TM

www.BDTIC.com/Intersil

REFERENCE AN400

March 1997

HS-3282

CMOS ARINC Bus Interface Circuit

Features

• ARlNC Specification 429 Compatible

• Data Rates of 100 Kilobits or 12.5 Kilobits

• Separate Receiver and Transmitter Section

• Dual and Independent Receivers, Connecting Directly

to ARINC Bus

• Serial to Parallel Receiver Data Conversion

• Parallel to Serial Transmitter Data Conversion

• Word Lengths of 25 or 32 Bits

• Parity Status of Received Data

• Generate Parity of Transmitter Data

• Automatic Word Gap Timer

• Single 5V Supply

• Low Power Dissipation

• Full Military Temperat ure Range

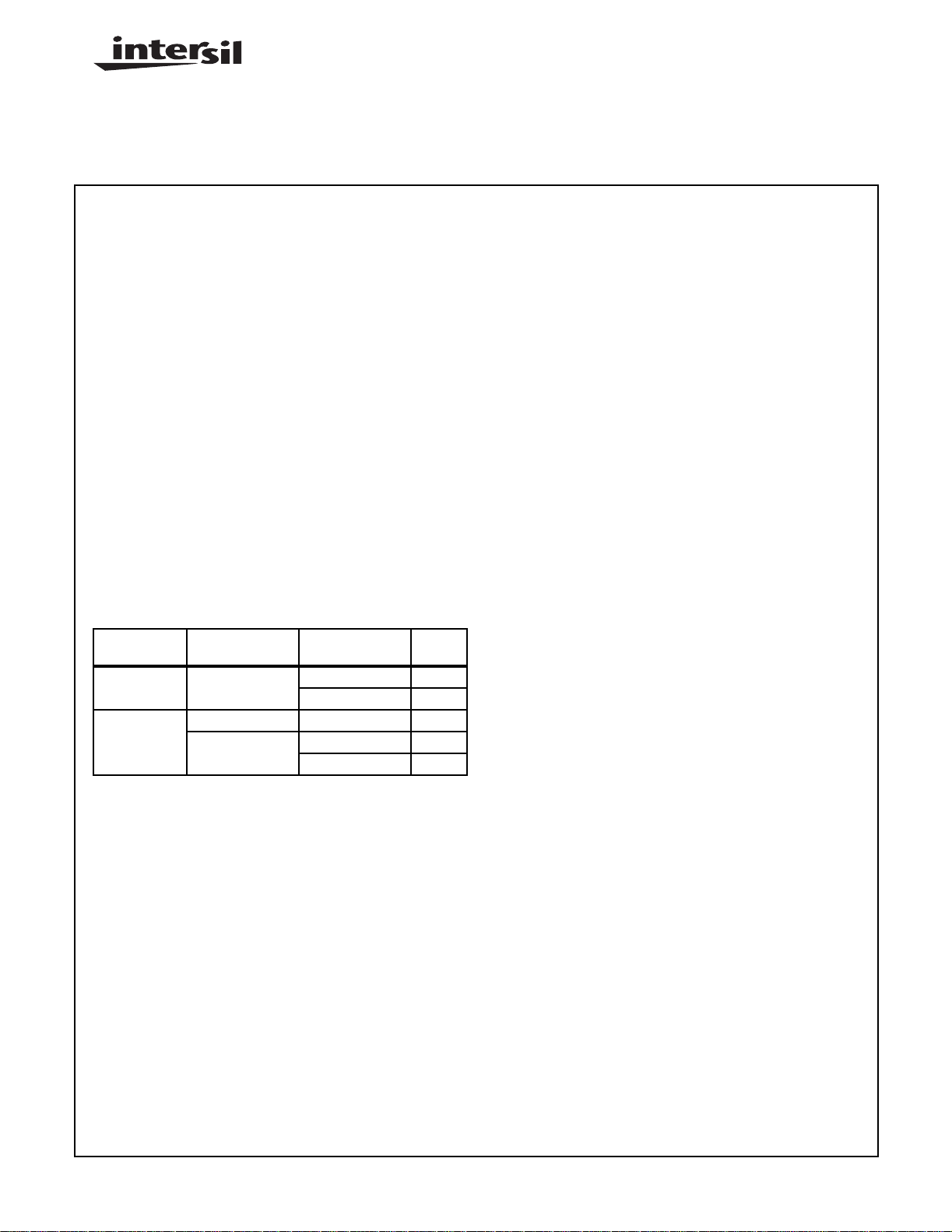

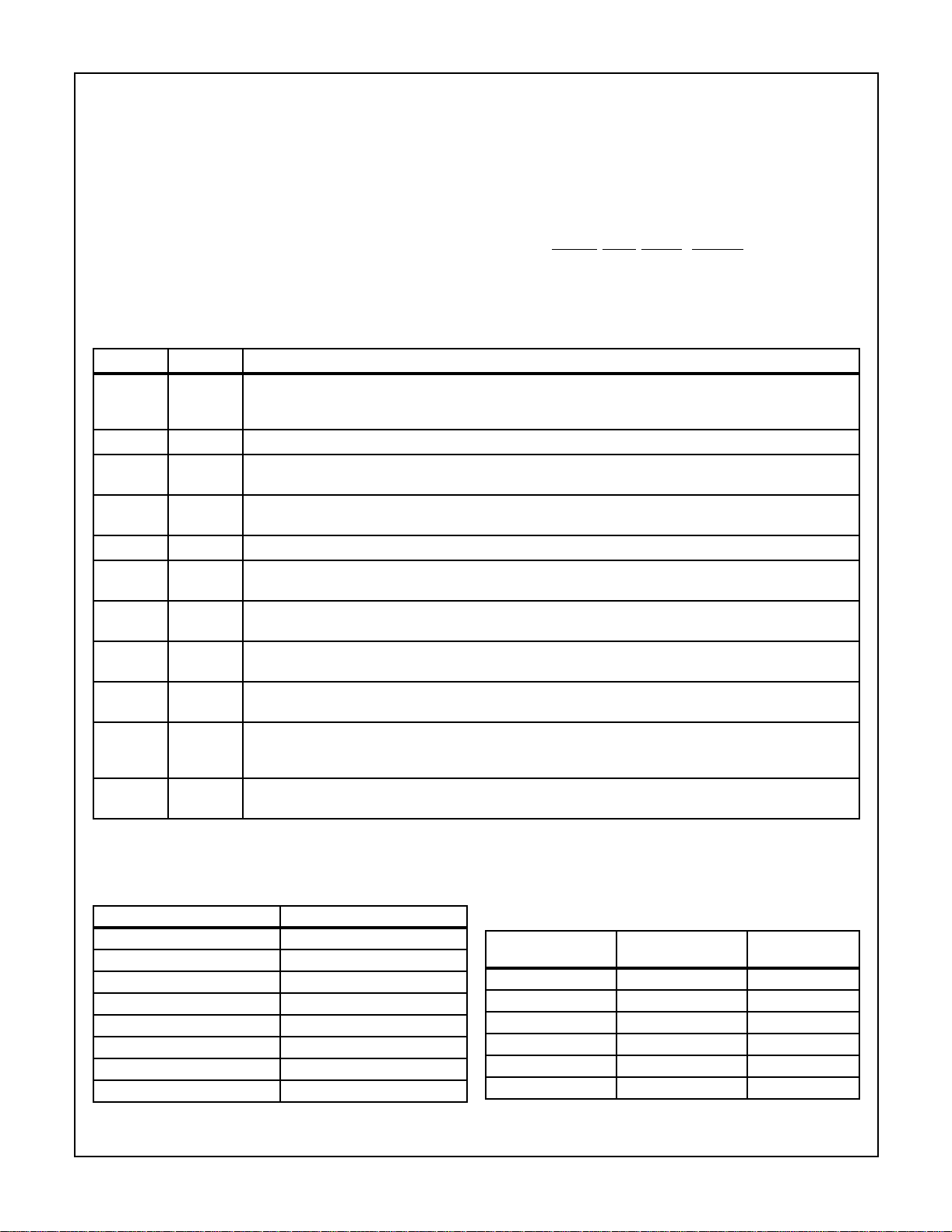

Ordering Information

PKG.

PACKAGE TEMP. RANGE PART NUMBER

o

CERDIP -55

SMD# 5962-8688001QA F40.6

CLCC -40

SMD# 5962-8688001XA J44.A

C to +125oC HS1-3282-8 F40.6

o

C to +85oC HS4-3282-9+ J44.A

o

C to +125oC HS4-3282-8 J44.A

-55

NO.

Description

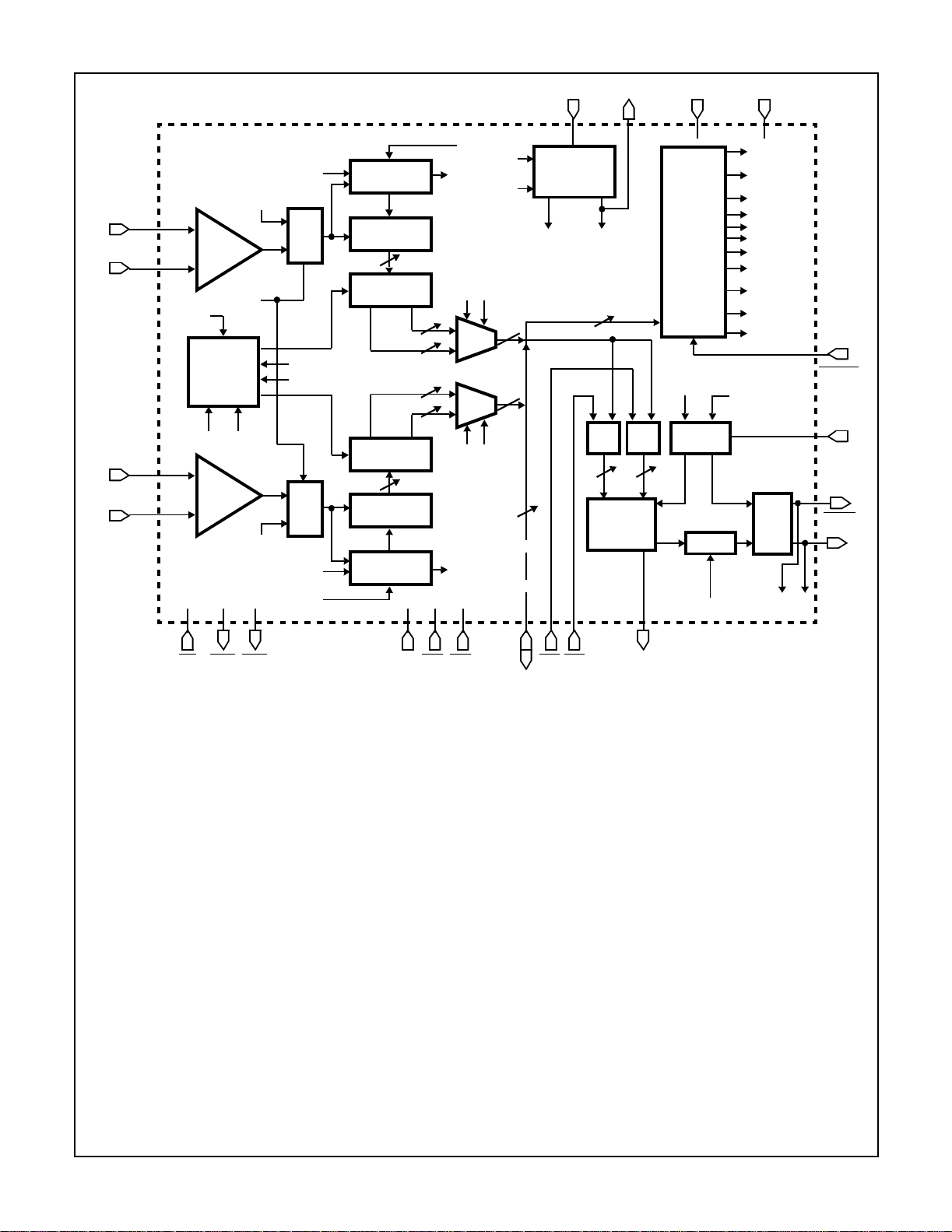

The HS-3282 is a high performance CMOS bus interface

circuit that is intended to meet the requirements of ARINC

Specification 429, and similar encoded, time multiplexed

serial data protocols. This device is intended to be used with

the HS-3182, a monolithic Dl bipolar differential line driver

designed to meet the specifications of ARINC 429. The

ARINC 429 bus interface circuit cons ists of two (2) receivers

and a transmitter operating independently as shown in

Figure 1. The two receivers operate at a frequency that is

ten (10) times the receiver data rate, which can be the same

or different from the transmitter data rate. Although the two

receivers operate at the same frequency, they are

functionally independent and each receive s serial data asynchronously. The transmitter section of the ARINC bus

interfa ce circ uit consis ts m ainly of a First -In Fi rst- Ou t (FIFO )

memory and tim ing circuit. The FIFO memory is used to hold

up to eight (8) ARINC data words for transmission serially.

The timing circuit is used to correctly separate each ARINC

word as required by ARINC Specification 429. Even though

ARINC Specification 429 specifies a 32-bit word, including

parity, the HS-3282 can be programm ed to also operate with

a word length of 25 bits. The incoming receiver data word

parity is checked, and a parity status is stor ed in the receiver

latch and output on Pin BD08 during the 1st word. [A logic

“0” indicates that an odd number of logic “1” s were received

and stored; a l ogic “1” indicat es that an even number of l ogic

“1”s were received and stored]. In the transmitter the parity

generator will generate either odd or even parity depending

upon the status of PARCK control signal. A logic “0” on

BD12 will cause odd parity to be used in the output data

stream.

Versatility is provided in both the transmitter and receiver by

the external clock input which allows the bus interface circuit

to operate at data rates from 0 to 100 kilobits. The external

clock must be ten (10) times the data rate to insure no data

ambiguity.

The ARINC bus interface circuit is fully guaranteed to

support the data rates of ARINC specification 429 over both

the voltage (±5%) and full military temperature range. It

interfaces with UL, CMOS or NMOS support circuitry, and

uses the standard 5-volt V

CAUTION: The se devices are s ensitive to electrostatic di schar ge; foll ow proper IC Handling Proced ures.

1-888-INTERSIL or 321-724-7143

Copyright © Intersil Americas Inc. 2002. All Rights Reserved

| Intersil (and design) is a trademark of Intersil Americas Inc.

183

CC

supply.

FN2964.2

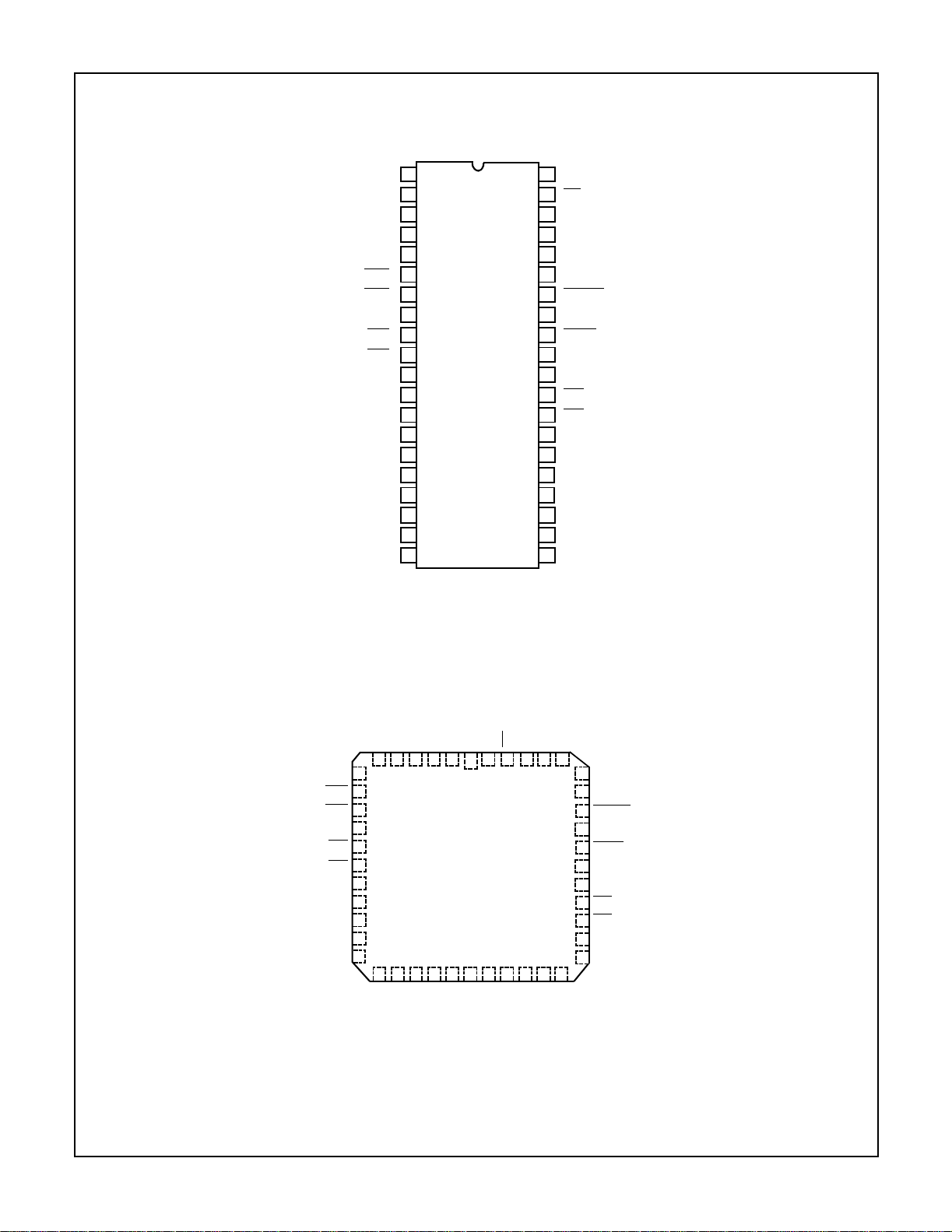

Pinouts

www.BDTIC.com/Intersil

V

DD

429DI1(A)

429DI1(B)

429DI2(A)

429DI2(B)

D/R1

D/R2

SEL

EN1

EN2

BD15

BD14

BD13

BD12

BD11

BD10

BD09

BD08

BD07

BD06

HS-3282

HS-3282 (CERDIP)

TOP VIEW

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

NC

MR

TX CLK

CLK

NC

NC

CWSTR

ENTX

429D0

429D0

TX/R

PL2

PL1

BD00

BD01

BD02

BD03

BD04

BD05

GND

NC

D/R1

D/R2

SEL

EN1

EN2

BD15

BD14

BD13

BD12

BD11

HS-3282 (CLCC)

TOP VIEW

DD

429DI1(A)

429DI1(B)

429DI2(A)

NC

429DI2(B)

7

8

9

10

11

12

13

14

15

16

17

NC

BD10

46 3

BD09

25

BD08

BD07

MR

V

NC

TXCLK

CLK

44

1

GND

BD06

BD05

NC

40414243

39

NC

38

NC

37

CWSTR

ENTX

36

429D0

35

429D0

34

TX/R

33

PL2

32

PL1

31

BD00

30

BD01

29

2827262524232221201918

BD04

BD03

BD02

184

HS-3282

www.BDTIC.com/Intersil

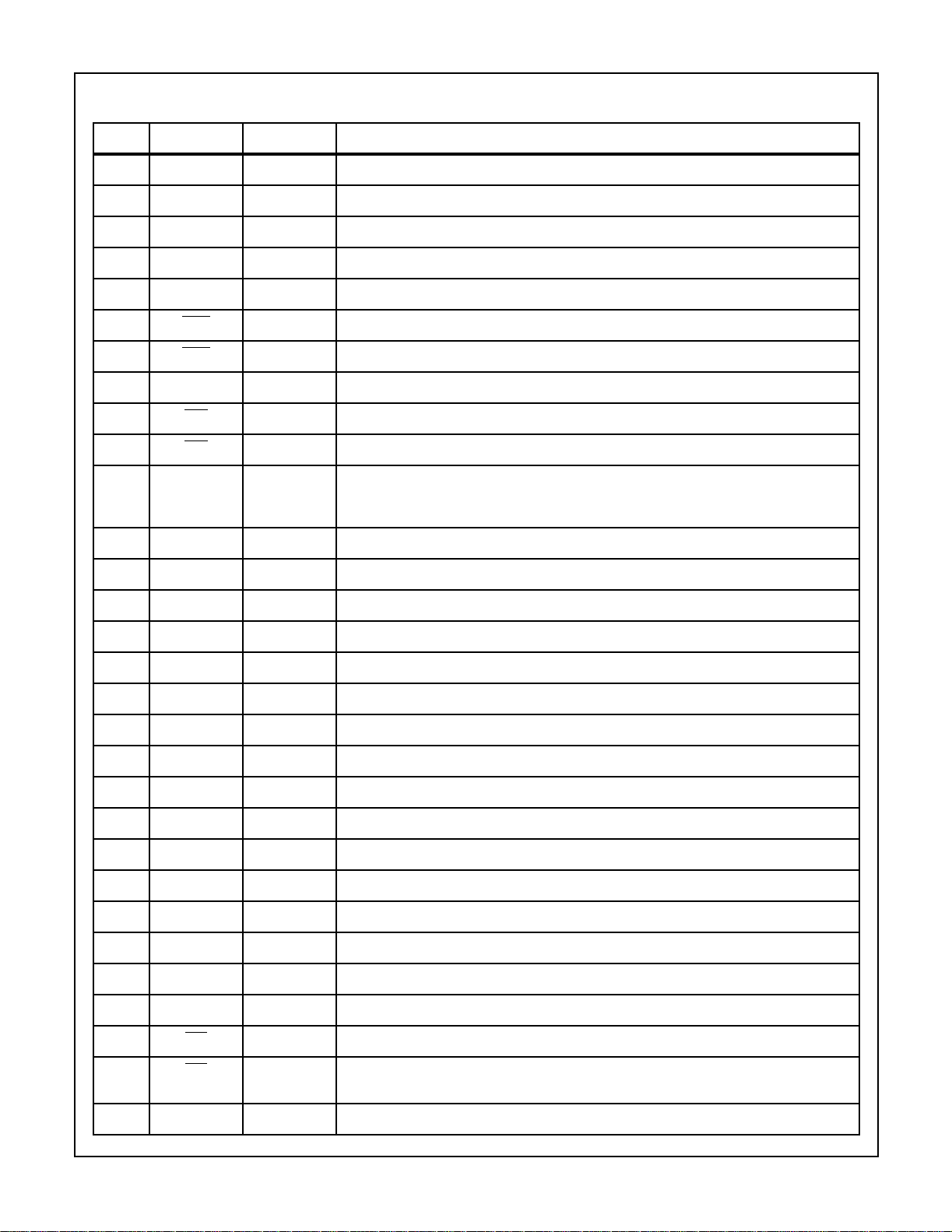

Pin Description

PIN SYMBOL SECTION DESCRIPTION

1V

2 429 DI1 (A) Receiver ARlNC 429 data input to Receiver 1.

3 429 DI1 (B) Receiver ARlNC 429 data input to Receiver 1.

4 429 Dl2 (A) Re ce iv er ARINC 42 9 data inpu t to Rece iv er 2.

5 429 DI2 (B) Receiv er ARINC 42 9 da t a in pu t to Receiver 2.

6D/R1

7D/R2

8 SEL Receiver Bus Data Selector - Input signal to select one of two 16-bit words from either Receiver 1 or 2.

9EN1

10 EN2

11 BD15 Recs/Trans Bi-directional data bus for fetching dat a from either of the Receivers, or for loading data in to

12 BD14 Recs/Trans See Pin 11.

13 BD13 Recs/Trans See Pin 11.

14 BD12 Recs/Trans See Pin 11.

CC

Recs/Trans Supply pin 5 volts ±5%.

Receiver Device ready flag output from Receiver 1 indicating a valid data word is ready to be fetched.

Receiver Device ready flag output from Receiver 2 indicating a valid data word is ready to be fetched.

Receiver Input signal to enable data from Receiver 1 onto the data bus.

Receiver Input signal to enable data from Receiver 2 onto the data bus.

the Transmitter memo ry o r con trol word re gister. Se e Contro l W ord T able f or descripti on o f

Control Word bits.

15 BD11 Recs/Trans See Pin 11.

16 BD10 Recs/Trans See Pin 11.

17 BD09 Recs/Trans See Pin 11.

18 BD08 Recs/Trans See Pin 11.

19 BD07 Recs/Trans See Pin 11.

20 BD06 Recs/Trans See Pin 11.

21 GND Recs/T rans Circuit Gr ound.

22 BD05 Recs/Trans See Pin 11.

23 BD04 Recs/Tr ans See Pin 11. Control Word function not applicable.

24 BD03 Recs/Tr ans See Pin 11. Control Word function not applicable.

25 BD02 Recs/Tr ans See Pin 11. Control Word function not applicable.

26 BD01 Recs/Tr ans See Pin 11. Control Word function not applicable.

27 BD00 Recs/Tr ans See Pin 11. Control Word function not applicable.

28 PL1

29 PL2

Transmitter Paralle l load input signal loading the first 16-bit word into the T ransmitter memory.

Transmitter Parallel load input signal loading the first 16-bit word into the Transmitter memory and ini-

tiates data transfer into the memory stack.

30 TX/R Transmitter Transmit ter flag output to indicate the memory is empty.

185

HS-3282

www.BDTIC.com/Intersil

Pin Description (Continued)

PIN SYMBOL SECTION DESCRIPTION

31 429D0 Transmitter Data output from Transmitter

32 429D0

33 ENTX Transmitter Transmitter Enable input signal to initiate data transmission from FIFO memory.

34 CWSTR

35 - - No co nn ec tion. Mu st be lef t op en .

36 - - No connection. Must be left open or tied low but never tied high.

37 CLK Recs/Trans External clock input. May be either ten (10) or eighty (80) times the data rate. If using both

38 TXCLK Transmitter Transmitter Clock output. Delivers a clock frequency equal to the transmitter data rate.

39 MR

40 - - No Connection.

Transmitter Data output from Transmitter.

Recs/Trans Control word input strobe signal to latch the control word from the databus into the control

word register.

ARINC data rates it must be ten (10) times the highest data rate, (typically 1MHz).

Recs/Trans Master Reset. Active low pulse used to reset FIFO, bit counters, gap timer, word count signal,

TX/R an d various other flags and contr ols. Master reset does not reset t he control word

register. Usually only used on Power-Up or System Reset.

Pinout

13 12345678910111214151617181920

28 40393837363534333231302927262524232221

NCNC NC

186

Operational Description

www.BDTIC.com/Intersil

HS-3282

The HS-3282 is designed to support ARINC Specification

429 and other serial data protocols that use a similar format

by collecting the receiving, transmitting, synchronizing,

timing and parity fu nctions on a single, low power LSl circui t.

It goes beyond the ARlNC requirements by providing for

either odd or even parity, and giving the user a choice of

either 25 or 32-bit word le ngths. The rece iver and transmit ter

sections operate independently of each other. The serial-toparallel conversion required of the receiver and the parallelto-serial conversion requirements of the transmitter have

been incorporated into the bus interface circuit.

Provisions have been made through the external clock input

to provide dat a rate flexibi li ty. This requires an external clock

that is 10 times the data rate.

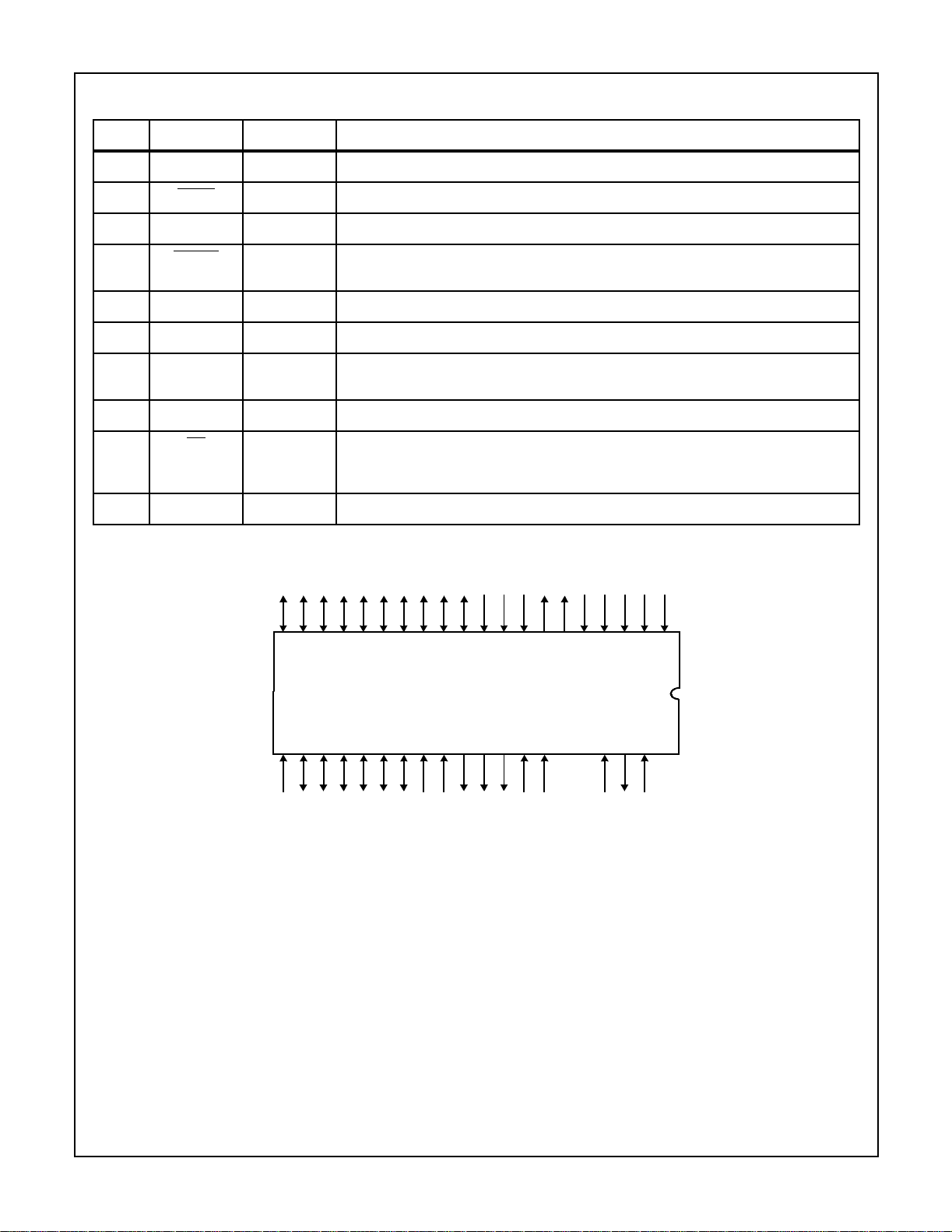

To obtain the flexibility discussed above, a number of

external control signals are required, To reduce the pin

count requirements, an internal contr ol word register is used.

The control word is latched from the data bus into the register by the Control

Word Strobe (CWSTR) signal going to a

logic “1”. Eleven (11) control functions are used, and along

with the Bus Data (BD) line are list ed below:

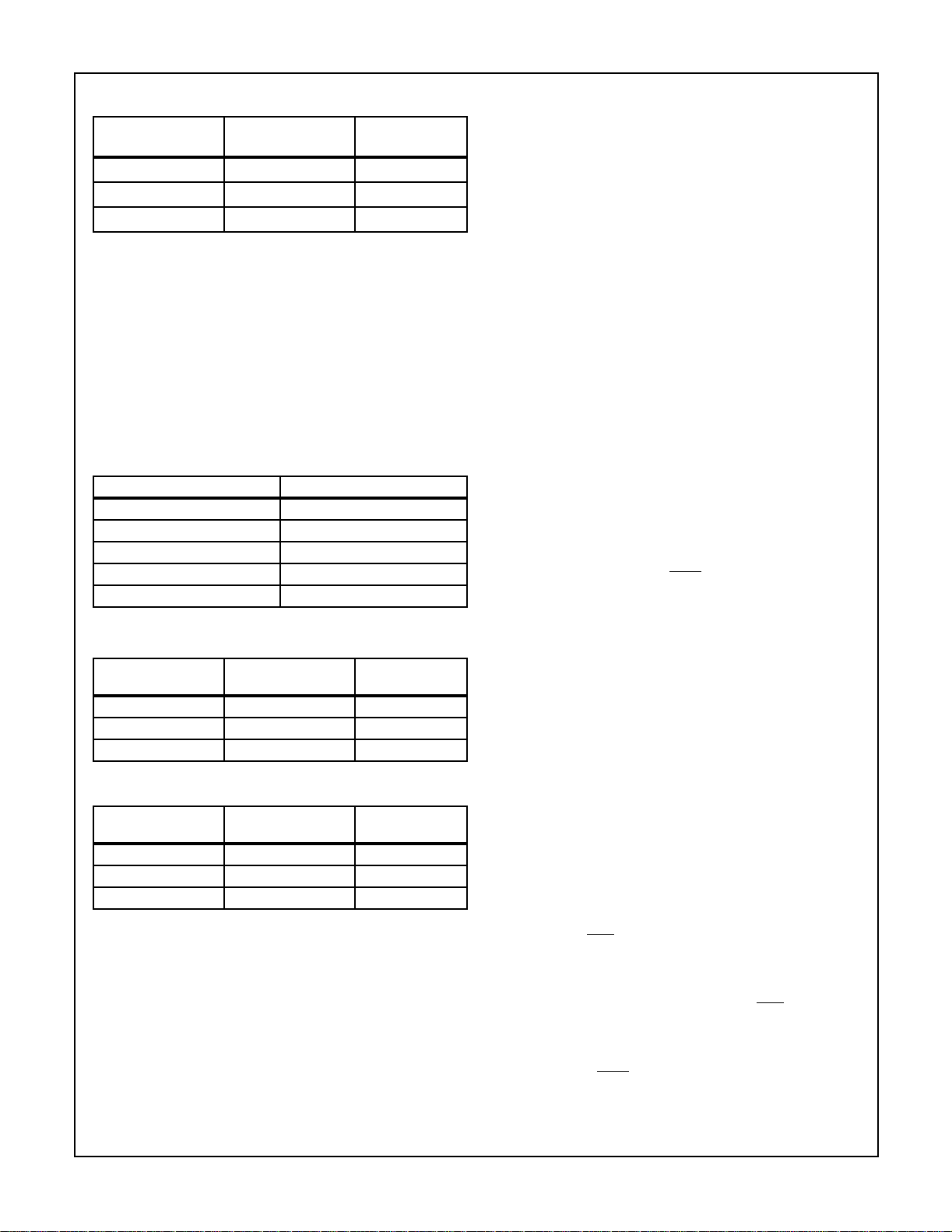

Control Word

PIN NAME SYMBOL FUNCTION

BD05 SLFTST Conne cts the se lf test si gnal from t he transmi tter dire ctly to th e receiver shift reg isters, bypassin g the input

recei vers . Rec eiv er 1 r ece ives Dat a True an d Rec eive r 2 re cei ves Da ta Not . Not e tha t th e tran smit ter out put

remains active. (Logic “0” on SLFTST Enables Self Test).

BD06 SDENB1 Signal to Activate the Source/Destination (S/D) Decoder for Receiver 1. (Logic “1” activates S/D Decoder).

BD07 X1 If SDENB1 = “1” then this bit is compared with ARlNC Data Bit #9. If Y1 also matches (see Y1), the word will be

BD08 Y1 If SDENBI = “ 1” then th is bit is co mpa red with ARIN C Da ta B it # 10 . If X1 also matc he s (se e X1 ), th e wor d wil l

BD09 SDENB2 Signal to activate the Source/Destination (S/D) Decoder for Receiver 2. (Logic “1” activates S/D Decoder).

BD10 X2 If SDENB2 = “1” then this bit is compared with ARlNC Data Bit #9. If Y2 also matches (see Y2), the word will be

BD11 Y2 If SDENB2 = “1” then this bit is compared with ARINC Data Bit #10. If X2 also matches (see X2), the word will

BD12 PARCK Signal us ed to inv ert the t ran smi t ter pa rit y bi t fo r te st of pa ri ty ci r cu its. Lo gic “ 0” se le ct s n orma l o dd par i ty. Log ic

BD13 TXSE L Selects hi gh o r low Tra nsm itter da ta rat e. I f TX SEL = “ 0” the n t ransm it ter da ta rate i s eq ua l to th e cl ock rat e

BD14 RCVSEL Selects high or low Receiver data rate. If RCVSEL = “0” then the received data rate should be equal to the clock

BD15 WLSEL Selects word length. If WLSEL = “0” a 32-bit word format will be selected. If WLSEL = “1” a 25-Bit word format

accepted by the Receiver 1. If SDENB1 = “0” this bit becomes a don’t care.

be accepted by the Receiver 1. If SDENB1 = “0” this bit becomes a don’t care.

accepted by the Receiver 2. If SDENB2 = “0” this bit becomes a don’t care.

be accepted by the Receiver 2. If SDENB2 = “0” this bit becomes a don’t care.

“I” selects even parity.

divide d by ten (10). If TXSE L = “1” then transmitter data rate is equal to the clock rate divided by eighty (80).

rate divide d by te n (10), i f RCVSEL = “1 “t hen th e re ceived data ra te shou ld be e qual to the cl ock rate di vide d

by eighty (80).

will be selected.

ARlNC 429 DATA FORMAT as input to the Receiver and

output from the Transm itter is as follows:

TABLE 1. ARINC 429 32-BIT DATA FORMAT

ARINC BIT # FUNCTION

1 - 8 Label

9 - 10 SDl or Data

11 LSB

12 - 27 Data

28 MSB

29 Sign

30, 31 SSM

32 Parity S tatus

This format is shuffled when seen on the sixteen bidirectional input/outputs. The format shown below is used from

the receivers and input to the transmitter :

TABLE 2A. WORD 1 FORMAT

BI-DIRECTIONAL

BIT # FUNCTION ARINC BlT #

15, 14 Data 13, 12

13 LSB 11

12, 11 SDl or Data 10, 9

10, 9 SSM Status 31, 30

8 Parity Status 32

7 - 00 Label 1 - 8

187

HS-3282

www.BDTIC.com/Intersil

TABLE 2B. WORD 2 FORMAT

BI-DIRECTIONAL

BlT# FUNCTION ARINC BIT#

15 Sign 29

14 MSB 28

13 - 00 Data 27 - 14

Receiver Parity Statu s:

0 = Odd Parity

1 = Even Parity

If the receiver input data word string is broken before the

entire data word is received, the receiver will reset and

ignore the partially received data word.

If the transmitter is used to transmit consecutive data words,

each word wil l be separated by a four (4) bit “null” state (both

positive and negative outputs will maintain a zero (0) volt

level.)

TABLE 3. ARINC 25-BIT DATA FORMAT

ARINC BIT # FUNCTION

1 - 8 Label

9LSB

11 - 23 Data

24 MSB

25 Parity S tatus

• The Line Receiver functions as a voltage level translator.

It transforms the 10 volt differential line voltage, ARINC

429 format, into 5 volt int ernal logic level.

• The output of the Line Receiver is one of two inputs to the

Self-Test Data Selector (SEL). The other input to the

Data Selector is the Self-Test Signal from the Transmitter

section.

• The incoming data, either Self-Test or ARlNC 429, is

double sampled by the Word Gap Timer to generate a

Data Clock. The Receiver sample frequency (RCVCLK),

1MHz, or 125kHz, is generated by the Receiver/Transmitter Timing Circuit. Thi s sampli ng freque ncy is ten t imes the

Data Rate to ensure no data ambiguity.

• The derived data clock then shifts the data down a 32-Bit

long Data Shift Register (Data S/RI). The Data Word

Length is selectable for either 25 Bits or 32 Bits long by

the Control Signal (WLSEL). As soon as the data word is

completely received, an internal signal (WDCNT1) is generated by the Word Gap Timer Circui t.

• The Source/Destination (S/D) Decoder compares the user

set code (X and Y) with Bits 9 and 10 of the Data Word. If

the two codes are matched, a positive signal is generated

to enable the WDCNT1 signal to latch in the received

data. Otherwise, the data word is ignored and no latching

action takes place. The S/D Decoder can be Enabled and

Disabled by the control signal S/D ENB. If the data word is

latched, an indicator flag (D/R1

valid data word is ready t o be fet ched by the user.

) is set. This indicates a

TABLE 4A. WORD 1 FORMAT

BI-DIRECTIONAL

BIT# FUNCTION ARINC BIT#

15 - 9 Don’t Care XXX

8 Parity Status 25

7 - 0 Label 1 - 8

TABLE 4B. WORD 2 FORMAT

BI-DIRECTIONAL

BIT# FUNCTION ARINC BlT#

15 MSB 24

14 - 1 Data 23 -10

0LSB9

Receiver Parity Statu s:

0 = Odd Parity

1 = Even Parity

No Source/Desti nation (S/D) in 25-Bit format.

Receiver Operat ion

Since the two receivers are functionally identical, only one

will be discussed in detail, and the block diagram will be

used for reference in this discussion. The receiver consists

of the following circuits:

• After the receiver data has been shifted down the shift

register, it is placed in a holding regist er. The device ready

flag will then be set indicating that data is ready to be

fetched. If the data is ignored and left in the holding register, it will be written over when the next data word is

received.

• The received data in the 32-bit holding register is placed

on the bus in the form of two (2)16-bit words regardless of

whether the format is for 32 or 25-bit data words. Either

word can be accessed first or repeatedly until the next

received data word falls into the holding regist er.

• The parity of the incoming word is checked and the status

(i.e., logic “0” for odd parity and logic “1” for even parity)

stored in the receiver latch and output on BD08 during the

Word No. 1.

• Assuming the u ser desires to access the dat a, he first set s

the Data Select Line (SEL) to a Logic “0” level and pulses

the Enable (EN1

Selector (SELl) to select the first-data word, which contains the label field and Enable it onto the Data Bus. To

obtain the second data word, the user sets the SEL line to

a Logic “1” level and pulse the Enable (EN1

The Enable pulse duration is matched to the user circuit

requirement needed to read the Data Word from the Data

Bus. The second Enable pulse is also used to reset the

Device Ready (D/R1

cycle.

) line. This action causes the Data

) line again.

) flip-flo p. This c omplete s a receiv ing

188

HS-3282

www.BDTIC.com/Intersil

Transmitter O peration

The Transmitter section consists of an 8-word deep by 31Bit long FIFO Memory, Parity Generator, Transmitter Word

Gap Timing Circuit and Drive r Circuit.

• The FlFO Memory is organized in such a way that data

loaded in the input register is automatically transferred to

the output register for Serial Data Transmission. This

eliminates a large amount of data managi ng time sinc e the

data need not be clocked from the input register to the

output register. The FIFO input register is made up of two

sets of 16 D-type flip-flops, which are clocked by the two

parallel load signals (PL1

precede PL2

written over. As soon as PL2

transferred to the FIFO. The data from the Data Bus is

clocked into the D-type flip-flop on the positive going edge

of the PL signals. If the FIFO memory is initially empty, or

the stack is not full, the data will be automatically

transferred down the Memory Stack and into the output

register or to the last empty FIFO storage register. If the

Transmitter Enable signal (ENTX) is not active, a Logic

“0”, the data remains at the output register. The FIFO

Memory has st orage locations to hold eight 31-bit words. If

the memory is full and the new data is again strobed with

PL

, the old data at the input register is written over by the

new data. Data will remain in the Memory until ENTX goes

to a Logic “1”. This activates the FIFO Clock and data is

shifted out serially to the Transmitter Driver. Data may be

loaded into the FIFO only whi le ENTX is inactive (low). It is

not possible to write data into the FIFO while transmitting.

WARNING: If PL1

i.e., while transmitting, the FlFO may be disrupted such

that it would require a MR

recover.

• The Output Register of the FIFO is designed such that it

can shift out a word of 24 Bits long or 31 Bits long. This

word length is again controlled by the WLSEL bit. The TX

word Gap Timer Circuit also automatically inserts a gap

equivalent to 4-Bit Times between each word. This gives a

minimum requirement of 29-Bit ti me or 36-Bit ti me for each

word transmission. Assuming the signal, ENTX, remains

at a Logic “1”, a transfer to stack signal is generated to

transfer the data down the Memory Stack one position.

This action is continued until the last word is shifted out of

the FIFO memory. At this time a Transmitter Ready (TX/R)

flag is generated to signal the user that the Transmitter is

ready to receive eight more data words. During transmission, if ENTX is taken low then high again, transmission

will cease leaving a portion of the word untransmitted, and

the data integrity of the FIFO will be destroyed.

• A Bit Counter is used to detect the last Bit shifted out of

the FIFO memory and appends the Parity Bit generated

by the Parity Generator. The Parity Generator has a

control signal, Parity Check (PARCK), which establishes

whether odd or even parity is used in the output data

word. PARCK set to a logic “0” will result in odd parity and

when set to a logic “1” will result in even parity.

. Mult iple PL1’s may occur and data will be

or PL2 is applied while ENTX is high,

and PL2). PL1 must always

is received, data is

(Master Reset) signal to

Sample Interface Technique

From Figure 1, one can see that the Data Bus is time shared

between the Receiver and Transmitter. Therefore, bus

controlling must be synchronously shared between the

Receiver and the Transm it ter.

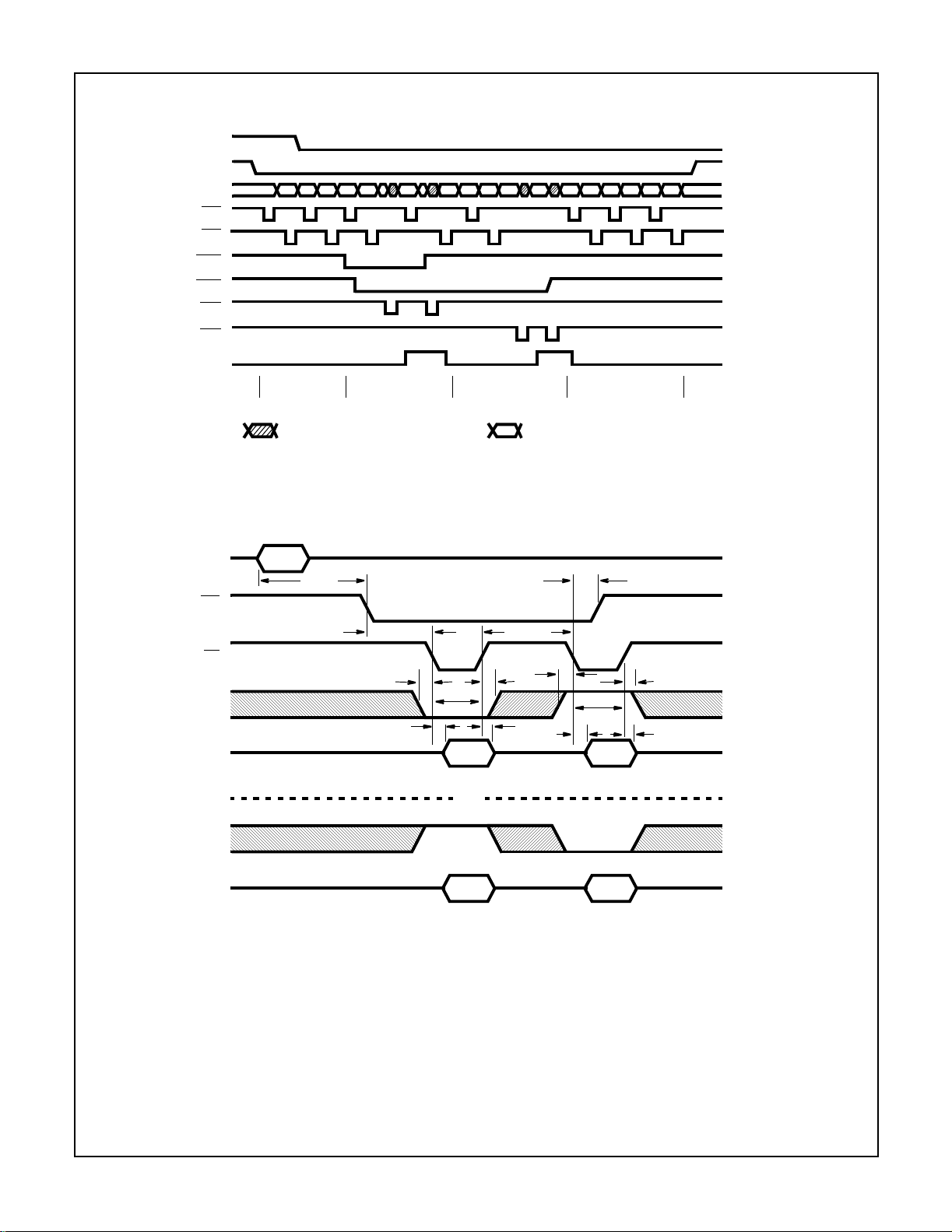

Figure 2 shows the typical interface timing control of the

ARlNC Chip for Receiving function and for Transmitting

function. Timing sequence for loading the Transmitter FIFO

Memory is shown in Timing Interval A. A transmitter Ready

(TX/R) Flag signals the user that the Transmitter Memory is

empty. The user then Enables the Transmitter Data, a 16-Bit

word, on the Data Bus and strobes the Transmitter with a

Parallel Load (PL1

word is similarly loaded into the Transmitter with PL2

also initiates data transfer to stack. This is continuous until

the Memory is full, which is eight 31-Bit words. The user

must keep track of the number of words loaded into the

Memory to ensure no data is written over by other data.

During the time the user is loading the Transmitter, he does

not have to service the Receiver, even if the Receiver flags

the user with the signal D/R1

ready to be fetched. This is shown by the Timing inte rval B. If

the user decides to obtain the received data before the

Transmitter is completely loaded, he sets the two parallel

load signals (PL1

EN1

while the signal SEL is at a Logic “0” state. After the

negative edge of EN1

received word becomes valid on the Data Bus. At the

positive edge of EN1

to ready the Receiver for the second 16-Bit word. Strobing

the Receiver with EN1

16-Bit word and resets the Receiver Ready Flag D/R1

user should now reset the signal SEL to a Logic “0” state to

ready the Receiver for another Read Cycle. During the time

period that the user is fetching the received words, he can

load the transmitter. This is done by interlacing the PL

signals with the EN signals as shown in the Timing Interval

B. Servicing the Receiver 2 is similar and is illustrated by

Timing interval C. Timing interval D shows the rest of the

Transmitter loading sequence and the beginning of the

transmissi on by switch ing the si gnal TX Enable to a Logic “1 ”

state. Timing interval E i s the time it takes to transmit all data

from the FlFO Memory, either 288 Bit times or 232 Bit times.

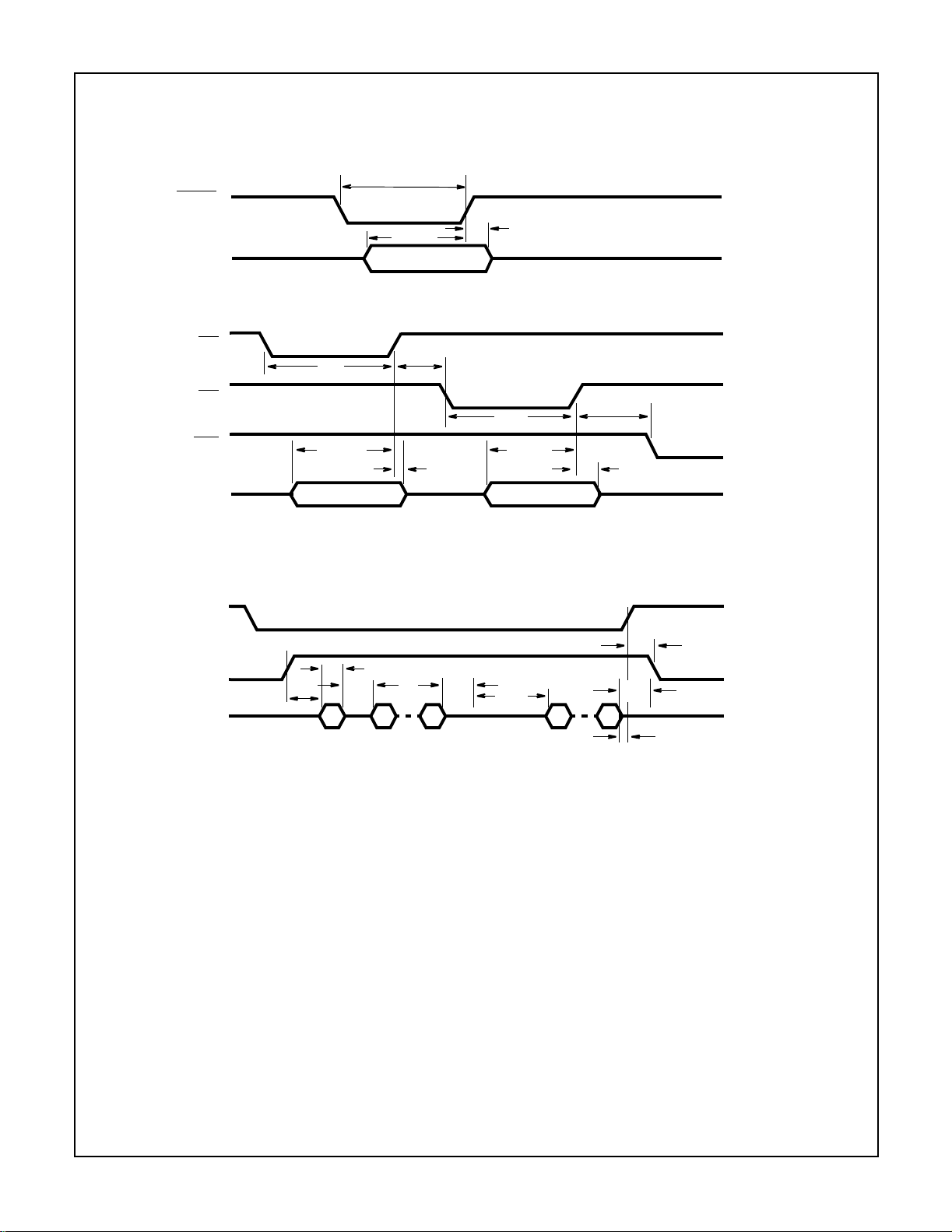

Repeater Operation

This mode of operation allows a data word that has been

received to be placed directly in the FIFO for transmission. A

timing diagram is shown in Figur e 7. A 32-bi t word is used in

this example. The data word is shifted into the shift register

and the D/R

line and EN1

receiver operation and places half the data word (16 bits) on

the data bus. By strobing PL1

these 16 bits will be taken off the bus and placed in the

FIFO. SEL is brought back hi gh and EN1

the second 16 bits of the data word. Again by strobing PL2

the same time the second 16 bits will be placed in the FIFO.

The parity bit will have been stripped away l eaving the 31-bit

data word in the FIFO ready for transmission as shown in

Figure 6.

) Signal. The second part of the 32-Bit

, which

that a valid received word is

and PL2) at a Logic “1” state, and strobes

, the first 16-Bit segment of the

, the user should toggle the signal SEL

, the second time, enables the second

. The

flag goes low. A logic “0” is placed on the SEL

is strobed. This is the same as the normal

at the same time as EN1,

is strobed again for

at

189

HS-3282

www.BDTIC.com/Intersil

429D11 (A)

429D11 (B)

429D12 (A)

429D12 (B)

2

LINE

RECEIV.

3

ER 1

S/DENB

4

5

39

MR6D/R17D/R2

TEST

S/D

DECODER

S/D CODER

LINE

RECEIV.

ER 2

V

13837

CONTROL

WORD

REGISTER

TX CLK

TX WORD

GAP

PARITY

PARCK

SLF

SELF

TEST

SELF

TEST

WLSEL

SEL

WDCNT 1

WDCNT 2

SEL

WLSEL

RCV CLK

WORD GAP

DATA CLOCK

DATA S/R 1

32

LATCH 1

LATCH 2

32

DATA S/R 2

DATA CLOCK

WORD GAP

8

SEL9EN110EN2

16

16

16

16

RCV CLK

RCVSEL

WDCNT 1

TXSEL

SEL EN1

SEL 1

SEL 2

SEL EN2

WDCNT 2

16

16

BD15BD00

DATA

BUS

16

11 - 20

22 - 27

TIMING

RCV

CLK

28 29

PL1 PL2

TXRCV

TX

CLK

11

F/F

D

16

FIFO

8 x 31

TX CLKCLK

F/F

30

TX/R

D

16

FIGURE 1. SINGLE CHIP ARINC 429 INTERFACE FUNCTIONAL BLOCK DIAGRAM

CC

SLF TST

(BD05)

S/D ENB1

(BD06)

S/D ENB2

(BD09)

X1 (BD07)

Y1 (BD06)

X2 (BD10)

Y2 (BD11)

PARCK

(BD12)

TXSEL

(BD13)

RCVSEL

(BD14)

WLSEL

(BD15)

WLSEL

DRVR

TXC

GND

21

SELF

TEST

34

33

32

31

CWSTR

ENTX

429D0

429D0

190

HS-3282

www.BDTIC.com/Intersil

Absolute Maximum Ratings Thermal Information

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+7.0V

Input, Output or I/O Voltage Applied

(Except Pins 2 - 5) . . . . . . . . . . . . . . . . GND -0.3V to V

Input Voltage Applied (Pins 2 - 5). . . . . . . . . . . . . . . . . -29V to +29V

ESD Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Class 1

DD

+0.3V

Operating C o ndi t io ns

Operating Voltage Range. . . . . . . . . . . . . . . . . . . +4.75V to +5.25V

Opera ting Temperature Range

HS-3282-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0

HS-3282-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -55

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

o

C to +70oC

o

C to +125oC

Thermal Resistance

CDIP Package. . . . . . . . . . . . . . . . . . . 35 8

CLCC Package . . . . . . . . . . . . . . . . . . 55 12

Maximum Junction Temperature. . . . . . . . . . . . . . . . . . . . . . +175

Maximum Storage Temperature Range . . . . . . . . .-65

Maximum Lead Temperature (Soldering 10s). . . . . . . . . . . . +300

θ

(oC/W) θJC (oC/W)

JA

o

C to +150oC

o

o

Die Characteristics

Gate Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2632 Gates

C

C

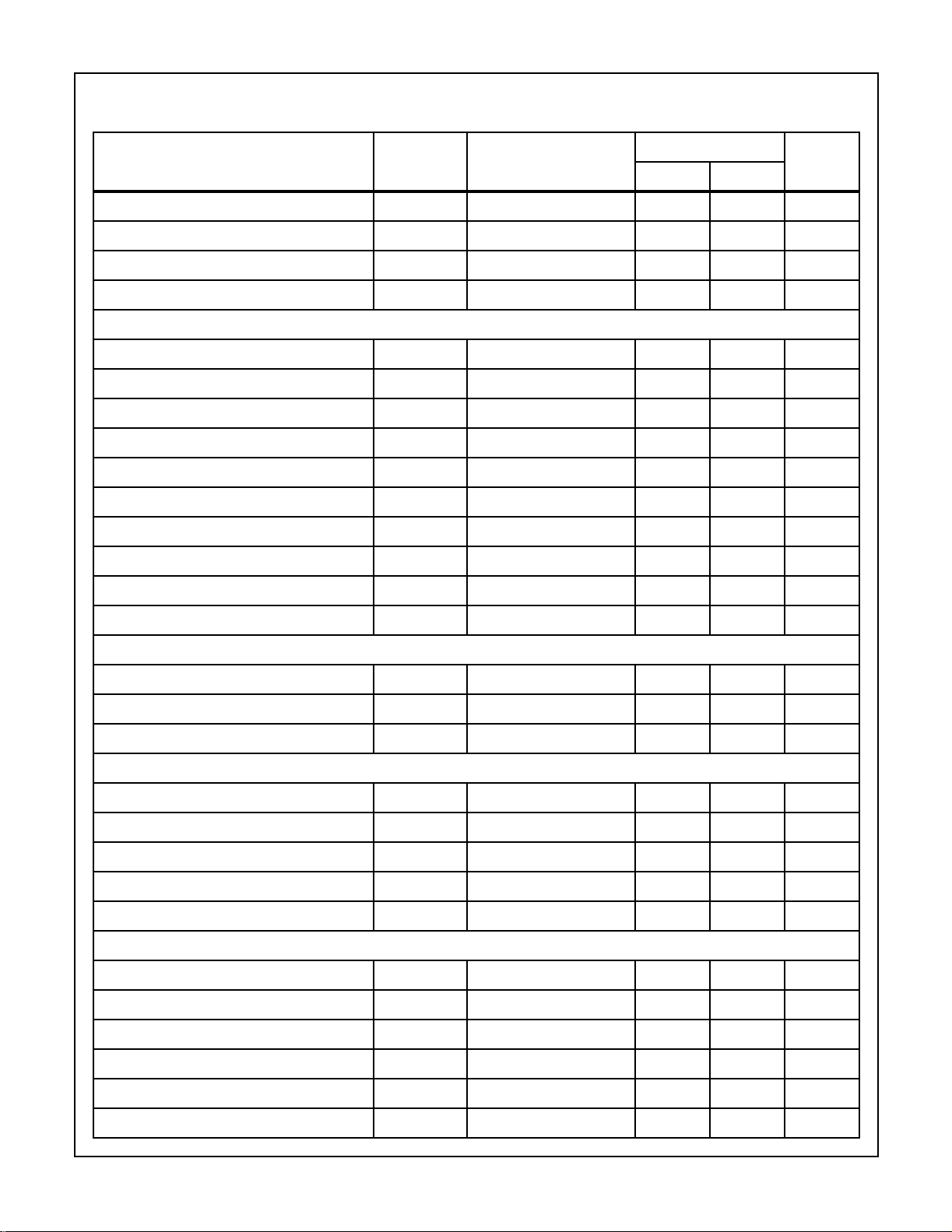

DC Electrical Performance Specifications V

PARAMETER SYMBOL CONDITIONS

ARlNC INPUTS Pins 2-3,4-5

Logic “1” Inp ut Voltage V

Logic “0” Inp ut Voltage V

Null Input Voltage V

Common Mode Voltage V

Input Leakage I

Input Leakage I

Differential Input Impedance RI VDD = 5.25V, VIN = +5V, -5V 12 - kΩ

Input lmpedance to V

Input lmpedance to GND RG V

BIDIRECTIONAL INPUTS Pins 11-20, 22-27

Logic “1” Inp ut Voltage V

Logic “0” Inp ut Voltage V

Input Leakage l

Input Leakage I

ALL OTHER INPUTS Pins 8-10, 28, 29, 33, 34, 37, 39

Logic “1” Inp ut Voltage V

Logic “0” Inp ut Voltage V

Input Leakage I

Input Leakage I

OUTPUTS Pins 6, 7, 11-20, 22-27, 30-32, 38, Supply Pin 1

Logic “1” Ou tp ut Vo lta ge V

Logic “0” Ou tp ut Vo lta ge V

Standby Suppl y Current l

Operating Supply Current l

DD

NUL

CH

lH

lL

RH VDD = 5.25V, VlN = 0V 12 - kΩ

IH

IL

IH

lL

IH

IL

lH

lL

OH

OL

CC1

CC2

VDD = 5.25V 6.7 13.0 V

lH

VDD = 5.25V -13.0 -6.7 V

IL

VDD = 4.75V, 5.25V -2.5 +2.5 V

VDD = 4.75V, 5.25V -5.0 +5.0 V

VDD = 5.25V, VIN = ±6.5V - 200 µA

VDD = 5.25V, VIN = 0.0V -450 - µA

VDD = 5.25V 2.1 - V

VDD = 4.75V - 0.7 V

VDD = 5.25V,VIN = 5.25V - 1.5 µA

VDD = 5.25V, VIN = 0.0V -1.5 - µA

VDD = 5.25V 3.5 - V

VDD = 4.75V - 0.7 V

VDD = 5.25V, VIN = 5.25V - 10 µA

VDD = 5.25V, VIN = 0.0V -75 - µA

VDD = 4.75V, IOH = -1.5mA 2.7 - V

VDD = 4.75V lOL= 1.8mA - 0.4 V

VDD = 5.25V, VIN = 0V Except 9,10,

29 = 5.25V

VDD = 5.25V, VIN = 5.25V Except 8,

33 = 0.0V, CLK = 1MHz

= 5V ±5%, TA = 0oC to +70oC (HS-3282-5),

DD

= Open, VlN = 5.0V 12 - kΩ

DD

T

= -55oC to +125oC (HS-3282-8)

A

LIMITS

-20mA

-20mA

UNITSMIN MAX

191

HS-3282

www.BDTIC.com/Intersil

AC Electrical Performance Specifications V

PARAMETER SYMBOL CONDITIONS

Clock Frequency FC V

Data Rate 1/ FD V

Data Rate 2/ FD V

Master Reset Pulse Width TMR V

RECEIVER TIMING

Receiver Ready Time From 32nd Bit 1/ TD/R2 V

Receiver Ready Time From 32nd Bit 2/ TD/R2 V

Device Ready to Enabl e Time TD/REN V

Data Enable Pulse Width TEN V

Data Enable to Data Enable Time TENEN V

Data Enable to Device Ready Reset Time TEND/R V

Output Dat a Valid to Enabl e Time TENDATA V

= 5V ±5%, TA = 0oC to +70oC (HS-3282-5),

DD

T

= -55oC to +125oC (HS-3282-8)

A

LIMITS

= 4.75V, 5.25V - 1 MHz

DD

= 4.75V, 5.25V - 100 kHz

DD

= 4.75V, 5.25V - 12.5 kHz

DD

= 4.75V, 5.25V 200 - ns

DD

= 4.75V, 5.25V - 16 µs

DD

= 4.75V, 5.25V - 128 µs

DD

= 4.75V, 5.25V 0 - ns

DD

= 4.75V, 5.25V 200 - ns

DD

= 4.75V, 5.25V 50 - ns

DD

= 4.75V, 5.25V - 200 ns

DD

= 4.75V, 5.25V - 200 ns

DD

UNITSMIN MAX

Data Enable to Data Select Time TENSEL V

Data Select to Data Enable Time TSELEN V

Outp ut D at a Di sa ble Time TDA TAE N V

CONTROL WORD TIMING

Control Word St robe Pulse Width TCWSTR V

Contro l Word Setup Time TCWSET V

Contro l Word Hold Time TCWHLD V

TRANSMITTER FIFO Write Timing

Parallel Load Pulse Width TPL V

Parallel Load to Parallel Load 2 Delay TPL12 V

Transmitter Ready Delay Time TTX/R V

Data Word Setup Time TDWSET V

Data Word Hold Time TDWHLD V

TRANSMITTER Output Timing

Enable Transmit to Output Data Valid Time 1/ TENDAT V

Enable Transmit to Output Data Valid Time 2/ TENDAT V

= 4.75V, 5.25V 20 - ns

DD

= 4.75V, 5.25V 20 - ns

DD

= 4.75V, 5.25V - 80 ns

DD

= 4.75V, 5.25V 130 - ns

DD

= 4.75V, 5.25V 130 - ns

DD

= 4.75V, 5.25V 0 - ns

DD

= 4.75V, 5.25V 200 - ns

DD

= 4.75V, 5.25V 0 - ns

DD

= 4.75V, 5.25V - 840 ns

DD

= 4.75V, 5.25V 110 - ns

DD

= 4.75V, 5.25V 0 - ns

DD

= 4.75V, 5.25V - 25 µs

DD

= 4.75V, 5.25V - 200 µs

DD

Output Data Bit Time 1/ TBlT V

Output Data Bit Time 2/ TBlT V

Output Data Null Time 1/ TNULL V

Output Data Null Time 2/ TNULL V

= 4.75V, 5.25V 4.95 5.05 µs

DD

= 4.75V, 5.25V 39.6 40.4 µs

DD

= 4.75V, 5.25V 4.95 5.05 µs

DD

= 4.75V, 5.25V 39.6 40.4 µs

DD

192

HS-3282

www.BDTIC.com/Intersil

AC Electrical Performance Specifications V

PARAMETER SYMBOL CONDITIONS

Data Word Gap Time 1/ TGAP VDD = 4.75V, 5.25V 39.6 40.4 µs

Data Word Gap Time 2/ TGAP V

Data Transmission Word to TX/R Set Time TDTX/R V

Enable Transmit Turnoff Time TENTX/R V

REPEATER OPERATION TIMING

Data Enable to Parallel Load Delay Time TENPL V

Data Enable Hold for Parallel Load Time TPLEN V

Enable Transmit Delay Time TTX/REN V

NOTES:

1. 100kHz Data Rate.

2. 12.5 kH z Data Rate .

Electrical Performance Specifications V

= 5V ±5%, TA = 0oC to +70oC (HS-3282-5),

DD

T

= -55oC to +125oC (HS-3282-8) (Continued)

A

= 4.75V, 5.25V 316.8 323.2 µs

DD

= 4.75V, 5.25V - 400 ns

DD

= 4.75V, 5.25V 0 - ns

DD

= 4.75V, 5.25V 0 - ns

DD

= 4.75V, 5.25V 0 - ns

DD

= 4.75V, 5.25V 0 - ns

DD

= 5V ±5%, TA = 0oC to +70oC (HS-3282-5),

DD

T

= -55oC to +125oC (HS-3282-8)

A

LIMITS

UNITSMIN MAX

(NOTE 1)

PARAMETER SYMBOL

Differential Input Capacita nce CD V

Input Ca pa ci t a nc e to V

lnput Capacita nc e to G ND CG V

Input Capacitance Cl V

Output Capacitance CO V

Clock Rise Time TLHC CLK = 1MHz, From 0.7V to 3.5V - 10 ns

Clock Fall Time THLC CLK = 1MHz, From 3.5V to 0.7V - 10 ns

Input Rise Time TLHI From 0.7V to 3.5V, Note 6 - 15 ns

Input Fall Time THLI From 3.5V to 0.7V, Note 6 - 15 ns

NOTES:

1. The pa rameters listed in this table are controlled via design or process parame ters and are not directly tested. These parameters are

characterized upon initial design and after major process and/or design changes affecting these parameters.

2. All measurements are referenced to device GND.

3. Pins 2-3, 4-5.

4. Pins 8-10, 28, 29, 33, 34, 37, 39.

5. Pins 6, 7, 11-20, 22-27, 30-32, 38.

6. Pins 8-20, 22-29, 33, 34.

DD

CH VDD = GND, f = 1MHz, Note 2, 3 - 20 pF

= Open, f = 1MHz, Note 2, 3 - 20 p F

DD

= Open, f = 1MHz, Note 2, 3 - 20 p F

DD

= Open, f = 1MHz, Note 2, 4 - 15 p F

DD

= Open, f = 1MHz, Note 2, 5 - 15 p F

DD

CONDITIONS

LIMITS

UNITSMIN MAX

193

Timing Waveforms

www.BDTIC.com/Intersil

TX/R

TX ENABLE

DATA BUS

PL1

PL2

D/R1

D/R2

EN1

EN2

SEL

TIME

INTERVAL A

TIME

INTERVAL B

HS-3282

TIME

INTERVAL C

TIME

INTERVAL D

TIME

INTERVAL E

429DI

D/R

EN

SEL

BD00-15

SEL

BUS IS BEING USED AS AN OUTPUT

BUS IS BEING USED AS AN INPUT

FIGURE 2. TYPICAL INTERFACE TIMING SEQUENCE

BIT

32

t

D/R

t

D/REN

t

SELEN

t

ENDATA

t

EN

WORD

1

OR

t

END/R

t

ENEN

t

SELEN

t

t

t

ENDATA

ENSEL

DATAEN

t

EN

WORD

2

t

ENSEL

t

DATAEN

BD00-15

WORD

2

WORD

1

FIGURE 3. RECEIVER TIMING

194

Timing Waveforms (Continued)

www.BDTIC.com/Intersil

CWSTR

BD00-15

HS-3282

t

CWSTR

t

t

CWSET

CONTROL WORD

FIGURE 4. CONTROL WORD TIMING

CWHLD

PL1

PL2

TX/R

BD00-15

TX/R

ENTX

42900

t

ENDAT

t

t

PL

t

DWSET

PL12

t

DWHLD

t

PL

t

DWSET

WORD 2WORD 1

FIGURE 5. TRANSMITTER FIFO WRITE TIMING

t

BIT

BIT

t

NUL

BIT

1

2

BIT

32

t

NUL

t

GAP

BIT

1

FIGURE 6. TRANSMITTER OUTPUT TIMING

t

TX/R

BIT

32

t

DWHLD

t

NUL

t

DTX/R

t

ENTX/R

195

Timing Waveforms (Continued)

www.BDTIC.com/Intersil

HS-3282

429DI

D/R

EN

SEL

PL1

PL2

TX/R

ENTX

429D0

BIT

32

t

EN

t

ENDAT

t

END/R

t

ENSEL

t

PLEN

t

TX/R

t

TX/REN

BIT

1

BIT

32

t

DTX/R

t

NUL

t

ENTX/R

t

D/R

t

SELEN

t

ENPL

t

D/REN

t

EN

ENEN

t

SELEN

t

ENPL

t

ENSEL

t

PLEN

t

FIGURE 7. REPEATER OPERATION TIMING

196

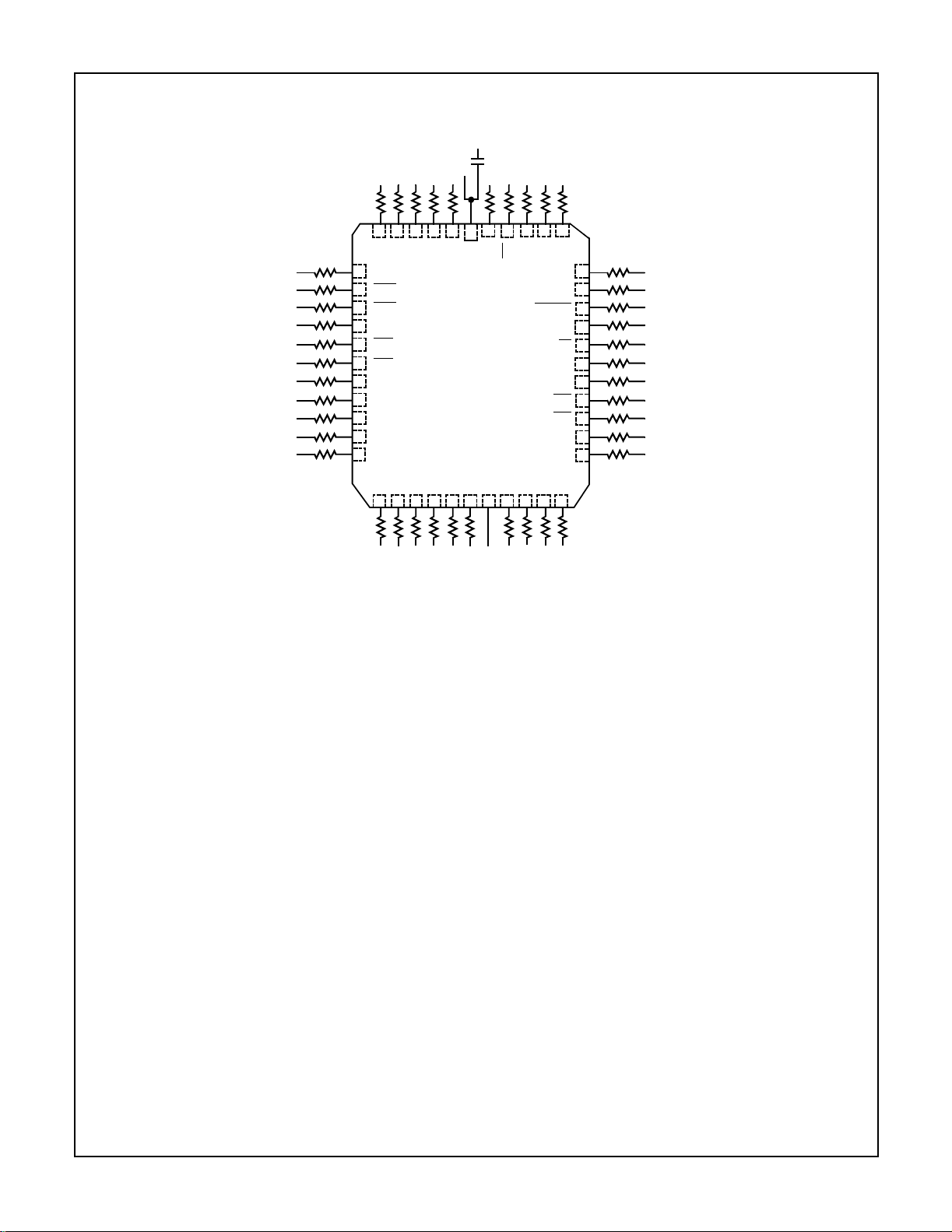

Burn-In Circuits

www.BDTIC.com/Intersil

GND

GND

GND

NC

NC

V

DD

F15

F14

F13

F12

F11

F10

HS-3282

HS-3282 CERDIP

V

C

DD

1

V

DD

F4

F4

F9

F8

F9

F8

F7

F6

10

11

12

13

14

15

16

17

18

19

20

2

3

4

5

6

7

8

9

DI1(A)

DI1(B)

DI2(A)

DI2(B)

D/R1

D/R2

SEL

EN1

EN2

BD15

BD14

BD13

BD12

BD11

BD10

BD09

BD08

BD07

BD06

TX CLK

CWSTR

NC

MR

CLK

NC

NC

ENTX

429D0

429D0

TX/R

PL2

PL1

BD00

BD01

BD02

BD03

BD04

BD05

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

NC

F15

NC

F0

NC

NC

V

DD

GND

NC

NC

NC

F8

F8

F0

F1

F2

F3

F4

F5

GND

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.inter sil.com/design/qua li ty

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No l icense is granted by i m plication or otherwise under any patent or patent rights of Intersil or its subsidia ries .

For information regarding Intersil Corporation and its products, see www.intersil.com

197

Burn-In Circuits

www.BDTIC.com/Intersil

V

F15

F14

F13

F12

F11

NC

NC

NC

DD

HS-3282 CLCC

GND

C

DD

V

NC

F4

GND

F4

GND

NC

25

46 3

NC

DI2(B)

DI2(A)

DI1(A)

7

NC

D/R1

8

9

D/R2

F9

F8

10

SEL

EN1

11

12

EN2

13

BD15

14

BD14

15

BD13

BD12

16

BD11

17

NC

DI1(B)

BD10

BD09

BD08

BD07

F15NCF0

1

CC

NC

MR

V

BD06

GND

BD05

TXCLK

CWSTR

ENTX

BD00

BD01

BD04

CLK

TX/R

PL2

PL1

BD03

2827262524232221201918

4041424344

NC

NC

D0

D0

NC

BD02

NC

39

38

37

36

35

34

33

32

31

30

29

NC

NC

V

DD

GND

NC

NC

NC

F8

F8

F0

F1

NOTES:

1. Resistors = 47kΩ, 5%, 1/4W (Min)

2. GND = Ground

= +5.5V, ±0.5V

3. V

DD

4. C = 0.01mF/Socket (Min)

5. F0 = 100kHz, F1 = F0/2, . . . F15 = F14/2

NC

F10

F09

F08

F07

F06

F05

F04

F03

GND

F02

198

Die Characteristics

www.BDTIC.com/Intersil

DIE DIMENSIONS:

246 x 224 x 19 mils)

(6250 x 5700 x 483µm)

METALLIZATION:

Type: Si-Al

Thickness: 11k

Å ±2kÅ

Metallization Mask Layout

(7)

D/R2

SEL (8)

EN1 (9)

(6) D/R1

GLASSIVATION:

Type: SiO

2

Thickness: 8kA ±1kÅ

WORST CASE CURRENT DENSITY:

HS-3282

(5) 429DI2(B)

(4) 429DI2(A)

(3) 429DI1(B)

2 x 10

DD

(2) 429DI1(A)

(1) V

5

A/cm

(40) N/C

(39) MR

2

(37) CLK

(38) TX CLK

(36) N /C

(10)

EN1

BD15 (11)

BD14 (12)

BD13 (13)

BD12 (14)

BD11 (15)

BD10 (16)

BD09 (17)

BD08 (18)

BD07 (19)

BD06 (20)

GND (21)

BD05 (22)

BD04 (23)

BD03 (24)

BD02 (25)

BD01 (26)

(35) N /C

(34) C WS TR

(33) EN T X

(32) 429D0

(31) 429D0

(30) TX / R

(29) PL 2

(28) PL 1

(27) BD00

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.inter sil.com/design/qua li ty

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No l icense is granted by i m plication or otherwise under any patent or patent rights of Intersil or its subsidia ries .

For information regarding Intersil Corporation and its products, see www.intersil.com

199

Loading...

Loading...