®

www.BDTIC.com/Intersil

ICL3221, ICL3222, ICL3223,

ICL3232, ICL3241, ICL3243

Data Sheet March 1, 2006

One Microamp Supply-Current, +3V to +5.5V,

250kbps, RS-232 Transmitters/Receivers

The Intersil ICL32XX devices are 3.0V to 5.5V powered

RS-232 transmitters/receivers which meet ElA/TIA-232 and

V.28/V.24 specifications, even at V

applications are PDAs, Palmtops, and notebook and laptop

computers where the low operational, and even lower

standby, power consumption is critical. Efficient on-chip

charge pumps, coupled with manual and automatic

powerdown functions (except for the ICL3232), reduce the

standby supply current to a 1µA trickle. Small footprint

packaging, and the use of small, low value capacitors ensure

board space savings as well. Data rates greater than

250kbps are guaranteed at worst case load conditions. This

family is fully compatible with 3.3V only systems, mixed 3.3V

and 5.0V systems, and 5.0V only systems.

The ICL324X are 3-driver, 5-receiver devices that provide a

complete serial port suitable for laptop or notebook

computers. Both devices also include noninverting alwaysactive receivers for “wake-up” capability.

The ICL3221, ICL3223 and ICL3243, feature an

automatic powerdown function which powers down the

on-chip power-supply and driver circuits. This occurs when

an attached peripheral device is shut off or the RS-232

cable is removed, conserving system power automatically

without changes to the hardware or operating system.

These devices power up again when a valid RS-232

voltage is applied to any receiver input.

Table 1 summarizes the features of the devices represented

by this data sheet, while Application Note AN9863

summarizes the features of each device comprising the

ICL32XX 3V family.

= 3.0V. Targeted

CC

FN4805.21

Features

• Pb-Free Plus Anneal Available as an Option

(RoHS Compliant) (See Ordering Info)

• 15kV ESD Protected (Human Body Model)

• Drop in Replacements for MAX3221, MAX3222,

MAX3223, MAX3232, MAX3241, MAX3243, SP3243

• ICL3221 is Low Power, Pin Compatible Upgrade for 5V

MAX221

• ICL3222 is Low Power, Pin Compatible Upgrade for 5V

MAX242, and SP312A

• ICL3232 is Low Power Upgrade for HIN232/ICL232 and

Pin Compatible Competitor Devices

• RS-232 Compatible with VCC = 2.7V

• Meets EIA/TIA-232 and V.28/V.24 Specifications at 3V

• Latch-Up Free

• On-Chip Voltage Converters Require Only Four External

0.1µF Capacitors

• Manual and Automatic Powerdown Features (Except

ICL3232)

• Guaranteed Mouse Driveability (ICL324X Only)

• Receiver Hysteresis For Improved Noise Immunity

• Guaranteed Minimum Data Rate . . . . . . . . . . . . . 250kbps

• Guaranteed Minimum Slew Rate . . . . . . . . . . . . . . . 6V/µs

• Wide Power Supply Range . . . . . . . Single +3V to +5.5V

• Low Supply Current in Powerdown State. . . . . . . . . . .1µA

Applications

• Any System Requiring RS-232 Communication Ports

- Battery Powered, Hand-Held, and Portable Equipment

- Laptop Computers, Notebooks, Palmtops

- Modems, Printers and other Peripherals

- Digital Cameras

- Cellular/Mobile Phones

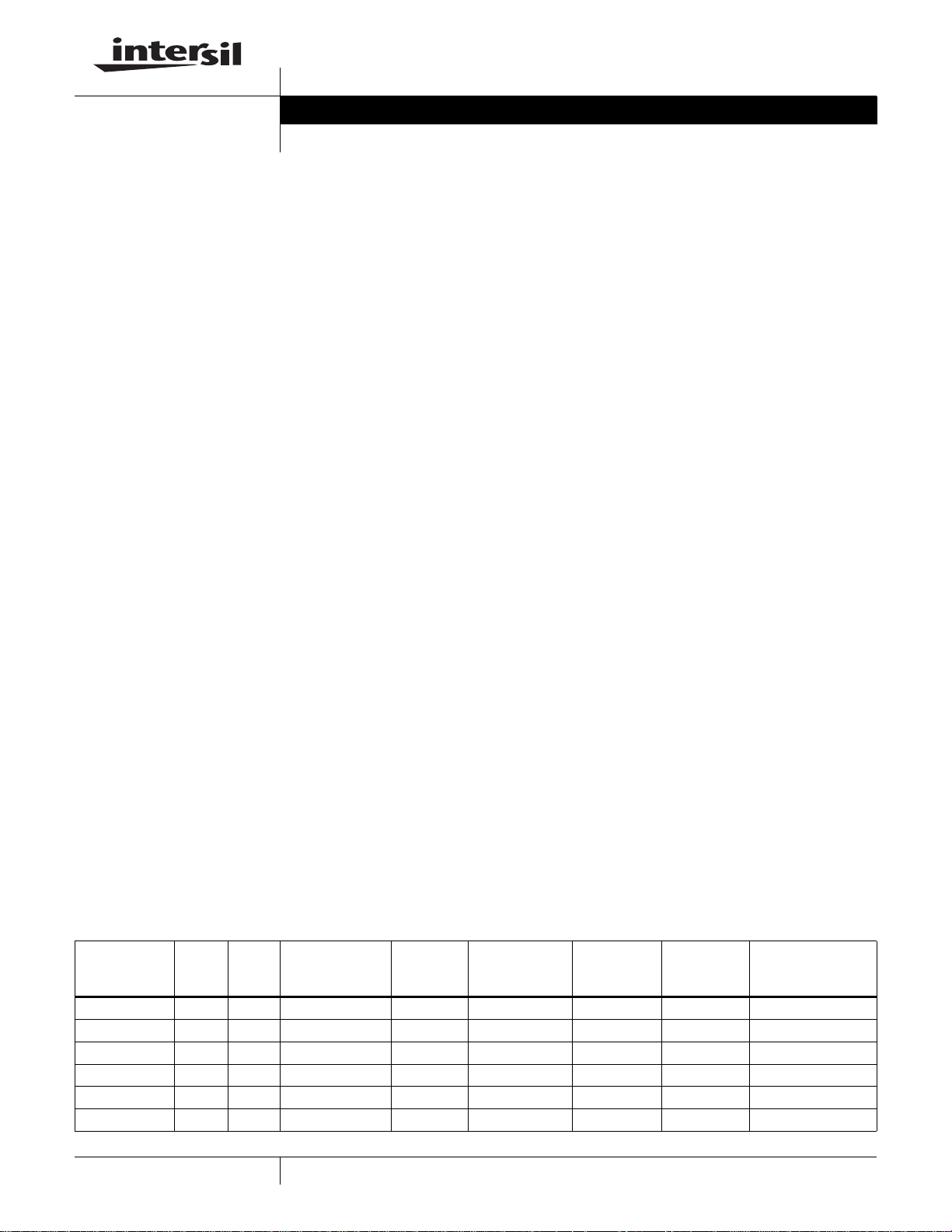

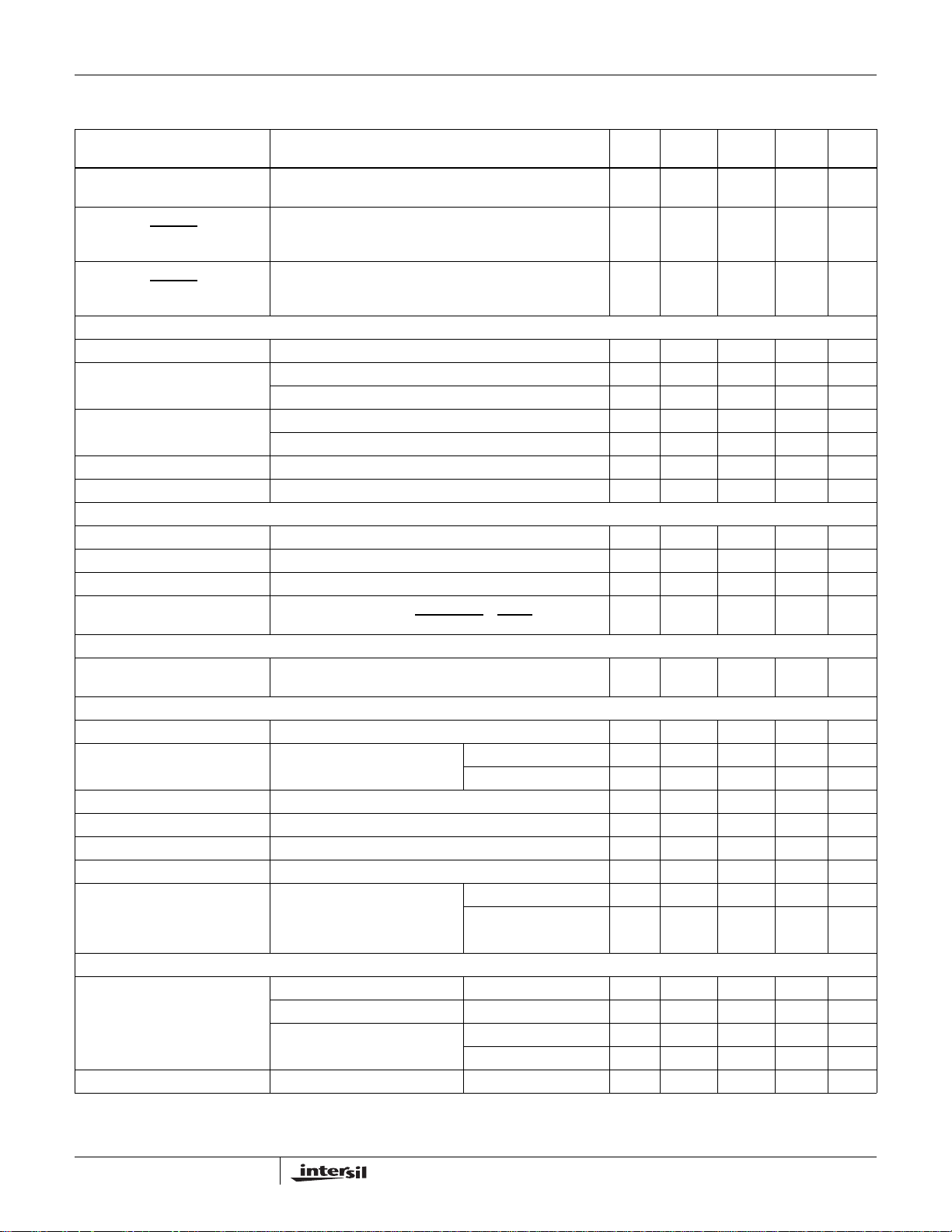

TABLE 1. SUMMARY OF FEATURES

NO. OF

PART NUMBER

NO. OF

ICL3221 1 1 0 250 Yes No Yes Yes

ICL3222 2 2 0 250 Yes No Yes No

ICL3223 2 2 0 250 Yes No Yes Yes

ICL3232 2 2 0 250 No No No No

ICL3241 3 5 2 250 Yes No Yes No

ICL3243 3 5 1 250 No No Yes Yes

Tx.

NO. OF

Rx.

1

MONITOR Rx.

(R

)

OUTB

DATA

RATE

(kbps)

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

Rx. ENABLE

FUNCTION?

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

MANUAL

READY

OUTPUT?

Copyright Intersil Americas Inc. 1999-2006. All Rights Reserved

POWER-

DOWN?

AUTOMATIC

POWERDOWN

FUNCTION?

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

www.BDTIC.com/Intersil

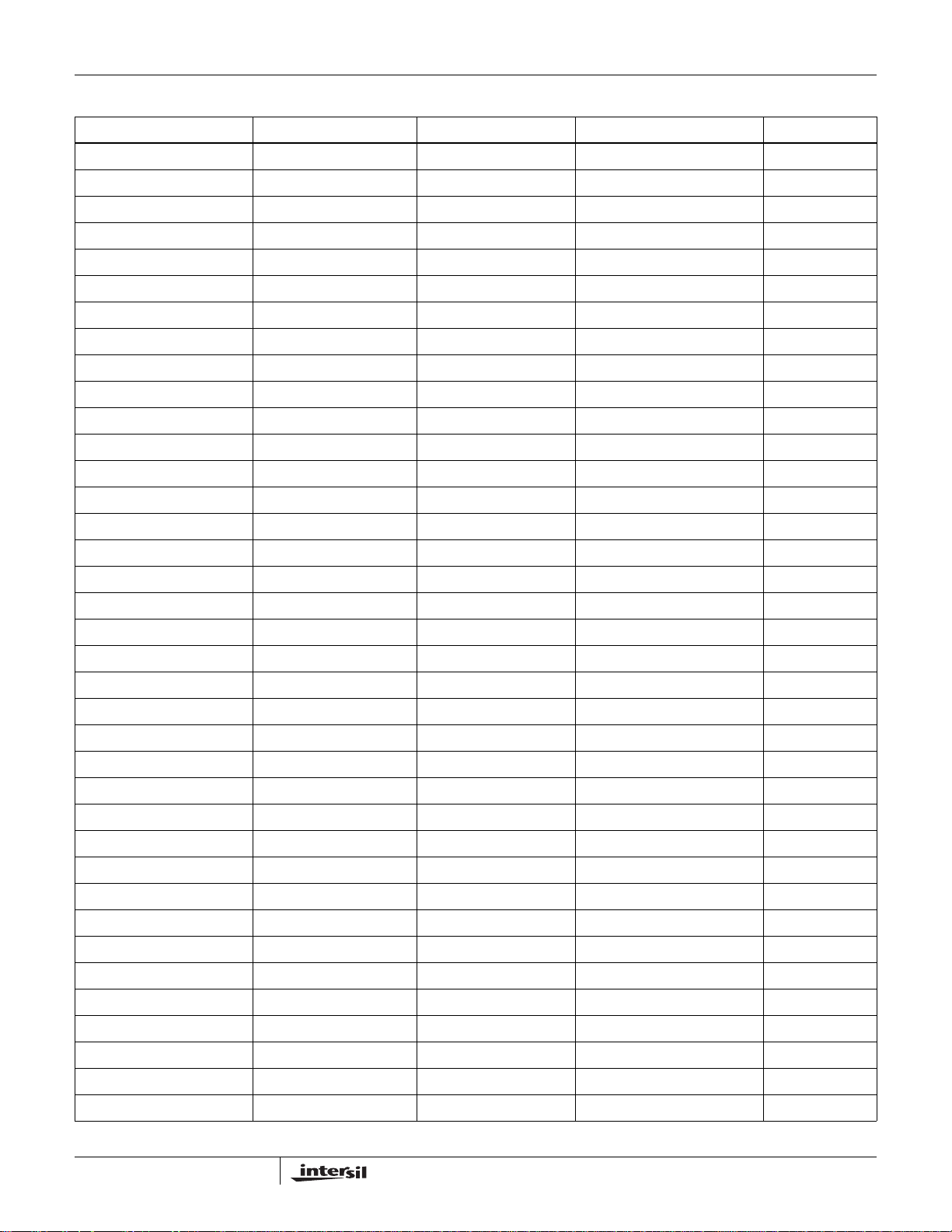

Ordering Information

PAR T N U MBER (NOTE 1) PART MARKING TEMP. RANGE (°C) PACKAGE PKG. DWG. #

ICL3221CA ICL3221CA 0 to 70 16 Ld SSOP M16.209

ICL3221CAZ (Note 2) ICL3221CAZ 0 to 70 16 Ld SSOP (Pb-free) M16.209

ICL3221CV ICL3221CV 0 to 70 16 Ld TSSOP M16.173

ICL3221CVZ (Note 2) 3221CVZ 0 to 70 16 Ld TSSOP (Pb-free) M16.173

ICL3221IA ICL3221IA -40 to 85 16 Ld SSOP M16.209

ICL3221IAZ (Note 2) ICL3221IAZ -40 to 85 16 Ld SSOP (Pb-free) M16.209

ICL3222CA ICL3222CA 0 to 70 20 Ld SSOP M20.209

ICL3222CAZ (Note 2) ICL3222CAZ 0 to 70 20 Ld SSOP (Pb-free) M20.209

ICL3222CB ICL3222CB 0 to 70 18 Ld SOIC M18.3

ICL3222CBZ (Note 2) 3222CBZ 0 to 70 18 Ld SOIC (Pb-free) M18.3

ICL3222CP ICL3222CP 0 to 70 18 Ld PDIP E18.3

ICL3222CPZ (Note 2) ICL3222CPZ 0 to 70 18 Ld PDIP* (Pb-free) E18.3

ICL3222CV ICL3222CV 0 to 70 20 Ld TSSOP M20.173

ICL3222CVZ (Note 2) ICL3222CVZ 0 to 70 20 Ld TSSOP (Pb-free) M20.173

ICL3222IA ICL3222IA -40 to 85 20 Ld SSOP M20.209

ICL3222IAZ (Note 2) ICL3222IAZ -40 to 85 20 Ld SSOP (Pb-free) M20.209

ICL3222IB ICL3222IB -40 to 85 18 Ld SOIC M18.3

ICL3222IV ICL3222IV -40 to 85 20 Ld TSSOP M20.173

ICL3222IVZ (Note 2) ICL3222IVZ -40 to 85 20 Ld TSSOP (Pb-free) M20.173

ICL3223CA ICL3223CA 0 to 70 20 Ld SSOP M20.209

ICL3223CAZ (Note 2) ICL3223CAZ 0 to 70 20 Ld SSOP (Pb-free) M20.209

ICL3223CP ICL3223CP 0 to 70 20 Ld PDIP E20.3

ICL3223CPZ (Note 2) ICL3223CPZ 0 to 70 20 Ld PDIP* (Pb-free) E20.3

ICL3223CV ICL3223CV 0 to 70 20 Ld TSSOP M20.173

ICL3223IA ICL3223IA -40 to 85 20 Ld SSOP M20.209

ICL3223IAZ (Note 2) ICL3223IAZ -40 to 85 20 Ld SSOP (Pb-free) M20.209

ICL3223IV ICL3223IV -40 to 85 20 Ld TSSOP M20.173

ICL3223IVZ (Note 2) ICL3223IVZ -40 to 85 20 Ld TSSOP (Pb-free) M20.173

ICL3232CA ICL3232CA 0 to 70 16 Ld SSOP M16.209

ICL3232CAZ (Note 2) 3232CAZ 0 to 70 16 Ld SSOP (Pb-free) M16.209

ICL3232CB ICL3232CB 0 to 70 16 Ld SOIC M16.3

ICL3232CBZ (Note 2) 3232CBZ 0 to 70 16 Ld SOIC (Pb-free) M16.3

ICL3232CBN 3232CBN 0 to 70 16 Ld SOIC (N) M16.15

ICL3232CBNZ (Note 2) 3232CBNZ 0 to 70 16 Ld SOIC (N) (Pb-free) M16.15

ICL3232CP ICL3232CP 0 to 70 16 Ld PDIP E16.3

ICL3232CPZ (Note 2) ICL3232CPZ 0 to 70 16 Ld PDIP* (Pb-free) E16.3

ICL3232CV ICL3232CV 0 to 70 16 Ld TSSOP M16.173

2

FN4805.21

March 1, 2006

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

www.BDTIC.com/Intersil

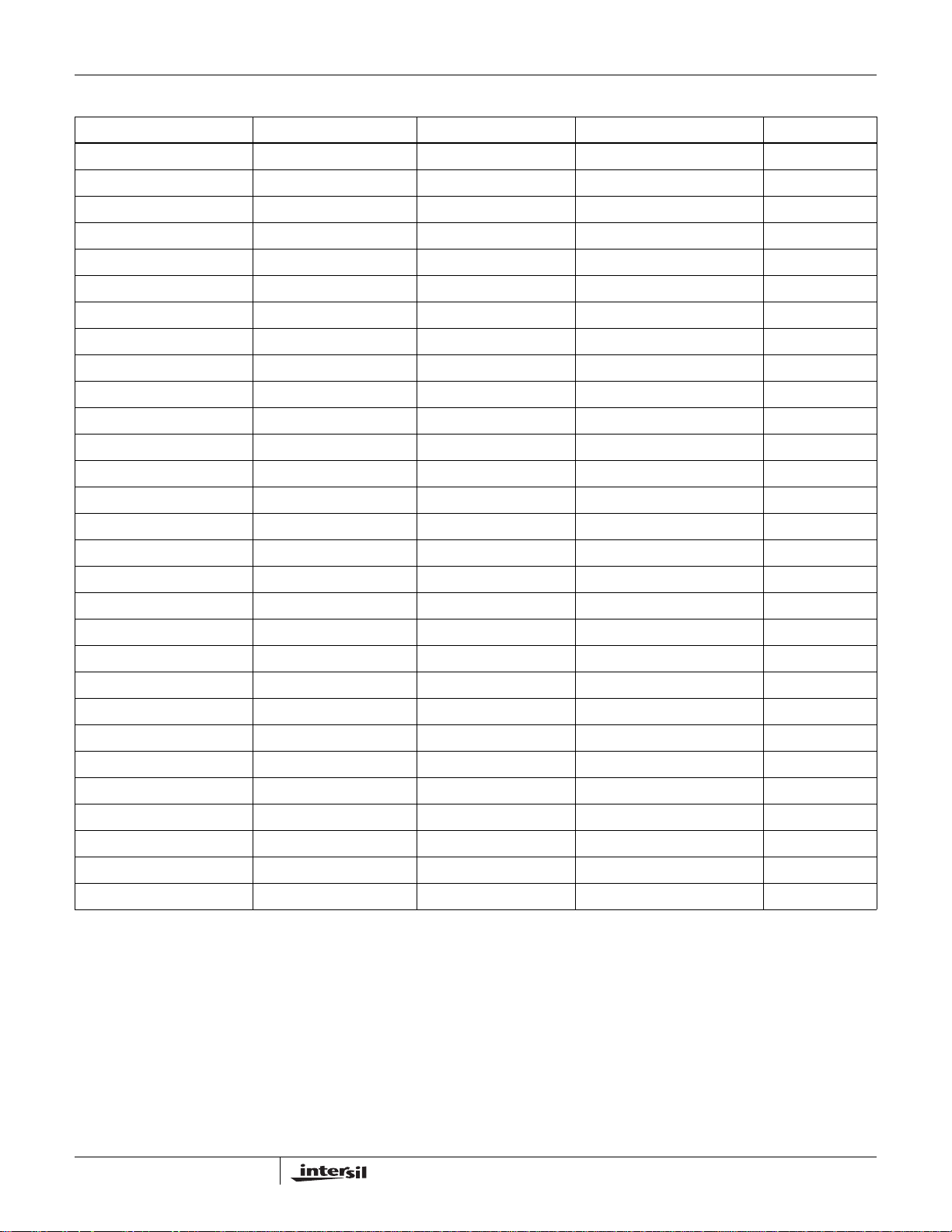

Ordering Information (Continued)

PAR T N U MBER (NOTE 1) PART MARKING TEMP. RANGE (°C) PACKAGE PKG. DWG. #

ICL3232CVZ (Note 2) 3232CVZ 0 to 70 16 Ld TSSOP (Pb-free) M16.173

ICL3232IA ICL3232IA -40 to 85 16 Ld SSOP M16.209

ICL3232IAZ (Note 2) 3232IAZ -40 to 85 16 Ld SSOP (Pb-free) M16.209

ICL3232IB ICL3232IB -40 to 85 16 Ld SOIC M16.3

ICL3232IBZ (Note 2) 3232IBZ -40 to 85 16 Ld SOIC (Pb-free) M16.3

ICL3232IBN 3232IBN -40 to 85 16 Ld SOIC (N) M16.15

ICL3232IBNZ (Note 2) 3232IBNZ -40 to 85 16 Ld SOIC (N) (Pb-free) M16.15

ICL3232IV ICL3232IV -40 to 85 16 Ld TSSOP M16.173

ICL3232IVZ (Note 2) 3232IVZ -40 to 85 16 Ld TSSOP (Pb-free) M16.173

ICL3241CA ICL3241CA 0 to 70 28 Ld SSOP M28.209

ICL3241CAZ (Note 2) ICL3241CAZ 0 to 70 28 Ld SSOP (Pb-free) M28.209

ICL3241CB ICL3241CB 0 to 70 28 Ld SOIC M28.3

ICL3241CBZ (Note 2) ICL3241CBZ 0 to 70 28 Ld SOIC (Pb-free) M28.3

ICL3241CV ICL3241CV 0 to 70 28 Ld TSSOP M28.173

ICL3241CVZ (Note 2) ICL3241CVZ 0 to 70 28 Ld TSSOP (Pb-free) M28.173

ICL3241IA ICL3241IA -40 to 85 28 Ld SSOP M28.209

ICL3241IAZ (Note 2) ICL3241IAZ -40 to 85 28 Ld SSOP (Pb-free) M28.209

ICL3241IB ICL3241IB -40 to 85 28 Ld SOIC M28.3

ICL3241IBZ (Note 2) ICL3241IBZ -40 to 85 28 Ld SOIC (Pb-free) M28.3

ICL3241IV ICL3241IV -40 to 85 28 Ld TSSOP M28.173

ICL3241IVZ (Note 2) ICL3241IVZ -40 to 85 28 Ld TSSOP (Pb-free) M28.173

ICL3243CA ICL3243CA 0 to 70 28 Ld SSOP M28.209

ICL3243CAZ (Note 2) ICL3243CAZ 0 to 70 28 Ld SSOP (Pb-free) M28.209

ICL3243CB ICL3243CB 0 to 70 28 Ld SOIC M28.3

ICL3243CBZ (Note 2) ICL3243CBZ 0 to 70 28 Ld SOIC (Pb-free) M28.3

ICL3243CV ICL3243CV 0 to 70 28 Ld TSSOP M28.173

ICL3243CVZ (Note 2) ICL3243CVZ 0 to 70 28 Ld TSSOP (Pb-free) M28.173

ICL3243IA ICL3243IA -40 to 85 28 Ld SSOP M28.209

ICL3243IAZ (Note 2) ICL3243IAZ -40 to 85 28 Ld SSOP (Pb-free) M28.209

*Pb-free PDIPs can be used for through hole wave solder processing only. They are not intended for use in Reflow solder processing applications.

NOTES:

1. Most surface mount devices are available on tape and reel; add “-T” to suffix.

2. Intersil Pb-free plus anneal products employ special Pb-free material sets; molding compounds/die attach materials and 100% matte tin plate

termination finish, which are RoHS compliant and compatible with both SnPb and Pb-free soldering operations. Intersil Pb-free products are MSL

classified at Pb-free peak reflow temperatures that meet or exceed the Pb-free requirements of IPC/JEDEC J STD-020.

3

FN4805.21

March 1, 2006

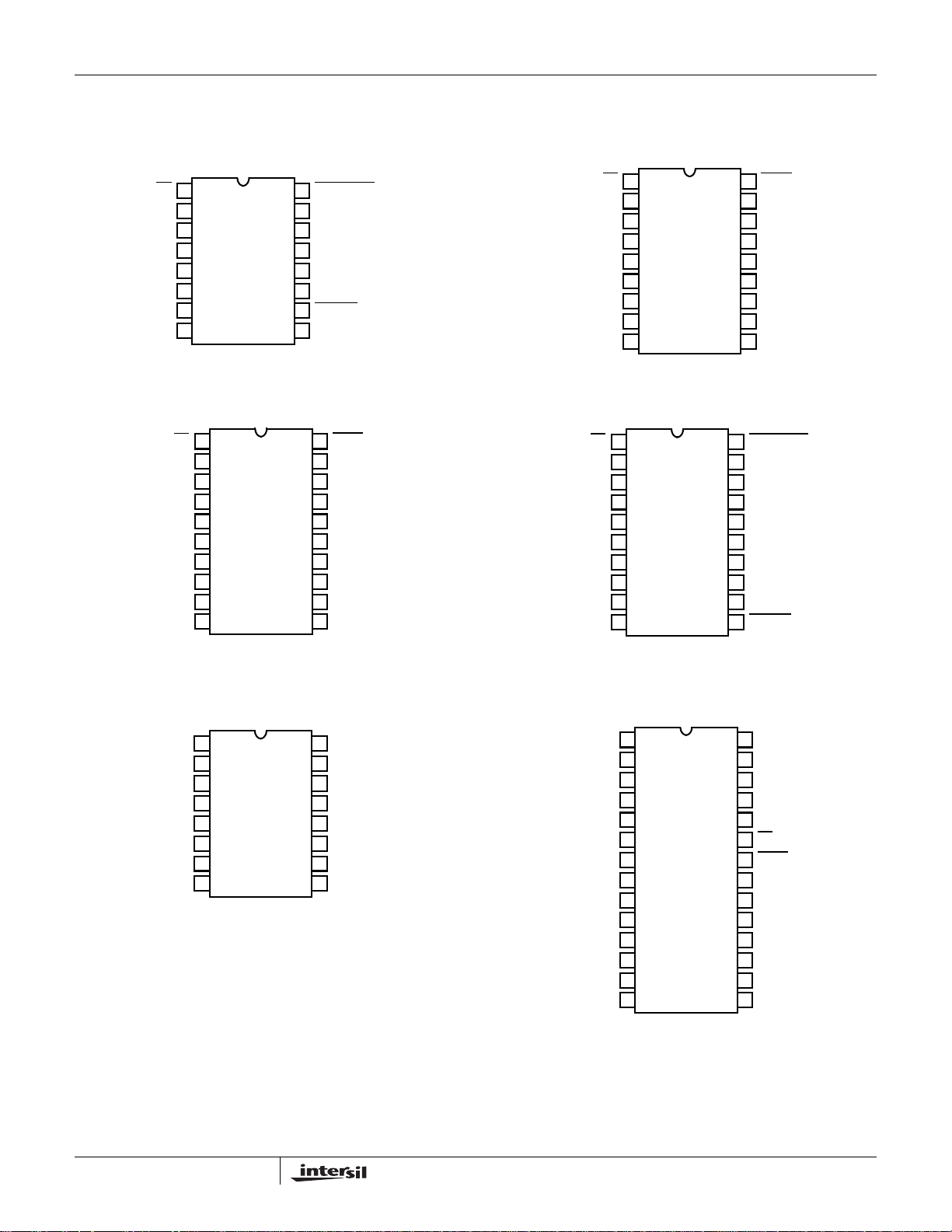

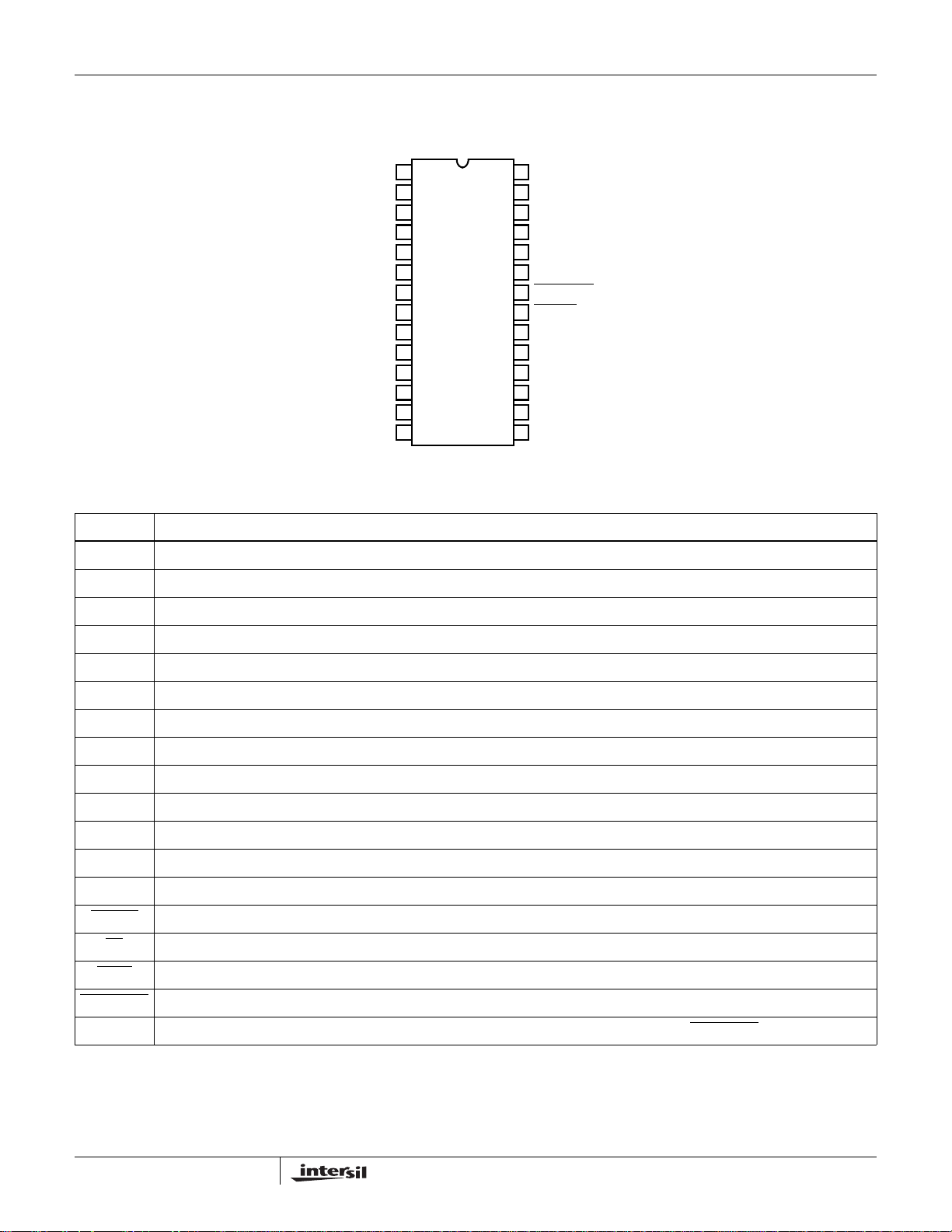

Pinouts

www.BDTIC.com/Intersil

ICL3221 (SSOP, TSSOP)

TOP VIEW

EN

1

C1+

2

3

V+

4

C1-

5

C2+

C2-

6

V-

7

R1

8

IN

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

ICL3222 (PDIP, SOIC)

TOP VIEW

EN

T2

C1+

C2+

OUT

R2

V+

C1-

C2-

1

2

3

4

5

6

V-

7

8

9

IN

FORCEOFF

16

V

15

CC

GND

14

T1

13

FORCEON

12

T1

11

INVALID

10

R1

9

OUT

IN

OUT

18

SHDN

V

17

CC

GND

16

15

T1

OUT

R1

14

IN

R1

13

OUT

T1

12

IN

T2

11

IN

10

R2

OUT

ICL3222 (SSOP, TSSOP)

TOP VIEW

SHDN

20

V

19

CC

GND

18

T1

17

OUT

R1

16

IN

R1

15

OUT

NC

14

T1

13

IN

12

T2

IN

NC

11

R2

T2

C1+

C2+

OUT

R2

OUT

EN

V+

C1-

C2-

1

2

3

4

5

6

V-

7

8

9

IN

10

ICL3232 (PDIP, SOIC, SSOP, TSSOP)

TOP VIEW

V

16

CC

GND

15

T1

14

OUT

R1

13

IN

R1

12

OUT

T1

11

IN

T2

10

IN

R2

9

OUT

T2

C1+

C1-

C2+

OUT

R2

V+

C2-

1

2

3

4

5

6

V-

7

8

IN

ICL3223 (PDIP, SSOP, TSSOP)

TOP VIEW

EN

1

C1+

2

3

V+

4

C1-

5

C2+

C2-

6

V-

7

T2

8

OUT

R2

9

IN

10

R2

OUT

ICL3241 (SOIC, SSOP, TSSOP)

TOP VIEW

C2+

1

C2-

2

3

V-

R1

4

IN

R2

5

IN

R3

6

IN

R4

7

IN

R5

8

IN

T1

9

OUT

10

T2

OUT

T3

11

OUT

T3

12

IN

T2

13

IN

T1

14

IN

FORCEOFF

20

V

19

CC

GND

18

T1

17

R1

16

R1

15

FORCEON

14

T1

13

12

T2

INVALID

11

C1+

28

V+

27

V

26

GND

25

C1-

24

EN

23

SHDN

22

R1

21

20

R2

R1

19

R2

18

R3

17

16

R4

R5

15

OUT

IN

OUT

IN

IN

CC

OUTB

OUTB

OUT

OUT

OUT

OUT

OUT

4

FN4805.21

March 1, 2006

Pinouts (Continued)

www.BDTIC.com/Intersil

Pin Descriptions

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

ICL3243 (SOIC, SSOP, TSSOP)

TOP VIEW

28

C1+

V+

27

V

26

CC

GND

25

C1-

24

FORCEON

23

FORCEOFF

22

INVALID

21

20

R2

R1

19

R2

18

R3

17

16

R4

R5

15

OUTB

OUT

OUT

OUT

OUT

OUT

T1

T2

T3

C2+

R1

R2

R3

R4

R5

OUT

OUT

OUT

T3

T2

T1

C2-

V-

1

2

3

4

IN

5

IN

6

IN

7

IN

8

IN

9

10

11

12

IN

13

IN

14

IN

PIN FUNCTION

V

CC

System power supply input (3.0V to 5.5V).

V+ Internally generated positive transmitter supply (+5.5V).

V- Internally generated negative transmitter supply (-5.5V).

GND Ground connection.

C1+ External capacitor (voltage doubler) is connected to this lead.

C1- External capacitor (voltage doubler) is connected to this lead.

C2+ External capacitor (voltage inverter) is connected to this lead.

C2- External capacitor (voltage inverter) is connected to this lead.

T

T

OUT

R

R

OUT

R

OUTB

INVALID

EN

SHDN

TTL/CMOS compatible transmitter Inputs.

IN

RS-232 level (nominally ±5.5V) transmitter outputs.

RS-232 compatible receiver inputs.

IN

TTL/CMOS level receiver outputs.

TTL/CMOS level, noninverting, always enabled receiver outputs.

Active low output that indicates if no valid RS-232 levels are present on any receiver input.

Active low receiver enable control; doesn’t disable R

OUTB

outputs.

Active low input to shut down transmitters and on-board power supply, to place device in low power mode.

FORCEOFF

Active low to shut down transmitters and on-chip power supply. This overrides any automatic circuitry and FORCEON (See Table 2).

FORCEON Active high input to override automatic powerdown circuitry thereby keeping transmitters active. (FORCEOFF

5

must be high).

March 1, 2006

FN4805.21

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

www.BDTIC.com/Intersil

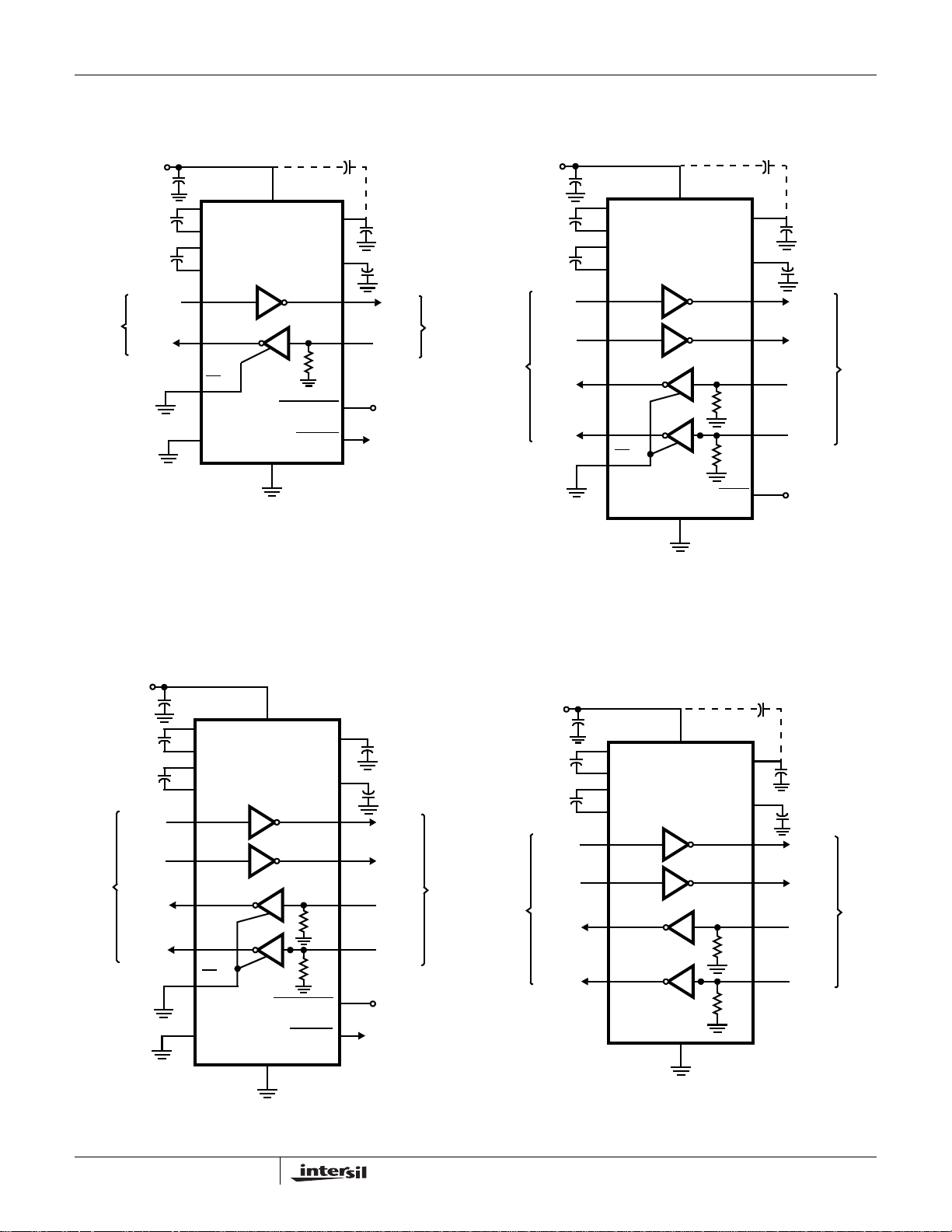

Typical Operating Circuits

ICL3221 ICL3222

C3 (OPTIONAL CONNECTION, NOTE)

+3.3V

TTL/CMOS

R1

LOGIC LEVELS

+

C

0.1µF

C

0.1µF

T1

OUT

0.1µF

2

C1+

1

+

4

C1-

5

2

C2+

+

6

C2-

11

IN

1

EN

12

FORCEON

15

V

CC

T

1

R

1

FORCEOFF

GND

14

NOTE: The negative terminal of C3 can be

connected to either V

or GND

CC

V+

V-

5kΩ

INVALID

3

7

13

89

16

10

+

C

+

0.1µF

C

0.1µF

+

3

4

T1

OUT

R1

IN

V

CC

TO POWER

CONTROL

LOGIC

RS-232

LEVELS

TTL/CMOS

LOGIC LEVELS

+3.3V

0.1µF

0.1µF

R1

R2

C

C

T1

T2

OUT

OUT

C3 (OPTIONAL CONNECTION, NOTE)

+

0.1µF

2

1

2

IN

IN

C1+

+

4

C1-

5

C2+

+

6

C2-

12

11

13

10

1

EN

V

CC

R

1

R

2

GND

17

T

1

T

2

5kΩ

5kΩ

SHDN

16

V+

V-

+

3

C

3

+

0.1µF

7

C

4

0.1µF

+

15

T1

OUT

8

T2

OUT

14

R1

IN

9

R2

IN

18

V

CC

RS-232

LEVELS

NOTE: The negative terminal of C3 can be

connected to either V

CC

or GND

ICL3223 ICL3232

+3.3V

TTL/CMOS

LOGIC LEVELS

C

0.1µF

C

0.1µF

T1

T2

R1

R2

1

2

OUT

OUT

+

0.1µF

2

C1+

+

4

C1-

5

C2+

+

6

C2-

13

IN

12

IN

15

1

EN

14

FORCEON

19

V

CC

T

1

T

2

R

1

R

2

FORCEOFF

GND

18

V+

V-

5kΩ

5kΩ

INVALID

3

C

3

+

0.1µF

7

C

4

0.1µF

+

17

T1

8

T2

16

R1

910

R2

20

V

CC

11

TO POWER

CONTROL LOGIC

OUT

OUT

IN

IN

RS-232

LEVELS

+3.3V

TTL/CMOS

LOGIC LEVELS

C

0.1µF

C

0.1µF

R1

R2

1

2

T1

T2

OUT

OUT

+

0.1µF

1

C1+

+

3

C1-

4

C2+

+

5

C2-

11

IN

10

IN

12

9

C3 (OPTIONAL CONNECTION, NOTE)

V

CC

R

R

2

GND

16

T

1

T

2

5kΩ

1

5kΩ

15

V+

V-

+

2

C

3

+

0.1µF

6

C

4

0.1µF

+

14

T1

OUT

7

T2

OUT

13

R1

IN

8

R2

IN

RS-232

LEVELS

NOTE: The negative terminal of C3 can be

connected to either V

CC

or GND

6

FN4805.21

March 1, 2006

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

www.BDTIC.com/Intersil

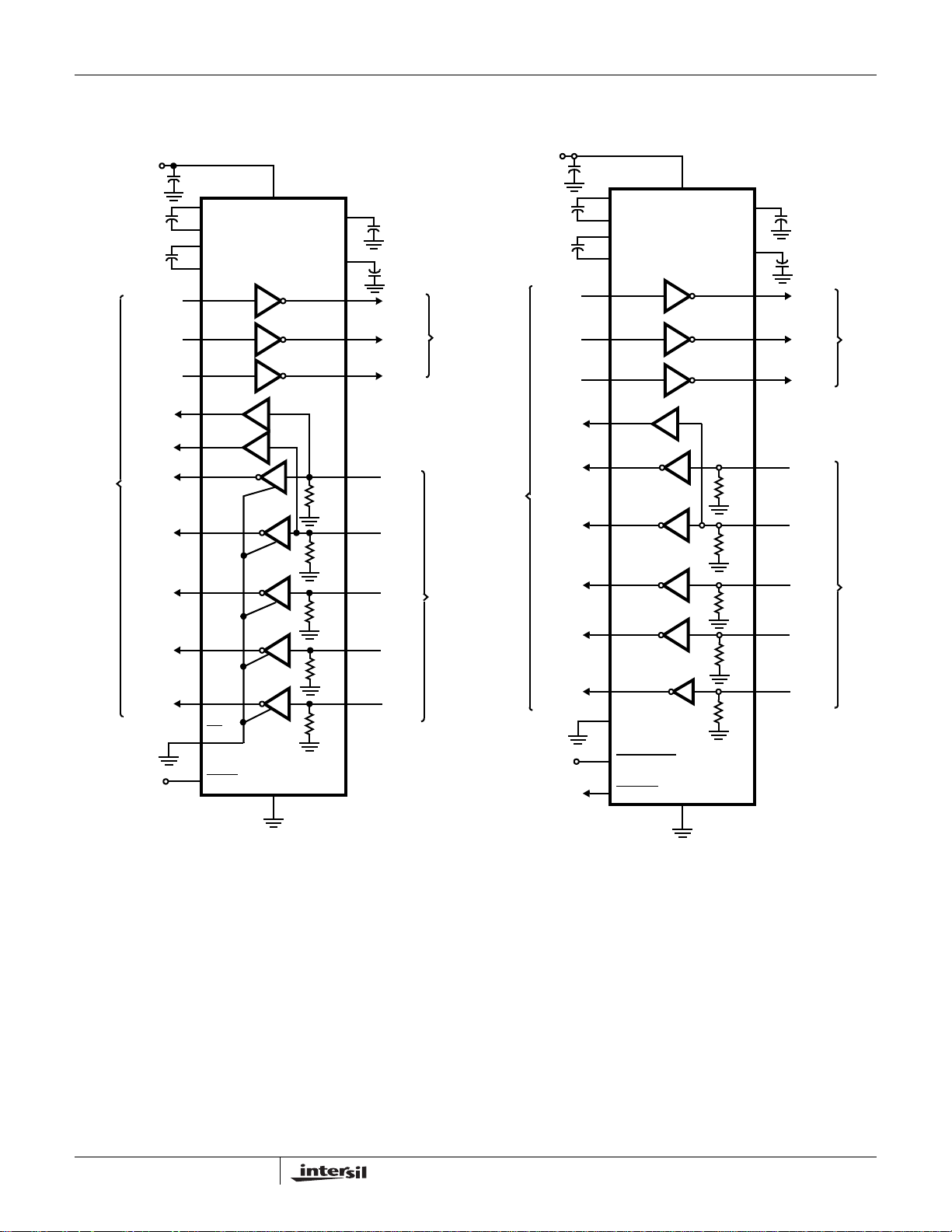

Typical Operating Circuits (Continued)

ICL3241 ICL3243

TTL/CMOS

LOGIC LEVELS

+3.3V

0.1µF

0.1µF

R1

R2

R1

R2

R3

R4

R5

V

+

0.1µF

28

T1

T2

T3

C

1

C

2

IN

IN

IN

C1+

+

24

C1-

1

C2+

+

2

C2-

V

14

13

12 11

21

OUTB

20

OUTB

19

OUT

R

OUT

R

OUT

R

OUT

R

CC

OUT

23

EN

22

SHDN

R

GND

CC

2

3

4

5

+3.3V

26

27

C

3

V+

V-

T

1

T

2

T

3

+

0.1µF

3

C

4

0.1µF

+

9

T1

OUT

10

T2

OUT

RS-232

LEVELS

T3

OUT

C

0.1µF

C

0.1µF

T1

T2

T3

+

0.1µF

28

1

2

C1+

+

24

C1-

1

C2+

+

2

C2-

14

IN

13

IN

12 11

IN

26

V

CC

T

1

T

2

T

3

V+

V-

27

C

3

+

0.1µF

3

C

4

0.1µF

+

9

T1

OUT

10

T2

T3

OUT

OUT

RS-232

LEVELS

20

R2

OUTB

5kΩ

5kΩ

5kΩ

5kΩ

5kΩ

4

R1

IN

518

R2

IN

617

R3

IN

RS-232

LEVELS

716

R4

IN

815

R5

IN

4

R1

IN

5kΩ

1

518

R2

IN

TTL/CMOS

LOGIC LEVELS

R1

R2

5kΩ

5kΩ

617

R3

IN

RS-232

LEVELS

716

R4

IN

R3

R4

OUT

OUT

OUT

OUT

19

R

1

R

2

R

3

R

4

5kΩ

815

R5

5kΩ

IN

25

R5

OUT

23

FORCEON

22

V

CC

21

FORCEOFF

INVALID

TO POWER

R

5

GND

25

CONTROL LOGIC

7

FN4805.21

March 1, 2006

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

www.BDTIC.com/Intersil

Absolute Maximum Ratings Thermal Information

VCC to Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to 6V

V+ to Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to 7V

V- to Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +0.3V to -7V

V+ to V- . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14V

Input Voltages

, FORCEOFF, FORCEON, EN, SHDN . . . . . . . . . -0.3V to 6V

T

IN

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±25V

R

IN

Output Voltages

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±13.2V

T

OUT

, INVALID. . . . . . . . . . . . . . . . . . . . . . . . -0.3V to VCC +0.3V

R

OUT

Short Circuit Duration

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Continuous

T

OUT

ESD Rating . . . . . . . . . . . . . . . . . . . . . . . . . See Specification Table

Operating Conditions

Temperature Range

ICL32XXCX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0°C to 70°C

ICL32XXIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to 85°C

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

is measured with the component mounted on a low effective thermal conductivity test board in free air. See Tech Brief TB379 for details.

3. θ

JA

Thermal Resistance (Typical, Note 3)

16 Ld PDIP Package* . . . . . . . . . . . . . . . . . . . . . . . 90

18 Ld PDIP Package* . . . . . . . . . . . . . . . . . . . . . . . 80

20 Ld PDIP Package* . . . . . . . . . . . . . . . . . . . . . . . 77

16 Ld Wide SOIC Package . . . . . . . . . . . . . . . . . . . 100

16 Ld Narrow SOIC Package. . . . . . . . . . . . . . . . . . 115

18 Ld SOIC Package . . . . . . . . . . . . . . . . . . . . . . . . 75

28 Ld SOIC Package . . . . . . . . . . . . . . . . . . . . . . . . 75

16 Ld SSOP Package . . . . . . . . . . . . . . . . . . . . . . . 135

20 Ld SSOP Package . . . . . . . . . . . . . . . . . . . . . . . 122

16 Ld TSSOP Package . . . . . . . . . . . . . . . . . . . . . . 145

20 Ld TSSOP Package . . . . . . . . . . . . . . . . . . . . . . 140

28 Ld SSOP and TSSOP Packages . . . . . . . . . . . . 100

Maximum Junction Temperature (Plastic Package) . . . . . . . 150°C

Maximum Storage Temperature Range . . . . . . . . . . . -65°C to 150°C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . 300°C

(SOIC, SSOP, TSSOP - Lead Tips Only)

*Pb-free PDIPs can be used for through hole wave solder processing

only. They are not intended for use in Reflow solder processing

applications.

θ

JA

(°C/W)

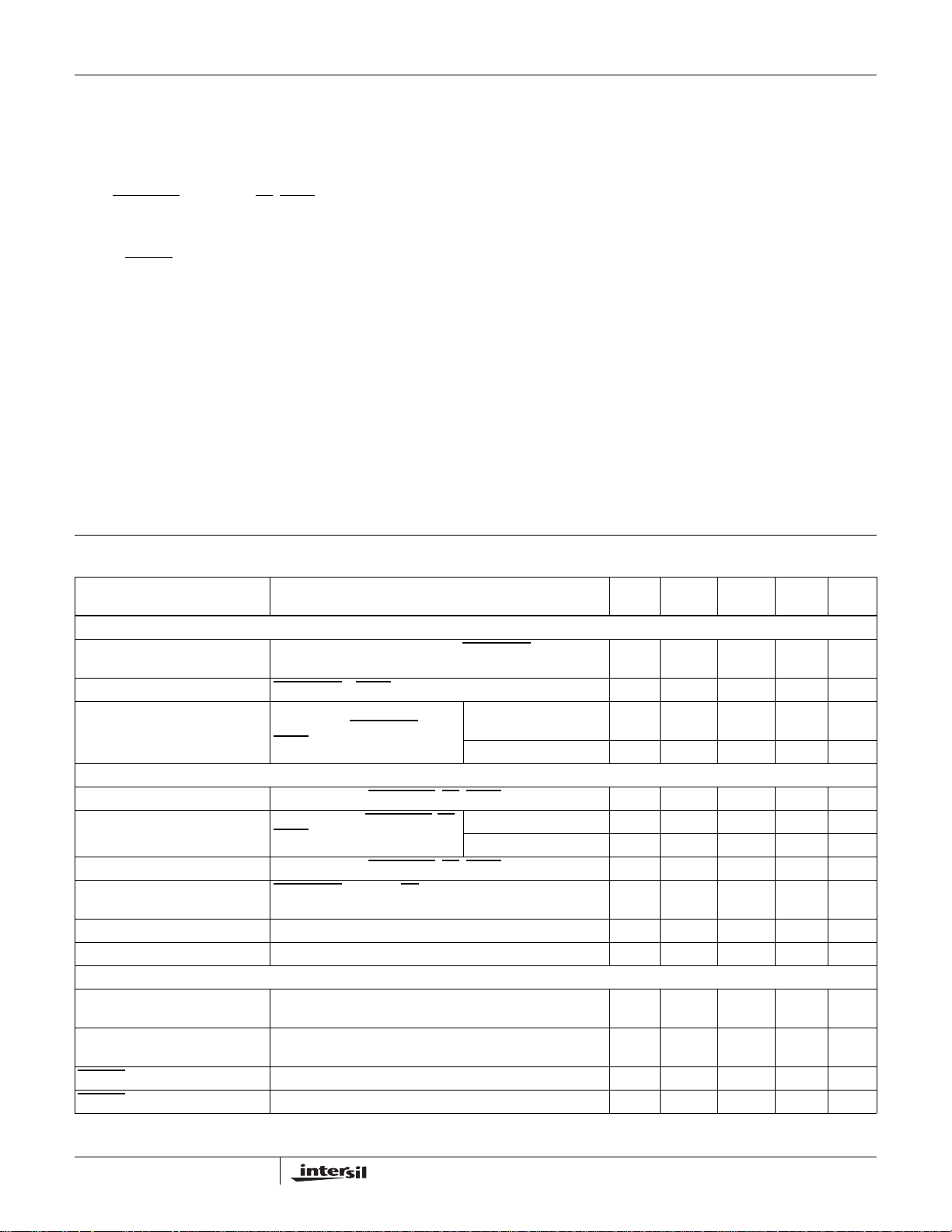

Electrical Specifications Test Conditions: VCC = 3V to 5.5V, C1 - C4 = 0.1µF; Unless Otherwise Specified.

Typicals are at TA = 25°C

TEMP

PARAMETER TEST CONDITIONS

DC CHARACTERISTICS

Supply Current, Automatic

Powerdown

Supply Current, Powerdown FORCEOFF

Supply Current,

Automatic Powerdown Disabled

LOGIC AND TRANSMITTER INPUTS AND RECEIVER OUTPUTS

Input Logic Threshold Low T

Input Logic Threshold High T

Input Leakage Current T

Output Leakage Current

(Except ICL3232)

Output Voltage Low I

Output Voltage High I

AUTOMATIC POWERDOWN (ICL3221, ICL3223, ICL3243 Only, FORCEON = GND, FORCEOFF = VCC)

Receiver Input Thresholds to

Enable Transmitters

Receiver Input Thresholds to

Disable Transmitters

INVALID

INVALID

Output Voltage Low I

Output Voltage High I

Open, FORCEON = GND, FORCEOFF =V

All R

IN

(ICL3221, ICL3223, ICL3243 Only)

= SHDN = GND (Except ICL3232) 25 - 1.0 10 µA

All Outputs Unloaded,

FORCEON = FORCEOFF

=V

SHDN

IN

IN

SHDN

IN

FORCEOFF

OUT

OUT

ICL32XX Powers Up (See Figure 6) Full -2.7 - 2.7 V

ICL32XX Powers Down (See Figure 6) Full -0.3 - 0.3 V

OUT

OUT

CC

, FORCEON, FORCEOFF, EN, SHDN Full - - 0.8 V

, FORCEON, FORCEOFF, EN,

, FORCEON, FORCEOFF, EN, SHDN Full - ±0.01 ±1.0 µA

=GND or EN=V

= 1.6mA Full - - 0.4 V

= -1.0mA Full V

= 1.6mA Full - - 0.4 V

= -1.0mA Full VCC-0.6 - - V

VCC = 3.15V,

ICL3221-32

=

VCC = 3.0V, ICL3241-43 25 - 0.3 1.0 mA

VCC = 3.3V Full 2.0 - - V

= 5.0V Full 2.4 - - V

V

CC

CC

CC

(°C) MIN TYP MAX UNITS

25 - 1.0 10 µA

25 - 0.3 1.0 mA

Full - ±0.05 ±10 µA

-0.6 V

CC

-0.1 - V

CC

8

FN4805.21

March 1, 2006

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

www.BDTIC.com/Intersil

Electrical Specifications Test Conditions: VCC = 3V to 5.5V, C1 - C4 = 0.1µF; Unless Otherwise Specified.

Typicals are at TA = 25°C (Continued)

TEMP

PARAMETER TEST CONDITIONS

Receiver Threshold to

Transmitters Enabled Delay (t

Receiver Positive or Negative

Threshold to INVALID

)

(t

INVH

Receiver Positive or Negative

Threshold to INVALID

(t

)

INVL

RECEIVER INPUTS

Input Voltage Range Full -25 - 25 V

Input Threshold Low V

Input Threshold High V

Input Hysteresis 25 - 0.3 - V

Input Resistance 25 3 5 7 kΩ

TRANSMITTER OUTPUTS

Output Voltage Swing All Transmitter Outputs Loaded with 3kΩ to Ground Full ±5.0 ±5.4 - V

Output Resistance V

Output Short-Circuit Current Full - ±35 ±60 mA

Output Leakage Current V

MOUSE DRIVEABILITY (ICL324X Only)

Transmitter Output Voltage

(See Figure 9)

TIMING CHARACTERISTICS

Maximum Data Rate R

Receiver Propagation Delay Receiver Input to Receiver

Receiver Output Enable Time Normal Operation (Except ICL3232) 25 - 200 - ns

Receiver Output Disable Time Normal Operation (Except ICL3232) 25 - 200 - ns

Transmitter Skew t

Receiver Skew t

Transition Region Slew Rate V

ESD PERFORMANCE

RS-232 Pins (T

All Other Pins Human Body Model ICL3221 - ICL3243 25 - ±2-kV

High Delay

Low Delay

, RIN) Human Body Model ICL3221 - ICL3243 25 - ±15 - kV

OUT

)

WU

= 3.3V 25 0.6 1.2 - V

CC

= 5.0V 25 0.8 1.5 - V

V

CC

= 3.3V 25 - 1.5 2.4 V

CC

= 5.0V 25 - 1.8 2.4 V

V

CC

= V+ = V- = 0V, Transmitter Output = ±2V Full 300 10M - Ω

CC

= ±12V, VCC= 0V or 3V to 5.5V

OUT

Automatic Powerdown or FORCEOFF

T1

=T2IN= GND, T3IN=VCC, T3

IN

GND, T1

=3kΩ, CL= 1000pF, One Transmitter Switching Full 250 500 - kbps

L

Output, C

PHL

PHL

CC

R

=3kΩ to 7kΩ,

L

Measured From 3V to -3V or -3V

to 3V

IEC61000-4-2 Contact Discharge ICL3221 - ICL3243 25 - ±8-kV

IEC61000-4-2 Air Gap Discharge ICL3221 - ICL3232 25 - ±8-kV

OUT

L

- t

PLH

- t

PLH

=3.3V,

and T2

= 150pF

Loaded with 2.5mA Each

OUT

= SHDN =GND

Loaded with 3kΩ to

OUT

t

PHL

t

PLH

= 200pF to 2500pF 25 4 8.0 30 V/µs

C

L

= 200pF to 1000pF 25 6 - 30 V/µs

C

L

ICL3241 - ICL3243 25 - ±6-kV

(°C) MIN TYP MAX UNITS

25 - 100 - µs

25 - 1 - µs

25 - 30 - µs

Full - - ±25 µA

Full ±5- -V

25 - 0.3 - µs

25 - 0.3 - µs

Full - 200 1000 ns

Full - 100 500 ns

9

FN4805.21

March 1, 2006

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

www.BDTIC.com/Intersil

Detailed Description

ICL32XX interface ICs operate from a single +3V to +5.5V

supply, guarantee a 250kbps minimum data rate, require

only four small external 0.1µF capacitors, feature low power

consumption, and meet all ElA RS-232C and V.28

specifications. The circuit is divided into three sections:

charge pump, transmitters and receivers.

Charge-Pump

Intersil’s new ICL32XX family utilizes regulated on-chip dual

charge pumps as voltage doublers, and voltage inverters to

generate ±5.5V transmitter supplies from a V

low as 3.0V. This allows these devices to maintain RS-232

compliant output levels over the ±10% tolerance range of

3.3V powered systems. The efficient on-chip power supplies

require only four small, external 0.1µF capacitors for the

voltage doubler and inverter functions at V

the Capacitor Selection section, and Table 3 for capacitor

recommendations for other operating conditions. The charge

pumps operate discontinuously (i.e., they turn off as soon as

the V+ and V- supplies are pumped up to the nominal

values), resulting in significant power savings.

Transmitters

The transmitters are proprietary, low dropout, inverting

drivers that translate TTL/CMOS inputs to EIA/TIA-232

output levels. Coupled with the on-chip ±5.5V supplies,

these transmitters deliver true RS-232 levels over a wide

range of single supply system voltages.

Except for the ICL3232, all transmitter outputs disable and

assume a high impedance state when the device enters the

powerdown mode (See Table 2). These outputs may be

driven to ±12V when disabled.

All devices guarantee a 250kbps data rate for full load

conditions (3kΩ and 1000pF), V

≥ 3.0V, with one

CC

transmitter operating at full speed. Under more typical

conditions of V

≥ 3.3V, RL=3kΩ, and CL= 250pF, one

CC

transmitter easily operates at 900kbps.

Transmitter inputs float if left unconnected, and may cause

I

increases. Connect unused inputs to GND for the best

CC

performance.

Receivers

All the ICL32XX devices contain standard inverting receivers

that three-state (except for the ICL3232) via the EN

FORCEOFF

products include noninverting (monitor) receivers (denoted

by the R

state of any control lines. All the receivers convert RS-232

signals to CMOS output levels and accept inputs up to ±25V

while presenting the required 3kΩ to 7kΩ input impedance

(See Figure 1) even if the power is off (V

receivers’ Schmitt trigger input stage uses hysteresis to

increase noise immunity and decrease errors due to slow

input signal transitions.

control lines. Additionally, the two ICL324X

label) that are always active, regardless of the

OUTB

CC

= 3.3V. See

CC

= 0V). The

CC

supply as

or

The ICL3221/22/23/41 inverting receivers disable only when

EN

is driven high. ICL3243 receivers disable during forced

(manual) powerdown, but not during automatic powerdown

(See Table 2).

ICL324X monitor receivers remain active even during

manual powerdown and forced receiver disable, making

them extremely useful for Ring Indicator monitoring.

Standard receivers driving powered down peripherals must

be disabled to prevent current flow through the peripheral’s

protection diodes (See Figures 2 and 3). This renders them

useless for wake up functions, but the corresponding

monitor receiver can be dedicated to this task as shown in

Figure 3.

V

CC

R

XIN

-25V ≤ V

FIGURE 1. INVERTING RECEIVER CONNECTIONS

RIN

≤ +25V

GND

5kΩ

R

GND ≤ V

XOUT

ROUT

≤ V

CC

Low Power Operation

These 3V devices require a nominal supply current of

0.3mA, even at V

= 5.5V, during normal operation (not in

CC

powerdown mode). This is considerably less than the 5mA

to 11mA current required by comparable 5V RS-232 devices,

allowing users to reduce system power simply by switching

to this new family.

Pin Compatible Replacements For 5V Devices

The ICL3221/22/32 are pin compatible with existing 5V

RS-232 transceivers - see the Features section on the front

page for details.

This pin compatibility coupled with the low Icc and wide

operating supply range, make the ICL32XX potential lower

power, higher performance drop-in replacements for existing

5V applications. As long as the ±5V RS-232 output swings

are acceptable, and transmitter input pull-up resistors aren’t

required, the ICL32XX should work in most 5V applications.

When replacing a device in an existing 5V application, it is

acceptable to terminate C

Operating Circuit. Nevertheless, terminate C

possible, as slightly better performance results from this

configuration.

to VCC as shown on the Typ ica l

3

to GND if

3

Powerdown Functionality (Except ICL3232)

The already low current requirement drops significantly

when the device enters powerdown mode. In powerdown,

supply current drops to 1µA, because the on-chip charge

pump turns off (V+ collapses to V

and the transmitter outputs three-state. Inverting receiver

outputs may or may not disable in powerdown; refer to

Table 2 for details. This micro-power mode makes these

devices ideal for battery powered and portable applications.

, V- collapses to GND),

CC

10

FN4805.21

March 1, 2006

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

www.BDTIC.com/Intersil

Software Controlled (Manual) Powerdown

Most devices in the ICL32XX family provide pins that allow

the user to force the IC into the low power, standby state.

On the ICL3222 and ICL3241, the powerdown control is via

a simple shutdown (SHDN

normal operation, while driving it low forces the IC into its

powerdown state. Connect SHDN

function isn’t needed. Note that all the receiver outputs

remain enabled during shutdown (See Table 2). For the

lowest power consumption during powerdown, the receivers

should also be disabled by driving the EN

next section, and Figures 2 and 3).

) pin. Driving this pin high enables

to VCC if the powerdown

input high (See

The ICL3221, ICL3223, and ICL3243 utilize a two pin

approach where the FORCEON and FORCEOFF

determine the IC’s mode. For always enabled operation,

FORCEON and FORCEOFF

are both strapped high. To

switch between active and powerdown modes, under logic

or software control, only the FORCEOFF

input need be

driven. The FORCEON state isn’t critical, as FORCEOFF

dominates over FORCEON. Nevertheless, if strictly manual

control over powerdown is desired, the user must strap

FORCEON high to disable the automatic powerdown

circuitry. ICL3243 inverting (standard) receiver outputs also

disable when the device is in manual powerdown, thereby

eliminating the possible current path through a shutdown

peripheral’s input protection diode (See Figures 2 and 3).

TABLE 2. POWERDOWN AND ENABLE LOGIC TRUTH TABLE

RS-232

SIGNAL

PRESENT

AT

RECEIVER

INPUT?

ICL3222, ICL3241

N.A. L N.A. L High-Z Active Active N.A. Manual Powerdown

N.A. L N.A. H High-Z High-Z Active N.A. Manual Powerdown w/ Rcvr. Disabled

N.A. H N.A. L Active Active Active N.A. Normal Operation

N.A. H N.A. H Active High-Z Active N.A. Normal Operation w/Rcvr. Disabled

ICL3221, ICL3223

No H H L Active Active N.A. L Normal Operation

No H H H Active High-Z N.A. L

Yes H L L Active Active N.A. H Normal Operation

Yes H L H Active High-Z N.A. H

No H L L High-Z Active N.A. L Powerdown Due to Auto Powerdown

No H L H High-Z High-Z N.A. L

Yes L X L High-Z Active N.A. H Manual Powerdown

Yes L X H High-Z High-Z N.A. H Manual Powerdown w/Rcvr. Disabled

No L X L High-Z Active N.A. L Manual Powerdown

No L X H High-Z High-Z N.A. L Manual Powerdown w/Rcvr. Disabled

ICL3243

No H H N.A. Active Active Active L Normal Operation

Yes H L N.A. Active Active Active H Normal Operation

No H L N.A. High-Z Active Active L Powerdown Due to Auto Powerdown

Yes L X N.A. High-Z High-Z Active H Manual Powerdown

No L X N.A. High-Z High-Z Active L Manual Powerdown

NOTE:

4. Applies only to the ICL3241 and ICL3243.

FORCEOFF

OR SHDN

INPUT

FORCEON

INPUTENINPUT

TRANSMITTER

OUTPUTS

RECEIVER

OUTPUTS

(NOTE 4)

R

OUTB

OUTPUTS

INVALID

OUTPUT MODE OF OPERATION

(Auto Powerdown Disabled)

(Auto Powerdown Enabled)

Logic

(Auto Powerdown Disabled)

(Auto Powerdown Enabled)

Logic

inputs

11

FN4805.21

March 1, 2006

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

www.BDTIC.com/Intersil

The INVALID output always indicates whether or not a valid

RS-232 signal is present at any of the receiver inputs (See

Table 2), giving the user an easy way to determine when the

interface block should power down. In the case of a

disconnected interface cable where all the receiver inputs

are floating (but pulled to GND by the internal receiver pull

down resistors), the INVALID

logic detects the invalid levels

and drives the output low. The power management logic

then uses this indicator to power down the interface block.

Reconnecting the cable restores valid levels at the receiver

inputs, INVALID

logic wakes up the interface block. INVALID

switches high, and the power management

can also be

used to indicate the DTR or RING INDICATOR signal, as

long as the other receiver inputs are floating, or driven to

GND (as in the case of a powered down driver). Connecting

FORCEOFF

and FORCEON together disables the

automatic powerdown feature, enabling them to function as

a manual SHUTDOWN

V

CC

POWERED

DOWN

UART

GND

input (See Figure 4).

V

CC

V

OUT = VCC

Rx

Tx

= GND

SHDN

V

CC

CURRENT

FLOW

OLD

RS-232 CHIP

FORCEOFF

LOGIC

CPU

PWR

MGT

FORCEON

INVALID

ICL3221/23/43

I/O

UART

FIGURE 4. CONNECTIONS FOR MANUAL POWERDOWN

WHEN NO VALID RECEIVER SIGNALS ARE

PRESENT

With any of the above control schemes, the time required to

exit powerdown, and resume transmission is only 100µs. A

mouse, or other application, may need more time to wake up

from shutdown. If automatic powerdown is being utilized, the

RS-232 device will reenter powerdown if valid receiver levels

aren’t reestablished within 30µs of the ICL32XX powering

up. Figure 5 illustrates a circuit that keeps the ICL32XX from

initiating automatic powerdown for 100ms after powering up.

This gives the slow-to-wake peripheral circuit time to

reestablish valid RS-232 output levels.

POWER

MANAGEMENT

UNIT

MASTER POWERDOWN LINE

0.1µF

1MΩ

FIGURE 2. POWER DRAIN THROUGH POWERED DOWN

PERIPHERAL

V

CC

TRANSITION

DETECTOR

WAKE-UP

V

CC

POWERED

DOWN

UART

TO

LOGIC

R

X

T

X

FORCEOFF = GND

OR SHDN

R2

OUTB

V

HI-Z

OUT =

R2

OUT

T1

IN

= GND, EN = V

CC

ICL324X

R2

T1

IN

OUT

FIGURE 3. DISABLED RECEIVERS PREVENT POWER DRAIN

FORCEOFF

ICL3221/23/43

FORCEON

FIGURE 5. CIRCUIT TO PREVENT AUTO POWERDOWN FOR

100ms AFTER FORCED POWERUP

Automatic Powerdown (ICL3221/23/43 Only)

Even greater power savings is available by using the

devices which feature an automatic powerdown function.

When no valid RS-232 voltages (See Figure 6) are sensed

on any receiver input for 30µs, the charge pump and

transmitters powerdown, thereby reducing supply current to

1µA. Invalid receiver levels occur whenever the driving

peripheral’s outputs are shut off (powered down) or when the

RS-232 interface cable is disconnected. The ICL32XX

powers back up whenever it detects a valid RS-232 voltage

level on any receiver input. This automatic powerdown

feature provides additional system power savings without

changes to the existing operating system.

12

FN4805.21

March 1, 2006

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

www.BDTIC.com/Intersil

2.7V

0.3V

-0.3V

-2.7V

FIGURE 6. DEFINITION OF VALID RS-232 RECEIVER LEVELS

VALID RS-232 LEVEL - ICL32XX IS ACTIVE

INDETERMINATE - POWERDOWN MAY OR

INVALID LEVEL - POWERDOWN OCCURS AFTER 30ms

INDETERMINATE - POWERDOWN MAY OR

VALID RS-232 LEVEL - ICL32XX IS ACTIVE

MAY NOT OCCUR

MAY NOT OCCUR

Automatic powerdown operates when the FORCEON input

is low, and the FORCEOFF

input is high. Tying FORCEON

high disables automatic powerdown, but manual powerdown

is always available via the overriding FORCEOFF

input.

Table 2 summarizes the automatic powerdown functionality.

Devices with the automatic powerdown feature include an

INVALID

output signal, which switches low to indicate that

invalid levels have persisted on all of the receiver inputs for

more than 30µs (See Figure 7). INVALID

switches high 1µs

after detecting a valid RS-232 level on a receiver input.

INVALID

operates in all modes (forced or automatic

powerdown, or forced on), so it is also useful for systems

employing manual powerdown circuitry. When automatic

powerdown is utilized, INVALID

= 0 indicates that the

ICL32XX is in powerdown mode.

RECEIVER

INPUTS

TRANSMITTER

OUTPUTS

INVALID

OUTPUT

V

V

CC

CC

0

V+

0

t

INVL

AUTOPWDN

t

INVH

INVALID

}

REGION

PWR UP

(standard) receiver outputs placing them in a high

impedance state. This is useful to eliminate supply current,

due to a receiver output forward biasing the protection diode,

when driving the input of a powered down (V

CC

= GND)

peripheral (See Figure 2). The enable input has no effect on

transmitter nor monitor (R

OUTB

) outputs.

Capacitor Selection

The charge pumps require 0.1µF capacitors for 3.3V

operation. For other supply voltages refer to Table 3 for

capacitor values. Do not use values smaller than those listed

in Table 3. Increasing the capacitor values (by a factor of 2)

reduces ripple on the transmitter outputs and slightly

reduces power consumption. C

increased without increasing C

increase C

without also increasing C2, C3, and C4 to

1

maintain the proper ratios (C

, C3, and C4 can be

2

’s value, however, do not

1

to the other capacitors).

1

When using minimum required capacitor values, make sure

that capacitor values do not degrade excessively with

temperature. If in doubt, use capacitors with a larger nominal

value. The capacitor’s equivalent series resistance (ESR)

usually rises at low temperatures and it influences the

amount of ripple on V+ and V-.

TABLE 3. REQUIRED CAPACITOR VALUES

V

CC

(V)

3.0 to 3.6 0.1 0.1

4.5 to 5.5 0.047 0.33

3.0 to 5.5 0.1 0.47

C

(µF)

1

C

2

, C3, C

(µF)

4

Power Supply Decoupling

In most circumstances a 0.1µF bypass capacitor is

adequate. In applications that are particularly sensitive to

power supply noise, decouple V

capacitor of the same value as the charge-pump capacitor C

to ground with a

CC

1

Connect the bypass capacitor as close as possible to the IC.

Operation Down to 2.7V

ICL32XX transmitter outputs meet RS-562 levels (±3.7V), at

full data rate, with V

typically ensure interoperability with RS-232 devices.

as low as 2.7V. RS-562 levels

CC

.

V-

FIGURE 7. AUTOMATIC POWERDOWN AND INVALID

TIMING DIAGRAMS

Transmitter Outputs when Exiting

Powerdown

Figure 8 shows the response of two transmitter outputs

when exiting powerdown mode. As they activate, the two

The time to recover from automatic powerdown mode is

typically 100µs.

transmitter outputs properly go to opposite RS-232 levels,

with no glitching, ringing, nor undesirable transients. Each

transmitter is loaded with 3kΩ in parallel with 2500pF. Note

Receiver ENABLE Control (ICL3221/22/23/41 Only)

Several devices also feature an EN input to control the

receiver outputs. Driving EN

high disables all the inverting

that the transmitters enable only when the magnitude of the

supplies exceed approximately 3V.

13

FN4805.21

March 1, 2006

5V/DIV

www.BDTIC.com/Intersil

FORCEOFF

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

for a single transmitter driving 1000pF and an RS-232 load

at 250kbps. The static transmitters were also loaded with an

T1

RS-232 receiver.

V

CC

0.1µF

+

2V/DIV

T2

VCC = +3.3V

C1 - C4 = 0.1µF

TIME (20µs/DIV)

FIGURE 8. TRANSMITTER OUTPUTS WHEN EXITING

POWERDOWN

Mouse Driveability

The ICL324X have been specifically designed to power a

serial mouse while operating from low voltage supplies.

Figure 9 shows the transmitter output voltages under

increasing load current. The on-chip switching regulator

ensures the transmitters will supply at least

±5V during worst

case conditions (15mA for paralleled V+ transmitters, 7.3mA

for single V- transmitter). The Automatic Powerdown feature

does not work with a mouse, so FORCEOFF

FORCEON should be connected to V

6

5

4

3

2

1

0

-1

-2

-3

-4

-5

TRANSMITTER OUTPUT VOLTAGE (V)

-6

0246810

FIGURE 9. TRANSMITTER OUTPUT VOLTAGE vs LOAD

V

= 3.0V

CC

T1

V

+

OUT

T2

V

T3

CC

13579

LOAD CURRENT PER TRANSMITTER (mA)

ICL3241/43

-

V

OUT

CURRENT (PER TRANSMITTER, i.e., DOUBLE

CURRENT AXIS FOR TOTAL V

CC

.

OUT+

and

V

+

OUT

V

-

OUT

CURRENT)

High Data Rates

The ICL32XX maintain the RS-232 ±5V minimum transmitter

output voltages even at high data rates. Figure 10 details a

transmitter loopback test circuit, and Figure 11 illustrates the

loopback test result at 120kbps. For this test, all transmitters

were simultaneously driving RS-232 loads in parallel with

1000pF, at 120kbps. Figure 12 shows the loopback results

V

+

C

1

+

C

2

V

CC

C1+

C1-

C2+

C2-

T

IN

R

OUT

EN

SHDN OR

FORCEOFF

CC

ICL32XX

T

OUT

V+

V-

R

IN

5K

FIGURE 10. TRANSMITTER LOOPBACK TEST CIRCUIT

5V/DIV

T1

IN

T1

OUT

R1

OUT

VCC = +3.3V

C1 - C4 = 0.1µF

5µs/DIV

FIGURE 11. LOOPBACK TEST AT 120kbps

5V/DIV.

T1

IN

T1

OUT

R1

OUT

VCC = +3.3V

C1 - C4 = 0.1µF

2µs/DIV.

FIGURE 12. LOOPBACK TEST AT 250kbps

+

C

3

C

4

+

1000pF

14

FN4805.21

March 1, 2006

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

www.BDTIC.com/Intersil

Interconnection with 3V and 5V Logic

The ICL32XX directly interface with 5V CMOS and TTL logic

families. Nevertheless, with the ICL32XX at 3.3V, and the

logic supply at 5V, AC, HC, and CD4000 outputs can drive

ICL32XX inputs, but ICL32XX outputs do not reach the

minimum V

for these logic families. See Table 4 for more

IH

information.

Typical Performance Curves VCC = 3.3V, TA = 25°C

6

V

+

4

2

1 TRANSMITTER AT 250kbps

1 OR 2 TRANSMITTERS AT 30kbps

0

-2

-4

TRANSMITTER OUTPUT VOLTAGE (V)

-6

1000 2000 3000 4000 50000

LOAD CAPACITANCE (pF)

OUT

V

OUT

-

TABLE 4. LOGIC FAMILY COMPATIBILITY WITH VARIOUS

SUPPLY VOLTAGES

SYSTEM

POWER-SUPPLY

VOLTAGE

(V)

V

CC

SUPPLY

VOLTAGE

(V) COMPATIBILITY

3.3 3.3 Compatible with all CMOS

families.

5 5 Compatible with all TTL and

CMOS logic families.

5 3.3 Compatible with ACT and HCT

CMOS, and with TTL. ICL32XX

outputs are incompatible with AC,

HC, and CD4000 CMOS inputs.

25

20

15

-SLEW

SLEW RATE (V/µs)

10

5

0 1000 2000 3000 4000 5000

+SLEW

LOAD CAPACITANCE (pF)

FIGURE 13. TRANSMITTER OUTPUT VOLTAGE vs LOAD

CAPACITANCE

45

ICL3221

40

35

30

25

20

15

SUPPLY CURRENT (mA)

10

5

0

0 1000 2000 3000 4000 5000

LOAD CAPACITANCE (pF)

250kbps

120kbps

20kbps

FIGURE 15. SUPPLY CURRENT vs LOAD CAPACITANCE

WHEN TRANSMITTING DATA

FIGURE 14. SLEW RATE vs LOAD CAPACITANCE

45

ICL3222 - ICL3232

40

35

30

25

20

15

SUPPLY CURRENT (mA)

10

5

0

0 1000 2000 3000 4000 5000

LOAD CAPACITANCE (pF)

250kbps

120kbps

20kbps

FIGURE 16. SUPPLY CURRENT vs LOAD CAPACITANCE

WHEN TRANSMITTING DATA

15

FN4805.21

March 1, 2006

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

www.BDTIC.com/Intersil

Typical Performance Curves VCC = 3.3V, TA = 25°C (Continued)

45

ICL324X

40

35

30

25

20

15

SUPPLY CURRENT (mA)

10

5

0

0

FIGURE 17. SUPPLY CURRENT vs LOAD CAPACITANCE

1000

WHEN TRANSMITTING DATA

2000

LOAD CAPACITANCE (pF)

3000

250kbps

120kbps

20kbps

4000

Die Characteristics

SUBSTRATE POTENTIAL (POWERED UP):

GND

TRANSISTOR COUNT:

ICL3221: 286

ICL3222: 338

ICL3223: 357

ICL3232: 296

ICL324X: 464

PROCESS:

Si Gate CMOS

5000

3.5

3.0

2.5

2.0

1.5

1.0

SUPPLY CURRENT (mA)

0.5

0

2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0

FIGURE 18. SUPPLY CURRENT vs SUPPLY VOLTAGE

ICL3221 - ICL3232

ICL324X

SUPPLY VOLTAGE (V)

NO LOAD

ALL OUTPUTS STATIC

ICL324X

16

FN4805.21

March 1, 2006

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

www.BDTIC.com/Intersil

Dual-In-Line Plastic Packages (PDIP)

N

D1

-C-

E1

-B-

A1

A2

E

A

L

e

C

C

L

e

A

C

e

B

INDEX

AREA

BASE

PLANE

SEATING

PLANE

D1

NOTES:

1. Controlling Dimensions: INCH. In case of conflict between English and

Metric dimensions, the inch dimensions control.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of

Publication No. 95.

4. Dimensions A, A1 and L are measured with the package seated in JEDEC seating plane gauge GS-3.

5. D, D1, and E1 dimensions do not include mold flash or protrusions.

Mold flash or protrusions shall not exceed 0.010 inch (0.25mm).

6. E and are measured with the leads constrained to be perpendicular to datum .

7. e

e

8. B1 maximum dimensions do not include dambar protrusions. Dambar

protrusions shall not exceed 0.010 inch (0.25mm).

9. N is the maximum number of terminal positions.

10. Corner leads (1, N, N/2 and N/2 + 1) for E8.3, E16.3, E18.3, E28.3,

E42.6 will have a B1 dimension of 0.030 - 0.045 inch (0.76 - 1.14mm).

12 3 N/2

-A-

B1

B

e

A

and eC are measured at the lead tips with the leads unconstrained.

B

must be zero or greater.

C

D

e

0.010 (0.25) C AM BS

-C-

E16.3 (JEDEC MS-001-BB ISSUE D)

16 LEAD DUAL-IN-LINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A - 0.210 - 5.33 4

A1 0.015 - 0.39 - 4

A2 0.115 0.195 2.93 4.95 -

B 0.014 0.022 0.356 0.558 B1 0.045 0.070 1.15 1.77 8, 10

C 0.008 0.014 0.204 0.355 -

D 0.735 0.775 18.66 19.68 5

D1 0.005 - 0.13 - 5

E 0.300 0.325 7.62 8.25 6

E1 0.240 0.280 6.10 7.11 5

e 0.100 BSC 2.54 BSC e

A

e

B

L 0.115 0.150 2.93 3.81 4

N16 169

0.300 BSC 7.62 BSC 6

- 0.430 - 10.92 7

NOTESMIN MAX MIN MAX

Rev. 0 12/93

17

FN4805.21

March 1, 2006

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

www.BDTIC.com/Intersil

Dual-In-Line Plastic Packages (PDIP)

N

D1

-C-

E1

-B-

A1

A2

E

A

L

e

C

C

L

e

A

C

e

B

INDEX

AREA

BASE

PLANE

SEATING

PLANE

D1

NOTES:

1. Controlling Dimensions: INCH. In case of conflict between English and

Metric dimensions, the inch dimensions control.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of

Publication No. 95.

4. Dimensions A, A1 and L are measured with the package seated in

JEDEC seating plane gauge GS-3.

5. D, D1, and E1 dimensions do not include mold flash or protrusions.

Mold flash or protrusions shall not exceed 0.010 inch (0.25mm).

6. E and are measured with the leads constrained to be perpendicular to datum .

7. e

e

8. B1 maximum dimensions do not include dambar protrusions. Dambar

protrusions shall not exceed 0.010 inch (0.25mm).

9. N is the maximum number of terminal positions.

10. Corner leads (1, N, N/2 and N/2 + 1) for E8.3, E16.3, E18.3, E28.3

may have a B1 dimension of 0.030 - 0.045 inch (0.76 - 1.14mm).

12 3 N/2

-A-

B1

B

e

A

and eC are measured at the lead tips with the leads unconstrained.

B

must be zero or greater.

C

D

e

0.010 (0.25) C AM BS

-C-

E18.3 (JEDEC MS-001-BC ISSUE D)

18 LEAD DUAL-IN-LINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A - 0.210 - 5.33 4

A1 0.015 - 0.39 -4

A2 0.115 0.195 2.93 4.95 -

B 0.014 0.022 0.356 0.558 B1 0.045 0.070 1.15 1.77 8, 10

C 0.008 0.014 0.204 0.355 D 0.845 0.880 21.47 22.35 5

D1 0.005 - 0.13 -5

E 0.300 0.325 7.62 8.25 6

E1 0.240 0.280 6.10 7.11 5

e 0.100 BSC 2.54 BSC -

e

A

e

B

L 0.115 0.150 2.93 3.81 4

N 18 18 9

0.300 BSC 7.62 BSC 6

- 0.430 - 10.92 7

NOTESMIN MAX MIN MAX

Rev. 2 11/03

18

FN4805.21

March 1, 2006

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

www.BDTIC.com/Intersil

Small Outline Plastic Packages (SOIC)

N

INDEX

AREA

123

-A-

E

-B-

SEATING PLANE

D

A

-C-

0.25(0.010) BM M

H

L

h x 45°

α

e

B

0.25(0.010) C AM BS

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of

Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm (0.006

inch) per side.

4. Dimension “E” does not include interlead flash or protrusions. Interlead

flash and protrusions shall not exceed 0.25mm (0.010 inch) per side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width “B”, as measured 0.36mm (0.014 inch) or greater above

the seating plane, shall not exceed a maximum value of 0.61mm

(0.024 inch).

10. Controlling dimension: MILLIMETER. Converted inch dimensions are

not necessarily exact.

M

A1

C

0.10(0.004)

M16.15 (JEDEC MS-012-AC ISSUE C)

16 LEAD NARROW BODY SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.0532 0.0688 1.35 1.75 -

A1 0.0040 0.0098 0.10 0.25 -

B 0.013 0.020 0.33 0.51 9

C 0.0075 0.0098 0.19 0.25 -

D 0.3859 0.3937 9.80 10.00 3

E 0.1497 0.1574 3.80 4.00 4

e 0.050 BSC 1.27 BSC -

H 0.2284 0.2440 5.80 6.20 -

h 0.0099 0.0196 0.25 0.50 5

L 0.016 0.050 0.40 1.27 6

N16 167

α

0° 8° 0° 8° -

NOTESMIN MAX MIN MAX

Rev. 1 6/05

19

FN4805.21

March 1, 2006

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

www.BDTIC.com/Intersil

Thin Shrink Small Outline Plastic Packages (TSSOP)

N

INDEX

AREA

123

0.05(0.002)

-AD

e

b

0.10(0.004) C AM BS

NOTES:

1. These package dimensions are within allowable dimensions of

JEDEC MO-153-AB, Issue E.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate

burrs. Mold flash, protrusion and gate burrs shall not exceed

0.15mm (0.006 inch) per side.

4. Dimension “E1” does not include interlead flash or protrusions.

Interlead flash and protrusions shall not exceed 0.15mm (0.006

inch) per side.

5. The chamfer on the body is optional. If it is not present, a visual

index feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. Dimension “b” does not include dambar protrusion. Allowable

dambar protrusion shall be 0.08mm (0.003 inch) total in excess

of “b” dimension at maximum material condition. Minimum space

between protrusion and adjacent lead is 0.07mm (0.0027 inch).

10. Controlling dimension: MILLIMETER. Converted inch dimensions are not necessarily exact. (Angles in degrees)

E1

-B-

SEATING PLANE

A

-C-

M

0.25(0.010) BM M

E

α

A1

0.10(0.004)

GAUGE

PLANE

0.25

0.010

A2

M16.173

16 LEAD THIN SHRINK SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A-0.043 - 1.10 -

A1 0.002 0.006 0.05 0.15 -

L

c

A2 0.033 0.037 0.85 0.95 -

b 0.0075 0.012 0.19 0.30 9

c 0.0035 0.008 0.09 0.20 -

D 0.193 0.201 4.90 5.10 3

E1 0.169 0.177 4.30 4.50 4

e 0.026 BSC 0.65 BSC -

E 0.246 0.256 6.25 6.50 -

L 0.020 0.028 0.50 0.70 6

N16 167

o

α

0

o

8

o

0

o

8

NOTESMIN MAX MIN MAX

-

Rev. 1 2/02

20

FN4805.21

March 1, 2006

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

www.BDTIC.com/Intersil

Small Outline Plastic Packages (SSOP)

N

INDEX

AREA

123

-A-

E

-B-

SEATING PLANE

D

A

-C-

0.25(0.010) BM M

H

GAUGE

PLANE

0.25

0.010

L

α

e

B

0.25(0.010) C AM BS

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of

Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.20mm (0.0078

inch) per side.

4. Dimension “E” does not include interlead flash or protrusions. Interlead

flash and protrusions shall not exceed 0.20mm (0.0078 inch) per side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. Dimension “B” does not include dambar protrusion. Allowable dambar

protrusion shall be 0.13mm (0.005 inch) total in excess of “B” dimension at maximum material condition.

10. Controlling dimension: MILLIMETER. Converted inch dimensions are

not necessarily exact.

M

A1

0.10(0.004)

A2

C

M16.209 (JEDEC MO-150-AC ISSUE B)

16 LEAD SHRINK SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A - 0.078 - 2.00 -

A1 0.002 - 0.05 - -

A2 0.065 0.072 1.65 1.85 -

B 0.009 0.014 0.22 0.38 9

C 0.004 0.009 0.09 0.25 -

D 0.233 0.255 5.90 6.50 3

E 0.197 0.220 5.00 5.60 4

e 0.026 BSC 0.65 BSC -

H 0.292 0.322 7.40 8.20 -

L 0.022 0.037 0.55 0.95 6

N16 167

α

0° 8° 0° 8° -

NOTESMIN MAX MIN MAX

Rev. 3 6/05

21

FN4805.21

March 1, 2006

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

www.BDTIC.com/Intersil

Small Outline Plastic Packages (SOIC)

N

INDEX

AREA

123

-A-

E

-B-

SEATING PLANE

D

A

-C-

0.25(0.010) BM M

H

L

h x 45°

α

e

B

0.25(0.010) C AM BS

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of

Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm (0.006

inch) per side.

4. Dimension “E” does not include interlead flash or protrusions. Interlead

flash and protrusions shall not exceed 0.25mm (0.010 inch) per side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width “B”, as measured 0.36mm (0.014 inch) or greater above

the seating plane, shall not exceed a maximum value of 0.61mm (0.024

inch)

10. Controlling dimension: MILLIMETER. Converted inch dimensions are

not necessarily exact.

M

A1

C

0.10(0.004)

M16.3 (JEDEC MS-013-AA ISSUE C)

16 LEAD WIDE BODY SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.0926 0.1043 2.35 2.65 -

A1 0.0040 0.0118 0.10 0.30 -

B 0.013 0.0200 0.33 0.51 9

C 0.0091 0.0125 0.23 0.32 -

D 0.3977 0.4133 10.10 10.50 3

E 0.2914 0.2992 7.40 7.60 4

e 0.050 BSC 1.27 BSC -

H 0.394 0.419 10.00 10.65 -

h 0.010 0.029 0.25 0.75 5

L 0.016 0.050 0.40 1.27 6

N16 167

α

0° 8° 0° 8° -

NOTESMIN MAX MIN MAX

Rev. 1 6/05

22

FN4805.21

March 1, 2006

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

www.BDTIC.com/Intersil

Small Outline Plastic Packages (SOIC)

N

INDEX

AREA

123

-A-

E

-B-

SEATING PLANE

D

A

-C-

0.25(0.010) BM M

H

L

h x 45°

α

e

B

0.25(0.010) C AM BS

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of

Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm (0.006

inch) per side.

4. Dimension “E” does not include interlead flash or protrusions. Interlead

flash and protrusions shall not exceed 0.25mm (0.010 inch) per side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width “B”, as measured 0.36mm (0.014 inch) or greater above

the seating plane, shall not exceed a maximum value of 0.61mm

(0.024 inch)

10. Controlling dimension: MILLIMETER. Converted inch dimensions are

not necessarily exact.

M

A1

C

0.10(0.004)

M18.3 (JEDEC MS-013-AB ISSUE C)

18 LEAD WIDE BODY SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.0926 0.1043 2.35 2.65 -

A1 0.0040 0.0118 0.10 0.30 -

B 0.013 0.0200 0.33 0.51 9

C 0.0091 0.0125 0.23 0.32 -

D 0.4469 0.4625 11.35 11.75 3

E 0.2914 0.2992 7.40 7.60 4

e 0.050 BSC 1.27 BSC -

H 0.394 0.419 10.00 10.65 -

h 0.010 0.029 0.25 0.75 5

L 0.016 0.050 0.40 1.27 6

N18 187

α

0° 8° 0° 8° -

NOTESMIN MAX MIN MAX

Rev. 1 6/05

23

FN4805.21

March 1, 2006

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

www.BDTIC.com/Intersil

Thin Shrink Small Outline Plastic Packages (TSSOP)

N

INDEX

AREA

123

0.05(0.002)

-AD

e

b

0.10(0.004) C AM BS

NOTES:

1. These package dimensions are within allowable dimensions of

JEDEC MO-153-AC, Issue E.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm

(0.006 inch) per side.

4. Dimension “E1” does not include interlead flash or protrusions. Interlead flash and protrusions shall not exceed 0.15mm (0.006 inch) per

side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. Dimension “b” does not include dambar protrusion. Allowable dambar

protrusion shall be 0.08mm (0.003 inch) total in excess of “b” dimension at maximum material condition. Minimum space between protrusion and adjacent lead is 0.07mm (0.0027 inch).

10. Controlling dimension: MILLIMETER. Converted inch dimensions

are not necessarily exact. (Angles in degrees)

E1

-B-

SEATING PLANE

A

-C-

M

0.25(0.010) BM M

E

α

A1

0.10(0.004)

GAUGE

PLANE

0.25

0.010

A2

L

c

M20.173

20 LEAD THIN SHRINK SMALL OUTLINE PLASTIC

PACKAGE

INCHES MILLIMETERS

SYMBOL

A - 0.047 - 1.20 A1 0.002 0.006 0.05 0.15 A2 0.031 0.051 0.80 1.05 -

b 0.0075 0.0118 0.19 0.30 9

c 0.0035 0.0079 0.09 0.20 -

D 0.252 0.260 6.40 6.60 3

E1 0.169 0.177 4.30 4.50 4

e 0.026 BSC 0.65 BSC -

E 0.246 0.256 6.25 6.50 -

L 0.0177 0.0295 0.45 0.75 6

N20 207

o

α

0

o

8

o

0

o

8

Rev. 1 6/98

NOTESMIN MAX MIN MAX

-

24

FN4805.21

March 1, 2006

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

www.BDTIC.com/Intersil

Shrink Small Outline Plastic Packages (SSOP)

N

INDEX

AREA

123

-A-

E

-B-

SEATING PLANE

D

A

-C-

0.25(0.010) B

H

α

e

B

0.25(0.010) C AMB

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section

2.2 of Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate

burrs. Mold flash, protrusion and gate burrs shall not exceed

0.20mm (0.0078 inch) per side.

4. Dimension “E” does not include interlead flash or protrusions. Interlead flash and protrusions shall not exceed 0.20mm (0.0078

inch) per side.

5. The chamfer on the body is optional. If it is not present, a visual

index feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. Dimension “B” does not include dambar protrusion. Allowable

dambar protrusion shall be 0.13mm (0.005 inch) total in excess

of “B” dimension at maximum material condition.

10. Controlling dimension: MILLIMETER. Converted inch dimensions are not necessarily exact.

M

A1

0.10(0.004)

S

GAUGE

PLANE

M

0.25

0.010

A2

M

L

M20.209 (JEDEC MO-150-AE ISSUE B)

20 LEAD SHRINK SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.068 0.078 1.73 1.99

A1 0.002 0.008’ 0.05 0.21

A2 0.066 0.070’ 1.68 1.78

B 0.010’ 0.015 0.25 0.38 9

C 0.004 0.008 0.09 0.20’

D 0.278 0.289 7.07 7.33 3

E 0.205 0.212 5.20’ 5.38 4

e 0.026 BSC 0.65 BSC

C

H 0.301 0.311 7.65 7.90’

L 0.025 0.037 0.63 0.95 6

N20 207

α

0 deg. 8 deg. 0 deg. 8 deg.

NOTESMIN MAX MIN MAX

Rev. 3 11/02

25

FN4805.21

March 1, 2006

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

www.BDTIC.com/Intersil

Thin Shrink Small Outline Plastic Packages (TSSOP)

N

INDEX

AREA

123

0.05(0.002)

-AD

e

b

0.10(0.004) C AM BS

NOTES:

1. These package dimensions are within allowable dimensions of

JEDEC MO-153-AE, Issue E.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm

(0.006 inch) per side.

4. Dimension “E1” does not include interlead flash or protrusions. Interlead flash and protrusions shall not exceed 0.15mm (0.006 inch) per

side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. Dimension “b” does not include dambar protrusion. Allowable dambar

protrusion shall be 0.08mm (0.003 inch) total in excess of “b” dimension at maximum material condition. Minimum space between protrusion and adjacent lead is 0.07mm (0.0027 inch).

10. Controlling dimension: MILLIMETER. Converted inch dimensions

are not necessarily exact. (Angles in degrees)

E1

-B-

SEATING PLANE

A

-C-

M

0.25(0.010) BM M

E

α

A1

0.10(0.004)

GAUGE

PLANE

0.25

0.010

A2

L

c

M28.173

28 LEAD THIN SHRINK SMALL OUTLINE PLASTIC

PACKAGE

INCHES MILLIMETERS

SYMBOL

A - 0.047 - 1.20 A1 0.002 0.006 0.05 0.15 A2 0.031 0.051 0.80 1.05 -

b 0.0075 0.0118 0.19 0.30 9

c 0.0035 0.0079 0.09 0.20 -

D 0.378 0.386 9.60 9.80 3

E1 0.169 0.177 4.30 4.50 4

e 0.026 BSC 0.65 BSC -

E 0.246 0.256 6.25 6.50 -

L 0.0177 0.0295 0.45 0.75 6

N28 287

o

α

0

o

8

o

0

o

8

Rev. 0 6/98

NOTESMIN MAX MIN MAX

-

26

FN4805.21

March 1, 2006

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

www.BDTIC.com/Intersil

Shrink Small Outline Plastic Packages (SSOP)

N

INDEX

AREA

123

-A-

E

-B-

SEATING PLANE

D

A

-C-

0.25(0.010) BM M

H

GAUGE

PLANE

0.25

0.010

L

α

e

B

0.25(0.010) C AM BS

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section 2.2

of Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate

burrs. Mold flash, protrusion and gate burrs shall not exceed

0.20mm (0.0078 inch) per side.

4. Dimension “E” does not include interlead flash or protrusions.

Interlead flash and protrusions shall not exceed 0.20mm (0.0078

inch) per side.

5. The chamfer on the body is optional. If it is not present, a visual

index feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. Dimension “B” does not include dambar protrusion. Allowable

dambar protrusion shall be 0.13mm (0.005 inch) total in excess of

“B” dimension at maximum material condition.

10. Controlling dimension: MILLIMETER. Converted inch dimensions

are not necessarily exact.

M

A1

0.10(0.004)

A2

C

M28.209 (JEDEC MO-150-AH ISSUE B)

28 LEAD SHRINK SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A - 0.078 - 2.00 -

A1 0.002 - 0.05 - -

A2 0.065 0.072 1.65 1.85 -

B 0.009 0.014 0.22 0.38 9

C 0.004 0.009 0.09 0.25 -

D 0.390 0.413 9.90 10.50 3

E 0.197 0.220 5.00 5.60 4

e 0.026 BSC 0.65 BSC -

H 0.292 0.322 7.40 8.20 -

L 0.022 0.037 0.55 0.95 6

N28 287

α

0° 8° 0° 8° -

NOTESMIN MAX MIN MAX

Rev. 2 6/05

27

FN4805.21

March 1, 2006

ICL3221, ICL3222, ICL3223, ICL3232, ICL3241, ICL3243

www.BDTIC.com/Intersil