HSP50215EVAL

User’s Manual January 1999 File Number

DSP Modulator Evaluation Board

Evaluation Kit

The HSP50215EVAL Kit provides the necessary tools to

evaluate the HSP50215 Digital Upconverter integrated

circuit and consists of a circuit board and a software

program. The kit is designed for evaluation of Digital

Quadrature Amplitude, FM, and Shaped FM modulation for

IF Communications Applications. The circuit board uses

baseband I and Q data patterns loaded through the 8-bit

parallel interface or the ISAbus interface. Data is output as

either a digital or analog modulated composite IF signal. Up

to four channels can be included in the composite IF output.

To facilitate the use of the board during evaluation, the kit

includes example files for configuration, shaping filters and

input stimulus.

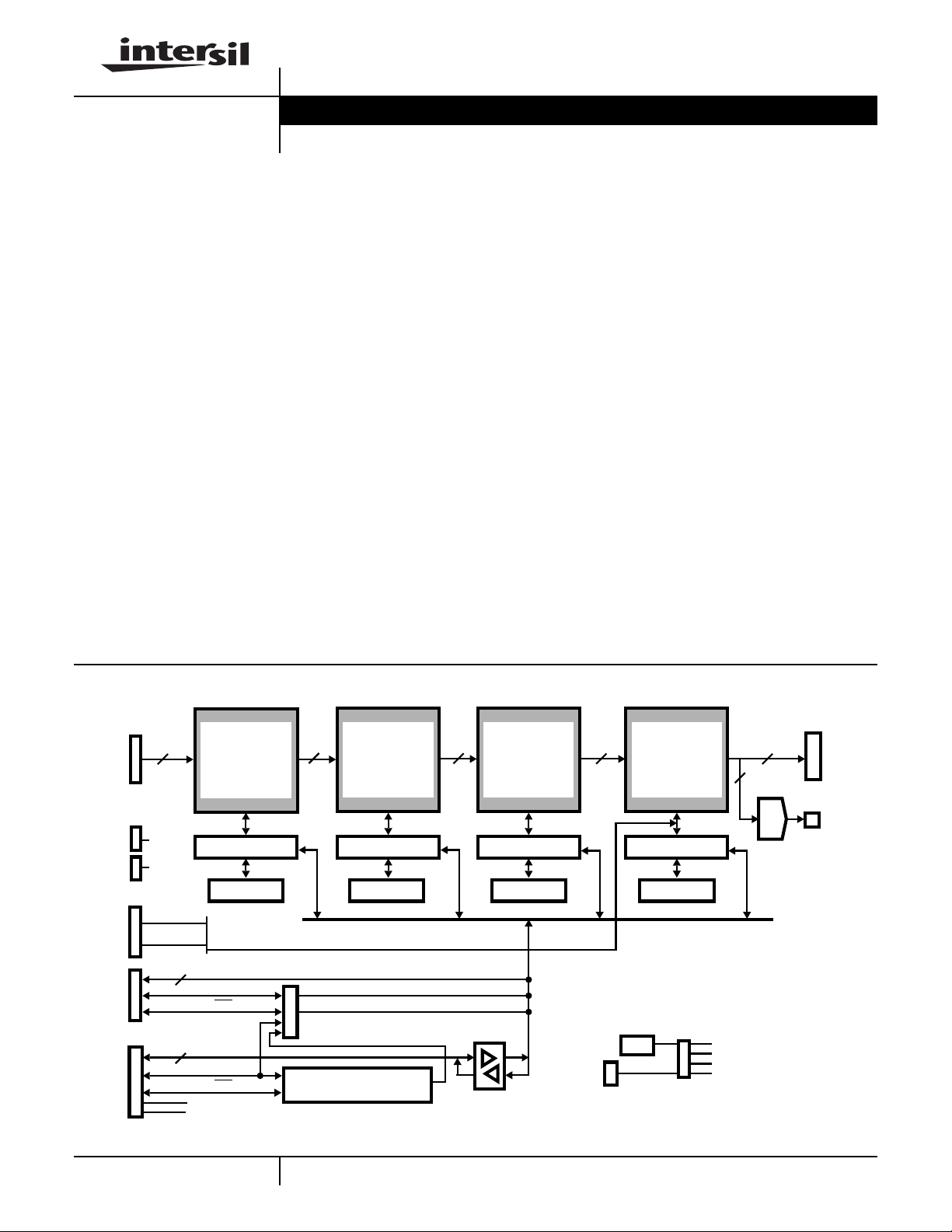

Circuit Board

The Functional BlockDiagram illustrates the major functions

of the circuit board. The circuit board is a ISAbus form factor

with 40 pin I/O header/connectors for cascade and output

signals. Baseband test patterns are loaded through the

ISAbus or 8-bit parallel interface. The external Cascade

Input allows expansion of the number of channels in the

composite signal. The board outputs data through both the

RF connector and the 40 pin header. Test connectors are

provided at key signal and control locations in the circuit.

4463.3

Features

• Multi-Channel Composite IF Output with 1-4 Channels

• Digital or Analog Composite Output

• Baseband Pattern Stimulus Files with Lengths to 64Kbits

• Example Baseband Patterns for BPSK, QPSK,

π/4QPSK,

16QAM, FM, GMSK and AWG Noise

• Baseband Patterns Loaded to RAM Via PC ISAbus or

Parallel Port, for Use as Modulator Baseband Data

• DOS Based Configuration/Status Software

Applications

• Evaluation Tool for the Performance of the Digital

UpConverter Configured as PSK, Quadrature Amplitude

(QAM), FM and Shaped FM (MSK) Modulators at Rates

from <1 KBPS to 1.5 MBPS

• Performance Evaluation Tool for Digital Upconversion

• Communications Test Equipment

Functional Block Diagram

40 PIN

CONNECTOR

16 16 16

(CASCADE

INPUT)

V

CC

-12V

DAT A

ADDRESS

8

PARALLEL

8

ISABUS

HSP50215

DIGITAL

UPCONVERTER

CHANNEL 4

FPGA

RAM

(INPUT DATA PATH AND CONTROL/STATUS INTERFACE)

(OPTIONAL FINAL STAGE BASEBAND DATA INPUT PATH)

DAT A

ADDRESS

WR

DAT A

ADDRESS

WR

V

CC

-12V

HSP50215

DIGITAL

UPCONVERTER

CHANNEL 3

FPGA FPGA FPGA

RAM RAM RAM

ADDRESS DECODE

HSP50215

DIGITAL

UPCONVERTER

CHANNEL 2

INTERFACE BUS

16

CLK

HSP50215

DIGITAL

UPCONVERTER

CHANNEL 1

OSC

16

14

D/A

HI5741

INTERNAL

CLOCKS

40 PIN

CONNECTOR

DIGITAL

ANALOG

IF OUTPUT

IF OUTPUT

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

http://www.intersil.com or 407-727-9207

| Copyright © Intersil Corporation 1999

HSP50215EVAL

Table of Contents

Functional Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Control Software Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

FIGURE 1. MENU TREE FOR THE CONTROL/STATUS SOFTWARE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Configuration/Test Headers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Typical Evaluation Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Getting Started. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Evaluation Circuit Board Configuration and Set Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Requirements for the Control Software Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installing the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

FIGURE 2. TYPICAL MODULATOR PERFORMANCE EVALUATION CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Verifying the Control Software and Board Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

FIGURE 3. MAIN MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

FIGURE 4. BOARD INTERFACE SUBMENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

FIGURE 5. TEST SUBMENU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Running the Control Software for Evaluation Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

FIGURE 6. MODULATOR CHANNEL CONFIGURATION SUBMENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

FIGURE 7. BOARD INTERFACE SUBMENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

FIGURE 8. CONFIGURE CHANNEL 1 SUBMENU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Learning Your Way Around. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Exercise #1: Generating A CW Tone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Exercise #2: Adjusting the level of the CW Tone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Exercise #3: Modulating the CW Tone with PN Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Exercise #4: CW and a Modulated Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Exercise #5: A Fourier Series Composite Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Exercise #6: Generating Additive White Gaussian Noise (AWGN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Background on Eb/No and SNR Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

An Example Eb/No Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Exercise #7: PRBS Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Generating User Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Detailed Circuit Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Signal Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Modulation Channel 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Modulation Channel 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Modulation Channel 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Modulation Channel 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PC/Controller Interface Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

ISA Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Parallel Interface Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Clocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Jumpered Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Power Supply Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Advanced Evaluation Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Non ISA (PC installed) Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Direct Modulator Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Using SERINADE™ Designed Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Appendix A - Circuit Board Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Appendix B - Initial Jumper Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Appendix C - Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Appendix D - Test Header Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Appendix E - Detailed Schematics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Appendix F - Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Appendix G - Descriptive File List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Example Configuration Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Example Filter Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

FIGURE 9. IS136B.IMP FREQUENCY RESPONSE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

FIGURE 10. RRC2A4X.IMP FREQUENCY RESPONSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

FIGURE 11. GS5T16X.IMP FREQUENCY RESPONSE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

FIGURE 12. S95MOD.IMP FREQUENCY RESPONSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

FIGURE 13. AMPS2.IMP FREQUENCY RESPONSE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

FIGURE 14. RRC35A4X.IMP FREQUENCY RESPONSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

FIGURE 15. GP1.IMP FREQUENCY RESPONSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

FIGURE 16. GP2.IMP FREQUENCY RESPONSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Example Stimulus Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Appendix H - Detailed Menu Item Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

PAGE

2

HSP50215EVAL

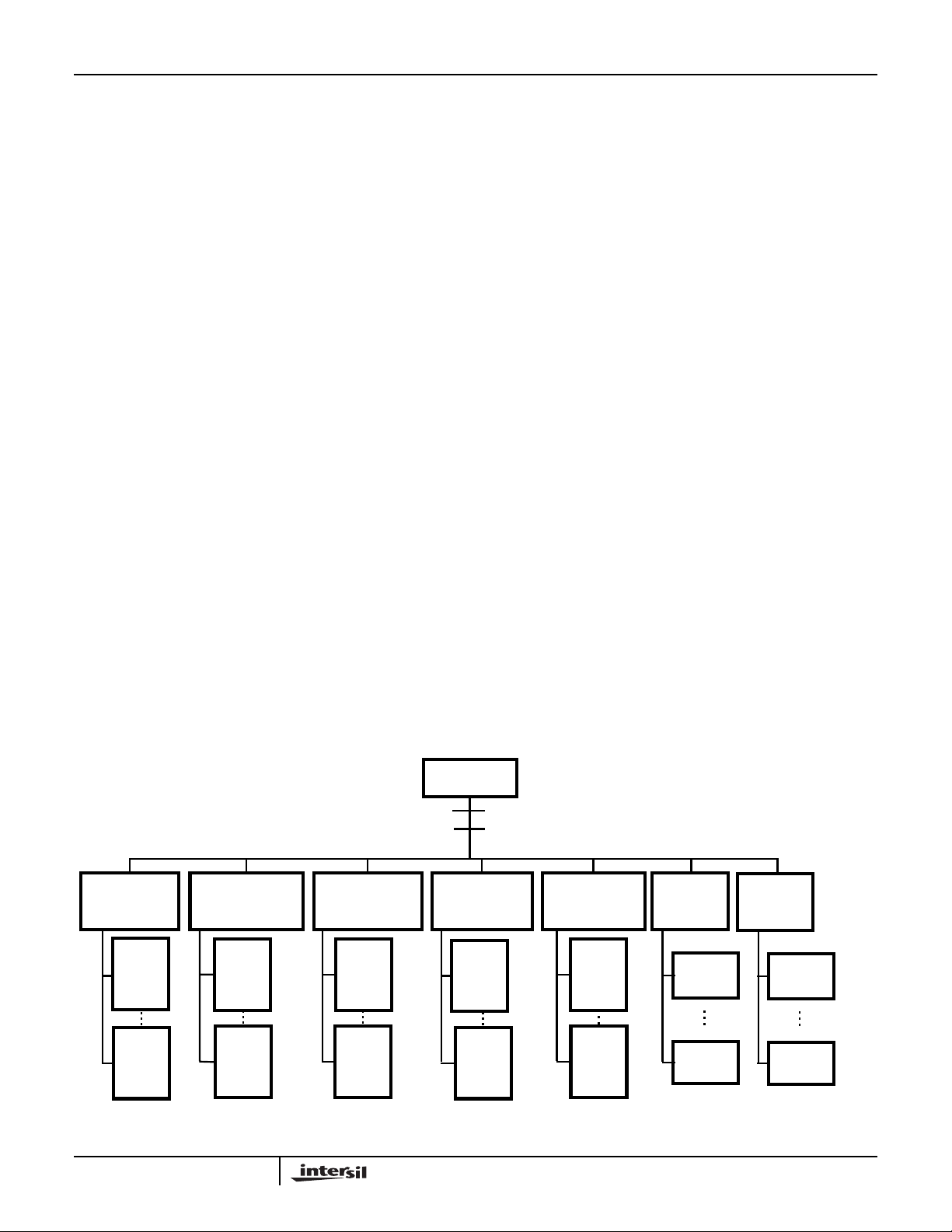

Control Software Program

The control software program, written for DOS based PC’ s , is

included in the evaluation kit. This software supports operation

of the evaluation circuit board in basic quadrature ASK and FM

modulation configurations

The control software MAIN MENU offers six submenus f or

various configuration selections and three command actions.

The menu tree is illustrated in Figure 1.

The 7 configuration submenus are:

• Board Configuration Menu

• Modulator Channel 1 Configuration Menu

• Modulator Channel 2 Configuration Menu

• Modulator Channel 3 Configuration Menu

• Modulator Channel 4 Configuration Menu

• Configure Board Menu

• Test Menu

The four command actions are:

• Load Configuration File

• Save Configuration File

• Compute Registers

• Exit

A typical operational sequence is:

A. Load Configuration File

Executing MAIN MENU item (5) brings up a screen with the

current file name and requests the name of the file to be

loaded. Once the new file name is entered, this command

loads the configuration setup and returns to the MAIN MENU

screen. This command allows the user to select a previously

saved configuration file f or displa y, revie w and editing.

B. Edit Configuration File

This is done by sequencing through each of the configuration

submenus and adjusting the parameters for the desired

hardware configuration.

- The BOARD CONFIGURATION MENU is used to select

control interface type, printer port (PRN) number, FPGA

addressing, and oscillator frequency.

- The MODULA TOR CHANNEL CONFIGURA TION

MENUS are used to select carrier center frequency , input

sample rate, modulation type, coefficient file name,

interpolation factor, impulse response length, Stimulus file

name, number of data samples, output attenuation, output

enabling, cascade input control, synchronization,

synchronization polarity , FIFO depth, Output F ormat, and

test register settings. There is a menu for each of the f our

modulator channels on the evaluation board.

C. Save Configuration File

Executing MAIN MENU item (6) brings up a screen with the

current file name and a request for a file name to be saved.

Once the new file name is entered, this command stores the

configuration setup to the new file.

WARNING: Failure to change the .cfg file name may result in overwriting of

an example file with an edited version of that file.

D. Compute Registers

This command will use the configuration data entered in MAIN

menu items 0-4, and generate a number of files which contain

the register values for the IC’s on the evaluation circuit board.

The computation is based on a .cfg file, which contains filter

(.imp) and stimulus (.imp) files for each of the 4 channels.The

computed register values are stored in a set of files identified by

the suffix of .1, .2, .3 and .4, indicating the channel to which the

parameters apply. The actual filename preceding the .1, .2, .3

or .4 suffix is automatically assigned to be the Configuration file

filename.

MAIN MENU

(5) LOAD CONFIGURATION FILE

(6) SAVE CONFIGURATION FILE

(0) (1) (2) (3) (4) (8)

BOARD

CONFIGURATION

ENTER

NEW

(1)

VALUE

MENU

ENTER

(7)

NEW

VALUE

MENU

MODULATOR MODULATOR

CHANNEL 1

CONFIGURATION

ENTER

(1) (1)

(16) (16)

NEW

VALUE

MENU

ENTER

NEW

VALUE

MENU

CHANNEL 2

CONFIGURATION

ENTER

NEW

VALUE

MENU

ENTER

NEW

VALUE

MENU

CONFIGURATION

(1)

(16)

(7) COMPUTE REGISTERS

(10) EXIT

MODULATOR

CHANNEL 3

ENTER

NEW

VALUE

MENU

ENTER

NEW

VALUE

MENU

MODULATOR

CHANNEL 4

CONFIGURATION

ENTER

(1)

(16)

NEW

VALUE

MENU

ENTER

NEW

VALUE

MENU

FIGURE 1. MENU TREE FOR THE CONTROL/STATUS SOFTWARE

3

CONFIGURE

BOARD

COMMAND

(1)

COMMAND

(5)

(9)

TEST

COMMAND

(1)

#1

(3)

#2

#1

COMMAND

#2

HSP50215EVAL

E. Configure Board Menu

This command accesses a menu called the BOARD,

INTERFACE MENU. The BOARD, INTERFACE MENU is

used to select among several board configure command

options, including configure channel 1, configure channel 2,

configure channel 3, configure channel 4, or configure all

modulator channels.

D. Test Menu

This command accesses a menu called the TEST MENU.

The TEST MENU is used to select among several “run”

options, including reset the board, write to a location while

reset, read to a location while reset, write to a location while

running, or read from a location while running.

For a detailed listing of every Menu screen, with selection

item definitions, refer to Appendix G - Descriptive File List.

Configuration/Test Headers

Fifteen dual row test headers located on the evaluation circuit

board are used to monitor signals and set control pins. The

pin assignments for each of these headers are found in

Appendix D - Test Header Pin Assignments.

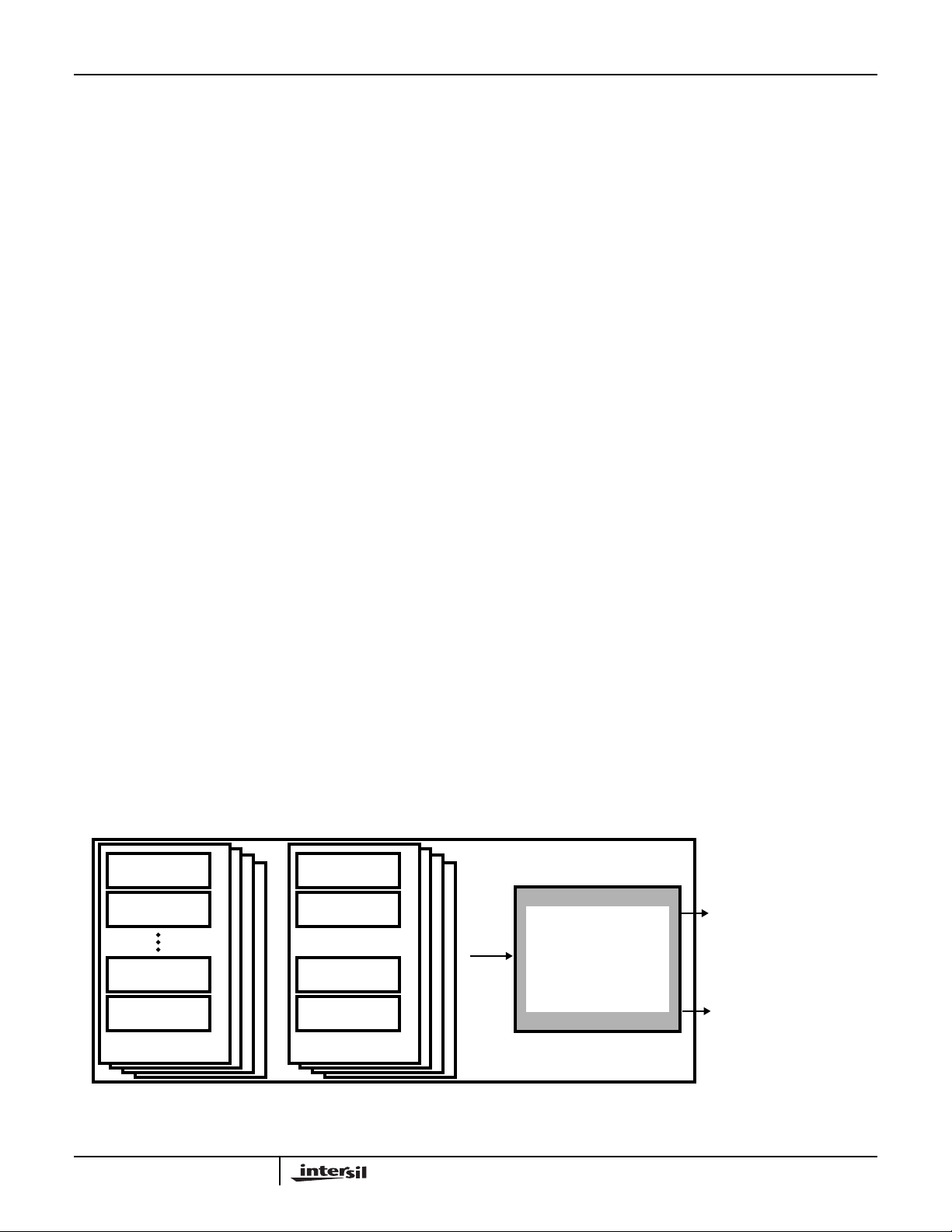

Typical Evaluation Configuration

Figure 2 identifies the configuration of a typical performance

evaluation setup. A test PRBS data pattern is created via a

stimulus file and used by a modulator to generate a

modulated IF signal. Noise and other signal impairment

stimulus files can be used with additional channels to create

a cascaded/summed composite IF signal that is routed to a

D/A converter (DAC), generating an output analog signal.

The digitized IF signal is also routed out of the circuit board

allowing multiple boards to be cascaded together. To check

out a complete communication systems, the modulator

output can be routed to a demodulator, whose baseband

output is connected to a Bit Error Rate Tester (BERT) for

measuring the Bit Error Rate (BER) performance.

Getting Started

Evaluation Circuit Board Configuration and Set Up

1. ___ Power down the host PC and remove the cover to allow access to the motherboard empty slots.

2. ___ Review the jumper configuration of the

HSP50215EVAL Board to verify that the jumpers are

properly set for the configuration desired. Appendices

B (especially the jumper diagram at the end of the appendix), D and E will be helpful in this verification.

3. ___ Install the HSP50215EVALintoone of the empty ISA

slots on the host PC motherboard. Make sure that a

good connection is made with the motherboard and

that the connectors fit in the slots in the rear of the PC

chassis properly. Record the oscillator frequency for

future reference: ____ ____ ____Hz

4. ___ Re-install the PC chassis cover and power up the

computer.

The circuit board is ready for use.

Requirements for the Control Software Program

In order to properly operate the HSP50215EVAL Control

Software Program included in the evaluation kit, the PC must

meet the following requirements:

PC/XT/AT or 100% compatible with a minimum of 640K of

RAM

DOS Version 3.0 or higher.

One parallel port with 25 pin connector.

Installing the Software

The instructions that follow will load both the

HSP50215EVAL software onto the “C” driveof the computer.

If you do not wish to run the software from the “C” drive,

consult your computer user’s manual for operation from

another drive. It is “good practice” to backup original disks

prior to installing the software on your computer.

1. ___ Insert the HSP50215EVALdistribution disk in DriveA

and copy the contents of the distribution diskette to the

targetdirectory on DriveC.

a way as to retain the file structure of the distribution disk.

Note: Thismust be donein such

CHANNEL #1

STIMULUS FILE

CHANNEL #1

FILTER FILE

CHANNEL #4

STIMULUS FILE

CHANNEL #4

FILTER FILE

CONFIGURATION FILE

CHANNEL #1

STIMULUS FILE

CHANNEL #1

FILTER FILE

CHANNEL #4

STIMULUS FILE

CHANNEL #4

FILTER FILE

CONFIGURATION FILE

FIGURE 2. TYPICAL MODULATOR PERFORMANCE EVALUATION CONFIGURATION

PERSONAL COMPUTER

HSP50215EVAL

EVALUATION BOARD

4

ANALOG IF OUTPUT

DIGITAL IF OUTPUT

HSP50215EVAL

2. ___ If a FIR filter design software tool is desired, then

downloading SERINADE from the Intersil Corporation website into the target directory is recommended. The web site is found at www.intersil.com and

SERINADE is found under the Products column of

the home page. Select

Products Listing

ment Tools

menu item. Select the

Digital Signal Processing

menu item. Select the

SERINADE

Develop-

menu

item. Download of SERINADE can be done from this

location.

The software must be run from the new target directory

established on the C drive.

Verifying the Control Software and Board Installation

1. ___ On the PC, change the directory to the target directory where the control software has been installed.

2. ___ Start the program by typing: HSP50215 <Enter>.

3. ___ The MAIN MENU screen will appear. It will look like

Figure 3.

+------------------------------------+

| HSP50215 EVALUATION BOARD SOFTWARE |

+------------------------------------+

MAIN MENU

(0) Board Configuration

(1) Modulator Channel 1 Configuration

(2) Modulator Channel 2 Configuration

(3) Modulator Channel 3 Configuration

(4) Modulator Channel 4 Configuration

(5) Load Configuration File

(6) Save Configuration File

(7) Compute Registers

(8) Configure Board

(9) Test Menu

(10) Exit

ENTER SELECTION: =

(C) Intersil Corporation 1997 Version 1.0

FIGURE 3. MAIN MENU

4. ___ Select item (0) for board configuration and type <Enter>. The BOARD INTERFACEMENU will appear as

shownin Figure 4. Use the menu items to change the

default board configuration to match the ev aluation

board interface, printer, FPGA addressing and oscillator frequency that you desire. Verify that these settings match the jumper configuration of your

evaluation board.

5. ___ Whenyouhavecompleted makingyourmodifications,

selectitem (0) and type <Enter> to returnto the MAIN

MENU.

6. ___ Select Main Menu item (9) and type <Enter> to enter

the Test Menu. The Test Menu is shown in Figure 5.

7. ___ Select Test Menu Item (6) and type <Enter> to enter

the Test Board submenu.

8. ___ A screenappearsthat indicatestheRAMAddress/Data Bus test results and the HSP50215 data bus test

results.Ifalltheitemshavepassedthetest,theboard

and software have been properly installed and you

are ready to begin evaluation testing. Skip to step 12.

If any test failed, proceed to step 9.

9. ___ If one of the tests shown on the screen for step 8 did

not pass, then the board jumper configuration should

be reviewed, as it is the most lik ely culprit.

+-------------------------------------+

| HSP50215 EVALUATION BOARD SOFTWARE |

+------------------------------------+

BOARD INTERFACE MENU

File Name ................ EXAMPLES\EX01QPSK

(1) Interface ...................... ISA

(2) ISA Base Address ............... 0x300

(3) Channel 1 FPGA Address ......... 0

(4) Channel 2 FPGA Address ......... 1

(5) Channel 3 FPGA Address ......... 2

(6) Channel 4 FPGA Address ......... 3

(7) Oscillator Freq ........... 50000000 Hz

(0) Main Menu

ENTER SELECTION:

(C) Intersil Corporation 1997 Version 1.0

FIGURE 4. BOARD INTERFACE SUBMENU

+------------------------------------+

| HSP50215 EVALUATION BOARD SOFTWARE |

+------------------------------------+

TEST MENU

File Name................... EXAMPLES\EX01QPSK

(1) Reset Board

(2) Write to Location While Reset

(3) Read from Location While Reset

(4) Write to Location While Running

(5) Read from Location While Running

(6) Test Board

(0) Main Menu

ENTER SELECTION:

(C) Intersil Corporation 1997 Version 1.0

FIGURE 5. TEST SUBMENU

10. ___ Next, the physicalinstallation should be checked.

11. ___ If the board is properly installed, then a verify that no

ISAbus card addressing contention exists. Steps 9,

10, AND 11 are the leading causes of board test failure.

5

HSP50215EVAL

Running the Control Software for Evaluation

Testing

12. ___ From the MAIN MENU, select the first MODULATOR

CONFIGURATION MENU, item (1), by typing: 1<Enter>. The MODULATOR CHANNEL 1 CONFIGURATION MENU will appear. It should match the entry

found in Figure 6.

13. ___ Make any adjustments to the parameters by entering

the desired item number for parameter selection and

editing each item via the respective parameter entry

submenu. When editing is complete, select item (0)

and type <Enter> to return to the MAIN MENU.

+------------------------------------+

| HSP50215 EVALUATION BOARD SOFTWARE |

+------------------------------------+

File Name............. EXAMPLES\EXO1QPSK

Channel 1

(1) Carrier Center Freq....... 5000000 Hz

(2) Input Sample Rate......... 24300 Hz

(3) Modulation Type........... QASK

(4) Coef File.............. FILTERS\ISA135B

(5) Interpolation (IP)........ 16 phase

(6) Impulse Response Length (DS).16 samples

(7) Stimulus File......... STIMULUS\QPSKPN

(8) # Data Samples:........... 1022

(9) Output Attenuation........ +15dB

(10) Output.................... Enabled

(11) Cascade Input............. Enabled

(12) Sync...................... Internal

(13) Sync Polarity............. L -> H

(14) FIFO Depth................ 3

(15) Output Format........... Offset Binary

(16) Test Register............. 0

(0) Main Menu

ENTER SELECTION:

17. ___ Select MAIN MENU item (8) by typing 8 <Enter>. The

BoardInterfaceMenuwillappearasshowninFigure 7.

18. ___ If youhaveidentifiedmore than one channel for operation, selection of menu item (5) will load all the channels with one command. See step 25 for this action.

In testing, there are times when most of the channels

will remain the same and one channel or one channel

input will change. Menu items (1) through (4) are for

selective channel or channel input configuration. Select the menu item (1), CONFIGURE CHANNEL 1

MENU, of the BOARD INTERFACE MENU by typing

1<Enter>. A menu will appear with three execution

options, as shown in Figure 8. This is the same menu

that will appear when BOARD INTERFACE MENU

items (2) through (5) are selected.

+------------------------------------+

| HSP50215 EVALUATION BOARD SOFTWARE |

+------------------------------------+

BOARD INTERFACE MENU

File Name................... EXAMPLES\EXO1QPSK

(1) Configure Channel 1

(2) Configure Channel 2

(3) Configure Channel 3

(4) Configure Channel 4

(5) Configure All Channels

(0) Main Menu

ENTER SELECTION:

(C) Intersil Corporation 1997 Version 1.0

(C) Intersil Corporation 1997 Version 1.0

FIGURE 6. MODULATOR CHANNEL CONFIGURATION SUB-

MENU

14. ___ Repeat Steps 12 and 13 for MAIN MENU items (2),

(3), and (4). These submenus control Modulator

Channels 2 through 4. These submenus are identical

to those found under MAIN MENU (1) with the exception of the Channel Number and the names of the coefficient file, and stimulus file.

15. ___ Select MAIN MENU item (6) by typing 6 <Enter>.

This will save the edited configuration file. Y ou are

prompted for a file name for your new configuration.

WARNING: Failure to change the .cfg file name may result in

overwriting of an example file with an edited version of that file.

16. ___ Select MAIN MENU item (7) by typing 7<Enter>. This

will compute the configuration register values and

generatethe.1, .2, .3, and .4 files. (Filter and stimulus

files with .imp file extensions must be created prior to

running the HSP50215EVAL software - See Appendix G - Descriptive File List) Note that MAIN MENU

items 1 through 7 can be executedwithout the evaluation circuit board installed.

FIGURE 7. BOARD INTERFACE SUBMENU

19. ___ Select the desired action from the three choices in

(1) Modulator

(2) Pattern RAM

(3) Both

ENTER NEW VALUE [1]:

FIGURE 8. CONFIGURE CHANNEL 1 SUBMENU

the BOARD INTERFACE submenu. The MODULATOR item does an initialization of the designated

channeland begins normal operation of that channel.

The PA TTERN RAM menu item allows individual

STIMULUS files to be downloaded. Selecting item

(3), allows both channel and stimulus configuration

with one command. Selection of an item will return

the user to the BOARD INTERFACE submenu.

20. ___ Items (2), (3), and (4) of the BOARD INTERFACE

submenu, configure only channel 2, 3, and 4 on the

board, respectively. Configure these channels and

return to the main BOARD INTERFACE submenu.

6

HSP50215EVAL

21. ___ Item (5) of the main BOARD INTERFACE submenu

does a full initialization and configuration of all four

channels on the board. Item (5) should be selected

wheneverthe board has been reset. After that, items

(2), (3) or (4) can be selected for a faster update.

22. ___ Select HARDWARE INTERFACE submenu item (0)

by typing 0 <Enter>. This returns the user to the

MAIN MENU. You have now configured your board

for its first test configuration. Youmaylook at the output with a scope or spectrum analyzer to verify that

the board is operating as desired.

23. ___ If the output is not as expected, review the configuration of all of the channels to be sure that you have

properly selected the stimulus, filtering and configuration.

24. ___ When designing a newconfigurationsornewstimulus,

it is best to begin by editing the example file that most

closely matches the desired signal or configuration.

Learning Your Way Around

This Section provides a step by step walk through of some

exercises to familiarize the user with the software screens

and the techniques used to generate a variety of stimulus

and configurations of the HSP50215EVAL Board. If the DAC

output is routed to a scope or a spectrum analyzer, then a

visual verification can be made of the configuration changes.

Note that these exercises assume that the concluding

configuration of the previous exercise is the configuration of

the board at the start of the next exercise. The first exercise

configures all channels to ensure success.

Exercise #1: Generating A CW Tone

This exercise will demonstrate the creation of a CW test

tone. The purpose of this exercise is to illustrate the

generation of a signal that is useful in a variety of testing

configurations.

Go to the main menu. Select Item (5), Load Configuration

File, and enter the following file name and path:

examples/ex01qpsk <Enter). Select Item (1), Modulator

Channel 1 Configuration, and enter the following

parameters:

(1)500,000Hz

(2)50,000Hz

(3)QASK

(7)Stimulus\bpskpn

Note: If you have not properly identified the stimulus file or the path to

that file, then the program will not download when you command the

software to configure the board, and will return you to the DOS prompt

at which point you will need to restart the control software and start

from scratch on the configuration.

(8)1

(9)3

(0)Returns to main menu

This configures channel one input stimulus to be a single bit,

sampled at 50kHz, and applied to a 500kHz QASK modulator

(See note below before leaving this item).

with 3dB attenuation. The filter has a data span of 16 samples

and 16 interpolation phases, and is referenced by the filter

filename IS136B. Notice that it was setting item (8) to 1 that

repeatedly sent a single bit to the modulator, creating the CW.

Select main menu item (2) and set the following parameters:

(1)250,000Hz

(2)25,000Hz

(3)QASK

(7)Stimulus\bpskpn

Note: If you have not properly identified the stimulus file or the path to

that file, then the program will not download when you command the

software to configure the board, and will return you to the DOS prompt

at which point you will need to restart the control software and start

from scratch on the configuration.

(See note below before entering this item)

(8)511

(9)48

(0)Returns to main menu

This configures channel two to be a 25Kbps PSK modulator

at 250kHz, but with the RF severely attenuated so as to be

effectively turned off. The IS136B filter is used here, as well

as in Channel 1.

Select main menu item (3) and set the following parameters:

(1)750,000Hz

(2)75,000Hz

(3)QASK

(7)Stimulus\bpskpn

Note: If you have not properly identified the stimulus file or the path to

that file, then the program will not download when you command the

software to configure the board, and will return you to the DOS prompt

at which point you will need to restart the control software and start

from scratch on the configuration.

(See note below before leaving this item).

(8)511

(9)48

(0)Returns to main menu

This configures channel three to be a 75Kbps PSK

modulator at 750kHz, but with the RF severely attenuated so

as to be effectively turned off. Once again, the IS136B filter

is used.

Select Item (4) and set the following parameters:

(1)500,000Hz

(2)501,000Hz

(3)QASK

(5)0

(6)4

(7)Stimulus\gn16k

Note: If you have not properly identified the stimulus file or the path to

that file, then the program will not download when you command the

software to configure the board, and will return you to the DOS prompt

at which point you will need to restart the control software and start

from scratch on the configuration.

(See note below before leaving this item)

7

HSP50215EVAL

(8)16384

(9)48

(0)Returns to main menu

This configures channel four to be a 351Kbps PSK

modulator at 500kHz with a Gaussian White Noise input and

with the RF severely attenuated so as to be effectively

turned off.

Select main menu item (6), save configuration file and enter

the following file name and path: examples/exercise.

Select main menu (7) to compute the register values.

Select main menu (8) to configure the board.

Select submenu item (5) to configure all channels.

Select submenu item (3) to load both the modulator and

Pattern RAM.

When the submenu reappears, the download is complete

and the scope or spectrum analyzer should show a single

CW tone at 500kHz at approximately 0.4Vpp.

Exercise #2: Adjusting the level of the CW Tone

This exercise will demonstrate the technique used in

adjusting the output amplitude of the CW test tone via the

Gain Control signal of the Digital Upconverter. This is but

one technique that can be used to set the level, noting that

scaling the input file can achieve the same result. The

HSP50215 data sheet notes that care must be taken in

setting the signal levelat the input to the shaping filter, at the

input to the interpolation filter, at the input to the mixer, and

at the cascade summer. Attention to these points will

eliminate the unwanted limiting or roll-over. The purpose of

this exercise is to introduce the user to a technique for

setting test signal levels.

Go to the main menu. Select Item (1), Modulator Channel 1

Configuration, and enter the following parameters:

(9)9

(0)Returns to main menu

This will reduce the output level by 6dB.

Select main menu (7) to compute the register values.

Select main menu (8) to configure the board.

Select submenu item (1) to configure channel 1.

Select submenu item (1) to load the modulator.

When the submenu reappears, the download is complete

and the scope or spectrum analyzer should show a single

CW tone at 500kHz at with half the amplitude of the signal in

Exercise 1. Note that if we had set the value to 48, the

channel is effectively turned off. Setting the value to 0 is the

maximum output level, but there is the risk that clipping will

occur when other signals are added into the CW tone.

Exercise #3: Modulating the CW Tone with PN Data

This exercise will demonstrate the creation a BPSK signal

using a Random PN sequence as a stimulus. The BPSK

stimulus will write the following values as (I,Q) pairs into the

modulator: (-0.707, -0.707), (+0.707, +0.707). This will

generate a BPSK signal. The purist may wish to edit this file

to have the values (+1,0), (-1,0), but the 45

not of concern, in general. The purpose of this exercise is to

demonstrate BPSK and provide insight into creating useful

test stimulus files, as well as to learn techniques for quick

test configuration.

Go to the main menu. Select Item (1) and set the following

parameters:

(8)24

(9)3

(0)Returns to main menu

This will return the output level to the original setting.

Select main menu (7) to compute the register values.

Select main menu (8) to configure the board.

Select submenu item (1) to configure channel 1.

Select submenu item (1) to load the modulator.

When the submenu reappears, the download is complete

and the scope or spectrum analyzer should show a filtered,

modulated signal at an output levelof approximately 0.4Vpp.

There should be 10 IF cycles per baud and the baud rate is

50kHz. Notice that it was setting item (8) to 24 that sent a PN

sequence to the modulator. The previous value of 1, held the

modulator at CW using an input of either a (-0.707, -0.707)

or (+0.707, +0.707).

Note that if a particular data pattern is required, copying and

editing the PN stimulus file for the number of data samples

that you desire, is a quick way to perform an impulse

response or some other useful test pattern such as 1/0 or

1000. Just remember to use the channel configuration menu

to only select the number of data samples to match the

entries that you have altered in the new file. Also,selecting a

standard PN length (2

Error Rate Tester to be used in conjunction with this

modulator in evaluation of the communication link.

Notice also, that the various options for configuring the board

are designed to save time during evaluation. If the only

parameters that have changed involve one modulator, then

the quickest configuration update downloads only the

parameters for that modulator. The next quickest update is if

the Pattern RAM and modulator for that single channel are

all that need downloading. You will appreciate this as you

apply the larger stimulus files, like the AWGN files. The

longest download involves updating the modulator and

Pattern RAM files for all channels.

9

-1, 215-1) allows a commercial Bit

o

phase offset is

8

HSP50215EVAL

Exercise #4: CW and a Modulated Signal

This exercise simulates a CW jammer interferer with a signal

of interest. The affect of interference is determined by how

close in frequency the CW is to the desired signal and what

the relative amplitude is to the signal of interest. We will use

the pre-configured channel 1 as the modulated signal and

configure channel 2 to be the interfering CW. The purpose of

this exercise is to introduce the user to simple dual channel

operation.

Go to the main menu. Select Item (2) and set the following

parameters:

(8)1

(9)6

(0)Returns to main menu

This will set channel 2 to CW at 3dB lower than the

modulated signal level and at half the frequency.

Select main menu (7) to compute the register values.

Select main menu (8) to configure the board.

Select submenu item (2) to configure channel 2.

Select submenu item (3) to load both the modulator and

Pattern RAM.

When the submenu reappears, the download is complete.

This particular signal is easier seen on the spectrum

analyzer than the scope. The CW is set at half the frequency

of the modulated signal. By turning one of the signals on and

off you can convince yourself that the desired combination of

signals is present. The power of the four channel modulator

should now be apparent. For signal testing, it is possible to

generate the signal of interest, two adjacent signals, and an

interferer signal. This test configuration is ideal for high

signal to noise, multi-channel applications.

Exercise #5: A Fourier Series Composite Signal

This exercise will demonstrate the use of 3 modulator

channels configured as CW tones. The fundamental will be

set at 12dB attenuation, the second harmonic at 18dB

attenuation and the third harmonic at 24dB attenuation. The

purpose is to introduce the operator to multiple channel

configurations.

Go to the main menu. Select Item (1) and set the following

parameters:

(8)1

(9)18

(0)Returns to main menu

Select Item (2) and set the following parameters:

(8)1

(9)12

(0)Returns to main menu

Select Item (3) and set the following parameters:

(8)1

(9)24

(0)Returns to main menu

Select main menu (7) to compute the register values.

Select main menu (8) to configure the board.

Select submenu item (5) to configure all channels.

Select submenu item (3) to load both the modulator and

Pattern RAM.

When the submenu reappears, the download is complete.

The output is the composite of three CW tones related by

harmonics and set at decreasing amplitude. The result is a

cyclical output. Note that the relative start phase of each CW

tone on each channel is determined by the relative time of

the channel configuration load. For example, by

reconfiguring individual channels (modulator only) you can

change the relative phase of the CW’s, changing the Fourier

Series, resulting in a different shape output waveform. You

mayalso find it interesting to adjust the amplitudes to try and

approximatea square wave.Adding the fourth modulator will

improve the approximation, remembering that these

exercises depend on the configuration returning to the last

one called out, in order for the next exercise to work.

Exercise #6: Generating Additive White Gaussian

Noise (AWGN)

This exercise will demonstrate the use of the “gn” stimulus

files. Noise will be considered alone, at first, then a

modulated signal will be added. The Gaussian Noise

stimulus files were generated with MATLAB®using the code

commands:

a = randn(8192,2);

b = 0.25*[a(:,1)/std(a(:,1)),a(:,2)/std(a(:,2))];

This is a sequence of numbers that are randomly selected in

the range of [-1 to +1], scaled by 0.25 for 4σ limiting,

normalized to set the standard deviation to exactly 0.25. This

baseband signal is input at the sample rate and will be

modulated to the IF set in parameter (1) of the modulator

channel being used for noise generation. As a rule of thumb,

set the AWGN sample rate to either a value that is at least

10 times the data sample rate, or at a value close to the IF

BW, but make it a prime number not an even multiple of the

data sample rate. The other parameter that determines the

randomness of the noise is setting (8), the number of data

samples. Two stimulus files have been created and the file

name includes the number of samples. The pn16k file has

16K data samples and the pn8K has 8K data samples. Since

the noise is averaged over the number of samples, once the

number becomes relatively large, the differences is primarily

9

MATLAB® is a registered trademark of The MathWorks, Inc.

HSP50215EVAL

the amount of time you care to wait to load the file. A rule of

thumb is to use as large a number as possible. Note that the

start of the noise sequence is determined by when the

stimulus file for that channel is loaded. If multiple channels

are required to be started together, then the board should be

set to use the internal synchronization logic to respond to a

single

external SYNCIN command. In noise applications, a

random start on the various channels is often the desired

condition. The purpose of this example is to demonstrate

both using noise stimulus for filter shape evaluation and for

establishing signal plus noise configurations.

Go to the main menu. Select Item (1) and set the following

parameters:

(8)511

(9)48

(0)Returns to main menu

Select Item (2) and set the following parameters:

(8)511

(9)48

(0)Returns to main menu

Select Item (3) and set the following parameters:

(8)511

Go to the main menu. Select Item (1) and set the following

parameters:

(9)3

(0)Returns to main menu

Select main menu (7) to compute the register values.

Select main menu (8) to configure the board.

Select submenu item (1) to configure channel 1.

Select submenu item (1) to load the modulator.

When the submenu reappears, the download is complete.

The output is AWGN summed with modulated signal.

The final step is to determine how to set a particular Signal

to Noise Ratio (SNR). In order to determine a C/N or E

the following system information must be known:

1)The vector length of the I/Q data vector. (This is the

magnitude of the input vector).

2)The standard deviation of the I and Q components of the

noise pattern vector.

3)The DC gains of the data and noise filters.

4)The input sample rates for the data and noise modulators

(it is assumed that the noise sample rate is higher than the

data sample rate).

b/No

(9)48

(0)Returns to main menu

Select Item (4) and set the following parameters:

(1)500,000Hz

(2)501,000Hz

(3)QASK

(4)Filters/bypass

(8)16384

(9)3

(0)Returns to main menu

Select main menu (7) to compute the register values.

Select main menu (8) to configure the board.

Select submenu item (5) to configure all channels.

Select submenu item (3) to load both the modulator and

Pattern RAM.

When the submenu reappears, the download is complete.

The output is a Gaussian Noise signal, sampled at 351kHz

and modulated to 500kHz IF. On a spectrum analyzer the

outline of the shaping filter is depicted. On the scope, a noisy

signal that is 0.4Vpp is displayed.

5) The noise bandwidth of the noise filters.

6) The multiplier settings for the gain in the modulators.

Items 1 through 5 are listed in the headers of the file or in the

control software menus. Item 6 can be obtained from the

computed register values found in the .1, .2, .3 and .4 files.

Background on Eb/No and SNR Calculations

The signal to noise ratio (C/N) is equal to:

C/NdB = 10LOG(A2/2σ2)

where σ is the standard deviation of the I and Q noise

vectors (they are equal), and A is the average length of the

I/Q vector.

The length of the I/Q vector in the stimulus file is modified by

the gain of the shaping filter and the gain of the

programmable attenuator in the HSP50215. The standard

deviationof the noise vector is likewise modified by the gains

of the filter and the attenuator.

After obtaining C/N, conversion to Eb/No is done by

normalizing for the data rate, NBW of the noise filter, and the

modulation type as follows:

E

=C/N-ModFactor-10LOG(symbol rate)+10LOG(NBW).

b/No

where NBW is the double sided noise bandwidth of the noise

filter.

Now lets add back in a modulated signal.

10

HSP50215EVAL

Adding the log of the noise bandwidth converts from C/N to

C/No. Subtracting the log of the symbol rate converts from

C/No to Es/No. The modulation factor converts from Es/No

to Eb/No using the equation:

MF = 10LOG[bits/symbol]

This yields MF = 0dB for BPSK, MF = 3.01dB for QPSK, and

MF = 4.77dB for 8 PSK.

An Example Eb/No Calculation

Data File:

QPSKPN, A = 1.0, F

Noise File:

GN16K, std dev. = 0.25, F

Data filter:

IS136B, DC gain = 0.658, NBW = 1.004 x F

Noise filter:

RRC35A4xDC gain = 0.5, NBW = 0.989xF

Signal Atten:

20 dB, 26 / 256 = 0.1016

Noise Atten:

14.6 dB, 48 / 256 = 0.1875

Begin by calculating C/NdB:

C/NdB= 10LOG((1.0x0.658x0.1016)2/2(0.25x0.5x0.1875)2)

= 10LOG((4.4693x103)/(1.0986x103))

= 6.094dB

Continue by calculating Eb/No:

Eb/No= 6.094-3.01-10LOG(128,000)+10LOG(0.989x400000)

= 3.084 - 51.072 + 55.973

= 7.98dB

Note that the values for A, standard deviation, DC gains, and

noise bandwidths are found in the file headers of the

example filter and stimulus files provided. When main menu

item (7) is executed, four configuration files are generated,

for the various channels. These files list the hex values for all

of the control registers of the HSP50215. The channel (1, 2,

3, or 4) is indicated by the file suffix. The value of the

multiplier for the attenuators is found in Register 17. This

value, converted to decimal and divided by 256, yields the

linear attenuation multiplier value.

Note that there is an error introduced due to the 8-bit

quantization of the gain control value. The error is small for

attenuations close to 0dB but can be on the order of a tenth

of a dB for attenuations greater than 15dB and as much as

1dB at the bottom of the range.

= 128ksym/sec

SAMP

SAMP

= 400ksamp/sec

SAMP

SAMP

Exercise #7: PRBS Data

This exercise will configure the board to bypass the filter and

not upconvert, so that the user PRBS data is output. This

configuration is useful for verifying stimulus files that are

short data sequences.

Go to the main menu. Select item (I) and set the following

parameters:

(9)48

(0)Returns to the main menu

This turns channel 1 off.

Select main menu, item (4) and set the following parameters:

(1)0

(7)Stimulus/bpskpn

(8)15

(9)3

(0)Returns to the main menu

This sets the channel 4 stimulus file to be a 15 bit PRBS.

The filter was already set to bypass. The IF is set to 0Hz.

Select main menu item (7) to compute the register values.

Select main menu item (8) to configure the board.

Select submenu item (5) to configure all 4 channels.

Select sumenu item (3) to load both the modulator and

pattern RAM.

When the submenu reappears, the download is complete.

The output wavefor m should be the input PRBS data

pattern. You should note that this configuration can be used

to verify the maximum input rate by changing the input

sample rate of channel 4 to be < f

sample rate will illustrate that with too high of an input

sample rate, the filter does not have sufficient time to

complete an output calculation, and no PRBS pattern is

output. By lowering the input sample rate again, until the

PRBS pattern reappears, the maximum input sample rate

can be determined for your evaluation board/oscillator

combination. Note that a similar process can be used to

determine the maximum input rate of each of the example

filter files, taking care to enter the proper DS and IP values

for each filter as noted in Appendix G - Descriptive File List.

/16. Varying the input

OSC

Generating User Configurations

Now that you understand the basics of controlling this

modulator evaluation board, you should be able to edit the

example configuration and stimulus files to obtain the test

figuration you desire. Remember that it is best to begin with

the files that most closely match the desired configuration.

Appendix G - Descriptive File List has a description of these

files.

11

HSP50215EVAL

Detailed Circuit Description

The reader should reference the detailed schematics,

found in Appendix E - Detailed Schematics, while reading

the detailed circuit description.

Signal Path

Modulation Channel 4

Baseband in-phase and quadrature (I and Q) data enters the

HSP50215EV AL via the host computer ISA interface (sheet

6), and is routed to an ACTEL® FPGA (U6 - U9) on one of the

four upconv erter channels (sheets 1-4). Data enters the

HSP50215 Digital UpConverter (U1, U2, U3, or U4) from the

associated ACTEL® FPGA via busses C(15:0) and DUA(9:0),

and the WR control line. The Digital Upconverter provides the

primary DSP processing for each channel. The control

software allows Modulation Channel 4 selection of the

modulation type (QASK, bandlimited FM and shaped FM),

Resampler frequency, IF frequency, gain control, as well as

shaping and interpolation filter configuration. The output of the

digital upconverter for modulation channel 4, U1, is routed to

the cascade input of modulation channel 3 (sheet 2 - U2).

Modulation Channel 4 also allows for external digital

cascade input, via connector J1. This input can be used for

cascading several evaluation boards together, or for

inclusion of any digitized IF signal, with the digital IF output

of the modulation channel 4 upconverter, U1. The sync and

clock signals are supplied to the connector from the clock

and sync selection circuitry found on sheet 4 of the

schematic.

JP1 and RZ1 provide control and selection for the channel 4

ACTEL® FPGA and associated Digital UpConverter. U13

and 14 provide the memory storage for data being

processed by the ACTEL® FPGA.

Four modulation channels are provided, so that HSP50215

evaluation can include processing a signal of interest in the

presence of two adjacent channel signals and an interferer

signal.

Modulation Channel 3

Sheet 2 of the schematic details the control and access

circuitry for modulation channel 3. U2 is the Digital

upconverter and U7 is the associated ACTEL® FPGA.The

control software allows Modulation Channel 2 selection of

the modulation type (QASK, bandlimited FM and shaped

FM), Resampler frequency, IF frequency, gain control, as

well as shaping and interpolation filter configuration.

JP2 and RZ2 provide control and selection for the channel 3

ACTEL® FPGA and associated Digital UpConverter. U15

and 16 provide the memory storage for data being

processed by the ACTEL® FPGA.

Care must be taken to ensure that the cascade input summed

with the modulation output of channel two do not limit inside

the digital upconverter for channel two. The gain control can

be used to provide sufficient back off. The output of the digital

upconverter for modulation channel 3, U2, is routed to the

cascade input of modulation channel 2 (sheet 3 - U3).

Modulation Channel 2

Sheet 3 of the schematic details the control and access

circuitry for Modulation Channel 2. U3 is the Digital

upconverter and U8 is the associated ACTEL® FPGA. The

control software allows Modulation channel 2 selection of the

modulation type (QASK, bandlimited FM and shaped FM),

Resampler frequency, IF frequency, gain control, as well as

shaping and interpolation filter configuration.

JP3 and RZ3 provide control and selection for the channel 2

ACTEL® FPGA and associated Digital UpConverter. U17

and 18 provide the memory storage for data being

processed by the ACTEL® FPGA.

Care must be taken to ensure that the cascade input

summed with the modulation output of channels 4 and 3 do

not limit inside the digital upconverter for channel 2. The

Gain control can be used to provide sufficient back off. The

output of the digital upconverter for modulation channel 2,

U3, is routed to the cascade input of modulation channel 1

(sheet 4 - U4).

Modulation Channel 1

Sheet 4 of the schematic details the control and access

circuitry for modulation channel 1. U4 is the Digital

upconverter and U9 is the associated ACTEL® FPGA. The

control software allows Modulation Channel 1 selection of

the modulation type (QASK, bandlimited FM and shaped

FM), Resampler frequency, IF frequency, gain control, as

well as shaping and interpolation filter configuration.

JP4 and RZ6 provide control and selection for the channel 1

ACTEL® FPGA and associated Digital Upconverter. U19

and 20 provide the memory storage for data being

processed by the ACTEL® FPGA.

Care must be taken to ensure that the cascade input

summed with the modulation output of channels 4 through 2

do not limit inside the digital upconverter for channel 1. The

Gain control can be used to provide sufficient back off. The

output of the digital upconverter for modulation channel 1,

U4, is routed to an output connector, J2, and to an DAC, U5,

found on sheet 5. J2 is the digital output that is the cascaded

IF outputs of channels 4 through 1. The DACoutput is routed

to J5 and provides 50Ω output at 0.5Vpp.

Modulation Channel 1 also has an input connector, J3, which

allows for direct control of one HSP50215 modulation

channel on the HSP50215EVAL. Input Connector J4

provides access to the control bus of the ACTEL® FPGA for

channel four.All other channels are expected to be not used,

to prevent bus contention during the control of the channel 1

upconverter, via the channel 1 ACTEL® FPGA.

12

ACTEL® is a registered trademark of Actel Corporation.

HSP50215EVAL

PC/Controller Interface Section

ISA Interface

The normal installation configuration of the HSP50215EVAL

Card is in a PC, using a standard ISA slot. J10 on sheet 6 of

the schematic details the card connector interface to the

computer ISA bus. JP6 is used to set the card address

location in the PC. The default card address shown on the

schematic is 110000, and should be used unless that

address has already been allocated in your PC

configuration. U21 and RZ7 perform the card decode from

the ISA interface and combine with U22 and U23 to generate

the Read, Write and Address handling necessary for proper

ISA interaction with the HSP50215EVAL.

Jumper JP9 allows for ISA control interface or an 8-bit

parallel port interface via connector J9. Set the jumper

configuration as shown in the schematic for ISA interface

operation. U24 provides the ISA bus interface to the

HSP50215EVAL 8-bit bus interface which downloads control

data to the ACTEL® FPGA’s on each of the four modulator

channels.

Parallel Interface Configuration

To configure the HSP50215EVAL to operate from a parallel

port interface, remove jumpers JP6 17-18, and remove

jumpers 1-2 and 5-6 from JP9. Install jumpers 3-4 and 7-8

on JP9. (Connects the external data bus, write signal and

the address signals to the appropriate labelled pins on the

J9 connector). Depending on the length of the cable

connected to J9, installation of R13 and 14 as well as C3

and 4 may be desirable to improve the signal quality of the

WR and address signals.

Clocking

Jumpered Options

Sheet 4 of the schematic contains the jumpers for several

clocking configurations. JP8 determines the source for the

CONNINCLK, MASTERCLK, and DACCLK clock drivers,

U11, on the board. When JP8 1-2 and 3-4 are installed,

then the clock source will be either an external source or

the on-board crystal oscillator and the connector clock is

driven by the card. These jumpers also route the clock to

the output connector, J2. When JP8-2-3 is installed, the

output connector is the source of the clock. The

configuration shown on the schematic is for internal cr ystal

clock source.

JP7 determines if the clock source is external or internal.

The default configuration shown in the schematic is for

operation from the internal crystal clock source, U10.

Termination of the external clock with 50Ω is done by

installing the JP10 jumper.

Jumper JP5 sets the source for the sync signal. Installing

jumpers J5 7-8 and 9-10 route the SYNCOUT from Channel

1 to the CASSYNC2 location on J1 and to the SYNCIN of

U1-4. Installing JP5 5-6 routes this sync signal to the output

connector.

JP5 also allows jumpering of additional digital IF output

resolution to the output connector, J2. Installing JP5 1-2 and 34 provides 2 bits of additional resolution on the output

connector.

Power Supply Connections

The +5V and -12V are supplied via the ISA interface when the

card is installed in a PC. When the card is used outside the

PC, +5V is input via J8 and -12V is input via J7. The +5V can

be supplied from any generic +5V

adapter. The e valuation board draws approximately 1.5A at

52MHz on the 5V

connector, J10 and is regulated to -5V with U12, shown on

sheet 5 of the schematic. If the ISA bus interface is used, then

jumper J11 must be installed. If an external -5V

used, then jumper J11 must not be installed. Any generic

5V

/200mA AC/DC power adapter can be used for the J7

DC

V

input. The evaluation board draws approximately 100mA

EE

at 52MHz on the -5V

input. The -12V is supplied from the ISA

DC

input.

DC

/2A AC/DC power

DC

supply is

DC

Advanced Evaluation Configurations

Non ISA (PC installed) Operation

The HSP50215EV AL can be oper ated external to a PC for

laboratory applications with other evaluation boards. The ISA

interface is disabled by configuring jumpers on the board.

Remove jumpers JP9 1-2 and 5-6.

Install jumpers JP9 3-4 and 7-8.

Remove jumper JP6 17-18 and 19-20.

Remove jumper JP-11 and provide external power supply

voltages -5.0V

The figure at the end of Appendix B - Initial Jumper Settings

is a visual reference jumper configuration for this

configuration.

The control processor must then be connected to the parallel

interface on J9. PDC(7-0) is the data bus, PARWR is the

Write signal and PARA is the Address signal. The installation

of R13 and R14 as well as C3 and C4 may help reduce

signal distortion for long cable interfaces. Once the parallel

port connection is made, and the jumpers set, the board is

ready for operation and control from the parallel interface

rather than the ISAbus interface.

As in the ISAbus configuration stimulus, and filter files are

used to operate the board.

at J7 and +5.0VDC at J8.

DC

13

HSP50215EVAL

Direct Modulator Control

The HSP50215EVAL Board provides a configuration that

allows a user direct access to the HSP50215 control busses

as well as to the ACTEL® FPGA bus interface. This mode is

intended for single channel only operation, as bus contention

will result if other channels are attempted to be controlled via

the parallel or ISA bus while the local control is active.

Modulation channel 1 is the channel that has connectors for

the local control of the DUC and ACTEL®. J4 provides the

HSP50215 interface and J3 provides the ACTEL® interface.

The user must design a cable to match the appropriate data

and control signals for these parts, if local control is to be

effective.

Disable the ACTEL by removing JP4 9-10

Using SERINADE™ Designed Filters

SERINADE, a filter design tool can be used to synthesize a

filter for the HSP50215 shaping filters. This procedure

assumes that the SERINADE .imp files are available for

import. Version 1.1 or higher is recommended.

File format is consistent with a SERINADE .imp file or

SIGLAB™ file.

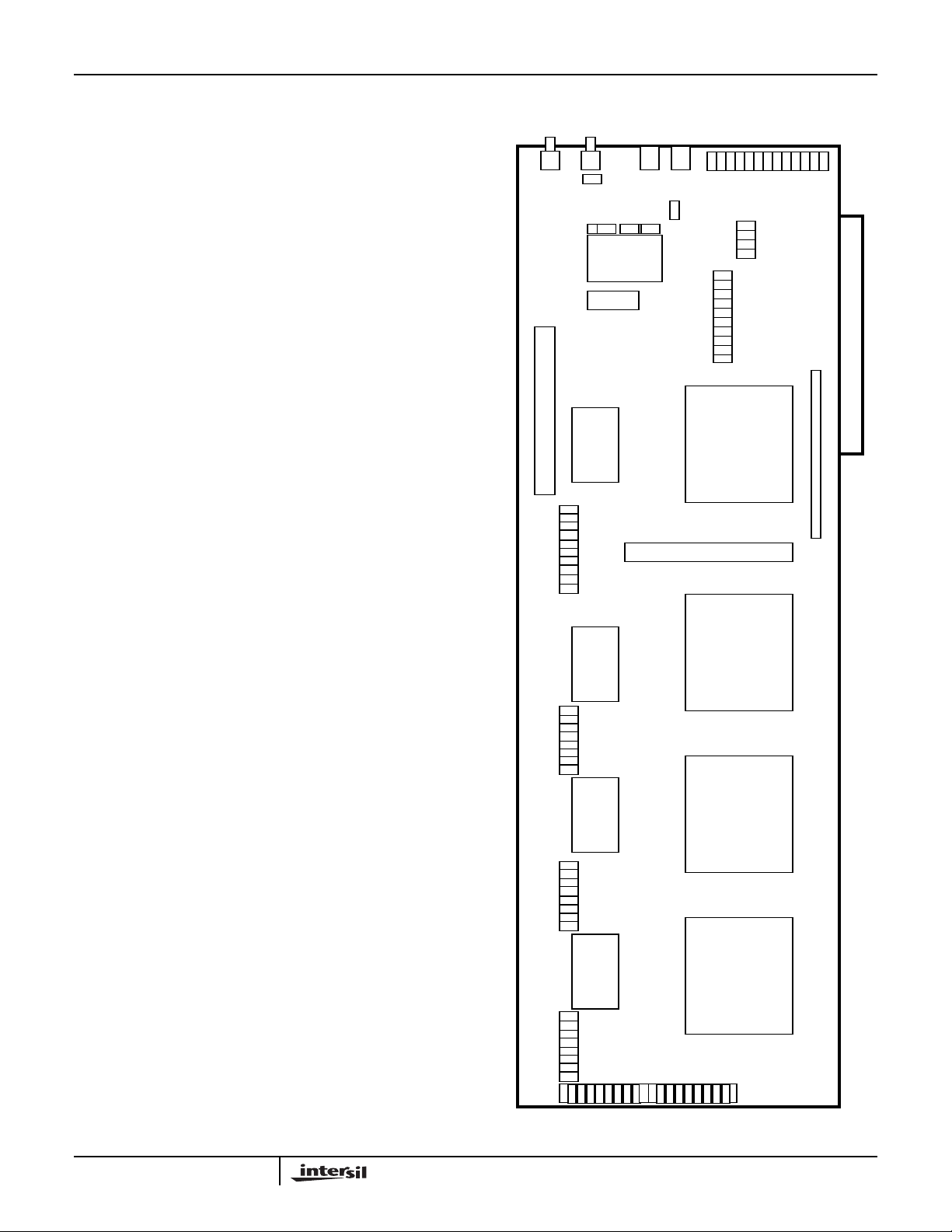

Appendix A - Circuit Board Layout

JP10

JP7JP8

JP11

U10

JP5

J2

U4

J6

JP9

JP6

U9

J4

U3

U2

JP2 JP3 JP4

U1

J3

U8

U7

U6

14

JP1

J1

SERINADE™ is a trademark of Intersil Corporation.

SIGLAB™ a trademark of The Athena Group, Inc.

Loading...

Loading...