HSP50016-EV

User’s Manual January 1999 File Number

DDC Evaluation Platform

The HSP50016-EV is the evaluation board for the

HSP50016 Digital Down Converter (DDC). It provides a

mechanism for rapid evaluation and prototyping. The

HSP50016-EV consists of a series of busses which provide

input, output, and control to the DDC. These busses are

brought out through dual 96 Pin connectors to support daisy

chaining HSP50016-EVs with other Intersil evaluation

boards for multichip prototyping and evaluation.

For added flexibility, the input and control busses can be

driven by registers on-board the HSP50016-EV which have

been downloadedwithdata via the parallel printer port of an

IBM PC™ or compatible. In addition, the DDC output can be

read into the PC via the status lines of the parallel port.

Together, the I/O and Control Registers can be used to drive

the target DDC with a PC based vector set while collecting

output data on the PC’s disk.

Jumper selectable clock sources provide three different

methods of clocking the part under evaluation. In mode one,

the clock signal is generated under PC based software

control. In mode two, the HSP50016-EV’son-board oscillator

maybe selected as the clock source. In mode three, the user

may provide an external clock through the 96 pin input

connector.

3637.1

Features

• Single HSP50016-EV May be Used to Evaluate the

HSP50016

• Maybe Daisy Chained to Support Evaluation of Multi-Chip

Solutions

• Parallel Port Interface to Support IBM PC™ Based

Evaluation and Control

• Three Clocking Modes for Flexibility in Performance

Analysis and Prototyping

• Dual 96-Pin Input/Output Connectors Conforming to the

VME J2/P2 Connector Standard

Applications

• PC Based Performance Analysis of HSP50016

• Rapid Prototyping

The HSP50016-EV was builtinto a 3U Euro-Card form factor

with dual 96 Pin Input/Output connectors. The I/O

connectors conform to the VME J2/P2 Connector Standard.

HSP50016 Evaluation Platform

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

http://www.intersil.com or 407-727-9207

| Copyright © Intersil Corporation 1999

HSP50016-EV

Getting Started

This section describes the initial evaluation system setup for

the HSP50016-EV evaluation board. The system setup

consists of the evaluation board, software installation, and

system test to verify proper operation of the board.

Assembly

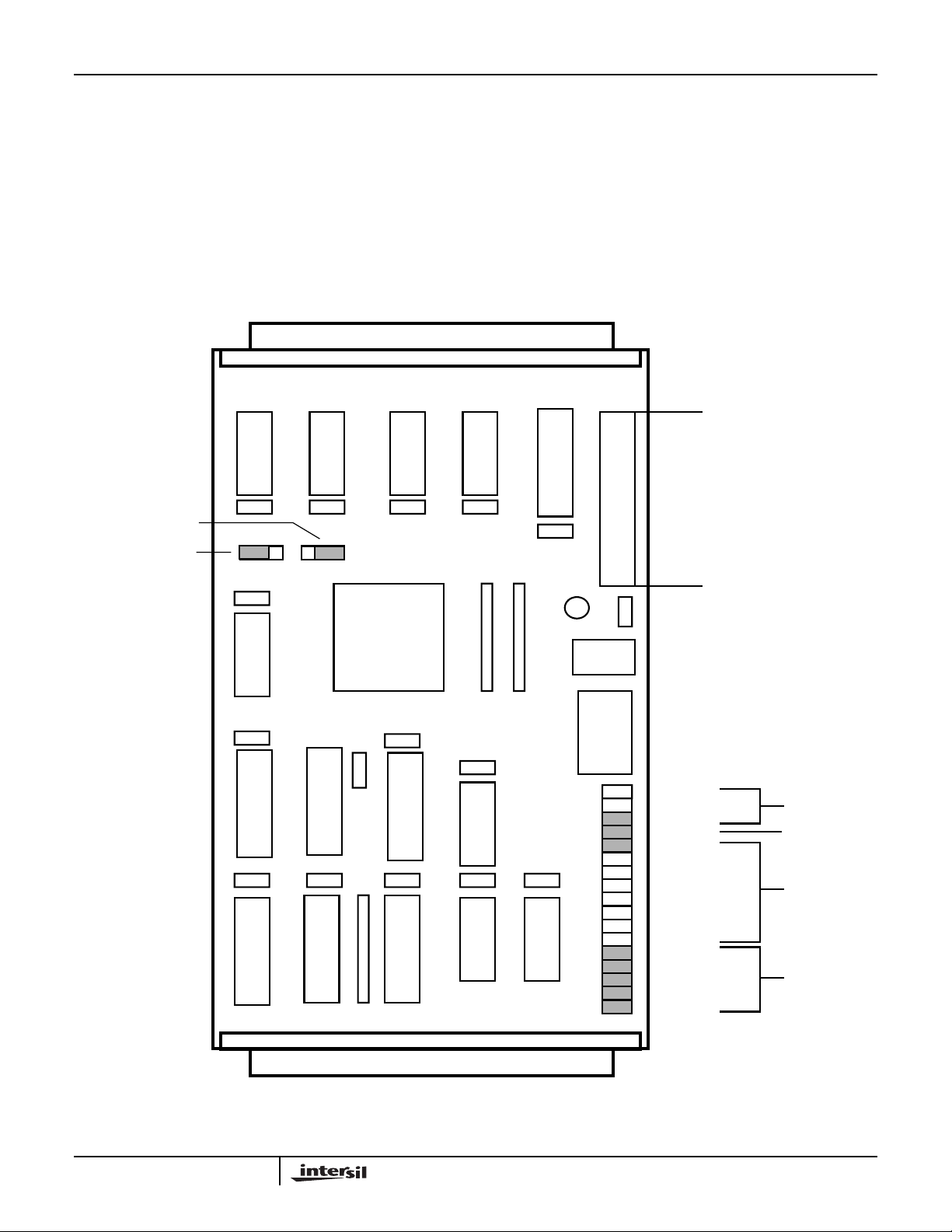

As part of the initial assembly, the HSP50016-EV must be

provided with the default jumper configuration to ensure

proper operation with the system test software. Each board

leaving the factory is supplied with the default configuration

as shown in Figure 1.

Before using the board with the supplied software, power

must be supplied to the board, and the HSP50016-EV must

be connected to the parallel port of the PC.

❏ Power is provided to the board by connecting the wall

mount power supply provided to connector J2. As an

alternative, power may be supplied by a standard 5V ±5%

supply through the J3 header or the HSP50016-EV’s 96

Pin DIN connectors P1 or P2.

❏ The HSP50016-EV is connected to the target PC by

connecting the HSP50016-EV’s26 Pin connector J1 to the

PC’s parallel port using the supplied ribbon cable.

System Requirements for the Evaluation Board

Software

The PC system targeted to run the HSP50016-EV software

(DDC-SOFT) and interface with the evaluation board must

meet the following requirements:

❏ IBM PC/XT/AT, PS/2, or 100% compatible with a minimum

of 640K of random access memory (RAM) (DDC-SOFT

does not require extended memory)

❏ At least 250kB of free disk space on the hard disk

❏ DOS Version 3.0 or higher

❏ One parallel port with 27 Pin D-Sub connector

Software Installation

The distribution diskette contains a program called

INSTALL.EXE which installs the DDC-SOFT software onto

the target hard disk. Note: The steps in this section assume

you are installing DDC-SOFT from a diskette in drive A: onto

a hard drive C:. If a different configuration is used, substitute

the letter of the drive where the diskette is located for drive

A: Substitute the letter for the hard drive for drive C:.

To start the installation program:

Make sure computer is on and the DOS prompt is displayed.

❏ Type: C:<Enter>

Create a subdirectory to contain the DDC-SOFT Programs

by typing:

❏ MD \DDCSOFT <Enter>

Change current directory to the DDCSOFT directory

❏ CD \DDCSOFT <Enter>

Start the installation process by typing:

❏ A:INSTALL <Enter>

The INSTALLprogram downloadsthe DDC-SOFTprograms,

DDCCTRL and DDCCMD, to the DDCSOFT subdirectory on

the target hard drive. In addition, a subdirectory called

DDC_CHK is created into which files used to perform

functional verification are downloaded.

Modifications to AUTOEXEC.BAT

To run the DDC-SOFT programs, DOS must be able to find

the executable files. To ensure that DOS can always find the

DDC-SOFT executables, modify the search path to include

the location of the DDC-SOFT directory. For example, if the

DDC-SOFT programs are installed on drive C: in a

subdirectory called\DDCSOFT, add the following line to the

end of the existing Path command in the AUTOEXEC.BAT

file:

❏ ;C:\DDCSOFT

If your AUTOEXEC.BAT file does not contain a PATH

command, add the following command to the file:

PATH=C:\DDCSOFT

❏ Reboot the PC so that the search path changes will take

effect.

System Test

Test software is provided to verify operation of the

HSP50016-EV Board. Prior to performing the system test, it

is assumed that the evaluation board has been assembled

and configured as described above, power has been applied

to the board, and the 26 Pin Connector J1 on board the

HSP50016-EV has been connected to the parallelport of the

target PC via the supplied cable. The system test is initiated

by the following:

Change the current directory to that which contains the

software required for the system test by typing:

❏ CD C:\DDCSOFT\DDC_CHK <Enter>

Run the system test software by typing:

❏ DDCCHK <Enter>

The DDCCHK.EXE batch file makes use of the Command

Line Interface (see Command Line Interface Section) to

initialize the evaluation board, clock a data vector through

the HSP50016-EV, and store the output to a file. The output

file is then compared, using the DOS command COMP, to a

file containing a set of vectors generated by a properly

functioning board. If the TEST_IN.DAT and TEST.OUT.DAT

files match, the assembled board passes operational

verification.

2

HSP50016-EV

When a successful compare has been done, the software

message returned is:

- Comparing files TEST_OUT.DAT and CMPRFILE.DAT

- FC: No differences encountered

The most common causes of test failuresare incorrect board

jumper settings, incorrect comm port selection, or a

corrupted eval.cfg file. It is helpful to delete the file

TEST_OUT.DAT, prior to the test, to ensure that DDC.CHK

runs properly and that a new TEST_OUT.DAT file was

created.

IQSTB SELECT

QOUT SELECT

JP20

11

JP19

P2

NOTE: if the operating system precedes DOS 6.0, the

user should answer NO to the COMP command prompt

to compare additional files. DOS Version 6.0 and above

use a different file compare command, so this step is

not necessary. DDCCHK checks the version

automatically and executes the proper compare routine.

The DDCCHK system test assumes that the LPT1 printer port

is being used for communication with the HSP50016-EV. If

another printer port is used, the Command Line Interface,

DDCCMD, m ust be used to configure the software for using

the correct port (see DDCCMD’s PPC and PP# command).

J1

CABLE

P1

JP1

JP2

JP3

JP5

JP6

JP7

JP8

JP9

JP10

JP11

JP12

JP13

JP14

JP15

JP16

JP17

JP18

J3

J2

EXT_CLK

OSC_CLK

PC_CLK

DATA_OE

ADDR0

ADDR1

ADDR2

ADDR3

ADDR4

ADDR5

ADDR6

ADDR7

DDC_CLK_INV

OUT_CLK_INV

CLK_OUT

CLK_IN

TAP_SEL

CLOCK

SELECT

OUTPUT

ENABLE

BOARD

ADDRESS

CLOCK

SELECT

FIGURE 1. LAYOUT OF HSP50016-EV SHOWING DEFAULT JUMPER CONFIGURATION

3

HSP50016-EV

HSP50016-EV Control Panel Software

The HSP50016-EV Control Panel is a graphical user

interface for controlling the operation of the HSP50016-EV

Board via an IBM PC or compatible. The control panel,

shown in Figure 3, supports loading the HSP50016's control

words; setting the state of control inputs; and specifying files

which serve as the sources and destinations for the

HSP50016's data and TAP inputs and outputs. Operation of

the control panel software is dependent on the clock source

provided to the HSP50016-EV as specified in the clock

select portion of the control panel. The HSP50016-EV

Control Panel is invoked by typing:

DDCCTRL <Enter>

Port Configuration

Communication between the Control Panel software and the

evaluationboard requires that the software knows which one

of the PC's parallel ports is being used for communication

with the HSP50016-EV and which board address the

HSP50016-EV has been configured for. The default

configuration assumes that LPT1 is being used and that the

HSP50016-EV has been configured for a board address of

0. The Port Configuration can be inspected by opening up

the port configuration window using the F9 function key. As

shown in Figure 4, the window displays the availableparallel

ports and their addresses. Also displayed are the current

port and HSP50016-EV board address being used by the

Control Panel software.

The current port and HSP50016-EV address are changed by

opening up the Port Configuration Window, using the

up/down arrow keys to select the desired parameter, and

toggling the space bar to change the selection. Proper

operation of the control panel software requires that the

HSP50016-EV board address specified in the port

configuration window matches the address jumpered in the

Address Selection Section of the HSP50016-EV’s headers

JP6-13.

Clock Select

The Clock Select portion of the control panel is used to tell

the Control Panel software which of four different clock

sources is being supplied to the HSP50016-EV. The choices

include one of two different software generated clocks

(Manual CLK or Port CLK), an oscillator clock provided by

the HSP50016-EV (Oscillator CLK), or an externally

supplied clock (External CLK). The clock mode selected

must be consistent with the Clock Select jumper position in

the HSP50016-EV’s headers JP1-3. If either Manual CLK or

Port CLK are specified in the Control Panel, the clock select

jumper must be inserted in JP3. If either Oscillator CLK or

External CLK is specified, the jumper must be inserted in

JP2 or JP1 respectively.

In Manual CLK mode, single clock pulses are sent to the

HSP50016 by depressing the F2 function key .The clock pulse

is software generatedby setting and clearing the PCCLK bit of

the Control Register U16 on the HSP50016-EV. After each

clock the HSP50016-EV's data outputs are inspected to see if

theyare ready to be read. If so, the data is read into the PC for

displayin the Control Panel. In this mode, file input and output

are supported (See File I/O Select Section).

In Port CLK mode, a free running clock is sent to the

HSP50016. The clock is started and stopped by depressing

the F2 function key. The clock pulses are software generated

by continually setting and clearing the PCCLK bit of Control

Register U16. After each clock the HSP50016-EV's data

outputs are inspected to see if they are ready to be read. If

so, the data is read into the PC for display in the Control

Panel. In this mode, file input and output are supported (see

File I/O Select Section).

In Oscillator CLK mode, the HSP50016 is supplied with a

clock by the oscillator on board the HSP50016-EV. In this

mode, the Control Panel can be used for modifying

and

IQSTRT, the control words, and the data and TAPinputs

to the DDC. However, the software is unable to provide file

based I/O to the evaluation board since the data rate

provided by the oscillator is much greater than that possible

through the parallel port of the PC. As a result, the Control

Panel disables file based I/O and the display of DDC output

in this mode.

Operation in External CLK mode is identical to that in

Oscillator CLK mode, except that the HSP50016 is supplied

with a clock through the 96 Pin DIN connector P1 on the

HSP50016-EV. Because this clock is asynchronous to the

PC, file based I/O and the DDC output displays are disabled.

The clocking mode used by the control panel is indicated by

the position of the “check mark” symbol within the Clock

Select portion of the Control Panel. A different clocking

mode may be selected by positioning the “check mark”

symbol in front of the desired clocking mode. The position of

the “check mark” is changed by using the cursor keys to

move the active window to the desired position and then

toggling the space bar to move the “check mark”.

RESET

File I/O Select

The File I/O Select portion of the Control Panel allows the

user to specify files which can be used as an input data

source or an output data destination for the HSP50016-EV.

The input data is loaded on to the input bus prior to the

software generated clock and the output data is read from

the output bus following the software generated clock.

If file based input is selected, the Control Panel software

down loads data from the specified file to registers on the

HSP50016-EV and clocks the data into the DATA0-15inputs

of the DDC. The Loop Count allows the user to simulate long

data streams by repeatedly sending the same input file.

If file based output is specified, the software reads the data

on the I and Q outputs of the HSP50016 and stores the data

in the specified file. The software automatically reads the

4

HSP50016-EV

output data and writes it into the output file as two’s

complement complex or real data. The configuration of the I,

Q, IQCLK and IQSTB pins is transparent to the user,

provided that none of the pins are three-stated and the DDC

Control Word fields Real Output, HDF Decimation Rate,

Number of Output Bits, I followed by Q and IQCLK rate are

compatible with each other. All valid output modes are

supported.

File based I/O is activated by using the space bar to toggle

the “check mark” symbol in the window proceeding the input

and output file identifiers in the control panel's file I/O

Section. If either file input or output is activated, the

respective file name must be entered in the window to the

right of the file identifier.File input or output may be disabled

at any time by toggling the respective “check mark”.

Note: File I/O is only valid when either the ‘Manual CLK’

or ‘Port CLK’ clocking modes are selected and it is

disabled if other clocking modes are specified.

Input and output data files are ASCII files whose format is

described in Appendix A. There is no limitation to the input

and output file size. Care must be taken if file output is

specified since data is collected in the file until file output is

deactivated or the DDCCTRL Program is exited.

TAP I/O files are similar, except that the TAP is available

regardless of the CLK setting. The format for the TAP input

and output files is given in Appendix B.

HSP50016 Data Inputs

The data window to the left of the HSP50016 icon is used to

specify hexadecimal values which drive the DDC's data

inputs DATA0-15. Data is entered into this window in

hexadecimal format starting with the most significant digit.

The contents of a particular data window may be edited by

following the window editing instructions in Appendix C.

If file input is selected, the data input is driven with data from

the specified file. On each clock the data window is updated

with the data sample down loaded from the file. In this mode

the data input window may not be manually updated.

HSP50016 Data I&Q Outputs

There are 32 bits available at P2. The control software for

the evaluation board performs a serial read via the PC Port.

Control Signals

The control signal portion of the control panel is used to

define the state of the DDC control signals

IQSTRT. The logical state of a control signal is set by using

the space bar to toggle the signal state in the window

preceding the specified control signal. When the evaluation

board is in Port CLK mode and

high, the DDC is automatically clocked five times. See the

HSP50016 Data Sheet for a complete description of the

control signals.

once after power up. The software DOES NOT do this

automatically.

RESET must be toggled low and high

RESET is set either low or

RESET and

Control Words

In the lower left hand corner of the control panel is a data

window which contains the hexadecimal values loaded into

the HSP50016's eight control words. The contents of a

particular control word may be updated by movingthe cursor

to the data window which is to be modified, selecting the

control word by pressing the space bar (which moves the

check mark to the desired control word) and depressing the

F4 key. A submenu pops up which parses that control word

into its various fields so that they may be examined or

modified individually.

The value entered into the data window is down loaded to

the HSP50016 and the submenu disappears when the user

depresses the F2 key. Leaving the window via the <Esc> key

ignores any changes made and returns to the main control

panel screen. If the update bit has been set, the new values

will update the configuration of the DDC and this will be

reflected in the submenu screen.

Note that all values displayed in this window are the last

values written to the control words, as opposed to

having been read from the DDC itself.

Help

Help windows are provided as a source of information for

control panel usage. The help window is activated by the F1

function key, and contains information based on the window

which is currently active.

Command Line Interface

As an alternative to the control panel, a command line

interface is provided which allows the user to control the

HSP50016-EV by issuing commands from the DOS prompt.

The commands perform basic I/O and configuration

functions by up or down loading data to the HSP50016

through the HSP50016-EV. The Command Line Program

has the following usage:

DDCCMD [Command] [ARG 1] [ARG 2] [ARG 3]

The Command specifies the action to be taken, and the

Arguments (ARG1, ARG2) represent additional data

required by the command. For example, to load Control

Word 1 with a value of 200000005(HEX) and set the update

bit, the user would type:

DDCCMD WCW 1 1 200000005 <Enter>

A summary of the command set is given in Table 2.

When several commands are to be entered consecutively,

the user may initiate the interactive command mode by

entering:

DDCCMD <Enter>

All commands are then entered as before, except that

control does not return to DOS between commands, and it is

not necessary to enter DDCCMD for each command. Note

5

HSP50016-EV

that the software automatically updates the control words

from the EVAL.CFG file upon entering the interactive mode.

Leaving the interactive mode is accomplished by typing

“quit” or “exit.”

DDCCMD gives the user the ability to control the evaluation

board via DOS batch files or system calls from a

programming language. The DDC_CHK6.BAT file discussed

in the System Test Section is an example of how the

Command Line Program might be used in a DOS batch file.

Configuration Jumpers

The Configuration Jumpers consists of the jumper headers

JP1-3 and JP5-20 as shown in Figure 1 and Table 1. Refer to

the evaluation board schematic found in the Appendices.

Most of these are self-explanatory, but the following bear

further discussion.

JP16

JP17

JP18

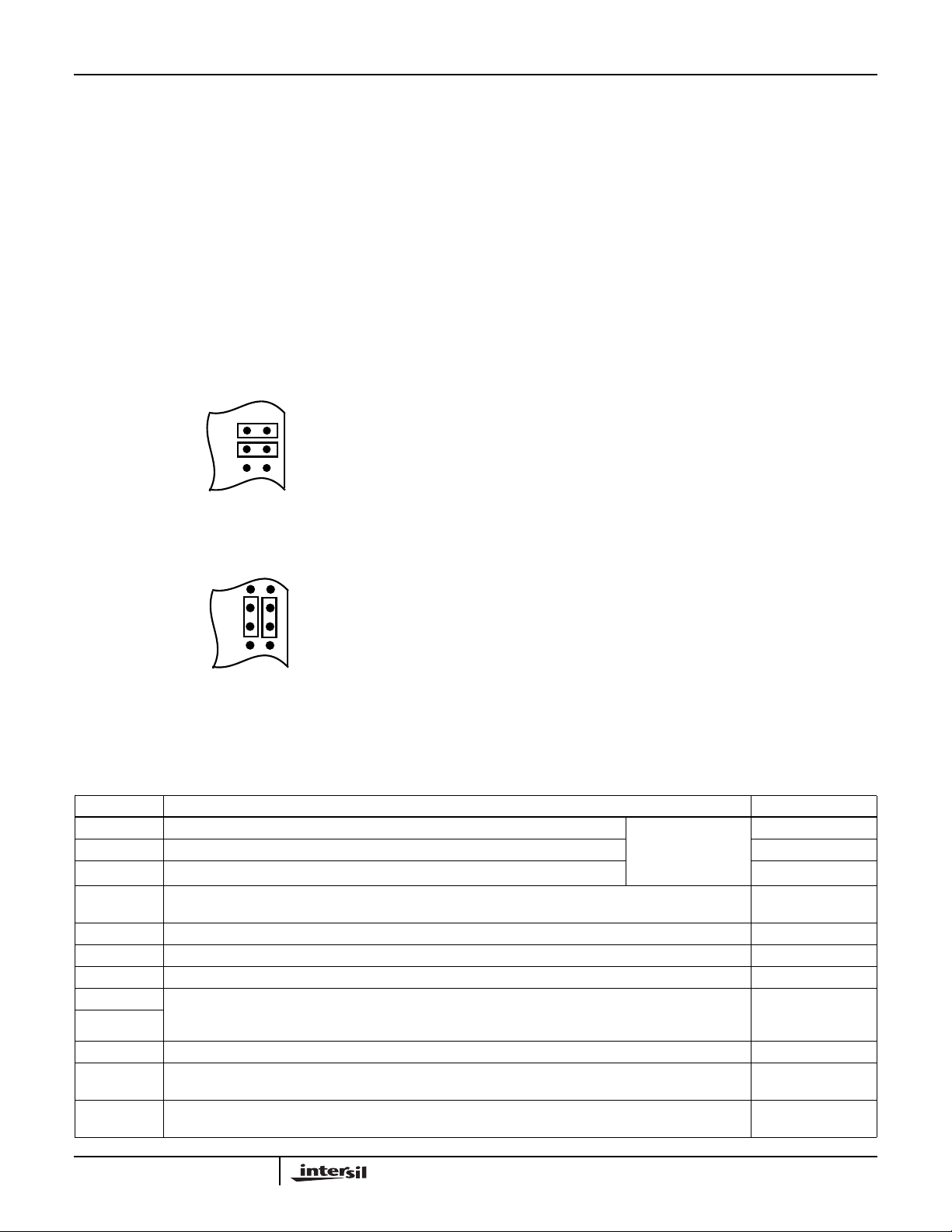

FIGURE 2. JUMPER CONFIGURATION IF CLOCK IS

SUPPLIED THROUGH P1 INPUT HEADER

JP15

JP16

JP17

JP18

FIGURE 3. JUMPER CONFIGURATION IF CLOCK IS

SUPPLIED THROUGH P2 OUTPUT HEADER

The jumpers JP16 and JP17 are used to select whether the

HSP50016's clock source is provided through the P1

connector or the P2 connector. If jumpers are inserted as

shown in Figure 2, a clock signal supplied through the

CLK_IN pin of the P1 input header drives a buffer whose

output clocks the HSP50016. The jumper inserted on JP16

feedsthe bufferedclock signal to the CLK_OUT pin of the P2

connector. If jumpers are inserted as shown in Figure 3, the

CLK_OUT pin of the P2 connector drives the clock buffer

which in turn drives the clock input of the HSP50016. The

jumper inserted between JP16 pin 2 and JP17 pin 2 allows

the CLKIN pin to be driven by the buffer output. NOTE: The

jumper placement shown in Figure 2 is the standard

configuration.

It is possible to configure the DDC so that the I, Q, IQCLK

and IQSTB outputs are in a high impedance state. Except for

IQSTB, these pins are pulled up on the evaluation board so

that they will not float under these conditions. Since IQSTB

can be either active high or low, it must be capable of being

pulled either way. JP19 determines whether IQSTB is pulled

up or down when it is three-stated. This jumper should be

installed such that IQSTB is pulled to its inactive state.

Note: The position of JP20 comes into play only when

parallel output from P2 is desired.

The jumper should be placed between pins 1 and 2 when

the DDC is configured for I followed by Q mode; the jumper

should be from JP20-2 to JP20-3 when I and Q are output

separately. The HSP50016-EV is shipped from the factory

with the default jumper configuration shown in Figure 1 and

Table 1. For the supplied software to properly control

operation of the HSP50016, it is assumed that the jumpers

are as specified in the default configuration; of course, once

the user is familiar with the operation of the board, this

configuration may be modified as required. The system test

software, DDCCHK, must be run using the default

configuration.

TABLE 1. DESCRIPTION OF JUMPER CONNECTIONS

JP DESCRIPTION DEFAULT

1 DDC CLK driven from external source when this jumper is installed. Only one of

2 DDC CLK driven from on board oscillator when this jumper is installed. 3 DDC CLK driven from PC software when this jumper is installed. Installed

5 DDC DATA0-15 driven from PC software when installed, otherwise data is from external source. Must be

installed or DATA0-15 lines must be driven to avoid damage to DDC.

6-13 Selects evaluation board address. Only one of these jumpers should be installed at a time. JP6 Installed

14 Selects input clock as inverted. Installed = non-inverted. Installed

15 Selects output clock as inverted. Installed = non-inverted. Installed

16 Direct flow of input and output clocks. JP16-1 is shorted to JP16-2 and JP17-1 is shorted to JP17-2 for the

17

18 TAP inputs driven by PC (installed) or from P2 (not installed). Installed

19 IQSTB pulled up (JP19-1 shorted to JP19-2) or pulled down (JP19-2 to JP19-3). Must be installed (in ei-

20 Serial to parallel converters configured for up to 32-bit, I followed by Q (JP20-1 to JP20-2) or 16 bit, I and

DDC CLK to be driven by the PC, on board oscillator, or connector pin P1C-20. To drive CLK from P2C20, jumper JP16-1 to JP17-1 and JP16-2 to JP17-2. JP1 must be installed in this configuration.

ther position) to avoid damage to evaluation board.

Q output separately (JP20-2 to JP20-3).

JP1, JP2 and JP3

selected

at a time.

JP16-1 to JP16-2,

-

Installed

JP17-1 to JP17-2

JP19-1 to JP19-2

JP20-2 to JP20-3

6

Loading...

Loading...