®

www.BDTIC.com/Intersil

HSP50214B

Data Sheet May 1, 2007 FN4450.4

Programmable Downconverter

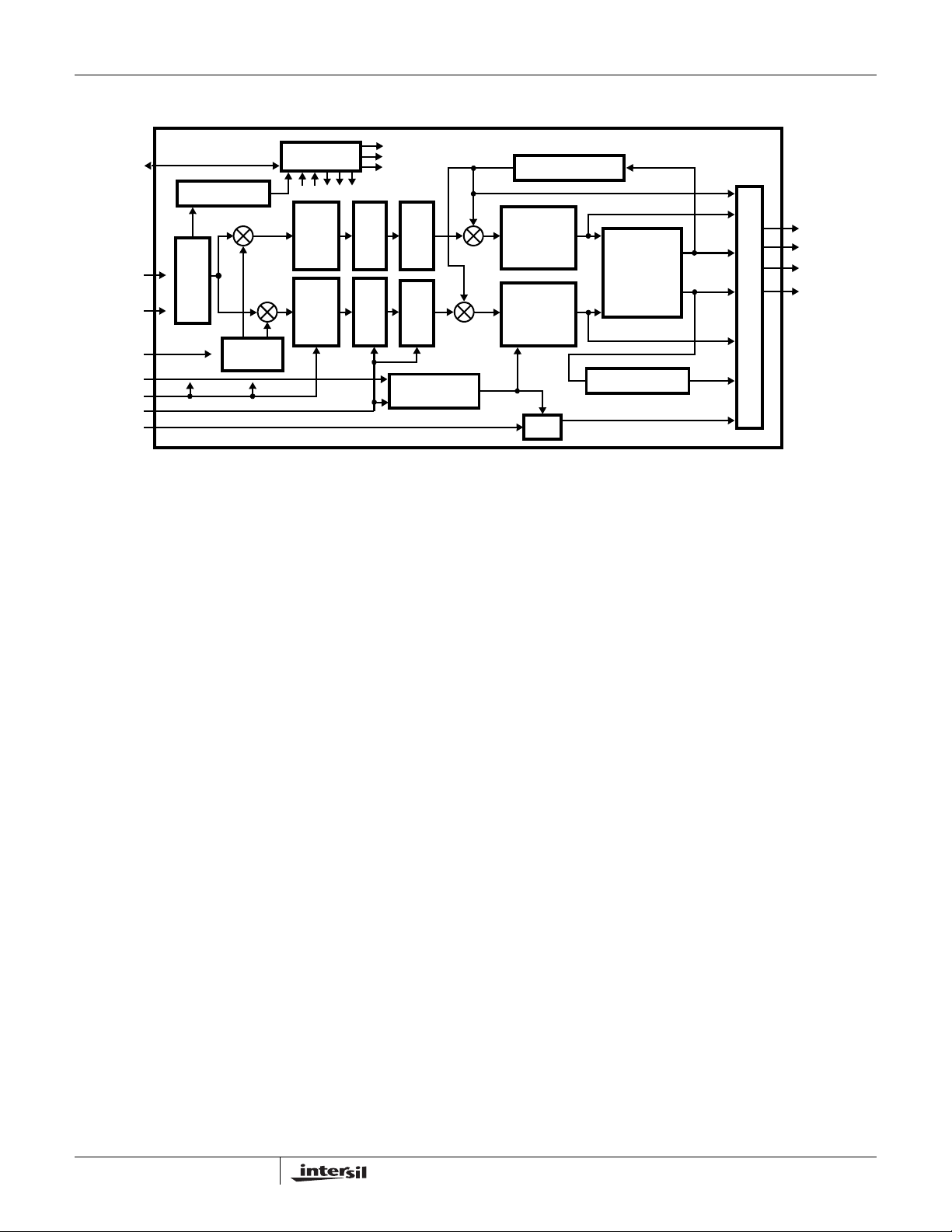

The HSP50214B Programmable Downconverter converts

digitized IF data into filtered baseband data which can be

processed by a standard DSP microprocessor. The

Programmable Downconverter (PDC) performs down

conversion, decimation, narrowband low pass filtering, gain

scaling, resampling, and Cartesian to Polar coordinate

conversion.

The 14-bit sampled IF input is down converted to baseband

by digi

tal mixers and a quadrature NCO, as shown in the

Block Diagram. A decimating (4 to 32) fifth order Cascaded

Integrator-Comb (CIC) filter can be applied to the data

before it is processed by up to 5 decimate-by-2 halfband

filters. The halfband filters are followed by a 255-tap

programmable FIR filter. The output data from the

programmable FIR filter is scaled by a digital AGC before

being re-sampled in a polyphase FIR filter. The output

section can provide seven types of data: Cartesian (I, Q),

polar (R, θ), filtered frequency (dθ/dt), Timing Error (TE), and

AGC level in either parallel or serial format.

Features

• Up to 65MSPS Front-End Processing Rates (CLKIN) and

55MHz Back-End Processing Rates (PROCCLK)

Clocks May Be Asynchronous

• Processing Capable of >100dB SFDR

• Up to 255-Tap Programmable FIR

• Overall Decimation Factor Ranging from 4 to 16384

• Output Samples Rates to ≅ 12.94MSPS with Output

Band

widths to ≅ 982kHz Lowpass

• 32-Bit Programmable NCO for Channel Selection and

Carrier Tracking

• Digital Resampling Filter for Symbol Tracking Loops and

Incommensurate Sample-to-Output Clock Ratios

• Digital AGC with Programmable Limits and Slew Rate to

Opt

imize Output Signal Resolution; Fixed or Auto Gain

Adjust

• Serial, Parallel, and FIFO 16-Bit Output Modes

• Cartesian to Polar Converter and Frequency Discriminator

for AFC Loops and Demodulation of AM, FM, FSK, and

DPSK

• Input Level Detector for External I.F. AGC Support

• Pb-Free Plus Anneal Available (RoHS Compliant)

Applications

• Single Channel Digital Software Radio Receivers

• Base Station Rx’s: AMPS, NA TDMA, GSM, and CDMA

• Compatible with HSP50210 Digital Costas Loop for PSK

Rece

ption

• Evaluation Platform Available

Ordering Information

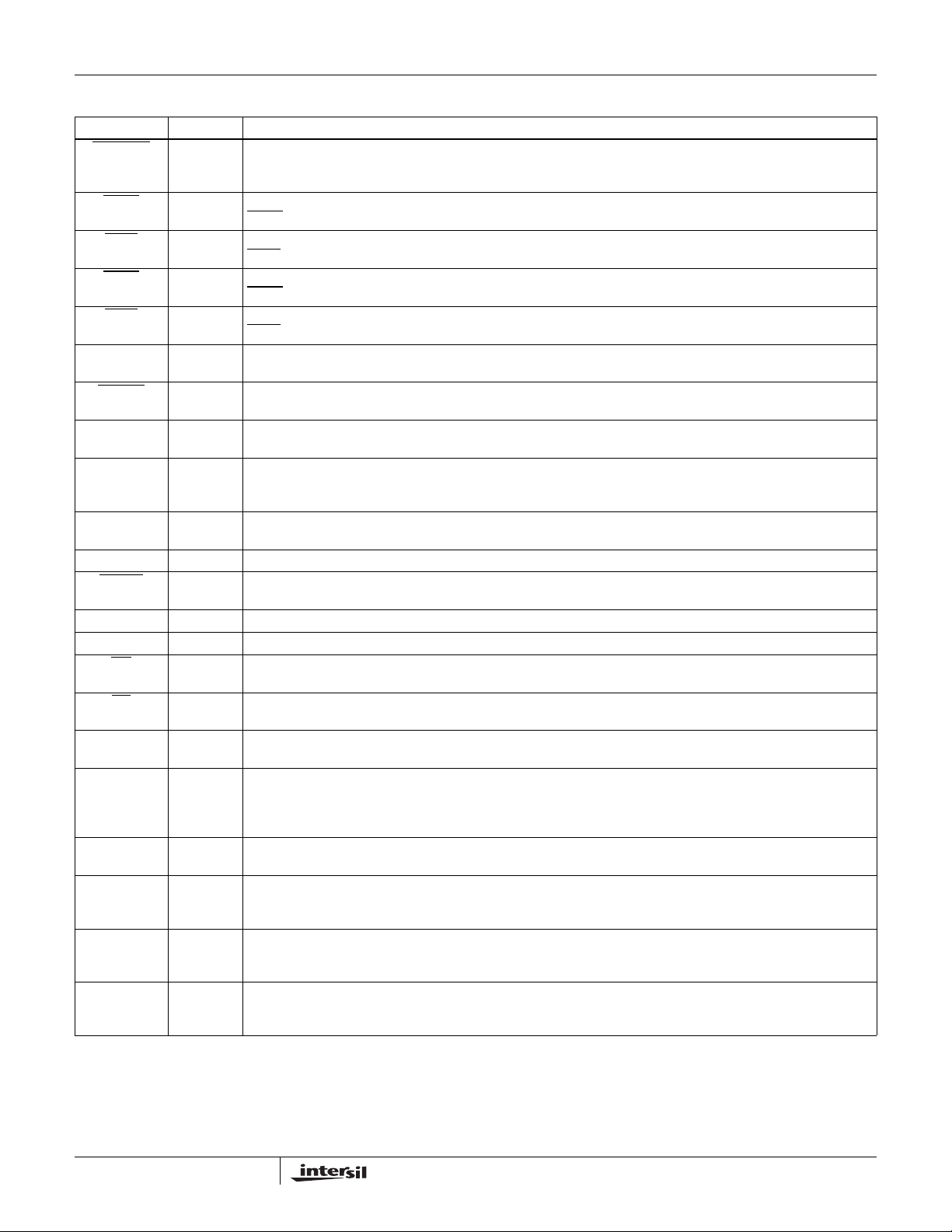

PART NUMBER PART MARKING TEMP. RANGE (°C) PACKAGE PKG. DWG. NO.

HSP50214BVC HSP50214BVC 0 to +70 120 Ld MQFP Q120.28x28

HSP50214BVCZ (Note) HSP50214BVCZ 0 to +70 120 Ld MQFP (Pb-free) Q120.28x28

HSP50214BVI HSP50214BVI -40 to +85 120 Ld MQFP Q120.28x28

HSP50214BVIZ (Note) HSP50214BVIZ -40 to +85 120 Ld MQFP (Pb-free) Q120.28x28

NOTE: Intersil Pb-free plus anneal products employ special Pbtermination finish, which are RoHS compliant and compatible with both SnPb and Pb-free soldering operations. Intersil Pb-free products are MSL

classified at Pb-free peak reflow temperatures that meet or exceed the Pb-free requirements of IPC/JEDEC J STD-020.

free material sets; molding compounds/die attach materials and 100% matte tin plate

1

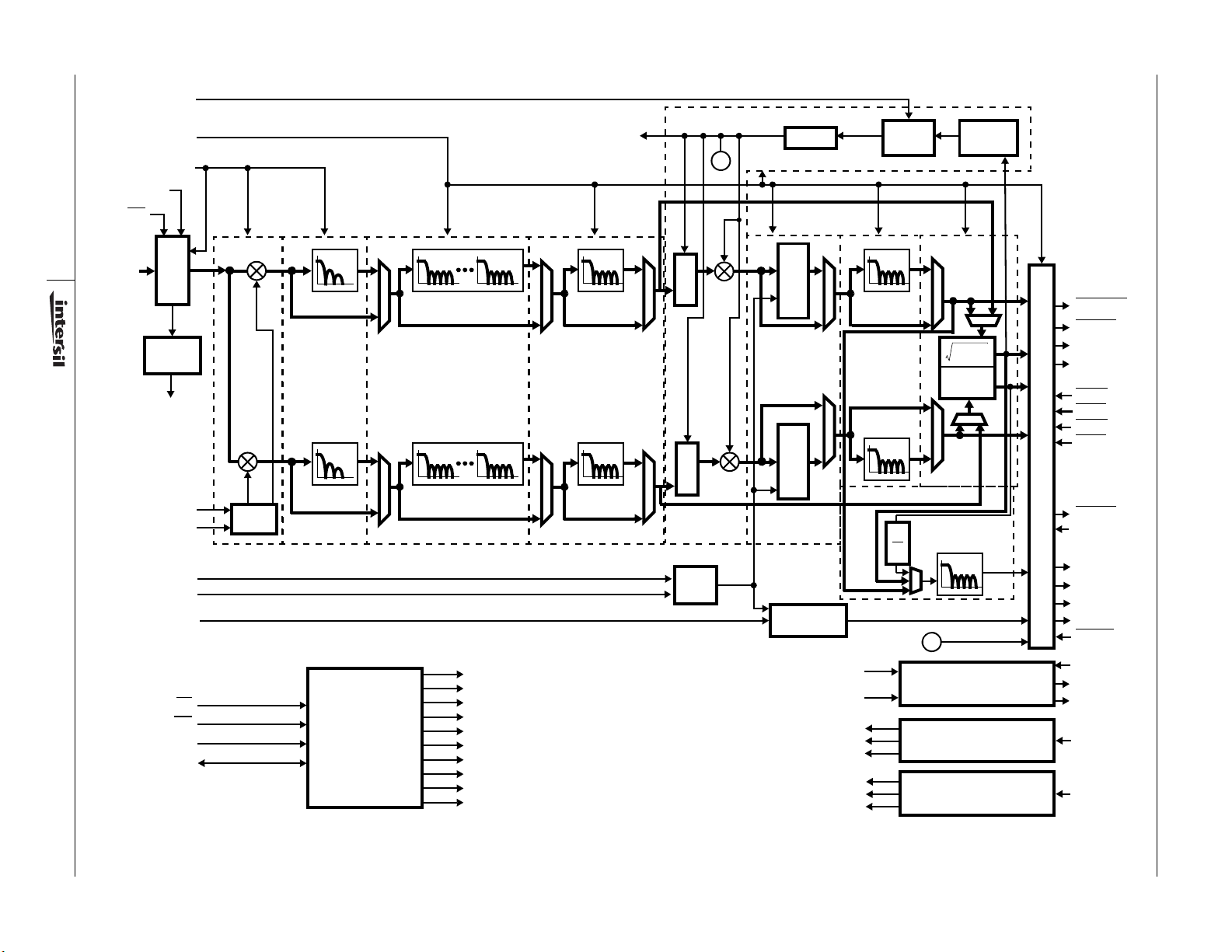

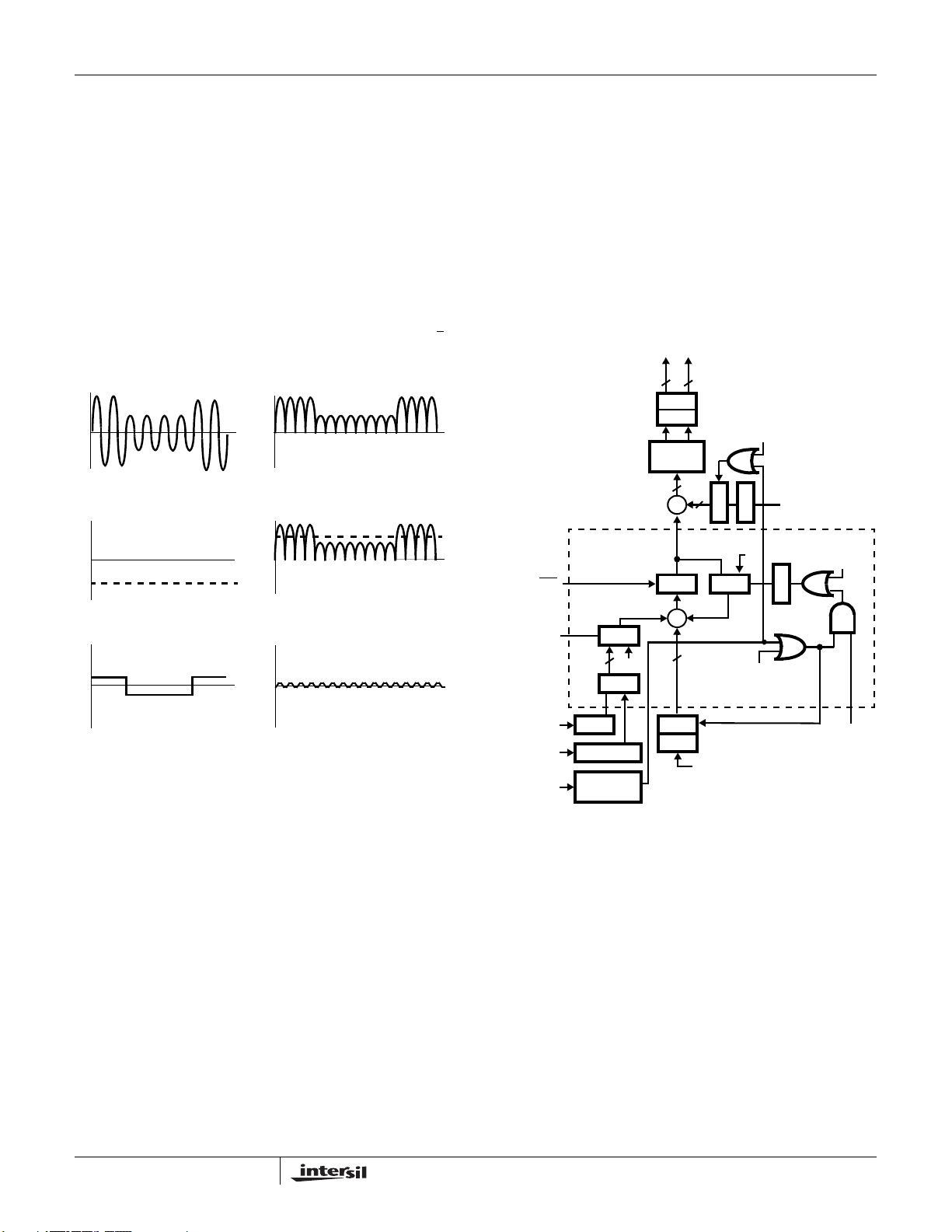

Block Diagram

www.BDTIC.com/Intersil

MICROPROCESSOR

C(7:0)

IN(13:0)

GAIN

ADJ

(2:0)

COF

SOF

CLKIN

PROCCLK

REFCLK

READ/WRITE

LEVEL DETECT

INPUT

SECTION

CARRIER

NCO

CONTROL

TH

5

ORDER

CIC

FILTER

TH

5

ORDER

CIC

FILTER

FILTERS

HALFBAND

FILTERS

HALFBAND

HSP50214B

255-TAP

FIR FILTER

255-TAP

FIR FILTER

RESAMPLING

NCO

AGC LOOP FILTER

POLYPHASE

FIR AND

HALFBAND

FILTERS

POLYPHASE

FIR AND

HALFBAND

FILTERS

Δ

I OUT

CARTESIAN

TO

POLAR

COORDINATE

CONVERTER

Q OUT

DISCRIMINATOR

TIMING ERROR

AGC

MAG.

PHASE

FREQ

SEROUTA

SEROUTB

AOUT(15:0)

BOUT(15:0)

OUTPUT FORMATTER

2

FN4450.4

May 1, 2007

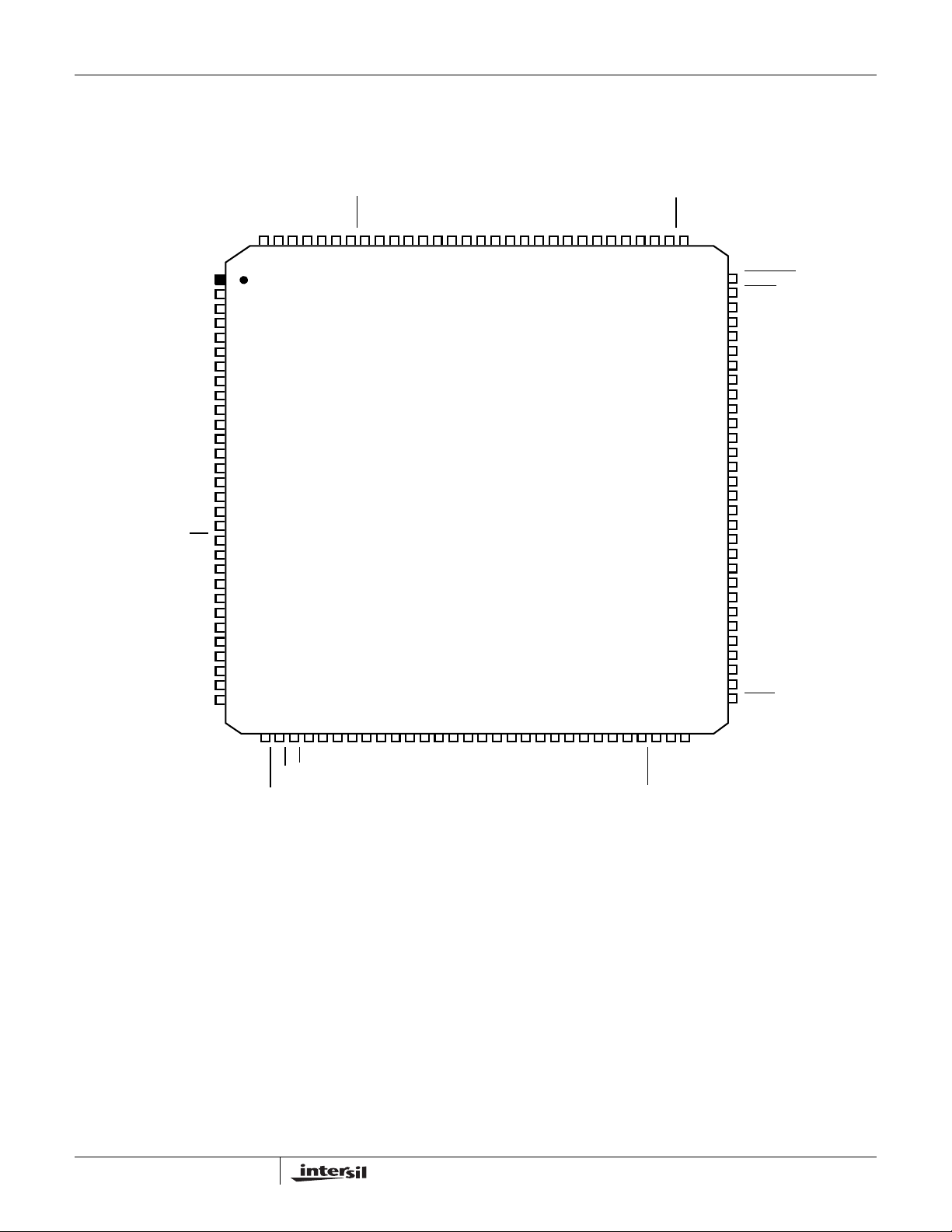

Pinout

www.BDTIC.com/Intersil

HSP50214B

HSP50214B

(120 LD MQFP)

TOP VIEW

OEAL

GND

AOUT0

AOUT1

AOUT2

AOUT3

AOUT4

NC

VCCAOUT5

AOUT6

AOUT7

AOUT8

AOUT9

NC

GND

AOUT10

AOUT11

IN11

IN13

IN12

GND

REFCLK

VCCAGCGNSEL

OEAH

AOUT13

AOUT14

AOUT15

AOUT12

IN10

IN9

IN8

GND

IN7

NC

IN6

IN5

IN4

IN3

IN2

GND

IN1

IN0

V

CC

CLKIN

GND

NC

ENI

GAINADJ2

GAINADJ1

GAINADJ0

COF

COFSYNC

GND

SOF

SOFSYNC

V

CC

SYNCIN1

SYNCIN2

103

102

101

100

117

118

119

120

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

32

31

115

116

333435363738394041424344454647484950515253545556575859

111

112

113

114

105

104

106

107

108

109

110

95

96

97

98

99

91

92

93

94

90

DATARDY

OEBH

89

BOUT15

88

BOUT14

87

V

86

CC

NC

85

BOUT13

84

BOUT12

83

BOUT11

82

BOUT10

81

BOUT9

80

BOUT8

79

GND

78

GND

77

PROCCLK

76

V

75

CC

MSYNCI

74

MSYNCO

73

72

GND

71

BOUT7

70

BOUT6

BOUT5

69

GND

68

BOUT4

67

NC

66

BOUT3

65

BOUT2

64

BOUT1

63

BOUT0

62

OEBL

61

60

3

SYNCOUT

WR

INTRRP

RD

GND

C7

C6NCC5

C3C2C1NCC0A2A1

C4

CC

V

A0

GND

SEL2

SEL1

GND

SEL0

CC

V

SEROE

SEROUTB

SERSYNC

SERCLK

FN4450.4

May 1, 2007

SEROUTA

HSP50214B

www.BDTIC.com/Intersil

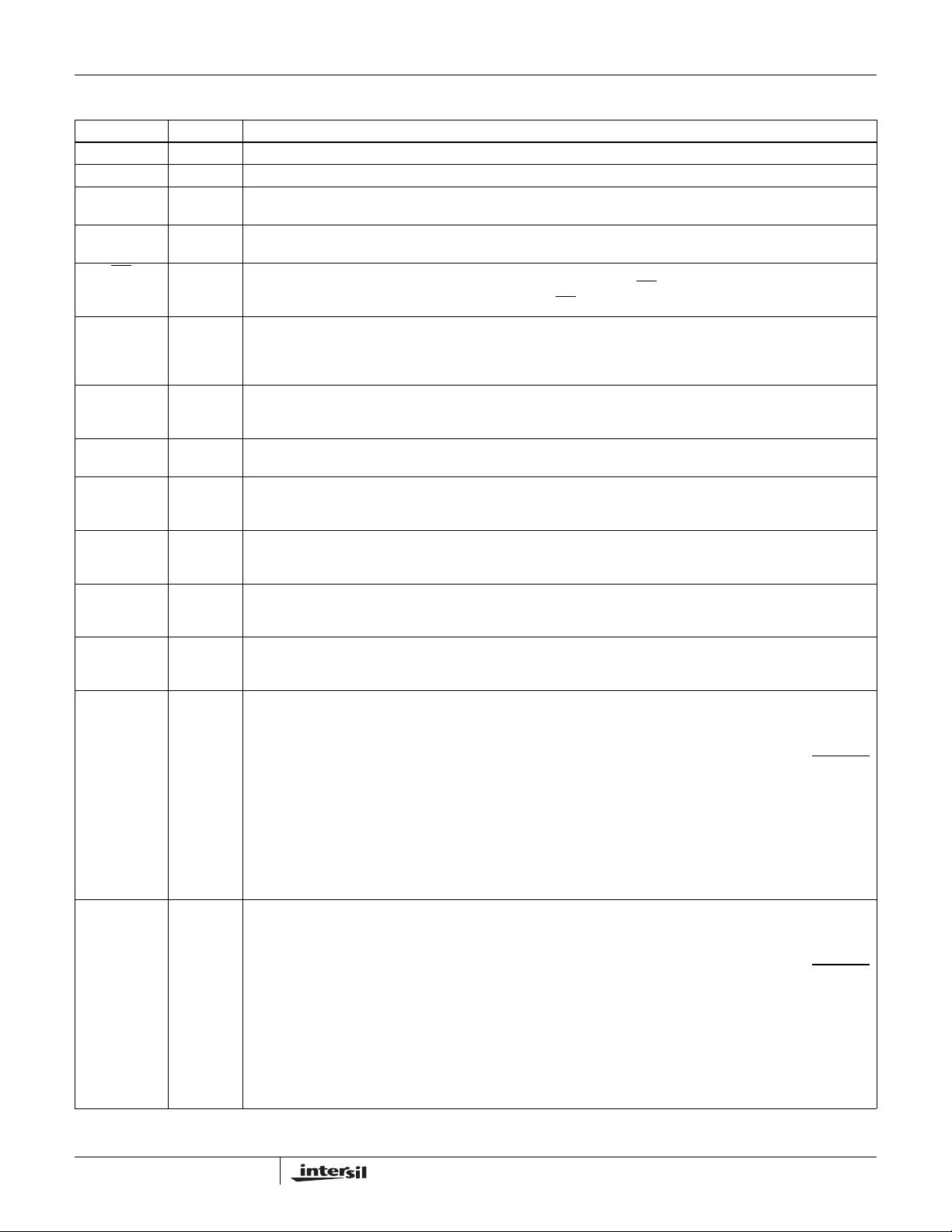

Pin Descriptions

NAME TYPE DESCRIPTION

V

CC

GND - Ground.

CLKIN I Input Clock. This clock should be a multiple of the input sample r

IN(13:0) I Input Data. The format of the input data may be set to offset binary or 2’s complement. IN13 is the MSB (see Control

ENI I Input Enable. Active Low. This pin enables the input to the part in one of two modes, gated or interpolated (see

GAINADJ(2:0) I GAINADJ Input. Adds an offset to the gain via the shifter following the mixer. GAINADJ value is added to the shift

PROCCLK I Processing Clock. PROCCLK is the clock for all processing functions fo

AGCGNSEL I AGC Gain Select. This pin selects between two AGC loop gain

COF I Carrier Offset Frequency Input. This serial inpu

COFSYNC I Carrier Offset Frequency Sync. This signal is asserted one CLK befor

SOF I Re-Sampler Offset Frequency Input. This se

SOFSYNC I Re-Sampler Offset Frequency Sync. This signal is asserted

AOUT(15:0) O Parallel Output Bus A. Two parallel output modes are available on th

BOUT(15:0) O Parallel Output Bus B. Two parallel output modes are available on th

- Positive Power Supply Voltage.

ate. All input section processing occurs on the rising

edge of CLKIN. The frequency of CLKIN is designated f

rd 0).

Wo

Control Word 0). In gated mode, one sample is taken per CLKIN when

designated f

co

de from the microprocessor (μP) interface. The shift code is saturated to a maximum code of F . The gain is of fset

by (6dB)(GAINADJ); (000 = 0dB gain adjust; 111 = 42dB gain adjust) GAINADJ2 is the MSB. See “Using the Input

Gain Adjust Control Signals” Section.

performed on PROCCLK’s rising edge. All output timing is derived from this clock.

This clock may be asynchronous to CLKIN.

Gain setting 1 is selected when AGCGNSEL = 1.

(see Serial Interface Section). The offset may be 8, 16, 24, or 32-bit s. The setup and hold times are relative to CLKIN.

This input is compatible with the outp ut o f t he HSP5 0210 Costas loop [1].

frequency word (see Serial Interface Section). The setup and hold times are relative to CLKIN. This input is

compatible with the output of the HSP50210 Costas loop [1].

NCO (see Serial Interface Section). The offset may be 8, 16, 24, or 32-bits. The setup and hold times are relative

to PROCCLK. This input is compatible with the output of the HSP50210 Costas loop [1].

(see Serial Interface Section). The setup and hold times are relative to PROCCLK. This input is compatible with the

output of the HSP50210 Costas loop [1].

Output Port, where the source is selected through Control Word 20 (see the Microprocessor Write Section) and

comes directly from the Output MUX Section (see Output Control Section). The most significant byte of AOUT

always outputs the most significant byte of the Parallel Direct Output Port whose data type is selected via μP

interface. AOUT15 is the MSB. In this mode, the AOUT(15:0) bus is updated as soon as data is available.

is asserted to indicate new data. For this mode, the output choices are: I, |r|, or f. The format is 2’s complement,

except for magnitude, which is unsigned binary with a zero as the MSB.

The second mode for parallel data is called the Buffer RAM Output Port. The Buffer RAM Output Port acts like a

O for blocks of information called data sets. Within a data set is I, Q, magnitude, phase, and frequency

FIF

information; a data type is selected using SEL(2:0). Up to 7 data sets are stored in the Buffer RAM Output Port. The

LSBytes of the AOUT and BOUT busses form the 16-bits for the buffered output mode and can be used for buffered

mode while the MSBytes are outputting data in the direct output mode. For this mode, the output formats are the

same as the Direct Output Port mode.

Output Port, where the source is selected through Control Word 20 (see the Microprocessor Write Section) and

comes directly from the Output MUX Section (see Output Control Section). The most significant byte of BOUT

always outputs the most significant byte of the Parallel Direct Output Port whose data type is selected via μP

interface. BOUT15 is the MSB. In this mode, the BOUT(15:0) bus is updated as soon as data is available.

is asserted to indicate new data. For this mode, the output choices are: Q, φ, or |r|. The format is 2’s complement,

except for magnitude which is unsigned binary with a zero as the MSB.

The second mode for parallel data is called the Buffer RAM Output Port. The Buffer RAM Output Port acts like a

O for blocks of information called data sets. Within a data set is I, Q, magnitude, phase, and frequency

FIF

information; a particular information is selected using SEL(2:0). Up to 7 data sets is stored in the Buffer RAM Output

Port. The least significant byte of BOUT can be used to either output the least significant byte of the B Parallel Direct

Output Port or the least significant byte of the Buffer RAM Output Port. See Output Section. For this mode the output

formats are the same as the Direct Output Port mode.

, which can be different from f

S

when ENI is used.

CLKIN

t pin is used to load the carrier of fset f reque ncy in to t he C arrie r NCO

rial input pin is used to load the offset frequency into the Re-Sampler

.

CLKIN

ENI is asserted. The input sample rate is

llowing the CIC Section. Processing is

s. This input is setup and held relative to PROCCLK.

e the most significant bit (MSB) of the offset

one CLK before the MSB of the offset frequency word

e HSP50214B. The first is called the Direct

e HSP50214B. The first is called the Direct

DATARDY

DATARDY

4

FN4450.4

May 1, 2007

HSP50214B

www.BDTIC.com/Intersil

Pin Descriptions (Continued)

NAME TYPE DESCRIPTION

DATARDY O Output Strobe Signal. Active Low. Indicates when new data from the Direct Output Port Section is available.

OEAH I Output enable for the MSByte of the AOUT bus. Active Low. The AOUT MSByte outputs are three-stated when

OEAL I Output enable for the LSByte of the AOUT bus. Active Low. The AOUT LSByte outputs are three-stated when

OEBH I Output enable for the MSByte of the BOUT bus. Active Low. The BOUT MSByte outputs are three-stated when

OEBL I Output enable for the LSByte of the BOUT bus. Active Low. The BOUT LSByte outputs are three-stated when

SEL(2:0) I Select Address is used to choose which information in a data set fr

INTRRP O Interrupt Output. Active Low. This output is asserted for 8 PROCCLK cycles when the Buffer RAM Output Port is

SEROUTA O Serial Output Bus A Data. I, Q, magnitude, phase, frequ

SEROUTB O Serial Output Bus B Data. Contents may be related to SEROUTA. I, Q, magnitude, phase, frequency, timing error

SERCLK O Output Clock for Serial Data Out. Derived from PROCCLK as give

SERSYNC O Serial Output Sync Signal. Serves as serial da

SEROE I Serial Output Enable. When high, the SEROUTA, SEROUTB, SERCLK, and SERSYNC signals are set to a high

C(7:0) I/O Processor Interface Data Bus. See Microprocessor Write Section. C7 is the MSB.

A(2:0) I Processor Interface Address Bus. See Microprocessor

WR I Processor Interface Write Strobe. C(7:0) is written to Control Words selected by A(2:0) in the Programmable Down

RD I Processor Interface Read Strobe. C(7:0) is read from output or status locations selected by A(2:0) in the

REFCLK I Reference Clock. Used as an input clock for the timing error de

MSYNCO O Multiple Chip Sync Output. Provided for synchronizing multiple parts when CLKIN and PROCCLK are

MSYNCI I Multiple Chip Sync Input. The MSYNCI pin of all the p

SYNCIN1 I CIC Decimation/Carrier NCO Update Sync. Can be used to synchronize the CIC Section, carrier NCO update, or

SYNCIN2 I FIR/Timing NCO Update/AGC Gain Update Sync. Can be used to synchronize the FIR, T

SYNCOUT O S trobe Output. This synchronization signal is generated by the μP

DATARDY is asserted for one PROCCLK cycle during the first clock cycle that data is available on the parallel out

busses. See Output Section.

OEAH is high.

OEAL is high.

OEBH is high.

OEBL is high.

least significant bytes of AOUT and BOUT. SEL2 is the MSB.

ready for reading.

ency, timing error and AGC information can be sequenced

in programmable order. See Output Section and Microprocessor Write Section.

and AGC information can be sequenced in pr

Section.

Section.

impedance.

Converter on the rising edge of this signal. See Microprocessor Write Section.

Programmable Down Converter on the falling edge of this signal. See Microprocessor Read Section.

REFCLK. REFCLK frequency must be less than or equal to PROCCLK/2.

asynchro

back end processing operating under PROCCLK. This output sync signal from one part is connected to the MSYNCI

signal of all the HSP50214Bs.

NOTE: MSYNCI must be connected t

both. See

High.

gain update, or any combination of the above. See the Multiple Chip Synchronization Section and Control Words 7,

8, and 10 in the Microprocessor Write Section. Active High.

generated by PROCLK or CLKIN (see Control Word 0 and Control Word 24 in the Microprocessor Write Section).

Active High.

nous. MSYNCO is the synchronization signal between the input section operating under CLKIN and the

the Multiple Chip Synchronization Section and Control Word 0 in the Microprocessor Write Section. Active

ogrammable order. See Output Section and Microprocessor Write

ta strobes. See Output Section and Microprocessor Write Section.

Write Section. A2 is the MSB.

arts should be tied to the MSYNCO of one part.

o an MSYNCO signal for operation.

om the Buffer RAM Output Port is sent to the

n by Control Word 20 in the Microprocessor Write

tector. The timing error is computed relative to

iming NCO update, AGC

interface for synchronizing multiple parts. Can be

5

FN4450.4

May 1, 2007

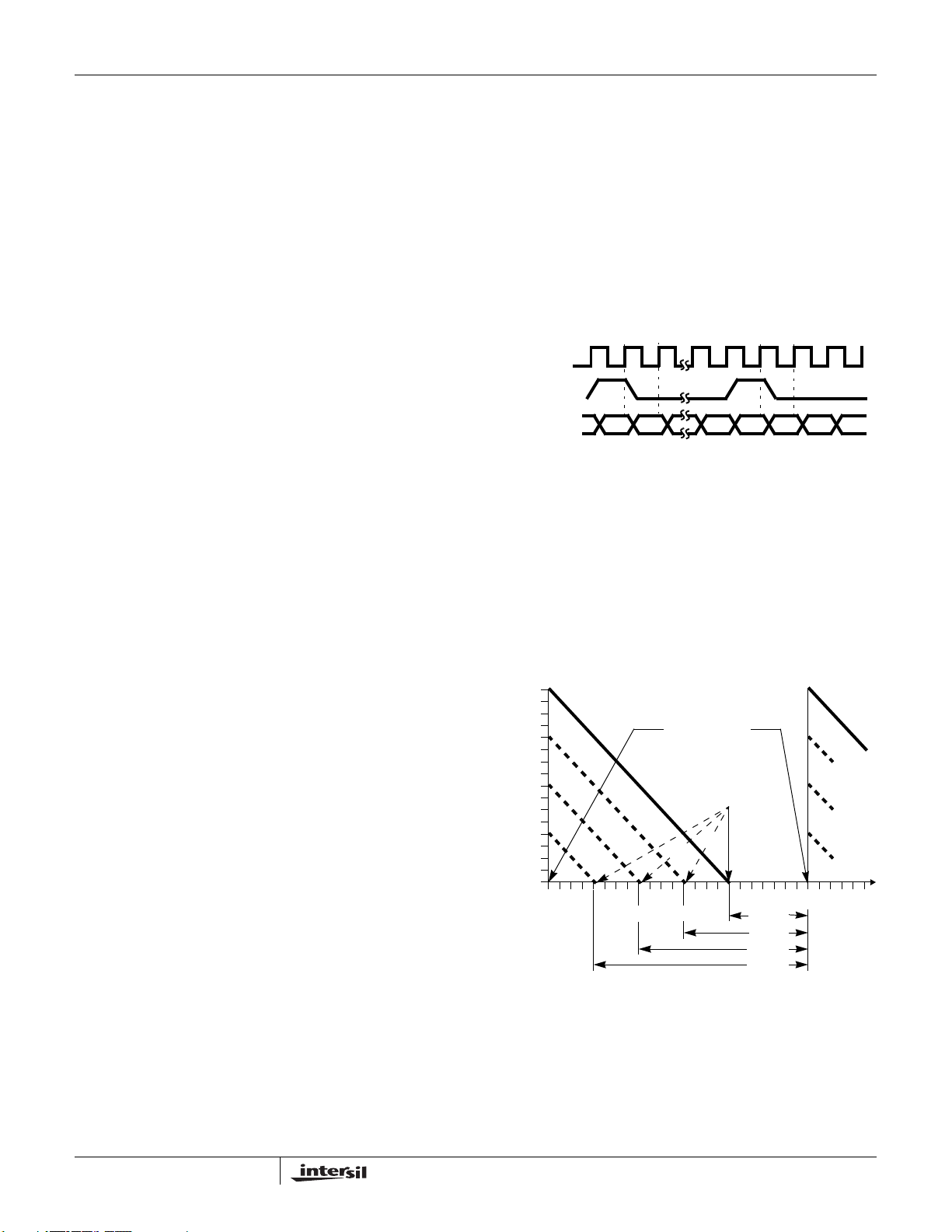

6

www.BDTIC.com/Intersil

AGCGNSEL

PROCCLK

GAINADJ(2:0)

ENI

IN(13:0)

DETECT

μPROCESSOR

INTERFACE

CLKIN

INPUT

LEVEL

TO

SECTION

MIXER

5TH ORDER

CIC

DECIMATE

FROM 4-32

TO OUTPUT FORMATTER

AND MICROPROCESSOR

0 TO 5 HALFBAND FILTER;

DECIMATION UP TO 32

INTERFACE

(CO = 1;

= 0)

C

n

255-TAP

PROGRAMMABLE

FIR FILTER

(DECIMATE UP TO 16)

AGCOUT

SHIFT

AGC

A

LIMIT

FILTER

POLYPHASE

RE-SAMPLER

LOOP

FILTER

INTERPOLATE

BY 2/4

HALFBAND

FILTERS

ERROR

DETECT

CARTESIAN

TO

POLAR

I

I2Q2+

Q

⎛⎞

----

atan

⎝⎠

I

Q

DATARDY

INTRRP

AOUT(15:0)

BOUT(15:0)

OEAH

OEAL

OEBH

OEBL

HSP50214B

(C

COS

COF

COFSYNC

(CARRIER TRACKING)

SOF

SOFSYNC

REFCLK

RD

WR

A(2:0)

C(7:0)

May 1, 2007

FN4450.4

SIN

NCO

MICROPROCESSOR

READ/WRITE

CONTROL

SECTION

OUTPUT SECTION

DISCRIMINATOR SECTION

INPUT SECTION

LEVEL DETECT SECTION

SYNCHRONIZATION SECTION

CARRIER NCO SECTIONS

CIC, HALFBAND FILTER, AND FIR SECTIONS

DIGITAL AGC SECTION

RE-SAMPLER/INTERPOLATION HALFBAND SECTION

TIMING NCO

= 1;

O

= 0)

C

n

(SYMBOL TRACKING)

SHIFT

NCO

FILTER

POLYPHASE

DIFFERENCE

CLKIN

PROCCLK

DISCRIMINATOR

dθ

PROGRAMMABLE

td

63-TAP

FIR FILTER

TIMING ERROR

AGCOUT

A

CHIP

SYNCHRONIZATION

CIRCUITRY

BACK END

SYNCHRONIZATION

CIRCUITRY

FRONT END

SYNCHRONIZATION

CIRCUITRY

OUTPUT FORMATTER

INTRRP

SEL(2:0)

SEROUTA

SEROUTB

SERCLK

SERSYNC

SEROE

MSYNCI

SYNCOUT

MSYNCO

SYNCIN2

SYNCIN1

FIGURE 1. FUNCTIONAL BLOCK DIAGRAM OF THE HSP50214B PROGRAMMABLE DOWNCONVERTER

HSP50214B

www.BDTIC.com/Intersil

Functional Description

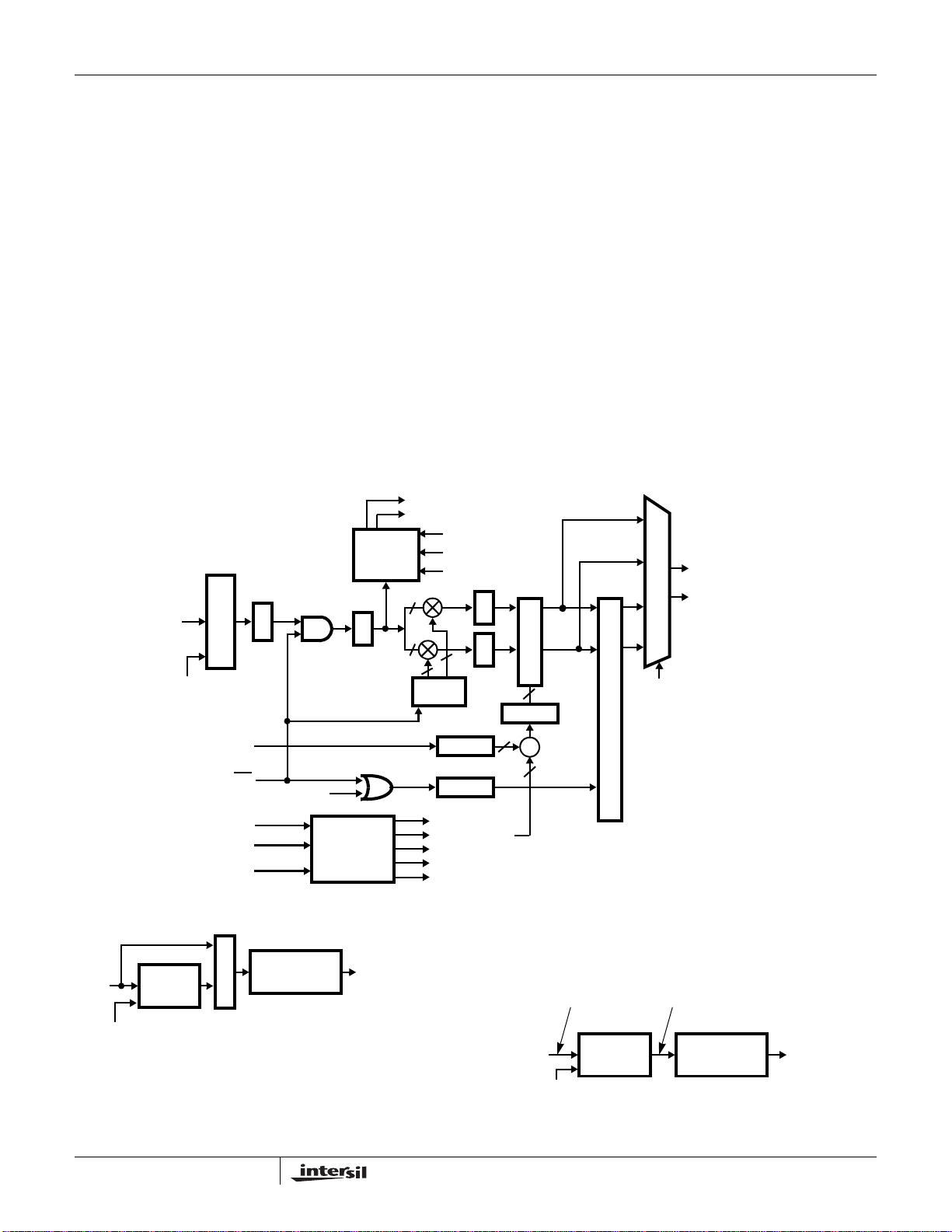

The HSP50214B Programmable Downconverter (PDC) is an

agile digital tuner designed to meet the requirements of a

wide variety of communications industry standards. The

PDC contains the processing functions needed to convert

sampled IF signals to baseband digital samples. These

functions include LO generation/mixing, decimation filtering,

programmable FIR shaping/bandlimiting filtering,

resampling, Automatic Gain Control (AGC), frequency

discrimination and detection as well as multi-chip

synchronization. The HSP50214B interfaces directly with a

DSP microprocessor to pass baseband and status data.

A top level functional block diagram of the HSP50214B is

sh

own in Figure 1. The diagram shows the major blocks and

multiplexers used to reconfigure th

e data path for various

architectures. The HSP50214B can be broken into 13

sections: Synchronization, Input, Input Level Detector,

Carrier Mixer/Numerically Control Oscillator (NCO), CIC

Decimating Filter, Halfband Decimating Filter, 255-Tap

Programmable FIR Filter, Automatic Gain Control (AGC),

Re-sampler/Halfband Filter, Timing NCO, Cartesian to Polar

Converter, Discriminator, and Output Sections. All of these

sections are configured through a microprocessor interface.

The HSP50214B has three clock inputs; two are required and

on

e is optional. The input level detector , carrier NCO, and CIC

decimating filter sections operate on the rising edge of the

input clock, CLKIN. The halfband filter , p rogrammable FIR

filter, AGC, Re-Sampler / Halfband filters, timing NCO,

di

scriminator, and ou tput sections ope ra te on the ri si ng edge

of PROCCLK. The third clock, REFCLK, is used to generate

timing error information.

NOTE: All of the clocks may be asynchronous.

PDC Applications Overview

This section highlights the motivation behind the key

programmable features from a communications system level

perspective. These motivations will be defined in terms of ability

to provide DSP processing capability for specific modulation

formats and communication applications. The versatility of the

Programmable Downconverter can be intimidating because of

the many Control Words required for chip configuration. This

section provides system level insight to help allay reservations

about this versatile DSP product. It should help the designer

capitalize on the greatest feature of the PDC - VERSATILITY

THROUGH PROGRAMMABILITY. It is this feature, when fully

understood, that brings the greatest return on design

investment by offering a single receiver design that can process

the many waveforms required in the communications

marketplace.

FDM Based Standards and Applications

Table 1 provides an overview of some common frequency

division multiplex (FDM) base station applications to which the

PDC can be

applied. The PDC provides excellent selectivity

for frequency division multiple access (FDMA) signals. This

high selectivity is achieved with 0.012Hz resolution frequency

control of the NCO and the sharp filter responses capable with

a 255-tap, 22-bit coefficient FIR filter . The 16-bi t resolution out

of the Cartesian to Polar Coordinate Converter are routed to

the frequency detector, which is follow ed by a 63-t ap, 22-bit

coefficient FIR filter structure for facilitating FM and FSK

detection. The 14-bit input resolution is the smallest bit

resolution found throughout the conversion and filtering

sections, providing excellent dynamic range in the DSP

processing. A unique input gain scaler adds an additional

42dB of range to the input level variation, to compensate for

changes in the analog RF front end receive equipment.

Synchronization circuitry allows precise timing control of the

base station reconfiguration for all receive channels

simultaneously. Portions of this table were corroborated with

reference [2].

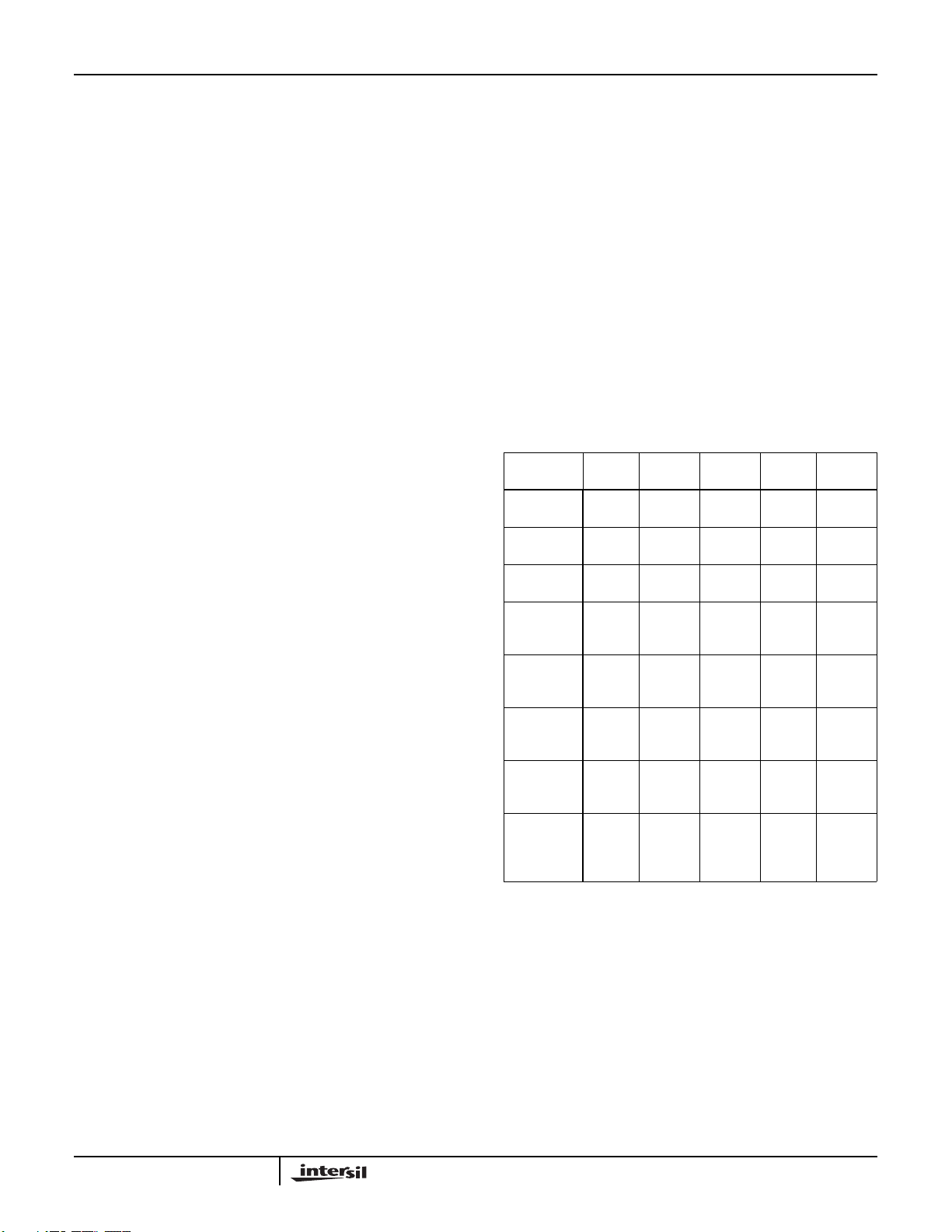

TABLE 1. CELLULAR PHONE BASE STA TION

STANDARD

RX BAND

CHANNEL

BW (kHz)

# TRAFFIC

CHANNELS

MODULA-

DEVIATION

CONTROL

MOD

DEVIATION

CONTROL

HANNEL

C

APPLICATIONS USING FDMA

(MHz)

VOICE

TION

PEAK

(kHz)

ULATION

PEAK

(kHz)

RATE

(Kbps)

AMPS

(

IS-91)

824-849 925-940 453-458

832 600

FSK FSK FSK FSK FSK

MCS-L1

MCS-L2

30 25.0

12.5

1200

FM FM FM FM FM

12 5 5 4 9.5

8 4.5 3.5 2.5 6.4

10 0.3 1.2 5.3 8

NMT-400

NMT-900 C450

890-915

12.5

200

1999

451-456 871-904

25

20.0

10.0

222

444

ETACS

NTACS

915-925

25.0

12.5

1240

800

TDM Based Standards and Applications

Table 2 provides an overview of some common Time D ivision

Multiplexed (TDM) base station applications to which the PDC

can be ap

applications, such as North American TDMA (IS136), where

30kHz is the received band of interest for the PCS

basestation, the PDC offers 0.012Hz frequency resolution in

downconversion in addition to α = 0.35 matched

(programmable) filtering capability. The π/4 DPSK modulation

can be processed using the PDC Cartesian to Polar

coordinate converter and dφ/dt detecto r circuitry or by

processing the I/Q samples in the DSP μP. The PDC provides

plied. For time division multiple access (TDMA)

7

FN4450.4

May 1, 2007

HSP50214B

www.BDTIC.com/Intersil

the ability to change the received signal gain and frequency,

synchronous with burst timing. The synchronous gain

adjustment allows the user to measure the power of the signal

at the A/D at the end of a burst, and synchronously reload that

same gain value at the arrival of the next user burst.

For applications other than cellular phones (where the

prea

mbles are not changed), the PDC frequency

discriminator output can be used to obtain correlation on the

preamble pattern to aid in burst acquisition.

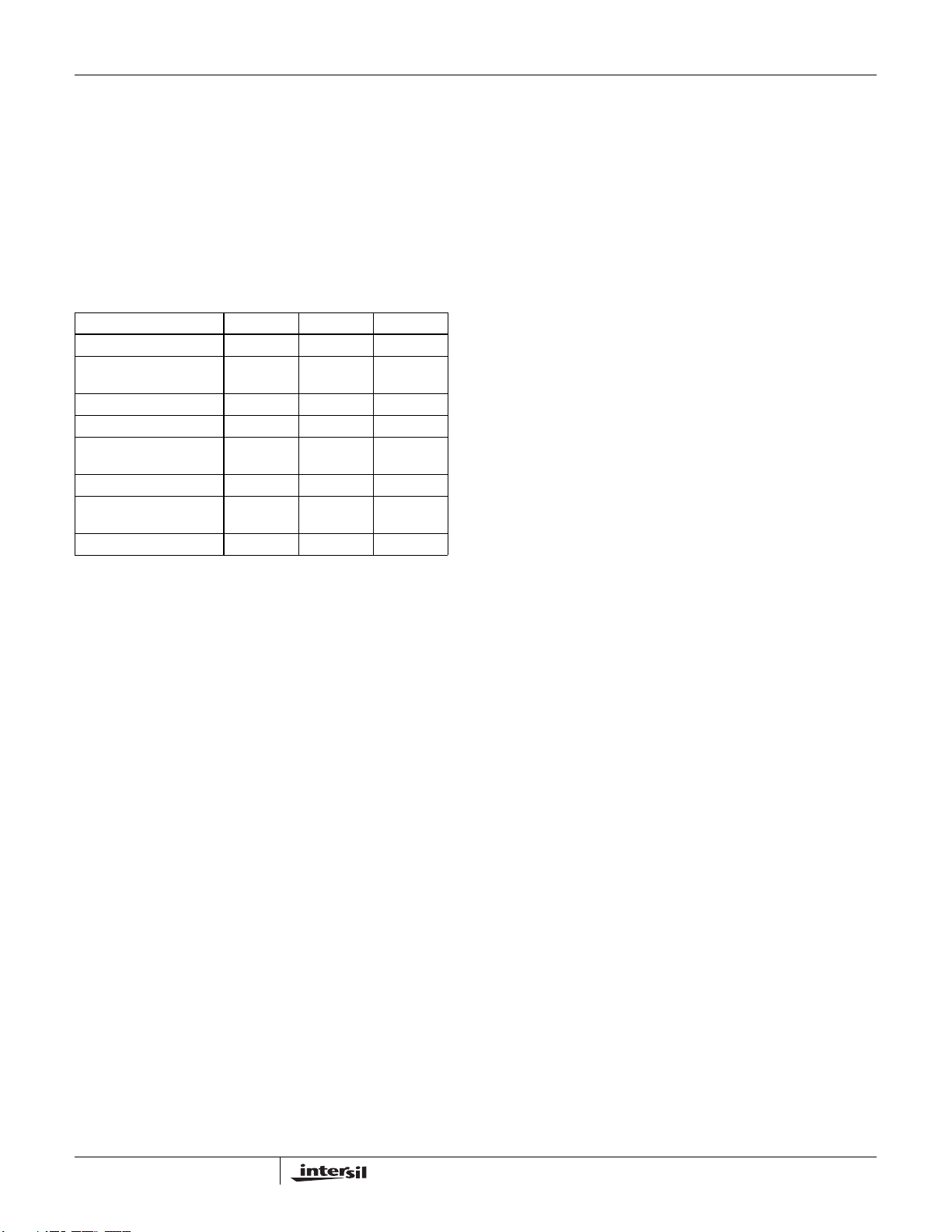

TABLE 2. CELLULAR BASESTATION APPLICATIONS USING

CHANNEL BW (kHz) 200 200 30

# TRAFFIC CHANNELS 8 16 3

VOICE MODULATION GMSK GMSK

CHANNEL RATE (Kbps) 270.8 270.8 48.6

CHANNEL RATE (Kbps) 270.8 270.8 48.6

Several applications are combinations of frequency and time

domai

TDMA signal that is frequency hopped. The individual

channels contain Gaussian MSK modulated signals. The

PDC again offers the 0.012Hz tuning resolution for dehopping the received signal. The combination of halfband

and 256-tap programmable, 22-bit coefficient FIR filters

readily performs the necessary matched filtering for

demodulation and optimum detection of the GMSK signals.

TDMA

STANDARD GSM PCN IS-54

TYPE Cellular Cellular Cellular

BASESTATION RX

BAN

D (MHz)

CONTROL

MODULATION

n multiple access schemes. For example, GSM is a

935-960 1805-1880 824-849

π/4

DQPSK

GMSK GMSK

π/4

DQPSK

CDMA Based Standards and Applications

For Code Division Multiple Access (CDMA) type signals, the

PDC offers the ability to have a single wideband RF front

end, from which it can select a single spread channel of

interest. The synchronization circuitry provides for easy

control of multiple PDC for applications where multiple

received signals are required, such as base-stations.

In IS-95 CDMA, the receive signal bandwidth is

app

roximately 1.2288MHz wide with many spread spectrum

channel in the band. The PDC supplies the downconversion

and filtering required to receive a single RF channel in the

presence of strong adjacent interference. Multiple PDC’s

would be sourced from a single receive RF chain, each

processing a different receive frequency channel. The

despreader would usually follow the PDC. In some very

specific applications, with short, fixed codes, the filtering and

despreading may be possible with innovative use of the

programmable, 22-bit coefficient FIR filter. The PDC offers

0.012Hz resolution on tuning to the desired receive channel

and excellent rejection of the portions of the band not being

processed, via the halfband and 255-tap programmable, 22bit coefficient FIR filter.

Traditional Modulation Formats

AM, ASK, FM AND FSK

The PDC has the capability to fully demodulate AM and FM

lated waveforms. The PDC outputs 15-bits of amplitude

modu

or 16-bits of frequency for these modulation formats. The FM

discriminator has a 63-tap programmable, 22-bit coefficient FIR

filter for additional signal conditioning of the FM signal. Digital

versions of these formats, ASK and FSK are also readily

processed using the PDC. Just as in the AM modulated case,

ASK signals will use 15-bit magnitude output of the Cartesian to

Polar Coordinate converter. Multi-tone FSK can be processed

several ways. The frequency information out of the

discriminator can be used to identify the received tone, or the

filter can be used to identify and power detect a specific tone of

the received signal. AMPS is an example of an FM application.

PM AND PSK

The PDC provides the downcon

matched filtering and coordinate conversion required for

demodulation of PM and PSK modulated waveforms. These

modulation formats will require external carrier and symbol

timing recovery loop filters to complete the receiver design.

The PDC was designed to interface with the HSP50210

Digital Costas Loop to implement the carrier phase and

symbol timing recovery loop filters (for continuous PSK

signals-not burst).

Digital modulation formats that combine amplitude and

ph

ase for symbol mapping, such as m-ary QAM, can also be

downconverted, demodulated, and matched filtered. The

received symbol information is provided with 16-bits of

resolution in either Cartesian or Polar coordinates to

facilitate remapping into bits and to recover the carrier

phase. External Symbol mapping and Carrier Recovery

Loop Filtering is required for this waveform.

version, demodulation,

Resampling and Interpolation Filters

Two key features of the resampling FIR filter are that the resampler filter allows the output sample rate to be

programmed with millihertz resolution and that the output

sample rate can be phase locked to an independent

separate clock. The re-sampler frees the front end sampling

clocks from having to be synchronous or integrally related in

rate to the baseband output. The asynchronous relationship

between front end and back end clocks is critical in

applications where ISDN interfaces drive the baseband

interfaces, but the channel sample rates are not related in

any way. The interpolation halfband filters can increase the

rate of the output when narrow frequency bands are being

processed. The increase in output rate allows maximum use

of the programmable FIR while preserving time resolution in

the baseband data.

8

FN4450.4

May 1, 2007

HSP50214B

www.BDTIC.com/Intersil

14-Bit Input and Processing Resolution

The PDC maintains a minimum of 14-bits of processing

resolution through to the output, providing over 84dB of

dynamic range. The 18-bits of resolution on the internal

references provide a spurious floor that is better than 98dBc.

Furthermore, the PDC provides up to 42dB of gain scaling to

compensate for any change in gain in the RF front end as

well as up to 96dB of gain in the internal PDC AGC. This

gain maximizes the output resolution for small signals and

compensates for changes in the RF front end gain, to handle

changes in the incoming signal.

Summary

The greatest feature of the PDC is its ability to be

reconfigured to process many common standards in the

communications industry. Thus, a single hardware element

can receive and process a wide variety of signals from PCS

to traditional cellular, from wireless local loop to SATCOM.

The high resolution frequency tuning and narrowband

filtering are instrumental in almost all of the applications.

Multiple Chip Synchronization

Multiple PDCs are synchronized using a MASTER/SLAVE

configuration. One part is responsible for synchronizing the

front end internal circuitry using CLKIN while another part is

responsible for synchronizing the backend internal circuitry

using PROCCLK.

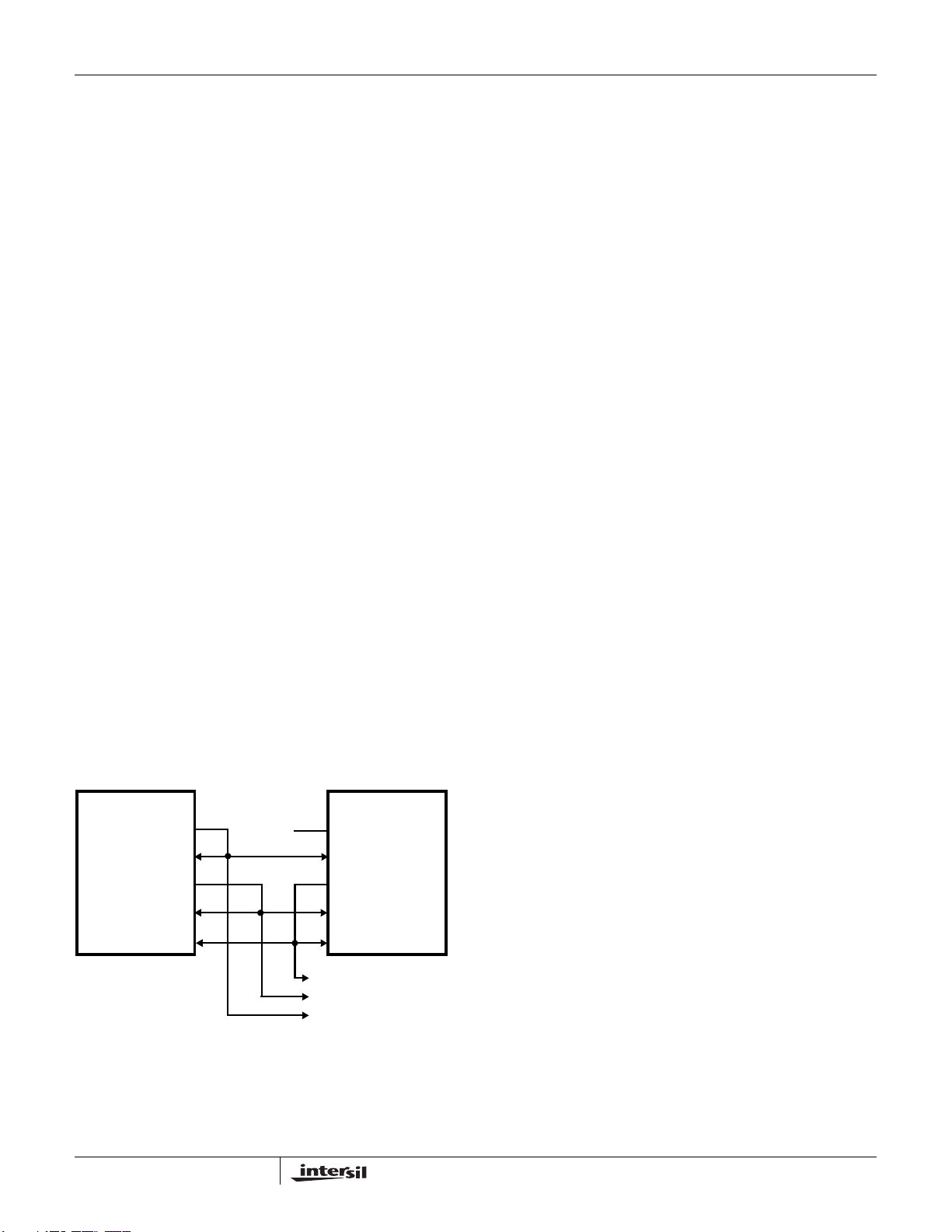

The PDC is synchronized with other PDCs using

lines: SYNCOUT, SYNCIN1, SYNCIN2, MSYNCO, and

MSYNCI. Figure 2 shows the interconnection of these five

signals for multiple chip synchronization where different

sources are used

PDC A is the Master sync through MSO.

PDC B configures the CLKIN sync through SYNCIN1.

PDC A configures the PROCCLK sync through SYNCIN2.

HSP50214B

(MASTER

SYNCIN2)

for CLKIN and PROCCLK.

AB

MSYNCO

MSYNCI

SYNCOUT

SYNCIN2

SYNCIN1

ALL OTHER SYNCIN1

ALL OTHER SYNCIN2

ALL OTHER MSI

FIGURE 2. SYNCHRONIZATION CIRCUIT

SYNCOUT for PDC B should be set to be synchronous with

C

LKIN (Control Word 0, Bit 3 = 0. See the Microprocessor

Write Section). SYNCOUT for PDC B is tied to the SYNCIN1

of all the PDCs. The SYNCIN1 can be programmed so that

five control

HSP50214B

MSYNCO

MSYNCI

SYNCOUT

SYNCIN2

SYNCIN1

(MASTER

SYNCIN1)

the carrier NCO and/or the 5th order CIC filter of all PDCs can

be synchronously loaded / updated using SYNCIN1. See

Co

ntrol Word 0, Bits 19 and 20 in the Microprocessor W ri te

Section for details.

SYNCOUT for one of the PDC’s other than PDC B, should

be

set for PROCCLK (bit 3 = 1 in Control Word 0). This

output signal is tied to the SYNCIN2 of all PDCs. The

SYNCIN2 can be programmed so that the AGC updates its

accumulator with the content s in the master registers

(Control Word 8, Bit 29 in the Microprocessor Write Section).

SYNCIN2 is also used to load or reset the timing NCO using

bit 5, Control Word 11. The halfband and FIR filters can be

reset on SYNCIN2 using Control Word 7, Bit 21. The

MSYNCO of one of the PDCs is then used to drive the

MSYNCI of all the PDCs (including its own).

For application configuration

s where CLKIN and PROCCLK

have the same source, SYNCIN1 and SYNCIN2 can be tied

together. However, if different enabling is desired for the

front end and backend processing of the PDC’s, these

signals can still be controlled independently.

In the HSP50214B, the Control Word 25 reset signal has

be

en extended so that the front end reset is 10 CLKIN

periods wide and the back end reset is 10 PROCCLK

periods wide. This guarantees that no enables will be caught

in the pipelines. In addition, the SYNCIN1 internal reset

signal, which is enabled by setting Control Word 7,

Bit 21 = 1, has been extended to 10 cycles.

In summary, SYNCIN1 is used to update carrier phase

of

fset, update carrier center frequency, reset CIC decimation

counters and reset the carrier NCO (clear the feedback in

the NCO). SYNCIN2 is used to reset the HB filter, FIR filter,

re-sampler / HB state machines and the output FIFO, load a

ne

w gain into the AGC and load a new re-sampler NCO

center frequency and phase offset.

Input Section

The block diagram of the input controller is provided in

Figure 3. The input can support offset binary or two’s

complement data and can be o

interpolated mode (see Control Word 0 from the

Microprocessor Write Section). The gated mode takes one

sample per clock when the input enable (ENI) is asserted.

The gated mode allows the user to synchronize a low speed

sampling clock to a high speed CLKIN.

The interpolated mode allows the user

sample rate and to zero-stuff the data prior to filtering. This

zero stuffing effectively interpolates the input signal up to the

rate of the input clock (CLKIN). This interpolated mode

allows the part to be used at rates where the sampling

frequency is above the maximum input rate range of the

halfband filter section, and where the desired output

bandwidth is too wide to use a Cascaded Integrator Comb

(CIC) filter without significantly reducing the dynamic range.

perated in gated or

to input data at a low

9

FN4450.4

May 1, 2007

HSP50214B

www.BDTIC.com/Intersil

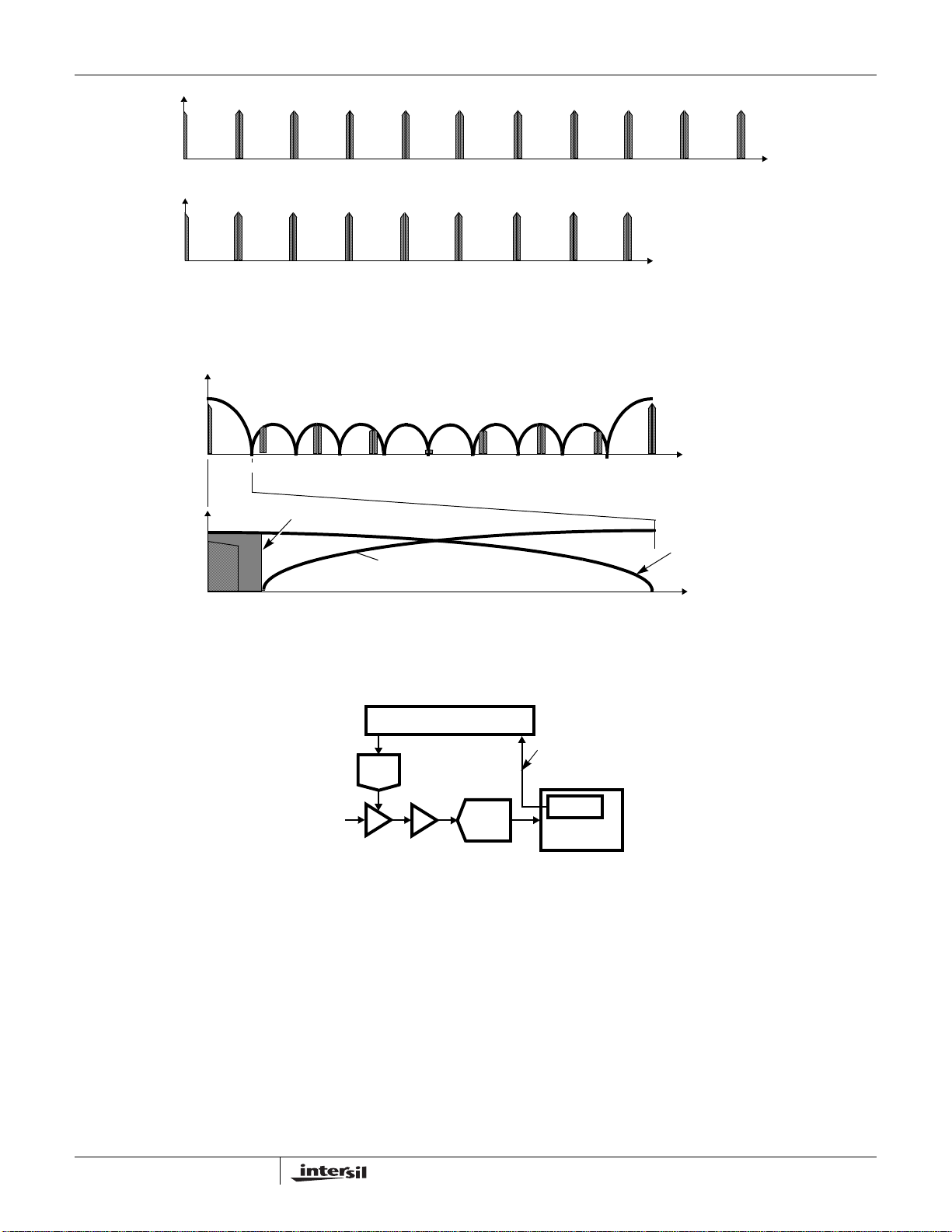

See Figures 4 to 7 for an interpolated input example,

detailing the associated spectral results.

Interpolation Example:

The specifications for the interpolated input example are:

CLKIN = 40MHz

Input Sample Rate = 5MSPS

PROCCLK = 28MHz

Interpolate by 8, Decimate by 10

Desired 85dB dynamic range output bandwidth = 500kHz

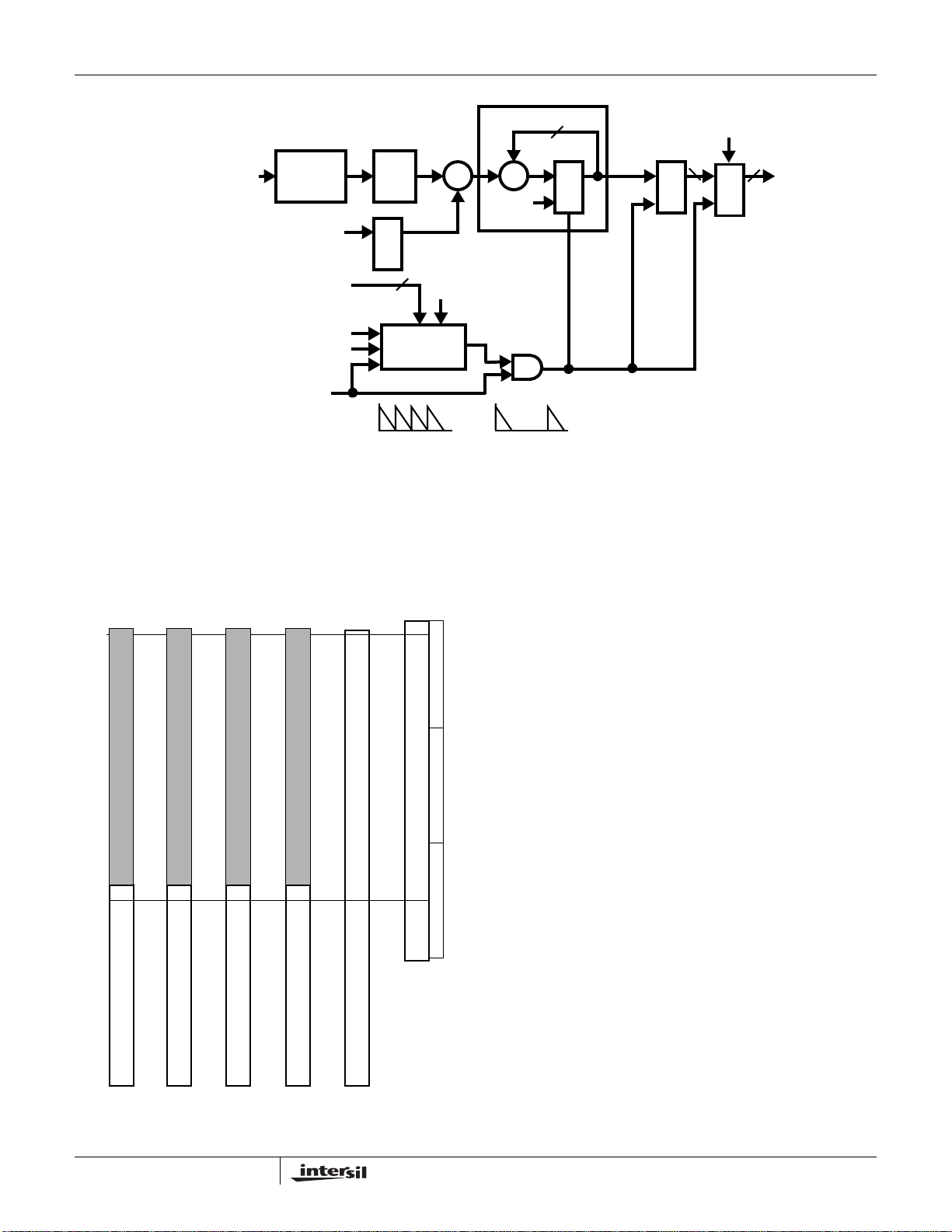

Input Level Detector

The Input Level Detector Section measures the average

magnitude error at the PDC input for the microprocessor by

comparing the input level against a programmable

threshold and then integrating the result. It is intended to

provide a gain error for use in an AGC loop with either the

RF/IF or A/D converter stages (see Figure 8). The AGC

loop includes Input Level Detector

an external gain control amplifier (or attenuator). The input

samples are rectified and added to a threshold

IN(13:0)

INPUT FORMAT

INPUT

FORMAT

†

GAINADJ(2:0)

, the microprocessor and

LEVEL

DETECT

REG

REG

INPUT LEVEL DETECTOR †

STATUS (0)

14

14

18

NCO††

EN

programmed via the microprocessor interface, as shown in

Figure 9. The bit weighting of the data path through the

input threshold detector is shown in Figure 10. The

threshold is a signed number, so it should be set to the

inverse of the de

to zero if the average input level is desired instead of the

error. The sum of the threshold and the absolute value of

the input is accumulated in a 32-bit accumulator. The

accumulator can handle up to 2

overflow. The integration time is controlled by an 18-bit

counter. The integration counter preload (ICPrel) is

programmed via the microprocessor interface through

Control Word 1. Only the upper 16-bits are programmable.

The 2 LSBs are always zero. Control Word 1, Bits 29-14

are programmed to:

ICPrel N()41+⁄=

where N is the desired integration period, defined as the

nu

mber of input samples to be integrated. N must be a

multiple of 4: [0, 4, 8, 12, 16 .... , 2

†

INPUT_THRESH †

INTG_MODE †

INTG_INTEVAL

15

REGREG

15

18

LIMIT

DELA Y 3

3

sired input level. The threshold can be set

18

samples without

(EQ. 1)

18

].

†

MUX

SHIFT

4

BYPASS †

CIC

∑

ENI

INTERP †

CONTROL WORD 0

CONTROL WORD 1

CLKIN

BYPASS

5MHz

CLKIN = 5MHz

Without Interpolation, the CIC bypass path exceeds the HB/FIR filter

inp

ut sample rate and the CIC filter path will not yield the desired

85dB dynamic range band width of 500kHz.

CIC

FILTER

MIN. R = 4

FIGURE 4. STATEMENT OF THE PROBLEM

PROCCLK = 28MHz

HB/FIR FILTER

MUX

MAX. fS = 4MHz

(EXCEEDED IN

BYPASS PATH)

CONTROL

LOGIC

FIGURE 3. BLOCK DIAGRAM OF THE INPUT SECTION

500kHz = 85dB

BANDWIDTH

(NOT ACHIEVED

WITH CIC FILTER

PATH)

INPUT_MODE †

INPUT_FMT †

INPUT_THRESH†

INTG_MODE†

INTG_INTEVAL†

DELA Y 3

4

†† See NCO Section for more details.

↑8 (0 STUFF) = 40MHz

5MHz

CLKIN = 40MHz

FIGURE 5. BLOCK DIAGRAM OF THE INTERPOLATION

CIC FILTER

10

† Controlled via microprocessor interface.

4MHz

R = ↓10

APPROACH

HB/FIR FILTER

500kHz = 85dB

BANDWIDTH

FN4450.4

May 1, 2007

HSP50214B

www.BDTIC.com/Intersil

f

S

5MHz 10MHz 15MHz 20MHz 25MHz 30MHz 35MHz 40MHz 45MHz 50MHz

5MHz 10MHz 15MHz 20MHz 25MHz 30MHz 35MHz 40MHz

2f

3f

S

THE INPUT DATA SPECTRUM SAMPLED AT RATE R = f

4f

S

5f

S

S

6f

S

7f

8f

S

S

f’S f’S/2 f’S/4 f’S/8 3f’S/8 5f’S/8 7f’S/8 3f’S/4

9f

S

10f

S

S

FIGURE 6. INTERPOLATION SPECTRUM: INTERPOLATE BY 8 THE INPUT DATA WITH ZERO STUFFING; SAMPLE AT RATE R = f’s

8MHz 12MHz 16MHz 20MHz 24MHz 28MHz 32MHz 36MHz 40MHz

4MHz

DECIMATE BY 10 AND CIC FILTER; SAMPLE AT RATE R = f’s/10

85dB DYNAMIC RANGE BANDWIDTH

4MHz2MHz1MHz 3MHz

CIC FILTER

FREQUENCY

RESPONSE

CIC FILTER ALIAS PROFILE

O.5MHz

FIGURE 7. ALIAS PROFILE AND THE 85dB DYNAMIC RANGE BANDWIDTH

INPUT

μPROC

DAC

IF

GCA

A/D

INPUT LEVEL

DETECTOR (24-BIT

ERROR VALUE)

THRESH

PDC

FIGURE 8. PROCESSOR BASED EXTERNAL IF AGC

11

FN4450.4

May 1, 2007

HSP50214B

www.BDTIC.com/Intersil

INPUT

|X|

R

E

G

16

COUNTER

CONTINUOUS SINGLE

ACCUMULATOR

18

2

17

2

16

2

15

2

14

2

13

2

12

2

11

2

10

2

9

2

8

2

7

2

6

2

5

2

4

2

3

2

2

2

1

2

0

2

-1

2

-2

2

-3

2

-4

2

-5

2

-6

2

-7

2

-8

2

-9

2

-10

2

-11

2

-12

2

-13

2

μPROC READ

0

18

2

17

2

16

2

15

2

14

2

13

2

12

2

11

2

10

2

9

2

8

2

7

2

6

2

5

2

4

2

3

2

2

2

1

2

0

2

-1

2

-2

2

-3

2

-4

2

-6dB

-12dB

-18dB

-24dB

-30dB

-36dB

-42dB

-48dB

-54dB

-60dB

-66dB

-72dB

-78dB

IN(13:0)

INPUT_THRESHOLD †

INTEGRATION_INTERVAL†

INTEGRATION_MODE †

† Controlled via microprocessor interface.

A/D

OUTPUT

f

0

2

S

-1

2

-2

2

-3

2

-4

2

-5

2

-6

2

-7

2

-8

2

-9

2

-10

2

-11

2

-12

2

-13

2

INPUT

0

2

-1

2

-2

2

-3

2

-4

2

-5

2

-6

2

-7

2

-8

2

-9

2

-10

2

-11

2

-12

2

-13

2

0

2

2

2

2

2

2

2

2

2

2

2

2

2

MAGNITUDE

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

GATING

LOGIC

START †

CLKIN

THESHOLD

0

-2

-1

2

-2

2

-3

2

-4

2

-5

2

-6

2

-7

2

-8

2

-9

2

-10

2

-11

2

-12

2

-13

2

FIGURE 10. INPUT THRESHOLD DETECTOR BIT WEIGHTING

+ +

“0”

FIGURE 9.

READ CODE A(2:0)

PORTS

000 010001

ACCUMULATOR

32

CLKIN

R

E

G

R

E

G

ADDR(2:0)

24

M

U

X

TO

μPROC

8

The integration period counter can be set up to run

continuously or to count down and stop. Continuous integration

counter operation lets the counter run, with sampling occurring

every time the counter reaches zero. Because the processor

samples the detector read port asynchronous to the CLKIN,

data can be missed unless the status bit is monitored by the

processor to ensure that a sample is taken for every integration

count down sequence.

Additionally , in the HSP50214B, the ability to alig n the

st

art/restart of the input level detector integration period with

an external event is provided. This allows the sync signals,

which are synchronized to external events, to be used to align

all of the gain adjustments or measurements. If Control W ord

27, Bit 17 is set to a logic one, the SYNCIN1 signal will cau se

the input level detector to start/restart its integration peri od. If

Control Word 27, Bit 17 is set to a logic zero, control of the

start/restart of the input level detector integration period does

not respond to SYNCIN1.

In the count down and stop mode, the microprocessor read

command

s can be synchronized to system events, such as the

start of a burst for a TDMA application. The integration counter

can be started at any time by writing to Control Word 2. At the

end of the integration period (counter = 0000), the upper 23-bits

of the accumulator are transferred to a holding register for

reading by the microprocessor. Note that it is not the restarting

of the counter (by writing to Control Word 2) that latches the

current value, but the end of the integration count. When the

accumulator results are latched, a bit is set in the Status

Register to notify the processor. Reading the most significant

byte of the 23-bits clears the status bit. See the Microprocessor

Read Section. Figure 11 illustrates a typical AGC detection

process.

12

FN4450.4

May 1, 2007

HSP50214B

www.BDTIC.com/Intersil

Typically, the average input error is read from the Input Level

Detector port for use in AGC Applications. By setting the

threshold to 0, however, the average value of the input signal

can be read directly. The calculation is:

dBFS

RMS

20() 1.111()level()N()16()()⁄[]log=

(EQ. 2)

where “level” is the 24-bit value read from the 3 level

Detector Registers and

“N” is the number of samples to be

integrated. Note that to get the RMS value of a sinusoid,

multiply the average value of the rectified sinusoid by 1.111.

For a full scale input sinusoid, this yields an RMS value of

approximately 3dBf

NOTE: 1.111 scales the rectified sinusoid average (2/π) to 1/ √2

.

A) INPUT SIGNAL

AMPLITUDE

C) THRESHOLD

AMPLITUDE

E) DETECTOR OUTPUT

AMPLITUDE

FIGURE 11. SIGNAL PROCESSING WITHIN LEVEL DETECTOR

.

S

B) RECTIFIED SIGNAL

AMPLITUDEAMPLITUDE

D) ACCUMULATOR INPUTS

F) CLOSED LOOP STEADY STATE

(CONSTANT INPUT)

AMPLITUDE

In the HSP50214B, the polarity of the LSB’s of the

integration period pre-load is selectable. If Control Word 27,

Bit 23 is set to a logic one, the two LSB’s of the integration

period preload are set to logic ones. This allows a power of

two to be set for the integration period, for easy

normalization in the processor. If Control Word 27, Bit 23 is

set to a logic zero, then the two LSB’s of the integration

period preload are set to zeros as in the HSP50214.

Carrier Synthesizer/Mixer

The Carrier Synthesizer/Mixer Section of the HSP50214B is

shown in Figure 12. The NCO has a 32-bit phase

accumulator, a 10-bit phase offset adder, and a sine/cosine

ROM.

The frequency of the NCO is the sum of a center

frequency Control Word, loaded via the microprocessor

interface (Control Word 3, Bits 0 to 31), and an offset

frequency, loaded serially via the COF and COFSYNC pins.

The offset frequency can be zeroed in Control Word 0, Bit 1.

Both frequency control terms are 32-bits and the addition is

modulo 2

32

. The output frequency of the NCO is computed

as:

fCfS* N 232()⁄ ,=

(EQ. 3)

or in terms of the programmed value:

NINTf

C

232fS⁄×[]

HEX

, =

where N is the 32-bit sum of the

terms, f

is the frequency of the carrier NCO sinusoids, fS is

C

center and offset frequency

(EQ. 3A)

the input sampling frequency, and INT is the integer of the

computation. See the Microprocessor Write Section on

instructions for writing Control Word 3.

TO MIXERS

PHASE

ACCUMULATOR

ENI

18 18

REG

REG

SIN/COS

ROM

18

+

REG

SINCOS

CARRIER

PHASE

STROBE

†

R

R

10

E

G

MUX

CARRIER

E

PHASE

G

OFFSET

†

CLEAR

0

R

E

G

PHASE

ACCUM

†

+

COF

ENABLE†

COFSYNC

COF

SYNCIN1

MUX

32

COF

REG

SYNC REG

SHIFT REG

SYNC

CIRCUITRY

32

0

CF

REG

CARRIER

FREQUENCY

STROBE

CARRIER

FREQUENCY

(f

)

C

†

CARRIER

LOAD ON

UPDATE

†

† Controlled via microprocessor interface.

FIGURE 12. BLOCK DIAGRAM OF NCO SECTION

For example, if N is 3267 (decimal), and f

is 65MHz, then fC

S

is 49.44Hz. If received data is modulated at a carrier

frequency of 10MHz, then the synthesizer/mixer should be

programmed for N = 27627627 (hex) or D89D89D8 (hex).

Because the input enable, ENI, controls the operation of the

pha

se accumulator, the NCO output frequency is computed

relative to the input sample rate, f

, not to f

S

CLKIN

. The

frequency control, N, is interpreted as two’s complement

because the output of the NCO is quadrature. Negative

frequency L.O.s select the upper sideband; positive freq uency

L.O.s select the lower sideband. The range of the NCO is

-f

/2 to +fS /2. The frequency resolution of the NCO is fS /(232)

S

or approximately 0.015Hz when CLKIN is 65MSPS and ENI is

tied low.

†

13

FN4450.4

May 1, 2007

HSP50214B

www.BDTIC.com/Intersil

The phase of the Carrier NCO can be shifted by adding a 10bit phase offset to the MSB’s (modulo 360o) of the output of

th

e phase accumulator. This phase offset control has a

resolution of 0.35

complement from -180

o

to 360

φ

(0 to 2π). The phase offset is given by:

2π PO 210⁄()× 29()PO 291–()≤≤–();=

OFF

o

and can be interpreted as two’s

o

to 180o (-π to π) or as binary from 0

512 to 511–()

(EQ. 4)

or, in terms of the parameter to be programmed:

PO INT 2

10

φ

()2π⁄]

OFF

HEX

π– φ

OFF

π<<();[=

(EQ. 4A)

where PO is the 10-bit two’s complement value loaded into the

Phase Offset Register (Control Word 4, Bits 9-0). For example,

a value of 32 (decimal) loaded into the Phase Offset Register

would produce a phase offset of 1 1.25

would produce an offset of 180

o

o

. The phase offset is loaded via

and a value of -512

the microprocessor interface. See the Microprocessor Write

Section on instructions for writing Control Word 4.

The most significant 18-bits from th

e phase adder are used

as the address a sin/cos lookup table. This lookup table

maps phase into sinusoidal amplitude. The sine and cosine

values have 18-bits of amplitude resolution. The spurious

components in the sine/cosine generation are at least

-102dBc. The sine and cosine samples are routed to the

mixer section where they are multiplied with the input

samples to translate the signal of interest to baseband.

The mixer multiplies the 14-bit i

nput by the 18-bit quadrature

sinusoids. The mixer equations are:

I

OUTIIN

Q

OUTIIN

ωc()cos×=

ωc()sin×=

(EQ. 5)

(EQ. 5A)

The mixer output is rounded symmetrically to 15-bits.

To allow the frequency and phase of multiple parts to be

ated synchronously, two set s of registers are used for

upd

latching the center frequency and phase offset words. The

offset phase and center frequency Control Words are first

loaded into holding registers. The contents of the holding

registers are transferred to active registers in one of two ways.

The first technique involves writing to a specific Control Word

Address. A processor write to Control Word 5, transfers the

center frequency value to the active register while a processor

write to Control Word 6 transfers the phase offset value to the

active register.

The second technique, designed for synchronizing updates to

multipl

e parts, uses the SYNCIN1 pin to update the active

registers. When Control Word 1, Bit 20 is set to 1, the SYNCIN1

pin causes both the center frequency and Phase Offset Holding

Registers to be transferred to active registers. Additionally,

when Control Word 0, Bit 0 is set to 1, the feedback in the

phase accumulator is zeroed when the transfer from the

holding to active register occurs. This feature provides

synchronization of the phase accumulator starting phase of

multiple parts. It can also be used to reset the phase of the

NCO synchronous with a specific event.

The carrier offset frequency is loaded using the COF and

COFSYN

C pins. Figure 13 details the timing relationship

between COF, COFSYNC and CLKIN. The offset frequency

wo

rd can be zeroed if it is not needed. Similarly, the

Sample Offset Frequency Register controlling the ReSampler NCO is loaded via the SOF and SOFSYNC pins.

The procedure for loading data through the two pin NCO

interfaces is identical except that the timing of SOF and

SOFSYNC is relative to PROCCLK.

CLKIN

COFSYNC/

SOFSYNC

COF/

SOF

NOTE: Data must be loaded MSB first.

FIGURE 13. SERIAL INPUT TIMING FOR COF AND SOF INPUTS

MSB

LSB

MSB

Each serial word has a programmable word width of either 8,

16

, 24, or 32-bits (See Control Word 0, Bits 4 and 5, for the

Carrier NCO programming and Control Word 11, Bits 3 and

4, for Timing NCO programming). On the rising edge of the

clock, data on COF or SOF is clocked into an input shift

register. The beginning of a serial word is designated by

asserting either COFSYNC or SOFSYNC “high” one CLK

period prior to the first data bit.

32†

30

28

26

†

24

22

20

18

†

16

14

12

10

†

8

6

SHIFT COUNTER VALUE

4

2

0

ASSERTION OF

COFSYNC, SOFSYNC

DATA TRANSFERRED

TO HOLDING REGISTER

(8)

(24)

(16)

CLK TIMES

(32)

54504642383430262218141062

T

††

D

T

††

D

T

††

D

T

††

D

† Serial word width can be: 8, 16, 24, 32 bits wide.

†† T

is determined by the COFSYNC, COFSYNC rate.

D

FIGURE 14. HOLDING REGISTERS LOAD SEQUENCE FOR

COF AND SOF SERIAL OFFSET FREQUENCY

DATA

NOTE: Serial Data must be loaded MSB first, and COFSYNC or

SOFSYNC should not be asserted for more than one

CLK cycle.

14

FN4450.4

May 1, 2007

HSP50214B

www.BDTIC.com/Intersil

NOTE: COF loading and timing is relative to CLKIN while SOF

loading and timing is relative to PROCCLK.

NOTE: T

can be 0, and the fastest rate is with 8-bit word width.

D

The assertion of the COFSYNC (or SOFSYNC) starts a count

down from the programmed word width. On following CLKs,

data is shifted into the register until the specified number of

bits have been input. At this point the contents of the register

are transferred from the Shift Register to the respecti ve 32-bit

Holding Register. The Shift Register can accept new data on

the following CLK. If the serial input word is defined to be less

than 32-bits, it will be transferred to the MSBs of the 32-bit

Holding Register and the LSBs of the Holding Register will be

zeroed. See Figure 14 for details.

CIC Decimation Filter

The mixer output may be filtered with the CIC filter or it may

be routed directly to the halfband filters. The CIC filter is use d

to reduce the sample rate of a wideband signal to a rate that

the halfbands and programmable filters can process, given

the maximum computation speed of PROCCLK. (See

Halfband and FIR Filter Sections for techniques to calculate

this value).

Prior to the CIC filter, the output of the

barrel shifter. The shifter is used to adjust the gain in 6dB

steps to compensate for the variation in CIC filter gain with

decimation. (See Equation 6). Fine gain adjustments must

be done in the AGC Section. The shifter is controlled by the

sum

of a 4-bit CIC Shift Gain word from the microprocessor

and a 3-bit gain word from the GAINADJ(2:0) pins. The three

bit value is pipelined to match the delay of the input samples.

The sum of the 3 and 4-bit shift gain words saturates at a

value of 15. Table 1 details the permissible values for the

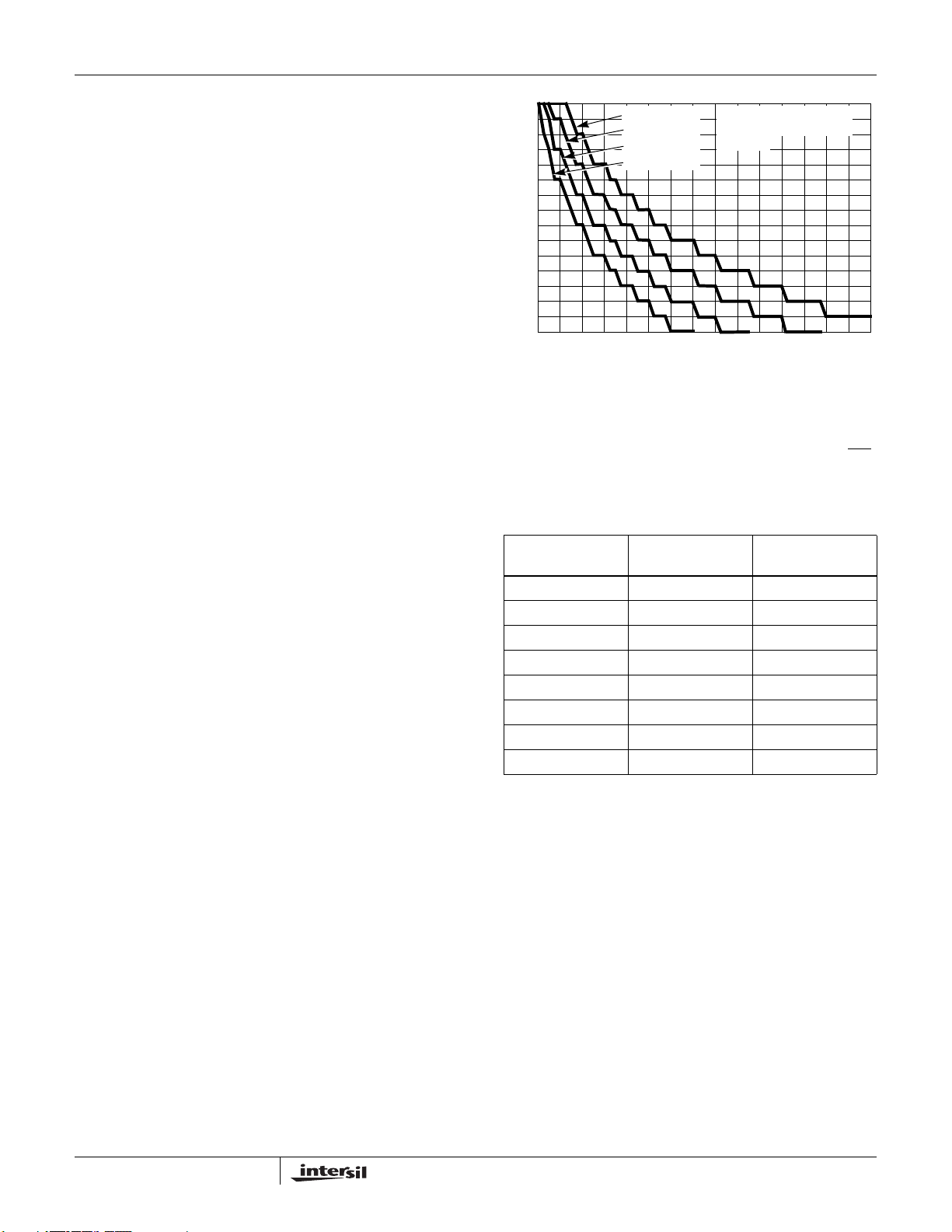

GAINADJ(2:0) barrel shifter control, while Figure 15 shows

the permissible CIC Shift Gain values.

The CIC filter structure for the HSP50214B is fifth order; that

is it ha

s five integrator/comb pairs. A fifth order CIC has

84dB of alias attenuation for output frequencies below 1/8

the CIC output sample rate.

mixer goes through a

15

14

13

12

11

10

9

8

7

6

5

4

3

2

CIC SHIFT GAIN (FROM PROCESSOR)

1

0

812202836445260

FIGURE 15. CIC SHIFT GAIN VALUES

The decimation factor of the CIC

8-BIT INPUT

10-BIT INPUT

12-BIT INPUT

14-BIT INPUT

164403224 645648

DECIMATION (R)

ALLOWABLE CIC SHIFT

GAINS ARE BELOW THE

CURVES

filter is programmed in

Control Word 0, Bits 12 - 7. The C IC Shift Gain is programmed

in Control Word 0, Bits 16-13. The CIC Bypass is set in

Control Word 0, Bit 6. When bypassing the CIC filter, the

ENI

signal must be de-asserted between samples, i.e., the CL KIN

rate must be ≥ 2 • f

TABLE 3. GAIN ADJUST CONTROL AND CIC DECIMATION

VALUE

ΔGAIN

(dB) GAIN ADJ(2:0)

0 000 32

6 001 27

12 010 24

18 011 21

24 100 18

30 101 16

36 110 12

42 111 10

.

S

MAX. CIC

DECIMATION

CIC Gain Calculations

The gain through the CIC filter increases with increased

decimation. The programmable barrel shifter that precedes

the first integrator in the CIC is used to offset this variation.

Gain variations due to decimation should be offset using the

4-bit CIC Shift Gain word. This allows the input signal level to

be adjusted in 6dB steps to control the CIC output level.

The gain at each stage of the CIC is:

kRN,=

where R is the decimation factor and N is the number of stages.

Th

e input to the CIC from the mixer is 15-bits, and the bit widths

of the accumulators for the five stages in the HSP50214B are

40, 36, 32, 32, and 32, as shown in Figure 16. This limits the

maximum decimation in the CIC to 32 for a full scale input.

If R is 32, the gain through all five integrator stages is 32

(The gain through the last four CIC stages is 2

15

20

, through the

May 1, 2007

(EQ. 6)

5

= 225.

FN4450.4

HSP50214B

www.BDTIC.com/Intersil

last 3 it is 215, etc.). The sum of the input bits and the growth

bits cannot exceed the accumulator size. This means that for a

decimation of 32 and 15 input bits, the first accumulator must

be 15 + 25 = 40-bits.

Thus, the value of the CIC Shift Gain word can be

calcul

ated:

SG = FLOOR 39 - [ IIN() - log

NOTE: The number of input bits is IIN. (If the number of bits into

the CIC filter is used, the value 40 replaces 39).

(R)5 for 4<R<32

2

for R = 4= 15

(EQ. 7)

For 14-bits, Equation 7 becomes:

SG FLOOR 25 log

15= for R 4=

R()5]for 4 R 32<<–[=

2

(EQ. 8A)

For 12-bits, Equation 7 becomes:

SG FLOOR 27 log

15= for 4 R 5≤≤

R()5]for 5 < R < 40–[=

2

(EQ. 8B)

For 10-bits, Equation 7 becomes:

SG FLOOR 29 log

R()5]for 6 < R < 52–[=

2

for 4 R 6≤≤15=

(EQ. 8C)

The CIC filter decimation counte

r can be loaded synchronous

with other PDC chips, using the SYNCIN1 signal and the CIC

External Sync Enable bit. The CIC external Sync Enable is set

via Control Word 0, Bit 19.

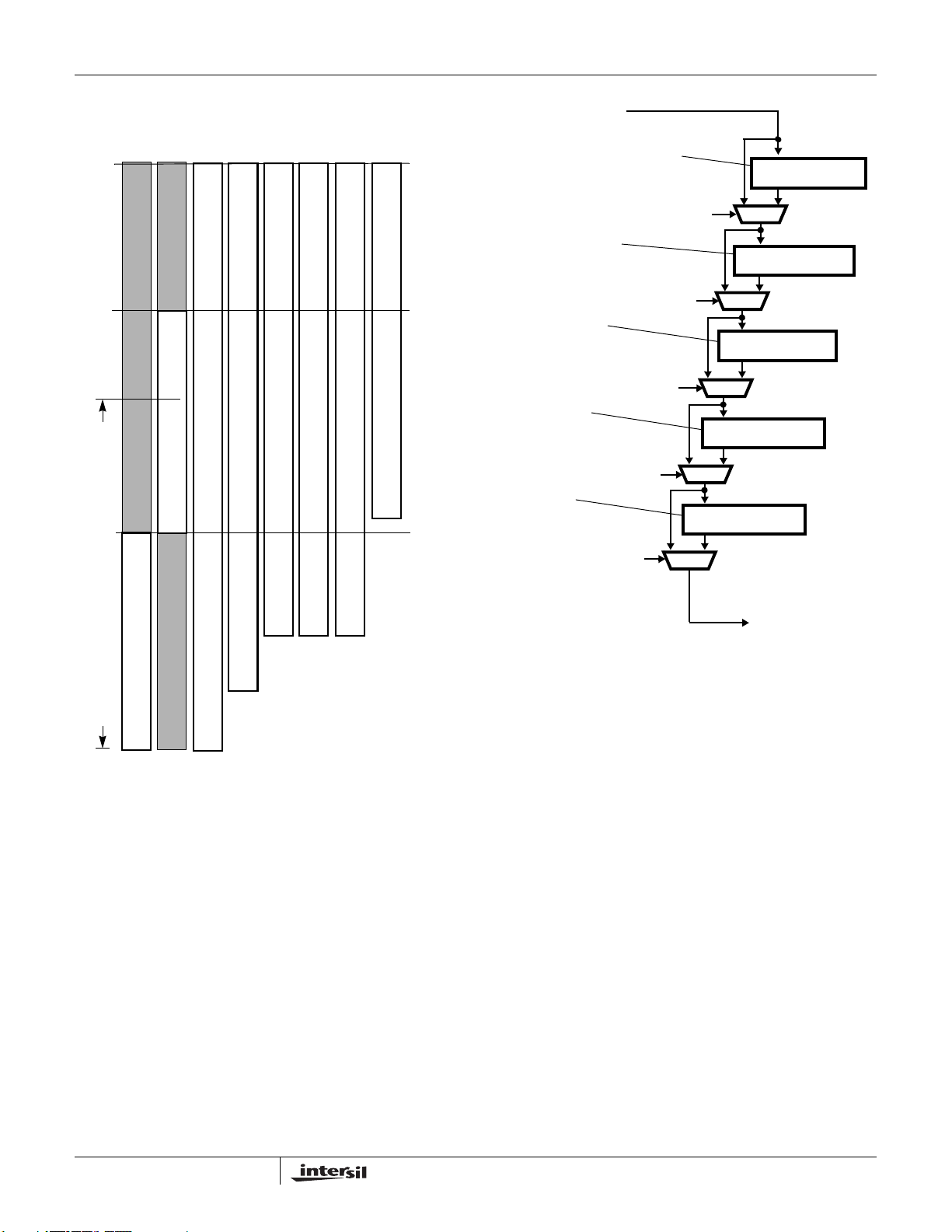

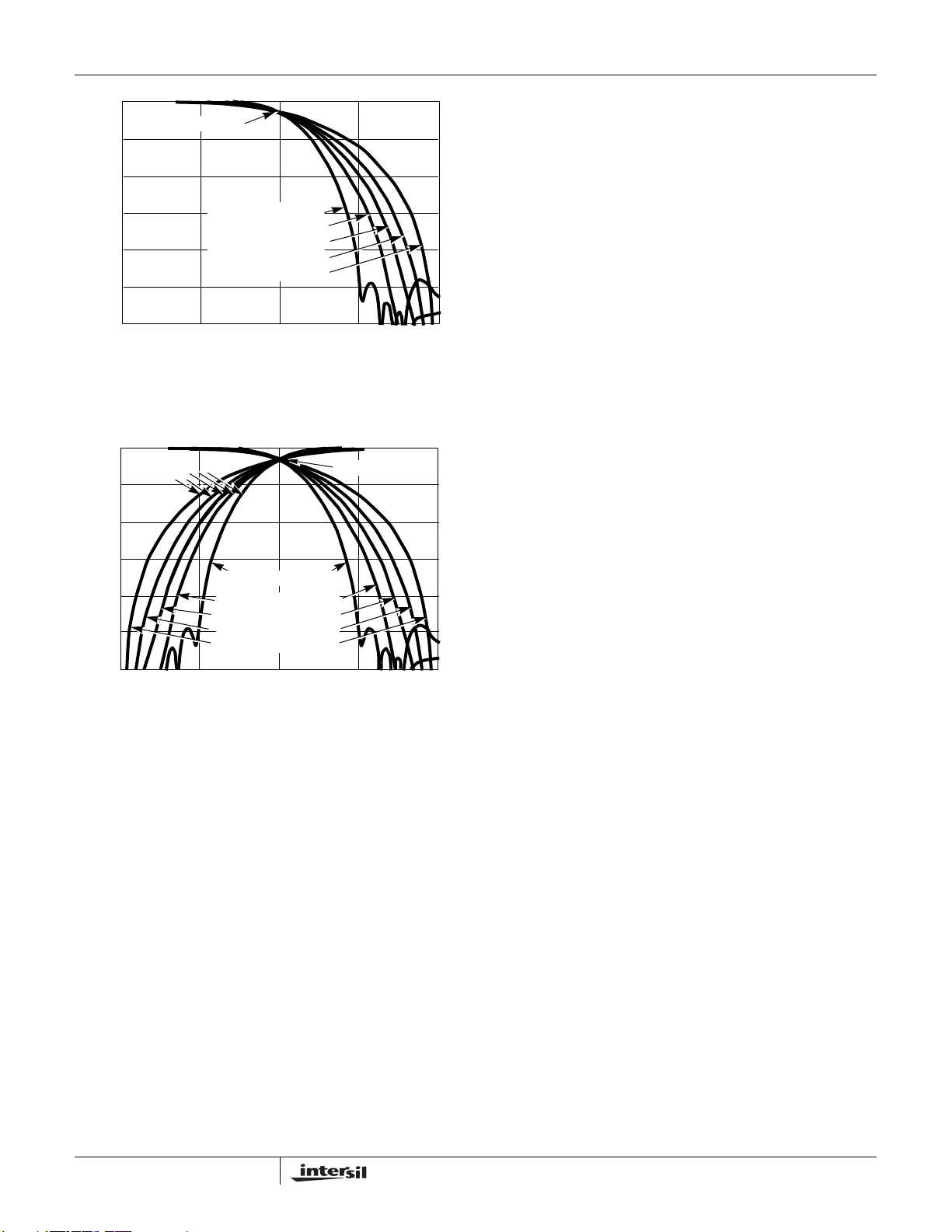

Halfband Decimating Filters

The Programmable Down Converter has five halfband filter

stages, as shown in Figure 17. Each stage decimates by 2

and filters out half of the available bandwidth. The first

ha

lfband, or HB1, has 7 taps. The remaining halfbands;

HB2, HB3, HB4, and HB5; have 11, 15, 19, and 23 taps

respectively. The coefficients for these halfbands are given

in Table 4. Figure 18 shows the frequency response of each

of the halfband filters with respect to normalized frequency,

F

. Frequency normalization is with respect to the input

N

sampling frequency of each filter section. Each stage is

activated by their respective bit location (15-20) in Control

Word 7. Any combination of halfband filters may be used, or

all may be bypassed.

For 8-bits, Equation 7 becomes:

SG FLOOR 31 log

15= for 4 R 9≤≤

Figure 15 is a plot of Equations 8A throug

R()5]for 9 < R < 64–[=

2

(EQ. 8D)

h 8D. The 4-bit CIC

Shift Gain word has a range from 0 to 15. The 6-bit

Decimatio

n Factor counter preload field, (R-1), has a range

from 0 to 63, limited by the input resolution as cited above.

Using the Input Gain Adjust Control Signals

The input gain offset control GAINADJ(2:0)) is provided to

offset the signal gain through the part, i.e., to keep the CIC

filter output level constant as the analog front end

attenuation is changed. The gain adjust offset is 6dB per

code, so the gain adjust range is 0 to 42dB. For example, if

12dB of attenuation is switched in at the receiver RF front

end, a code of 2 would increase the gain at the input to the

CIC filter up 12dB so that the CIC filter output would not drop

by 12dB. This fixed gain adjust eliminates the need for the

software to continually normalize.

One must exercise care when using this function as it can

cause ove

shifter from the gain adjust control signals is the equivalent

of an extra bit of input. The maximum decimation in the CIC

is reduced accordingly. With a decimation of 32, all 40-bits of

the CIC are needed, so no input offset gain is allowed. As

the decimation is reduced, the allowable offset gain

increases. Table 3 shows the decimation range versus

desired offset gain range. T able 3 assumes that the CIC Shift

Gain has been programmed per Equation 7 or 8A.

rflow in the CIC filter. Each gain adjust in the

16

FN4450.4

May 1, 2007

OUTPUT SHIFTER BITS TAKEN WHEN CIC IS BYPASSED

-

www.BDTIC.com/Intersil

HSP50214B

HALFBAND

FILTER INPUT

f

= fS

1

F

HB1

= F

HB2

OR F

HB4

IN

= fS OR fS/2

OR F

HB1

†

OR F

HB2

†

/2

HB3

†

/2

HB1

/2

†

†

/2

= F

HB1

HB2

SECTION

FN = f

S

HALFBAND FILTER 4

0

HALFBAND FILTER 5

0

1

F

= F

5

HALFBAND FILTER 1

0

HALFBAND FILTER 2

0

1

F

HB2

HALFBAND FILTER 3

0

1

F

= F

HB3

1

F

= F

HB4

HB3

OR F

HB4

HALFBAND

FILTER OUTPUT

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

-25

-26

-27

-28

-29

-30

-31

ACC5

CIC

OUTPUT

0

-1

2

-2

2

-3

2

-4

2

-5

2

-6

2

-7

2

-8

2

-9

2

-10

2

-11

2

-12

2

-13

2

-14

2

-15

2

-16

2

-17

2

-18

2

-19

2

-20

2

-21

2

-22

2

-23

2

CONTROL WORD 7, BIT 18

F

CONTROL WORD 7, BIT 15

F

N

CONTROL WORD 7, BIT 16

= F

F

N

CONTROL WORD 7, BIT 17

FN = F

HB3

= F

N

HB4

CONTROL WORD 7, BIT 19

† Each halfband section decimates by 2.

FIGURE 17. BLOCK DIAGRAM OF HALFBAND FILTER

INPUT

(SHFT=0)

(SHFT=15)

0

-1

2

-2

2

-3

2

-4

2

-5

2

-6

2

-7

2

-8

2

-9

2

-10

2

-11

2

-12

2

-13

2

-14

2

0

-1

2

-2

2

-3

2

-4

2

-5

2

-6

2

-7

2

-8

2

-9

2

-10

2

-11

2

-12

2

-13

2

-14

2

2

2

2

2

2

2

2

2

ACC2

ACC3

ACC4

0

0

0

0

-1

-1

2

-2

2

-3

2

-4

2

-5

2

-6

2

-7

2

-8

2

-9

2

-10

2

-11

2

-12

2

-13

2

-14

2

-15

2

-16

2

-17

2

-18

2

-19

2

-20

2

-21

2

-22

2

-23

2

-24

2

-25

2

-26

2

-27

2

-28

2

-29

2

-30

2

-31

2

-32

-33

-34

-35

-36

-37

-38

-39

-1

2

2

-2

-2

2

2

-3

-3

2

2

-4

-4

2

2

-5

-5

2

2

-6

-6

2

2

-7

-7

2

2

-8

-8

2

2

-9

-9

2

2

-10

-10

2

2

-11

-11

2

2

-12

-12

2

2

-13

-13

2

2

-14

-14

2

2

-15

-15

2

2

-16

-16

2

2

-17

-17

2

2

-18

-18

2

2

-19

-19

2

2

-20

-20

2

2

-21

-21

2

2

-22

-22

2

2

-23

-23

2

2

-24

-24

2

2

-25

-25

2

2

-26

-26

2

2

-27

-27

2

2

-28

-28

2

2

-29

-29

2

2

-30

-30

2

2

-31

-31

2

2

-32

2

-33

2

-34

2

-35

2

0

-1

2

2

-2

2

2

-3

2

2

-4

2

2

-5

2

2

-6

2

2

-7

2

2

-8

2

2

-9

2

2

-10

2

2

-11

2

2

-12

2

2

-13

2

2

-14

2

2

-15

2

2

-16

2

2

-17

2

2

-18

2

2

-19

2

2

-20

2

2

-21

2

2

-22

2

2

-23

2

2

-24

2

2

-25

2

2

-26

2

2

-27

2

2

-28

2

2

-29

2

2

-30

2

2

-31

2

2

ACC1

INPUT

NOTE: If 14 input bits are not needed, the gain adjust can be in

creased by one for each bit that the input is shifted down

at the input. For example, if only 12-bits are needed, an

offset range of 24dB is possible for a decimation of 24.

FIGURE 16. CIC FILTER BIT WEIGHTING

Since each halfband filter section decimates by 2, the total

decimation through the halfband filter is given by:

DECHB2N=

(EQ. 9)

where N = Number of Halfband Filters Selected (1 - 5).

17

FN4450.4

May 1, 2007

0

www.BDTIC.com/Intersil

-20

-40

HSP50214B

-6dB BANDWIDTH

-60

-80

MAGNITUDE (dB)

-100

-120

HALFBAND FILTER 5

HALFBAND FILTER 4

HALFBAND FILTER 3

HALFBAND FILTER 2

HALFBAND FILTER 1

0.125 0.25 0.375 0.5

NORMALIZED FREQUENCY (FN)

FIGURE 18. HALFBAND FILTER FREQUENCY RESPONSE

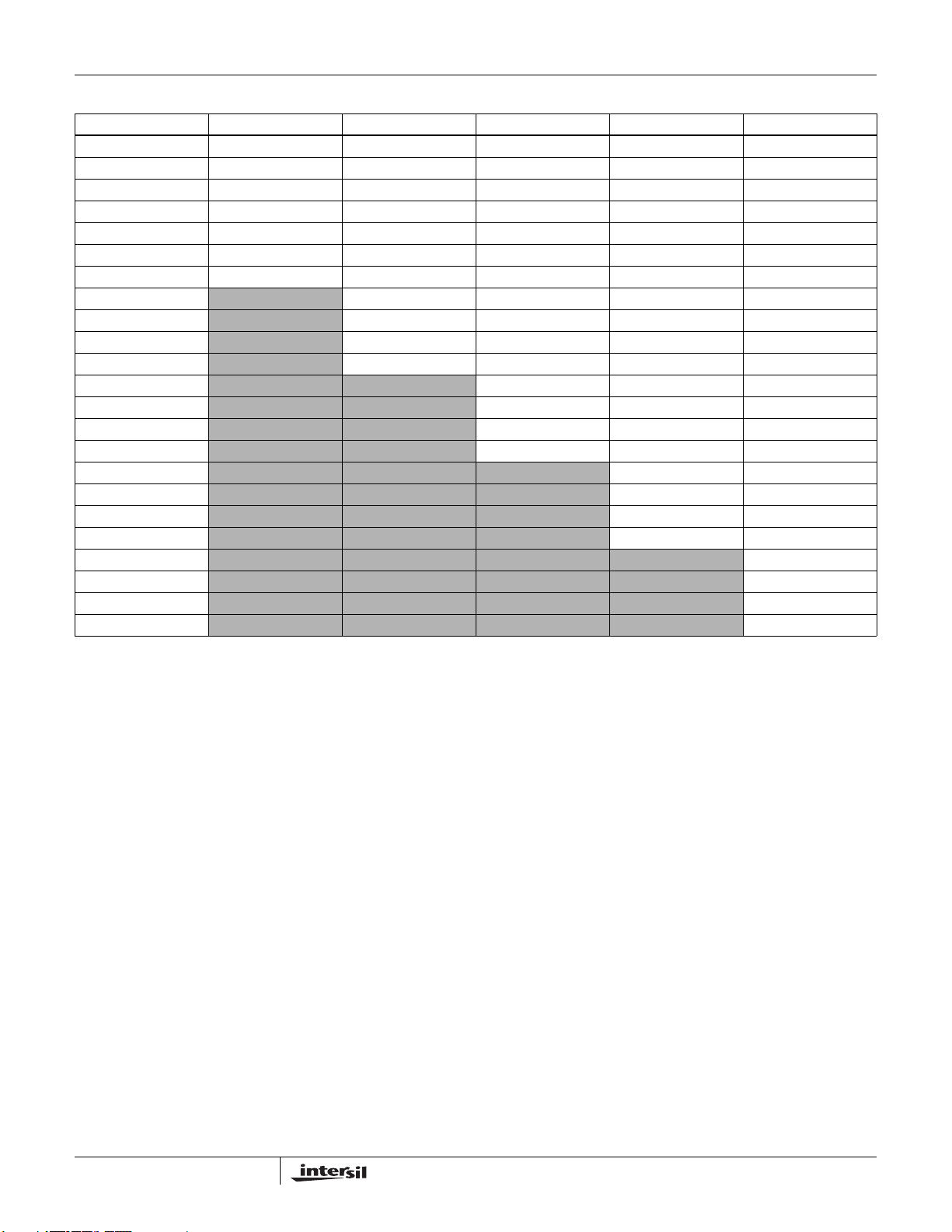

0

ALIAS

PROFILES

-20

-40

-60

-80

MAGNITUDE (dB)

-100

-120

HALFBAND FILTER 5

HALFBAND FILTER 4

HALFBAND FILTER 3

HALFBAND FILTER 2

HALFBAND FILTER 1

0.125 0.25 0.375 0.5

NORMALIZED FREQUENCY (FN)

-6dB BANDWIDTH

FIGURE 19. HALFBAND FILTER ALIAS CONSIDERATIONS

18

FN4450.4

May 1, 2007

HSP50214B

www.BDTIC.com/Intersil

TABLE 4. HALFBAND FILTER COEFFICIENTS

COEFFICIENTS HALFBAND #1 HALFBAND #2 HALFBAND #3 HALFBAND #4 HALFBAND #5

C0 - 0.031303406 0.005929947 -0.00130558 0.000378609 -0.000347137

C1 0.000000000 0.000000000 0.000000000 0.000000000 0.000000000

C2 0.281280518 -0.049036026 0.012379646 -0.003810883 0.00251317

C3 0.499954224 0.000000000 0.000000000 0.000000000 0.000000000

C4 0.281280518 0.29309082 -0.06055069 0.019245148 -0.010158539

C5 0.000000000 0.499969482 0.000000000 0.000000000 0.000000000

C6 - 0.031303406 0.29309082 0.299453735 -0.069904327 0.03055191

C7 0.000000000 0.499954224 0.000000000 0.000000000

C8 -0.049036026 0.299453735 0.304092407 -0.081981659

C9 0.000000000 0.000000000 0.500000000 0.000000000

C10 0.005929947 -0.06055069 0.304092407 0.309417725

C11 0.000000000 0.000000000 0.500000000

C12 0.012379646 -0.069904327 0.309417725

C13 0.000000000 0.000000000 0.000000000

C14 -0.00130558 0.019245148 -0.081981659

C15 0.000000000 0.000000000

C16 -0.003810883 0.03055191

C17 0.000000000 0.000000000

C18 0.000378609 -0.010158539

C19 0.000000000

C20 0.00251317

C21 0.000000000

C22 -0.000347137

NOTE: While Halfband filters are typically selected starting with the last stage in the filter chain to give the maximum alias free ban

a higher throughput rate may be obtained using other filter combinations. See Application Note 9720, “Calculating Maximum

Processing Rates of the PDC”.

dwidth,

Depending on the number of halfbands used, PROCCLK

must operate at a minimum rate above the input sample

rate, f

, to the halfband. This relationship depends on the

S

number of multiplies for each of the halfband filter stages.

The filter calculations take 3, 4, 5, 6, and 7 multiplies per

input for HB1, HB2, HB3, HB4, and HB5 respectively. If we

keep the assumption that f

is the input sampling frequency,

S

then Equation 10 shows the minimum ratio needed.

)+

)+

HB5

)+

)+

)]/2T

(EQ. 10)

f

PROCCLK/fS

(6)(HB4)(2

(5)(HB3)(2

(4)(HB2)(2

(3)(HB1)(2

(HB4 + HB5)

(HB3+HB4+HB5)

(HB2+HB3+ HB4+HB5)

(HB1+HB2+HB3+HB4+HB5)

≥ ([(7)(HB5)(2

where

HB1 = 1 if this section is selected and 0 if it is bypassed;

HB2 = 1 if this section is selected and 0 if it is bypassed;

HB3 = 1 if this section is selected and 0 if it is bypassed;

HB4 = 1 if this section is selected and 0 if it is bypassed;

HB5 = 1 if this section is selected and 0 if it is bypassed;

T = number of Halfband Filters Selected. Th

e range for T is

from 0 to 5.

19

Examples of PROCCLK Rate Calculations

Suppose we enable HB1, HB3, and HB5. Using Figure 16,

HB1= 1, HB3 = 1, and HB5 = 1. Since stage 2 and stage 4

are no

t used, HB2 and HB4 = 0. PROCCLK must operate

faster than (7x2+5x4+3x8)/8 = 7.25 times faster than f

.

S

If all five halfbands are used, then PROCCLK must operate at

(7x2+6x4+5x8+4x16+3x32)/32 = 7.4375 times faster than f

S

255-Tap Programmable FIR Filter

The Programmable FIR filter can be used to implement real

filters with even or odd symmetry, using up to 255 filter taps,

or complex filters with up to 64 taps. The FIR filter takes

advantage of symmetry in coefficients by summing data

samples that share a common coefficient, prior to

multiplication. In this manner, two filter taps are calculated

per multiply accumulate cycle. Asymmetric filters cannot

share common coefficients, so only one tap per multiply

accumulate cycle is calculated. The filter can be effectively

bypassed by setting the coefficient C

coefficients, C

= 0.

N

= 1 and all other

0

FN4450.4

May 1, 2007

.

HSP50214B

www.BDTIC.com/Intersil

Additionally, the Programmable FIR filter provides for

decimation factors, R, from 1 to 16. The processing rate of

the Filter Compute Engine is PROCCLK. As a result, the

frequency of PROCCLK must exceed a minimum value to

ensure that a filter c alculatio n is complete before the result is

required for output. In configurations which do not use

decimation, one input sample period is available for filter

calculation before an output is required. For configurations

which employ decimation, up to 16 input sample periods

may be available for filter calculation.

For real filter configurations, use Equatio

calculate the number of taps availabl

sample rate.

TAPS floor PROCCLK F

SYM) SYM()ODD#()[]–

SAMP

for real filters, and

TAPS floor (PROCCLK F

SAMP

for complex filters, where floor is defined as the integer

portion

of a number; PROCCLK is the compute clock; f

= the FIR input sample rate; R = Decimation Factor; SYM =

1 for symmetrical filter, 0 for asymmetrical filter; ODD# = 1

for an odd number of filter taps, 0 = an even number of taps.

Use Equation 12A to calculate the maximum input rate.

F

SAMP

PROCCLK() R() R floor Taps()[[+[⁄ +=

SYM()ODD#()]1 SYM+()⁄]]

for real filters, and

F

SAMP

PROCCLK()R()[]R floor Taps()2()][+[]⁄=

for complex filters, where floor[x], PROCCLK, f

Decimation Factor, SYM, and ODD# are defined as in

Equation 11A.

Use Equation 13 to calculate the maximum output sample

rate for both real and complex

F

FIROUT

F

()R⁄=

SAMP

filters.

The coefficients are 22-bits and are loaded using writes to

Con

trol Words 128 through 255 (see Microprocessor Write

Section). For real filters, the same coefficients are used by I

and Q paths. If the filter is configured as a symmetric filter