®

www.BDTIC.com/Intersil

HM-6642/883

Data Sheet March 2004

512 x 8 CMOS PROM

The HM-6642/883 is a 512 x 8 CMOS NiCr fusible link

Programmable Read Only Memory in the popular 24 pin,

byte wide pinout. Synchronous circuit design techniques

combine with CMOS processing to give this device high

speed performance with very low power dissipation.

On-chip address latches are provided, allowing easy

interfacing with recent generation microprocessors that use

multiplexed address/data bus structures, such as the 8085.

The output enable controls, both active low and active high,

further simplify microprocessor system interfacing by

allowing output data bus control independent of the chip

enable control. The data output latches allow the use of the

HM-6642/883 in high speed pipelined architecture systems,

and also in synchronous logic replacement functions.

Applications for the HM-6642/883 CMOS PROM include low

power hand held microprocessor based instrumentation and

communications systems, remote data acquisition and

processing systems, processor control store, and

synchronous logic replacement.

FN3013.2

Features

• This Circuit is Processed in Accordance to MIL-STD-883

and is Fully Conformant Under the Provisions of

Paragraph 1.2.1.

• Low Power Standby and Operating Power

- ICCSB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100µA

- ICCOP . . . . . . . . . . . . . . . . . . . . . . . . . . 20mA at 1MHz

• Fast Access Time. . . . . . . . . . . . . . . . . . . . . . . 120/200ns

• Wide Operating . . . . . . . . . . . . . . . . . . . .-55°C to +125°C

• Temperature Range

• Industry Standard Pinout

• Single 5.0V Supply

• CMOS/TTL Compatible Inputs

• Field Programmable

• Synchronous Operation

• On-Chip Address Latches

• Separate Output Enable

All bits are manufactured storing a logical “0” and can be

selectively programmed for a logical “1” at any bit location.

Ordering Information

TEMP.

PKG.

RANGE (°C) 120ns 200ns

SBDIP -55 to +125 HM1-6642B/883 HM1-6642/883 D24.6

SLIM

-55 to +125 HM6-6642B/883 HM6-6642/883 D24.3

SBDIP

CLCC -55 to +125 - HM4-6642/883 J28.A

PKG.

DWG. #

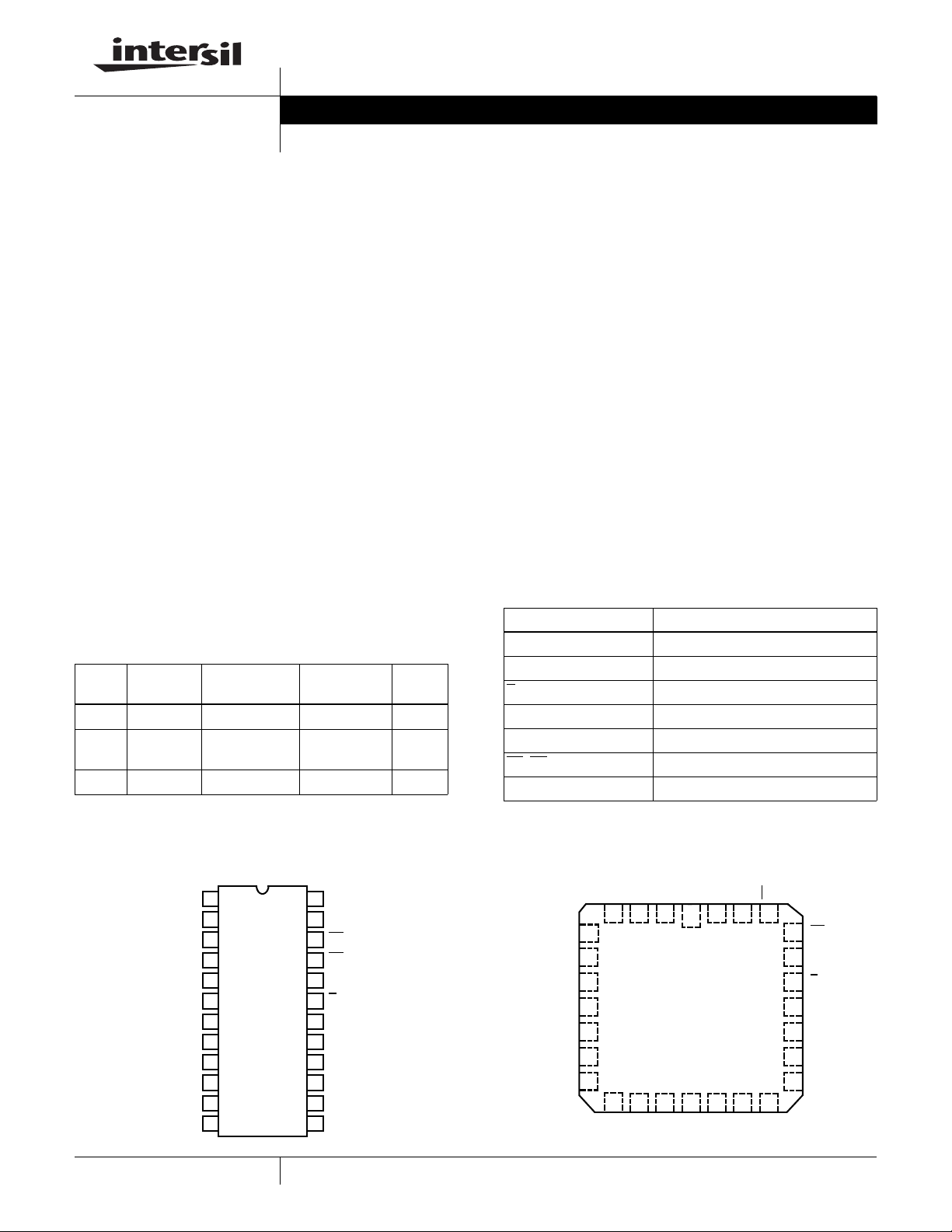

Pinouts

M-6642/883 (SBDIP)

TOP VIEW

A7

A6

A5

A4

A3

A2

A1

A0

Q0

Q1

Q2

GND

1

2

3

4

5

6

7

8

9

10

11

12

24

V

CC

A8

23

22

G1

21

G2

20

G3

E

19

P

18

17

Q7

Q6

16

Q5

15

Q4

14

Q3

13

Pin Description

PIN DESCRIPTION

NC No Connect

A0-A8 Address Inputs

E

Q Data Output

V

Power (+5V)

CC

, G2, G3 Output Enable

G1

P (Note) Program Enable

NOTE: P should be hardwired to GND except during programming.

A4

5

A3

6

A2

7

A1

8

9

A0

NC

10

Q0

11

Chip Enable

HM-6642/883 (CLCC)

TOP VIEW

A5

A6

A7

NC

3 2 14

14 15 16 17 1812 13

Q1

Q2

GND

NC

CC

A8

V

28 27 26

Q3Q5Q4

G1

25

G2

24

G3

E

23

22

P

21

NC

20

Q7

19

Q6

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright © Intersil Americas Inc. 2004. All Rights Reserved

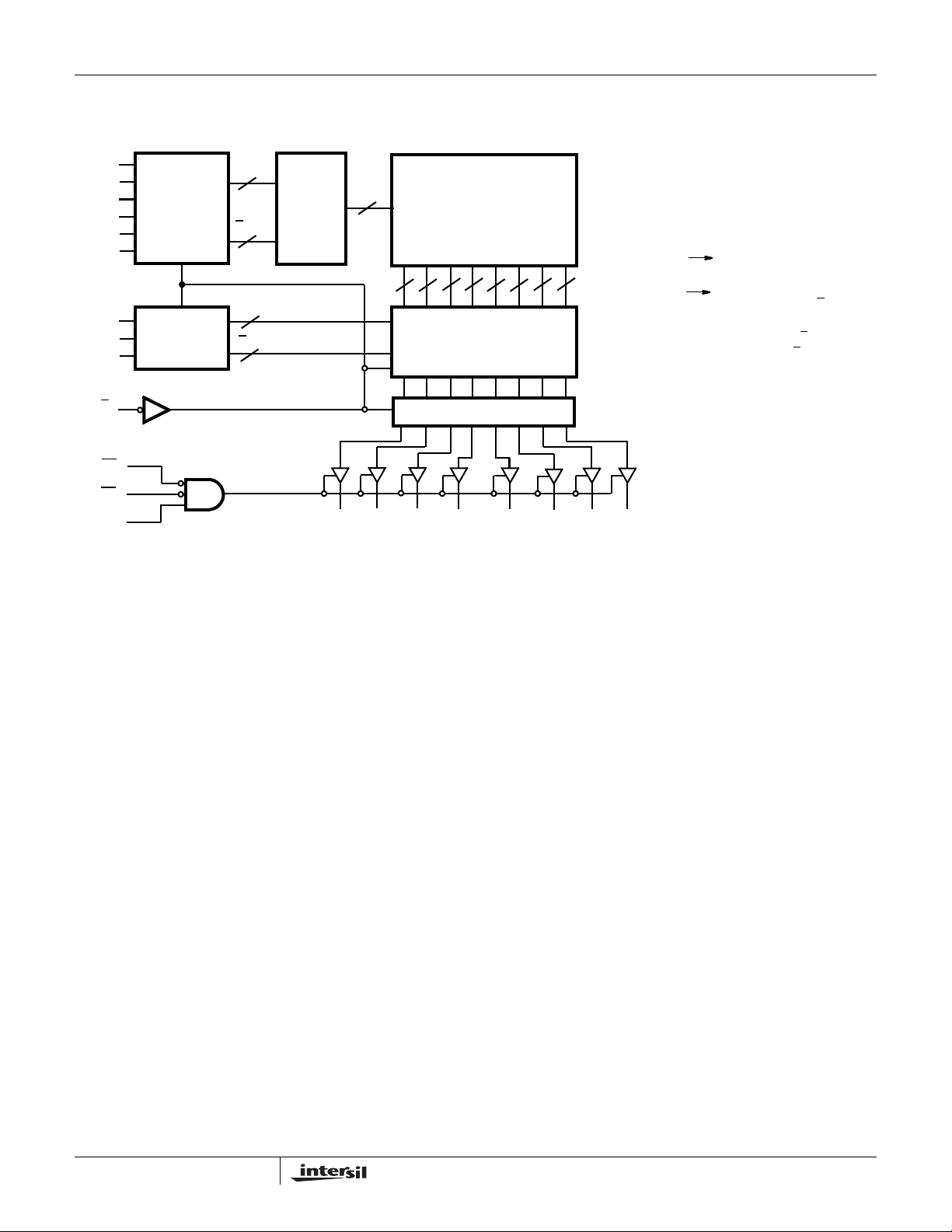

Functional Diagram

www.BDTIC.com/Intersil

HM-6642/883

A8

A7

A6

A5

A4

A3

A2

A1

A0

E

G1

G2

G3

LATCHED

ADDRESS

REGISTER

LATCHED

ADDRESS

REGISTER

A

6

GATED

ROW

A

DECODER

6

A

3

A

3

64

8 8

D

Q0 Q1 Q2 Q3 Q4 Q5 Q6 Q7

64 x 64

MATRIX

8 8

8 8

GATED COLUMN

DECODER

8-BIT DATA LATCH

ALL LINES POSITIVE LOGIC - ACTIVE HIGH

THREE STATE BUFFERS:

A HIGH

DATA LATCHES:

8

8

L HIGH

Q LATCHES ON RISING EDGE OF E

ADDRESS LATCHES AND GATED DECODERS:

LATCH ON FALLING EDGE OF E

GATE ON FALLING EDGE OF E

P SHOULD BE HARDWIRED TO GND EXCEPT

DURING PROGRAMMING

OUTPUT ACTIVE

Q = D

2

HM-6642/883

www.BDTIC.com/Intersil

Absolute Maximum Ratings Thermal Information

Supply Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +7.0V

Input, Output or I/O Voltage. . . . . . . . . . . . GND-0.3V to VCC+0.3V

Typical Derating Factor . . . . . . . . . . . 5mA/MHz Increase in ICCOP

ESD Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Class 1

Operating Conditions

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . +4.5V to +5.5V

Operating Temperature Range . . . . . . . . . . . . . . . .-55°C to +125°C

Input Low Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to +0.8V

Input High Voltage . . . . . . . . . . . . . . . . . . . . . . . . . 2.4 to VCC+0.3V

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

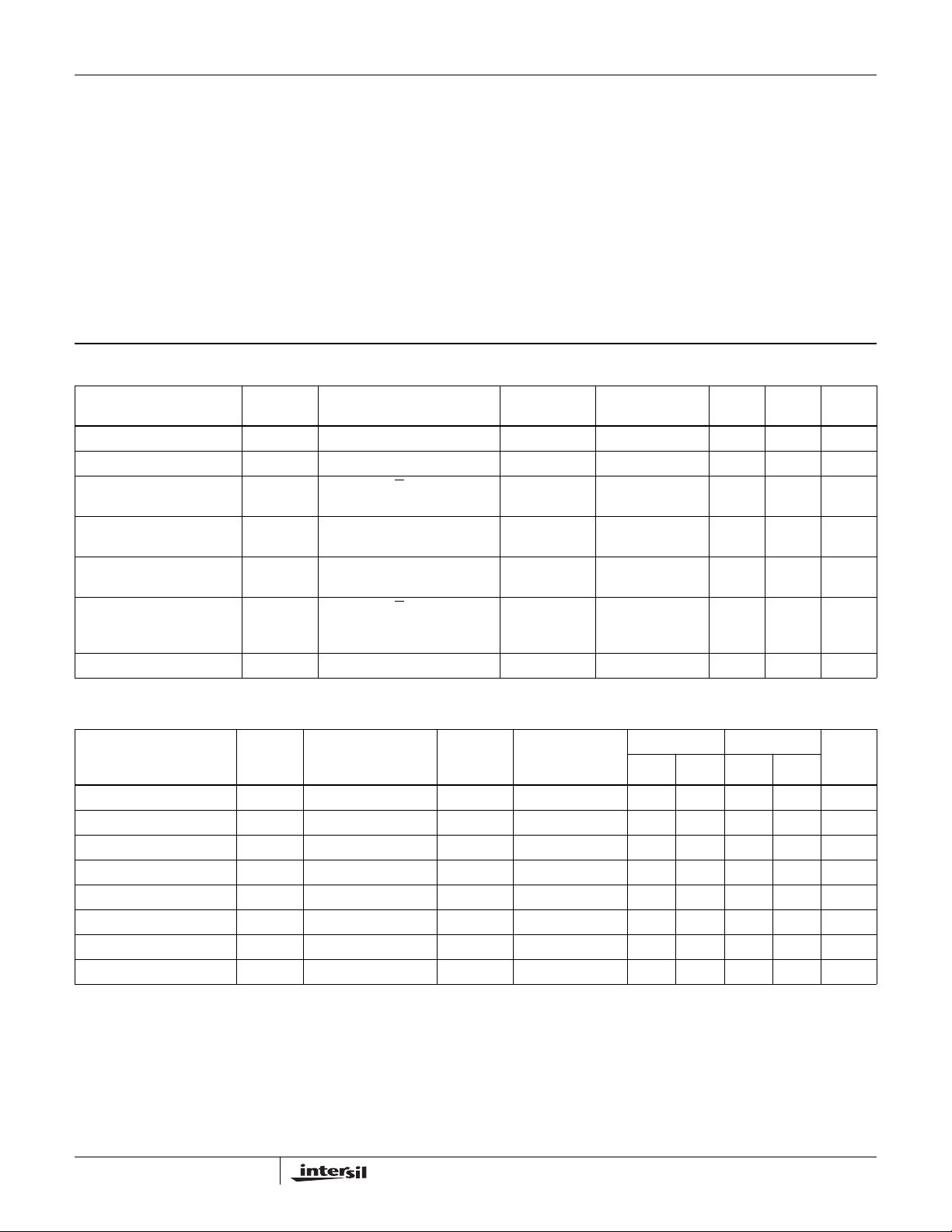

TABLE 1. HM-6642/883 DC ELECTRICAL PERFORMANCE SPECIFICATIONS

Device Guaranteed and 100% Tested

(NOTES 1, 4)

PARAMETER SYMBOL

High Level Output Voltage VOH VCC = 4.5V, IO = -1.0mA 1, 2, 3 -55 ≤ T

Low Level Output Voltage VOL VCC = 4.5V, IO = +3.2mA 1, 2, 3 -55 ≤ TA ≤ +125 - 0.4 V

High Impedance Output

Leakage Current

Input Leakage Current II VCC = 5.5V, VI = GND or VCC,

Standby Supply Current ICCSB VI = VCC or GND, VCC = 5.5V,

Operating Supply Current ICCOP VCC = 5.5V, G

Functional Test FT VCC = 4.5V (Note 5) 7, 8A, 8B -55 ≤ T

IIOZ VCC = 5.5V, G

CONDITIONS

= 5.5V,

VI/O = GND or VCC

P Not Tested

IO = 0mA

= GND,

G = VCC, (Note 3), f = 1MHz,

IO = 0mA, VI = VCC or GND

Thermal Resistance (Typical) θ

SBDIP Package . . . . . . . . . . . . . . . . . . 52 14

Slim SBDIP . . . . . . . . . . . . . . . . . . . . . 70 19

CLCC Package . . . . . . . . . . . . . . . . . . 58 14

Maximum Storage Temperature Range . . . . . . . . . .-65°C to +150°C

Maximum Junction Temperature . . . . . . . . . . . . . . . . . . . . . . +175°C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . +300°C

Die Characteristics

Gate Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1680 Gates

GROUP A

SUBGROUPS

1, 2, 3 -55 ≤ TA ≤ +125 -1.0 1.0 µA

1, 2, 3 -55 ≤ T

1, 2, 3 -55 ≤ T

1, 2, 3 -55 ≤ T

TEMPERATURE

(°C) MIN MAX UNITS

≤ +125 2.4 - V

A

≤ +125 -1.0 1.0 µA

A

≤ +125 - 100 µA

A

≤ +125 - 20 mA

A

≤ +125 - - -

A

(°C/W) θ

JA

JC

(°C/W)

Device Guaranteed and 100% Tested

PARAMETER SYMBOL

Address Access Time TAVQV VCC = 4.5V and 5.5V 9, 10, 11 -55 ≤ T

Output Enable Access Time TGVQV VCC = 4.5V and 5.5V 9, 10, 11 -55 ≤ T

Chip Enable Access Time TELQV VCC = 4.5V and 5.5V 9, 10, 11 -55 ≤ TA ≤ +125 - 120 - 200 ns

Address Setup Time TAVEL VCC = 4.5V and 5.5V 9, 10, 11 -55 ≤ T

Address Hold Time TELAX VCC = 4.5V and 5.5V 9, 10, 11 -55 ≤ T

Chip Enable Low Width TELEH VCC = 4.5V and 5.5V 9, 10, 11 -55 ≤ T

Chip Enable High Width TEHEL VCC = 4.5V and 5.5V 9, 10, 11 -55 ≤ T

Read Cycle Time TELEL VCC = 4.5V and 5.5V 9, 10, 11 -55 ≤ T

NOTES:

1. All voltages referenced to VSS.

2. A.C. measurements assume transition time < 5ns; input levels = 0.0V to 3.0V; timing reference levels = 1.5V; output load = 1TTL equivalent load

and CL ≅ 50pF.

3. Typical derating = 5mA/MHz increase in ICCOP.

4. All tests performed with P hardwired to GND.

5. Tested as follows: f = 1MHz, VIH = 2.4V, VIL = 0.8V, IOH = -1mA, IOL = +1mA, VOH ≥ 1.5V, VOL ≤ 1.5V.

TABLE 2. HM-6642/883 AC ELECTRICAL PERFORMANCE SPECIFICATIONS

(NOTES 1, 2, 4)

CONDITIONS

GROUP A

SUB-

GROUPS

TEMPERATURE

(°C)

≤ +125 - 140 - 220 ns

A

≤ +125 - 50 - 150 ns

A

≤ +125 20 - 20 - ns

A

≤ +125 25 - 60 - ns

A

≤ +125 120 - 200 - ns

A

≤ +125 40 - 150 - ns

A

≤ +125 160 - 350 - ns

A

HM-6642B/883 HM-6642/883

UNITSMIN MAX MIN MAX

3

CONFORMANCE GROUPS METHOD SUBGROUPS

www.BDTIC.com/Intersil

Initial Test 100%/5004 -

Interim Test 100%/5004 1, 7, 9

PDA 100%/5004 1

Final Test 100%/5004 2, 3, 7, 8A, 8B, 10, 11

Group A Samples/5005 1, 2, 3, 7, 8A, 8B, 9, 10, 11

Groups C & D Samples/5005 1, 7, 9

Switching Waveform

TAVE L

HM-6642/883

TABLE 3. APPLICABLE SUBGROUPS

TAVQ V

TELAX

TAVE L

A

TEHEL

E

Q

TGXQZ

G

(NOTE)

TIME

REFERENCE

NOTE: G has the same timing as G except signal is inverted.

ADD VALID

-1 0 1 2 3 456

Test Load Circuit

TELEH

TELEL

TELQV

TGVQX

TGVQV

FIGURE 1. READ CYCLE

NEXT ADD

TEHEL

DATA VALID

TGXQZ

DUT

CL

(NOTE)

1.5V IOLIOH

±

NOTE:

TEST HEAD

CAPACITANCE,

INCLUDES STRAY

AND JIG CAPACITANCE

FIGURE 2. TEST LOAD CIRCUIT

EQUIVALENT CIRCUIT

4

Burn-In Circuits

www.BDTIC.com/Intersil

HM-6642/883 (0.300 INCH) SBDIP HM-6642/883 (0.600 INCH) SBDIP

1

2

3

4

5

6

7

8

9

10

11

12

VCC/2

F8

F7

F6

F5

F4

F3

F2

F1

2.4K

2.4K

2.4K

A7

A6

A5

A4

A3

A2

A1

A0

Q0

Q1

Q2

GND

VCC

A8

G1

G2

G3

Q7

Q6

Q5

Q4

Q3

HM-6642/883

VCC

2.4K

2.4K

2.4K

2.4K

2.4K

C

F9

F10

F11

F12

F0

GND

VCC/2

24

23

22

21

20

19

E

18

P

17

16

15

14

13

F10

F9

F8

F7

F6

F5

F4

F3

VCC/2

1

A7

2

A6

3

A5

4

A4

5

A3

6

A2

7

A1

8

A0

9

Q0

10

Q1

11

Q2

12

GND

VCC

A8

G1

G2

G3

Q7

Q6

Q5

Q4

Q3

24

23

22

21

20

19

E

18

P

17

16

15

14

13

HM-6642/883 CLCC

C

VCC

F9

F10

F11

F12

F0

GND

VCC/2

NOTES:

1. F0 = 100kHz ± 10%.

2. All Resistors = 47kΩ.

3. Unless Otherwise Noted.

4. VCC = 5.5V ± 0.5V.

5. VIL = 4.5V ± 10%.

6. C = 0.01µF Min.

F5

F4

F3

F2

F1

VCC

1.5K

1.5K

1.5K

1.5K

1.5K

1.5K

1.5K

1.5K

R1

NC

F6

F7

F8

C

NC

3 2

4 28 27 26

5

6

7

8

9

10

11

1

14 15 16 17 1812 13

NC

VCC

F9

F10

25

24

23

22

NC

21

20

19

F11

F12

F0

820

820

820

820

820

820

820

820

R2

5

Die Characteristics

www.BDTIC.com/Intersil

DIE DIMENSIONS:

136 x 168 x 19 ± 1mils

METALLIZATION:

Type: Si - Al

Thickness: 11k

Å ± 15kÅ

Metallization Mask Layout

HM-6642/883

GLASSIVATION:

Type: SiO

Thickness: 8kÅ ± 1kÅ

WORST CASE CURRENT DENSITY:

1.7 x 105 A/cm

HM-6642/883

A4 A5 A6 A7 VCC A8 G1 G2

2

2

A3

A2

G3

E

P

A1

A0

Q0 Q1 Q2 GND Q3 Q4 Q5 Q6

6

Q7

HM-6642/883

www.BDTIC.com/Intersil

Ceramic Leadless Chip Carrier Packages (CLCC)

j x 45

E1

o

B

h x 45

-E-

E2

e1

o

A

-F-

0.010 E HS S

L

D

D3

0.007 E FM S HS

B1

L2

D1

-H-

D2

B2

J28.A MIL-STD-1835 CQCC1-N28 (C-4)

28 PAD CERAMIC LEADLESS CHIP CARRIER PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.060 0.100 1.52 2.54 6, 7

A1 0.050 0.088 1.27 2.23 -

B-----

B1 0.022 0.028 0.56 0.71 2, 4

E

E3

0.010 E FSS

A1

PLANE 2

PLANE 1

e

L3

B3

L1

B2 0.072 REF 1.83 REF B3 0.006 0.022 0.15 0.56 -

D 0.442 0.460 11.23 11.68 D1 0.300 BSC 7.62 BSC D2 0.150 BSC 3.81 BSC D3 - 0.460 - 11.68 2

E 0.442 0.460 11.23 11.68 E1 0.300 BSC 7.62 BSC E2 0.150 BSC 3.81 BSC E3 - 0.460 - 11.68 2

e 0.050 BSC 1.27 BSC e1 0.015 - 0.38 - 2

h 0.040 REF 1.02 REF 5

j 0.020 REF 0.51 REF 5

L 0.045 0.055 1.14 1.40 L1 0.045 0.055 1.14 1.40 L2 0.075 0.095 1.90 2.41 L3 0.003 0.015 0.08 0.038 -

ND 7 7 3

NE 7 7 3

N28 283

NOTES:

1. Metallized castellations shall be connected to plane 1 terminals

and extend toward plane 2 across at least two layers of ceramic

or completely across all of the ceramic layers to make electrical

connection with the optional plane 2 terminals.

2. Unless otherwise specified, a minimum clearance of 0.015 inch

(0.38mm) shall be maintained between all metallized features

(e.g., lid, castellations, terminals, thermal pads, etc.)

3. Symbol “N” is the maximum number of terminals. Symbols “ND”

and “NE” are the number of terminals along the sides of length

“D” and “E”, respectively.

4. The required plane 1 terminals and optional plane 2 terminals (if

used) shall be electrically connected.

5. The corner shape (square, notch, radius, etc.) may vary at the

manufacturer’s option, from that shown on the drawing.

6. Chip carriers shall be constructed of a minimum of two ceramic

layers.

7. Dimension “A” controls the overall package thickness. The maximum “A” dimension is package height before being solder dipped.

8. Dimensioning and tolerancing per ANSI Y14.5M-1982.

9. Controlling dimension: INCH.

NOTESMIN MAX MIN MAX

Rev. 0 5/18/94

7

HM-6642/883

www.BDTIC.com/Intersil

Ceramic Dual-In-Line Metal Seal Packages (SBDIP)

LEAD FINISH

c1

-A-

-B-

S

bbb C A - B

BASE

PLANE

SEATING

PLANE

S1

b2

ccc

b

CA - BM

D

A

A

e

DS S

NOTES:

1. Index area: A notch or a pin one identification mark shall be located adjacent to pin one and shall be located within the shaded

area shown. The manufacturer’s identification shall not be used

as a pin one identification mark.

2. The maximum limits of lead dimensions b and c or M shall be

measured at the centroid of the finished lead surfaces, when

solder dip or tin plate lead finish is applied.

3. Dimensions b1 and c1 apply to lead base metal only. Dimension

M applies to lead plating and finish thickness.

4. Corner leads (1, N, N/2, and N/2+1) may be configured with a

partial lead paddle. For this configuration dimension b3 replaces

dimension b2.

5. Dimension Q shall be measured from the seating plane to the

base plane.

6. Measure dimension S1 at all four corners.

7. Measure dimension S2 from the top of the ceramic body to the

nearest metallization or lead.

8. N is the maximum number of terminal positions.

9. Braze fillets shall be concave.

10. Dimensioning and tolerancing per ANSI Y14.5M - 1982.

11. Controlling dimension: INCH.

-DBASE

E

S

S

D

Q

S2

-C-

METAL

b1

M

(b)

SECTION A-A

A

L

(c)

M

eA

aaa

eA/2

CA - BM DS S

c

D24.3 MIL-STD-1835 CDIP4-T24 (D-9, CONFIGURATION C)

24 LEAD CERAMIC DUAL-IN-LINE METAL SEAL PACKAGE

INCHES MILLIMETERS

SYMBOL

A - 0.200 - 5.08 -

b 0.014 0.026 0.36 0.66 2

b1 0.014 0.023 0.36 0.58 3

b2 0.045 0.065 1.14 1.65 b3 0.023 0.045 0.58 1.14 4

c 0.008 0.018 0.20 0.46 2

c1 0.008 0.015 0.20 0.38 3

D - 1.280 - 32.51 -

E 0.220 0.310 5.59 7.87 -

e 0.100 BSC 2.54 BSC eA 0.300 BSC 7.62 BSC -

eA/2 0.150 BSC 3.81 BSC -

L 0.125 0.200 3.18 5.08 -

Q 0.015 0.060 0.38 1.52 5

S1 0.005 - 0.13 - 6

S2 0.005 - 0.13 - 7

o

α

90

105

o

90

o

105

aaa - 0.015 - 0.38 bbb - 0.030 - 0.76 ccc - 0.010 - 0.25 -

M - 0.0015 - 0.038 2

N24 248

NOTESMIN MAX MIN MAX

o

Rev. 0 4/96

-

8

HM-6642/883

www.BDTIC.com/Intersil

Ceramic Dual-In-Line Metal Seal Packages (SBDIP)

LEAD FINISH

c1

-A-

-B-

S

bbb C A - B

BASE

PLANE

SEATING

PLANE

S1

b2

ccc

b

CA - BM

D

A

A

e

DS S

NOTES:

1. Index area: A notch or a pin one identification mark shall be located adjacent to pin one and shall be located within the shaded

area shown. The manufacturer’s identification shall not be used

as a pin one identification mark.

2. The maximum limits of lead dimensions b and c or M shall be

measured at the centroid of the finished lead surfaces, when

solder dip or tin plate lead finish is applied.

3. Dimensions b1 and c1 apply to lead base metal only. Dimension

M applies to lead plating and finish thickness.

4. Corner leads (1, N, N/2, and N/2+1) may be configured with a

partial lead paddle. For this configuration dimension b3 replaces

dimension b2.

5. Dimension Q shall be measured from the seating plane to the

base plane.

6. Measure dimension S1 at all four corners.

7. Measure dimension S2 from the top of the ceramic body to the

nearest metallization or lead.

8. N is the maximum number of terminal positions.

9. Braze fillets shall be concave.

10. Dimensioning and tolerancing per ANSI Y14.5M - 1982.

11. Controlling dimension: INCH.

-DBASE

E

S

S

D

Q

S2

-C-

METAL

b1

M

(b)

SECTION A-A

A

L

(c)

M

eA

aaa

eA/2

CA - BM DS S

c

D24.6 MIL-STD-1835 CDIP2-T24 (D-3, CONFIGURATION C)

24 LEAD CERAMIC DUAL-IN-LINE METAL SEAL PACKAGE

INCHES MILLIMETERS

SYMBOL

A - 0.225 - 5.72 -

b 0.014 0.026 0.36 0.66 2

b1 0.014 0.023 0.36 0.58 3

b2 0.045 0.065 1.14 1.65 b3 0.023 0.045 0.58 1.14 4

c 0.008 0.018 0.20 0.46 2

c1 0.008 0.015 0.20 0.38 3

D - 1.290 - 32.77 -

E 0.500 0.610 12.70 15.49 -

e 0.100 BSC 2.54 BSC eA 0.600 BSC 15.24 BSC -

eA/2 0.300 BSC 7.62 BSC -

L 0.120 0.200 3.05 5.08 -

Q 0.015 0.075 0.38 1.91 5

S1 0.005 - 0.13 - 6

S2 0.005 - 0.13 - 7

o

α

90

105

o

90

o

105

aaa - 0.015 - 0.38 bbb - 0.030 - 0.76 ccc - 0.010 - 0.25 -

M - 0.0015 - 0.038 2

N24 248

NOTESMIN MAX MIN MAX

o

Rev. 0 4/94

-

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

9

Loading...

Loading...