Page 1

查询ICL7104供应商

August 1997

ICL8052/ICL7104,

ICL8068/ICL7104

14-Bit/16-Bit, Microprocessor-

Compatible, 2-Chip, A/D Converter

Features

• 16-Bit/14-Bit Binary Three-State Latched Outputs Plus

Polarity and Overrange

• Ideally Suited for Interface to UARTs and

Microprocessors

• Conversion on Demand or Continuously

• Guaranteed Zero Reading for 0V Input

• True Polarity at Zero Count for Precise Null Detection

• Single Reference Voltage for True Ratiometric

Operation

• Onboard Clock and Reference

• Auto-Zero, Auto-Polarity

• Accuracy Guaranteed to 1 Count

• All Outputs TTL Compatible

• ±4V Analog Input Range

• Status Signal Available for External Sync, A/Z in

Preamp, Etc.

Description

The ICL7104, combined with the ICL8052 or ICL8068,

forms a member of Intersil’ high performance A/D converter

family. The ICL7104-16, performs the analog switching and

digital function for a 16-bit binary A/D converter, with full

three-state output, UART handshake capability, and other

outputs for easy interfacing. The ICL7014-14 is a 14-bit

version. The analog section, as with all Intersil’ integrating

converters, provides fully precise Auto-Zero, Auto-Polarity

(including ±0 null indication), single reference operation,

very high input impedance, true input integration over a

constant period for maximum EMI rejection, fully

rationmetric operation, over-range indication, and a

medium quality built-in reference. The chip pair also offers

optional input buffer gain for high sensitivity applications, a

built-in clock oscillator, and output signals for providing an

external Auto-Zero capability in preconditioning circuitry,

synchronizing external multiplexers, etc.

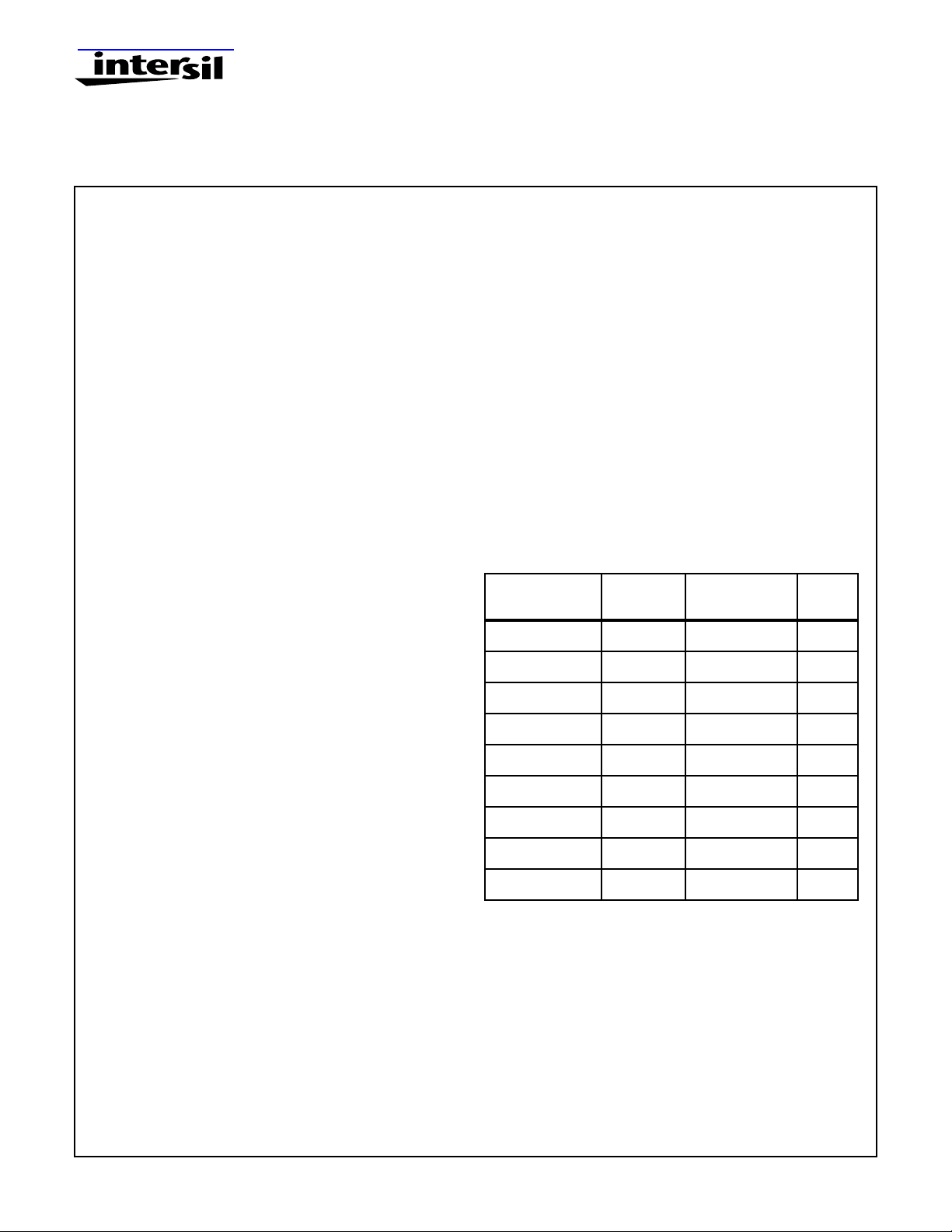

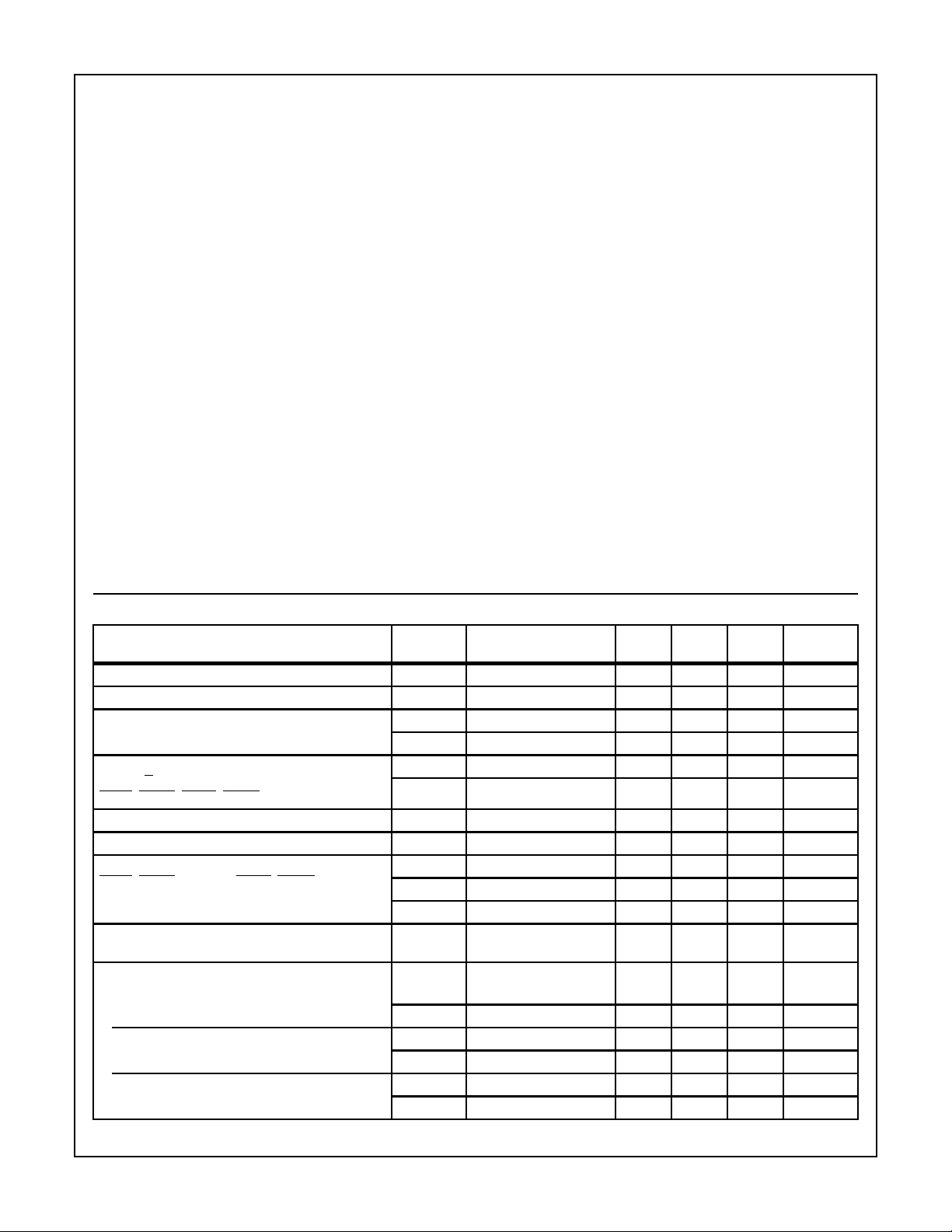

Ordering Information

TEMP.

PART NUMBER

ICL8052CPD 0 to 70 14 Ld PDIP E14.3

lCL8052CDD 0 to 70 14 Ld CERDIP F14.3

RANGE (oC) PACKAGE

PKG.

NO.

lCL8052ACPD 0 to 70 14 Ld PDIP E14.3

ICL8052ACDD 0 to 70 14 Ld CERDIP F14.3

ICL8068CDD 0 to 70 14 Ld CERDIP F14.3

ICL8068ACDD 0 to 70 14 Ld CERDIP F14.3

lCL8068ACJD 0 to 70 14 Ld CERDIP F14.3

ICL7104-14CPL 0 to 70 40 Ld PDIP E40.6

lCL7104-16CPL 0 to 70 40 Ld PDIP E40.6

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143 | Copyright © Intersil Corporation 1999

5-6

File Number 3091.1

Page 2

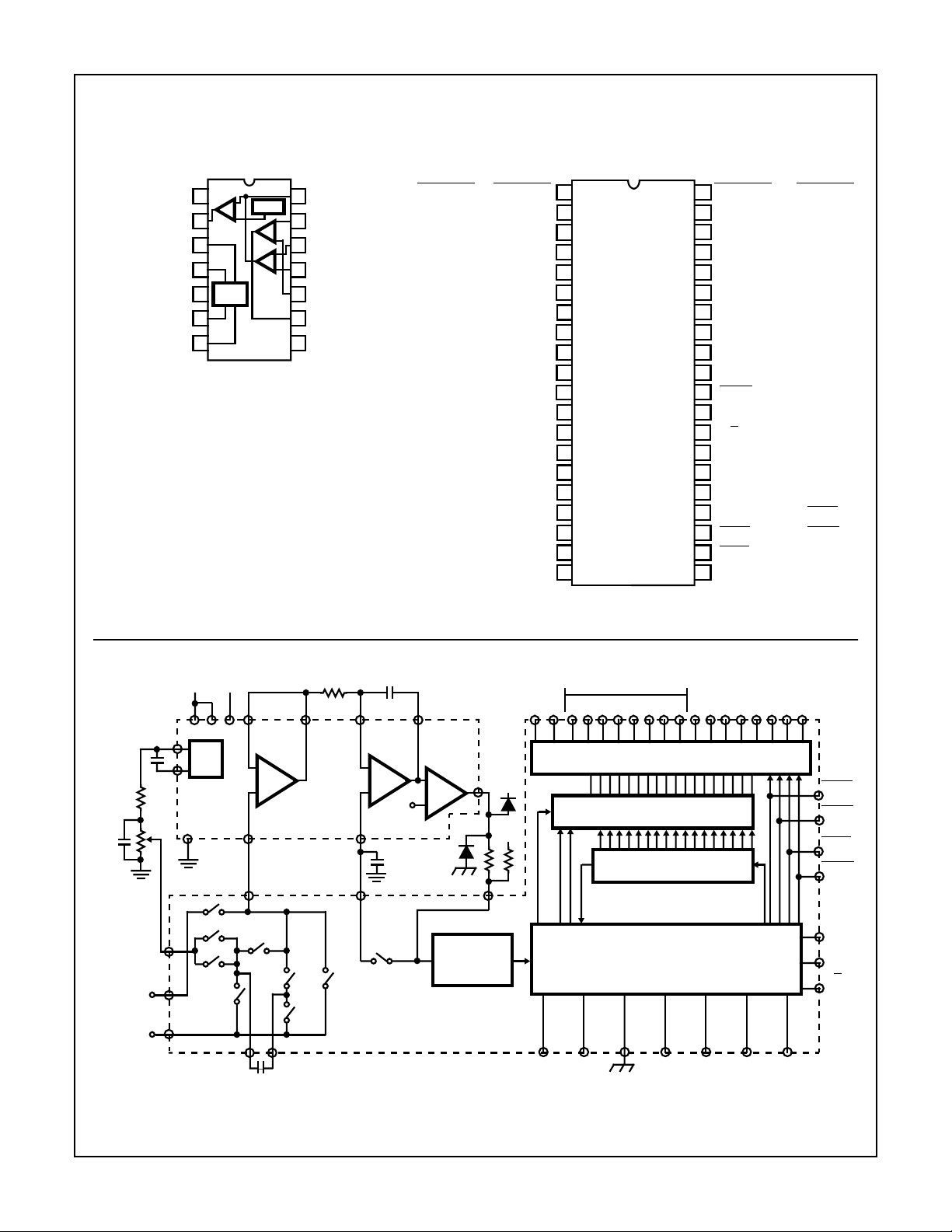

Pinouts

ICL8052/ICL7104, ICL8068/ICL7104

COMP OUT

REF CAP

REF BYPASS

GND

REF OUT

REF SUPPLY

ICL8052/ICL8068

(CERDIP, PDIP)

TOP VIEW

V-

1

2

3

4

5

6

7

(OUTLINE DWGS DD, JD, PD)

V

REF

-1.2V

ICL8052/

ICL8068

INT OUT

14

+BUFF IN

13

+INT IN

12

-INT IN

11

-BUFF IN

10

BUFF OUT

9

V++

8

V++

DIG GND

STTS

POL

OR

BIT 16

BIT 15

BIT 14

BIT 13

BIT 12

BIT 11

BIT 10

BIT 9

BIT 8

BIT 7

BIT 6

BIT 5

BIT 4

BIT 3

BIT 2

ICL7104

(PDIP)

TOP VIEW

ICL7104-14ICL7104-16 ICL7104-14 ICL7104-16

DIG GND

BIT 14

BIT 13

BIT 12

BIT 11

BIT 10

V++

STTS

POL

OR

BIT 9

NC

NC

BIT 8

BIT 7

BIT 6

BIT 5

BIT 4

BIT 3

BIT 2

1

2

3

4

5

6

7

8

9

10

ICL7104-14

(OUTLINE DWGS DL,

11

12

13

14

15

16

17

18

19

20

JL, PL)

40

V-

39

COMP IN

38

REFCAP 1

37

V

AZ

36

ANALOG

35

GND

REFCAP 2

34

BUF IN

33

ANALOG I/P

32

V+

31

CE/LD

30

SEN

29

R/

28

MODE

27

CLK 2

26

CLK 1

25

CLK 3

24

HBEN

23

LBEN

22

BIT 1

21

REF

H

HBEN

MBEN

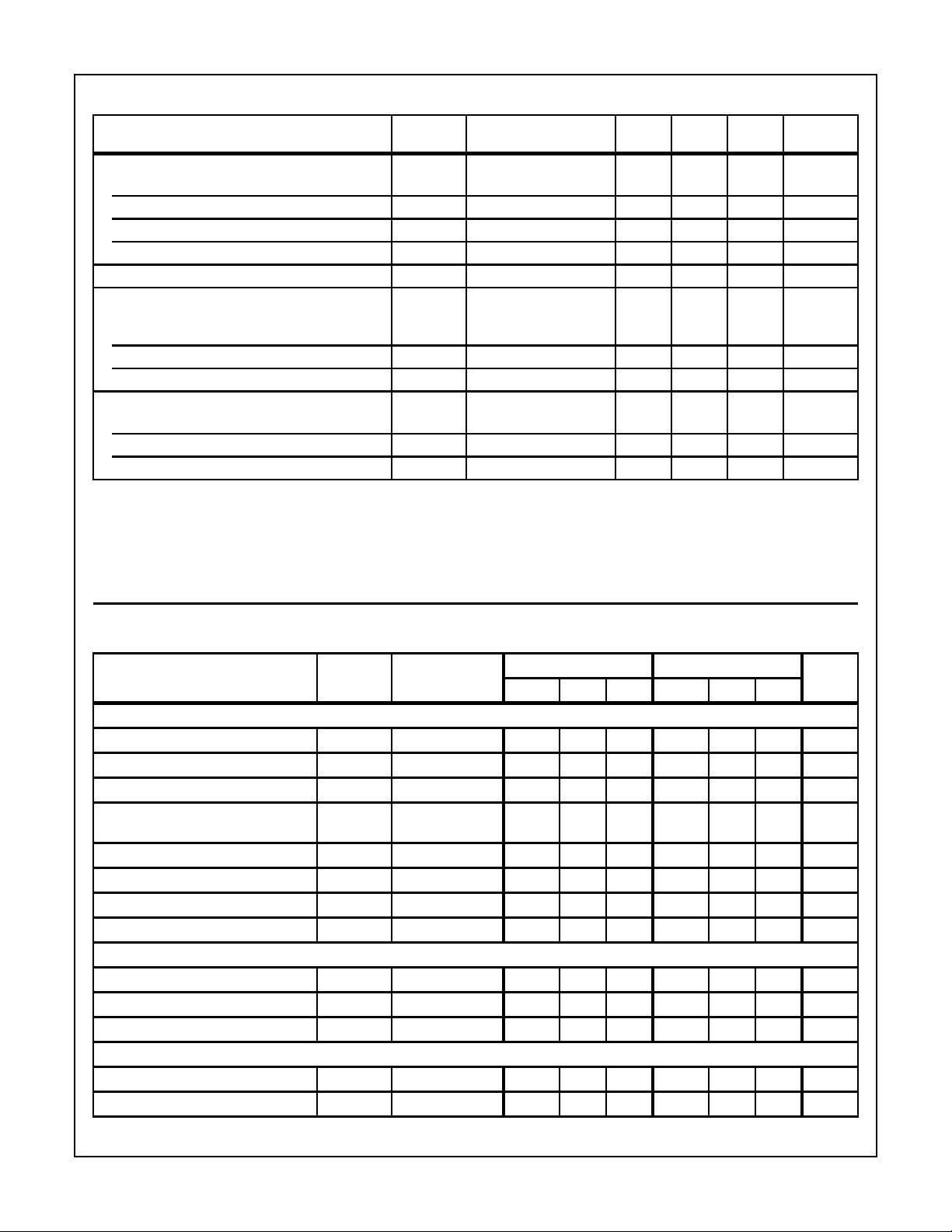

Functional Block Diagram

-15V

+15V

BUF OUT

A1

8052/8068

SW9

34

REF CAP (2)REF CAP (1)

5kΩ

10µF

ANALOG

INPUT

ANALOG

GND

V

REF

OUT

300pF

REF

10kΩ

-BUF IN

10

1

78

6

INT.

3

REF.

+BUF IN5

+BUF IN AZ

SW3

37

SW5

SW4

32

35

SW7

BUFFER

13

SW6

SW8 SW2

38

C

REF

-

+

FIGURE 1. ICL8052A (8068A)/ICL7104 16-BIT/14-BIT A/D CONVERTER FUNCTIONAL DIAGRAM

R

INT

C

INTEG.

-

A2

+

12+INT IN

SW1

INT

C

-1.2V

AZ

INT OUT-INT IN

14119

COMP.

-

A3

+

COMP IN

CROSSING

DETECTOR

2

50kΩ

ZERO

COMP

OUT

7104

+5V

-15V

300kΩ

393633

+15V31+5V

BITS

14 1316 15 10 912 11 6 587 2143OR POL

8 96 7 12 1310 11 16 1714 15 20 2118 195 4

THREE-STATE OUTPUTS

LATCHES

COUNTER

CONTROL LOGIC

40

21

CLOCK

-15V

25

26

CLOCK

(2)(1)

STTS

24

23 MBEN

22

30 CE/LD

29

27

28

3

HBEN

LBEN

SEN

MODE

R/

H

5-7

Page 3

ICL8052/ICL7104, ICL8068/ICL7104

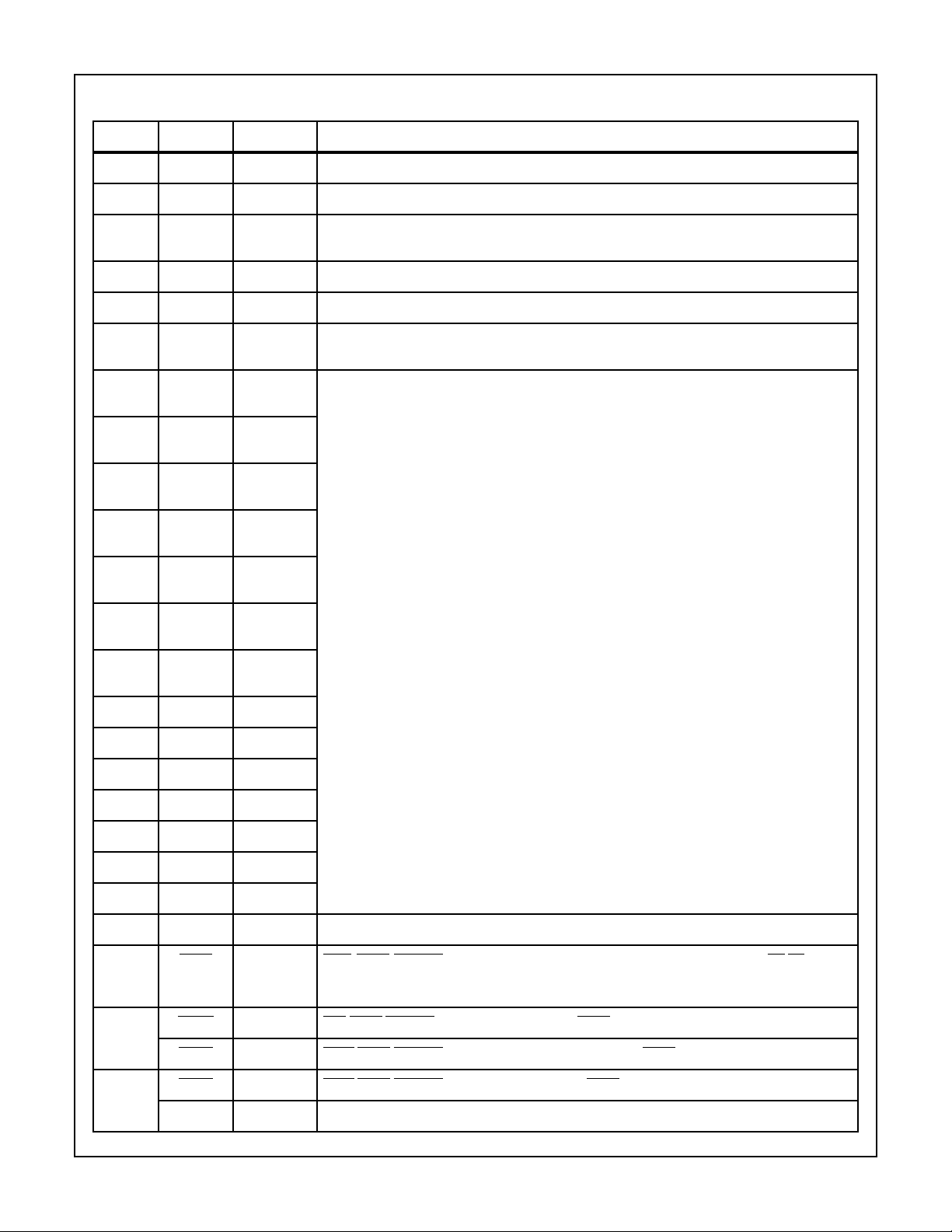

Pin Descriptions

PIN NO. SYMBOL OPTION DESCRIPTION

1 V++ Positive Supply Voltage: Nominally +15V.

2 GND Digital Ground: 0V, ground return.

3 STTS Status Output: HI during integrate and deintegrate until data is latched. LO when analog section

is in auto-zero configuration.

4 POL Polarity: Three-state output. HI for positive input.

5 OR Over Range: Three-state output.

6 BIT 16

BIT 14

7 BIT 15

BIT 13

8 BIT 14

BIT 12

9 BIT 13

BIT 11

10 BIT 12

BIT 10

11 BIT 11

BIT 9

12 BIT 10

NC

13 BIT 9

NC

14 BIT 8

15 BIT 7

16 BIT 6

-16

-14 Most Significant Bit (MSB).

-16

-14

-16

-14

-16

-14

-16

-14

-16

-14

-16

-14

-16

-14

DATA Bits: Three-state outputs. See Table 3 for format of ENABLES and bytes. HIGH = true.

17 BIT 5

18 BIT 4

19 BIT 3

20 BIT 2

21 BIT 1 Least Significant Bit (LSB).

22 LBEN LOW BYTE ENABLE: If not in handshake mode (see pin 27) when LO (with CE/LD, pin 30)

activates low-order byte outputs, BITS 1-8. When in handshake mode (see pin 27), serves as a

low byte flag output. See Figures 11, 12, 13.

23 MBEN -16 MID BYTE ENABLE: Activates Bits 9-16, see LBEN (pin 22)

HBEN -14 HIGH BYTE ENABLE: Activates Bits 9-14, POL, OR, see LBEN (pin 22)

24 HBEN -16 HIGH BYTE ENABLE: Activates POL, OR, see LBEN (pin 22).

CLOCK3 -14 RC oscillator pin: Can be used as clock output.

5-8

Page 4

ICL8052/ICL7104, ICL8068/ICL7104

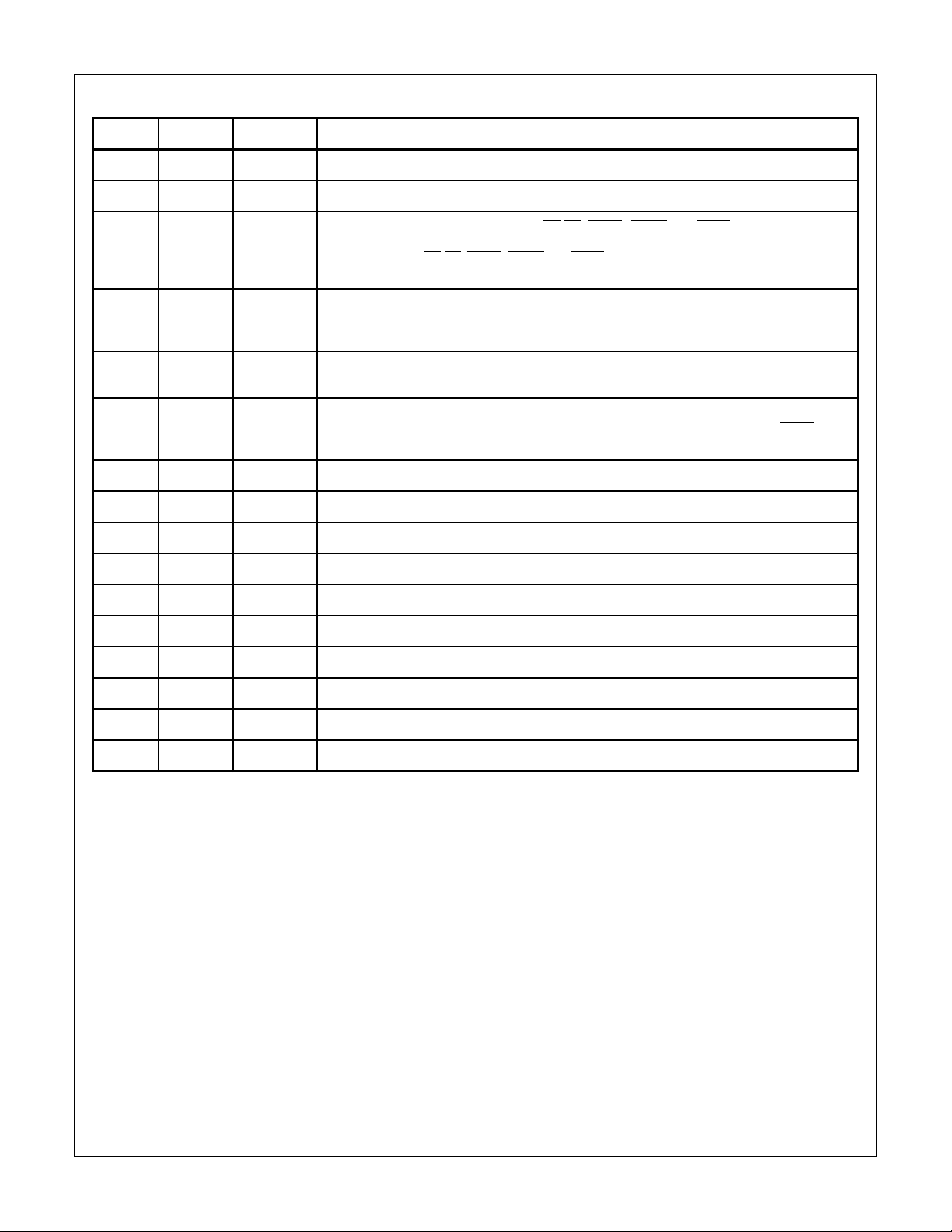

Pin Descriptions (Continued)

PIN NO. SYMBOL OPTION DESCRIPTION

25 CLOCK 1 Clock Input: External clock or ocsillator.

26 CLOCK 2 Clock Output: Crystal or RC oscillator.

27 MODE INPUT LO: Direct output mode where CE/LD, HBEN, MBEN and LBEN act as inputs directly

controlling byte outputs. If pulsed HI causes immediate entry into handshake mode (see Figure

13). If HI, enables CE/LD, HBEN, MBEN and LBEN as outputs. Handshake mode will be entered

and data output as in Figures 11 and 12 at conversion completion.

28 R/H RUN/HOLD: Input HI conversions continuously performed every 217(-16) or 215(-14) clock

pulses. Input LO conversion in progress completed, converter will stop in Auto-Zero 7 counts

before input integrate.

29 SEN SEND ENABLE: Input controls timing of byte transmission in handshake mode. HI indicates

‘send’.

30 CE/LD CHIP ENABLE/ LOAD: WITH MODE (PIN 27) LO, CE/LD serves as a master output enable;

when HI, the bit outputs and POL, OR are disabled. With MODE HI, pin serves as a LOAD strobe

(-ve going) used in handshake mode. See Figures 11 and 12.

31 V+ Positive Logic Supply Voltage: Nominally +5V.

32 AN I/P Analog Input: High Side.

33 BUF IN Buffer Input: Buffer Analog to analog chip (ICL8052 or ICL8086).

34 REFCAP2 Reference Capacitor: Negative Side.

35 AN. GND Analog Ground: Input low side and reference low side.

36 A-Z Auto-Zero node.

37 V

38 REFCAP1 Reference Capacitor: Positive side.

39 COMP-IN Comparator Input: From 8052/8068.

40 V- Negative Supply Voltage: Nominally -15V.

REF

Voltage Reference: Input (positive side).

5-9

Page 5

ICL8052/ICL7104, ICL8068/ICL7104

Absolute Maximum Ratings Thermal Information

ICL8052, ICL8068

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±18V

Differential Input Voltage

(8068) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±30V

(8052) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±6V

Input Voltage (Note 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±15V

Output Short Circuit Duration All Outputs (Note 3). . . . . . . Indefinite

ICL7104

V+ Supply (GND to V+) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12V

V++ to V-. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32V

Positive Supply Voltage (GND to V++) . . . . . . . . . . . . . . . . . . . . 17V

Negative Supply Voltage (GND to V-). . . . . . . . . . . . . . . . . . . . .-17V

Analog Input Voltage (Pins 32 - 39)(Note 4). . . . . . . . . . . . V++ to V-

Digital Input Voltage

(Pins 2 - 30) (Note 5) . . . . . . . . . . . . (GND - 0.3V) to (V+ + 0.3V)

Operating Conditions

Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . . .0oC to 70oC

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

1. θJA is measured with the component mounted on an evaluation PC board in free air.

2. For supply voltages less than ±15V, the absolute maximum input voltage is equal to the supply voltage.

3. Short circuit may be to ground or either supply. Rating applies to 70oC ambient temperature.

4. Input voltages may exceed the supply voltages provided the input current is limited to ±100µA.

5. Connecting any digital inputs or outputs to voltages greater than V+ or less than GND may cause destructive device latchup. For this

reason it is recommended that the power supply to the ICL7104 be established before any inputs from sources not on that supply are

applied.

Thermal Resistance (Typical, Note 1) θJA (oC/W) θJC (oC/W)

14 Ld PDIP Package. . . . . . . . . . . . . . 100 N/A

40 Ld PDIP Package. . . . . . . . . . . . . . 60 N/A

14 Ld CERDIP Package . . . . . . . . . . . 75 20

Maximum Junction Temperature (Ceramic Package). . . . . . . . . 175oC

Maximum Junction Temperature (Plastic Package) . . . . . . . . 150oC

Maximum Storage Temperature Range . . . . . . . . . .-65oC to 150oC

Maximum Lead Temperature (Soldering, 10s) . . . . . . . . . . . .300oC

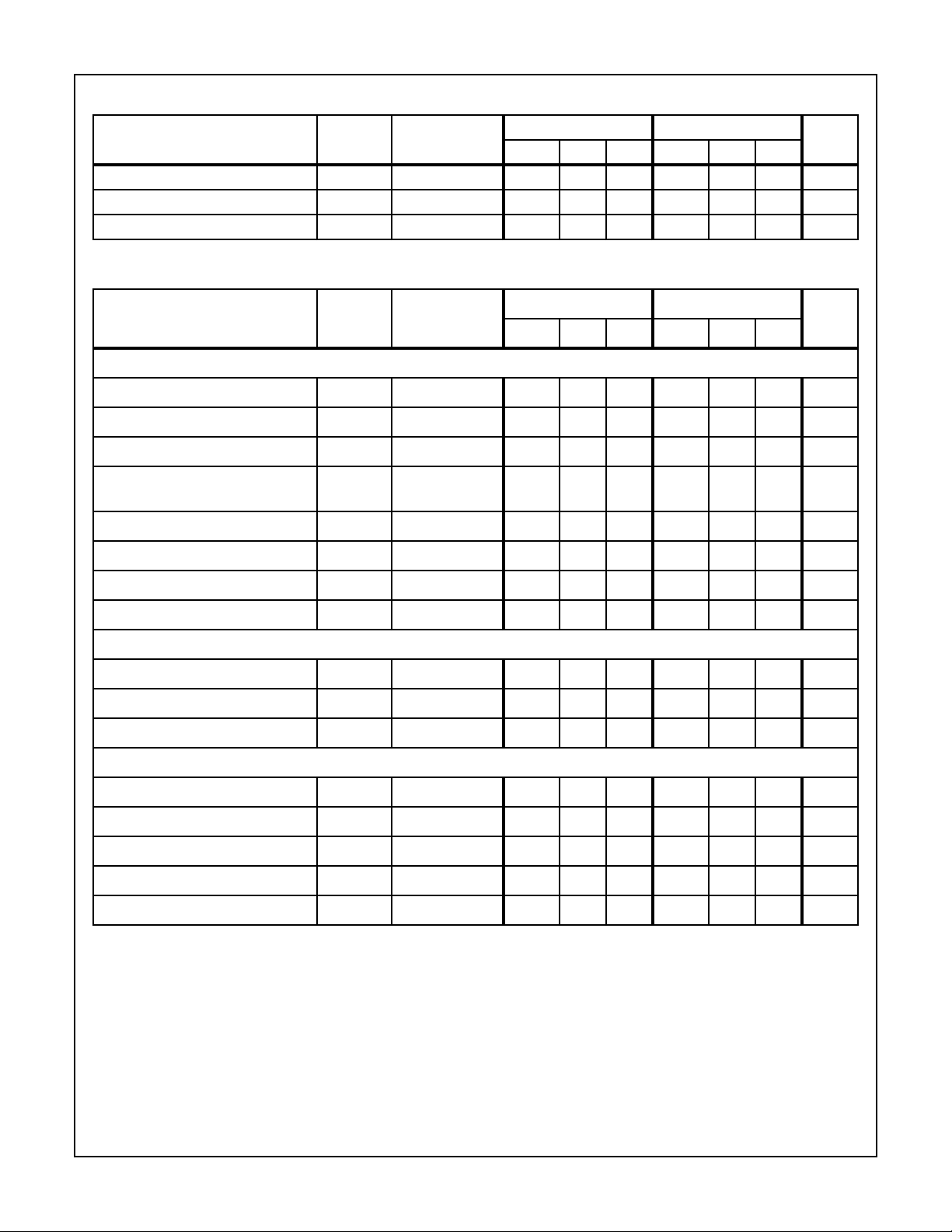

ICL7104 Electrical Specifications V+ = +5V, V++ = +15V, V- = -15V, T

TEST

PARAMETER SYMBOL

Clock Input, CLK 1 I

Comparator I/P, COMP IN (Note 6) I

Inputs with Pulldown, MODE I

Inputs with Pullups

SEN, R/

H

LBEN, MBEN, HBEN, CE/LD (Note 7)

Input High Voltage, All Digital Inputs V

Input Low Voltage, All Digital Inputs V

Digital Outputs Three-Stated On,

LBEN, MBEN (16 Only), HBEN, CE/LD

BIT n, POL, OR (Note 8)

Digital Outputs Three-Stated Off

Bit n, POL, OR

Non Three-State Digital Output

STTS V

Clock 2 V

Clock 3 (-14 Only) V

IN

IN

IH

I

IL

I

IH

I

IL

IH

IL

V

OL

V

OH

V

OH

I

OL

OL

V

OH

OL

V

OH

OL

V

OH

CONDITIONS MIN TYP MAX UNITS

VIN = +5V to 0V ±2 ±7 ±30 µA

VIN = 0V to +5V -10 ±0.001 10 µA

VIN = +5V 1 5 30 µA

VIN = 0V -10 ±0.01 10 µA

VIN = +5V -10 ±0.01 10 µA

VIN = 0V -30 -5 -1 µA

IOL= 1.6mA - 0.27 0.4 V

IOH= -10µA - 4.5 - V

IOH= -240µA 2.4 3.5 - V

0 ≤ V

≤ V+ -10 ±0.001 +10 µA

OUT

IOL= 3.2mA - 0.3 0.4 V

IOH= -400µA 2.4 3.3 - V

IOL= 320µA - 0.5 - V

IOH = -320µA - 4.5 - V

IOL= 1.6mA - 0.27 0.4 V

IOH= -320µA 2.4 3.5 - V

= 25oC, f

A

= 200kHz

CLOCK

2.5 2.0 - V

- 1.5 1.0 V

5-10

Page 6

ICL8052/ICL7104, ICL8068/ICL7104

ICL7104 Electrical Specifications V+ = +5V, V++ = +15V, V- = -15V, T

= 25oC, f

A

= 200kHz (Continued)

CLOCK

TEST

PARAMETER SYMBOL

CONDITIONS MIN TYP MAX UNITS

Switch

Switch 1 r

Switches 2, 3 r

Switches 4, 5, 6, 7, 8, 9 r

Switch Leakage I

Clock Frequency (Note 9) f

DS(ON)

DS(ON)

DS(ON)

D(OFF)

CLOCK

- 25k - Ω

- 4k 20k Ω

- 2k 10k Ω

-15- pA

DC 200 400 kHz

Supply Currents

+5V Supply Current

I+ Frequency = 200kHz - 200 600 µA

All outputs high impedance

+5V Supply Current I++ Frequency = 200kHz - 0.3 1.0 mA

-5V Supply Current I- Frequency = 200kHz - 25 200 µA

Supply Voltage Range

Logic Supply V+ Note 10 4 - 11 V

Positive Supply V++ 10 - 16 V

Negative Supply V- -16 - -10 V

NOTES:

6. This specification applies when not in Auto-Zero phase.

7. Apply only when these pins are inputs, i.e., the mode pin is low, and the 7104 is not in handshake mode.

8. Apply only when these pins are outputs, i.e., the mode pin is high, or the 7104 is in handshake mode.

9. Clock circuit shown in Figures 14 and 15.

10. V+ must not be more positive than V++.

ICL8068 Electrical Specifications V

PARAMETER SYMBOL

= ±15V, Unless Otherwise Specified

SUPPLY

TEST

CONDITIONS

ICL8068 ICL8068A

UNITSMIN TYP MAX MIN TYP MAX

EACH OPERATIONAL AMPLIFIER

Input Offset Voltage V

Input Current (Either Input) (Note 11) I

OS

IN

VCM = 0V - 20 65 - 20 65 mV

VCM = 0V - 175 250 - 80 150 pA

Common-Mode Rejection Ratio CMRR VCM = ±10V 70 90 - 70 90 - dB

Non-Linear Component of Common-

VCM = ±2V - 110 - - 110 - dB

Mode Rejection Ratio (Note 12)

Large Signal Voltage Gain A

RL = 50kΩ 20,000 - - 20,000 - - V/V

V

Slew Rate SR - 6 - - 6 - V/µs

Unity Gain Bandwidth GBW - 2 - - 2 - MHz

Output Short-Circuit Current I

SC

-5--5-mA

COMPARATOR AMPLIFIER

Small-Signal Voltage Gain A

Positive Output Voltage Swing +V

Negative Output Voltage Swing -V

VOL

RL= 30kΩ - 4000 - - - - V/V

O

O

12 13 - 12 13 - V

-2.0 -2.6 - -2.0 -2.6 - V

VOLTAGE REFERENCE

Output Voltage V

Output Resistance R

O

O

1.5 1.75 2.0 1.60 1.75 1.90 V

-5--5-Ω

5-11

Page 7

ICL8052/ICL7104, ICL8068/ICL7104

ICL8068 Electrical Specifications V

PARAMETER SYMBOL

= ±15V, Unless Otherwise Specified (Continued)

SUPPLY

TEST

ICL8068 ICL8068A

CONDITIONS

UNITSMIN TYP MAX MIN TYP MAX

Temperature Coefficient TC - 50 - - 40 - ppm/oC

Supply Voltage Range V

Supply Current Total I

SUPPLY

SUPPLY

ICL8052 Electrical Specifications V

= ±15V, Unless Otherwise Specified

SUPPLY

±10 - ±16 ±10 - ±16 V

- - 14 - 8 14 mA

ICL8052 ICL8052A

TEST

PARAMETER SYMBOL

CONDITIONS

UNITSMIN TYP MAX MIN TYP MAX

EACH OPERATIONAL AMPLIFIER

Input Offset Voltage V

Input Current (Either Input) (Note 11) I

OS

IN

VCM = 0V - 20 75 - 20 75 mV

VCM = 0V - 5 50 - 2 10 pA

Common-Mode Rejection Ratio CMRR VCM = ±10V 70 90 - 70 90 - dB

Non-Linear Component of Common-

VCM = ±2V - 110 - - 110 - dB

Mode Rejection Ratio (Note 12)

Large Signal Voltage Gain A

RL = 50kΩ 20,000 - - 20,000 - - V/V

V

Slew Rate SR - 6 - - 6 - V/µs

Unity Gain Bandwidth GBW - 1 - - 1 - MHz

Output Short-Circuit Current I

SC

-20- -20-mA

COMPARATOR AMPLIFIER

Small-Signal Voltage Gain A

Positive Output Voltage Swing +V

Negative Output Voltage Swing -V

VOL

RL= 30kΩ - 4000 - - - - V/V

O

O

12 13 - 12 13 - V

-2.0 -2.6 - -2.0 -2.6 - V

VOLTAGE REFERENCE

Output Voltage V

Output Resistance R

O

O

1.5 1.75 2.0 1.60 1.75 1.90 V

-5--5-Ω

Temperature Coefficient TC - 50 - - 40 - ppm/oC

Supply Voltage Range V

Supply Current Total I

SUPPLY

SUPPLY

±10 - ±16 ±10 - ±16 V

- 6 12 - 6 12 mA

NOTES:

11. The input bias currents are junction leakage currents which approximately double for every 10oC increase in the junction temperature,

TJ. Due to limited production test time, the input bias currents are measured with junctions at ambient temperature. In normal operation

the junction temperature rises above the ambient temperature as a result of internal power dissipation, PD. TJ = TA + R

R

is the thermal resistance from junction to ambient. A heat sink can be used to reduce temperature rise.

θJA

θJAPD

where

12. This is the only component that causes error in dual-slope converter.

5-12

Page 8

ICL8052/ICL7104, ICL8068/ICL7104

System Electrical Specifications: ICL8068/ICL7104 V++ = +15V, V+ = +5V, V- = -15V, f

TEST

PARAMETER

Zero Input Reading VIN = 0V, V

Ratiometric Error (Note 13) VIN = V

Linearity Over ± Full Scale (Error of

Reading from Best Straight Line)

Differential Linearity (Difference

between Worst Case Step of Adjacent

Counts and Ideal Step)

Rollover Error (Difference in Reading

for Equal Positive & Negative Voltage

Near Full Scale)

Noise (P-P Value Not Exceeded 95%

of Time)

Leakage Current at Input (Note 14) VIN = 0V - 100 165 - 100 165 pA

Zero Reading Drift VIN = 0V,

Scale Factor Temperature Coefficient

(Note 15)

CONDITIONS

= 2V -00000 ±00000 +00000 -00000 ±00000 +00000 Counts

REF

= 2V -1 0 1 -1 0 1 LSB

REF

-4V ≤ VIN≤ +4V - 0.5 1 - 0.5 1 LSB

-4V ≤ VIN≤ +4V - 0.01 - - 0.01 - LSB

-VIN = +VIN≅ 4V - 0.5 1 - 0.5 1 LSB

VIN = 0V,

Full Scale = 4V

0oC to 70oC

VIN = 4V,

0oC to 50oC

ext. ref. 0ppm/oC

ICL8068A/ICL7104-14 ICL8068A/ICL7104-16

-2--2-µV

- 0.5 - - 0.5 - µV/oC

- 2 5 - 2 5 ppm/oC

System Electrical Specifications: ICL8052/ICL7104 V++ = +15V, V+ = +5V, V- = -15V, f

= 200kHz (Note 16)

CLOCK

= 200kHz (Note 16)

CLOCK

UNITSMIN TYP MAX MIN TYP MAX

TEST

PARAMETER

Zero Input Reading VIN = 0V, V

Ratiometric Error (Note 15) VIN = V

Linearity Over ± Full Scale (Error of

Reading from Best Straight Line)

Differential Linearity (Difference

between Worst Case Step of Adjacent

Counts and Ideal Step)

Rollover Error (Difference in Reading

for Equal Positive and Negative

Voltage Near Full Scale)

Noise (Peak-to-Peak Value Not

Exceeded 95% of Time)

Leakage Current at Input (Note 14) VIN = 0V - 20 30 - 20 30 pA

Zero Reading Drift VIN = 0V,

Scale Factor Temperature Coefficient VIN = 4V,

NOTES:

13. Tested with low dielectric absorption integrating capacitor.

14. The input bias currents are junction leakage currents which approximately double for every 10oC increase in the junction temperature,

TJ. Due to limited production test time, the input bias currents are measured with junctions at ambient temperature. In normal operation the junction temperature rises above the ambient temperature as a result of internal power dissipation, PD. TJ = TA + R

where R

15. The temperature range can be extended to 70oC and beyond if the Auto-Zero and Reference capacitors are increased to absorb the

high temperature leakage of the 8068. See note 14 above.

16. System Electrical Specifications are not tested; for reference only.

is the thermal resistance from junction to ambient. A heat sink can be used to reduce temperature rise.

θJA

CONDITIONS

= 2V -00000 ±00000 +00000 -00000 ±00000 +00000 Counts

REF

= 2V -1 0 1 -1 0 1 LSB

REF

-4V ≤ VIN≤ +4V - 0.5 1 - 0.5 1 LSB

-4V ≤ VIN≤ +4V - 0.01 - - 0.01 - LSB

-VIN = +VIN≈ 4V - 0.5 1 - 0.5 1 LSB

VIN = 0V,

Full Scale = 4V

0oC to 70oC

0oC to 50oC

ext. ref. 0ppm/oC

ICL8052A/ICL7104-14 ICL8052A/ICL7104-16

UNITSMIN TYP MAX MIN TYP MAX

-30- -30-µV

- 0.5 - - 0.5 - µV/oC

- 2 - - 2 - ppm/oC

θJAPD

5-13

Page 9

ICL8052/ICL7104, ICL8068/ICL7104

CONTROL

CONVERT

8052A/

8068A

MODE

CE/LD

7104

CONVERT

R/

H

OR

POL

MSB

8052A/

8068A

MODE

7104 -16

CE/LD HBEN MBEN LBEN

R/

H

OR

POL

MSB

18

LSB

FIGURE 2. FULL 18-BIT THREE-STATE OUTPUT

CONVERT

MODE

CE/LD

2

8

8052A/

8068A

7104

R/

POL

MSB

H

OR

≥18

OR CHIP SELECT 2

CHIP SELECT 1

2

16

8052A/

8068A

MODE

CE/LD

7104

CONVERT

R/

H

OR

POL

MSB

10

CE/LD

AS INPUT

HBEN

AS INPUT

MBEN

AS INPUT

LBEN

AS INPUT

HIGH BYTE

DAT A

MIDDLE

BYTE

ENABLE

LOW BYTE

ENABLE

LSB

HBEN MBEN LBEN

CONTROL

t

DAB

= HIGH IMPEDANCE

8

HBEN MBEN LBEN

CONTROL

LSB

FIGURE 3. VARIOUS COMBINATIONS OF BYTE DISABLES

t

BEA

t

DAT A

VALID

DHB

DAT A

VALID

FIGURE 4. DIRECT MODE TIMING DIAGRAM

HBEN MBEN LBEN

t

DAC

CONTROL

t

CEA

DAT A

VALID

DAT A

VALID

DAT A

VALID

LSB

t

8

DHC

5-14

Page 10

ICL8052/ICL7104, ICL8068/ICL7104

TABLE 1. DIRECT MODE TIMING REQUIREMENTS (Note: Not tested in production)

SYMBOL DESCRIPTION MIN TYP MAX UNIT

t

BEA

t

DAB

t

DHB

t

CEA

t

DAC

t

DHC

t

CWH

XBEN (Min) Pulse Width. - 300 - ns

Data Access Time from XBEN. - 300 - ns

Data Hold Time from XBEN. - 200 - ns

CE/LD Min. Pulse Width. - 350 - ns

Data Access Time from CE/LD. - 350 - ns

Data Hold Time from CE/LD. - 280 - ns

CLOCK 1 High Time. - 1000 - ns

TABLE 2. HANDSHAKE TIMING REQUIREMENTS (Note: Not tested in production)

SYMBOL DESCRIPTION MIN TYP MAX UNIT

t

MW

t

SM

t

ME

t

MB

t

CEL

Mode Pulse (Min). - 20 - ns

Mode Pin Set-Up Time. - -150 - ns

Mode Pin High to Low Z CE/LD High Delay. - 200 - ns

Mode Pin High to XBEN Low Z (High) Delay. - 200 - ns

Clock 1 High to CE/LD Low Delay. - 700 - ns

t

CEH

t

CBL

t

CBH

t

CDH

t

CDL

t

SS

t

CBZ

t

CEZ

t

CWH

Clock 1 High to CE/LD High Delay. - 600 - ns

Clock 1 High to XBEN Low Delay. - 900 - ns

Clock 1 High to XBEN High Delay. - 700 - ns

Clock 1 High to Data Enabled Delay. - 1100 - ns

Clock 1 Low to Data Disabled Delay. - 1100 - ns

Send ENABLE Set-Up Time. - -350 - ns

Clock 1 High to XBEN Disabled Delay. - 2000 - ns

Clock 1 High to CE/LD Disabled Delay. - 2000 - ns

Clock 1 High Time. 1250 1000 - ns

5-15

Page 11

ICL8052/ICL7104, ICL8068/ICL7104

CLOCK 1

(PIN 25)

EITHER:

MODE PIN

OR

INTERNAL

LATCH PULSE IF

MODE “HI”

MODE

CE/LD

SEN

SIGNAL)

HBEN

O/R, POL

01-14

LBEN

BITS 1-5

UART

NORM

INTERNAL

(EXTERNAL

t

H

L

H

L

H

L

H

L

H

L

H

L

H

L

HANDSHAKE MODE

CWH

t

MW

t

CEL

t

ME

DON’T CARE DON’T CARE

t

MB

TRIGGERED BY

t

SM

DON’T CARE STABLE

IGNORED IGNORED

t

CEH

EXT EXT

t

CBL

DATA VALID, STABLE

t

CDH

OR

-16 HAS EXTRA (

t

SS

t

THREE-STATE

MBEN) PHASE

t

CBH

CDL

DATA VALID, STABLE

t

CEZ

t

CBZ

THREE-STATE WITH PULLUP

FIGURE 5. HANDSHAKE MODE TIMING DIAGRAM

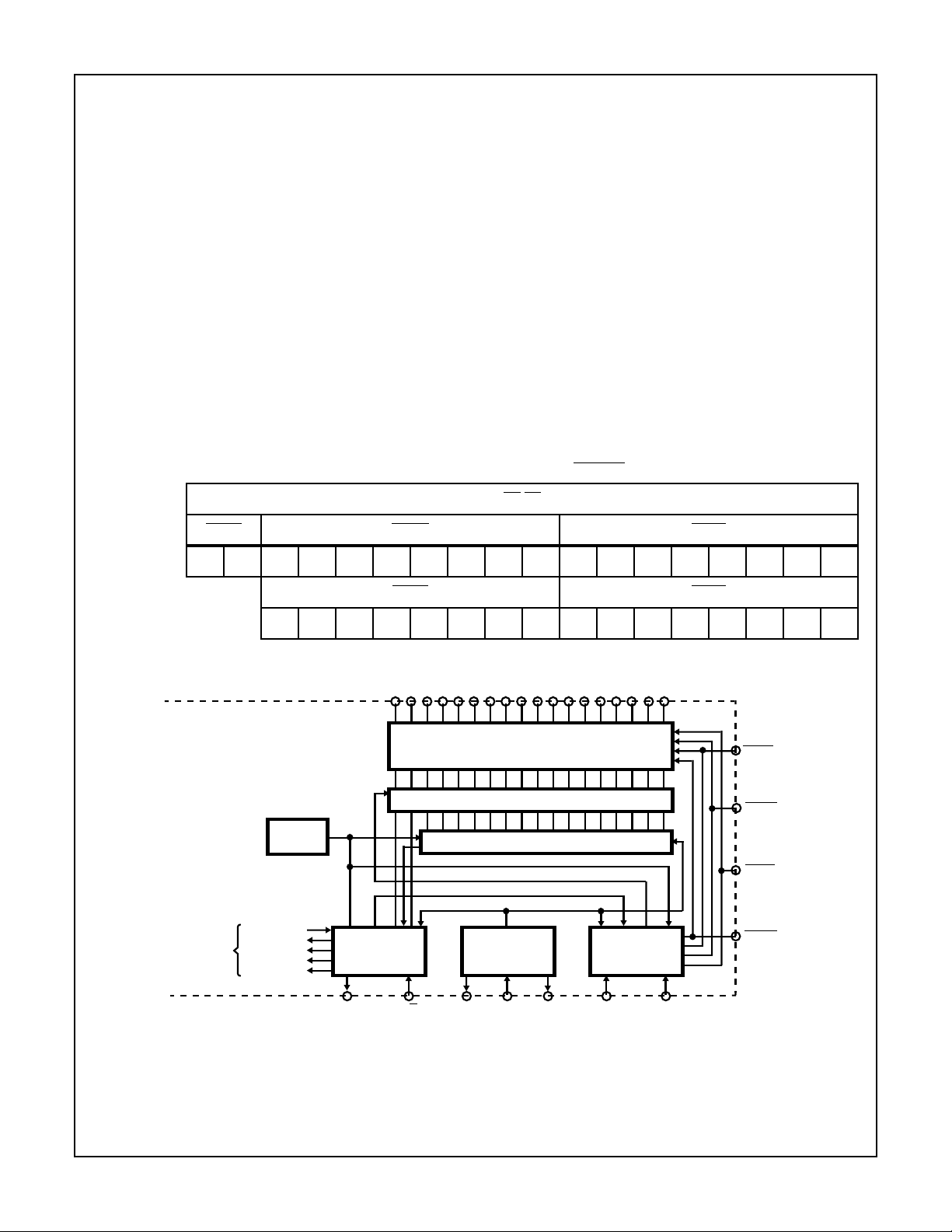

Detailed Description

ANALOG SECTION

Figure 6 shows the equivalent Circuit of the Analog Section

of both the ICL7104/8052 and the ICL7104/8068 in the 3

different phases of operation. If the Run/

or tied to V+, the system will perform conversions at a rate

determined by the clock frequency: 131,072 for - 16 and

32,368 for - 14 clock periods per cycle (see Figure 8

conversion timing).

Auto-Zero Phase I (Figure 6A)

During Auto-Zero, the input of the buffer is shorted to analog

ground thru switch 2, and switch 1 closes a loop around the

integrator and comparator. The purpose of the loop is to

charge the Auto-Zero capacitor until the integrator output no

longer changes with time. Also, switches 4 and 9 recharge

the reference capacitor to V

REF

.

Input Integrate Phase II (Figure 6B)

During input integrate the Auto-Zero loop is opened and the

analog input is connected to the buffer input thru switch 3.

(The reference capacitor is still being charged to V

during this time.) If the input signal is zero, the buffer,

integrator and comparator will see the same voltage that

existed in the previous sate (Auto-Zero). Thus the integrator

output will not change but will remain stationary during the

entire Input Integrate cycle. If V

IN

unbalanced condition exists compared to the Auto-Zero

phase, and the integrator will generate a ramp whose slope

is proportional to V

. At the end of this phase, the sign of

IN

the ramp is latched into the polarity F/F.

Hold pin is left open

REF

is not equal to zero, an

Deintegrate Phase III (Figures 6C and 6D)

During the Deintegrate phase, the switch drive logic uses the

output of the polarity F/F in determining whether to close

switches 6 and 9 or 7 and 8. If the input signal was positive,

switches 7 and 8 are closed and a voltage which is V

REF

more negative than during Auto-Zero is impressed on the

buffer input. Negative inputs will cause +V

to be applied

REF

to the buffer input via switches 6 and 9. Thus, the reference

capacitor generates the equivalent of a (+) reference or a (-)

reference from the single reference voltage with negligible

error. The ref erence v oltage returns the output of the integrator to the zero-crossing point established in Phase I. The

time, or number of counts, required to do this is proportional

to the input voltage. Since the Deintegrate phase can be

twice as long as the Input integrate phase, the input voltage

required to give a full scale reading = 2V

NOTE: Once a zero crossing is detected, the system automatically

reverts to Auto-Zero phase for the leftover Deintegrate time (unless

RUN/HOLD is manipulated, see RUN/HOLD input in detailed

description, digital section).

REF

.

5-16

Page 12

ICL8052/ICL7104, ICL8068/ICL7104

AN

I/P

AN

I/P

9

- +

C

9

- +

C

3

REF

3

REF

R

INT

BUFFER

-

A1

+

678

2

V

REF

4

C

INT

INTEGRATOR

-

A2

+

C

AZ

1

COMP.

-

A3

+

ZERO

CROSS.

DET.

POL

ZERO

CROSSING

F/F

CL

CL

QD

FIGURE 6A. PHASE I AUTO-ZERO

R

INT

BUFFER

-

A1

+

678

2

V

REF

4

C

INT

INTEGRATOR

-

A2

+

C

AZ

1

COMP.

-

A3

+

ZERO

CROSS.

DET.

POL

POL

F/F

CL

ZERO

CROSSING

F/F

CL

CL

POL

QD

PHASE II

QD

FIGURE 6B. PHASE II INTEGRATE INPUT

+AN

I/P

-AN

I/P

9

- +

C

9

- +

C

3

REF

3

REF

R

INT

BUFFER

-

A1

+

678

2

V

REF

4

C

INT

INTEGRATOR

-

A2

+

C

AZ

1

COMP.

-

A3

+

ZERO

CROSS.

DET.

POL

ZERO

CROSSING

F/F

CL

CL

QD

FIGURE 6C. PHASE III + DEINTEGRATE

R

INT

BUFFER

-

A1

+

678

2

V

REF

4

C

INT

INTEGRATOR

-

A2

+

C

AZ

1

COMP.

-

A3

+

ZERO

CROSS.

DET.

POL

ZERO

CROSSING

F/F

CL

CL

QD

FIGURE 6D. PHASE III DEINTEGRATE

5-17

Page 13

ICL8052/ICL7104, ICL8068/ICL7104

TABLE 3. THREE-STATE BYTE FORMATS AND ENABLE PINS

CE/LD

HBEN MBEN LBEN

ICL7104-16 POL O/R B16 B15 B14 B13 B12 B11 B10 B9 B8 B7 B6 B5 B4 B3 B2 B1

HBEN LBEN

ICL7104-14 POL O/R B14 B13 B12 B11 B10 B9 B8 B7 B6 B5 B4 B3 B2 B1

TABLE 4. TYPICAL COMPONENT VALUES (V++ = +15V, V+ = 5V, V- = 5V, V- = -15V, f

CLOCK

= 200kHz)

ICL8052/8068 WITH ICL7104-16 ICL7104-14 UNIT

Full scale V

IN

200 800 4000 100 4000 mV

Buffer Gain 10 1 1 10 1 V/V

R

C

C

C

V

INT

INT

AZ

REF

REF

100 43 200 47 180 kΩ

0.33 0.33 0.33 0.1 0.1 µF

11111µF

10 1 1 10 1 µF

100 400 2000 50 2000 mV

Resolution 3.1 12 61 6.1 244 µV

10-50K

5kΩ

300pF

10kΩ

REF

OUT

+15V

6

3

INT.

REF.

+BUF IN5

-15V

78

1

100kΩ

-BUF IN

10

BUFFER

-

A1

+

13

R

INT

BUF OUT

8068

C

INTEG.

-

A2

+

12+INT IN

INT

-1.2V

INT OUT-INT IN

14119

COMP.

-

A3

+

2

COMP

OUT

+5V

-15V

TO ICL7104

FIGURE 7. ADDING BUFFER GAIN TO ICL8068

Buffer Gain

At the end of the auto-zero interval, the instantaneous noise

voltage on the auto-zero capacitor is stored, and subtracts

from the input voltage while adding to the reference voltage

during the next cycle. The result is that this noise voltage

effectively is somewhat greater than the input noise voltage

of the buffer itself during integration. By introducing some

voltage gain into the buffer, the effect of the auto-zero noise

(referred to the input) can be reduced to the level of the

inherent buffer noise. This gener ally occurs with a buffer gain

of between 3 and 10. Further increase in buffer gain merely

increases the total offset to be handled by the auto-zero

loop, and reduces the available buffer and integrator swings,

without improving the noise performance of the system. The

circuit recommended for doing this with the

ICL8068/ICL7104 is shown in Figure 7. With careful layout,

the circuit shown can achieve effective input noise voltages

on the order of 1 to 2µV, allowing full 16-bit use with full scale

inputs of a low as 150mV. Note that at this level, thermoelectric EMFs between PC boards, IC pins, etc., due to local

temperature changes can be very troublesome. For further

discussion, see Application Note AN030.

ICL8052 vs ICL8068

The ICL8052 offers significantly lower input leakage currents

than the ICL8068, and may be found preferable in systems

with high input impedances. However, the ICL8068 has

substantially lower noise voltage, and for systems where

system noise is a limiting factor, particularly in low signal

level conditions, will give better performance.

5-18

Page 14

ICL8052/ICL7104, ICL8068/ICL7104

Component Value Selection

For optimum performance of the analog section, care must

be taken in the selection of values for the integ rator capacitor

and resistor, auto-zero capacitor, reference voltage, and

conversion rate. These values must be chosen to suit the

particular application.

Integrating Resistor

The integrating resistor is determined by the full scale input

voltage and the output current of the buffer used to charge

the integrator capacitor. This current should be small

compared to the output short circuit current such that

thermal effects are kept to a minimum and linearity is not

affected. Values of 5 to 40µA give good results with a

nominal of 20µA. The exact value may be chosen by:

R

NOTE: If gain is used in the buffer amplifier then

Integrating Capacitor

The product of integrating resistor and capacitor is selected

to give 9 volt s wing for full scale inputs. This is a compromise

between possibly saturating the integrator (at +14 volts) due

to tolerance build-up between the resistor, capacitor and

clock and the errors a lower voltage swing could induce due

to offsets referred to the output of the comparator. In

general, the value of C

C

A very important characteristic of the integrating capacitor is

that it have low dielectric absorption to prevent roll-over or

full scale voltage (see note)

------------------------------------------------------------------------ -=

INT

R

INT

(32768 for - 16)

(8192 for -14)

----------------------------------------------------------------------------------------------------------=

INT

20µA

BufferGain()(full scale voltage)

--------------------------------------------------------------------------------------- -=

INT

Integrator Output Voltage Swing

20µA

is given by:

20µA× clock period×

ratiometric errors. A good test for dielectric absorption is to

use the capacitor with the input tied to the reference.

This ratiometric condition should read half scale (100...000)

and any deviation is probably due to dielectric absorption.

Polyprop ylene capacitors giv e undetectable errors at reasonable cost. Polystyrene and polycarbonate capacitors may

also be used in less critical applications.

Auto-Zero and Reference Capacitor

The size of the auto-zero capacitor has some influence on

the noise of the system, a large capacitor giving less noise.

The reference capacitor should be large enough such that

stray capacitance to ground from its nodes is negligible.

NOTE: When gain is used in the buffer amplifier the reference

capacitor should be substantially larger than the auto-zero capacitor.

As a rule of thumb, the reference capacitor should be approximately

the gain times the value of the auto-zero capacitor. The dielectric

absorption of the reference cap and auto-zero cap are only important

at power-on or when the circuit is recovering from an ov erload. Thus,

smaller or cheaper caps can be used here if accurate readings are

not required for the first few seconds of recovery.

Reference Voltage

The analog input required to generate a full scale output is

V

IN

= 2V

REF

.

The stability of the reference voltage is a major factor in the

overall absolute accuracy of the converter. The resolution of

the ICL7104 at 16 bits is one part in 65536, or 15.26ppm.

Thus, if the reference has a temperature coefficient of

50ppm/C (on board reference) a temperature change of

1/3C will introduce a one-bit absolute error. For this reason,

it is recommended that an external high quality reference be

used where the ambient temperature is not controlled or

where high-accuracy absolute measurements are being

made.

INTEGRATOR

OUTPUT

INTERNAL CLOCK

INTERNAL LATCH

STATUS OUTPUT

PHASE I PHASE II PHASE III

-16 32768 32768 65536

-14 8192 8192 16384

POLARITY

DETECTED

NUMBER OF COUNTS TO ZERO CROSSING

PROPORTIONAL TO V

FIGURE 8. CONVERSION TIMING

COUNTS

IN

5-19

ZERO CROSSING

OCCURS

ZERO CROSSING

DETECTED

DEINT PHASE IIIINT PHASE IIAZ PHASE I AZ

AFTER ZERO CROSSING,

ANALOG SECTION WILL

BE IN AUTOZERO

CONFIGURATION

Page 15

ICL8052/ICL7104, ICL8068/ICL7104

Detailed Description

DIGITAL SECTION

The digital section includes the clock oscillator circuit, a

16-bit or 14-bit binary counter with output latches and TTLcompatible three-state output drivers, polarity, over-range

and control logic and UART handshake logic, as shown in

the Block Diagram Figure 9 (16-bit version shown).

Throughout this description, logic levels will be referred to as

“low” or “high”. The actual logic levels are defined under

“ICL7104 Electrical Specification”. For minimum power consumption, all inputs should swing from GND (low) to V+

(high). Inputs driven from TTL gates should have 3 - 5kΩ

pullup resistors added for maximum noise immunity.

MODE Input

The MODE input is used to control the output mode of the

converter. When the MODE pin is connected to GND or left

open (this input is provided with a pulldown resistor to

TABLE 5. THREE-STATE BYTE FORMATS AND ENABLE PINS

HBEN MBEN LBEN

ensure a low level when the pin is left open), the converter is

in its “Direct” output mode, where the output data is directly

accessible under the control of the chip and byte enable

inputs. When the MODE input is pulsed high, the converter

enters the UART handshake mode and outputs the data in

three bytes for the 7104-16 or two b ytes for the 7104-14 then

returns to “direct” mode. When the MODE input is left high,

the converter will output data in the handshake mode at the

end of every conversion cycle. (See section entitled “Handshake Mode” for further details).

STATUS Output

During a conversion cycle, the STATUS output goes high at

the beginning of Input Integrate (Phase II), and goes low

one-half clock period after new data from the conversion has

been stored in the output latches. See Figure 8 for details of

this timing. This signal may be used as a “data valid” flag

(data never changes while STATUS is low) to drive interrupts, or for monitoring the status of the converter.

CE/LD

ICL7104-16 POL O/R B16 B15 B14 B13 B12 B11 B10 B9 B8 B7 B6 B5 B4 B3 B2 B1

HBEN LBEN

ICL7104-14 POL O/R B14 B13 B12 B11 B10 B9 B8 B7 B6 B5 B4 B3 B2 B1

TO

ANALOG

SECTION

INITIAL

CLEAR

COMP OUT

AZ

INT

DEINT(+)

DEINT(-)

CONVERSION

CONTROL

LOGIC

STATUS26R/H

18/16 THREE-STATE OUTPUTS

18/16 LATCHES

18/16 BIT COUNTER

LATCH

CLOCK

OSCILLATOR

AND CLOCK

CIRCUITRY

25

23

242

CLOCK

CLOCK

CLOCK

(1)

(2) (3)

HANDSHAKE

LOGIC

21

MODE

27

SEND

HBEN

MBEN

(-16 ONLY)

LBEN

CE/LD

FIGURE 9. DIGITAL SECTION

5-20

Page 16

ICL8052/ICL7104, ICL8068/ICL7104

DEINT TERMINATED

AT ZERO CROSSING

INTEGRATOR

OUTPUT

INTERNAL

CLOCK

INTERNAL

LATCH

STATUS

OUTPUT

HOLD

RUN/

INPUT

Run/

Hold Input

When the Run/

Hold input is connected to V+ or left open

DETECTION

FIGURE 10. RUN/HOLD OPERATION

(this input has pullup resistor to ensure a high level when the

pin is left open), the circuit will continuously perform

conversion cycles, updating the output latches at the end of

every Deintegrate (Phase III) portion of the conversion cycle

(See Figure 8). (See under “Handshake Mode” for

exception.) In this mode of operation, the conversion cycle

will be performed in 131,072 for 7104-16 and 32768 for

7104-14 clock periods, regardless of the resulting value.

If Run/

Hold goes low at any time during Deintegrate (Phase

III) after the zero crossing has occurred, the circuit will

immediately terminate Deintegrate and jump to Auto-Zero.

This feature can be used to eliminate the time spent in

Deintegrate after the zero-crossing. If Run/

Hold stays or

goes low, the converter will ensure a minimum Auto-Zero

time, and then wait in Auto-Zero until the Run/

Hold input

goes high. The converter will begin the Integrate (Phase II)

portion of the next conversion (and the STATUS output will

go high) seven clock periods after the high level is detected

at Run/

Hold. See Figure 10 for details.

Using the Run/

Hold input in this manner allows an easy

“convert on demand” interface to be used. The converter

may be held at idle in Auto-Zero with Run/

Run/

Hold goes high the conversion is started, and when the

Hold low. When

STATUS output goes low the new data is valid (or transferred) to the UART - see Handshake Mode). Run/

Hold may

now go low terminating Deintegrate and ensuring a minimum

Auto-Zero time before stopping to wait for the next

conversion. Alternately, Run/

Hold can be used to minimize

conversion time by ensuring that it goes low during Deintegrate, after zero crossing, and goes high after the hold point

is reached. The required activity on the Run/

Hold input can

be provided by connecting it to the CLOCK3 (-14), CLOCK2

(-16) Output. In this mode the conversion time is dependent

on the input value measured. Also refer to Intersil Application

Bulletin A030 for a discussion of the effects this will have on

Auto-Zero performance.

If the Run/

Hold input goes low and stays low during AutoZero (Phase I), the converter will simply stop at the end of

the Auto-Zero and wait for Run/

Hold to go high. As above,

OPTION

MIN

MAX

-14

7161

8185

-16

28665

32761

STATIC IN

HOLD STATE

7 COUNTS

INT

PHASE

Integrate (Phase II) begins sev en clock periods after the high

level is detected.

Direct Mode

When the MODE pin is left at a low level, the data outputs

[bits 1 through 8 low order byte, See Table 3 for format of

middle (-16) and high order bytes] are accessible under

control of the byte and

These

ENABLE inputs are all active low, and are provided

CHIP ENABLE terminals as inputs.

with pullup resistors to ensure an inactive high level when

left open. When the

CHIP ENABLE input is low, taking a b yte

ENABLE input low will allow the outputs of that byte to

become active (three-stated on). This allows a variety of

parallel data accessing techniques to be used. The timing

requirements for these outputs are shown under AC

Specifications and Table 1.

It should be noted that these control inputs are asynchronous with respect to the converter clock - the data may be

accessed at any time. Thus it is possible to access the data

while it is being updated, which could lead to scrambled

data. Synchronizing the access of data with the conversion

cycle by monitoring the STATUS output will prevent this.

Data is never updated while STATUS is low. Also note the

potential bus conflict described under “Initial Clear Circuitry”.

Handshake Mode

The handshake output mode is provided as an alternative

means of interfacing the ICL7104 to digital systems, where

the A/D converter becomes active in controlling the flow of

data instead of passively responding to chip and byte

ENABLE inputs. This mode is specifically designed to allow

a direct interface between the ICL7104 and industry-standard UARTs (such as the Intersil CMOS UARTs, IM6402/3)

with no external logic required. When triggered into the

handshake mode, the ICL7104 provides all the control and

flag signals necessary to sequence the three (ICL7106-16)

or two (ICL7104-14) bytes of data into the UART and initiate

their transmission in serial form. This greatly eases the task

and reduces the cost of designing remote data acquisition

stations using serial data transmission to minimize the

number of lines to the central controlling processor.

5-21

Page 17

ICL8052/ICL7104, ICL8068/ICL7104

Entry into the handshake mode will occur if either of two

conditions are fulfilled; first, if new data is latched (i.e., a

conversion is completed) while MODE pin (pin 27) is high, in

which case entry occurs at the end of the latch cycle; or

secondly, if the MODE pin goes from low to high, when entry

will occur immediately (if new data is being latched, entry is

delayed to the end of the latch cycle). While in the

handshake mode, data latching is inhibited, and the MODE

pin is ignored. (Note that conversion cycles will continue in

the normal manner). This allows versatile initiation of handshake operation without danger of false data generation; if

the MODE pin is held high, every conversion (other than

those completed during handshake operations) will start a

new handshake operation, while if the MODE pin is pulsed

high, handshake operations can be obtained “on demand.”

When the converter enters the handshake mode, or when

the MODE input is high, the chip and byte

nals become TTL-compatible outputs which provide the control signals for the output cycle. The Send

(SEN) (pin 29) is used as an indication of the ability of the

external device to receive data. The condition of the line is

sensed once every clock pulse, and if it is high, the next (or

first) byte is enabled on the next rising CLOCK 1 (pin 25)

clock edge, the corresponding byte

and the

low for one full clock pulse only, returning high.

On the next falling CLOCK 1 clock pulse edge, if SEN

remains high, or after it goes high again, the byte output

lines will be put in the high impedance state (or three-stated

off). One half pulse later, the byte

cleared high, and (unless finished) the

byte

(2 in the case of the 14-bit device) bytes have been sent.

The bytes are individually put into the low impedance state

i.e.: three-stated on during most of the time that their byte

ENABLE pin is (active) low. When receipt of the last byte has

been acknowledged by a high SEN, the handshake mode

will be cleared, re-enabling data latching from conversion,

and recognizing the condition of the MODE pin again. The

byte and

low, but held by their (weak) pullups. These timing relationships are illustrated in Figures 11, 12, and 13, and Table 2.

Figure 11 shows the sequence of the output cycle with SEN

held high. The handshake mode (Internal MODE high) is

entered after the data latch pulse (since MODE remains high

the

outputs). The high level at the SEN input is sensed on the

same high to low internal clock edge. On the next to high

internal clock edge, the

assume a low level and the high-order byte (POL and OR,

and except for -16, Bits 9 - 14) outputs are enabled. The

CE/LD output remains low for one full internal clock period

only, the data outputs remain active for 1

periods, and the high byte

clock periods. Thus the

edge may be used as a synchronizing signal to ensure valid

data, and the byte

byte identification flag. With SEN remaining high the converter completes the output cycle using

CHIP ENABLE / LOAD pin (pin 30) (CE/LD) goes

ENABLE pin will go low. This will continue until all three

CHIP ENABLE will be three-stated off, if MODE is

CE/LD, LBEN, MBEN and HBEN terminals are active as

CE/LD and the HBEN outputs

CE/LD output low level or low to high

ENABLE as an output may be used as a

ENABLE line goes low,

ENABLE remains low for two

ENABLE termi-

ENABLE pin

ENABLE pin will be

CE/LD and the next

1

/2 internal clock

CE/LD, MBEN and

LBEN while the remaining byte outputs (see Table 3) are

activated. The handshake mode is terminated when all bytes

are sent (3 for -16, 2 for -14).

Figure 12 shows an output sequence where the SEN input is

used to delay portions of the sequence, or handshake, to

ensure correct data transfer. This timing diagram shows the

relationships that occur using an industry-standard IM6402/3

CMOS UART to interface to serial data channels. In this

interface, the SEN input to the ICL7104 is driven by the

TBRE (Transmitter Buffer Register Empty) output of the

UART, and the

TBRL (Transmitter Buffer Register Load) input to the UART.

The data outputs are paralleled into the eight Transmitter

Buffer Register inputs.

Assuming the UART Transmitter Buffer Register is empty,

the SEN input will be high when the handshake mode is

entered after new data is stored. The

minals will go low after SEN is sensed, and the high order

byte outputs become active. When

end of one clock period, the high order byte data is clocked

into the UART Transmitter Buffer Register. The UART TBRE

output will now go low, which halts the output cycle with the

HBEN output low, and the high order byte outputs active.

When the UART has transferred the data to the Transmitter

Register and cleared the Transmitter Buffer Register, the

TBRE returns high. On the next ICL7104 internal clock high

to low edge, the high order byte outputs are disabled, and

one-half internal clock later, the

At the same time, the

puts go low, and the corresponding byte outputs become

active. Similarly, when the

one clock period, the enabled data is clocked into the UART

Transmitter Buffer Register, and TBRE again goes low.

When TBRE returns to a high it will be sensed on the next

ICL7104 internal clock high to low edge, disabling the data

outputs. For the 16-bit device, the sequence is repeated for

LBEN. One-half internal clock later, the handshake mode will

be cleared, and the chip and byte

high and stay active (as long as MODE stays high).

With the MODE input remaining high as in these examples,

the converter will output the results of every conversion

except those completed during a handshake operation. By

triggering the converter into handshake mode with a low to

high edge on the MODE input, handshake output sequences

may be performed on demand. Figure 13 shows a

handshake output sequence triggered by such an edge. In

addition, the SEN input is shown as being low when the converter enters handshake mode. In this case, the whole output sequence is controlled by the SEN input, and the

sequence for the first (high order) byte is similar to the

sequence for the other bytes. This diagram also shows the

output sequence taking longer than a conversion cycle. Note

that the converter still makes conversions, with the STATUS

output and Run/

difference is that new data will not be latched when in

handshake mode, and is therefore lost.

CE/LD terminal of the ICL7104 drives the

CE/LD and HBEN ter-

CE/LD goes high at the

HBEN output returns high.

CE/LD and MBEN (-16) or LBEN out-

CE/LD returns high at the end of

ENABLE terminals return

Hold input functioning normally. The only

5-22

Page 18

INTEGRATOR OUTPUT

INTERNAL CLOCK

INTERNAL LATCH

STATUS OUTPUT

MODE INPUT

INTERNAL MODE

SEN INPUT

CE/LOAD

HBEN

HIGH BYTE DATA

LBEN

LOW BYTE DATA

LBEN

LOW BYTE DATA

ICL8052/ICL7104, ICL8068/ICL7104

ZERO-CROSSING OCCURS

UART

NORM

MODE HIGH ACTIVATES

CE/LD, HBEN, LBEN

ZERO-CROSSING DETECTED

SEN

SENSED

DATA VALID

DISABLES OUTPUTS

FOR -16 MBEN SEQUENCE INSERTED HERE

SEN

SENSED

MODE LOW NOT IN HANDSHAKE MODE

DATA VALID

CE/LD, HBEN, MBEN, LBEN

DATA VALID

THREE-STATE WITH PULLUPTHREE-STATE HIGH IMPEDANCEDON’T CARE

TERMINATES

UART MODE

INTEGRATOR

OUTPUT

INTERNAL

CLOCK

INTERNAL

LATCH

STATUS

OUTPUT

MODE

INPUT

INTERNAL

MODE

SEN INPUT

(UART TBRE)

CE/LOAD

(UART TBRL)

HBEN

HIGH BYTE

DAT A

MBEN

MIDDLE

BYTE DATA

LBEN

LOW BYTE

DAT A

UART

NORM

FIGURE 11. HANDSHAKE WITH SEN HELD POSITIVE

ZERO-CROSSING OCCURS

ZERO-CROSSING DETECTED

DATA VALID

DATA VALID

DATA VALID

THREE-STATE HIGH IMPEDANCEDON’T CARE

FIGURE 12. HANDSHAKE - TYPICAL UART INTERFACE TIMING

5-23

Page 19

ICL8052/ICL7104, ICL8068/ICL7104

POSITIVE TRANSITION

CAUSES ENTRY INTO

UART MODE

INTERNAL

CLOCK

INTERNAL

LATCH

STATUS

OUTPUT

MODE

INPUT

MODE

HBEN

DAT A

MBEN

LBEN

DAT A

UART

NORM

INTERNAL

SEN INPUT

CE/LOAD

AS OUTPUT

HIGH BYTE

MIDDLE

BYTE DATA

LOW BYTE

Initial Clear Circuitry

ZERO-CROSSING OCCURS

ZERO-CROSSING DETECTED

LATCH PULSE INHIBITED

DATA VALID

IN UART MODE

DEINT PHASE III

DATA VALID

STATUS OUTPUT UNAFFECTED

BY UART MODE

FIGURE 13. HANDSHAKE TRIGGERED BY MODE

DATA VALID

THREE-STATE WITH PULLUPTHREE-STATE HIGH IMPEDANCEDON’T CARE

The internal logic of the 7104 is supplied by an internal

regulator between V++ and Digital Ground. The regulator

includes a low-voltage detector that will clear various

registers. This is intended to ensure that on initial power-up,

the control logic comes up in Auto-Zero, with the 2nd, 3rd,

and 4th MSB bits cleared, and the “mode” F/F cleared (i.e.,

in “direct” mode). This, however, will also clear these registers if the supply voltage “glitches” to a low enough value.

Additionally, if the supply voltage comes up too fast, this

clear pulse may be too narrow for reliable clear ing. In general, this is not a problem, but if the UART internal “MODE”

F/F should come up set, the byte and chip

ENABLE lines will

become active outputs. In many systems this could lead to

bus conflicts, especially in non-handshake systems. In any

case, SEN should be high (held high for non-handshake systems) to ensure that the MODE F/F will be cleared as fast as

possible (see Figure 11 for timing). For these and other

reasons, adequate supply bypass is recommended.

Oscillator

The ICL7104-14 is provided with a versatile three terminal

oscillator to generate the internal clock. The oscillator may

be overdriven, or may be operated as an RC or crystal

oscillator.

Figure 14 shows the oscillator configured for RC operation.

The internal clock will be of the same frequency and phase

as the voltage on the CLOCK 3 pin. The resistor and

capacitor should be connected as shown. The circuit will

oscillate at a frequency given by f = 0.45/RC. A 50 - 100kΩ

resistor is recommended for useful ranges of frequency. For

optimum 60Hz line rejection, the capacitor value should be

chosen such that 32768 (-16), 8192 (-14) clock periods is

close to an integral multiple of the 60Hz period.

CLOCK

25

1

CLOCK

f

OSC

26

2

R

= 0.45/RC

CLOCK

C

24

3

NOTE: Clock 3 has the same output drive as the bit outputs.

FIGURE 14. RC OSCILLATOR (ICL7104-14 ONLY)

As a result of pin count limitations, the ICL7104-16 has only

CLOCK 1 and CLOCK 2 available, and cannot be used as

an RC oscillator. The internal clock will correspond to the

inverse of the signal on CLOCK 2. Figure 15 shows a crystal

oscillator circuit, which can be used with both 7104 versions.

If an external clock is to be used, it should be applied to

CLOCK 1. This internal clock will correspond to the signal

applied to this pin.

V+

25

CLOCK

1

CLOCK

†

CRYSTAL

FIGURE 15. CRYSTAL OSCILLATOR

26

†CAPACITOR VALUE

2

DEPENDS ON CRYSTAL

TYP 0-30pF

5-24

Page 20

ICL8052/ICL7104, ICL8068/ICL7104

Power Supply Sequencing

Because of the nature of the CMOS process used to

fabricate the ICL7104, and the multiple power supplies

used, there are certain conditions of these supplies under

which a disabling and potentially damaging SCR action can

occur. All of these conditions involve the V+ supply (Norm

+5V) being more positive than the V++ supply. If there is

any possibility of this occurring during start-up, shut down,

under transient conditions during operation, or when inserting a PC board into a “hot” socket, etc., a diode should be

placed between V+ and V++ to prevent it. A germanium or

Schottky rectifier diode would be best, but in most cases a

silicon rectifier is adequate.

Analog and Digital Grounds

Extreme care must be taken to avoid ground loops in the

layout of ICL8068 or ICL8052/7104 circuits, especially in

16-bit and high sensitivity circuits. It is most important that

return currents from digital loads are not fed into the analog

ground line. A recommended connection sequence for the

ground lines is shown in Figure 16.

Application Notes

Some application notes that may be found useful are listed

here:

AnswerFAX

NOTE # DESCRIPTION

AN016 “Selecting A/D Converters”, by Dave

Fullagar

AN017 “The Integrating A/D Converter”, by Lee

Evans

AN018 “Do’s and Don’ts of Applying A/D

Converters,” by Peter Bradshaw and Skip

Osgood

AN030 “Building a Battery-Operated Auto

Ranging DVM with the ICL7106”

DOC. #

9016

9017

9018

9030

V

DIGITAL

LOGIC

BUFF

OUT

AZ

COMP

BUFF

-IN

(IF USED)

DEVICE PIN

+

IN

-

I/P

FILTER

CAP

PIN 35

ICL7104

AN GND

DIG GND

ICL7104

PIN 2

C

8068 PIN 2

REF

VOLTAGE

V

REF

EXTERNAL

REFERENCE

(IF USED)

PIN 35

ICL7104

AN GND

+5V SUPPLY BYPASS CAPACITOR(S)

+15V -15V

BOARD

EDGE

SUPPLY

RETURN

FIGURE 16. GROUNDING SEQUENCE

5-25

Page 21

ICL8052/ICL7104, ICL8068/ICL7104

ICL7104 with ICL8052/8068 Integrating A/D Converter Equations

• Oscillator

CRYSTAL or RC (RC on -14 Part Only)

f

(Typ) 200kHz

OSC

f

= 0.45/RC (ICL7104-14 Only)

OSC

C

> 50pF and R

OSC

OSC

> 50K

• Oscillator Period

= 1/f

t

OSC

OSC

• Integration Clock Frequency

CLOCK

= f

OSC

f

• Integration Period

= 8192 x t

t

INT

t

= 32768 x t

INT

OSC

OSC

(7104-14)

(7104-16)

• 60/50Hz Rejection Criterion

t

INT/t60Hz

or t

INT/t50Hz

= Integer

• Optimum Integration Current

= 20µA

I

INT

• Full Scale Analog Input Voltage

(Typ) = 200mV to 2V = 2V

V

INFS

• Integrate Resistor

INT

BufferGain()V

------------------------------------------------------------ -=

R

I

INT

×

INFS

REF

• Integrate Capacitor

t

()I

()

INT

C

INT

INT

--------------------------------=

V

INT

• Integrator Output Voltage

t

()I

()

INT

V

INT

V

INT

(Typ) = 9V

INT

--------------------------------=

C

INT

• Output Count

V

IN

Count 8192

Count 32768

× (7104-14)=

× (7104-16)=

---------------

V

REF

V

---------------

V

REF

IN

• Output Type:

Binary Amplitude with Polarity and Overrange Bits.

• Power Supply: ±15V, +5V

V++ = +15V

V- = -15V

V+ = +5V

≅ 1.75V

V

REF

If V

not used, float output pin.

REF

• Auto Zero Capacitor Values

0.01µF < C

AZ

< 1µF

• Reference Capacitor Value

= (Buffer Gain) x C

C

REF

AZ

ICL7104 - 14

ICL7104 - 16

AUTOZERO

(COUNT)

24,576 - 8,193

98,304 - 32,769

CONVERSION TIME (IN CONTINUOUS MODE):

INTEGRATE

(FIXED COUNT)

8192

32768

† t

32,768

131,072

OSC

† t

OSC

FIGURE 17.

(7104 - 14)

(7104 - 16)

DEINTEGRATE

(COUNT)

0 - 16383

0 - 65535

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate

and reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which

may result from its use. No license is granted by implication or otherwise under an y patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

5-26

Loading...

Loading...