Page 1

®

www.BDTIC.com/Intersil

HSP50210

Data Sheet July 2, 2008

Digital Costas Loop

The Digital Costas Loop (DCL) performs many of the

baseband processing tasks required for the demodulation of

BPSK, QPSK, 8-PSK, OQPSK, FSK, AM and FM

waveforms. These tasks include matched filtering, carrier

tracking, symbol synchronization, AGC, and soft decision

slicing. The DCL is designed for use with the HSP50110

Digital Quadrature Tuner to provide a two chip solution for

digital down conversion and demodulation.

The DCL processes the In-phase (I) and Quadrature (Q)

components of a baseband signal which have been digitized

to 10 bits. As shown in the block diagram, the main signal

path consists of a complex multiplier, selectable matched

filters, gain multipliers, cartesian-to-polar converter, and soft

decision slicer. The complex multiplier mixes the I and Q

inputs with the output of a quadrature NCO. Following the

mix function, selectable matched filters are provided, which

perform integrate and dump or root raised cosine filtering

(α ~ 0.40). The matched filter output is routed to the slicer,

which generates 3-bit soft decisions, and to the cartesian-topolar converter, which generates the magnitude and phase

terms required by the AGC and Carrier Tracking Loops.

The PLL system solution is completed by the HSP50210

error detectors and second order Loop Filters that provide

carrier tracking and symbol synchronization signals. In

applications where the DCL is used with the HSP50110,

these control loops are closed through a serial interface

between the two parts. To maintain the demodulator

performance with varying signal power and SNR, an internal

AGC loop is provided to establish an optimal signal level at

the input to the slicer and to the cartesian-to-polar converter.

FN3652.5

Features

• Clock Rates Up to 52MHz

• Selectable Matched Filtering with Root Raised Cosine or

Integrate and Dump Filter

• Second Order Carrier and Symbol Tracking Loop Filters

• Automatic Gain Control (AGC)

• Discriminator for FM/FSK Detection and Discriminator

Aided Acquisition

• Swept Acquisition with Programmable Limits

• Lock Detector

• Data Quality and Signal Level Measurements

• Cartesian-to-Polar Converter

• 8-Bit Microprocessor Control - Status Interface

• Designed to Work With the HSP50110 Digital Quadrature

Tuner

• 84 Lead PLCC

• Pb-Free Available (R oH S compliant)

Applications

• Satellite Receivers and Modems

• BPSK, QPSK, 8-PSK, OQPSK, FSK, AM and FM

Demodulators

• Digital Carrier Tracking

• Related Products: HSP50110 Digital Quadrature Tuner,

D/A Converters HI5721, HI5731, HI5741

• HSP50110/210EVAL Digital Demod Evaluation Board

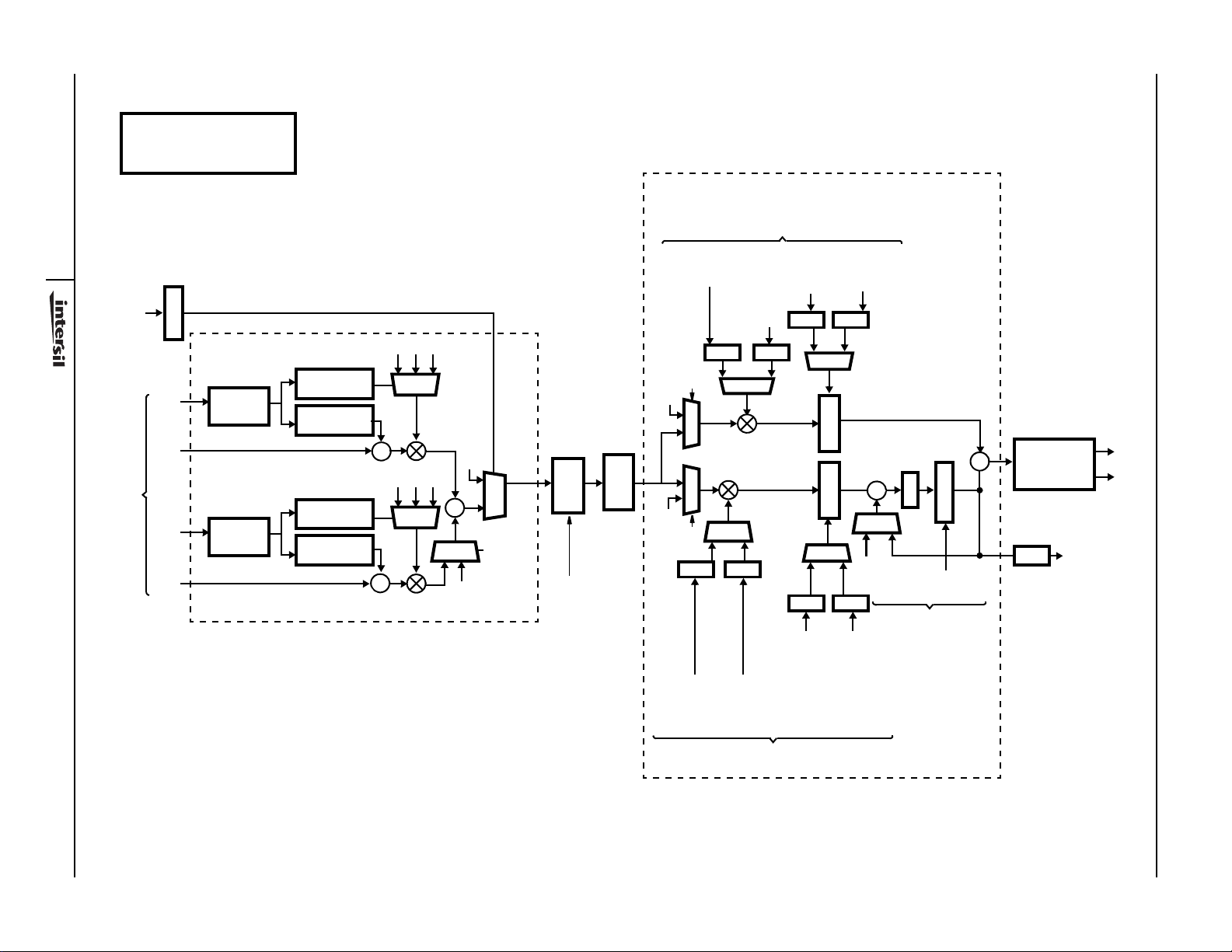

Block Diagram

CARRIER

TRACK

CONTROL

HI/LO

I SER OR

(9-0)

I

IN

SERCLK

OR CLK

Q SER OR

Q

(9-0)

IN

SYMBOL

TRACK

CONTROL

CONTROL/

STATUS

BUS

(COF)

LEVEL

DETECT

(SOF)

COS

10

10

13

NCO

SIN

SYMBOL

TRACKING

LOOP FILTER

1

CARRIER ACQ/TRK

LOOP FILTER

I

RRC

FILTER

Q

RRC

FILTER

CONTROL

INTERFACE

CARRIER PHASE

ERROR DETECT

LOOP

FILTER

INTEGRATE/

DUMP

INTEGRATE/

DUMP

SYMBOL

PHASE

ERROR

DETECT

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

LEVEL

DETECT

8

CARTESIAN

8

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

LOCK

DETECT

MAGNITUDE

8

PHASE

TO

POLAR

Copyright Intersil Americas Inc. 2000, 2008. All Rights Reserved

8

SLICER

3

3

Q

I

DATA PATH MULTIPLEXER

LKINT

THRESH

A

OUT(9-0)

10

10

B

OUT(9-0)

SMBLCLK

OEA

OEB

Page 2

Pinout

www.BDTIC.com/Intersil

IIN6

IIN7

IIN8

IIN9

SERCLK

GND

SSYNC

HSP50210

HSP50210

(84 LD PLCC)

TOP VIEW

HI/LO

ISER

QSER

VCC

THRESH

SLOCLK

OEA

AOUT8

AOUT9

GND

AOUT7

AOUT5

AOUT6

AOUT4

757677787980818283841234567891011

IIN5

IIN4

IIN3

IIN2

GND

IIN1

IIN0

SYNC

QIN9

QIN8

QIN7

QIN6

QIN5

QIN4

VCC

QIN3

QIN2

QIN1

QIN0

SOFSYNC

SOF

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

C1

C2

C3

C4

C5

C6

C7

A0

A1

WR

COF

COFSYNC

GND

VCC

A2

RD

C0

FZ-ST

FZ-CT

LKINT

535251504948474645444342414039383736353433

GND

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

AOUT3

AOUT2

AOUT1

AOUT0

SMBLCLK

VCC

CLK

GND

BOUT9

BOUT8

BOUT7

BOUT6

BOUT5

GND

BOUT4

BOUT3

BOUT2

BOUT1

BOUT0

OEB

VCC

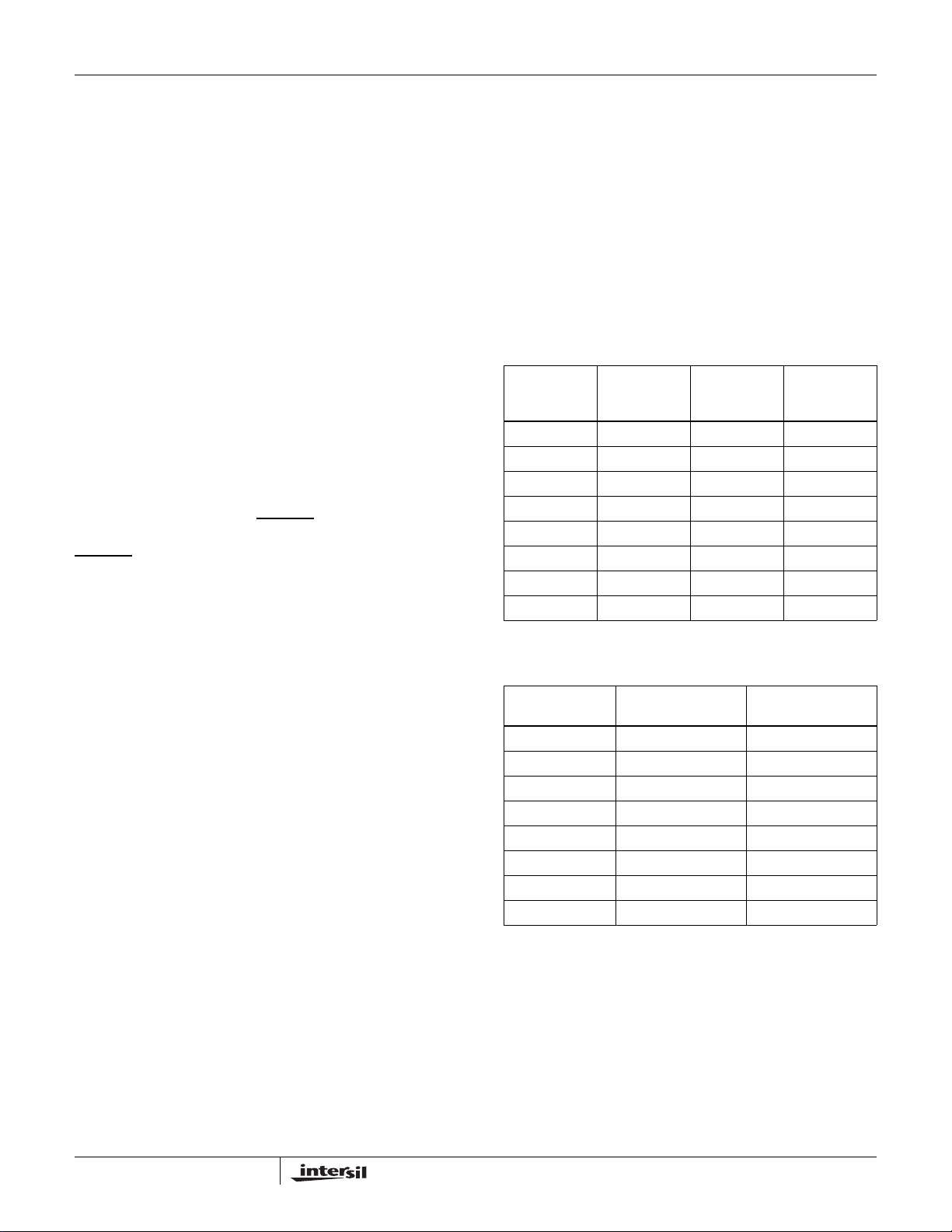

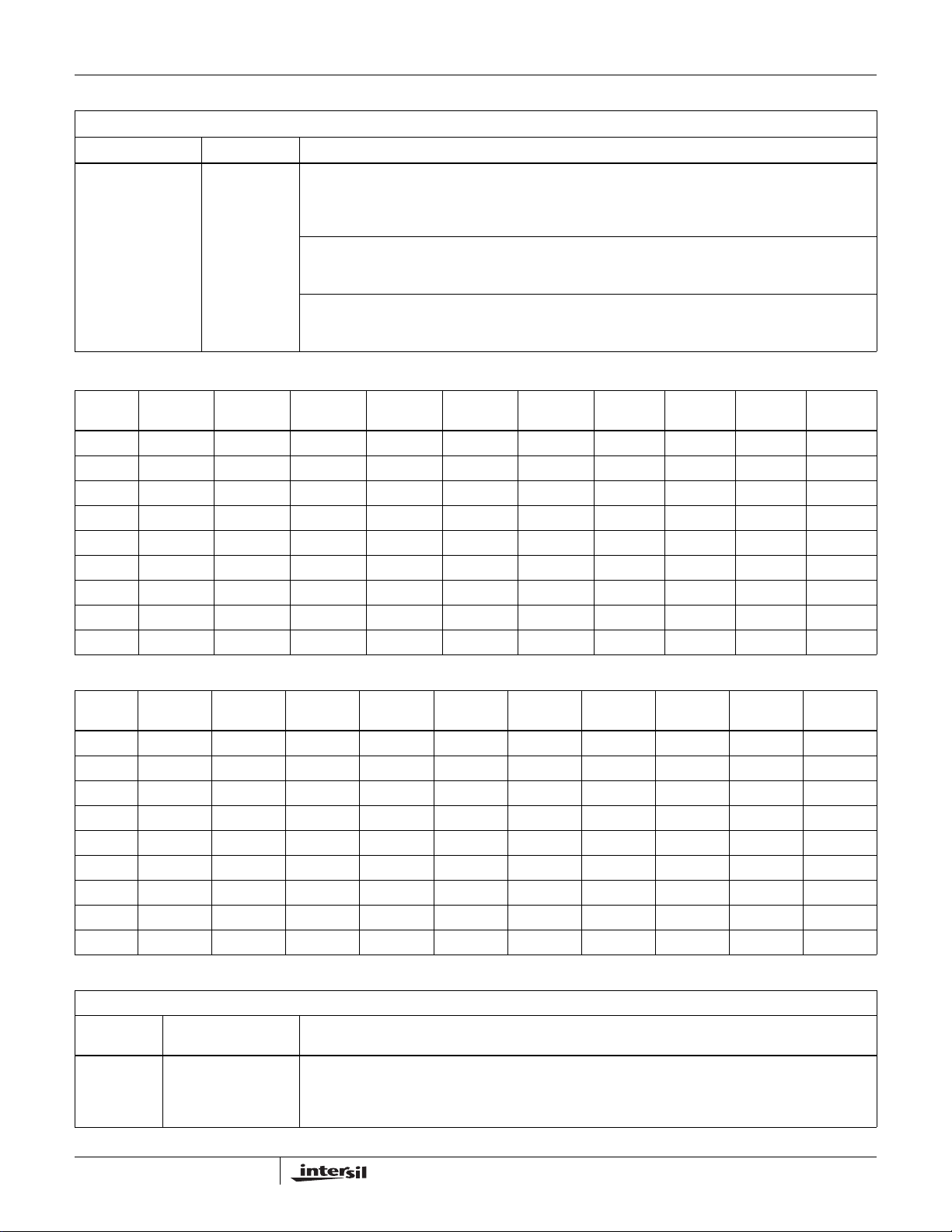

Ordering Information

PART NUMBER PART MARKING TEMP. RANGE (°C) PACKAGE PKG. DWG. #

HSP50210JC-52 HSP50210JC-52 0 to +70 84 Ld PLCC N84.1.15

HSP50210JC-52Z (Note) HSP50210JC-52Z 0 to +70 84 Ld PLCC (Pb-free) N84.1.15

HSP50210JI-52 HSP50210JI-52 -40 to +85 84 Ld PLCC N84.1.15

HSP50210JI-52Z (Note) HSP50210JI-52Z -40 to +85 84 Ld PLCC (Pb-free) N84.1.15

NOTE: These Intersil Pb-free plastic packaged products employ special Pb-free material sets, molding compounds/die attach materials, and 100%

matte tin plate plus anneal (e3 termination finish, which is RoHS compliant and compatible with both SnPb and Pb-free soldering operations). Intersil

Pb-free products are MSL classified at Pb-free peak reflow temperatures that meet or exceed the Pb-free requirements of IPC/JEDEC J STD-020.

2

FN3652.5

July 2, 2008

Page 3

HSP50210

www.BDTIC.com/Intersil

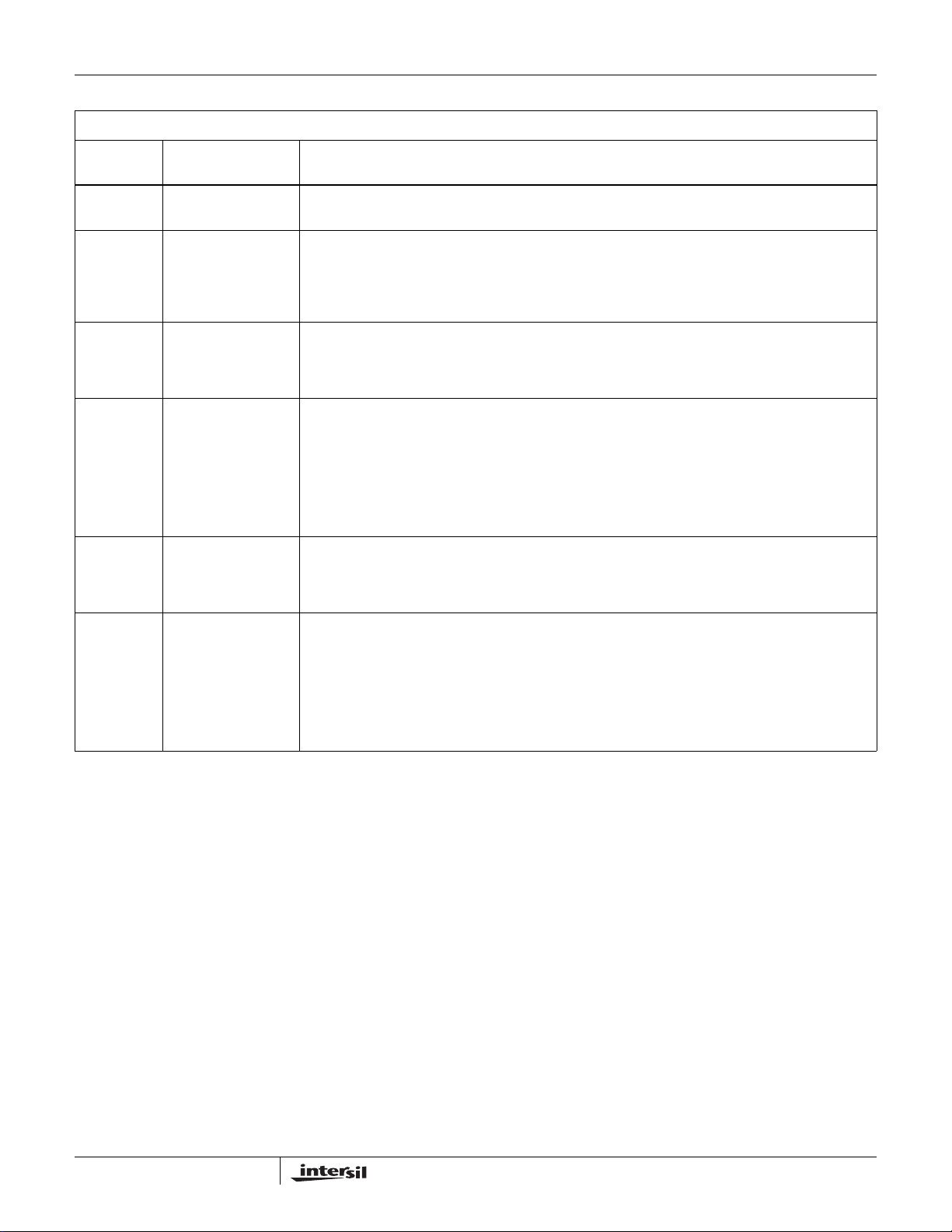

Pin Description

NAME TYPE DESCRIPTION

VCC - +5V Power Supply.

GND - Ground.

IIN9-0 I In-Phase Parallel Input. Data may be two’s complement or offset binary format (see Table 15). These inputs are

sampled by CLK when the SYNC

QIN9-0 I Quadrature Parallel Input. Data may be two’s complement or offset binary format (see Table 15). These inputs are

sampled by CLK when the SYNC

SYNC

COF O Carrier Offset Frequency. The frequency term generated by the Carrier Tracking Loop Filter is output serially via this

COFSYNC O Carrier Offset Frequency Sync. This signal is asserted one CLK or SLOCLK cycle before the MSB of the serial data

SOF O Sampler Offset Frequency. Sample frequency correction term generated by the Symbol Tracking Loop Filter is

SOFSYNC O Sampler Offset Frequency Sync. This signal is asserted one CLK or SLOCLK cycle before the MSB of the serial data

A2-0 I Address Bus. The address on these pins specify a target register for reading or writing (see “Microprocessor

C7-0 I/O Microprocessor Interface Data Bus. This bi-directional bus is used for reading and writing to the processor interface.

WR

RD

I Data Sync. When SYNC is asserted “Low”, data on IIN9-0 and QIN9-0 is clocked into the processing pipeline by the

rising edge of CLK.

pin. The new offset frequency is shifted out MSB first by CLK or SLOCLK starting with the clock cycle after the

assertion of COFSYNC.

word. (Programmable Polarity, see Table 42 on page 42, Bit 11).

output serially via this pin. The frequency word is shifted out MSB first by CLK or SLOCLK starting with the clock

cycle after assertion of SOFSYNC.

word. (Programmable Polarity, see Table 42 on page 42, Bit 12).

Interface” on page 27). A0 is the LSB.

These are the data I/O pins for the processor interface. C0 is the LSB.

I Write. This is the write strobe for the processor interface (see “Microprocessor Interface” on page 27).

I Read. This is the read enable for the processor interface (see “Microprocessor Interface” on page 27).

signal is active Low. IIN9 is the MSB. See “Input Controller” on page 6.

signal is active Low. QIN9 is t heMSB. “Input Controller” on page 6.

FZ_ST I Freeze Symbol Tracking Loop. Asserting this pin “high” zeroes the sampling error into the Symbol Tracking Loop

FZ_CT I Freeze Carrier Tracking Loop. Asserting this pin “high” zeroes the carrier Phase Error input to the Carrier Tracking

LKINT O Lock Detect Interrupt. This pin is asserted “high” for at least 4 CLK cycles when the Lock Detector Integration cycle

THRESH

SLOCLK O Slow Clock. Optional serial clock used for outputting data from the Carrier and Symbol Tracking Loop Filters. The

ISER I In-Phase Serial Input. Serial data input for In-Phase Data. Data on this pin is shifted in MSB first and is synchronous

QSER I Quadrature Serial Input. Serial data input for Quadrature Data. Data on this pin is shifted in MSB first and is

SSYNC I Serial Word Sync. This input is asserted “high” one CLK before the first data bit of the serial word (see Figure 2).

SERCLK I Serial Clock. May be asynchronous to other clocks. Used to clock in serial data (see “Input Controller” on page 6).

AOUT9 -0 O A Output. Data on this output depend on the configuration of Output Selector. AOUT9 is the MSB (see Table 43 on

BOUT9-0 O B Output. Data on this output depend on the configuration of Output Selector. BOUT9 is the MSB (see T able 43 page 44).

SMBLCLK O Symbol Clock. 50% duty cycle clock aligned with soft bit decisions (see Figure 19).

Filter (see “Symbol Tracking Loop Filter” on page 17).

Loop Filter.

is finished (see “Lock Detector” on page 23). Used as an interrupt for a pr ocessor. The Lock Detect Interrupt may

be asserted “high” longer than 4 CLK cycles, depending on the Lock Detector mode.

O Threshold Exceeded. This output is asserted “low” when the magnitude out of the Cartesian to Polar converter

exceeds the programmable Power Detect Threshold (see Table 16 on page33 and “AGC” on page 10).

clock is programmable and has a 50% duty cycle. Note: Not used when the HSP50110 is used with the HSP50210

(see Table 42 page 42).

to SERCLK (see “Input Controller” on page 6).

synchronous to SERCLK (see “Input Controller” on page 6).

page 44).

3

FN3652.5

July 2, 2008

Page 4

HSP50210

www.BDTIC.com/Intersil

Pin Description (Continued)

NAME TYPE DESCRIPTION

OEA I A Output Enable. This pin is the three-state control pin for the AOUT9-0. When OEA is high, the AOUT9-0 is high

impedance.

OEB

HI/LO

CLK I System Clock. Asynchronous to the processor interface and serial inputs.

I B Output Enable. This pin is the three-state control pin for the BOUT9-BOUT0. When OEB is high, the AOUT9-0 is

high impedance.

0 HI/LO. The output of the Input Level Detector is provided on this pin (see “Input Level Detector” o n page 6). This

signal can be externally averaged and used to control the gain of an amplifier to close an AGC loop around the A/D

converter. This type of AGC sets the level based on the median value on the input.

4

FN3652.5

July 2, 2008

Page 5

AGC

www.BDTIC.com/Intersil

LOOP

HI/LO

SYNC

5

IIN9-0

QIN9-0

SSYNC

SERCLK

ISER

QSER

LEVEL

DETECT

INPUT CONTROLLER

SYNTHESIZER/

I

Q

MIXER

COS

NCO

MATCHED FILTERING

M

U

X

M

U

X

SIN

RRC

RRC

M

U

X

M

U

X

FILTER

I AND D

I AND D

GAIN ERROR

DETECT

M

U

X

M

U

X

CARTESIAN

TO

POLAR

I2+Q

Q

TAN-1( )

SLICER

2

I

THRESH

SMBLCLK

SYMBOL TRACKING

SOFSYNC

SOF

COFSYNC

COF

SLOCLK

C7-0

A2-0

CLK

FRZ_ST

FRZ_CT

July 2, 2008

FN3652.5

8

WR

RD

SERIAL

OUTPUT

FORMATTER

MICROPROCESSOR

INTERFACE

FROM

LOCK

DETECTOR

ACQUISITION

CONTROL

FIGURE 1. FUNCTIONAL BLOCK DIAGRAM OF THE HSP50210

2ND ORDER LOOP

FILTER

CARRIER TRACKING

2ND ORDER LOOP

FILTER

SYMBOL PHASE

ERROR DETECT

CARRIER PHASE

ERROR DETECT

DISCRIMINATOR

FREQUENCY

ERROR DETECT

LOCK

DETECT

AOUT9-0

BOUT9-0

OEA

OEB

d

dt

LKINT

HSP50210

Page 6

HSP50210

www.BDTIC.com/Intersil

Functional Description

The HSP50210 Digital Costas Loop (DCL) contains most of

the baseband processing functions needed to implement a

digital Costas Loop Demodulator. These functions include

LO generation/mixing, matched filtering, AGC, carrier phase

and frequency error detection, timing error detection, carrier

loop filtering, bit sync loop filtering, lock detection,

acquisition/tracking control, and soft decision slicing for

forward error correction algorithms. While the DCL is

designed to work with the HSP50110 Digital Quadrature

Tuner (DQT) as a variable rate PSK demodulator for satellite

demodulation, functions on the chip are common to many

communications receivers.

The DCL provides the processing blocks for the three

tracking loops commonly found in a data demodulator: the

Automatic Gain Control (AGC) loop, the Carrier Tracking

Loop, and a Symbol Tracking Loop. The AGC loop adjusts

for input signal power variations caused by path loss or

signal-to-noise variations. The carrier tracking loop removes

the frequency and phase uncertainties in the carrier due to

oscillator inaccuracies and doppler. The symbol tracking

loop removes the frequency and phase uncertainties in the

data and generates a recovered clock synchronous with the

received data. Each loop consists of an error detector , a loop

filter, and a frequency or gain adjustment/control. The AGC

loop is internal to the DCL, while the symbol and carrier

tracking loops are closed external to the DCL. When the

DCL is used together with the HSP50110, the tracking loops

are closed around the baseband filtering to center the signal

in the filter bandwidth. In addition, the AGC function is

divided between the two chips with the HSP50110 providing

the coarse AGC, and the HSP50210 providing the fine or

final AGC.

A top level block diagram of the HSP50210 is shown in

Figure 1. This diagram shows the major blocks and the

multiplexers used to reconfigure the data path for various

architectures.

Input Controller

In-Phase (I) and Quadrature (Q) data enters the part through

the Input Controller. The 10-bit data enters in either serial or

parallel fashion using either two’s complement or offset

binary format. The input mode and binary format is set in the

Data Path Configuration Control Register, bits 14 and 15

(see Table 15 on page 32).

If Parallel Input mode is selected, I and Q data are clocked

into the part through IIN0-9 and QIN0-9 respectively. Data

enters the processing pipeline when the input enable

(SYNC

) is sampled “low” by the processing clock (CLK). The

enable signal is pipelined with the data to the various

processing elements to minimize pipeline delay where

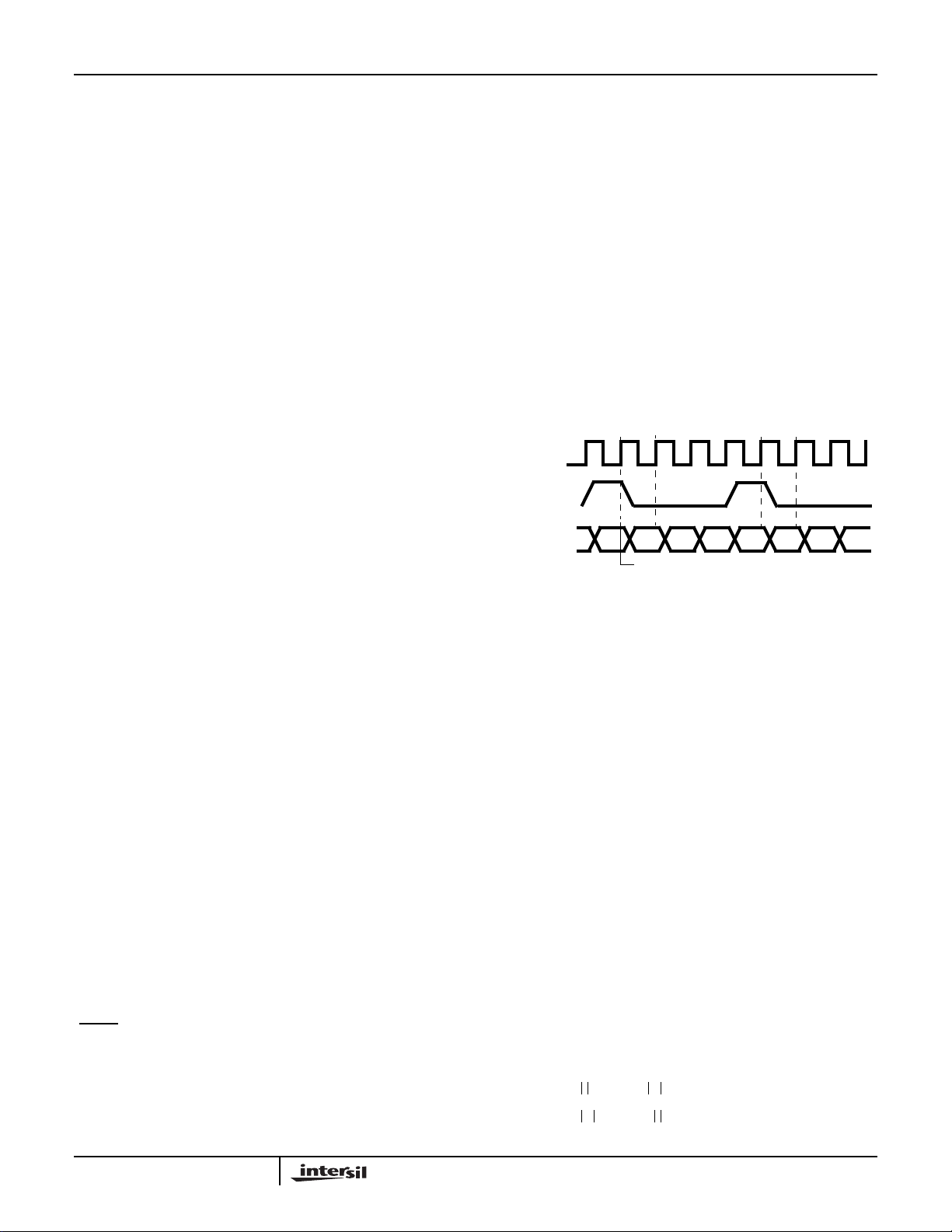

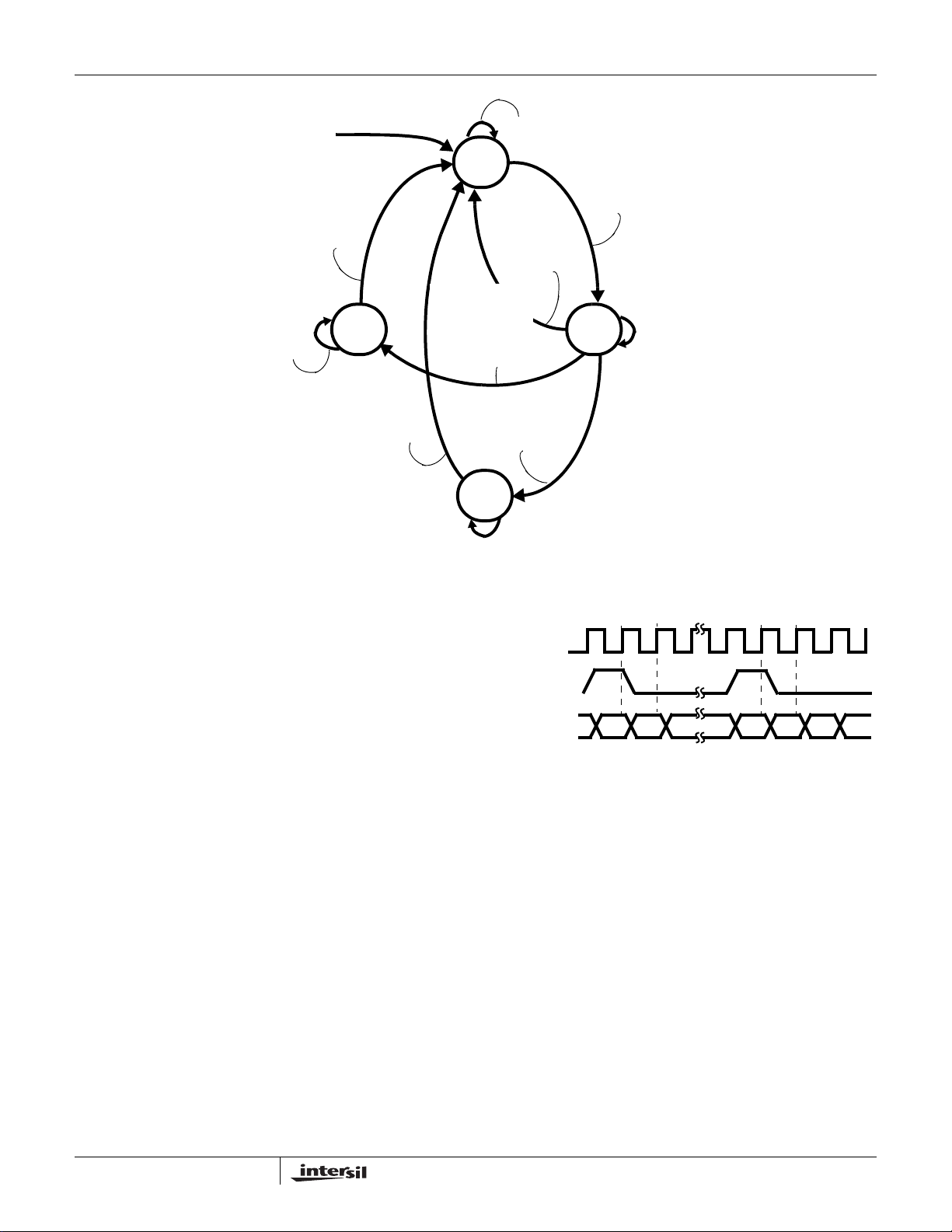

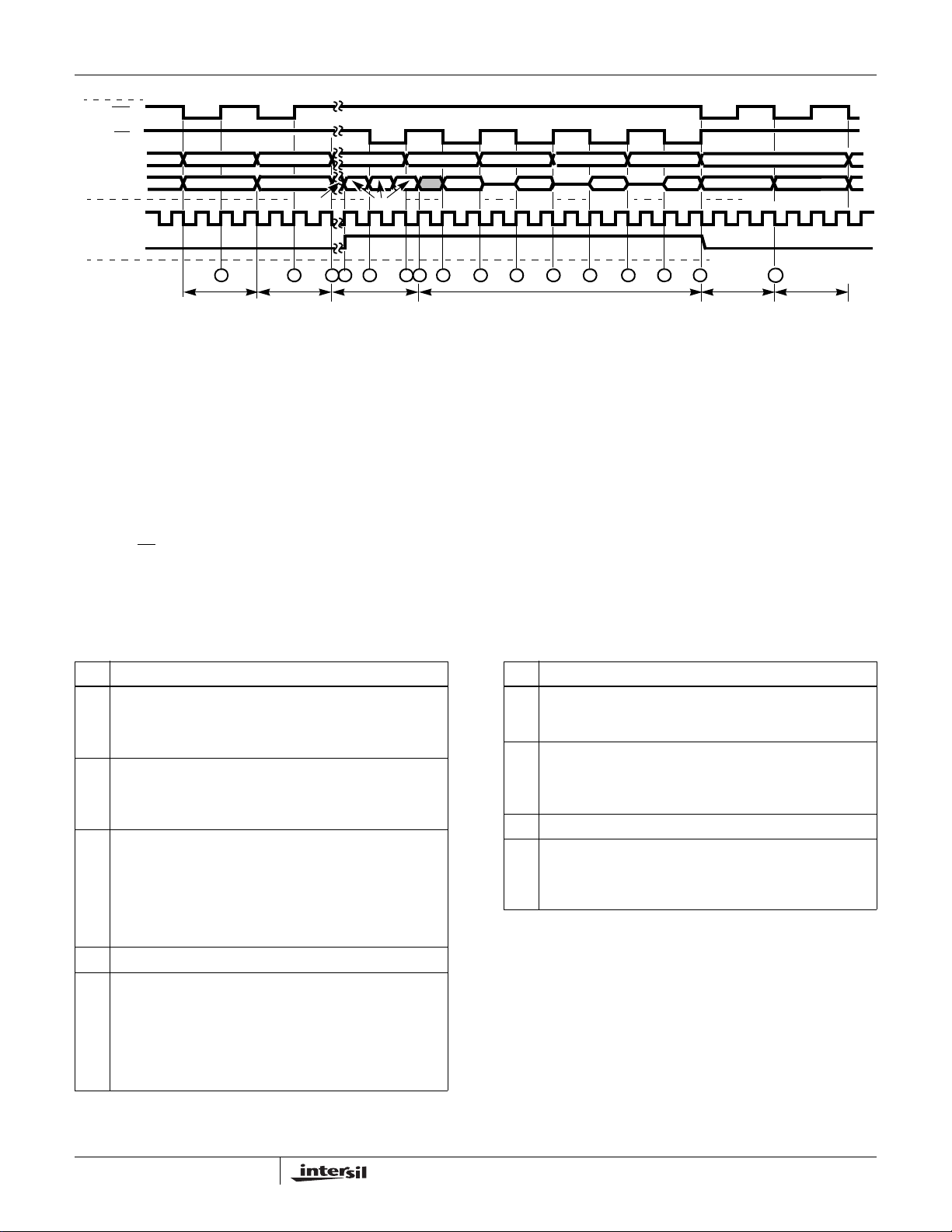

possible. As a result, the pipeline delay through the AGC,

Carrier Tracking, and Symbol Tracking Loop Filters is

measured in CLKs; not input data samples.

If serial input mode is selected, the I and Q data enters via

the ISER and QSER pins using SERCLK and SSYNC. The

beginning of a serial word is designated by asserting

SSYNC ‘high’ one SERCLK prior to the first data bit, as

shown in Figure 2. On the following SERCLKs, data is

shifted into the register until all 10 bits have been input. Data

shifting is then disabled and the contents of the register are

held until the next assertion of SSYNC. The assertion of a

SSYNC transfers data into the processing pipeline, and the

Shift Register is enabled to accept new data on the following

SERCLK. When data is transferred to the processing

pipeline by SSYNC, a processing enable is generated which

follows the data through the pipeline. This enable allows the

delay through processing elements (like the loop filters) to be

minimized since their pipeline delay is expressed in CLKs

not SSYNC periods. Note: SSYNC should not be

asserted for more than one SERCLK cycle.

SERCLK

SSYNC

ISER/QSER

NOTE: Data must be loaded MSB first.

FIGURE 2. SERIAL INPUT TIMING FOR ISER AND QSER INPUTS

MSB

SSYNC LEADS 1st DATA BIT

MSB

Input Level Detector

The Input Level Detector generates a one-bit error signal for

an external IF AGC filter and amplifier. The error signal is

generated by comparing the magnitude of the input samples

to a user programmable threshold. The HI/LO pin is then

driven “high” or “low” depending on the relationship of its

magnitude to the threshold. The sense of the HI/LO pin is

programmable so that a magnitude exceeding the threshold

can either be represented as a “high” or “low” logic state.

The Input Level Detector (HI/LO output) threshold and the

sense are set by the Data Path Configuration Control

Register bits 16 to 23 and 13 (see Table 15 page 32).

Note: The Inpu t Level Detector is typically not used in

applications which use the HSP50210 with the

HSP50110.

The high/low outputs can be integrated by an external loop

filter to close an AGC loop. Using this method, the gain of

the loop forces the median magnitude of the input samples

to the threshold. When the magnitude of half of the samples

is above the threshold (and half is below), the error signal is

integrated to zero by the loop filter. The magnitude of the

complex input is estimated using Equation 1:

Mag (I, Q) I 0.375 Q if I Q and>×+=

Mag (I, Q) Q 0.375 I if Q I>×+=

(EQ. 1)

6

FN3652.5

July 2, 2008

Page 7

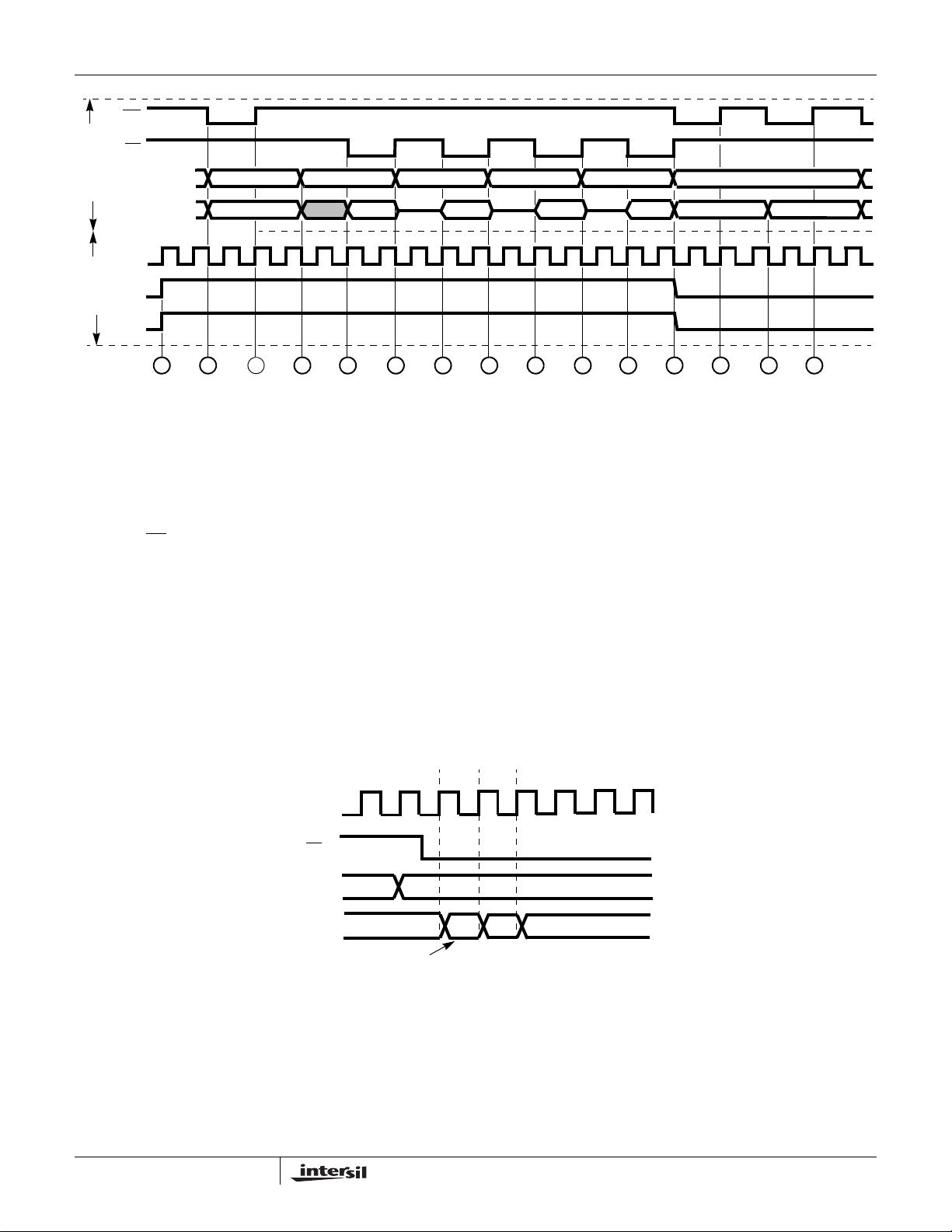

REGISTER ENABLE RATE

www.BDTIC.com/Intersil

@ = SYNC RATE

= TWICE SYMBOL RATE

*

! = SYMBOL RATE

BLANK = CLK RATE

MID AND END

SYMBOL SAMPLES

TO SYMBOL TRACKING

I

MID

I

END

Q

MID

Q

END

D

HI/LO

MATCHED FILTERING

7

REG

REG

DETECT

LEVEL

IIN9-0QIN9-0

NCO MIXER

COMPLEX

MULTIPLY

BYPASS

MIXER

BYPASS

R

E

G

R

E

M

G

U

X

R

R

E

E

G

G

R

R

E

E

G

G

@

@

RRC

15 TAP RRC

15 TAP RRC

M

U

R

R

X

E

E

G

G

R

R

E

E

G

G

R

R

L

E

E

I

G

G

M

R

R

I

E

E

T

G

G

DUMP

+

DUMP

+

M

U

X

DATA DE-SKEW

OQPSK

“0”

R

R

E

E

G

G

@

*

“0”

M

U

X

R

E

G

M

U

X

@

SIN

COS

REG REG

REG REG

SIN/COS

ROM

REG

+

REG

CF

REGISTER

ROOT RAISED COSINE

(RRC)

AGC LOOP FILTER

L

I

R

M

E

I

G

UPPER

GAIN

LIMIT

T

LOWER

GAIN

LIMIT

@ OR !

INTEGRATE AND DUMP

R

E

+

G

LOOP GAIN

EXPONENT

FALSE LOCK

COMPARE

S

H

I

F

T

*

TWO SAMPLE

SUMMER

S

H

F

T

R

E

I

G

*

S

R

H

E

I

G

F

T

LOOP GAIN

MANTISSA

REG

R

E

G

BYPASS

I AND D

+

M

U

X

+

HOLD AGC

M

U

X

E

M

U

X

D

E

M

U

X

M

U

X

AGC ERROR DETECT

“0”

AGC THRESHOLD

GAIN

ERROR

POWER

THRESHOLD

CARTESIAN TO

POLAR

2

DELAY

I2+Q

Q

-1

TAN

( )

DELAY

I

PHASE OUT AT

MAG OUT AT

-

+

COMPARE

SOFT

DECISION

SLICER

TEST

M

U

X

5

REG

5

REG

@ OR

@ OR !

R

E

G

R

E

G

R

E

G

R

E

G

O

R

U

E

**

T

G

P

R

U

! OR ! OR

E

T

G

S

E

L

E

8

C

T

8

AOUT9-0 BOUT9-0

R

E

G

R

E

G

HSP50210

*

TO

CARRIER

TRACKING

AND

DISCRIMINATOR

THRESH

R

E

G

FROM CARRIER TRACKING

LOOP FILTER

July 2, 2008

FN3652.5

FIGURE 3. MAIN DATA PATH

Page 8

HSP50210

www.BDTIC.com/Intersil

NCO/Mixer

The NCO/Mixer performs a complex multiply between the

baseband input and the output of a quadrature NCO

(Numerically Controlled Oscillator). When the HSP50210

(DQT) is used with the HSP50110 (DCL), the NCO/Mixer

shortens the Carrier Tracking Loop (i.e., minimizes pipeline

delay around the loop) while providing wide loop

bandwidths. This becomes important when operating at

symbol rates near the maximum range of the part.

There are three configurations possible for closing the

Carrier Tracking Loop when the DQT and the DCL are used

together. The first configuration utilizes the NCO on the DQT

and bypasses the NCO in the DCL. The Data Path

Configuration Control Register (see Table 15 on page 32),

Bit 10, and Carrier Loop Filter Control Register #1

(see Table 21 on page 34), Bit 6, are used to bypass the

DCL NCO/Mixer and route the Loop filter outputs,

respectively. The DQT provides maximum flexibility in NCO

control with respect to frequency and phase offsets.

The second configuration feeds the lead Carrier Loop filter

term to the DCL NCO/Mixer, and the lag Loop filter Term to

the DQT NCO. This reduces the loop transport delay while

maintaining wide loop bandwidths and reasonable loop

damping factors. This configuration is especially useful in

SATCOM applications with medium to high symbol rates.

The Carrier Loop Filter Control Register #1, Bit 5 is where

the lead/lag destination is set.

The final configuration feeds both the lead and lag Carrier

Loop Filter terms back to the DCL NCO/Mixer. This provides

the shortest transport delay. The DCL NCO/Mixer provides

only for frequency/phase control from the Carrier Loop filter.

The center frequency of this NCO/Mixer is set to the average

of the Upper and Lower Carrier Loop Limits programmable

parameters. These parameters are set in the two control

registers bearing their names (see Tables 23 and 24 on

page 35).

The NCO/Mixer uses a complex multiplier to multiply the

baseband input by the output of a quadrature NCO. This

operation is represented by Equations 2 and 3:

I

OUTIIN

Q

OUTIIN

Equation 3 illustrates how the complex multiplier implicitly

performs the summing function when the DCL is configured

as a modulator. The quadrature outputs of the NCO are

generated by driving a sine/cosine look-up table with the

output of a phase accumulator, as shown in Figure 3 on

page 7. Each time the phase accumulator is clocked, its sum

is incremented by the contents of the Carrier Frequency (CF)

Register. As the accumulator sum increments from 0 to 2

the SIN/COS ROM produces quadrature outputs whose

phase advances from 0 to 360°. The CF Register contains a

ωC()cos Q

ωC()sin Q

IN

IN

ωC()sin–=

ωC()cos+=

(EQ. 2)

(EQ. 3)

32

32-bit phase increment, which is updated with the output of

Carrier Tracking Loop. Large phase increments take fewer

clocks to step through the sine wave cycle, which results in a

higher frequency NCO output.

The CF Register sets the NCO frequency using Equation 4:

F

CfCLK

CF INT F

where f

complement hexadecimal value loaded into the Carrier

Frequency Register. As an example, if the CF Register is

loaded with a value of 4000 0000 (Hex), and the CLK

frequency is 40MHz, the NCO would produce quadrature

terms with a frequency of 10MHz. When CF is a negative

value, a clockwise cos/sin vector rotation is produced. When

CF is positive, a counterclockwise vector rotation is

produced.

Note: The NCO is set to a fixed frequency by programming

the upper and lower limits of the Carrier Tracking Loop Filter

to the same value and zeroing the lead gain.

×=

32

⁄()2

[]H=

CfCLK

is the CLK frequency, and CF is the 32-bit two’s

CLK

32

CF()2⁄

(EQ. 4)

Matched Filtering

The HSP50210 provides two selectable matched filters: a

Root Raised Cosine Filter (RRC) and an Integrate and Dump

(I and D) filter. These are shown in Figure 3. The RRC filter

is provided for shaped data pulses and the I and D filter is

provided for square wave data. The filters may be cascaded

for better adjacent channel rejection for square wave data. If

these two filters do not meet baseband filtering

requirements, then they can be bypassed and an external

digital filter (such as the HSP43168 Dual FIR Filter or the

HSP43124 Serial I/O Filter) used to implement the desired

matched filter. The desired filter configuration is set in the

Data Path Configuration Control Register, bits 1 through 7

(see Table 15 on page 32).

The sample rate of the baseband input depends on the

symbol rate and filtering configuration chosen. In

configurations which bypass both filters or use only the RRC

Filter, the input sample rate must be twice the symbol rate. In

configurations which use the I and D Filter, the input sample

rate is decimated by the I and D Filter, down to two samples

per symbol. I and D configurations support input sample

rates up to 32x the input symbol rate.

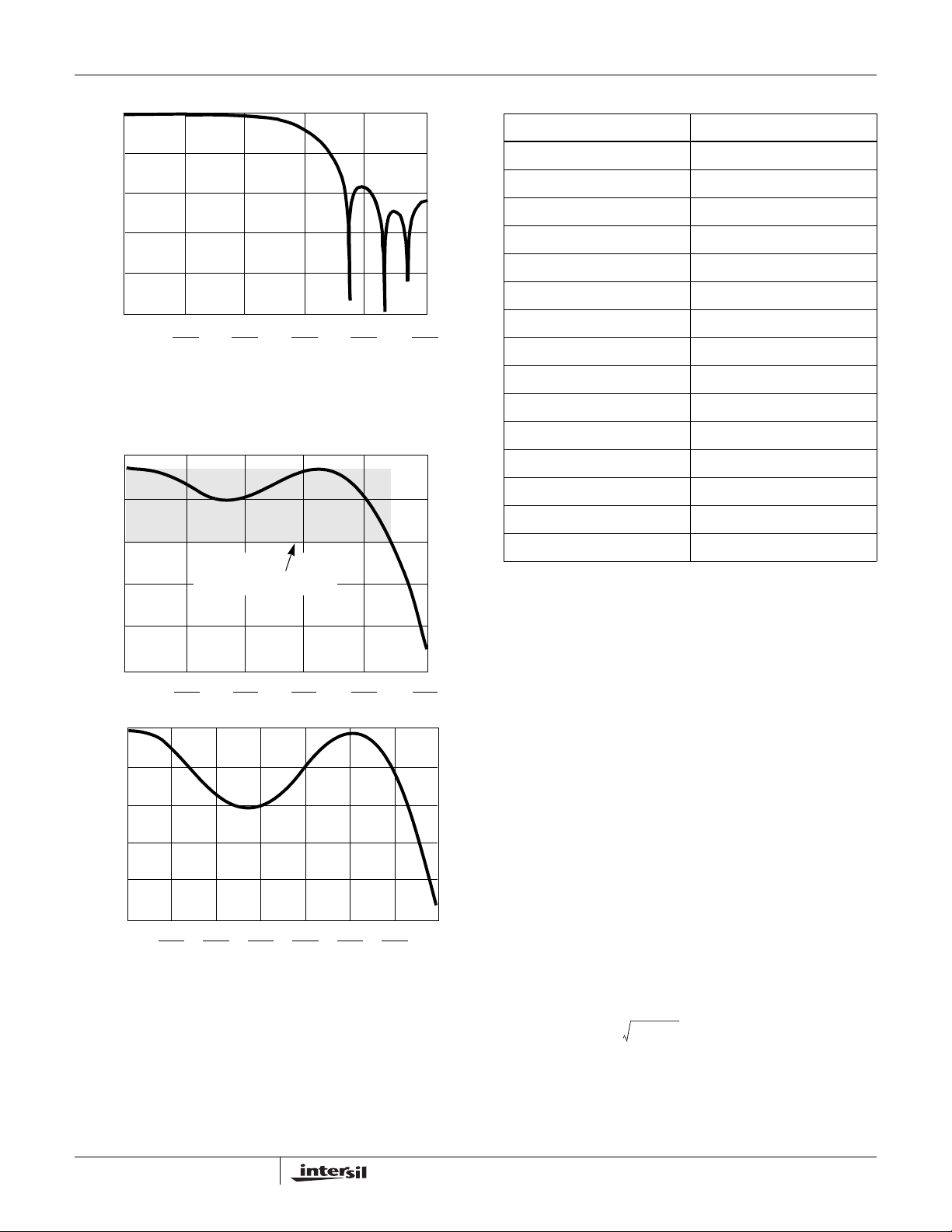

The RRC filter is a fixed coefficient 15 Tap FIR filter. It has

~40% excess bandwidth beyond Nyquist, which equates to

α = ~0.4 shape factor. The filter frequency response is

shown in Figures 4 and 5. In addition, the 9-bit filter

coefficients are listed as integer values in Table 1. The noise

,

equivalent bandwidth of the RRC filter and other filter

configurations possible with the HSP50110/210 chipset are

given in Appendix A.

8

FN3652.5

July 2, 2008

Page 9

HSP50210

www.BDTIC.com/Intersil

0

-20

-40

-60

-80

NORMALIZED MAGNITUDE (dB)

-100

0

f

CLK

10

FREQUENCY (NORMALIZED TO INPUT SAMPLE RATE)

2f

CLK

10

3f

CLK

10

4f

CLK

10

f

CLK

2

FIGURE 4. RRC FILTER IN HSP50210

0

-0.18

-0.36

SHOWN BELOW

-0.54

-0.72

NORMALIZED MAGNITUDE (dB)

-0.90

0

0

-0.07

-0.14

-0.21

-0.28

NORMALIZED MAGNITUDE (dB)

-0.35

0

FREQUENCY (NORMALIZED TO INPUT SAMPLE RATE)

ENLARGED FOR CLARITY

f

CLK

20

2f

CLK

25

3f

f

CLK

f

CLK

25

40

CLK

40

3f

CLK

25

f

CLK

10

4f

CLK

25

5f

CLK

40

f

CLK

5

3f

CLK

20

FIGURE 5. PASSBAND RIPPLE OF RRC FILTER IN HSP50210

TABLE 1. ROOT RAISED COSINE COEFFICIENTS

COEFFICIENT INDEX COEFFICIENT

02

1-2

21

38

4-16

5-14

686

7 160

886

9-14

10 -16

11 8

12 1

13 -2

14 2

The I and D filter consists of an accumulator, a

programmable shifter and a two sample summer, as shown

in Figure 3. The programmable shifter is provided to

compensate for the gain introduced by the accumulator (see

Table 15). The accumulator provides Integrate and Dump

Filtering for decimation factors up to 16. The two sample

summer provides the moving average required for an

additional decimation factor of 2. A decimation factor of 1

(bypass), 2, 4, 8, 16, or 32 may be selected. At the maximum

decimation rate, a baseband signal sampled at 32x the

symbol rate can be filtered.

The output of the two sample summer is demultiplexed into

two sample streams at the symbol rate. The demultiplexed

data streams from the I and Q processing paths are fed to

the Symbol Tracking Block and Soft decision slicer. The

multiplexed data streams on I and Q are provided as one of

the selectable inputs for the Cartesian-to-Polar Converter.

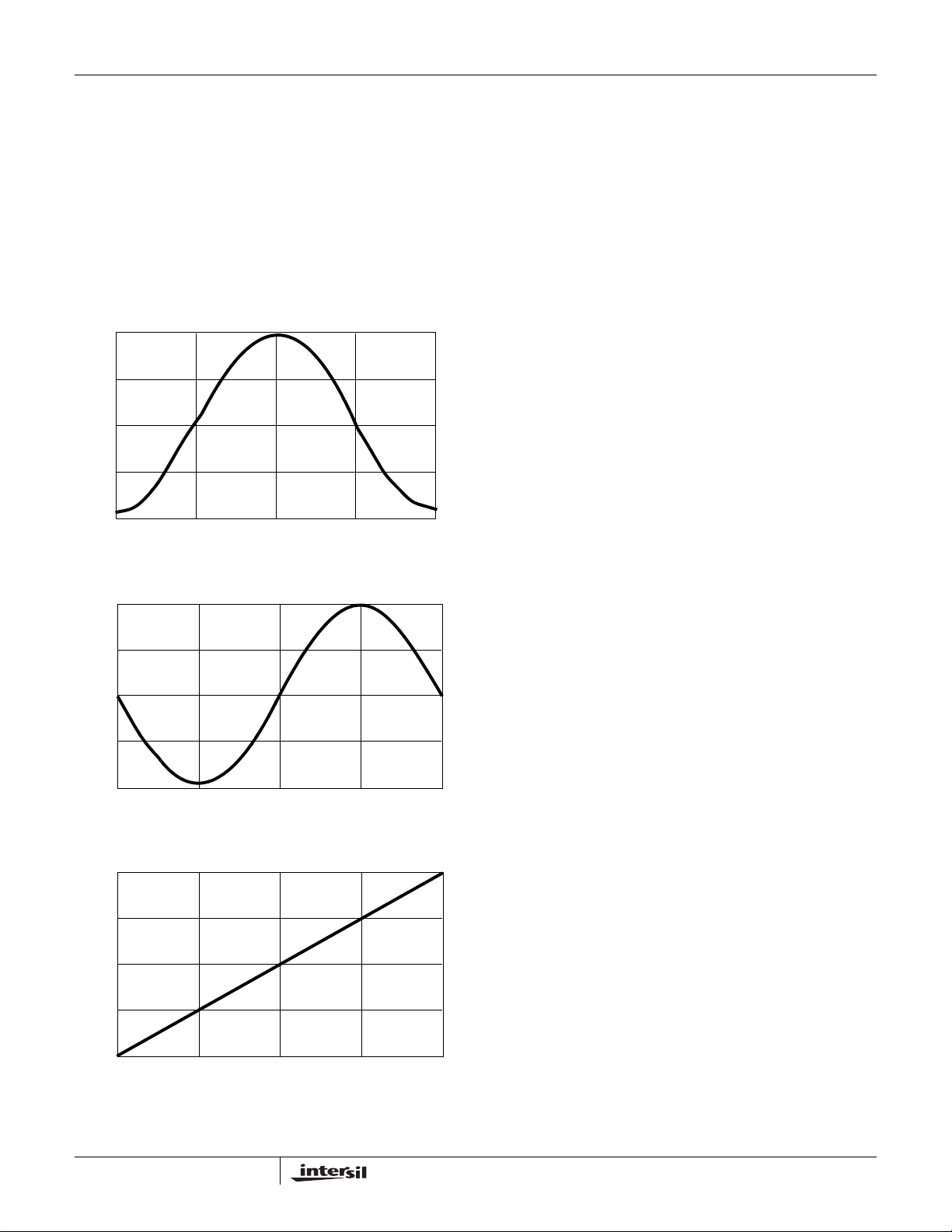

Cartesian/Polar Converter

The Cartesian/Polar Converter maps samples on the I and Q

processing paths to their equivalent phase/magnitude

representation. The magnitude conversion is equivalent to

Equation 5:

Mag (I, Q) 0.81()∗I2Q2+()=

where 0.81 is the gain of the conversion process. The

magnitude output is an 8-bit unsigned value ranging from 0.0

to 1.9922.

9

(EQ. 5)

FN3652.5

July 2, 2008

Page 10

HSP50210

www.BDTIC.com/Intersil

The phase conversion is equivalent to Equation 6:

Phase (I, Q) tan

-1

where tan

( ) is the arctangent function. The phase

1–

QI⁄(),=

(EQ. 6)

conversion output is an 8-bit two’s complement output,

which ranges from -1.0 to 0.9922 (80 to 7f HE X,

respectively). The -1 to almost 1 range of the phase output

represents phase values from -π to π, respectively. An

example of the I/Q to phase mapping is shown in Figures 6A

through 6C. The phase and magnitude values may be output

via the Output Selector bits 0 through 3 (see Tab le 43).

1.0

0.5

0

MAGNITUDE

-0.5

-1.0

-π

FIGURE 6A. I INPUT TO CARTESIAN/POLAR CONVERTER

1.0

0.5

0

MAGNITUDE

-0.5

-1.0

-π

FIGURE 6B. Q INPUT TO CARTESIAN/POLAR CONVERTER

1.0

0

INPUT PHASE

0

INPUT PHASE

π/2 π-π/2

π/2 π-π/2

The I/Q data path selected for input to the Cartesian-to-Polar

converter determines the input data rate of the AGC and

carrier tracking loops. If the I/Q data path out of the Integrate

and Dump Filter is selected, the AGC is fed with magnitude

values produced by the end-symbol samples. Magnitude

values produced by midsymbol samples are not used

because these samples occur on symbol transitions, resulting

in poor signal magnitude estimates. The Carrier Tracking

block is fed with phase values generated from both the end

and mid-symbol samples. The carrier tracking loop filte r,

however, is only fed with Ph ase Erro r terms gen erate d by the

end symbol samples. If the input of the I and D is selected for

input to the coordinate converter , the control loops are fed with

data at the I/Q data rate. The desired dat a p a th input to the

Cartesian to Polar converter is specified in the Data Path

Configuration Control Register , Bit 8 (see Table 15 on

page 32).

AGC

The AGC loop operates on the main data path (I and Q) and

performs three signal level adjusting functions:

1. Maximizing dynamic range

2. Compensating for SNR variations

3. Maintaining an optimal level into the Soft Decision Slicer.

The AGC Loop Block Diagram, shown in Figure 7, consists

of an Error Detector, a Loop Filter, and Signal Gain Adjusters

(multipliers). The AGC Error Detector generates an error

signal by subtracting the programmable AGC threshold from

the magnitude output of the Cartesian to Polar Converter.

This difference signal is scaled (gain adjusted via multiplier

and shifter), then filtered (integrated) by the AGC Loop Filter

to generate the gain correction to the I and Q signals at the

multipliers. If a fixed gain is desired, set the upper and lower

limits equal.

The AGC responds to the magnitude of the sum of all the

signals in the bandpass of the narrowest filter preceding the

Cartesian to Polar Coordinate Converter. This filter may be

the Integrate and Dump filter shown in Figure 7 on page 12,

the RRC filter upstream in the HSP50210 data path, or some

other filter outside the DCL chip. The magnitude signal

usually contains several components:

0.5

2. The noise comp onent, and

3. Interfering signals component.

1. The signal of interest component,

0

At high SNR’s the signal of interest is significantly greater

than the other components. At lower SNR’s, components 2

-0.5

OUTPUT VOLTAGE

or 3 may become greater than the signal of interest.

Narrowing the filter bandwidth is the primary technique

-1.0

-π

0

INPUT PHASE

π/2 π-π/2

used to mitigate magnitude contributions of component 3.

This will also improve the SNR by reducing the magnitude

contributions of element 2. Consideration of the range of

signal amplitudes expected into the HSP50210, in

FIGURE 6C. CARTESIAN/POLAR CONVERTER PHASE OUTPUT

conjunction with a gain distribution analysis, will provide the

10

FN3652.5

July 2, 2008

Page 11

A

HSP50210

www.BDTIC.com/Intersil

necessary insight to set the signal level into the Soft

Decision Slicer to yield opti mum perf or ma nce .

Note: Failure to consider the variations due to noise or

interfering signals, can result in signal limiting in the

HSP50210 processing algorithms, which will degrade the

system Bit Error Rate performance.

The AGC Loop is configured by the Power Detect Threshold

and AGC Loop Parameters Control Registers (see Tables 16

and 17 on page 33). Seven programmable parameters must be

set to configure the AGC Loop and its status outputs. Two

parameters, the Power Threshold and the AGC Threshold are

associated with the Error Detector and are represented in 8-bit

fractional unsigned binary format: 2

02-12-22-32-42-52-62-7

.

While the format provides a range from 0 to 1.9961 for the

thresholds, the Cartesian-to-Polar Converter scales the I

and Q input magnitudes by 0.81. Thus, if a full scale (±1)

complex (I and Q) input signal is presented to the converter,

the output will be √(0.81)

2

+ (0.81)2 = 1.1455. The AGC

Threshold parameter value is the desired magnitude of the

signal as it enters the Soft Decision Slicer. It is the parameter

that will determine the error signal in the AGC loop. The

Power Threshold, on the other hand, determines only the

power threshold at which the THRESH

signal is asserted. If

the signal magnitude exceeds the threshold, then the

THRESH

is asserted. This may be used for signal detection,

power detection or external AGC around the A/D converter.

The AGC Threshold parameter is set in the AGC Loop

Parameters Control Register, Bits 16 through 23 (see

Table 17 on page 33). The Power Threshold parameter is

set in the Power Detect Threshold Control Register, Bits 0

through 7 (see Table 16 on page 33). Note that these two

threshold parameters are not required to be set to identical

or even related values, since they perform independent

functions.

The Enable AGC parameter sets the AGC Error Detector

output to zero if asserted and to normal error detection

output when not asserted. This control bit is set in the AGC

Loop Parameter Control Register, Bit 31 (see Tables 17 on

page 33). This bit is used to disable the AGC loop.

The remaining AGC parameters determine the AGC loop

characteristics: gain tracking, tracking rate and tracking limits.

The AGC Loop gain is set via two parameters: AGC Loop Gain

Exponent and AGC Loop Gain Mantissa. In general, the higher

the loop gain, the faster signal level acquisition and tracking,

but this must be tempered by the specific signal characteristics

of the application and the remaining programmable loop

parameters. For the HSP50210, the AGC Loop Gain provides

for a variable attenuation of t he input to the loop filter. The AGC

gain mantissa is a 4-bit value which provides error signal

scaling from 0.000 to 0.9375, with a resolution of 0.0625.

Table 2 on page 11 details the discrete set of decimal values

possible for the AGC Loop Gain mantissa. The exponent

-7

provides a shift factor scaling from 2

to 2

-14

. Table 3 on

page 11 details the discrete set of decimal values possible for

the AGC Loop Gain Exponent. When combined, the exponent

and mantissa provide a loop gain defined as Equation 7:

GC Loop Gain: G

AGC

M()24–()[]2

7E+()–

()[]=

(EQ. 7)

where M is a binary number with a range from 0 to 15 and E

is a 3-bit binary value from 0 to 7. M and E are the

parameters set in the AGC Loop Parameters Control

Register, Bits 24 through 30 (see Table 17 on page 33). The

composite range of the AGC loop Gain is 0.0000 to

[0.9375][2 to 7]. This will scale the AGC error signal to a

range of 0.000 to (1.1455)(0.9375)(2 to 7) = 1.07297(2 to 7).

TABLE 2. AGC LOOP GAIN BINARY MANTISSA TO DECIMAL

SCALED MANTISSA MAPPING

BINARY

CODE

(MMMM)

0000 0.0000 1000 0.5000

0001 0.0625 1001 0.5625

0010 0.1250 1010 0.6250

0011 0.1875 1011 0.6875

0100 0.2500 1100 0.7500

0101 0.3125 1101 0.8125

0110 0.3750 1110 0.8750

0111 0.4375 1111 0.9375

TABLE 3. AGC LOOP BINARY EXPONENT TO SCALED

BINARY CODE

(EEE)

000 0 2

001 1 2

010 2 2

011 3 2

100 4 2

101 5 2

110 6 2

111 7 2

DECIMAL

SCALED

MANTISSA

DECIMAL EXPONENT MAPPING

DECIMAL/HEX

EXPONENT

BINARY

CODE

(MMMM)

DECIMAL SCALED

DECIMAL

SCALED

MANTISSA

EXPONENT

-7

-8

-9

-10

-11

-12

-13

-14

11

FN3652.5

July 2, 2008

Page 12

HSP50210

www.BDTIC.com/Intersil

READ

REG

AGC GAIN = (1.0 + M) x 2

GAIN

ADJUST

G

AGC

I

Q

AGC LOOP FILTER

AGC

AGC

UPPER

E

LOWER

LIMIT †

LIMIT †

L

R

I

E

M

G

I

T

1.0000 TO 15.8572 = G

(0 TO 24dB)

AGC LOOP

GAIN

MANTISSA †

-7

TO 2

(2

S

R

H

I

E

+

0.000 TO 1.07297(2

L

I

M

I

T

F

G

T

AGC

CART/POLAR INPUT SELECT†

AGC LOOP

EXPONENT †

-14

(0.000 TO 0.9375)

)

R

E

G

-7

)

I AND D FILTER

I AND D FILTER

FIGURE 7. AGC LOOP BLOCK DIAGRAM

The AGC Loop Filter integrates the scaled error signal to

provide a correction control term to the multipliers in the I and

Q path. The loop filter accumulator has internal upper and

lower limiters. The upper eight bits of the accumulator output

map to an exponent and mantissa format that is used to set

these upper and lower limits. The format, illustrated in Figure

8, is used for the AGC Upper Limit, AGC Lower Limit and the

Correction Control Term (AGC output). This format should not

be confused with the similar format used for the AGC Loop

Gain. The input to the AGC Loop Filter is included in Figure 8

to show the relative weighting of the input to output of the loop

filter. The loop filter input is represented as the eleve n letter

“G”s. Lower case “e” and “m” detail the format for the AGC

Upper and Lower Limits. This change in type case should help

keep the AGC Limits and AGC Gain formats from being

confused. The AGC Upper and Lower Limits are set in the

AGC Loop Parameters Control Register, Bit s 0 throu gh15,

(see Table 17). This 6-bit unsigned mantissa format provides

for an AGC output control range from 0.0000 to 0.9844, with a

resolution of 0.015625. The 2-bit exponent format provides an

AGC output control range from 1 to 8. The decimal values for

each of the 64 binary mantissa values is detailed in Table 4,

while Table 5 details the decimal value for the 4 exponent

values.

GAIN

M

U

X

“0”

ENABLE AGC †

The AGC Output is implemented in the multiplier according

to Equations 8 and 9.

where m and e are the binary values for mantissa and

exponent found in Ta bles 4 and 5.

Note: This format is identical to the format used to program

the AGC Upper and Lower Limits, but in this usage it is not a

programmed value. It is a representation of the digital AGC

output number, which is presented to the Gain Adjuster

(multipliers) to correct the gain of the I and Q data signals in

the main data path.

These equations yield a composite (mantissa and

exponent) AGC output range of 0.0000 to 1.9844(2

is a logarithmic range from 0dB to 24dB. Figure 9 has

graphed the results of Equations 8 and 9 for both the linear

and logarithmic equations. Figure 9 also has a linear

estimate of the logarithmic equation. This linear

approximation will be used in calculating the AGC response

time.

M

U

X

Out

Out

AGC ERROR DETECT

COMPARE

POWER

THRSHLD †

+

GAIN

ERROR

AGC THRSHLD †

CARTESIAN TO POLAR

G

1.0

AGC linear–

AGC dB–

I2+Q

TAN

20 log 1.0 m

R

E

THRESH

G

-

1.64

-----------=

-1

( )

dcloutlvl agc thresh

where dcloutlvl is the

2

2

Q

I

magnitude output expressed

in dB from Full Scale (dBFS)

0.8

MAGNITUDE

(0 TO 1.1455)

PHASE

=

† Indicates a microprocessor control signal.

1.0 m

+()2e()=

AGC

+()2e()[]=

AGC

3

) which

1.64

⎛⎞

------------

⎝⎠

2

(EQ. 8)

(EQ. 9)

1 20 .2-1 2-2 2-3 2-4 2-5 2-6 2-7 2-8 2-9 2-10 2-11 2-12 2-13 2-14 2-15 2-16 2-17 2-18

2

ee.mmmmmm

GGGG GGGGGG G

FIGURE 8. AGC OUTPUT AND AGC LIMITS BIT WEIGHTING

12

FN3652.5

July 2, 2008

Page 13

HSP50210

www.BDTIC.com/Intersil

TABLE 4. AGC GAIN MANTISSA TO DECIMAL MAPPING

DECIMAL

VALUE

BINARY CODE

(MMMMMM

TABLE 5. AGC GAIN EXPONENT TO DECIMAL MAPPING

BINARY CODE

AGC

000000 0.000000 100000 0.500000

000001 0.015625 100001 0.515625

000010 0.031250 100010 0.531250

000011 0.046875 100011 0.546875

000100 0.062500 100100 0.562500

000101 0.078125 100101 0.578125

000110 0.093750 100110 0.593750

000111 0.109375 100111 0.609375

001000 0.125000 101000 0.625000

001001 0.140625 101001 0.640625

001010 0.156250 101010 0.656250

001011 0.171875 101011 0.671875

001100 0.187500 101100 0.687500

001101 0.203125 101101 0.703125

001110 0.218750 101110 0.718750

001111 0.234375 101111 0.734375

010000 0.250000 110000 0.750000

010001 0.265625 110001 0.765625

010010 0.281250 110010 0.781250

010011 0.296875 110011 0.796875

010100 0.312500 110100 0.812500

010101 0.328125 110101 0.828125

010110 0.343750 110110 0.843750

010111 0.359375 110111 0.859375

011000 0.375000 111000 0.875000

011001 0.390625 111001 0.890625

011010 0.406250 111010 0.906250

011011 0.421875 111011 0.921875

011100 0.437500 111100 0.937500

011101 0.453125 111101 0.953125

011110 0.468750 111110 0.968750

011111 0.484375 111111 0.984375

00 0 2

01 1 2

10 2 2

11 3 2

OF AGC

)

MANTISSA

BINARY CODE

(MMMMMM

DECIMAL/HEX

EXPONENT

AGC

DECIMAL SCALED

DECIMAL

VALUE

OF AGC

)

MANTISSA

EXPONENT

0

1

2

3

224

240

24

18

12

6

0

256

16

12

LINEAR ESTIMATE IN dB

8

4

DATA PATH GAIN (LINEAR)

1

0

0

1632486480

(8 MSBs OF LOOP FILTER ACCUMULATOR)

FIGURE 9. GAIN CONTROL TRANSFER FUNCTION

GAIN dB

96

112

128

144

GAIN CONTROL WORD

160

176

192

GAIN

LINEAR

208

There are two techniques for setting a fixed gain for the

AGC. The first is to set Control Word 2 Bit 31 = 1. This

precludes any error update of present AGC gain value. The

second is to set the upper and lower AGC limits to the

desired gain using Figure 9. The upper and lower limits

have the same value for this case.

The HSP50210 provides two mechanisms for monitoring

signal strength. The first, which involved the THRESH

signal, has already been described. The second

mechanism is via the Microprocessor Interface. The 8 most

significant bits of the AGC loop filter output can be read by

a microprocessor. Refer to the “Microprocessor Interface”

on page 27 for details of how to read this value. This AGC

value has the format describ ed i n Fi gur e 8.

AGC Bit Weighting and Loop Response

The AGC loop response is a function of the programmable

gain, the bit weightings inherent in the connection of each

element of the loop, the AGC Loop filter limits and the

magnitude of the input gain error step. Table 6 on page 14

details the bit weighting between each element of the AGC

Loop from the error detector through the weighting at the

gain adjuster in the signal path. The AGC Loop Gain sets the

growth rate of the sum in the loop filter accumulator. The

Loop filter output growth rate determines how quickly the

AGC loop traces the transfer function shown previously in

Figure 9. To calculate the rate at which the AGC can adjust

over a given period of time, a gain step is introduced to the

gain error detector and the amount of change that is

observed between clocks at the AGC Level Adjusters

(multipliers) is the AGC response time in dB per symbol.

This AGC loop will respond immediately with the greatest

correction term, then asymptotically approach zero

correction.

We begin calculation of the loop response with a full scale

error detector input of ±1. This error input is scaled by the

Cartesian to Polar converter, the error detecto r and th e AGC

GAIN (dB)

13

FN3652.5

July 2, 2008

Page 14

HSP50210

www.BDTIC.com/Intersil

Loop Gain, accumulated in the loop filter , limited and output to

the gain adjusters. The AGC loop tries to make the error

correction as quickly as possible, but is limited by the AGC

Loop Gain and potentially, the AGC limits. The maximum

AGC response is the maximum gain adjustment made in any

given clock cycle. This involves applying maximum Loop gain

TABLE 6. AGC BIT WEIGHTING

AGC

ACCUM

BIT

POSITION

22 Shifter → E1 12

21 Shifter → E0 6

20 Multiplier → M-1 3

19 M-2 1.5

18 M-3 0.75

17 M -4 0.375

16 M -5 0.1875

15 Multiplier → 1 M -6 0.09375

14

13 1 G -8 0.02344

12 2 G -9 0.01172

11 3 G -10 0.00586

10 4 G -11 0.00293

9 5 G -12 0.00146

8 8(S) = 1(S) 0. 12(S) 12(S) = 1 1 6 G -13 0.000732

77= 0• x1111= 0•

6 6 = 1 x 10 10 = 1 1 G -15 0.000183

5 5 = 2 x 9 9 = 2 2 G -16 0.0000916

4 4 = 3 x 8 8 = 3 3 G -17 0.0000458

3 3 = 4 7 7 = 4 4 G -18 0.0000229

2 2 = 5 6 6 = 5 5 -19 0.0000114

1 1 = 6 5 5 = 6 6 -20 0.00000572

0 0 = 7 4 -21 0.00000286

GAIN

ERROR

INPUT

GAIN

ERROR

BIT

WEIGHT

AGC LOOP

FILTER GAIN

(MANTISSA)

AGC LOOP

FILTER

GAIN

MULTIPLIER

(OUTPUT)

3

2

1

0

and setting the AGC limits as wide as possible. A calculation

using only exponent terms of the various gains will be

sufficient to yield a rough order of magnitude of the range of

the AGC Loop response. The results are shaded in the last

column of Table 6 on page 14 and provided in detail in

Equations 10 and 11.

AGC

LOOP

FILTER

GAIN BITS

KEPT

(rnd) SHIFT = 0 SHIFT = 7

0• • 0-7 0.04688

0• G -14 0.000366

AGC

OUTPUT

AND AGC

LIMITS BIT

WEIGHT

RESOLUTION

AGC GAIN

(dB)

AGC Response

AGC Response

where (0.5) is the MSB of the 0.81 scaling in the Cartesian-to-Polar Coo rdinate Con verter, (0.5) is the MSB of the mantissa of the

Loop Gain, (2

= Input (Cartesian to Polar Converter Gain)(Error Detector Gain)(AGC Loop Gain)(AGC Output Weighting)

MAX

MAX

-7)

10.5()± 0.5()27–()24() 129–()24()± 0.04688dB symbol time⁄===

is the maximum shift gain, and 24 is the maximum loop filter gain.

A similar procedure is used to calculate the minimum AGC response rate.

AGC Response

MIN

10.5()± 0.5()2

14–

()24() 12

16–

()24()± 0.000366dB symbol time⁄===

Thus, the expected range for the AGC rate is approximately 0.0004 to 0.0469dB/symbol time.

14

(EQ. 10)

(EQ. 11)

FN3652.5

July 2, 2008

Page 15

SYNTHESIZER/

www.BDTIC.com/Intersil

MIXER

G = 1.0, 0.5 (NOTE 1)

PART

INPUT

(NOTE 4)

0

BINARY

POINT

-2

-1

2

AGC GAIN

MANTISSA

1.0 TO 1.9844

(0.0156 STEPS)

G = 1.0 - 1.9844*2

RRC

FILTER

G = 1.0, 1.13 (NOTE 2)

G

1

0

-2

-1

2

-2

0

2

-1

2

AGC

HSP50210

EXPONENT

0

3

TO 2

2

3

ACCUMULATOR

G = 1 TO 16

L

I

8

M

/

I

T

5

-2

4

2

3

2

2

2

1

2

0

2

-1

2

INT/DUMP

0

-2

-1

2

INTEGRATE AND

DUMP FILTER

INT/DUMP

SHIFTER

0 TO 2-4

G = 2

4

-2

3

2

2

2

1

2

0

2

-1

2

SAMPLE PAIR

SUMMER

G = 0.5, 1.0 (NOTE 3)

L

I

M

I

T

4

-2

3

2

2

2

1

2

0

2

-1

2

0

-2

-1

2

INPUT TO

SOFT DECISION

SLICER

AND

SYMBOL TRACKING

BLOCK

0

-2

-1

2

-9

2

INPUT TO CARTESIAN-TO-POLAR CONVERTER

-10

2

RND

IF AGC OUTPUT SELECTED

-10

2

RND

-9

2

-7

2

RND

INPUT TO CARTESIAN-TO-POLAR CONVERTER

-7

2

IF INT/DUMP OUTPUT SELECTED

-11

2

-6

2

-6

2

-7

2

NOTES:

1. If the Mixer is enabled, the result of the complex multiply is scaled by two (G = 0.5). If the mixer is bypassed, the data passes unmodified (G = 1.0).

2. If the Root Raised Cosine Filter is enabled, a gain of G = 1.13 is introduced. If the RRC filters bypassed, the gain is unity.

-7

3. If the integrate and Dump Filter is bypassed the Sample Pair summer has a gain of G = 1.0 and the 2

-bit position is set to 1. If the integrate

and dump is enabled, the sample pair sum is scaled by one half (G = 0.5).

4. The negative sign on the MSBs indicates use of 2’s complement data format.

FIGURE 10. GAIN DISTRIBUTION AND INTERMEDIATE BIT WEIGHTINGS

Gain Distribution

The gain distribution in the DCL is shown in Figure 10.

These gains consist of a combination of fixed,

programmable, and adaptive gains. The fixed gains are

introduced by processing elements such as the Mixer and

Square Root of Root Raised Cosine Filter. The adaptive

gains are set to compensate for variations in input signal

strength.

The main signal path, with processing block gains and path

bit weightings, is shown in Figure 10. The quadrature inputs

to the HSP50210 are 10-bit fractional two’s complement

numbers with relative bit weightings, as shown in Figure 10.

Following the AGC, the signal path is limited to 8 bits and

passed through the Integrate and Dump Filter en route to the

Soft Decision Slicer and Symbol Tracking Block. The I and D

Filter uses an accumulator together with a sample pair summer

to achieve the desired decimation rate. The I and D shifter is

provided to compensate for the gain introduced by the I and D

Accumulator. The accumulator introduces gain equal to the

decimation factor R, and the shifter gain can be set to 1/R. For

example, if the I and D Filter decimation of 16 is chosen, the I

and D Accumulator will accumulate 8 samples before dumping,

which produces a gain of 8. Thus, for unity gain, the I and D

Shifter would be set for a gain of 2

-3

. The Sample Pair Summer

is unity gain since its output is scaled by one-half.

The first element in the processing chain is the Mixer, which

scales the quadrature outputs of the complex multiplier by

1/2 providing a gain of G = 0.5. If the Mixer is bypassed, the

signal is passed unmodified with a gain of 1.0. Following the

mixer, the quadrature signal is passed to the fixed coefficient

RRC filtering block, which has a gain of 1.13 if enabled and

1.0 if bypassed. Next, the AGC supplies gain to maintain an

optimal signal level at the input to the Soft Decision Slicer,

Cartesian-to-Polar Converter, and the Symbol Tracking

Loop. The gain supplied by the AGC ranges from 1.0 to

1.9844*2

3

.

Symbol Tracking

The symbol tracking loop adjusts the baseband sampling

frequency to force sampling of the baseband waveform at

optimal points for data decisions. The key elements of this loop

are the Sampling Error Detector and Symbol Tracking Loop

Filter shown in Figure 11. The output of these two blocks is a

frequency correction term which is used to adjust the baseband

sample frequency external to the HSP50210. In typical

applications, the frequency correction term is fed back to the

HSP50110 to adjust baseband sampling via the Resampling

NCO (see HSP501 10 Datasheet).

15

FN3652.5

July 2, 2008

Page 16

REGISTER ENABLE RATE

www.BDTIC.com/Intersil

! = SYMBOL RATE

BLANK = CLK RATE

SYMBOL TRACK

LOOP FILTER

LEAD GAIN

16

FRZ_ST

MID AND END

SYMBOL SAMPLES

END

MID

!

END

MID

R

E

G

SAMPLING ERROR DETECTOR

I

I

Q

Q

DATA

DECISION

MID-SYMBOL

DATA

DECISION

MID-SYMBOL

TRANSITION

DETECT

TRANSITION

MID-POINT

TRANSITION

DETECT

TRANSITION

MID-POINT

LEAD

MANTISSA

‘0’ ‘-1’‘1’

MUX

ACQ

ZERO

LEAD

“0”

LEAD

MANTISSA

TRACK

REG REG

MUX

-

+

“0”

‘0’ ‘-1’‘1’

‘0’

MUX

SINGLE/

DOUBLE

RAIL

SAMPLING

MUX

-

+

+

MUX

ERROR

INVERT

INVERT

ERROR

!

ERROR

ACCUM.

“0”

ZERO

LAG

REG REG

LAG

MANTISSA

ACQ

MUX MUX

MUX

LAG

MANTISSA

TRACK

LEAD

EXPONENT

ACQ

REG

REG REG

LAG

EXPONENT

ACQ

MUX

SHIFT SHIFT

MUX

LEAD

EXPONENT

TRACK

REG

+

MUX

LOAD

ACC

LAG

EXPONENT

TRACK

REG

LIMIT

ACC LIMITS

UPPER/LOWER

LAG

ACCUMULATOR

+

SERIAL

OUTPUT

FORMATTER

SOFSYNC

REG

TO

μP

INTERFACE

SOF

HSP50210

July 2, 2008

FN3652.5

FIGURE 11. SYMBOL TRACKING

LAG GAIN

Page 17

HSP50210

www.BDTIC.com/Intersil

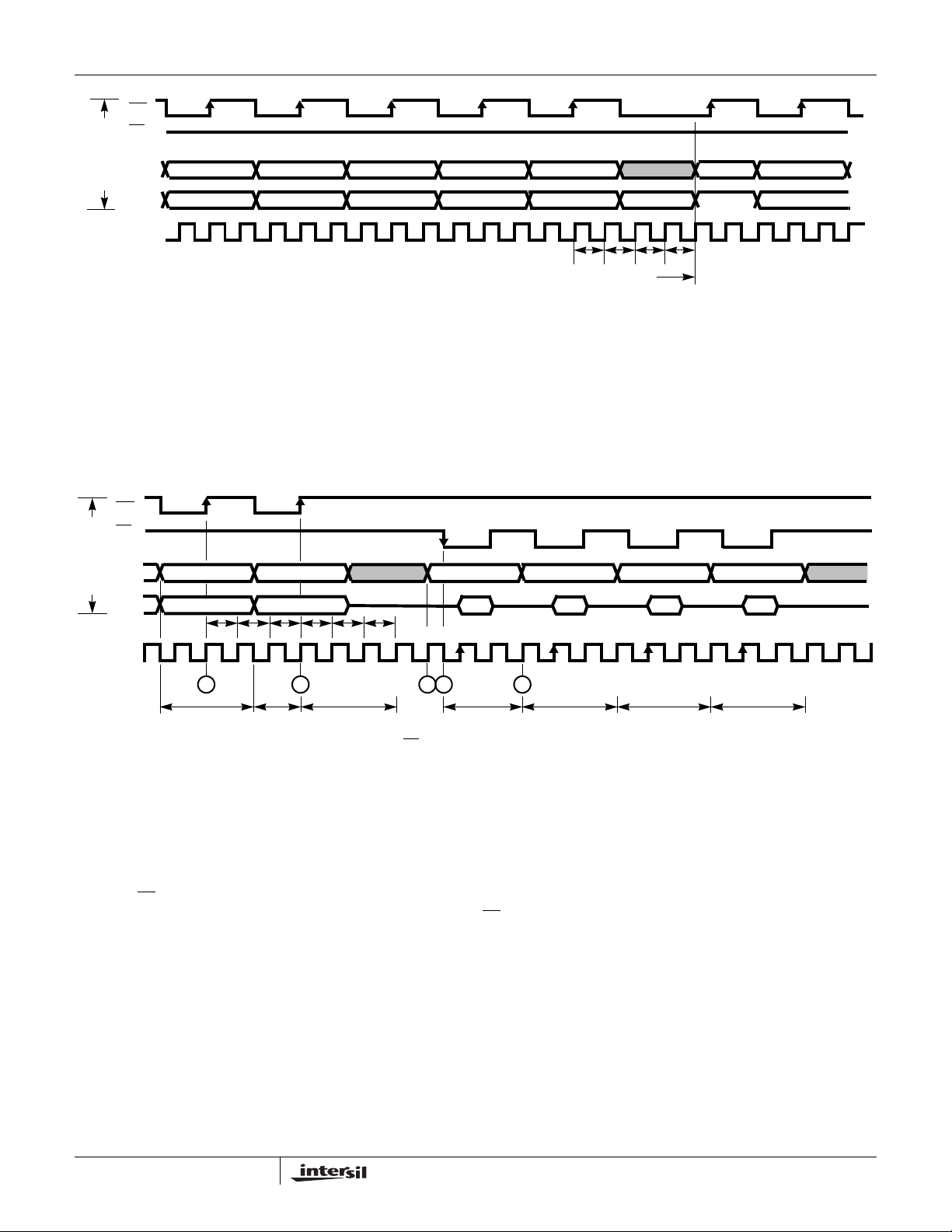

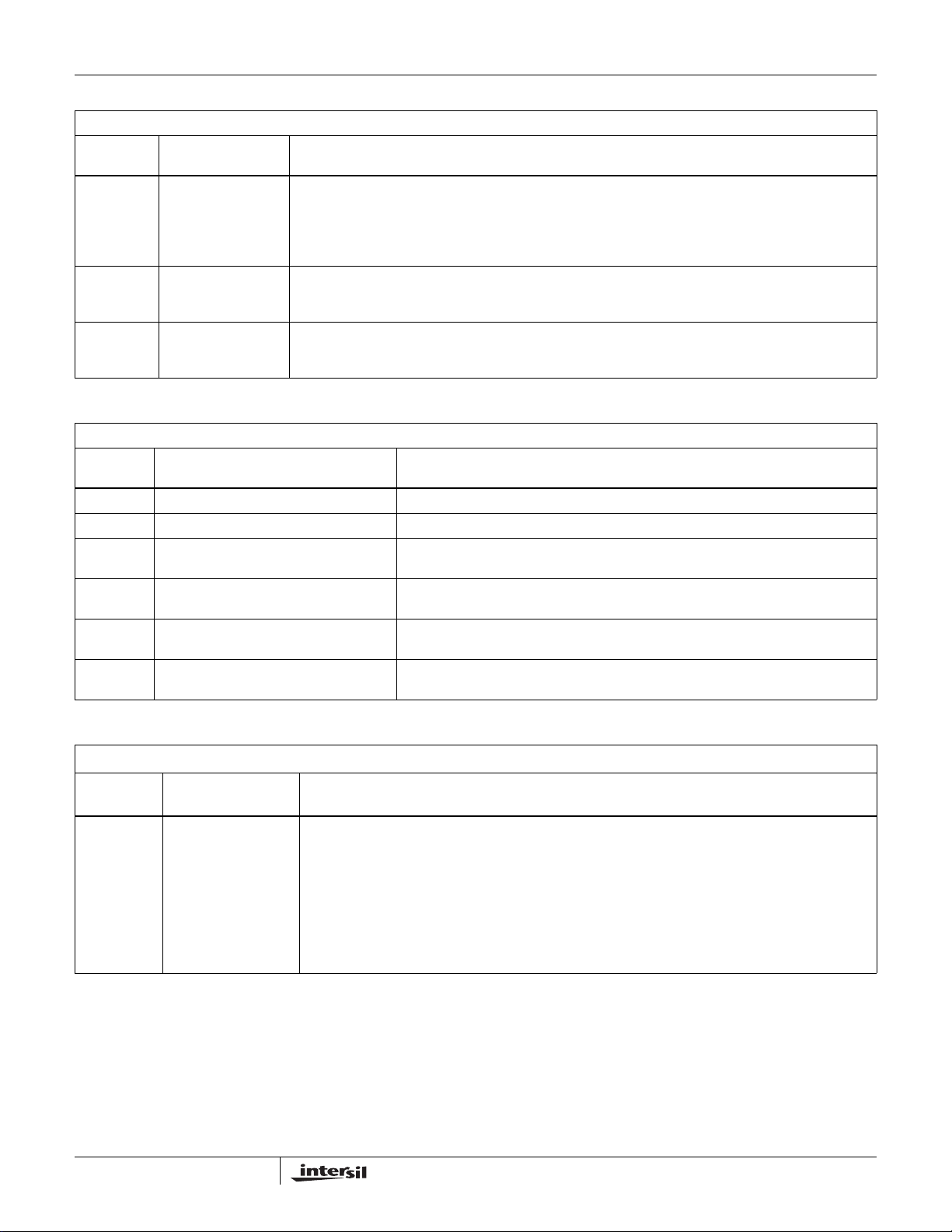

Sampling Error Detector

The Sampling Error Detector is a decision based error

detector which determines sampling errors on both the I and

Q processing paths. The detector assumes that it is fed with

samples of the baseband waveform taken in the middle of

the symbol period (mid-symbol sample) and between

symbols (end-symbol sample) as shown in Figure 12. The

sampling error is a measure of how far the mid-symbol

sample is from the symbol transition mid-point. The

transition mid-point is half way between two symbol

decisions. The detector makes symbol decisions by

comparing the end-symbol samples against a selectable

threshold set (see Modulation Order Select bits 9 through 10

in Table 29 on page 37). The error term is generated by

subtracting the mid-symbol sample from the transition midpoint. The sign of the error term is negated for negatively

sloped symbol transitions. If no symbol transitions are

detected the error detector output is zeroed. Errors on both

the I and Q processing paths are summed and divided by

two if Double Rail error detection is selected (see Symbol

Tracking Configuration Control Register, Bit 8: Table 29 on

page 37).

The sampling Error Detector provides an error accumulator

to compensate for the processing rate of the loop filter. The

error detector generates outputs at the symbol rate, but the

loop filter can only accept inputs every eight f

Thus, if the symbol rate is faster than 1/8 CLK, the error

accumulator should be used to accumulate the error until the

loop filter is ready for a new input. If the error accumulator is

not used when the symbol rate exceeds 1/8 CLK, some error

outputs will be missed. For example, if f

error accumulation is required for symbol rates greater than

5 MSPS (f

be scaled accordingly if the accumulator is used.

/8). Note: The loop filter lead gain term must

CLK

MID-SYMBOL

SAMPLE

CLK

X

X

SAMPLING

ERROR

FIGURE 12. TRACKING ERROR ASSOCIATED WITH

BASEBAND SAMPLING ON EITHER I OR Q RAIL

(BPSK/QPSK)

X

X

TRANSITION

X

X

MIDPOINT

clocks.

CLK

= 40MHz, then

END-SYMBOL

SAMPLE

EXPECTED

SYMBOL

LEVELS

Symbol Tracking Loop Filter

The Symbol Tracking Loop Filter is a second order lead/lag

filter. The sampling error is weighted by th e lag gain and

accumulated to give the integral response (see Figure 11).

The Lag Accumulator output is summed with the sampling

error weighted by the Lead Gain. The result is a frequency

term which is output serially, via the SOF output, to the

NCO/VCO controlling the baseband sample rate (see “Serial

Output Interfaces” on page 23). In basic configurations, the

SOF output of the HSP50210 is connected to the SOF input of

the HSP501 10.

Two sets of registers are provided to store the loop gain

parameters associated with acquisition and tracking. The

appropriate loop gain parameters are selected manually via

the Microprocessor Interface or automatically via the Carrier

Lock Detector. The loop filter’s lead and lag gain terms are

represented as a mantissa and exponent. The mantissa is a

4-bit value which weights the loop filter input from 1.0 to

1.9375. The exponent defines a shift factor that provides

additional weighting from 2

mantissa and exponent provide a gain range between 2

and

~1.0 as given by Equation 10.

Lead/Lag Gain = (1.0+M*2-4)*2

where M = a 4-bit binary number from 0 to 15, and E is a 5-bit

binary value ranging from 0 to 31. For example, if M = 0101

and E = 001 10, the Gain = 1.3125*2

Control Registers described in Tables 32 and 33 beginning on

page 38.

A limiter is provided on the lag accumulator output to keep the

baseband sample rate within a user defined range (see

Tables 30 and 31 on page 38). If the lag accumulator exceeds

either the upper or lower limit, the accumulator is loaded with

the limit. For additional loop filter control, the loop filter output

can be frozen by asserting the FZ_ST pin which null the

sampling error term into the loop filter. The lag accu mulator

can be initialized to a particular value and can be rea d via the

microprocessor interface as described in “Reading from the

Microprocessor Interface” on page 27, and Table 34 on

page 39. The symbol tracking loop filter bit weighting is

identical to the carrier tracking loop bit weighting, shown in

Figures 9 and 10.

-1

-32

to 2

. Together the loop gain

-(32 -E)

-26

. They are stored in the

-32

(EQ. 10)

Soft Decision Slicer

The Soft Decision Slicer encodes the I/Q end-symbol

samples into 3-bit soft decisions. The input to the slicer is

assumed to be a bipolar (2ary) baseband signal

representing encoded values of either ‘1’ or ‘0’. The most

significant bit of the 3-bit soft decision represents a hard

decision with respect to the mid-point between the expected

symbol values. The 2 LSBs represent a level of confidence

in the decision. They are determined by comparing the

magnitude of the slicer input to multiples (1x, 2x, and 3x) of a

programmable soft decision threshold (see Figure 13).

17

FN3652.5

July 2, 2008

Page 18

HSP50210

www.BDTIC.com/Intersil

HARD DECISION

THRESHOLD

‘1’ DECISION

STRONGER WEAKER STRONGERWEAKER

-0.5

THRESHOLD

2x THRESHOLD

3x THRESHOLD

FS

1/2

MSB

1/3

0

1/3

MSB

1/2

-FS

FIGURE 13. OVERLAY OF THE HARD/SOFT DECISION

THRESHOLDS ON THE SYMBOL PROBABILITY

DENSITY FUNCTIONS (PDFs) FOR BPSK/QPSK

SIGNALS)

0.0

MSB-1

MSB-1

MSB-1

MSB-1

‘0’ DECISION

‘0’‘1’

0.5

THRESHOLD

2x THRESHOLD

3x THRESHOLD

PROBABILITY

DENSITY

FUNCTION

THRESHOLD

THRESHOLD

The soft decision threshold represents a range of

magnitude values from 0.0 to ~0.5. Note: Since the input to

the slicer has a range of 0.0 to

~1.0, the threshold setting

should be set to less than 1.0/3 = 0.33. This avoids

saturation. The slicer decisions are output in either a two’s

complement or sign/magnitude format (see Soft Decision

Slicer Configuration Control Register, Bit 7: Table 41 on

page 42). The slicer input to output mapping for a range of

input magnitudes is given in Table 7. For example, a

negative input to the slicer whose magnitude is greater

than twice the programmable threshold but less than 3x the

threshold would produce a sign/magnitude output of 110

(BINARY). The I and Q inputs to the slicer are encoded i nto

3-bit soft decisions ISOFT(2-0) and QSOFT(3-0). These

signals are routed to the OUTA(9-4) outputs by the Output

Configuration Control Register Selector bits 0-3 (see

Table 43 on page 44).

TABLE 7. SLICER INPUT TO OUTPUT MAPPING

SLICER INPUT MAGNITUDE

RELATIVE TO

SIGNAL

+>>>011011

+>>≤ 010 010

+>≤ < 001 001

+ ≤ < < 000 000

- ≤ < < 100 111

->≤ < 101 110

->>≤ 110 101

->>>111100

INPUT POLARITY

1x

THRESHOLD2xTHRESHOLD

3x

THRESHOLD

SIGN/MAGNITUDE

OUTPUT

TWO’S

OUTPUT

COMPLEMENT

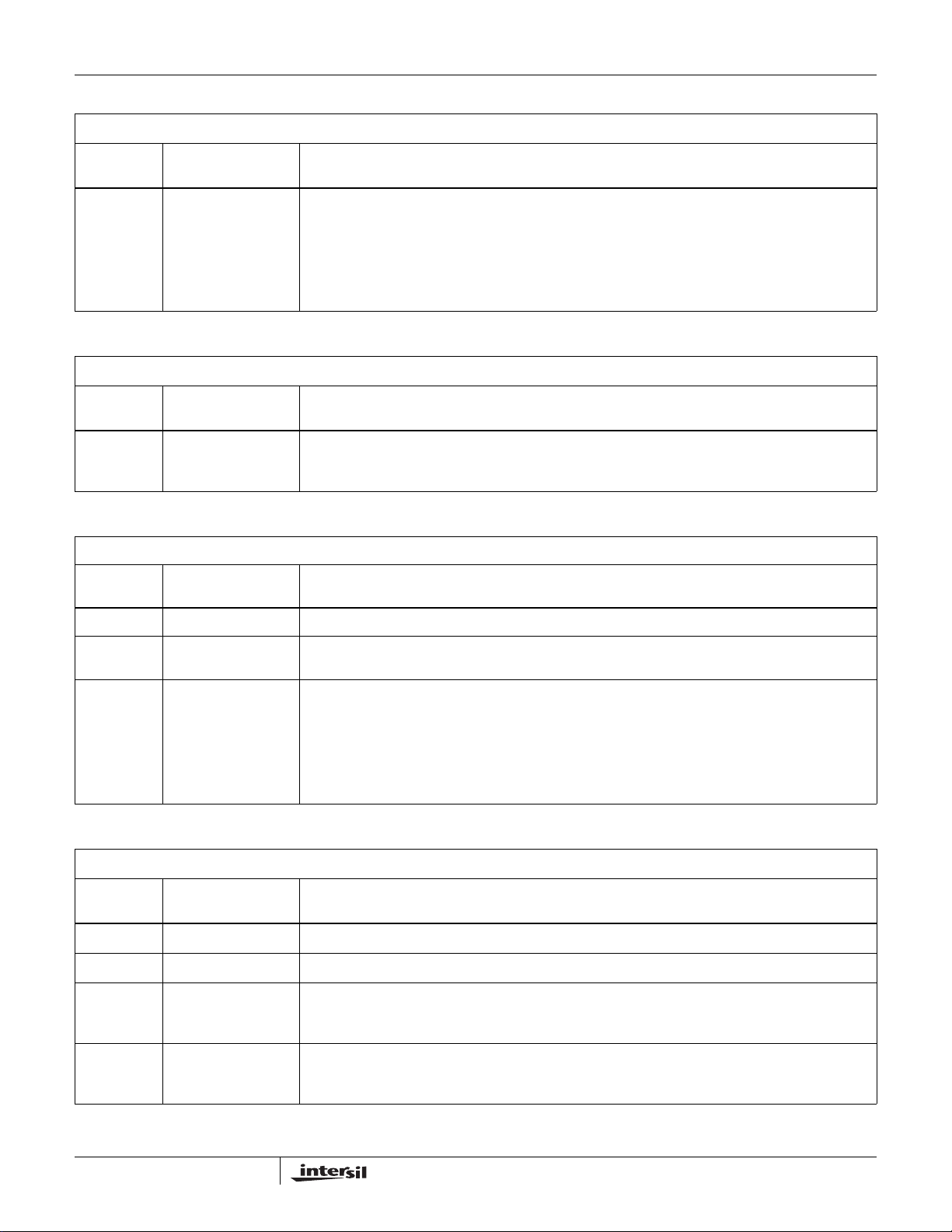

Carrier Phase Error Detector

The Carrier Phase Error is computed by removing the

phase modulation from the phase output of the

Cartesian-to-Polar Converter. To remove the modulation,

the phase term is rotated and multiplied (modulo 2π) to fold

the Phase Error into an arc centered about 0° but

encompasses the whole plane, as shown in Figure 14. The

phase rotation is performed by adding a 4-bit two’s

complement phase offset (resolution 22.5°) to the 4 MSBs

of the 8-bit phase term. The multiplication is performed by

left shifting the result from 0 to 3 positions with the MSBs

discarded and zeros inserted into the LSBs. For example,

Carrier Phase Error produces I/Q constellation points which

are rotated from the expected constellation points as

shown in Figure 14. By adding an offset of 45° (0010 0000

binary) and multiplying by 4 (left shift by two positions) the

phase modulation is removed, and the error is folded into a

90° arc centered at 0°. The left axis represents a decision

boundary of ±45°C, implying the vertical axis is ±22.5° as

shown in Figure 15. The phase offset and shift factors

required for different PSK orders is given in Table 9 on

page 21. Configuration of the Carrier Phase Error Detector

is done via the Carrier Phase Error Detector Control

Register, bit s 0 to 5, (see Table 18 on page 33). The Phase

Error term may be selected for output via the Output

Selector Configuration Control Register, bits 0 to 3 (see

Table 43 on page 44).

18

FN3652.5

July 2, 2008

Page 19

HSP50210

www.BDTIC.com/Intersil

In applications where Phase Error terms are generated

faster than the processing rate of the Carrier Loop Filter, an

error accumulator is provided to accumulate errors until the

loop filter is ready for a new input. Phase Error terms are

generated at the rate I/Q samples are input to the Cartesian

to Polar Converter. However, the Carrier Loop Filter cannot

accept new input faster than CLK/6 since six CLK(f

CLK

)

clock edges are required to complete its processing cycle. If

the error accumulator is not used and the I/Q sample rate

exceeds CLK/6, error terms will be missed.

Note: The carrier Phase Error terms input to the loop filter

are only generated from the end-symbol samples when the

output of the I and D filter is selected for input to the

Cartesian-to-Polar converter.

Note: The loop filter lead gain term must be scaled

accordingly if the accumulator is used.

90°

45°

I

X

0°±180°

Q

X

XX

-90°

DECISION

REGION

BOUNDARY

SHIFT

FACTOR

θ

E

ACTUAL

CONSTELLATION

DECISION

REGION

BOUNDARY

FIGURE 14. PHASE ERROR DETECTOR OPERATION (QPSK)

MODULA TION

POINT

INPUT TO CARTESIAN/POLAR CONVERTER

90°

Q

X

XX

θ

E

PHASE ROTATION BY 45°

TABLE 8. BASIC PHASE ERROR DETECTOR SETTINGS

TYPE

CW 0

BPSK 0

QPSK 45

8-PSK 22.5

X

-90°

PROJECTION OF PHASE ERROR (θ

PHASE

OFFSET

° (00 HEX) 0 (no shift) ±180

° (00 HEX) 1 (left shift 1) ±90

° (20 HEX) 2 (left shift 2) ±45

° (10 HEX) 3 (left shift 3) ±22

EXPECTED

CONSTELLATION

POINT

I

0°±180°

DECISION

REGION

BOUNDARY

22.5°

Q

-22.5°

MULTIPLICATION BY 4

(MODULO 2π)

) ABOUT 0°

E

PHASE ERROR

θ

X

RANGE

E

0°±45°

I

Carrier Loop Filter

The Carrier Loop Filter is second order lead/lag filter as

shown in Figure 14. The loop filter is similar to the Symbol

Tracking Loop Filter except for the additional terms from the

AFC Loop Filter and the Frequency Sweep Block. The

output of the Lag Accumulator is summed with the weighted

Phase Error term on the lead path to produce a frequency

control term. The Carrier Loop Filter is configured for

operation by the Control Registers described in Tables 21

through 28 beginning on page 34.

The Carrier Tracking Loop is closed by using the loop filter

output to control the NCO or VCO used to down convert the

channel of interest. In basic configurations, the frequency

correction term controls the Synthesizer NCO in the

HSP50110 Digital Quadrature Tuner via the COF and

COFSYNC pins of the HSP50210’s serial interface (see

“Serial Output Interfaces” on page 23). In applications where

the carrier tracking is performed using the NCO on board the

HSP50210, the loop filter output is fed to the on-board NCO

as a frequency control.

The gain for the lead and lag paths of the Carrier Loop Filter

are set through a programmable mantissa and exponent.

The mantissa is a 4-bit value which weights the loop filter

input from 1.0 to 1.9375. The exponent defines a shift factor

-1

that provides additional weighting from 2

to 2

-32

. Together

the loop gain mantissa and exponent provide a gain range

between 2

Lead/Lag Gain = (1.0+M*2-4)*2

-32

and ~1.0 as given by Equation 11.

-(32 -E)

(EQ. 11)

where M = a 4-bit binary number from 0 to 15, and E is

a 5-bit binary value ranging from 0 to 31. For example, if

M = 0101 and E = 00110, the Gain = 1.3125*2

-26

. The loop

gain mantissa and exponent are set in the Carrier Loop Gain

Control Registers (see T ables 25 through 26 on page 36).

The Phase Error input to the Carrier Loop Filter is an 8-bit

fractional two’s complement number between ~1.0 to -1.0

(Format -2

0

. 2-12-22-32-42-52-62-7). Some LSBs are zero for

BPSK, QPSK and 8-PSK. If minimum loop gain is used, the

Phase Error is shifted in significance by 2

-32

. With maximum

loop gain, the Phase Error is passed almost unattenuated.

The output of the Carrier Loop filter is a 40-bit fractional

two’s complement number between ~1.0 and -1.0 (Format -

0

2

. 2-12-22-3..... 2

-392-40

). In typical applications, the 32

MSBs of the loop filter output represent the frequency

control word needed to adjust the down converting NCO for

phase lock. Tables 9 and 10 beginning on page 21 illustrate

the bit weighting of the Carrier Loop Filter into the NCO for

both tracking and acquisition sweep modes.

A limiter is provided on the Carrier lag accumulator output to

keep frequency tracking within a user defined range (see

Tables 23 and 24 on page 35). If the lag accumulator

exceeds either the upper or lower limit the accumulator is

loaded with the limit. For additional loop filter control, the

Carrier Loop Filter output can be frozen by asserting the

FZ_CT pin which nulls the Phase Error term into the loop

filter. Also, the lag accumulator can be initialized to a

particular value via the Microprocessor Interface as

described in Tab le 28 on page 37 and can be read via the

microprocessor interface as described in “Reading from t he

Microprocessor Interface” on page 27.

19

FN3652.5

July 2, 2008

Page 20

20

www.BDTIC.com/Intersil

FRZ_CT

TO POLAR

CONVERTER

PHASE OUTPUT

FROM CARTESIAN

DETECT

TO LOCK

TO OUTPUT

SELECT BLOCK

REG

CARRIER PHASE

ERROR DETECT

PHASE

OFFSET

+

SHIFT

REG

PHASE ERROR

θ

)

(

E

DELAY

(1, 2, 4, 8, 16)

-

+

DISCRIMINATOR

SHIFT LEFT

0, 1, 2, 3

“0”

@ OR

*

MUX

ERROR

INVERT

PHASE

ERROR

REGISTER ENABLE RATE

@ = SYNC RATE

CARRIER

LOOP FILTER

MANTISSA

ZERO

LEAD

“0”

@ OR !

INVERT

ERROR

ACCUM.

“0”

ZERO

LAG

MANTISSA

CARRIER LEAD GAIN

LEAD

ACQ

MUX

MUXMUX

MUX

LAG

ACQ

CARRIER LAG GAIN

EXPONENT

LEAD

MANTISSA

TRACK

LAG

MANTISSA

TRACK

EXPONENT

LEAD

ACQ

LAG

ACQ

LEAD

EXPONENT

TRACK

MUX

SHIFT SHIFT

MUX

LAG

EXPONENT

TRACK

+

+

MUX

LOAD

ACC

FROM

MICROPROCESSOR

INTERFACE

UPPER/LOWER

LAG

ACCUMULATOR

REG

LIMIT

ACC LIMITS

LEAD/LEAD + LAG

+

LAG/LEAD + LA G

= TWICE SYMBOL

*

! = SYMBOL RATE

BLANK = CLK RATE

REG

MUX

MUX

REG

REG

SERIAL

OUTPUT

FORMATTER

TO

μP

INTERFACE

TO NCO

COF

COFSYNC

HSP50210

ERROR

ACCUM.

“0”

ZERO

AFC LOOP FILTER

MUX

MUX

AFC

MANTISSA

ACQ

@ OR !

ERROR

FREQUENCY

+

SHIFT

FREQUENCY

SHIFT

SHIFT LEFT

0, 1, 2, 3

July 2, 2008

FN3652.5

“0”

REG

CARRIER

FREQUENCY

ERROR DETECT

MUX

ERROR

INVERT

INVERT

FREQUENCY

ERROR

FIGURE 15. CARRIER ACQUISITION/TRACKING LOOP BLOCK DIAGRAM

MANTISSA

TRACK

AFC GAIN

MUX

EXPONENT

ACQ

SHIFT

EXPONENT

TRACK

FREQUENCY SWEEP

SHIFT

MUX

SWEEP RATE

MANTISSA

ACQ

“0”

TRACK

SWEEP RATE

EXPONENT

ZERO

SWEEP

Page 21

HSP50210

www.BDTIC.com/Intersil

TABLE 9. BIT WEIGHTING IN THE CARRIER LOOP FILTER TO THE NCO - TRACKING

OUTPUT

FREQUENCY

RESOLUTION

CLK

/2

CLK

/4

CLK

/8

CLK

/16

CLK

/32

CLK

/64

CLK

/128

CLK

/256

CLK

/512

CLK

/1024

CLK

/2048

CLK

/4096

CLK

/8192

CLK