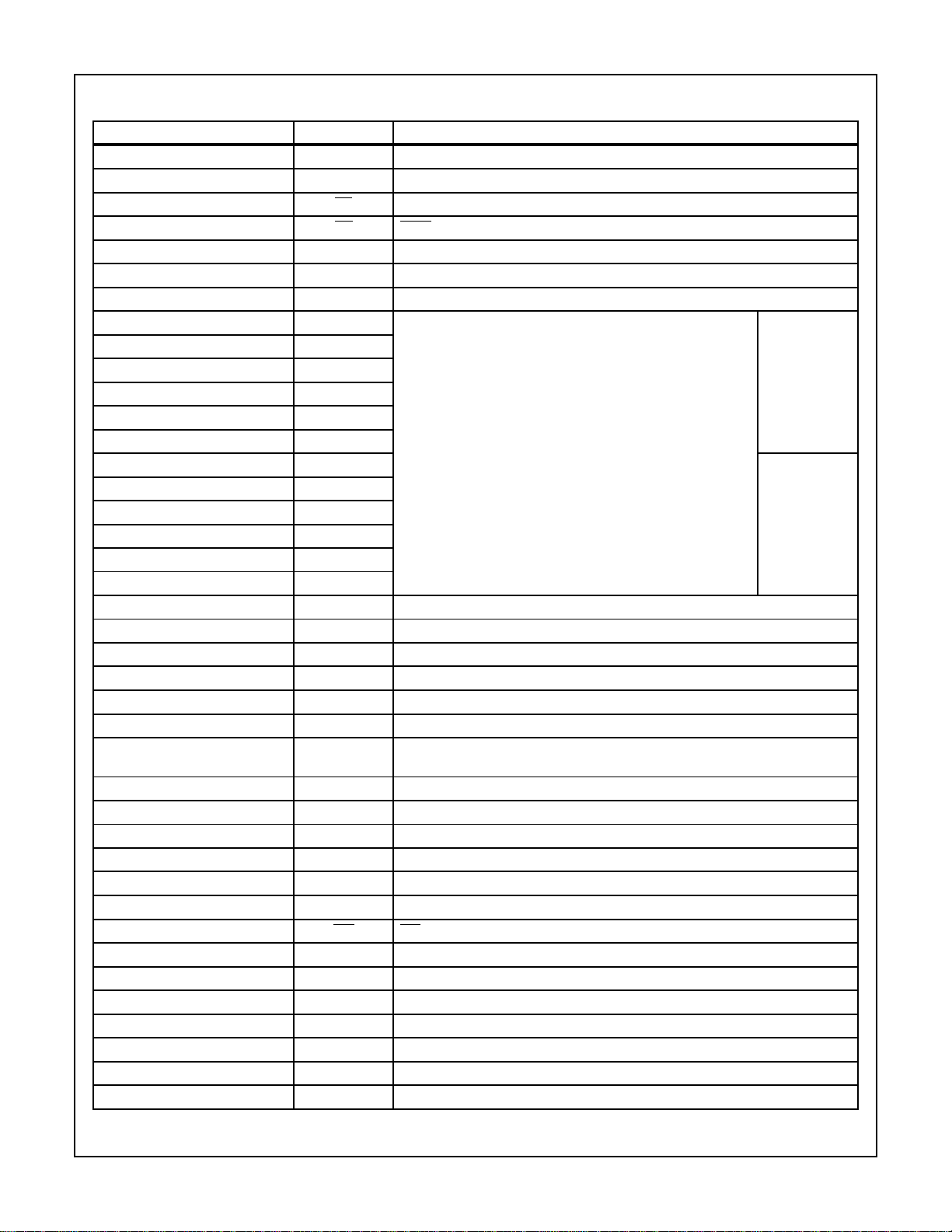

Ordering Information

RESOLUTION WITH NO MISSION

PART NO. TEMP. RANGE (oC) PACKAGE

ICL7112JCDL 0 to 70 40 Ld CERDIP 11-Bit

CODES

ICL7112KCDL 0 to 70 40 Ld CERDIP 12-Bit

ICL7112LCDL 0 to 70 40 Ld CERDIP 12-Bit (Note)±

ICL7112JIDL -25 to 85 40 Ld CERDIP 11-Bit

ICL7112KIDL -25 to 85 40 Ld CERDIP 12-Bit

ICL7112LIDL -25 to 85 40 Ld CERDIP 12-Bit (Note)±

ICL7112JMDL -55 to 125 40 Ld CERDIP 11-Bit

ICL7112KMDL -55 to 125 40 Ld CERDIP 12-Bit

ICL7112LMDL -55 to 125 40 Ld CERDIP 12-Bit (Note)±

NOTE: Over operating temperature range.

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-71 43

Copyright © Intersil Americas Inc. 2002. All Rights Reserved

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

6-1

File Number 3639.1

Page 2

Pinout

AGNDf

DGND

(MSB) D

(LSB) D

NC

CS

RD

A

BUS

D

D

D

D

D

D

D

D

D

D

NC

ICL7112

ICL7112

TOP VIEW

1

2

3

4

5

0

6

7

8

11

9

10

10

9

11

8

12

7

13

6

14

5

15

4

16

3

17

2

18

1

19

0

20

ICL7112

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

NC

AGNDs

V

REF

V

IN

COMP

-

V

C

AZ

WR

TEST

OSC2

OSC1

TEST

PROG

+

V

OVR

EOC

NC

NC

NC

NC

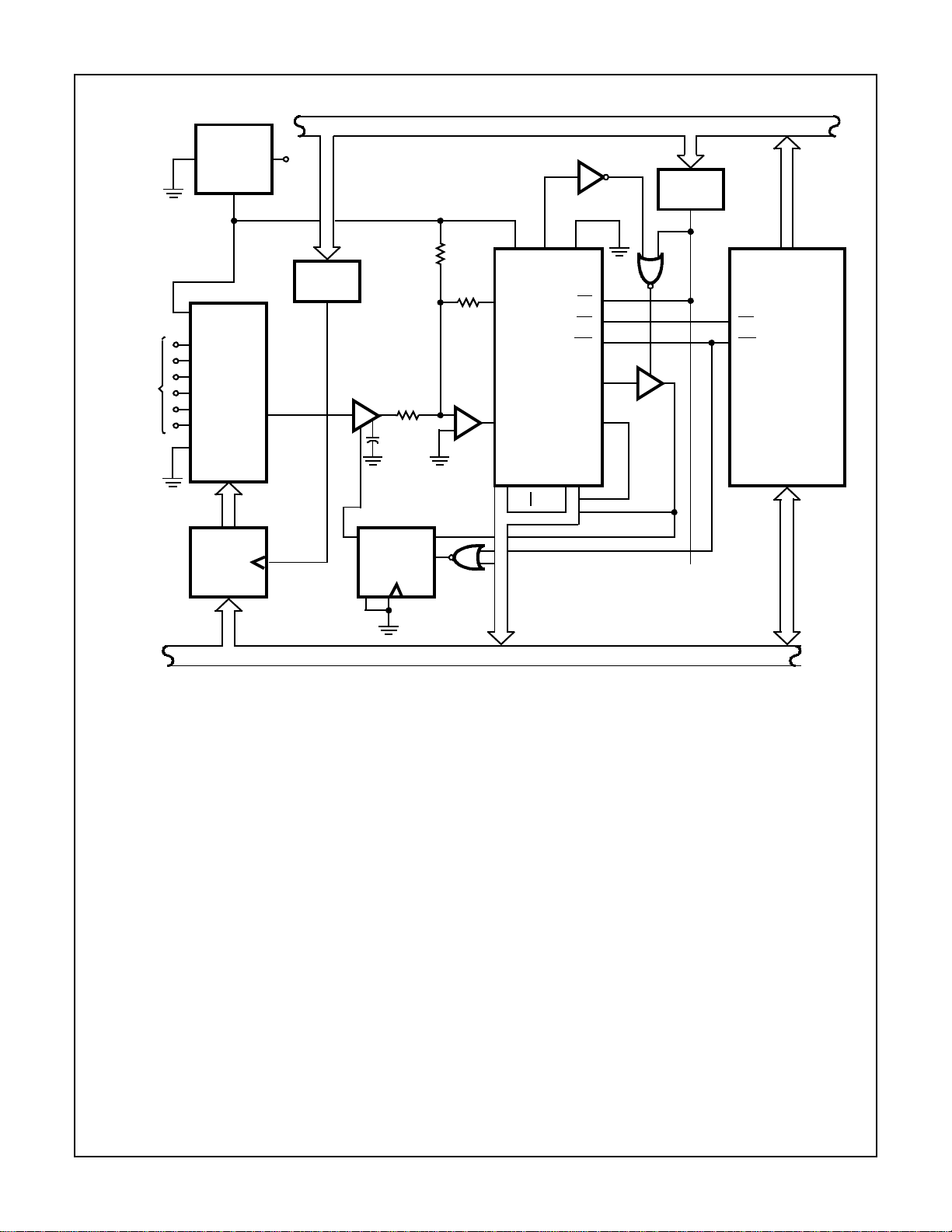

Functional Block Diagram

V

REF

AGND

Y

DGND

+

-

V

DAC

R-1.85R

PROM

LATCH

V

IN

R

IN

COMP

+

C

AZ

-

CONTROL LOGIC

ADDER

ACCCUM

SAR

OSC1 OSC2

LATCH

WR

EOC

THREE-STATE

OUTPUTS

CSRD

0

OVR

D

(MSB)

11

D

(LSB)

0

BUSA

6-2

Page 3

ICL7112

Absolute Maximum Ratings T

Supply Voltage (V+ to DGND) . . . . . . . . . . . . . . . . . . -0.3V to +6.5V

Supply Voltage (V

V

, VIN to DGND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±25V

REF

AGND to DGND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +1V to -1V

V

, VIN, AGND Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25mA

REF

Digital I/O Pin Voltages. . . . . . . . . . . . . . . . . . . . . -0.3V to V+ +0.3V

PROG to DGND Voltage . . . . . . . . . . . . . . . . . . . . V

-

to DGND). . . . . . . . . . . . . . . . . . . +0.3V to -6.5V

=25oC Thermal Information

A

Thermal Resistance (Typical, Note 1) θ

CERDIP Package . . . . . . . . . . . . . . . . ___ ___

Maximum Power Dissipation (Note 2) . . . . . . . . . . . . . . . . . . 500mW

Derate above 70

o

C at 10mW/oC

Maximum Junction Temperature (Ceramic Package) . . . . . . . . 175

-

to (V+ +0.3V)

Maximum Storage Temperature Range . . . . . . . . . . -65

Maximum Lead Temperature (Soldering 10s). . . . . . . . . . . . . 300

(oC/W) θJC (oC/W)

JA

o

C to 150oC

o

o

Operating Conditions

ICL7112XCXX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 to 70

ICL7112XIXX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -25 to 70

ICL7112XMXX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -55 to 125

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

is measured with the component mounted on an evaluation PC board in free air.

1. θ

JA

2. All voltages with respect to DGND, unless otherwise noted.

3. Assumes all leads soldered or welded to printed circuit board.

Electrical Specifications Test Conditions: V+ = +5V, V- = -5V, V

PARAMETER SYMBOL

ACCURACY

Resolution RES 12 Bits

Resolution with No

Missing Codes

Integral Linearity

Error

Unadjusted Full

Scale Error

RES

Notes 4, 5, 6 R

(NMC)

I

LE

Notes 4, 5 R

FSE Adjust-

able to

Zero

Zero Error ZE Notes 4, 5 R

ANALOG INPUT

Analog Input

Range

Input Resistance R

Temperature

Coefficient of R

V

IN

IN

Notes 5, 8 4 - 9 4 - 9 4 - 9 kΩ

TC (RIN)T

IN

REFERENCE INPUT

Analog Reference V

Reference

Resistance

R

REF

REF

POWER SUPPLY SENSITIVITY

Power Supply

PSRR V

+

Rejection Ration

LOGIC INPUT

Low State

V

IL

Input Voltage

TEST

CONDITIONS

T

-T

MIN

MAX

T

-T

MIN

MAX

CR

T

MIN TMAX

IR

T

-T

MIN

MAX

MR

T

-T

MIN

MAX

T

-T

MIN

MAX

-T

MIN

MAX

, V- = 4.5 -5.5V RM

T

-T

MIN

MAX

T

-T

MIN

MAX

11

M

10

--±0.024

M

--±0.10

M

--±0.10

M

--±0.10

M

--±1

M

0 -10.30-10.30-10.3V

- -300 - - -300 - - -300 - ppm/oC

- -10.0 - - -10.0 - - -10.0 - V

-5 - -5--5-kΩ

- ±0.5 ±1

--0.8--0.8--0.8V

= -10V, TA = 25oC, f

REF

= 500kHz, Unless Otherwise Noted

CLK

JKL

UNITSMIN TYP MAX MIN TYP MAX MIN TYP MAX

--1211--1212--

±0.030

±0.12

±0.13

±0.14

±1.5

±2

--±0.012

±0.020

--±0.08

±0.10

--±0.08

±0.11

--±0.08

±0.12

--±1

±1.5

- ±0.5 ±1

±2

--±0.012

±0.020

--±0.08

±0.10

--±0.08

±0.11

--±0.08

±0.12

--±1

±1.5

- ±0.5 ±1±2LSB

Bits

%FSR

%FSR

C

C

6-3

Page 4

ICL7112

Electrical Specifications Test Conditions: V+ = +5V, V- = -5V, V

TEST

PARAMETER SYMBOL

High State

V

IH

CONDITIONS

T

MIN

-T

MAX

2.4 - - 2.4 - - 2.4 - - V

= -10V, TA = 25oC, f

REF

JKL

Input Voltage

Logic Input

I

LIH

0 < VIN < V

+

- 110-110-110µA

Current

Logic Input

C

IN

- 15 - -15 - -15 - pF

Capacitance

LOGIC OUTPUT

Low State Output

Voltage

High State Output

Voltage

Three-State Output

Current

Logic Output

Capacitance

V

V

I

C

OL

OH

OX

OUT

= 1.6mA

OUT

I

OUT

0 < V

= -200µA

< V

OUT

T

T

+

MIN

MIN

-T

-T

MAX

MAX

Three-State - 15 - - 15 - - 15 - pF

--0.4--0.4--0.4V

2.8 - - 2.8 - - 2.8 - - V

-1 - -1--1-µA

I

POWER REQUIREMENTS

Supply Voltage

Range

Supply Current,

I+, I-

V

SUPPLY

I

SUPPLY

Functional Operation Only ±4.5 - ±6.0 ±4.5 - ±6.0 ±4.5 - ±6.0 V

T

MIN

-T

R

MAX

-246-246-246mA

M

NOTES:

4. Full scale range (FSR) is 10V (reference adjusted).

5. Assume all leads are soldered or welded to printed circuit board.

6. “J” and “K” versions not production tested. Guaranteed by Integral Linearity Test.

7. Typical values are not tested, for reference only.

8. Not production tested. Guaranteed by design.

= 500kHz, Unless Otherwise Noted

CLK

UNITSMIN TYP MAX MIN TYP MAX MIN TYP MAX

AC Electrical Specifications Test Conditions V + = +5V, V- = -5V, T

derived from extensive characterization testing. Parameters are not production tested

PARAMETER SYMBOL

READ CYCLE TIMING

Propagation Delay CS

Propagation Delay A0 to Data t

Propagation Delay RD

Propagation Delay Data to Three-State t

Propagation Delay EOC High to Data t

to Date t

to Data t

cd

ad

rd

rx

ed

WRITE CYCLE TIMING

WR

Low Time t

Propagation Delay WR Low to EOC Low t

EOC High Time t

Conversion Time t

Clock Frequency Range f

wr

we

eo

conv

CLK

NOTE:

9. All typical values have been characterized, but are not tested.

RD Low, A0 Valid - - 200

CS Low, RD Low - - 200

CS Low, A0 Valid - - 200

Wait Mode 1 - 2

Free Run Mode 0.5 - 1.5 1/f

Functional Operation Only - 500 - kHz

TEST

CONDITIONS MIN TYP MAX UNITS

= 25oC, f

A

= 500kHz, unless otherwise noted. Data

CLK

--150

--200

150 - - ns

--20

ns

CLK

6-4

Page 5

ICL7112

Pin Descriptions

PIN NO. NAME DESCRIPTION

1 No connection.

2AGND

3CS

4RD

5A

0

6 BUS Bus select (low = outputs enabled by A

7 DGND Digital GrouND return.

8D

9D

10 D

11 D

12 D

13 D

14 D

15 D

16 D

17 D

18 D

11

10

9

8

7

6

5

4

3

2

1

19 D0 Bit 0 (least significant bit).

20 No connection.

21 No connection.

22 No connection.

23 No connection.

24 No connection.

25 EOC End of conversion flag (low = busy, high = conversion complete).

26 OVR OVerRange flag (valid at end of conversion when output code exceeds full-scale;

27 V

+

28 PROG Used for programming only. Must tie to V

29 TEST Used for programming only. Must tie to V

30 OSC1 Oscillator inverter input.

31 OSC2 Oscillator inverter output.

32 TEST Must tie to V

33 WR

34 C

35 V

AZ

-

36 COMP Used in test, tie to V

37 V

38 V

IN

REF

39 AGND

40 No connection

NOTE: The voltage of CAZ is driven; NEVER connect directly to ground.

FORCE input for analog ground.

f

Chip Select enables reading and writing (active low).

ReaD (active low).

Byte select (low = D0 -D7, high = D8 -D11, OVR).

Bit 11 (most significant bit).

Bit 10

Bit 9

Bit 8

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

three-state output enabled with high byte).

Positive power supply input.

+

for normal operation.

WRite pulse input (low starts new conversion).

Auto-zero capacitor connection (Note).

Negative power supply input.

SENSE line for input voltage.

SENSE line for reference input.

SENSE line for analog ground.

s

, high = all outputs enabled together).

0

High Byte

Output

Data

Bits

(High =True)

Low Byte

+

for normal operation.

+

for normal operation.

-

.

6-5

Page 6

Timing Diagrams

CS

WR

EOC

D0 - D

EOC

CS

A

0

RD

13

= DON’T CARE

ICL7112

t

CD

VALID

t

AD

t

RD

t

ED

= DON’T CARE

FIGURE 1. READ CYCLE TIMING

t

WR

FIGURE 2. WRITE CYCLE TIMING

VALID

t

WE

t

RX

t

CONV

t

EO

TABLE 2: I/O CONTROL

CS

WR RD A0BUS FUNCTION

0 0 x x x Initiates a conversion.

1 x x x x Disables all chip commands.

0 x 0 0 0 Low byte is enabled.

0 x 0 1 0 High byte is enabled.

0 x 0 x 1 Low and High bytes enabled togeth-

x x 1 x x Disables outputs (high-impedance).

TABLE 3: TRANSFER FUNCTION

INPUT VOLTAGE EXPECTED OUTPUT CODE

= -10.0V OVR MSB LSB

V

REF

0

+0.00244

+0.30029 0 0 0000111101 1

+4.99756

+5.00000

+9.99512

+9.99756

+10.00000

+10.00244

+10.29000 1 0 0000111101 1

er.

0

0

0

0

0

0

1

1

0

0

0

1

1

1

0

0

0000000000

0000000000

1111111111

0000000000

1111111111

1111111111

0000000000

0000000000

0

1

1

0

0

1

0

1

Detailed Description

The ICL7112 is basically a successive approximation A/D

converter with an internal structure much more complex than

a standard SAR-type converter. The Functional Block Diagram shows the functional diagram of the ICL7112 12-bit

A/D converter. The additional circuitry incorporated into the

ICL7112 is used to perform error correction and to maintain

the operating speed in the 40µs range.

The internal DAC of the ICL7112 is designed around a radix

of 1.85, rather than the traditional 2.00. This radix gives each

bit of the DAC a weight of approximately 54% of the previous

bit. The result is a usable range that extends to 3% beyond

the full-scale input of the A/D. The actual value of each bit is

measured and stored in the on-chip PROM. The absolute

value of each bit weight then becomes relatively unimportant

because of the error correction action of the ICL7112.

The output of the high-speed auto-zeroed comparator is fed

to the data input of a successive approximation register

(SAR). This register is uniquely designed for the ICL7112 in

that it tests bit pairs instead of individual bits in the manner of

a standard SAR. At the beginning of the conversion cycle,

the SAR turns on the MSB (D

The sequence continues for each bit pair, B

) and the MSB 4-bit (D7).

11

and B

X

x-4

, until

only the four LSBs remain. The sequence concludes by testing the four LSBs individually.

The SAR output is fed to the DAC register and to the preprogrammed PROM where it acts as PROM address. PROM

data is fed to a full-adder/accumulator where the decoded

results from each successive phase of the conversion are

summed with the previous results. After 20 clock cycles, the

accumulator contains the final binary data which is latched

and sent to the three-state output buffers. The accuracy of

the A/D converter depends primarily upon the accuracy of

the data that has been programmed into the PROM during

6-6

Page 7

ICL7112

the final test portion of the manufacturing process.

The error correcting algorithm built into the ICL7112 reduces

the initial accuracy requirements of the DAC. The overlap in

the testing of bit pairs reduces the accuracy requirements on

the comparator which has been optimized for speed. Since

the comparator is auto-zeroed, no external adjustment is

required to get ZERO code for ZERO input voltage.

Twenty clock cycles are required for the complete 12-bit conversion. The auto-zero circuitry associated with the comparator is employed during the last three clock cycles of the

conversion to cancel the effect of offset voltage. Also during

this time, the SAR and accumulator are reset in preparation

for the start of the next conversion.

The overflow output of the full-adder is also the OVer Range

(OVR) output of the ICL7112. Unlike standard SAR type A/D

converters, the ICL7112 has the capability of providing valid

usable data for inputs that exceed the fullscale range by as

much as 3%.

Optimizing System Performance

When using A/D converters with 12 or more bits of resolution, special attention must be paid to grounding and the

elimination of potential ground loops. A ground loop can be

formed by allowing the return current from the lCL7112’s

DAC to flow through traces that are common to other analog

circuitry. If care is not taken, this current can generate small

unwanted voltages that add to or detract from the reference

or input voltages of the A/D converter.

Figure 3 and Figure 4 show two different grounding techniques. Although the difference between the two circuits may

not be readily apparent, the circuit of Figure 3 is very likely to

have significant ground loop errors which the circuit of Figure 4 avoids. In Figure 3, the supply currents for analog

ground, digital ground, and the reference voltage all flow

through a lead, common to the input. This will generate a DC

offset voltage due to the currents flowing in the resistance of

the common lead. This offset voltage will vary with the input

voltage and with the digital output. Even the auto-zero loop

of the ICL7112 cannot remove this error.

Figure 4 shows a much better arrangement. The ground and

reference currents do not flow through the input common

lead, eliminating any error voltages. Note that the supply

currents and any other analog system currents must also be

returned carefully to analog ground. The clamp diodes will

protect the ICL7112 against signals which could result from

separate analog and digital grounds. The absolute maximum

voltage rating between AGND and DGND is ±1.0V. The two

inverse-parallel diodes clamp this voltage to less than ±0.7V.

Input Warning

As with any CMOS integrated circuit, no input voltages

should be applied to the lCL7112 until the ±5V power supplies have stabilized.

Interfacing To Digital Systems

The_ICL7112 provides three-state data output buffers, CS,

RD

, WR, and bus select inputs (A0 and BUS) for interfacing

to a wide variety of microcomputers and digital systems. The

I/O Control Truth Table shows the functions of the digital

control lines. The BUS select and A

enable the output data onto either 8-bit or 16-bit data buses.

A conversion is initiated by a WR

(pin 3) is low. Data is enabled on the bus when the chip is

selected and RD

(pin 4) is low.

Figure 5 illustrates a typical interface to an 8-bit microcomputer. The “Start and Wait” operation requires the fewest

external components and is initiated by a low level on the

WR

input to the ICL7112 after the I/O or memory mapped

address decoder has brought the CS

ing a delay or utility routine for a period of time greater than

the conversion time of the ICL7112, the processor issues

two consecutive bus addresses to read output data into two

bytes of memory. A low level on A

high level enables the MSBs.

lines are provided to

0

pulse (pin 33) when CS

input low. After execut-

enables the LSBs, and a

0

V

IN +

SOURCE -

V

REF -

SOURCE +

FIGURE 3. IMPROPER GROUNDING TECHNIQUE WILL CAUSE GROUND LOOP ERRORS

V

IN

ICL7112

V

REF

AGND

DGND

6-7

Page 8

ICL7112

V

IN +

SOURCE -

V

REF -

SOURCE +

V

IN

ICL7112

V

REF

AGND

DGND

FIGURE 4. RECOMMENDED GROUNDING TECHNIQUE TO ELIMINATE GROUND LOOP ERRORS

ADDRESS BUS

A

0

A

0

ICL7112

ADDRESS

DECODE

CS

RD

WR

BUS

OVR

RD

WR

A0 - A

µP

N

CS

OVR

- D

D

8

11

7

WAIT

WR

CS

A

0

RD

START

CONVERSION

D0 - D

FIGURE 5. “START AND WAIT” OPERATION

By adding a three-state buffer and two control gates, the

End-of-Conversion (EOC) output can be used to control a

“Start and Poll” interface (Figure 6). In this mode, the A

CS

lines connect the EOC output to the data bus along with

the most significant byte of data. After pulsing the WR

and

0

line to

initiate a conversion, the microprocessor continually reads

the most significant byte until it detects a high level on the

EOC bit. The “Start and Poll” interface increases data

throughput compared with the “Start and Wait” method by

eliminating delays between the conversion termination and

- D

D

0

7

DATA BUS

READ

LOW BYTE

READ

HIGH BYTE

the microprocessor read operation.

Other interface configurations can be used to increase data

throughput without monopolizing the microprocessor during

waiting or polling operations by using the EOC line as an

interrupt generator as shown in Figure 7. After the conversion cycle is initiated, the microprocessor can continue to

execute routines that are independent of the A/D converter

until the converter’s output register actually holds valid data.

For fastest data throughput, the ICL7112 can be connected

directly to the data bus but controlled by way of a Direct

6-8

Page 9

ICL7112

Memory Access (DMA) controller as shown in Figure 8.

Applications

Figure 9 shows a typical application of the ICL7112 12- bit

A/D converter. A bipolar input voltage range of +10V to -10V

is the result of using the current through R

scale offset on the input amplifier (A

swings from 0V to -1 0V. The overall gain of the A/D is varied

by adjusting the 100Ω trim resistor, R

5

automatically zeroed every conversion, the system gain and

offset stability will be superb as long as a reference with a

tempco of 1ppm/

o

C and stable external resistors are used.

If is important to note that since the 7112’s DAC current

flows in A

, the amplifier should be a wideband (GBW >

1

20MHz) type to minimize errors.

The clock for the ICL7112 is taken from whatever system

clock is available and divided down to the level for a conversion time of 40µs. Output data is controlled by the BUS and

A

inputs. Here they are set for 8-bit bus operation with BUS

0

grounded and A

under the control of the address decode

0

section of the external system.

Because the ICL7112’s internal accumulator generates

accurate output data for input signals as much as 3% greater

than full-scale, and because the converter’s OVR output

flags overrange inputs, a simple microprocessor routine can

be employed to precisely measure and correct for system

gain and offset errors. Figure 10 shows a typical data acquisition system that uses a 10V reference, input signal multiplexer, and input signal Track/Hold amplifier. Two of the

multiplexer’s input channels are dedicated to sampling the

system analog ground and reference voltage. Here, as in

Figure 9, bipolar operation is accommodated by an offset

resistor between the reference voltage and the summing

junction of A

. A flip-flop in IC3 sets 1C2’s Track/Hold input

1

after the microprocessor has initiated a WR command, and

resets when EOC goes high at the end of the conversion.

The first step in the system calibration routine is to select the

multiplexer channel that is connected to system analog

ground and initiate a conversion cycle for the ICL7112. The

results represent the system offset error which comes from

the sum of the offsets from IC

, IC2, and A1. Next the chan-

1

nel connected to the reference voltage is selected and measured. These results, minus the system offset error,

represent the system full-scale range. A gain error correction

factor can be derived from this data. Since the lCL7112 provides valid data for inputs that exceed full-scale by as much

as 3%, the OVR output can be thought of as a valid 13th

data bit. Whenever the OVR bit is high, however, the total

12-bit result should be checked to ensure that it falls within

100% and 103% of full-scale. Data beyond 103% of fullscale should be discarded.

to force a 1/2

2

). The output of A

1

. Since the ICL7112 is

1

Clock Considerations

The ICL7112 provides an internal inverter which is brought

out to pins OSC1 and OSC2, for crystal or ceramic resonator

oscillator operation. The clock frequency is calculated from:

=

20

------ ----------- -

t

CONV

f

CLK

6-9

Page 10

()

ICL7112

ADDRESS BUS

A

0

WR

CS

EOC

D0 - D

A

ICL7112

D

8

7

0

- D

WR

RD

A0 - A

µP

- D

D

0

N

CS

7

ADDRESS

DECODE

WR

CS

RD

EOC

BUS

OVR

11

1/4 74125

DATA BUS

(B)

END OF

CONVERSION

A

RD

0

START

CONVERSION

POLL

READ

HIGH BYTE

READ

HIGH BYTE

READ

LOW BYTE

FIGURE 6. START AND POLL” OPERATION

6-10

Page 11

ICL7112

ADDRESS BUS

A

0

WR

D0 - D

A

0

ICL7112

- D

D

8

7

INTERRUPT

WR

EOC

BUS

OVR

11

CS

RD

ADDRESS

DECODE

DATA BUS

RD

WR

INT

A0 - A

µP

- D

D

0

N

7

CS

EOC

A

RD

0

START

CONVERSION

READ

LOW BYTE

READ

HIGH BYTE

FIGURE 7. USING EOC AS AN INTERRUPT

6-11

Page 12

ICL7112

ADDRESS BUS

A

0

EOC

D0 - D

A

0

ICL7112

D

7

DRQ

DACK

A0 - A

N

N

DMA

11

CS

WR

EOC

RD

CS

CONTROLLER

BUS

OVR

- D

8

11

D

- D

0

7

DATA BUS

DACK

N

A

0

READ

LOW BYTE

END OF

CONVERSION

READ

HIGH BYTE

START

CONVERSION

FIGURE 8. DATA TO MEMORY VIA DMA CONTROLLER

6-12

Page 13

10V

REFERENCE

INPUT VOLTAGE

+10V TO -10V

HI

LO

R

R

1

100k

ICL7112

+5V

28 32 29 27 500KHz

OSC

EOC

DATA

OUT

WR

RD

CS

A

+

30

DIVIDER

25

26

HIGH

BYTE

13

14

LOW BYTE

21

33

4

3

ADDRESS

5

0

DECODE

PINS 1, 20, 21, 22, 23, 24, 40

NO CONNECTIONS

SYSTEM

CLOCK

8-BIT

DATA BUS

4

R

5

100K

R

R

2

A

2

-

+

A

2

-

+

DIODES

1N914

3

50k

0.22µF

100k

PROG TEST V

36

V

REF

37

V

IN

34

CAZ

AGND

39

AGND

2

COMP

TEST

ICL7112

V+DGND BUS

36 35 7 6

DIGITAL

-5V

GROUND

FIGURE 9. TYPICAL APPLICATION WITH BIPOLAR INPUT RANGE, FORCED GROUND, AND 10V ULTRA STABLE REFERENCE

6-13

Page 14

ADDRESS BUS

ANALOG

INPUTS

REFERENCE

10V

I

S

IC

1

IH5108

OUT

I

R

- A

A

0

2

DATA

LATCH

V

CC

ADDRESS

DECODE

IC 2

LF398

Q

1/2 4013

D

ADDRESS

DECODE

V

V

REF

S

0

ICL7112

BUSA

A0 - A

N

CS

RD

WR

RD

WR

µP

EOC

10k

+

V

R

D8 - D13D0 - D

OVR

7

1/2

74125

D

- D

0

7

R

IC

3

S

DATA BUS

FIGURE 10. MULTI-CHANNEL DATA ACQUISITION SYSTEM WITH ZERO AND REFERENCE LINES BROUGHT TO MULTIPLEXER

FOR SYSTEM GAIN AND OFFSET ERROR CORRECTION

6-14

Loading...

Loading...