HIP9021

PRELIMINARY

August 1996

Features

• MOSFET Driver and DC Motor Controller

• Torque Control and Overload Protection

• Battery Power Supply . . . . . . . . . . . . . . . . +5V to +15V

• BiMOS IC with Low Operating Current

- Maximum Supply Current . . . . . . . . . . . . . . . . .1.5mA

- Maximum Input Leakage Currents . . . . . . . . . . 1.5µA

• 500µA Maximum Supply Current

•1µA Maximum Input Leakage Currents

• Typical Oscillator Frequency . . . . . . . . . . . . . . . . .5kHz

• Power-On-Reset Control

• 10mA Drive Capability for Gate Output

• Operating Temperature. . . . . . . -40

o

Applications

• Portable Battery Operated Electric Drills

• Controller for Small DC Electric Motors

• Torque/Drive Controller for Inductive Loads

• Intelligent MOSFET Drive

Ordering Information

TEMP.

PART NUMBER

HIP9021IB -40 to +85 8 Ld SOIC M8.15

RANGE (oC) PACKAGE

N-Channel MOSFETs in Motor Control Systems

C to +85oC Range

Portable Battery Drive/Torque Controller for

Description

The HIP9021IB is a dedicated Power MOSFET driver which

drives a DC motor. As a system, motor speed is controlled

while controlling torque. The primary application is drive control for portable drills while providing overload protection.

The main function of the HIP9021IB is to produce a pulse

width modulated square wave signal which drives the gate of

an N-Channel Power MOSFET. The duty-cycle is determined by the setting of an external potentiometer at the

TRIGGER (speed control) input. As the TRIGGER voltage

level is decreased the duty-cycle of the square wave and the

speed of the motor is increased.

The torque of the motor is limited by the voltage level sensed

at the drain of the external Power MOSFET. When the current reaches an adjustable limit set at the TORQUE input,

the drive of the Power MOSFET is disabled.

The system control components include 2 adjustable potentiometer controls and 2 capacitors for the operating frequency and torque delay control. A fixed or battery supply

voltage in the range of 5V to 15V may be used.

The HIP9021IB is provided in a small outline plastic package

for a compact surface mount to a ceramic substrate. The

surface mount assembly can be fit directly into the trigger of

a portable electric drill.

PKG.

NO.

Pinout

HIP9021IB

(SOIC)

TOP VIEW

DRAIN

1

GND

OSC

2

3

4

TRIGGER

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

http://www.intersil.com or 407-727-9207

| Copyright © Intersil Corporation 1999

8

V

DD

7

GATE

6

DELAY

5

TORQUE

1

File Number 4055

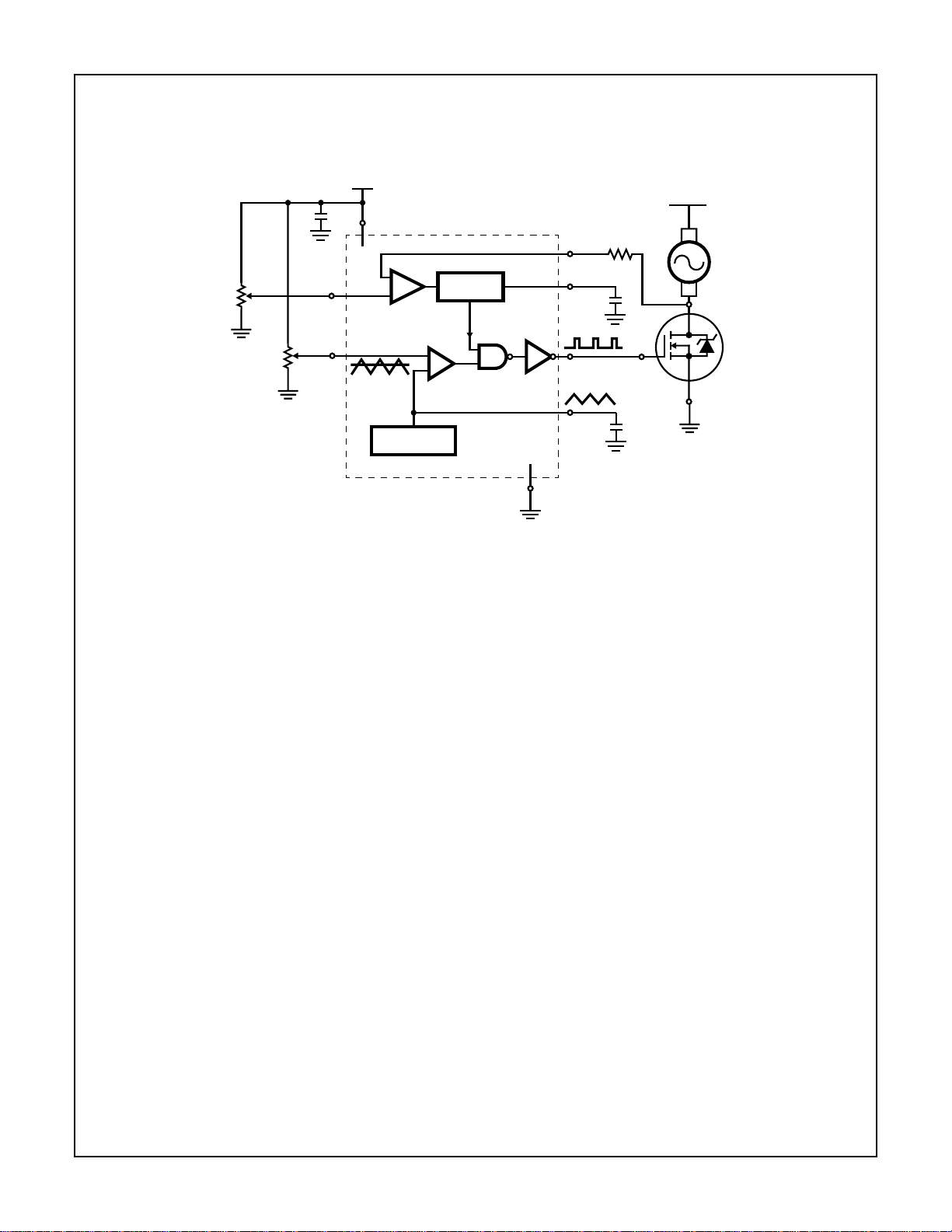

Block Diagram

HIP9021

V

BATT

V

DD

+

DRAIN

TORQUE

LEVEL SET

TORQUE

TRIGGER

SPEED

CONTROL

+

-

OSCILLATOR

HIP9021

CONTROL

& LOGIC

GC

+

DELAY

GATE

OSC

GND

2

HIP9021

Absolute Maximum Ratings Thermal Information

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +16V

Input Voltage. . . . . . . . . . . . . . . . . . . . . . . GND -0.3V to VCC +0.3V

Maximum Current, IDD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50mA

Maximum Transient Reverse Current, IR (10s). . . . . . . . . . . . -50mA

Operating Conditions

Typical Power Supply Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . .7.5V

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . +5V to +15V

Operating Temperature Range. . . . . . . . . . . . . . . . . -40oC to 150oC

Typical Oscillator Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . 5kHz

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

Thermal Resistance (Typical, Note 1) θJA (oC/W)

SOIC Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Maximum Storage Temperature Range . . . . . . . . . .-65oC to 150oC

Maximum Junction Temperature . . . . . . . . . . . . . . . . . . . . . . 150oC

Maximum Lead Temperature (Soldering 10s). . . . . . . . . . . . . 300oC

(Lead Tips Only)

Electrical Specifications V

DD

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

DC Supply Current I

OSC Source Current +I

OSC Sink Current -I

OSC Threshold Voltage V

OSC Trigger Voltage V

TRIGGER Input Leak Current I

TORQUE Input Leak Current I

DELAY Current at 1V I

DELAY Current at 2V I

DELAY Threshold Voltage V

DRAIN Input Resistance R

DRAIN Current I

GATE Output Source Current I

GATE Output Voltage V

GATE Output Slew Rate V

= 7.5V, Figure 1 Test Circuit, Table 1 Conditions, TA = +25oC Unless Otherwise Specified

DD

OSC

OSC

OSC(TH)

OSC(TR)

TRIGGER

TORQUE

DELAY1

DELAY2

DELAY(TH)

DRAIN

DRAIN

GATE

GATE

GATE(S/R)

Measured in Typical Application Circuit,

Duty Cycle = 50%, See Figure 2

0.1 1.2 3.1 mA

19 25 32 µA

-32 -25 -19 µA

4.75 4.95 5.25 V

2.30 2.45 2.65 V

- 0.02 1.5 µA

- 0.02 1.5 µA

1.5 3.4 6 µA

13250 mA

1.8 1.9 2 V

150 260 350 kΩ

1 1.7 4.6 mA

10 18 - mA

6.5 7.4 - V

-10- V/µs

DELAY Output Framed Pulse

Duty Cycle

FP/DC Gate Duty Cycle = 50%;

V

TORQUE

= GND; V

DRAIN

= V

GATE;

DELAY =10kΩ to GND, Ref er to Figure 1

DELAY Output Framed Pulse Delay, V

GATE

to V

DELAY

Typical Oscillator Frequency f

FP/DLY

OSC

for the Test circuit and Timing Diagram of

the DELAY Output Pulse Frame.

TA = 25oC - 5 - kHz

TA = -40oC - 7.2 - kHz

TA = 85oC - 3.6 - kHz

NOTES:

1. θJA is measured with the component mounted on an evaluation PC board in free air.

3

-44- %

-3- %

2V

5V

7.5V

15KΩ

1V

2V

5V

2V

5V

V

TRIGGER

22nF

V

DRAIN

1nF

V

TORQUE

1nF

1

DRAIN

5

TORQUE

2

TRIGGER

V

DD

OSC

HIP9021

V

DD

CONTROL

+

-

+

HIP9021

10µF

8

+

& LOGIC

GC

GND

0.01µF

10nF

1nF

1V

2V

3.75V

2.5V

5V

10K

R

D

V

DELAY

6

DELAY

V

V

GATE

OSC

7

GATE

4

OSC

3

V

GATE

V

DELAY

GATE PULSE WIDTH

FRAMED PULSE WIDTH

FRAMED PULSE DELAY

V

DD

GND

1V

GND

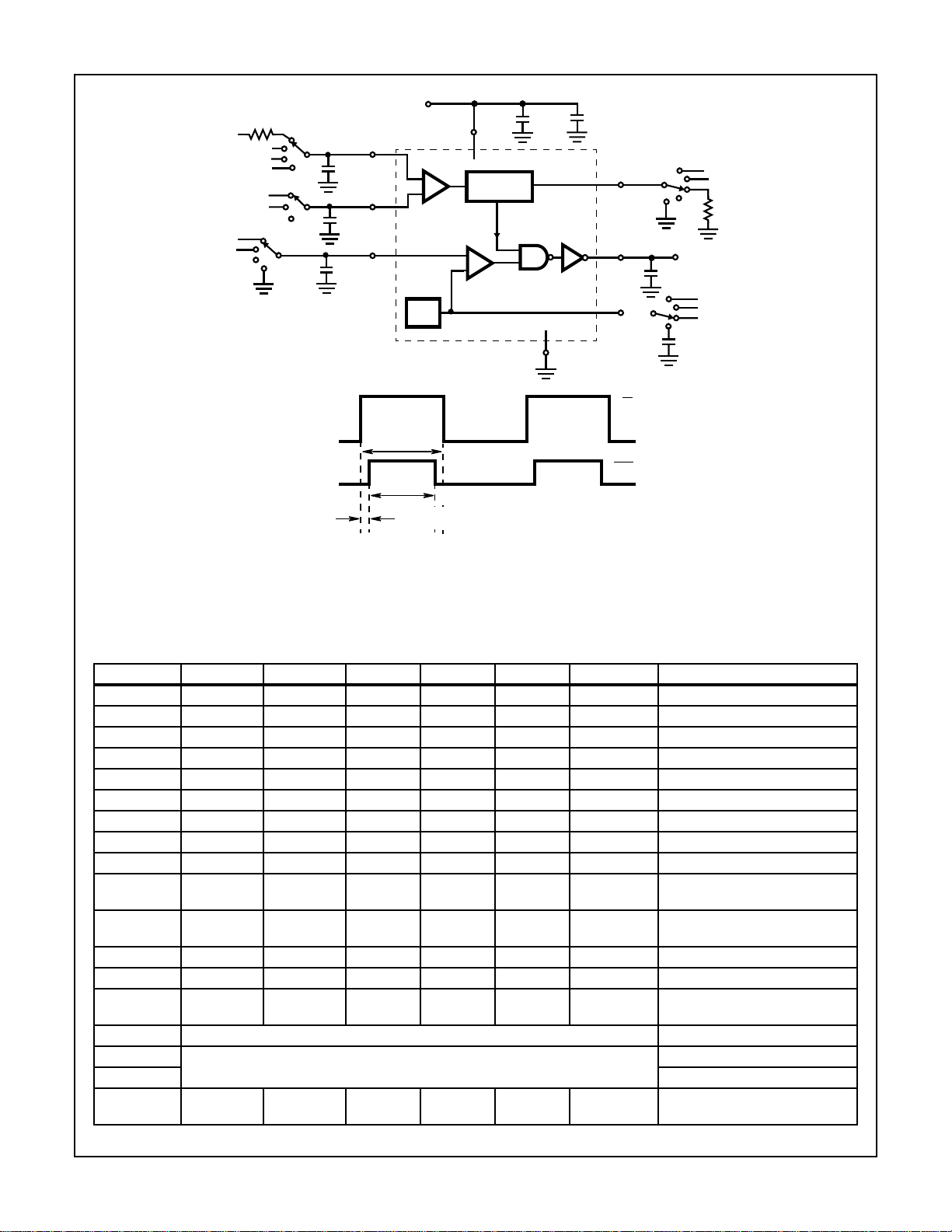

NOTE: The timing diagrams relate to the delay output framed pulse and show the time duration of the delay pulse “framed” inside of the gate

pulse. The framed pulse duty cycle and delay, in percent, are measured in reference to the gate pulse which is set at 50% duty cycle. The

Delay output framed pulse delay is one-half of the difference of the gate pulse width minus delay output framed pulse width.

FIGURE 1. ELECTRICAL CHARACTERISTICS TEST CIRCUIT FOR SIGNAL FUNCTIONS OF THE HIP9021

TABLE 1. SWITCH POSITIONS OF FIGURE 1 FOR ELECTRICAL CHARACTERISTIC TESTING

SYMBOL DRAIN TRIGGER OSC TORQUE DELAY GATE MEASURE

I

DD

+I

OSC

-I

OSC

V

OSC(TH)

V

OSC(TG)

I

TRIGGER

I

TORQUE

I

DELAY1

I

DELAY2

V

DELAY(TH)

R

DRAIN

I

DRAIN

V

GATE

I

GATE

V

GATE(S/R)

15KΩ to 2V GND 3.75V 2V Open Open IDD Current Into VDDPin

15KΩ to 2V GND 2.5V 2V Open Open Source Current From OSC Pin

15KΩ to 2V GND 5V 2V Open Open Sink Current Into OSC Pin

1V Open 1nF 2V Open Open Positive Peak OSC Voltage

1V Open 1nF 2V Open Open Negative Peak OSC Voltage

15KΩ to 2V 5V 5V 2V Open Open TRIGGER Leakage Current

15KΩ to 2V Open 5V 5V Open Open TORQUE Leakage Current

15KΩ to 2V 7.5V 1nF Open 1V Open Current to DELAY Pin

15KΩ to 2V 7.5V 1nF Open 2V Open Current to DELAY Pin

1V Ramp Up 1nF 2V GND Read V

GATE

Measure V

V

Less Than 0.5V

GATE

TRIGGER

When

5V GND 1nF 2V GND Open DRAIN Current; Calculate

R

= 5V/I

DRAIN

DRAIN

1V 7.5V 5V 2V Open Open DRAIN Current

5V GND 1nF 2V Open Open Measure V

2V GND 1nF 2V GND Set to

V

-0.5V

OUT

Measure I

with V

GATE

= V

GATE

Source Current

GATE

= V

OUT

OUT

-0.5V

Refer to Figure 2 Application Circuit, 50% GATE Output Duty Cycle GATE Output Slew Rate

FP/DC Reference Figure 1 Waveforms

FP/DLY Reference Figure 1 Waveforms

f

OSC

1V V

OSC(TH)

-

1nF 2V GND 25KΩ Load GATE Output Timing

-1V

4

HIP9021

Pin Descriptions

NAME NUMBER DESCRIPTION

DRAIN 1 The input to the DRAIN pin senses the drain of a power MOSFET Output Motor Driver. The DRAIN volt-

age is an image of the current flowing through the power MOSFET. By limiting this voltage, the torque of

the motor can be controlled.

TRIGGER 2 The TRIGGER input is an analog voltage control level used to fix the duty-cycle at the DRAIN Output. A

voltage level here is determined by a potentiometer adjustment. The TRIGGER voltage level is com-

pared with the triangle signal from the internal oscillator to produce a pulse-width modulated signal.

GND 3 Negative pole of the battery or system ground reference.

OSC 4 Oscillator output normally terminated in a charge/discharge capacitor. A constant current is flowing in

and out to charge and discharge the external capacitor.

TORQUE 5 The TORQUE input is a reference level adjustment for torque control. The voltage reference is compared

with DRAIN input. If V

DELAY 6 An external capacitor at the DELAY output is used to delay the torque control action. The external ca-

pacitor at the DELAY pin will start to be charged if a MOSFET output over-current condition is detected.

The purpose of the capacitor is to delay the disabling action of the signal GATE drive.

GATE 7 The GATE output drives the Gate of the Power MOSFET.

DRAIN

> V

TORQUE

, the GATE output pulse drive must be disabled.

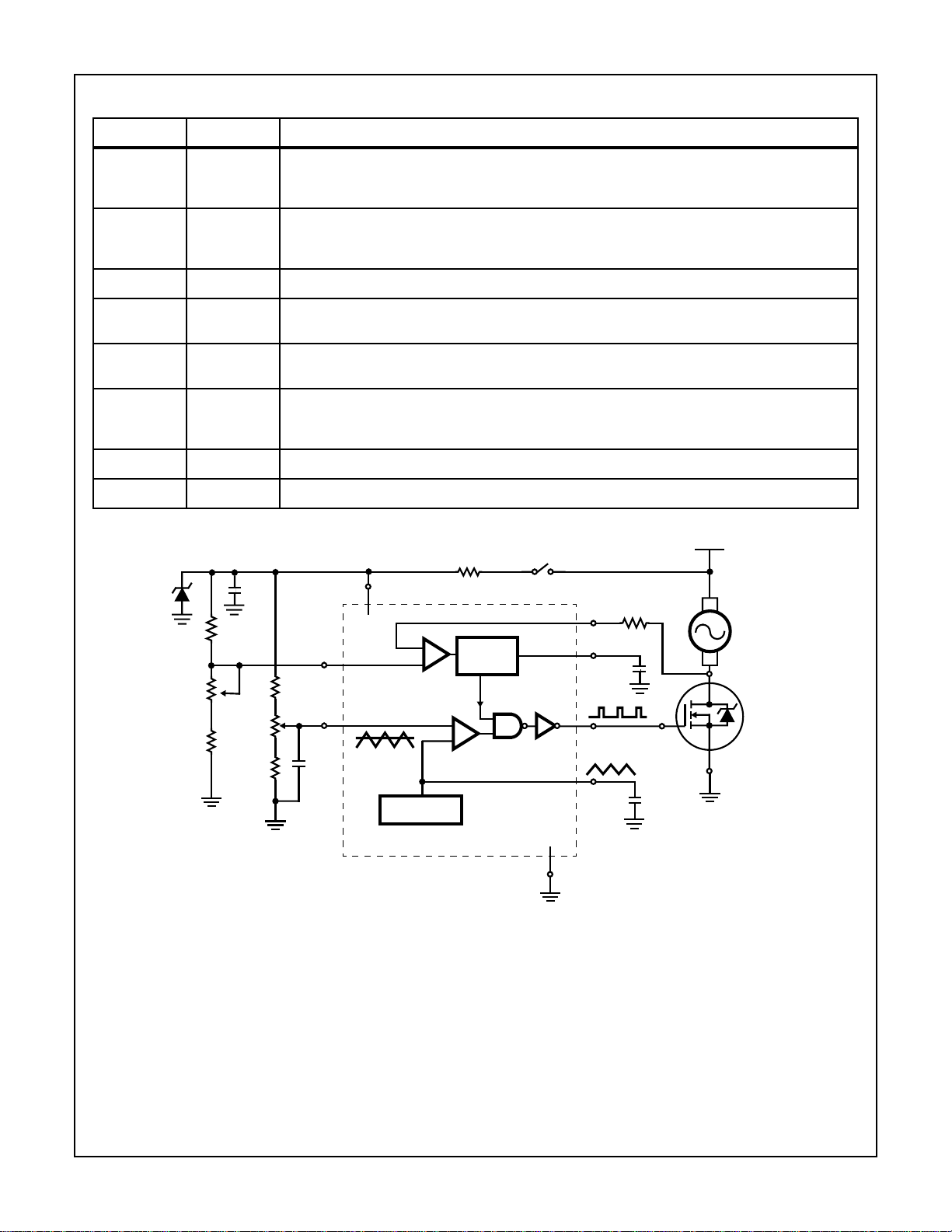

V

DD

7.5V 330Ω

180K

TORQUE

LEVEL SET

100K

5.6K

8 Positive pole of the battery or Power Supply Voltage, nominally 7.5V.

SW

V

1µF

200K

270K

CONTROL

TORQUE

470K

TRIGGER

1nF

SPEED

DD

+

OSCILLATOR

HIP9021

+

-

CONTROL

& LOGIC

GC

+

GND

DRAIN

DELAY

GATE

OSC

15K

3.3µF

1nF

V

BATT

PORTABLE

ELECTRIC

DRILL MOTOR

RFP45N03L

N-CHANNEL

POWER

MOSFET

NOTE: The value chosen for the torque level set pot is dependent on the type of power MOSFET and motor characteristics.

The TRIGGER is a combined SW/Speed Control function. Motor speed increases as the TRIGGER voltage decreases.

Speed control range: 2.35V (Min) < V

TRIGGER

< 5.25V (Max)

FIGURE 2. TYPICAL OPERATING CIRCUIT SHOWING THE HIP9021IB AS AN N-CHANNEL MOSFET DRIVER IN A PORTABLE

BATTERY ELECTRIC DRILL APPLICATION

5

HIP9021

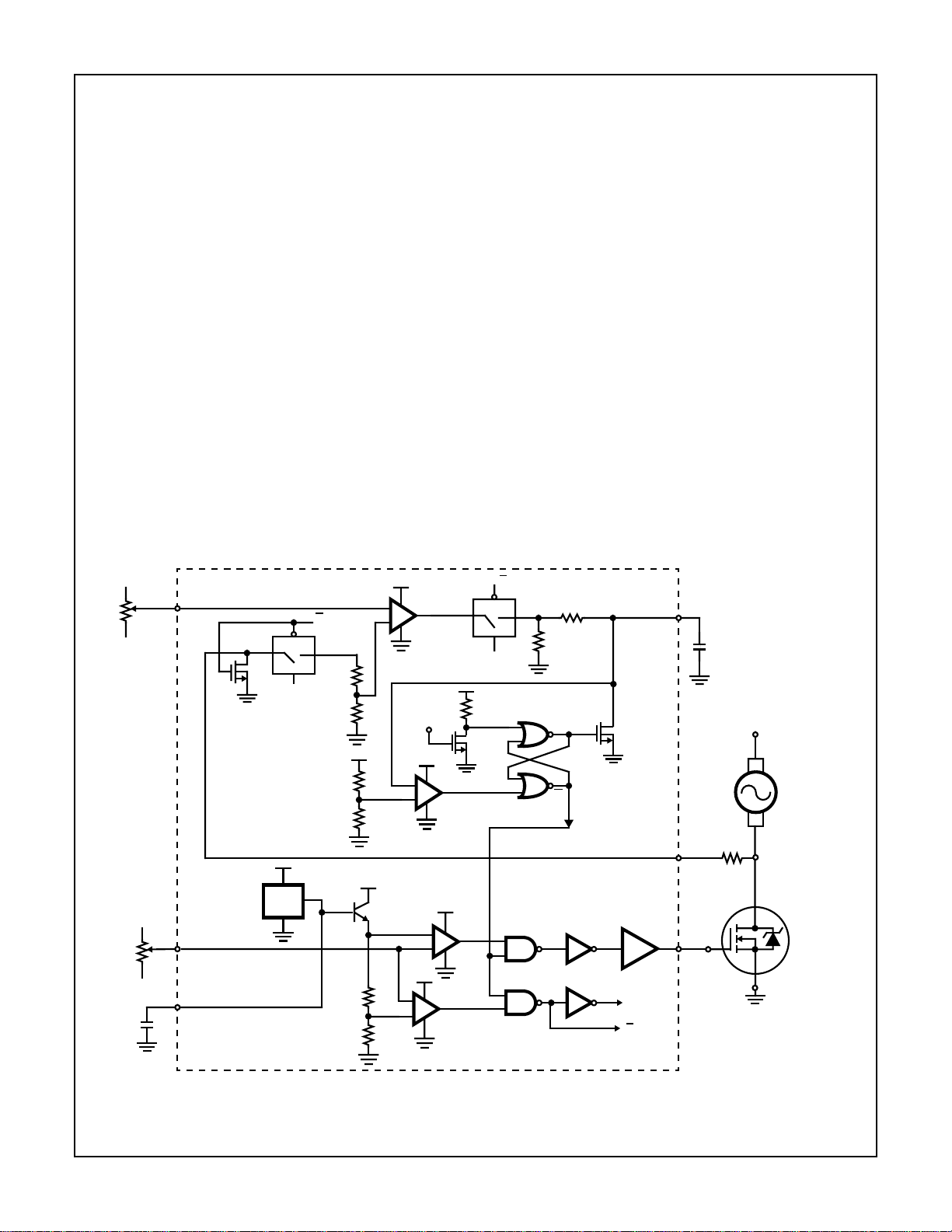

Functional Description

Oscillator

The Oscillator triangle waveform is generated by the charge

and discharge of a 1nF external capacitor connected to the

OSC pin. The OSC terminal has a source and sink drive from a

current mirror which delivers ±25µA. The charge and discharge

of the external capacitor is controlled by 2 comparators which

compare respectively V

V

. The period of the triangle wave is nominally 200µs.

DD

Gate Driver

The TRIGGER input signal is compared from the triangle

waveform of the oscillator to produce a square wave signal.

The duty cycle of the GATE dr ive signal is increased as the

TRIGGER input level increases. The output of the comparator is then NANDed with a GATE Control signal which can

enable or disable the GATE output. The NAND gate output is

buffered to deliver 18mA typical GATE drive current.

Torque Effect

The triangle signal, after going through a divider, is also

compared with TRIGGER input level. This produces another

square wave of the same period but with a duty-cycle that is

smaller than the GATE by ~5%. This square wave is used to

enable the comparison between DRAIN and TORQUE

inputs while the MOSFET is conducting.

with 2/3 VDD and V

OSC

OSC

with 1/3

A torque effect condition exists when 80% of the DRAIN signal is higher than the TORQUE input level set voltage of the

potentiometer. During this time, the e xternal delay capacitor of

3.3µF is charged through an internal 100K resistor. When the

voltage at the DELAY pin reaches 0.25 x V

, the RS flip-flop

DD

is then set and the Gate Control (GC) signal shown in Figure

3 goes to low. The Output GATE drive signal is then disabled.

This situation remains even if the voltage on the DELAY pin

stays under 0.25 x V

for a sustained period of time.

DD

At the same time, when the RS flip-flop is set, the external

capacitor at the DELAY pin is discharged via the nMOS

device, Q2 which is driven by the Q output of the flip-flop.

Power-On Reset (POR)

In reference to Figure 3, the power on of the chip will cause

the reset of the RS Gate Control flip-flop when Q1 is

switched low. As an initial condition, the Gate Control (GC)

signal is reset high. Since power on is the only way to reset

the RS flip-flop, a disabled GATE drive signal due to a torque

effect condition requires a switched (trigger) reset.

The POR (power on reset) threshold requires that V

DD

be less

than 2V to initiate a reset. The POR circuit is based on the

behavior of the voltage reference cell that produces a constant

1.15V (REF. BIAS) when V

is over 2V. When Q1 is forward

DD

biased, the Q1 drain voltage goes low to reset the input of the

RS flip-flop.

TORQUE

TRIGGER

1nF

OSC

PULL

DOWN

OSC

V

DD

-

φ

50K

φ

200K

6K

2K

2K

40K

+

LOAD

COMP

REF.

BIAS

1.15V

Q1

+

DELAY

COMP

+

-

+

150K

POR

φ

100K

φ

330K

R

S

Q

Q

CONTROL

Q2

GATE

(GC)

BUF

DELAY

DRAIN

GATE

3.3µF

15K

V

BATT

MOTOR

POWER

MOSFET

φ

φ

FIGURE 3. DETAILED LOGIC DIAGRAM OF THE PORT ABLE DRIVE/T ORQUE CONTROLLER FOR N-CHANNEL POWER MOSFETS

SHOWING THE DRAIN AND T ORQUE, THE GATE CONTROL LOGIC AND THE TRIGGER (SPEED) CONTROL.

6

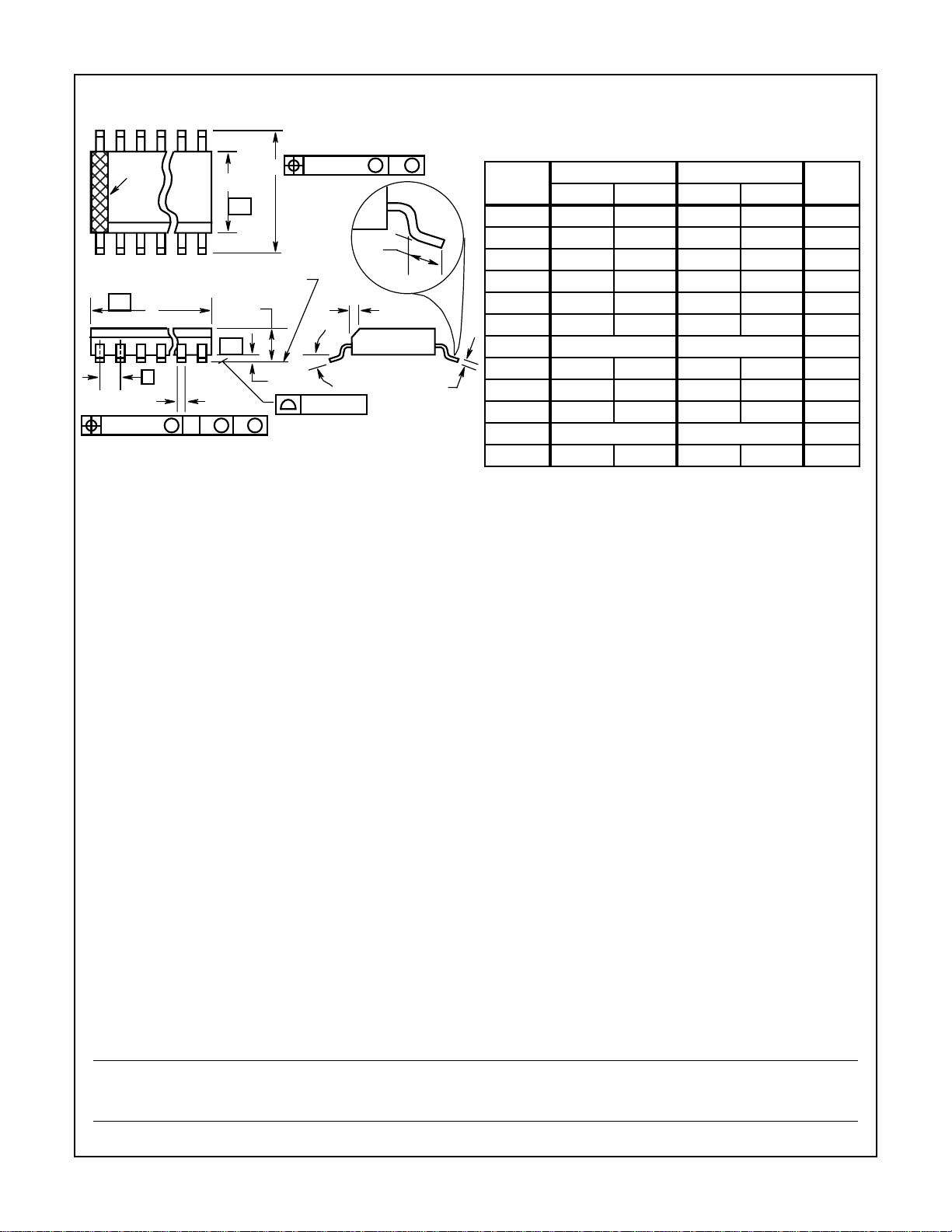

Small Outline Plastic Packages (SOIC)

HIP9021

N

INDEX

AREA

123

-A-

0.25(0.010) B

H

E

-B-

SEATING PLANE

D

A

-C-

M

L

h x 45

M

o

α

e

B

0.25(0.010) C AMB

M

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section

2.2 of Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate

burrs. Mold flash, protrusion and gate burrs shall not exceed

0.15mm (0.006 inch) per side.

4. Dimension “E” does not include interlead flash or protrusions. Interlead flash and protrusions shall not exceed 0.25mm (0.010

inch) per side.

5. The chamfer on the body is optional. If it is not present, a visual

index feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width “B”, as measured 0.36mm (0.014 inch) or greater

above the seating plane, shall not exceed a maximum value of

0.61mm (0.024 inch).

10. Controlling dimension: MILLIMETER. Converted inch dimensions are not necessarily exact.

A1

0.10(0.004)

S

M8.15 (JEDEC MS-012-AA ISSUE C)

8 LEAD NARROW BODY SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.0532 0.0688 1.35 1.75 -

A1 0.0040 0.0098 0.10 0.25 -

B 0.013 0.020 0.33 0.51 9

C 0.0075 0.0098 0.19 0.25 D 0.1890 0.1968 4.80 5.00 3

E 0.1497 0.1574 3.80 4.00 4

e 0.050 BSC 1.27 BSC H 0.2284 0.2440 5.80 6.20 -

C

h 0.0099 0.0196 0.25 0.50 5

L 0.016 0.050 0.40 1.27 6

N8 87

o

α

0

o

8

o

0

o

8

Rev. 0 12/93

NOTESMIN MAX MIN MAX

-

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate

and reliable. However, no responsibility is assumed by Intersil or its subsidiaries f or its use; nor for any infringements of patents or other rights of third parties which

may result from its use. No license is granted by implication or otherwise under an y patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

7

Loading...

Loading...