Page 1

HIP6502

Data Sheet December 1999 File Number 4775.1

Multiple Linear Power Controller with

ACPI Control Interface

The HIP6502 complements either an HIP6020 or an

HIP6021 in ACPI-compliant designs for microprocessor and

computer applications. The IC integrates four linear

controllers/regulators, switching, monitoring and control

functions into a 20-pin SOIC package. One linear controller

generates the 3.3V

/3.3VSBvoltage plane from the ATX

DUAL

supply’s 5VSB output, powering the south bridge and the

PCI slots through an external pass transistor during sleep

states (S3, S4/S5). A second transistor is used to switch in

the ATX 3.3V output for operation during S0 and S1/S2

(active) operating states. Two linear controllers/regulators

supply a choice of either or both of the computer system’s

2.5V or 3.3V memory power through external pass

transistors in active states. During sleep states, integrated

pass transistors supply the sleep power. Another controller

powers up the 5V

plane by switching in the ATX 5V

DUAL

output in active states, and the ATX 5VSB in sleep states.

One internal regulator outputs a dedicated, noise-free 2.5V

clock chip supply. The HIP6502’s operating mode (active

outputs or sleep outputs) is selectable through two digital

control pins,

5V

DUAL

state, the 3.3V

S3 and S5. Enabling sleep state support on the

output is offered through the EN5VDL pin. In active

DUAL

and 3.3V

linear regulators use

MEM

external N-channel pass MOSFETs to connect the outputs

directly to the 3.3V input supplied by an ATX (or equivalent)

power supply, for minimal losses. In sleep state, power

delivery on both outputs is transferred to NPN transistors external to the controller on the 3.3V

3.3V

. Active state regulation on the 2.5V

MEM

, internal on the

DUAL

MEM

output is

performed through an external NPN transistor. In sleep

state, conduction on this output is transferred to an internal

pass transistor. The 5V

output is powered through two

DUAL

external MOS transistors. In sleep states, a PMOS (or PNP)

transistor conducts the current from the ATX 5VSB output;

while in active state, current flow is transferred to an NMOS

transistor connected to the ATX 5V output. The operation of

the 5V

output is dictated not only by the status of the

DUAL

S3 and S5 pins, but that of the EN5VDL pin as well. The

3.3V

5VSB voltage is applied to the chip. The 2.5V

/3.3VSB output is active for as long as the ATX

DUAL

CLK

output is

only active during S0 and S1/S2, and uses the 3V3 pin as

input source for its internal pass element.

Ordering Information

Features

• Provides 5 ACPI-Controlled Voltages

-5V

- 3.3V

- 2.5V

- 3.3V

- 2.5V

USB/Keyboard/Mouse (Active/Sleep)

DUAL

/3.3VSB PCI/Auxiliary/LAN (Active/Sleep)

DUAL

RDRAM (Active/Sleep)

MEM

SDRAM (Active/Sleep)

MEM

Clock/Processor Terminations (Active Only)

CLK

• Excellent Output Voltage Regulation

- 3.3V

/3.3VSB Output: ±2.0% Over Temperature;

DUAL

Sleep State Only

- 2.5V

Temperature; Both Operational States (3.3V

MEM

and 3.3V

Output: ±2.0% Over

MEM

MEM

in

sleep only)

- 2.5V

Output: ±2.0% Over Temperature

CLK

• Small Size

- Very Low External Component Count

• Dual Memory Voltage Support Via MSEL Pin

- 2.5V for RDRAM Memory

- 3.3V for SDRAM Memory

- Both 2.5V and 3.3V for Flexible Systems

• Under-Voltage Monitoring of All Outputs with Centralized

FAULT Reporting and Temperature Shutdown

Applications

•

Motherboard Power Regulation for ACPI-Compliant

Computers

Pinout

HIP6502

(SOIC)

TOP VIEW

VSEN2

5VSB

VSEN1

3V3DLSB

3V3DL

VCLK

3V3

EN5VDL

S3

S5

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

MSEL

DRV2

5V

12V

SS

5VDL

5VDLSB

DLA

FAULT

GND

TEMP.

PART NUMBER

HIP6502CB 0 to 70 20 Ld SOIC M20.3

HIP6502EVAL1 Evaluation Board

RANGE (oC) PACKAGE

1

PKG.

NO.

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

| Copyright © Intersil Corporation 1999

Page 2

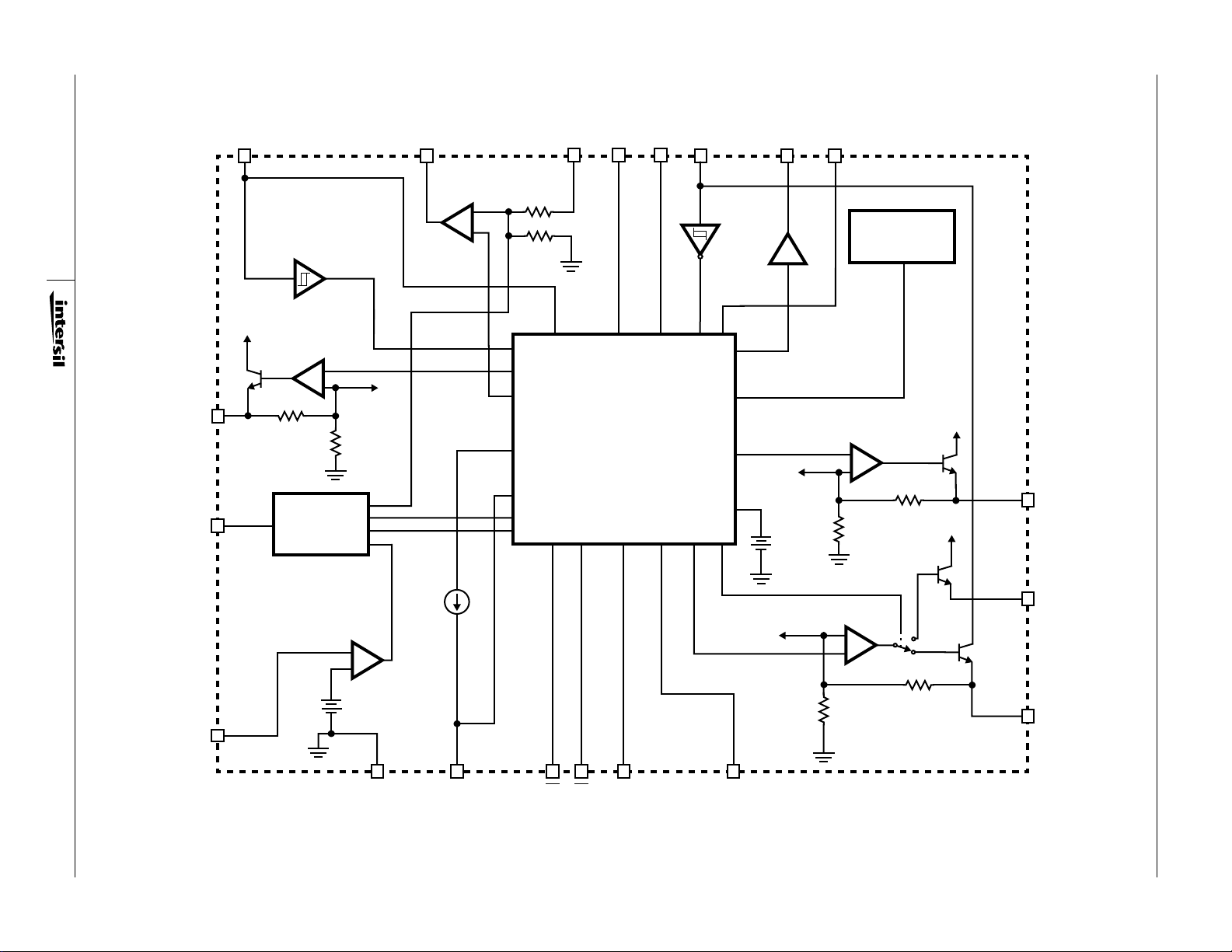

Block Diagram

12V

2

TO 5VSB

12V MONITOR

EA3

10.2V/9.2V

+

3V3DLSB

EA4

-

+

3V3DL

5V

3V3

5VSB

5VSB POR

4.5V/4.0V

5VDLSB

DLA

TEMPERATURE

MONITOR

(TMON)

-

TO UV

VSEN1

FAULT

UV DETECTOR

DETECTOR

MONITOR AND CONTROL

TO

UV DETECTOR

+

1.265V

-

TO 3V3

EA3

+

HIP6502

-

VCLK

TO 5V

5VDL

3.75V

-

+

UV COMPARATOR

+

-

GND

SS

10µA

S3

S5

EN5VDL

FIGURE 1.

MSEL

TO UV

DETECTOR

DRV2

EA2

-

+

VSEN2

Page 3

Simplified Power System Diagram

+5V

IN

+12V

IN

+5V

SB

+3.3V

IN

Q6

3.3V

MEM

3.3V

Q2

3.3V

DUAL

FAULT

MSEL

SHUTDOWN

SX

EN5VDL

/3.3V

3.3V

SB

Q3

2

Typical Application

HIP6502

LINEAR

REGULATOR

LINEAR

CONTROLLER

HIP6502

FIGURE 2.

LINEAR

CONTROLLER

LINEAR

REGULATOR

CONTROL

LOGIC

Q1

V

2.5V

V

2.5V

MEM

CLK

Q5

Q4

5V

DUAL

5V

+5V

IN

+12V

IN

+5V

SB

+3.3V

IN

V

OUT1

3.3V

3.3V

FAULT

SLP_S3

SLP_S5

EN5VDL

MSEL

SHUTDOWN

MEM

V

OUT3

DUAL

/3.3V

Q2

SB

Q6

C

OUT1

C

Q3

OUT3

VSEN1

5V

3V3DLSB

3V3DL

FAULT

S3

S5

EN5VDL

MSEL

SS

C

SS

12V

3V3

HIP6502

GND

5VSB

DRV2

VSEN2

C

OUT2

VCLK

5VDLSB

DLA

5VDL

C

OUT4

Q1

C

OUT5

Q5

Q4

V

2.5V

2.5V

V

5V

OUT2

V

OUT4

OUT5

DUAL

MEM

CLK

FIGURE 3.

3

Page 4

HIP6502

Absolute Maximum Ratings Thermal Information

Supply Voltage, V

12V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GND - 0.3V to +14.5V

DLA, DRV2. . . . . . . . . . . . . . . . . . . . . . . .GND - 0.3V to V

All Other Pins. . . . . . . . . . . . . . . . . . . . .GND - 0.3V to 5VSB + 0.3V

ESD Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Class 3

Recommended Operating Conditions

Supply Voltage, V

Digital Inputs, VSX,V

Ambient Temperature Range. . . . . . . . . . . . . . . . . . . . .0oC to 70oC

Junction Temperature Range. . . . . . . . . . . . . . . . . . . . 0oC to 125oC

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

1. θJA is measured with the component mounted on an evaluation PC board in free air.

Electrical Specifications Recommended Operating Conditions, Unless Otherwise Noted Refer to Figures 1, 2 and 3

VCC SUPPLY CURRENT

Nominal Supply Current I

Shutdown Supply Current I

POWER-ON RESET, SOFT-START, AND VOLTAGE MONITORS

Rising 5VSB POR Threshold - - 4.5 V

5VSB POR Hysteresis - 0.2 - V

Rising 12V Threshold - - 10.2 V

12V Hysteresis - 1.0 - V

Rising 3V3 and 5V Thresholds -90- %

3V3 and 5V Hysteresis -5- %

Soft-Start Current I

Shutdown Voltage Threshold V

3.3V

Regulation - - 2.0 %

VSEN1 Nominal Voltage Level V

VSEN1 Undervoltage Rising Threshold - 2.77 - V

VSEN1 Undervoltage Hysteresis - 110 - mV

VSEN1 Output Current I

2.5V

Regulation - - 2.0 %

VSEN2 Nominal Voltage Level V

VSEN2 Undervoltage Rising Threshold - 2.075 - V

VSEN2 Output Current I

DRV2 Output Drive Current I

3.3V

Sleep State Regulation - - 2.0 %

3V3DL Nominal Voltage Level V

LINEAR REGULATOR (V

MEM

LINEAR REGULATOR (V

MEM

/3.3VSB LINEAR REGULATOR (V

DUAL

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +7.0V

5VSB

Thermal Resistance (Typical, Note 1) θJA (oC/W)

SOIC Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

+0.3V

12V

Maximum Junction Temperature (Plastic Package) . . . . . . . .150oC

Maximum Storage Temperature Range. . . . . . . . . . -65oC to 150oC

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . .300oC

(SOIC - Lead Tips Only)

. . . . . . . . . . . . . . . . . . . . . . . . . . . +5V ±5%

5VSB

EN5VDL

, V

. . . . . . . . . . . . . . 0 to +5.25V

MSEL

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

-30- mA

-10- µA

- - 0.8 V

- 3.3 - V

OUT1

OUT2

5VSB

5VSB(OFF)VSS

)

VSEN1

VSEN1

)

VSEN2

VSEN2

DRV2

)

OUT3

3V3DL

= 0.8V - 14 - mA

SS

SD

MSEL > 1.8V - 3.3 - V

5VSB = 5V 250 300 - mA

MSEL < 2.0V - 2.5 - V

5VSB = 5V 250 300 - mA

5VSB = 5V 220 - - mA

4

Page 5

HIP6502

Electrical Specifications Recommended Operating Conditions, Unless Otherwise Noted Refer to Figures 1, 2 and 3 (Continued)

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

3V3DL Undervoltage Rising Threshold - 2.77 - V

3V3DL Undervoltage Hysteresis - 110 - mV

3V3DLSB Output Drive Current I

3V3DLSB

DLA Output Impedance -90- Ω

2.5V

LINEAR REGULATOR (V

CLK

OUT4

)

Regulation - - 2.0 %

VCLK Nominal Voltage Level V

VCLK

VCLK Undervoltage Rising Threshold - 2.10 - V

VCLK Undervoltage Hysteresis -80- mV

VCLK Output Current (Note 2) I

5V

SWITCH CONTROLLER (V

DUAL

OUT5

VCLK

)

5VDL Undervoltage Rising Threshold - 4.22 - V

5VDL Undervoltage Hysteresis - 170 - mV

5VDLSB Output Drive Current I

5VDLSB

5VDLSB Pull-Up Impedance to 5VSB - 350 - Ω

TIMING INTERVALS

Active State Assessment Past Input UV

Thresholds (Note 3)

Active-to-Sleep Control Input Delay - 200 - µs

CONTROL I/O (S3, S5, EN5VDL, MSEL, FAULT)

High Level Input Threshold - - 2.2 V

Low Level Input Threshold 0.8 - - V

S3, S5 Internal Pull-up Impedance to 5VSB - 70 - kΩ

FAULT Output Impedance FAULT = high - 100 - Ω

TEMPERATURE MONITOR

Fault-Level Threshold (Note 4) 140 - Shutdown-Level Threshold (Note 4) - 155 -

NOTES:

2. At Ambient Temperatures Less Than 50oC.

3. Guaranteed by Correlation.

4. Guaranteed by Design.

5VSB = 5V 5 8.5 - mA

- 2.5 - V

V

= 3.3V 500 800 - mA

3V3

5VDLSB = 4V, 5VSB = 5V -20 - -40 mA

20 25 30 ms

o

o

C

C

5

Page 6

HIP6502

Functional Pin Description

3V3 (Pin 7)

Connect this pin to the ATX 3.3V output. This pin provides

the output current for the 2V5CLK pin, and is monitored for

power quality.

5VSB (Pin 2)

Provide a very well de-coupled 5V bias supply for the IC to

this pin by connecting it to the ATX 5VSB output. This pin

provides the output current for the VSEN1 and VSEN2 pins,

as well as the base current for Q2. The voltage at this pin is

monitored for power-on reset (POR) purposes.

5V (Pin 18)

Connect this pin to the ATX 5V output. This pin provides the

base bias current for Q1, and is monitored for power quality.

12V (Pin 17)

Connect this pin to the ATX 12V output. This pin provides the

gate bias voltage for Q3, Q5 and Q6, and is monitored for

power quality.

GND (Pin 11)

Signal ground for the IC. All voltage levels are measured with

respect to this pin.

S3 and S5 (Pins 9 and 10)

These pins switch the IC’s operating state from active (S0,

S1/S2) to S3 and S4/S5 sleep states. These are digital

inputs featuring internal 50kΩ (typical) resistor pull-ups to

5VSB. Internal circuitry de-glitches these pins for

disturbances lasting as long as 2µs (typically). Additional

circuitry blocks any illegal state transitions (such as S3 to

S4/S5 or vice versa). Respectively, connect

computer system’s

SLP_S3 and SLP_S5 signals.

MSEL (Pin 20)

Unconnected, this pin is held at approximately 1.9V by an

internal resistor divider. Pulling this pin below 0.9V enables

the 2.5V

above 2.9V enables the 3.3V

levels) and disables 2.5V output. Leaving the pin open

enables both memory regulators.

output and disables 3.3V

MEM

output (typical voltage

MEM

EN5VDL (Pin 8)

This pin enables or disables sleep state support on the

5V

is a digital input pin whose status can only be changed

during active state operation or during chip shutdown (SS

pin grounded by external open-drain device or chip bias

below POR level). The input information is latched-in when

entering a sleep state, as well as following 5VSB POR

release or exit from shutdown. EN5VDL is internally pulled

high through a 40µA current source.

output in response to S3 and S4/S5 requests. This

DUAL

S3 and S5 to the

output. Pulling it

MEM

FAULT (Pin 12)

In case of an undervoltage on any of the outputs or on any of

the monitored ATX outputs, or in case of an overtemperature

event, this pin is used to report the fault condition by being

pulled to 5VSB.

SS (Pin 16)

Connect this pin to a small ceramic capacitor (no less than

5nF; 0.1µF recommended). The internal soft-start (SS)

current source along with the external capacitor creates a

voltage ramp used to control the ramp-up of the output

voltages.Pulling this pin low with an open-drain device shuts

down all the outputs as well as forces the FAULTpin low.The

C

capacitor is also used to provide a controlled voltage

SS

slew rate during active-to-sleep transitions on the 3.3V

and V

MEM

outputs.

DUAL

VSEN2 (Pin 1)

Connect this pin to the 2.5V memory output (V

sleep states, this pin is regulated to 2.5V through an internal

pass transistor capable of delivering 300mA (typically). The

active-state voltage at this pin is regulated through an

external NPN transistor connected at the DRV2 pin. During

all operating states, the voltage at this pin is monitored for

under-voltage events.

OUT2

). In

DRV2 (Pin 19)

Connect this pin to the base of a suitable NPN transistor.

This pass transistor regulates the 2.5V output from the ATX

3.3V during active states operation.

3V3DL (Pin 5)

Connect this pin to the 3.3V dual/stand-by output (V

In sleep states, the voltage at this pin is regulated to 3.3V;in

active states, ATX 3.3V output is delivered to this node

through a fully on N-MOS transistor. During all operating

states, this pin is monitored for under-voltage events.

OUT3

).

3V3DLSB (Pin 4)

Connect this pin to the base of a suitable NPN transistor. In

sleep state, this transistor is used to regulate the voltage at

the 3V3DL pin to 3.3V.

DLA (Pin 13)

Connect this pin to the gates of suitable N-MOSFETs, which

in active state, switch in the ATX 3.3V and 5V outputs into

the 3.3V

respectively.

MEM

, 3.3V

/3.3VSB and 5V

DUAL

DUAL

outputs,

5VDL (Pin 15)

Connect this pin to the 5V

operating state, the voltage at this pin is provided through a

fully on MOS transistor. This pin is also monitored for undervoltage events.

DUAL

output (V

OUT5

). In either

,

6

Page 7

HIP6502

5VDLSB (Pin 14)

Connect this pin to the gate of a suitable P-MOSFET or

bipolar PNP. In sleep state, this transistor is switched on,

connecting the ATX 5VSB output to the 5V

DUAL

regulator

output.

VSEN1 (Pin 3)

Connect this pin to the 3.3V memory output (V

sleep states, this pin is regulated to 3.3V through an internal

pass transistor capable of delivering 300mA (typically). The

active-state voltage at this pin is provided from the ATX3.3V

through a fully on external N-MOS transistor. During all

operating states, the voltage at this pin is monitored for

under-voltage events.

OUT1

). In

VCLK (Pin 6)

This pin is the output of the internal 2.5V clock chip regulator

(V

). This internal regulator operates only in active

OUT4

states (S0, S1/S2) and is shut off during any sleep state,

regardless of the configuration of the chip. This pin is

monitored for under-voltage events.

Description

Operation

The HIP6502 controls 5 output voltages (Refer to Figures 1,

2, and 3). It is designed for microprocessor computer

applications with 3.3V, 5V, 5VSB, and 12V bias input from an

ATX power supply. The IC is composed of three linear

controllers/regulators supplying the computer system’s

3.3V

and PCI slots’ 3.3V

SB

RDRAM and 3.3V SDRAM memory power (V

an integrated regulator dedicated to 2.5V clock chip

(V

voltage (V

), a dual switch controller supplying the 5V

OUT4

), as well as all the control and monitoring

OUT5

functions necessary for complete ACPI implementation.

Initialization

The HIP6502 automatically initializes upon receipt of input

power. The Power-On Reset (POR) function continually

monitors the 5VSB input supply voltage, initiating 3.3V

soft-start operation after exceeding POR threshold. At 3ms

(typically) after 3.3V

status is latched in and the chip proceeds to ramp up the

remainder of the voltages, as required.

finishes its ramp-up, the EN5VDL

SB

AUX

power (V

), the 2.5V

OUT3

OUT2,VOUT1

DUAL

SB

Additionally, the internal circuitry does not allow the

transition from an S3 (suspend to RAM) state to an S4/S5

(suspend to disk/soft off) state or vice versa. The only ‘legal’

transitions are from an active state (S0, S1) to a sleep state

(S3, S5) and vice versa.

TABLE 1. 5V

EN5VDL S5 S3 5VDL COMMENTS

0 1 1 5V S0, S1 States (Active)

0100VS3

0 0 1 Note Maintains Previous State

0 0 0 0V S4/S5

1 1 1 5V S0, S1 States (Active)

1105VS3

1 0 1 Note Maintains Previous State

1 0 0 5V S4/S5

NOTE: Combination Not Allowed.

DUAL

OUTPUT (V

) TRUTH TABLE

OUT5

Functional Timing Diagrams

Figures 4 through 6 are timing diagrams, detailing the power

up/down sequences of all three outputs in response to the

status of the enable (EN5VDL) and sleep-state pins (

S5), as well as the status of the ATX supply.

5VSB

S3

),

S5

3.3V,

5V, 12V

3V3DLSB

DLA

3V3DL

5VDLSB

5VDL

FIGURE 4. 5V

3.3V

TIMING DIAGRAM FOR EN5VDL = 1;

DUAL

/3.3V

DUAL

SB

S3,

Operational Truth Table

The EN5VDL pin offers the choice of supporting or disabling

5VDUAL output in S3 and S4/S5 sleep states. Table 1

describes the truth combinations pertaining to this output.

Not shown in any of the tables are the 3.3V

the 2.5V

outputs. The 3.3V

CLK

/3.3VSB output powers

DUAL

up as soon as the 5VSB ATX output is available. The

2.5V

output operation is restricted by the chip’s POR and

CLK

is only available in active state (S0, S1). For additional

information, see the soft-start sequence diagrams.

7

DUAL

/3.3VSBand

The status of the EN5VDL pin can only be changed while in

active (S0, S1) states, when the bias supply (5VSB pin) is

below POR level, or during chip shutdown (SS pin shorted to

GND or within 3ms of 5VSB POR); a status change of this

pin while in a sleep state is ignored.

Page 8

5VSB

S3

S5

3.3V,

5V, 12V

3V3DLSB

DLA

3V3DL

HIP6502

proportional to the SS (soft-start) pin voltage. As the SS pin

voltage slews from about 1.25V to 2.5V, the input clamp

allows a rapid and controlled output voltage rise.

5VSB

(1V/DIV)

SOFT-START

(1V/DIV)

5VDLSB

5VDL

FIGURE 5. 5V

3V

TIMING DIAGRAM FOR EN5VDL = 0;

DUAL

/3V

DUAL

SB

Not shown in these diagrams is the deglitching feature used

to protect against false sleep state tripping. Both

S3 and S5

pins are protected against noise by a 2µs filter (typically 1 4µs). This feature is useful in noisy computer environments if

the control signals have to travel over significant distances.

Additionally, the

transitioning to sleep states. Once the

S3 pin features a 200µs delay in

S3 pin goes low, an

internal timer is activated. At the end of the 200µs interval, if

the

S5 pin is low, the HIP6502 switches into S5 sleep state; if

the

S5 pin is high, the HIP6502 goes into S3 sleep state.

5VSB

S3

S5

3.3V,

5V, 12V

INTERNAL

VSEN1, 2

DEVICES

DRV2

VSEN2

DLA

VSEN1

VCLK

FIGURE 6. 2.5V

MEM

, 3.3V

MEM

, AND 2.5V

CLK

TIMING

DIAGRAM; MSEL FLOATING (NOT CONNECTED)

Soft-Start Circuit

SOFT-START INTO SLEEP STATES (S3, S4/S5)

The 5VSB POR function initiates the soft-start sequence. An

internal 10µA current source charges an external capacitor.

The error amplifiers reference inputs are clamped to a level

0V

V

0V

OUTPUT

VOLTAGES

(1V/DIV)

T1 T2

T0

V

OUT3

(3.3V

T3

DUAL

/3.3VSB)

TIME

T5T4

OUT5

V

OUT1

V

(2.5V

(5V

OUT2

MEM

DUAL

(3.3V

)

MEM

V

(2.5V

)

)

OUT4

CLK

)

FIGURE 7. SOFT-START INTERVAL IN A SLEEP STATE

(ALL OUTPUTS ENABLED)

Figure 7 shows the soft-start sequence for the typical

application start-up in sleep state with all output voltages

enabled. At time T0 5VSB (bias) is applied to the circuit. At

time T1 the 5VSB surpasses POR level. An internal fast

charge circuit quickly raises the SS capacitor voltage to

approximately 1V, then the 10µA current source continues

the charging. The soft-start capacitor voltage reaches

approximately 1.25V at time T2, at which point the

3.3V

/3.3VSB error amplifier’s reference input starts its

DUAL

transition, causing the output voltage to ramp up

proportionally.The ramp-up continues until time T3 when the

3.3V

/3.3VSB voltage reaches the set value. After this

DUAL

output reached its set value, as the soft-start capacitor

voltage reaches approximately 2.75V, the under-voltage

monitoring circuit of this output is activated and the soft-start

capacitor is quickly discharged to approximately 1.25V.

Following the 3ms (typical) time-out between T3 and T4, the

MSEL and EN5VDL selections are latched in, and the softstart capacitor commences a second ramp-up designed to

smoothly bring up the remainder of the voltages required by

the system. At time T5 all voltages are within regulation

limits, and as the SS voltage reaches 2.75V, all the

remaining UV monitors are activated and the SS capacitor is

quickly discharged to 1.25V, where it remains until the next

transition.

8

Page 9

HIP6502

SOFT-START INTO ACTIVE STATES (S0, S1)

S3 and S5 are logic high at the time the 5VSB is

If both

applied, the HIP6502 will assume active state wake-up and

keep off the controlled external transistors and the VCLK

output until some time (typically 25ms) after the ATX’s main

outputs used by the application (3.3V, 5V, and 12V) exceed

the set thresholds. This time-out feature is necessary in

order to insure the main ATX outputs are stabilized. The

time-out also assures smooth transitions from sleep into

active when sleep states are being supported.

3.3V

/3.3VSB output, whose operation is only

DUAL

dependent on 5VSB presence, will come up right as bias

voltage reaches POR level.

+12V

+5VSB

0V

INPUT VOLTAGES

(2V/DIV)

+5V

+3.3V

OUTPUT

VOLTAGES

(1V/DIV)

IN

IN

IN

V

OUT5

DLA PIN

(2V/DIV)

SOFT-START

(5V

DUAL

(1V/DIV)

)

are ramped-up, reaching regulation limits at time T3.

Simultaneous with the beginning of the memory and clock

voltage ramp-up, at time T2, the DLA pin is pulled high,

turning on Q3, Q5, and Q6 in the process, and bringing the

3.3V

MEM

and 5V

outputs in regulation. Shortly after

DUAL

time T3, as the SS voltage reaches 2.75V, the soft-start

capacitor is quickly discharged down to approximately2.45V,

where it remains until a valid sleep state request is received

from the system.

It is important to note that in the typical application (as

pictured in Figure 3) the 3.3V memory output is powered up

during active state operation, regardless of the MSEL pin

status. Sleep state support on this output is, however,

dependent on the MSEL status.

Fault Protection

All the outputs are monitored against undervoltage events. A

severe overcurrent caused by a failed load on any of the

outputs, would, in turn, cause that specific output to

suddenly drop. If any of the output voltages drop below 80%

(typical) of their set value, such event is reported by having

the FAULT pin pulled to 5V. Additionally, exceeding the

maximum current rating of an integrated regulator (output

with pass regulator on chip) can lead to output voltage

drooping; if excessive, this droop can ultimately trip the

under-voltage detector and send a FAULT signal to the

computer system.

V

(

3.3V

OUT1

V

(3.3V

OUT3

0V

T1 T2

T0

FIGURE 8. SOFT-START INTERVALIN ACTIVE STATE

(2.5/3.3V

/3.3VSB)

DUAL

)

MEM

TIME

OUTPUT SHOWN IN 2.5V SETTING)

MEM

(2.5V

T3

V

OUT2, 4

MEM

, 2.5V

CLK

)

During sleep to active state transitions from conditions

where the outputs are initially 0V (such as S5 to S0 transition

on the 5V

sequence directly into active state), the 3.3V

5V

DUAL

output with EN5VDL = 0, or simple power-up

DUAL

MEM

and

outputs go through a quasi soft-start by being pulled

high through the body diodes of the N-Channel MOSFETs

connected between these outputs and the 3.3V and 5V ATX

outputs. Figure 8 shows this start-up.

5VSB is already present when the main ATX outputs are

turned on at time T0. As a result of +3.3V

ramping up, the 3.3V

MEM

and 5V

DUAL

and +5V

IN

IN

output capacitors

charge up through the body diodes of Q6 and Q5,

respectively (see Figure 3). At time T1, all main ATX outputs

exceed the HIP6502’s undervoltage thresholds, and the

internal 25ms (typical) timer is initiated. At T2 the time-out

initiates a soft-start, and the 2.5V memory and clock outputs

A FAULT condition occurring on an output when controlled

through an external pass transistor will only set off the

FAULT flag, and it will not shut off or latch off any part of the

circuit. A FAULT condition occurring on an output when

controlled through an internal pass transistor, will set off the

FAULT flag, and it will shut off the faulting regulator only. If

shutdown or latch off of the entire circuit is desired in case of

a fault, regardless of the cause, this can be achieved by

externally pulling or latching the SS pin low. Pulling the SS

pin low will also force the FAULT pin to go low and reset an

internally latched-off output.

Special consideration is given to the initial start-up

sequence. If, following a 5VSB POR event, the

3.3V

/3.3VSB output is ramped up and is subject to an

DUAL

undervoltage event before the remainder of the controlled

voltages have been brought up, then the FAULT output goes

high and the entire IC latches off. Latch-off condition can be

reset by cycling the bias power (5VSB). Undervoltage events

on the 3.3V

/3.3VSB output at any other times are

DUAL

handled according to the description found in the second

paragraph under the current heading.

Another condition that could set off the FAULT flag is chip

over-temperature. If the HIP6502 reaches an internal

temperature of 140

o

C (typical), the FAULT flag is set off, but

the chip continues to operate until the temperature reaches

o

155

C (typical), when unconditional shutdown of all outputs

takes place. Operation resumes at 140

o

C and the

9

Page 10

HIP6502

temperature cycling occurs until the fault-causing condition

is removed.

Output Voltages

The output voltages are internally set and do not require any

external components. Selection of the memory voltages is

done by means of the MSEL pin. Leaving the MSEL pin

floating enables support of both memory outputs. Pulling the

MSEL pin below 0.9V enables support only for the 2.5V

MEM

output. It is important to notice that in a typical application

(such as that presented in Figure 3), setting the MSEL low

will not prevent the 3.3V

state. Pulling the MSEL pin above 2.9V enables 3.3V

from being operational in active

MEM

MEM

output support, only. Following every 3.3VSB ramp-up, chip

reset (see Soft-Start Circuit), or at the exit from an S4/S5

sleep state, the MSEL setting is latched in. During active

state (S0/S1/S2) and S3 sleep state, any changes in MSEL

status are ignored.

Application Guidelines

Soft-Start Interval

The 5VSB output of a typical ATX supply is capable of

725mA. During power-up in a sleep state, it needs to provide

sufficient current to charge up all the output capacitors and

simultaneously provide some amount of current to the output

loads. Drawing excessive amounts of current from the 5VSB

output of the ATX can lead to voltage collapse and induce a

pattern of consecutive restarts with unknown effects on the

system’s behavior or health.

The built-in soft-start circuitry allows tight control of the slewup speed of the output voltages controlled by the HIP6502,

thus enabling power-ups free of supply drop-off events.

Since the outputs are ramped up in a linear fashion, the

current dedicated to charging the output capacitors can be

calculated with the following formula:

I

SS

I

COUT

I

SS

------------------------------

CSSVBG×

Σ C

OUTVOUT

×()×=

- soft-start current (typically 10µA)

CSS - soft-start capacitor

VBG - bandgap voltage (typically 1.26V)

Σ(C

OUT

x V

) - sum of the products between the

OUT

capacitance and the voltage of an output (total charge

delivered to all outputs)

Due to the various system timing events, it is recommended

that the soft-start interval not be set to exceed 30ms.

Shutdown

In case of a FAULT condition that might endanger the

computer system, or at any other time, all the HIP6502

outputs can be shut down by pulling the SS pin below the

specified shutdown level (typically 0.8V) with an open drain

or open collector device capable of sinking a minimum of

2mA. Pulling the SS pin low effectively shuts down all the

, where

pass elements. Upon release of the SS pin, the HIP6502

undergoes a new soft-start cycle and resumes normal

operation in accordance to the ATX supply and control pins

status.

Layout Considerations

The typical application employing a HIP6502 is a fairly

straight forward implementation. Like with any other linear

regulator, attention has to be paid to the few potentially

sensitive small signal components, such as those connected

to sensitive nodes or those supplying critical by-pass

current.

The power components (pass transistors) and the controller

IC should be placed first. The controller should be placed in

a central position on the motherboard, closer to the memory

load if possible, but not excessivelyfar from the clock chip or

the processor. Insure the VSEN1 and VSEN2 connections

are properly sized to carry 250mA without significant

resistive losses; similar guideline applies to the VCLK

output, which can deliver as much as 800mA (typical). As

the current for the VCLK output is provided from the ATX

3.3V, the connection from the 3V3 pin to the 3.3V plane

should be sized to carry the maximum clock output current

while exhibiting negligiblevoltage losses. Similarly,the 5VSB

pin and the 5V pin are carrying significant levels of current for best results, insure these pins are connected to their

respective sources through adequate traces. The pass

transistors should be placed on pads capable of heatsinking

matching the device’s power dissipation. Where applicable,

multiple via connections to a large internal plane can

significantly lower localized device temperature rise.

Placement of the decoupling and bulk capacitors should

follow a placement reflecting their purpose. As such, the

high-frequency decoupling capacitors should be placed as

close as possible to the load they are decoupling; the ones

decoupling the controller close to the controller pins, the

ones decoupling the load close to the load connector or the

load itself (if embedded). Even though bulk capacitance

(aluminum electrolytics or tantalum capacitors) placement is

not as critical as the high-frequency capacitor placement,

having these capacitors close to the load they serve is

preferable.

The only critical small signal component is the soft-start

capacitor,C

control IC and connect to ground through a via placed close

to the capacitor’s ground pad. Minimize any leakage current

paths from SS node, since the internal current source is only

10µA.

. Locate this component close to SS pin of the

SS

10

Page 11

HIP6502

+12V

IN

+5V

SB

C

BULK5

Q1

IN

V

C

V

OUT2

BULK2

OUT5

C

HF5

Q5

+5V

+3.3V

Q4

IN

C

HF2

LOAD

IN

C

LOAD

C

C

HF1

V

OUT1

LOAD

BULK4

HF4

Q3

C

V

LOAD

HF3

OUT3

C

Q2

5VSB

5VDLSB

5VDL

C

5VSB

BULK1

C

12V

12V

C

SS

SS

VSEN1

3V3DLSB

HIP6502

3V3DL

C

BULK3

VCLK

3V3

Q6

KEY

ISLAND ON POWER PLANE LAYER

ISLAND ON CIRCUIT/POWER PLANE LAYER

VIA CONNECTION TO GROUND PLANE

GND

DLA

5V

VSEN2

DRV2

C

FIGURE 9. PRINTED CIRCUIT BOARD ISLANDS

A multi-layer printed circuit board is recommended. Figure 9

shows the connections of most of the components in the

converter. Note that the individual capacitors shown each

could represent numerous physical capacitors. Dedicate one

solid layer for a ground plane and make all critical

component ground connections through vias placed as close

to the component terminal as possible. Dedicate another

solid layer as a power plane and break this plane into

smaller islands of common voltage levels. Ideally, the power

plane should support both the input power and output power

nodes. Use copper filled polygons on the top and bottom

circuit layers to create power islands connecting the filtering

components (output capacitors) and the loads. Use the

remaining printed circuit layers for small signal wiring.

Component Selection Guidelines

LOAD

transient load regulation, paying attention to their parasitic

components (ESR, ESL).

Also, during the transition between active and sleep states,

there is a short interval of time during which none of the

power pass elements are conducting - during this time the

output capacitors have to supply all the output current. The

output voltage drop during this brief period of time can be

easily approximated with the following formula:

V

∆ I

OUT

∆V

- output voltage drop

OUT

ESR

I

OUT

C

- output capacitor bank ESR

OUT

- output current during transition

- output capacitor bank capacitance

OUT

ESR

×=

OUT

OUT

--------------- -+

C

t

t

OUT

, where

tt - active-to-sleep or sleep-to-active transition time (10µs typ.)

The output voltage drop is heavily dependent on the ESR

(equivalent series resistance) of the output capacitor bank,

the choice of capacitors should be such as to maintain the

output voltage above the lowest allowable regulation level.

V

(V

CLK

The output capacitor for the V

) Output Capacitors Selection

OUT4

linear regulator provides

CLK

loop stability. Figure 10 outlines a capacitance vs. equivalent

series resistance envelope. For stable operation and

optimized performance, select a C

OUT4

capacitor or

combination of capacitors with characteristics within the

shown envelope.

10

1

ESR (Ω)

0.1

0.01

10

100

CAPACITANCE (µF)

1000

Output Capacitors Selection

The output capacitors for all outputs should be selected to

allow the output voltage to meet the dynamic regulation

requirements of active state operation (S0, S1). The load

transient for the various microprocessor system’s

components may require high quality capacitors to supply

the high slew rate (di/dt) current demands. Thus, it is

recommended that the output capacitors be selected for

11

FIGURE 10. C

OUTPUT CAPACITOR

OUT4

Input Capacitors Selection

The input capacitors for an HIP6502 application have to

have a sufficiently low ESR as to not allow the input voltage

to dip excessively when energy is transferred to the output

capacitors. If the ATX supply does not meet the

specifications, certain imbalances between the ATX’s

outputs and the HIP6502’s regulation levels could have as a

Page 12

HIP6502

result a brisk transfer of energy from the input capacitors to

the supplied outputs. At the transition between active and

sleep states, this phenomena could result in the 5VSB

voltage dropping below the POR level (typically 4.1V) and

temporarily disabling the HIP6502. The solution to a

potential problem such as this is using larger input

capacitors with a lower total combined ESR.

Transistor Selection/Considerations

The HIP6502 usually requires one P-Channel (or bipolar

PNP), three N-Channel MOSFETs and two bipolar NPN

transistors.

One important criteria for selection of transistors for all the

linear regulators/switching elements is package selection for

efficient removal of heat. The power dissipated in a linear

regulator/switching element is

P

LINEARIOVINVOUT

–()×=

Select a package and heatsink that maintains the junction

temperature below the rating with the maximum expected

ambient temperature.

Q1

The active element on the 2.5V

bipolar NPN capable of conducting the maximum active

memory current and exhibit a current gain (h

40 at this current and 0.7V V

output has to be a

MEM

.

CE

) of minimum

fe

Q2

The NPN transistor used as sleep state pass element (Q2)

on the 3.3V

of 100 at 1.5V V

operating temperature range.

output has to have a minimum current gain

DUAL

and 500mA ICE throughout the in-circuit

CE

Q3, 4, 6

The three N-Channel MOSFETs are used to switch the 3.3V

and 5V inputs provided by the ATXsupply into the 3.3V

3.3V

/3.3VSB, and 5V

DUAL

outputs, while in active (S0,

DUAL

MEM

S1) state. The main criteria for the selection of these

transistors is output voltage budgeting. The maximum

r

allowed at highest junction temperature can be

DS(ON)

expressed with the following equation:

r

DS ON()max

V

- minimum input voltage

INmin

V

OUTmin

I

OUTmax

-------------------------------------------------- -=

- minimum output voltage allowed

- maximum output current

INminVOUTmin

I

OUTmax

, where

V

–

The gate bias availablefor these MOSFETs is of the order of

8V.

Q5

If a P-Channel MOSFET is used to switch the 5VSB output

of the ATX supply into the 5V

states (as dictated by EN5VDL status), then the selection

criteria of this device is proper voltage budgeting. The

maximum r

4.5V of V

GS

, however, has to be achieved with only

DS(ON)

, so a logic level MOSFET needs to be selected.

If a PNP device is chosen to perform this function, it has to

have a low saturation voltage while providing the maximum

sleep current and have a current gain sufficiently high to be

saturated using the minimum drive current (typically 20mA).

output during S3 and S5

DUAL

,

12

Page 13

HIP6502 Application Circuit

Figure 11 shows an application circuit of an ACPIsanctioned power management system fora microprocessor

computer system. The power supply provides the

3.3V

voltage (V

(V

OUT2

5V

+12VDC ATX supply outputs. Q4 can also be a PNP, such as

/3.3VSB voltage (V

DUAL

OUT1

), the 2.5V

voltage (V

DUAL

+5V

+12V

+3.3V

+5V

), the RDRAM 2.5V

OUT3

clock voltage (V

CLK

) from +3.3V, +5VSB, +5V, and

OUT5

IN

IN

IN

SB

C1

1µF

), the SDRAM 3.3V

memory voltage

MEM

OUT4

), and the

C3

1µF

MEM

HIP6502

12V

3V3

an MMBT2907AL. For detailed information on the circuit,

including a Bill-of-Materials and circuit board description,

see Application Note AN9862.

Also see Intersil Corporation’s web page

(http://www.intersil.com) or Intersil’s AnswerFAX

(407-724-7800) for the latest information.

+

C2

220µF

5VSB

C4

1µF

V

OUT1

3.3V

MEM

2SD1802

V

OUT3

3.3V

DUAL

CONFIGURATION

HARDWARE

SLP_S3

SLP_S5

HUF76113SK8

Q2

/3.3V

SB

1µF

Q6

C17

1µF

1/2 HUF76113DK8

C9

+

Q3

+

220µF

C10

C5,16

2X150µF

5V

VSEN1

3V3DLSB

3V3DL

FAULT

EN5VDL

MSEL

S3

S5

SS

U1

HIP6502

DRV2

VSEN2

VCLK

5VDLSB

DLA

5VDL

2X150µF

C11

150µF

C6,7

+

+

+

C14

150µF

Q1

2SD1802

C8

1µF

C12

1µF

Q5

1/2 HUF76113DK8

C15

1µF

V

2.5V

V

2.5V

Q4

FDV304P

V

5V

OUT2

MEM

OUT4

CLK

OUT5

DUAL

SHUTDOWN

(FROM OPEN-DRAIN N-MOS)

13

C13

0.1µF

GND

FIGURE 11. TYPICAL HIP6502 APPLICATION DIAGRAM

Page 14

Small Outline Plastic Packages (SOIC)

HIP6502

N

INDEX

AREA

123

-A-

E

-B-

SEATING PLANE

D

A

-C-

0.25(0.010) BM M

H

L

h x 45

o

α

e

B

0.25(0.010) C AM BS

M

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of

Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm (0.006

inch) per side.

4. Dimension“E” doesnotincludeinterlead flash orprotrusions.Interlead

flash and protrusions shall not exceed 0.25mm (0.010 inch) per side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width “B”, as measured 0.36mm (0.014 inch) or greater

above the seating plane, shall not exceed a maximum value of

0.61mm (0.024 inch)

10. Controllingdimension: MILLIMETER. Converted inch dimensions

are not necessarily exact.

A1

C

0.10(0.004)

M20.3 (JEDEC MS-013-AC ISSUE C)

20 LEAD WIDE BODY SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.0926 0.1043 2.35 2.65 -

A1 0.0040 0.0118 0.10 0.30 -

B 0.013 0.0200 0.33 0.51 9

C 0.0091 0.0125 0.23 0.32 D 0.4961 0.5118 12.60 13.00 3

E 0.2914 0.2992 7.40 7.60 4

e 0.050 BSC 1.27 BSC H 0.394 0.419 10.00 10.65 h 0.010 0.029 0.25 0.75 5

L 0.016 0.050 0.40 1.27 6

N20 207

o

α

0

o

8

o

0

o

8

Rev. 0 12/93

NOTESMIN MAX MIN MAX

-

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil semiconductor products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (321) 724-7000

FAX: (321) 724-7240

14

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Intersil (Taiwan) Ltd.

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

Loading...

Loading...