Intersil Corporation HSP50415 Datasheet

TM

HSP50415

Data Sheet March 2000

Wideband Programmable Modulator

(WPM)

The HSP50415 Wideband Programmable Modulator (WPM)

is a quadrature amplitude modulator/upconverter designed

for wideband digital modulation. The WPM combines

shaping andinterpolationfilters, acomplex modulator, timing

and carrier NCOs and dual DACs into a single package.

The HSP50415 supports vector modulation, accepting up to

16-bit In phase (I) and Quadrature (Q) samples to generate

virtually any quadrature AM or PM modulation format. A

constellation mapper and 24 Symbol span interpolation

shaping filter is provided for the input baseband signals. Gain

adjustment is provided after the shaping FIR filter. A timing

error generator in the input section allows the on-chip timing

NCO to track the input timing.

The WPM includes a Numerically Controlled Oscillator

(NCO) driven interpolation filter, which allows the input and

output sample rate to have a non-integer or variable

relationship. This re-sampling feature simplifies use of

sample rates that donothave harmonic or integer frequency

relationships to the input data rate and decouples the carrier

from the DATACLK.

A complex quadrature modulator modulates the baseband

data on a programmable carrier center frequency. The

WPM offers digital output spurious Free Dynamic Range

(SFDR) that exceeds 70dB at the maximum output sample

rate of 100MSPS, for input sample rates as high as

25MSPS. X/SIN(X) rolloff compensation filtering is

provided. Real 14-bit digital output data is available prior to

the 12-bit DACs providing 20mA full scale output current.

File Number 4559.5

Features

• Output Sample Rates. . . . . . . . . . . . . . . . . . to 100MSPS

• Input Data Rates . . . . . . . . . . . . . . . .Up to 25MSPS (I/Q)

• 32-Bit Programmable Carrier NCO

• X/SIN(X) Rolloff Compensation

• Programmable I and Q Shaping FIR Filters:

- Up to 24 Symbol Span

• Fixed or NCO Controlled Interpolation:

- Interpolation Range . . . . . . . . . . . . . . . . . . 4 to > 128K

- Digital PLL to Lock to Input Symbol Clock

• Digital Signal Processing Capable of >70dB SFDR

• Dual 12-bit D/A Processing Capable of >50 dB SFDR

Applications

• Wide-Band Digital Modulation

• Base Station Modulators

• HSP50415EVAL1 Evaluation Board Available

Ordering Information

PART

NUMBER

HSP50415VI -40 to 85 100 Ld MQFP Q100.14x20

HSP50415EVAL1 Evaluation CCA, Development S/W, and User’s

Manual

TEMP

RANGE (oC) PACKAGE PKG. NO

Block Diagram

W/R

CONTROL

DAT A

DATACLK

2XSYMCLK

REFCLK

µP

INTERFACE

DAT A

INTERFACE/

FIFO

SYMBOL NCO/

4-1

CARRIER

NCO

COS SIN

I

CONST

MAP

Q

1-888-INTERSIL or 321-724-7143 | Intersil and Design is a trademark of Intersil Corporation. | Copyright © Intersil Corporation 2000

SHAPING/

INTERPOLATION

FILTERS

SHAPING/

INTERPOLATION

FILTERS

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

COMPLEX

MIXER

X

SIN(X)

X

SIN(X)

CLK MULTIPLIER

14

/

12-BIT

DAC

12-BIT

DAC

ANALOG PLLDIGITAL PLL

DIGITAL OUT

I OUT

Q OUT

CLK

Functional Block Diagram

CE

WR

4-2

RD

RESET

ADDR<2:0>

CDATA<7:0>

INTREQ

µP

INTERFACE

x2, 4, 8, 16

INTERPOLATION INTERPOLATION INTERPOLATION

I GAIN

x2 x2 TO > 8192

CARRIER

NCO

COS SIN

I GAIN

I OFFSET

14

/

IOUT<13:0>

DIN<15:0>

ISTRB

DATACLK

TXEN

FEMPT

FOVRFL

FFULL

2XSYMCLK X 2

REFCLK

REFLO

REFIO

FSADJ

SYSCLK/2

INTERFACE/

PHASE FREQ.

ERROR DETECT

VOLTAGE REF

DAT A

FIFO

CONST.

I

MAP

FIR

BYPASS BYPASS BYPASS

Q GAIN

HALFBAND

INTERPOLATION

FILTER

COMPLEX

MIXER

X

SIN(X)

BYPASS

Q GAIN

Q OFFSET

12-BIT

DAC

IOUTA

IOUTB

ICOMP1

ICOMP2

QCOMP2

QCOMP1

HSP50415

Q

BYPASS

LOOP FILTER

FIR

BYPASS BYPASS BYPASS

SYMBOL NCO

HALFBAND

INTERPOLATION

LOCK

DETECTOR

FILTER

÷

2

SYSCLK

CLK DIVIDER

1, 2, 4, 8

÷

APLL

SELECTOR

X

SIN(X)

BYPASS

FREQUENCY

DETECTOR

CLK MULTIPLIER

X 1, 2, 4, 8, 16, 32

(VCO DIVIDER)

PHASE

12-BIT

DAC

SYSCLK

CHARGE PUMP

VOLTAGE

CONTROLLED

OSCILLATOR

QOUTA

QOUTB

LOCKDET

PLLRC

CLK

BYPASS

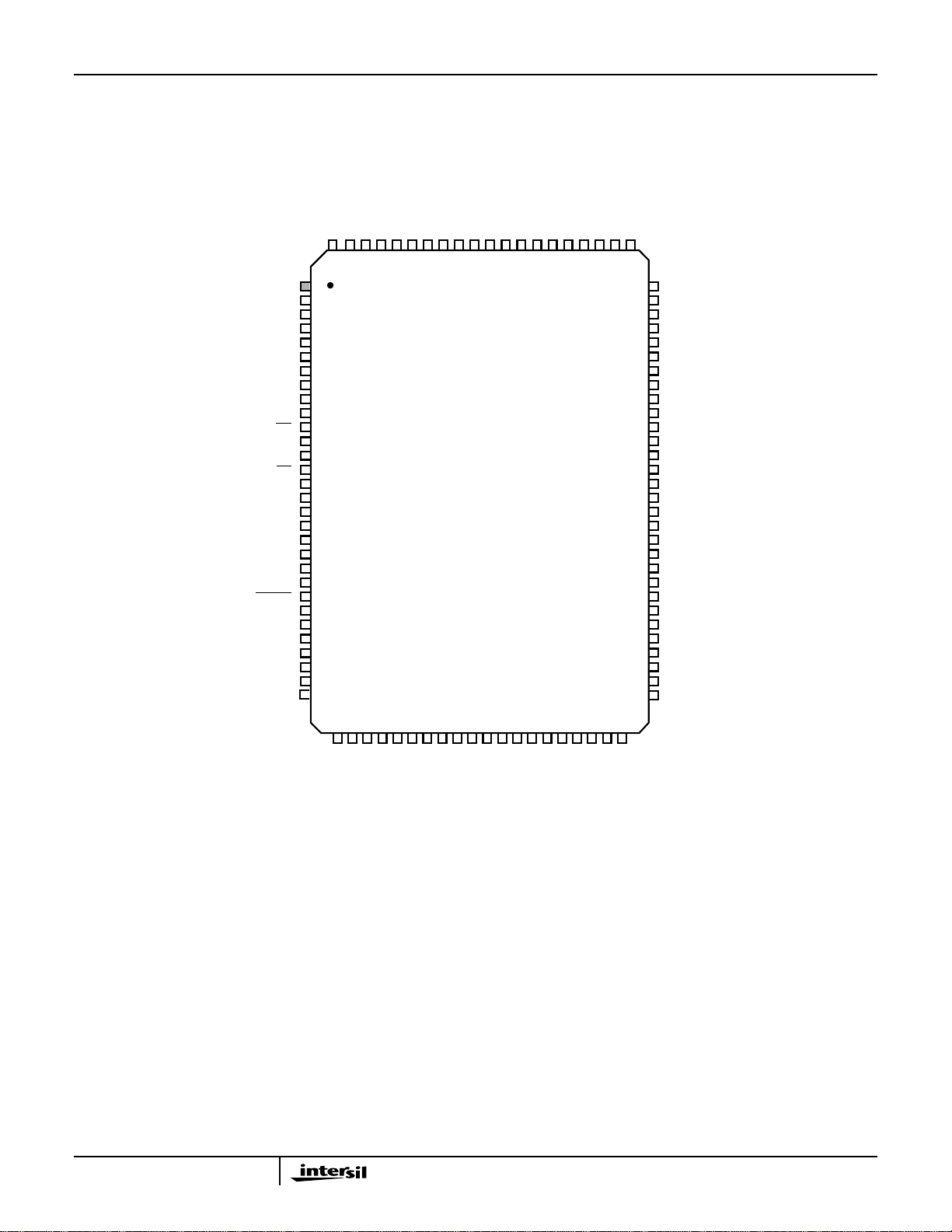

Pinout

HSP50415

100 LEAD MQFP

TOP VIEW

CDATA0

CDATA1

CDATA2

VDD

CDATA3

CDATA4

GND

CDATA5

CDATA6

CDATA7

RD

WR

GND

CE

ADDR0

ADDR1

ADDR2

REFCLK

2XSYMCLK

INTREQ

NC

VDD

RESET

CLK

GND

DVDD

DGND

PLLRC

PGND

PVDD

DIN5

VDD

DIN4

GND

DIN3

DIN2

DIN1

DIN0

DATACLK

99 98 97 96 95 94 93 91 89 87 85 84 83 818286889092100

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

HSP50415

DIN6

DIN7

DIN8

DIN9

DIN11

DIN10

GND

DIN12

VDD

DIN13

DIN14

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

DIN15

ISTRB

TXEN

LOCKDET

FOVRFL

FEMPTY

FFULL

GND

SYSCLK/2

IOUT13

VDD

IOUT12

IOUT11

IOUT10

IOUT9

IOUT8

GND

IOUT7

IOUT6

VDD

IOUT5

IOUT4

IOUT3

IOUT2

IOUT1

IOUT0

GND

VDD

RESV

RESV

4-3

32 33 34 35 36 37 38 40 42 44 46 47 48 50494543413931

DVDD

DGND

QOUTB

AVDD

AGND

QOUTA

QCOMP1

AGND

REFLO

QCOMP2

REFIO

FSADJ

AVDD

ICOMP2

ICOMP1

IOUTA

AGND

IOUTB

RESV

RESV

HSP50415

Pin Descriptions

NAME TYPE DESCRIPTION

VDD - Digital power.

GND - Digital ground.

DVDD - DAC digital power.

DGND - DAC digital ground.

AVDD - DAC analog power.

AGND - DAC analog ground.

PVDD - PLL analog power.

PGND - PLL analog ground.

PLLRC I PLL loop filter provides for the addition of less expensive RC components in place of a crystal oscillator. The

recommended values for this pin are detailed in the ‘System CLK Generation’ section.

CLK I System and DAC clock input when APLL not in use, otherwise it is the reference to the APLL.

SYSCLK/2 O Sample Clock Divided by Two. All digital output data and status pins are output from this clock. The polarity of

SYSCLK/2 may be programmed via Register 2 bit-3.

2XSYMCLK O Tristatable Symbol NCO Clock Output Multiplied by Two. The polarity of 2XSYMCLK may be programmed via

register 2 bit-15.

REFCLK I External digital PLL reference clock input.

DIN<15:0> I Data Bus. The DIN<15:0> bus loads the input data.

DATACLK I Asynchronous data clock for DIN<15:0>.

TXEN I DIN<15:0> may be optionally gated with the TXEN pin (burst mode) or input free-running as defined by register 2

bits 18-17. The polarity of TXEN may be programmed via register 2 bit-5.

ISTRB I Data samples are input as I then Q serially with the ISTRB pin active with the I sample.The polarity of ISTRBmay

be programmed via Register 2 bit-4.

CDATA<7:0> I/O µP Bidirectional DataBus. The CDATA<7:0>databus is used for loading the configuration dataand samplevectors

for modulation. CDATA7 is the MSB.

RD I µP Read control input.

WR I µP Write strobe input.

CE I Chip enable input.

ADDR<2:0> I µP AddressBus. The ADDR<2:0>bus isused for addressingthe properregisters for loadingthe configurationdata

and sample vectors for modulation. ADDR2 is the MSB.

INTREQ O TristatableActive High Interrupt RequestOutput. The INTREQ output is enabled via register 2bit-8. Register 9 bits

6-0 enable individual events for INTREQ.

RESET While the RESET input is asserted (driven low), all processing halts andthe WPM is reset. A software reset is also

available via register 10H.

IOUT<13:0> O Tristatable In-Phase Output Samples. IOUT<13:0> outputs are enabled via register 2 bit-7.

QOUT<13:0> O Tristatable Quadrature Output Samples. QOUT<13:0> outputs are enabled via register 2 bit-6. The QOUT<13:0>

outputs are not available on the MQFP package.

FEMPT,

FOVRFL,

FFULL

LOCKDET O Tristatable Status Flag of the Digital PLL. This may be used to generate an interrupt request via INTREQ.

IOUTA,

QOUTA

IOUTB,

QOUTB

O TristatableStatus Flags forFIFO Level Monitoring. These outputs are enabled viaregister 2 bits 13-11. FIFOstatus

thresholds and control are configured via register 2 bits 23-16.

The LOCKDET output is enabled via register 2 bit-10.

O Current Outputs of the Device. Full scale output current is achieved when all input bits are set to binary 1.

O ComplementaryCurrentOutputs ofthe Device. Full scaleoutput currentis achieved on thecomplementary outputs

when all input bits are set to binary 0.

4-4

HSP50415

Pin Descriptions (Continued)

NAME TYPE DESCRIPTION

ICOMP1,

QCOMP1

ICOMP2,

QCOMP2

REFLO I Reference Low Select. When the internal reference is enabled, this pin serves as the precision ground reference

REFIO I Reference voltage input if internal reference is disabled. Reference voltage output if internal reference is enabled. Use

FSADJ I Full Scale Current Adjust. Use a resistor to ground to adjust full scale output current. Full Scale Output Current =

RESV - Reserved. These pins must be floating (not connected) for proper operation.

NC - No Connection. Pins may be connected to GND, AGND, DGND or left floating.

I Compensation Pin for use in Reducing Bandwidth/Noise. Each pin should be individually decoupled to AVDDwith

a 0.1µF capacitor. To minimize crosstalk, the partwas designed so that these pins must be connected externally,

ideally directly under the device packaging. The voltage on these pins is used to drive the gates of the PMOS

devices that make up the current cells. Only the ICOMP1 pin is driven and therefore QCOMP1 needs to be

connected to ICOMP1, but de-coupled separately to minimize crosstalk.

I Compensation Pin for Internal Bias Generation. Each pin should be individually decoupled to AGND with a 0.1µF

capacitor. The voltage generated at these pins represents the voltage used to supply 2.0V nominal power to the

switch drivers. This arrangement helps to minimize clock feedthrough to the current cell transistors for reduced

glitch energy and improved spectral performance.

point for the internal voltage reference circuitry and therefore needs to have a good connection to analog ground

to enableinternal 1.2V reference.To disablethe internal reference circuitrythis pin should be connected toAVDD.

0.1µF cap to ground when internal reference is enabled.

32 x V

FSADJ/RSET

is typically 1.2V if the internal reference is used.

. Where V

is the voltage at this pin. V

FSADJ

tracks the voltage on the REFIO pin; which

FSADJ

Functional Description

The HSP50415 is a wideband programmablemodulator that

accepts an input quadrature data stream at programmable

symbol rates of up to 25MSPS (QPSK) and outputs a

modulated quadrature data stream at the final sample rate

up to 100MHz. The allowable symbol rates depend on the

modulation type selected (QPSK, 16QAM, etc.). The input

data format is parallel with respectto thebits, but serial with

respect to the I and Q samples and may be input at a

constant symbol rate or burst in at a different rate. The

HSP50415 can symbol map the input data streamper a user

programmable look up table thus allowing any standard to

be supported. The mapped symbols are then interpolated to

the finalsample rate and low-passfiltered in order to limitthe

spectral occupancy of the signal. The first stage filter

coefficients are user programmable, with subsequent filter

stages having fixed coefficients. The HSP50415 then

modulates the symbol data at the final sample rate onto a

carrier signal that is tunable from 0.023Hz - 50MHz (for a

final sample rate of 100MHz) producing a quadrature signal.

The signal may then be optionally X/SIN(X) filtered to

compensate for the SIN(X)/X roll-off of the DACs. To correct

forsystem (or DACinduced) gain imbalances between the In

phase and Quadraturesignals there is a final gain correction

stage prior to the output. The final Intermediate Frequency

(IF) digital output can be converted to differential analog

signals via the onboard 12-bit DACs or may be optionally

brought out as 14-bit digital data. The 100-pin MQFP

package provides a real digital output at 1/2 the final sample

rate.

System CLK Generation

The HSP50415 receives I and Q input data serially at twice

the input symbol rate. The data is converted to a parallel

quadrature data stream at the symbol rate by the Front End

Data Input Block. This data stream is upsampled to the final

output sample rate of the device(FSout). This output sample

rate (maximum rate of 100MHz) is used to clock the last

stage of the digital logic and the dual 12-bit DACs and may

be provided externally on the CLK pin or may be generated

by an internal analog PLL (APLL). When enabled, the APLL

uses the CLK pin as a reference and provides a selectable

CLK multiplier of x2, x4, x8, x16 or x32 or CLK divider of /2,

/4 or /8.

An external loop filter is required to be supplied at PLLRC.

The recommend configuration is shown in Figure 1, with

suggested component values calculated as:

User Input Terms:

APLLclkdivider=APLL CLK divider programmed input

APLLvcodivider=APLL VCO divider programmed input

Fclk=CLK frequency input

Fscale=loop bandwidth divisor input

Pm=loop phase margin input (degrees)

Component calculation formulas:

C1=(Fvcogain*Icp)/(wo*wo*sqrt(kk))

C2=kk*C1

R1=1/sqrt(Fvcogain*Icp*C1*sqrt(C2/C1))

Where:

Fvcogain=231000000/APLLvcodivider

Icp=0.000353

4-5

HSP50415

kk=(1+(sin(Pm*pi/180)))/(1-(sin(Pm*pi/180)))

wo=2*pi*((Fclk/APLLclkdivider)/Fscale)

A MATLAB or Excel program for calculating the component

values is available. For improved APLL performance,

utilization of specific calculated values is recommended over

the general purpose ones shown in Figure 1.

Symbol NCO

As the data flows through the device, the sample rate

increases up to the final sample rate, with the SYMBOL

NCO generating all of the necessary intermediate sample

rate clocks. Each stage’s input and output sample rate is

dependent on the interpolation rate through the stage.

Figure 1shows the various symbolclocks that are generated

on the chip. The symbol rateclock (symclk) used internally is

multiplied by 2 and output on pin 2XSYMCLK for use in

SYSCLK/2

÷2

driving the input DATACLK if a symbol rate synchronous

(non-burst) mode is required.

The SYMBOL NCO is a 32-bit accumulator. The 32-bit

frequency step (Phinc) is the sum of the user programmable

32-bit symbol Phinc and any error term generated by the

Digital Phase Lock Loop (DPLL) while locking to an external

symbol rate. The DPLL error term may be disabled by a

control bit. The symbol rates supportedare from 0.023Hz up

to 25MHz (for FSout of 100MHz) with 32-bit frequency

resolution. The formula for programming the symbol Phinc

register is given as:

symbolPhinc = (symbolRate / FSout) * 2^32

The SYMBOL NCO also has a counter mode in which the

symbol clocks are generated upon the counter reaching the

16-bit user programmable rollover count value. This mode is

useful forcases where the frequency is aninteger number of

the system clock (SYSCLK/2).

BYPASS

sysclk

APLL

SELECTOR

CLK

DIN<15:0>

INTERFACE

DATACLK

2XSYMCLK

Internal IC signal names are shown in lowercase.

DAT A

FIFO

X 2

I

CONST.

MAP

Q

INT.

FIR

I GAIN

symclk

(symbol rate) (symbol rate X 1,2,4,8,16,32)

FIGURE 1. SAMPLE RATE CLK GENERATION

HALFBAND

SYMBOL NCO

COMPLEX

DC TO 20MHz: C1=690PF, C2=11NF, R1=120Ω

20 TO 100MHz: C1=130PF, C2=2NF, R1=620Ω

MIXERFILTER

X

SIN(X)

I GAIN I OFFSET

PLLRC

C1

12-BIT

DAC

R1

C2

IOUTA

IOUTB

4-6

HSP50415

TABLE 1. HSP50415 FILTER CONFIGURATIONS AND RESULTING SYMBOL NCO RATES

BYPASS HALFBAND

BYPASS FIR FILTER FIR INTERPOLATION

0 x2 (Note) 0 Symbol Rate x 4 PhincLL x 4

0 x4 0 Symbol Rate x 8 PhincLL x 8

0 x8 0 Symbol Rate x 16 PhincLL x 16

0 x16 0 Symbol Rate x 32 PhincLL x 32

0 x2 (Note) 1 Symbol Rate x 4 PhincLL x 4

0 x4 1 Symbol Rate x 4 PhincLL x 4

0 x8 1 Symbol Rate x 8 PhincLL x 8

0 x16 1 Symbol Rate x 16 PhincLL x 16

1 Not applicable 0 Symbol Rate x 2 PhincLL x 2

1 Not applicable 1 Symbol Rate x 1 PhincLL x 1

NOTE: An optional decimate by two mode allows the device to achieve interpolation by a factor of two in the Shaping FIR.

FILTER

INTERPOLATINGFILTER

DATA INPUT RATE SYMBOL NCO PHINC

The SYMBOL NCO 32-bit Phinc value is adjusted

automatically such that the SYMBOL NCO runs at the input

rate of the interpolating filter, since this is the fastest rate

prior to the FSout rate. Table 1 lists possible filter

configurations of the HSP50415 and the resulting

interpolating filter rate. This resulting rate is affected by rate

adjustments (interpolation) in the previous filter blocks.

Digital Phase Lock Loop

The HSP50415 contains a Digital Phase Lock Loop (DPLL)

that performs symbol tracking to an external symbol clock

(REFCLK). The DPLL consists of a programmable

phase/frequency error detector followed by a loop filter and

lock detector stage. The phase/frequency error detector

block diagram is shown in Figure 2.

The DPLL uses two (integer) counters to give added

frequency programming flexibility. The programmed symbol

rates are functions of the both the REFCLK divider and the

NCO divider (N = NCO divider + 1, see Figure 2), each of

which can be changed separately. As an example, these two

counters can be set to generate a non-integer output (NCO

Symbol rate) frequency (16/3) of the input reference

frequency (REFCLK). In this case NCO divider = 16, and

REFCLK divider =3. If REFCLK is the desired symbol rate,

then the REFCLK divider will be the same value as the NCO

divider.If REFCLK isfor example2x the desired symbolrate,

then therefClk divider will be 2x the NCO divider.REFCLK is

divided down by the REFCLK divider. The internal symbol

clk is divided down by the NCO divider. When the carry-out

of the REFCLK divider is generated, the symbol NCO is

sampled. The phase and frequency (dphi/dt) should be zero

if the two rates are phase and frequency locked. If not, the

sampled phase value is the phaseError. This value is

subtracted from the previous phaseError to generate the

frequency error. Both of these error terms are input to the

loop filter which scales and integrates these error terms and

produces a final symbol nco error term. This final error term

gets addedto the SYMBOL NCO toadjust the symbol rateto

try to track to the divided down external REFCLK input. The

loop filter error term must be enabled in the software for this

error term to be added to the symbol NCO. Otherwise the

Digital PLL has no effect on the symbol rate.

The minimum value the REFCLK divider and NCO divider

values may be programmed to is the larger of 32/clkDivisor

or 0x04, where clkDivisor is FSout/REFCLKrate. This is due

to the minimum number of system clock (SYSCLK/2) cycles

the loop filter requires to process the new error terms. The

maximum rate of this clock is FSout/4 or 25MHz for FSout of

100MHz. The phaseError and freqError terms are input to

the loop filter block which is a standard lead/lag type second

order loop filter as shown in Figure 3. The loop filter requires

32 clock cycles to process a new error term.

The phaseError is weightedby the lag gain and added to the

freqError weighted by the frequency gain and this sum is

accumulated to give the integral response. The lag

accumulator is compared to upper and lower limits and

forced to the limit value if either limit isexceeded. This keeps

the SYMBOL NCO frequency within the expected symbol

rate uncertainty and limits the pull in range. This

accumulator output is then added to the phaseError

weighted by the lead gain to get a proportional response.

This lead term should be zeroed during initial tracking. The

gain values are user programmable with a mantissa and

exponent of the following format

Gain = 01.MMMM * 2^(EEEEE-17)

where MMMM denotes the 4-bit gain value and EEEEE is

the 5-bit shift value.

The phaseError and freqError signals may be monitored on

the digital outputs for test or the lock detect pin may be used

to monitor the symbol tracking phase error. The lock detect

pin indicates whether the DPLL has phase locked to the

external symbol clock. The lock detect status may also be

used to generate an interrupt event. The lock detect block

diagram is shown in Figure 4.

4-7

NCO divider<13:0>

HSP50415

REFCLK divider<7:0>

REFCLK

CLK

frequencyGain

freqError<15:0>

lagGain

phaseError<21:0>

leadGain

8-BIT

COUNTER

TC

SYNC

14-BIT

COUNTER

8 upper bits of phaseAccum14-bit countValue

enable

carryOut

R R

SYMBOL NCO

FIGURE 2. PHASE/FREQUENCY ERROR DETECTOR

UL<31:0>

LL<13:0>

41

LIMITER R R

/

FIGURE 3. DPLL LOOP FILTER

FIFOFreqError<8*7,7:0>

freqError<15:0>

_

phaseError<21:0>

DPLL

PhincError<31:0>

positive lockedValue

negative notLockedValue

threshold<20:0>

phaseErrorMag<20:0>

analogPLLlockStatus

useAPLLlockStatus

_

carryOut

AO

A1

S

FIGURE 4. LOCK DETECTION BLOCK DIAGRAM

The Lock Detector compares the magnitude of the

phaseError to a programmable 21-bit threshold value. If the

carry out from this comparison is “1” then the phaseError is

greater than or equal to the threshold value and a negative

value is added to the lock integrator. If the carry out is “0”

then the phaseError is less than the threshold and a positive

value is added. As the phaseError magnitude stays below

the threshold level the lock integrator will grow from a

negative number to a positive one thus indicating a locked

condition. The lock integrator resets to a full-scale negative

value. The sign bit of the lock integrator is output as the

LOCKDET status flag. The values added or subtracted to

the lock integrator are user selectable as follows in Table 2.

lockIntegrator<8> LOCKDET

AO

Z

Z

A1

S

bit=1 indicates phaseErr > thld so NOT

locked

R

lockIntegrator<8:0>

TABLE 2. LOCK INTEGRATOR ADDENDS

LOCK

FACTOR CARRY OUT ADDEND

BINARY

VALUE

0xx 1 -0.5 111111000

1xx 1 -0.25 111111100

x00 0 +0.0625 000000001

x01 0 +0.1250 000000010

x10 0 +0.2500 000000100

x11 0 +0.5000 000001000

4-8

HSP50415

Front-End Data Input Block

The HSP50415 accepts input data in a parallel bit fashion

with I and Q samples input serially asshown in Figure 5. The

signal pins on the device that input data to the front-end are

the DIN<15:0> bus, the ISTRB and TXEN control pins and

the DATACLK pin.

Iin<15:0>, Qin<15:0>

serial Data Stream

at symbol Rate x2

FIGURE 5. SERIAL TO PARALLEL DATA CONVERSION

FRONT END

DATA INPUT

BLOCK

All data is synchronous to the DATACLK. Further references

to bit-widths will be with respect to a single channel (I and Q

channels are identical). The input data may be from 1-bit up

to 16-bits wide with bits positioned on the LSB’s of the bus.

The data samples are input as I then Q serially with the

ISTRB pin active with the I sample. The maximum data rate

is 50MHz at FSout of 100MHz or twice the maximum symbol

rate. The data written into the chip may be gated with the

TXEN pin (burst Mode) or input free-running. The ISTRB

and TXEN pins have user-programmable active states thus

allowing spectral inversion to be implemented by simply

changing the ISTRB polarity. Figure 6 shows the input data

timing (assuming the ISTRB pin is an active high).

DATACLK

DIN<15:0>

ISTRB

FIGURE 6. I/Q INPUT DATA TIMING

I Q I Q

Once a valid pair of I and Q samples has been received, the

data pairis written into the 256x32-bit FIFO. The datais read

out of the FIFO at the symbol rate using the internally

generated symbol clock which is synchronous to the clock

pin. This internally generated symbol clock is available on

the 2XSYMCLK pin of the chip. It has been multiplied up to

twice the symbol rate to facilitate tying it to the DATACLK pin

in symbol rate synchronous modes.The data is always input

to the chip at twice the rate at which it is written to the FIFO

since Iand Q are inputserially. In asymbol rate synchronous

mode, the data is input to the front-end at twice the symbol

rate,writtento the FIFO atthe symbol rate and readfrom the

FIFO also at the symbol rate. This mode ensures that no

FIFO overflow or underflow conditions will occur. Optionally,

in a totally synchronous mode, the FIFO may be bypassed

altogether if power conservation is critical.

Reading data out of the FIFO for transmission may be

optionally gated by the TXEN pin if the user wishes to burst

the data into the chip and delay transmission of the data. If

Iout<15:0>

Qout<15:0>

at symbol rate

the data reads are not gated, then after 2 FIFO locations

have been written, data reads are initiated. Via userprogrammable bits, the data may be zeroed leaving the

front-end if the FIFO runs out of data or in gated-read mode,

if the TXEN pin is inactive. Conversely, writing data into the

FIFO may be optionally disabled upon a FIFO full condition.

Control of the starting address for the gated reads is userprogrammable where the address may be zeroed upon start

of transmission or simply incremented from where it left off

on the last transmission.

The FIFO logic contains user programmable threshold

detection (high and low thresholds) as well as full/empty

detection. There are 4 status flags available to the user for

FIFO level monitoring: FIFOOverFlow (FOVRFL), FIFOFull

(FFULL), FIFOUnderFlow,and FIFO empty (FEMPT).These

status flags may be monitored via 3 output pins: the

underflow and empty share one pin with a user selectable

function. Any one of these flags may be used to trigger an

interrupt on the INTREQ pin if the mask register for that

status bit is set. A rising edge of the status signal will set the

interrupt status register bit and cause an external interrupt if

enabled. The only way to clear the status bit and INTREQ

pin is to write a “1” to the corresponding status register bit.

Another feature of the FIFO is the adaptive symbol rate

control logic. The internal symbol rate of the device is

controlled by the digital PLL if enabled. Since the data is

read out of the FIFO at the internal symbol rate, there may

arise a needfor the FIFO toadjust the symbol rate ifthe data

is not being written in and read out at the same rate. This is

achieved by either adding or subtracting a frequency error

term to the digital PLL’s loop filter frequency term or by

forcing the loop filter lag term to its programmed limit. If a

FIFO overflow occurs, then the data is being written into the

FIFO faster than it is being read out, which indicates the

symbol rate needs to be increased thus speeding up the

reads. This scenario wouldcause the FIFO to try to increase

the final symbol rate error term by either adding the FIFO

frequency error term (user programmable) to the loop filter’s

frequency error term or force the loop filter lag accumulator

to its programmed upper limit. If a FIFO underflow occurs,

then the data is being read out of the FIFO faster than it is

being written in and the FIFO would attempt to slow down

the symbol rateby subtracting the frequency error termor by

forcing the lag accumulator to its lower limit. This adaptive

rate control is user programmable via Register 2 bits 21:20.

Constellation Mapper

The I/Q data pair from the Front End Input Block enters the

constellation mapper at the internal symbol rate and is

mapped via a user programmable look up table to new

symbol data. The symbol mapping is only supported for I/Q

bit widths of 4-bits (256-QAM) or less. The I data is

concatenated with the Q data to form the 8-bit address

(Iin<3:0>:Qin<3:0>) to the 256x8-bit RAM. The 8-bit data

output from the RAM is the new symbol data in the form

4-9

Loading...

Loading...