Page 1

TM

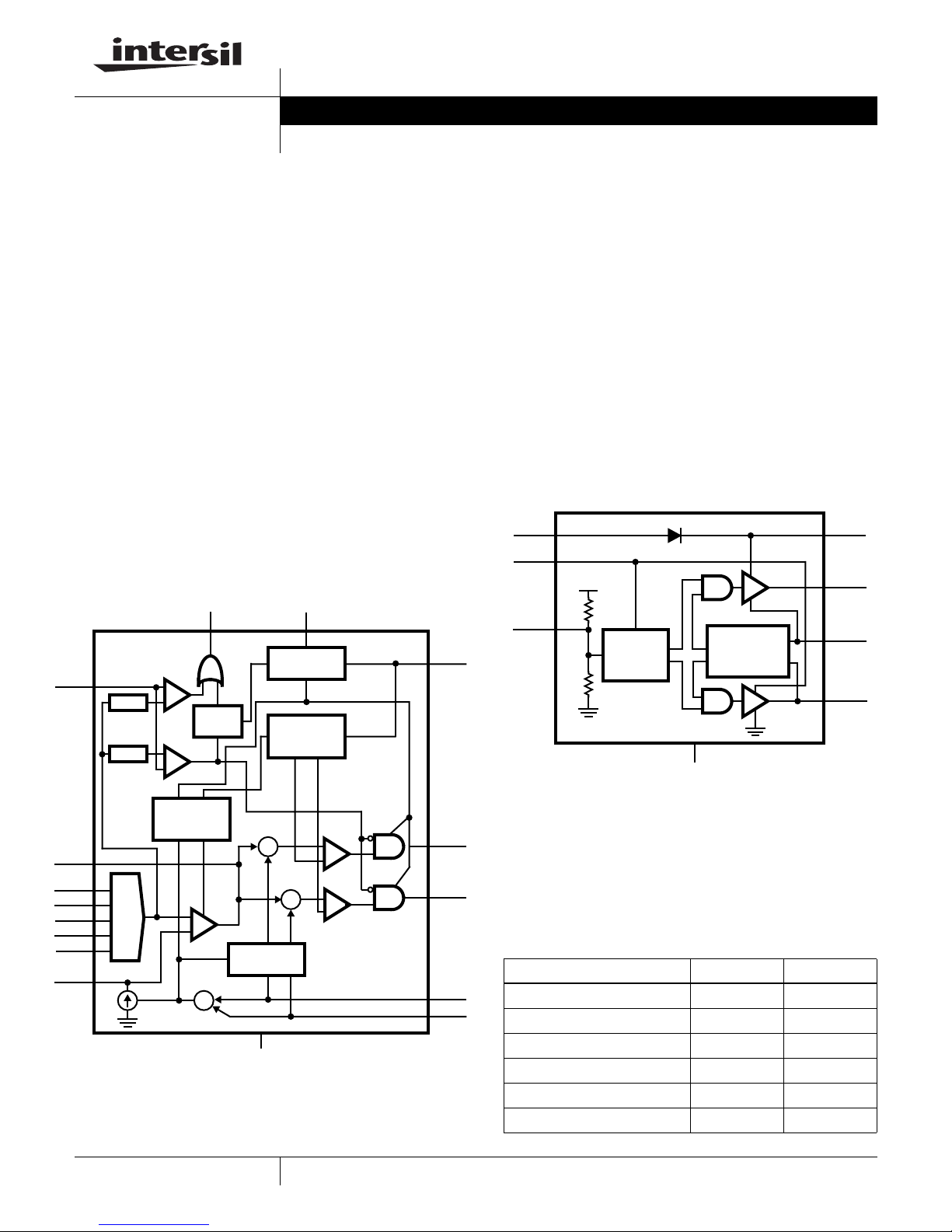

FIGURE 2. HIP6601A BLOCK DIAGRAM

PVCC 7 2 BOOT

VCC 6

CONTROL

LOGIC

SHOOT

THROUGH

PROTECTION

+5V

PWM 3

10k

UGATE

PHASE

LGATE

1

8

5

4

GND

10k

HIP6302EVAL1 - Multiphase Power Conversion

for AMD Athlon Processors up to 35A

Application Note February 2002

Introduction

Each generation of computer microprocessor brings

performance advances in computing power. Performance

improvements are made possible by advances in fabrication

technology that enable greater device density. Newer

processors are operating at lower voltages and higher clock

speeds both of which contribute to greater demands on the

microprocessor core voltage supply in terms of higher peak

currents and higher current-slew rates.

Intersil’s family of multi-phase DC-DC converter solutions

provide the ideal solution to supply the core-voltage needs of

present and future high-performance microprocessors.

Intersil HIP6302 and HIP6601

The HIP6302 controller IC works with two HIP6601A or

HIP6603A single-channel driver ICs or a single HIP6602A

dual-channel driver IC [3] to form a highly integrated solution

for high-current, high slew-rate applications. The HIP6302

regulates output voltage, balances load currents and

provides protective functions for two synchronous-rectified

buck-converter channels.

AN9888.1

Author: Matt Harris

provides feedback for droop compensation and over-current

protection. A five-bit DAC provides a digital interface to

program the 1% accurate reference and a window

comparator toggles PGOOD if the output voltage is out of

range and acts to protect the load in case of over voltage.

For more detailed descriptions of the HIP6302 functionality,

refer to the HIP6302 Data Sheet [1].

The HIP6601A is a driver IC capable of delivering up to 2A of

gate-charging current for rapidly switching both MOSFETs in

a synchronous-rectified bridge. The HIP6601A accepts a

single logic input to control both upper and lower MOSFETs.

Adaptive shoot-through protection is provided on both

switching edges to provide optimal dead time, and bootstrap

circuitry permits greater enhancement of the upper

MOSFET. For a more detailed description of the HIP6601A,

refer to the HIP6601A Data Sheet [2].

PGOOD VCC

15

VSEN

10

x 0.9

x 1.15

COMP

6

1VID4

2VID3

3VID2

DAC

4VID1

5VID0

7FB

The integrated high-bandwidth error amplifier provides

voltage regulation, while current-sense circuitry maintains

UV

+

OV

LATCH

S

OVP

+

-

SOFT START

AND FAULT

LOGIC

+

-

∑

FIGURE 1. HIP6302 BLOCK DIAGRAM

+

-

E/A

CURRENT

DETECTION

+

+

9

phase-current balance between the two power channels and

16

POWER-ON

RESET (POR)

THREE STATE

CLOCK AND

SAWTOOTH

GENERATOR

∑

+

∑

-

GND

PWM

+

-

PWM

+

-

8

FS/DIS

13

PWM1

12

PWM2

1411ISEN1

ISEN2

The HIP6302EVAL1 Board and Reference

Design

With the VID jumpers set to 1.7V (00110), the evaluation

board meets the output voltage and current specifications

indicated in Table 1.

TABLE 1. HIP6302EVAL1 OUTPUT PARAMETERS

MIN MAX

Static Regulation 1.65V 1.75V

Transient Regulation 1.60V 1.85V

Over-Voltage Protection 1.90V 2.00V

Continuous Load Current - 35A

Over-Current Trip Level 41A 57A

Load-Current Transient - 35A/µs

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

|

Intersil (and design) is a trademark of Intersil Americas Inc.

Copyright © Intersil Americas Inc. 2002. All Rights Reserved

Page 2

PGOOD, 5V/DIV

1ms/DIV

0A

0V

0V

0V

ICC5, 10A/DIV

VCORE, 1V/DIV

FS/EN, 5V/DIV

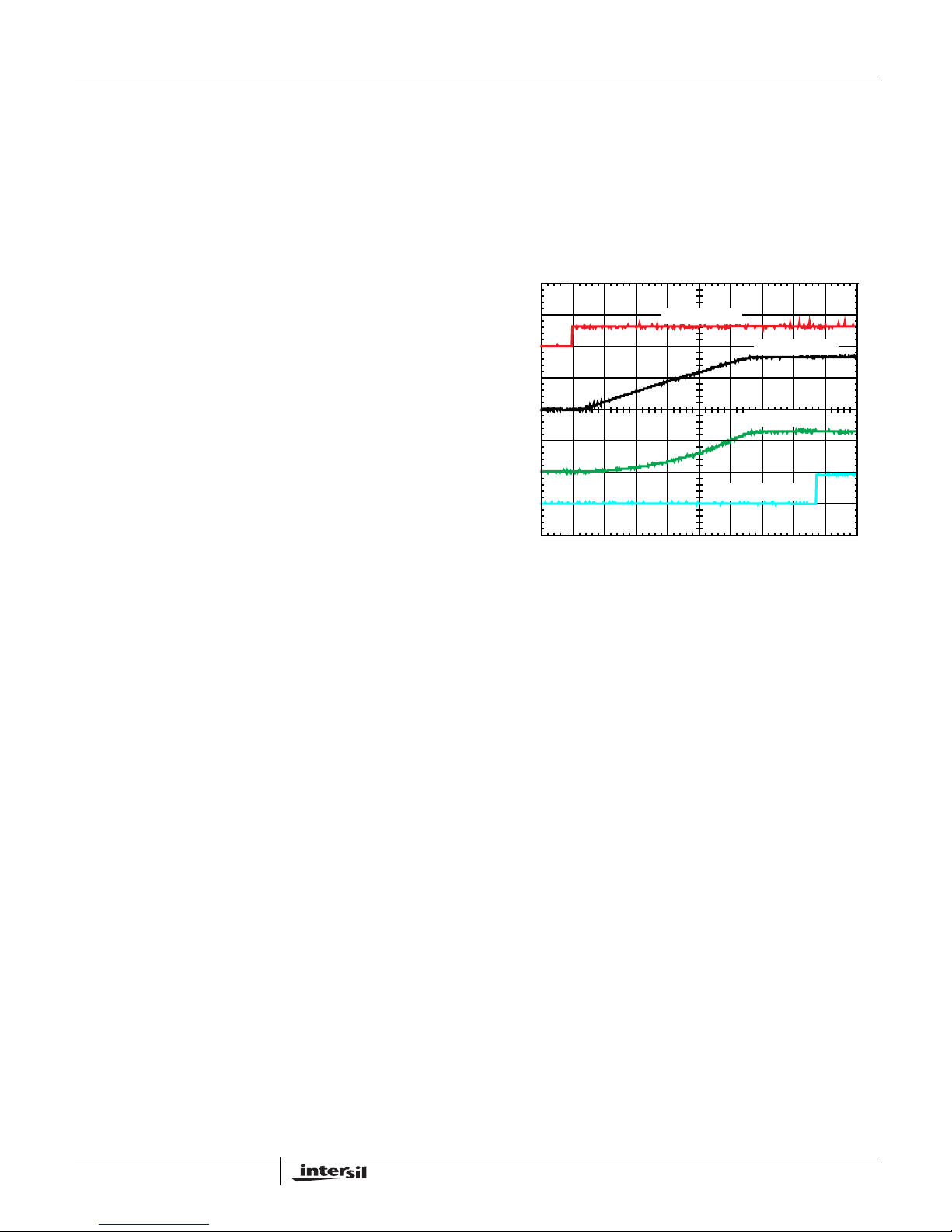

FIGURE 3. HIP6302EVAL1 START-UP WAVEFORMS

Application Note AN9888

The HIP6302EVAL1 evaluation board incorporates a

reference design intended to meet the core-voltage

requirements for AMD Athlon

microprocessors up to 35A.

Additional circuitry is provided to facilitate circuit evaluation

including input and output power connectors, VID jumpers,

numerous probe points, an LED power-good indicator, and a

load-transient generator.

Powering the HIP6302EVAL1

For convenience, the HIP6302EVAL1 provides two methods

of making input power connections. The 20-pin header, J1,

interfaces with a standard ATX power supply and may be the

most convenient method of powering the board.

J2, J3, and J4 are standard banana-jack connectors that can

be used to supply power using bench-top power supplies.

These inputs provide greater versatility in testing and design

validation by allowing the 12V and 5V power-input voltage

levels to be varied independently. In this way power-on level

and power-sequencing issues can be easily examined.

To start the evaluation board, insert the 20-pin connector

from an ATX supply into J1. If using bench-top supplies,

connect a 12V supply to J2 and a 5V supply to J3. Connect

the grounds from both supplies to J4.

Start Up

The waveforms in Figure 3 demonstrate the normal start-up

sequence with the HIP6302EVAL1 connected to a 55m

load. After FS/EN is released, VCORE exhibits a linear ramp

until reaching its 1.7V set point. The gradual increase of

VCORE over approximately 5ms limits the current required

from the input supply, ICC5, to a level that does not strain the

supply. The HIP6302 asserts PGOOD once VCORE is within

regulation limits.

Ω

Important

There are two things to consider when using bench-top

supplies. If the 5V supply is applied prior to the 12V supply,

the HIP6302 will begin operating before the HIP6601As. This

allows the HIP6302 to complete its soft-start cycle before the

drivers are capable of switching power to the output. When

the 12V power input is then applied, there is a large transient

as the controller tries to instantly bring the output to its fullvoltage level. This can result in an overcurrent protection

cycle and an abnormal start-up waveform. It can be avoided

by applying 5V supply after or at the same time as the 12V

supply or by using an ATX power supply.

The second problem can occur when operating the transient

load generator. Not all bench-top and ATX power supplies

are capable of responding to load transients, and they may

allow a momentary voltage dip on VCC5. This can activate

the power-on-reset function in the HIP6302 and cause the

output power to cycle. It can be remedied by connecting a

5600

µ F or larger capacitor between VCC5 and ground. The

capacitor, if necessary, simulates the distributed capacitance

that exists on the computer motherboard.

Transient Response

The HIP6302EVAL1 is equipped with a load-transient

generator that applies a 0–36A transient load current with

rise and fall rates of approximately 35A/

the transient is between 100

µ

s and 200 µ

rate is kept low in order to limit power dissipation in the load

MOSFETs and resistors. Removal of the HI/LO jumper (JP2)

causes the current to decrease from about 36A to about

31A. The load-transient generator operates when the

HIP6302EVAL1 is properly connected to a 12V power

source and SW1 is in the ON position. Operation ceases

when SW1 is moved into the OFF position or 12V is

removed from the board.

The HIP6302EVAL1 achieves the specified transient

performance while maintaining a favorable balance between

low cost, high efficiency and small profile. When the duty

cycle changes rapidly in response to a transient load current,

the inductor current immediately begins to change in order to

meet the demand. During the time the inductor current is

increasing, the output-filter capacitors are supplying the

load. It follows that the amount of required capacitance

decreases as the capability of the inductors to rapidly

assume the load current increases.

µ

s. The duration of

s, and the repetition

2

Athlon™ is a trademark of Advanced Micro Devices, Inc.

Page 3

3

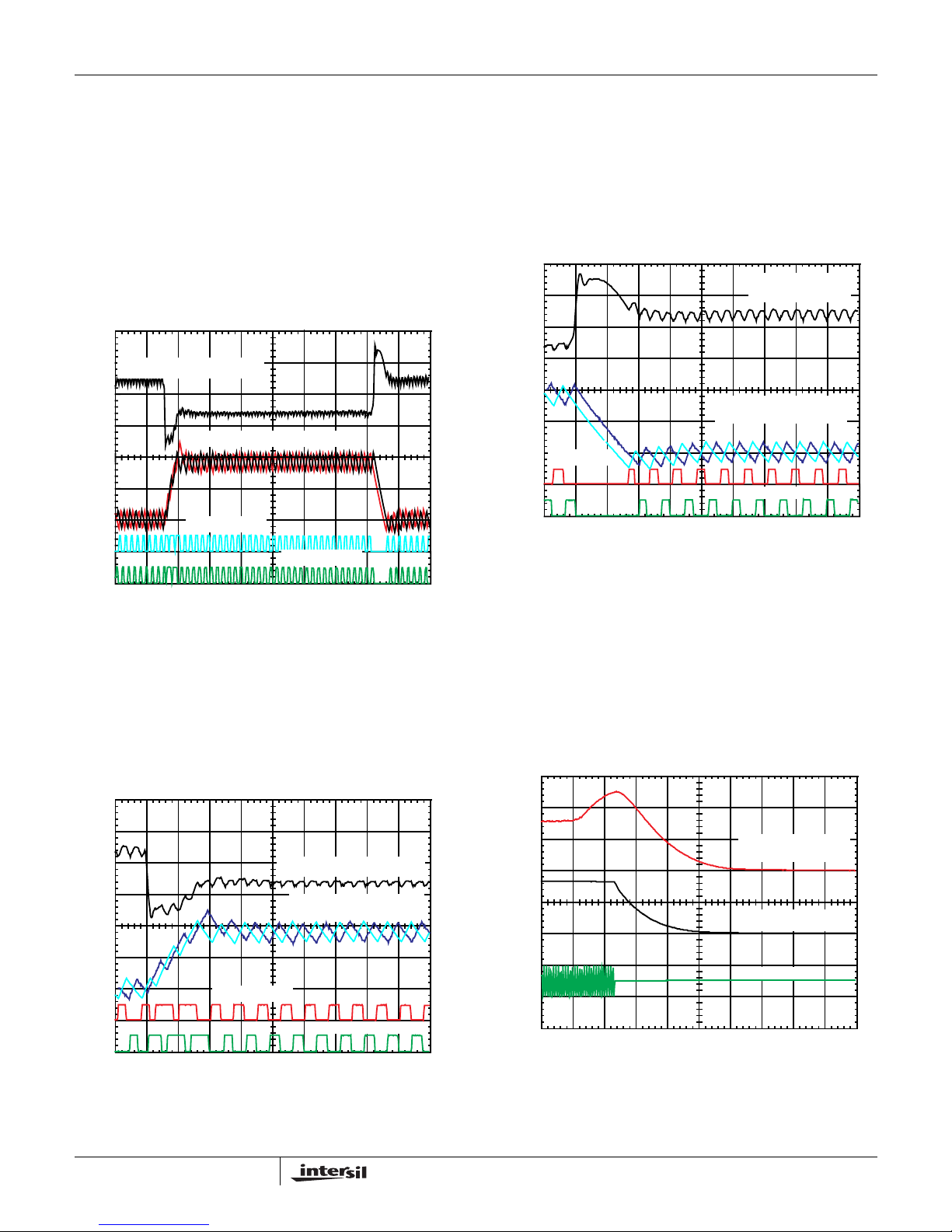

5µs/DIV

0V

0A

1.7V

0V

PWM2, 10V/DIV

CORE VOLTAGE,

FIGURE 6. TRANSIENT-RESPONSE TRAILING EDGE

PWM1, 10V/DIV

INDUCTOR CURRENTS,

10A/DIV

50mV/DIV

FIGURE 7. OVERCURRENT BEHAVIOR

50µs/DIV

0A

0V

0V

CORE VOLTAGE,

OUTPUT CURRENT,

PWM1, 5V/DIV

20A/DIV

500mV/DIV

Application Note AN9888

Figure 4 shows the core voltage, inductor current, and PWM

signals changing in response to the transient load current.

The upper waveform shows the core voltage deviating from

its no-load setting of 1.72V to a minimum of about 1.62V

upon the application of current. The voltage then settles to its

1.67V full-load setting. On load removal, the core voltage

peaks at a level of 1.78V before settling again to its 1.72V

no-load setting. Although the specified operating range

allows deviations as low as 1.60V and as high as 1.85V, a

minimum of 20mV is reserved to allow for the reference

tolerance and the tolerances of other components that

contribute to the overall system accuracy.

CORE VOLTAGE, 50mV/DIV

1.7V

INDUCTOR CURRENTS, 10A/DIV

0A

0V

0V

FIGURE 4. HIP6302EVAL1 TRANSIENT RESPONSE

PWM1, 10V/DIV

PWM2, 10V/DIV

20µs/DIV

Figure 5 is a close-up showing the core-voltage, inductorcurrent and PWM signals responding at the leading edge of

the transient load

current. The PWM signals increase to their

maximum duty cycle of 75% on the first pulse following the

start of the transient. The inductor currents begin to increase

immediately and are carrying all of the load within 10

µ s. The

very fast transient response is due to the precision 18MHz

error amplifier and optimal compensation of the control loop.

The close up in Figure 6 shows the core-voltage, inductorcurrent and PWM signals changing in response to the

trailing edge of the transient load current. Again, the duty

cycles immediately decrease to zero, and the inductors

begin shedding load current at the maximum rate. Note that

the inductor currents briefly go negative as the transient

settles. The capacitors are slightly over charged at the end of

the transient, and the discharge path is in the reverse

direction through the inductors.

Overcurrent Protection

µ

When the current out of either ISEN pin exceeds 82

HIP6302 detects an overcurrent condition and responds by

placing the PWM outputs into a high-impedance state. This

signals the HIP6601 to turn off both upper and lower

MOSFETs in order to remedy the overcurrent condition.This

behavior is seen in Figure 7 where PWM1 goes immediately to

2.5VDC when the output current reaches approximately 50A.

The output voltage then quickly falls to zero.

A, the

1.7V

CORE VOLTAGE, 50mV/DIV

INDUCTOR CURRENTS,

10A/DIV

0A

0V

0V

FIGURE 5. TRANSIENT-RESPONSE LEADING EDGE

PWM1, 10V/DIV

5µs/DIV

PWM2, 10V/DIV

Page 4

4

Application Note AN9888

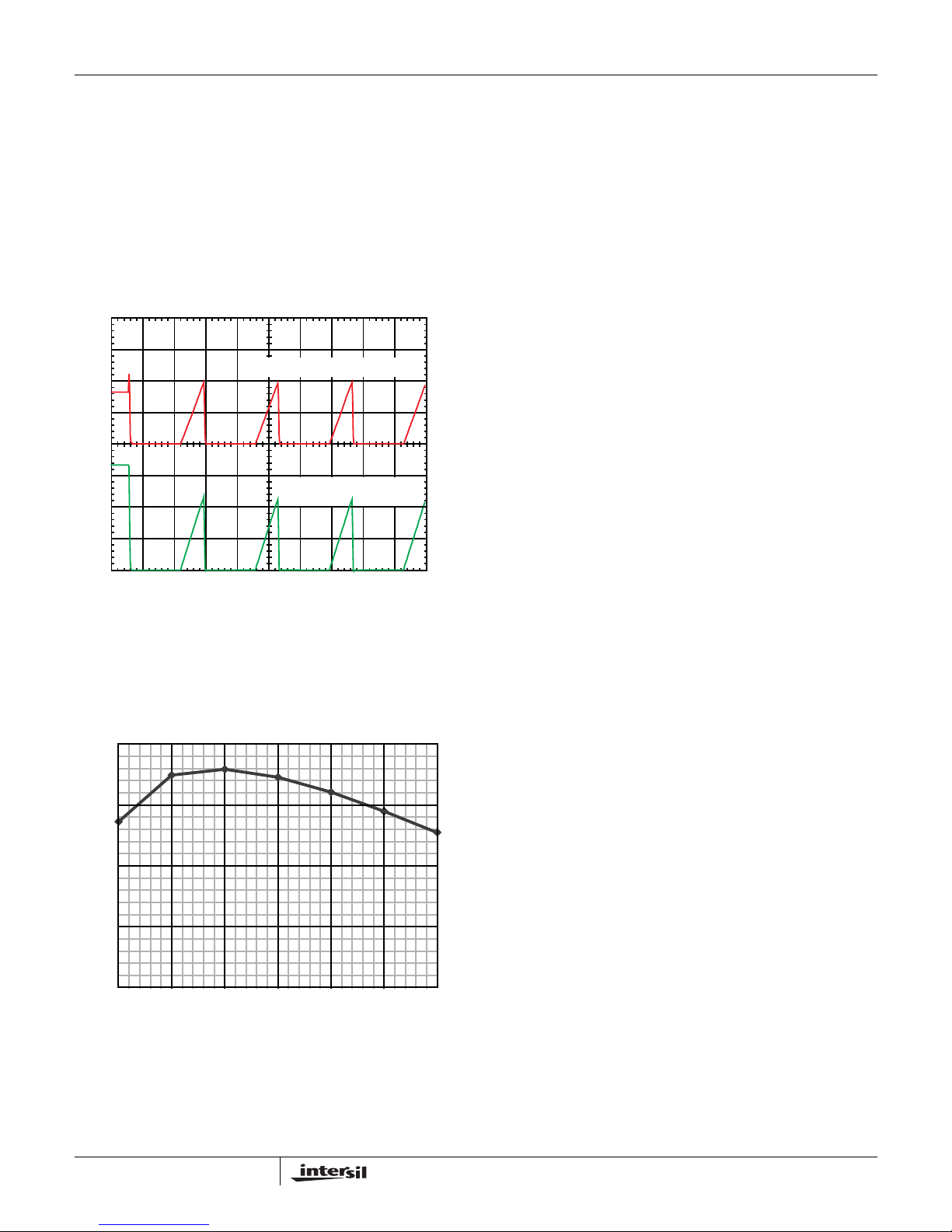

After the initial over-current trip, the HIP6302 waits for a

period of time equal to 2048/f

SW

(f

is the switching

SW

frequency) before initiating a soft-start cycle. If the over-load

condition remains, another over-current trip will occur before

the end of the soft-start sequence. This repetitive overcurrent cycling is illustrated in Figure 8, and will continue

indefinitely unless the fault is cleared or power to the

converter is removed. Because of the wait period, the worst

case power delivered during overcurrent cycling is equal to

45% of the power delivered during normal operation at full

load. Therefore, indefinite over-current cycling does not

create a thermal problem for the circuit.

OUTPUT CURRENT, 20A/DIV

0A

CORE VOLTAGE,

500mV/DIV

0V

FIGURE 8. OVERCURRENT BEHAVIOR

5ms/DIV

Efficiency

Figure 9 shows the efficiency versus current plot for the

HIP6302EVAL1 for 5A through 35A. The measurements

were made at room temperature with natural convection

cooling only..

90

Summary

The HIP6302EVAL1 is intended to provide a convenient

platform to evaluate the performance of the HIP6302 HIP6601A chip set in the specific implementation indicated

in Table 1. The design demonstrates a favorable trade off

between low cost, high efficiency, and small footprint. The

following pages include schematic, bill of materials, and

layout drawings to facilitate implementation of this solution.

The evaluation board is simple and convenient to operate,

and test points are available to evaluate the most commonly

tested parameters. Example waveforms are given for

reference.

The HIP6302 and HIP6601A provide a versatile 2-phase

power solution for low-voltage applications from 25A to

approximately 40A, and together they result in the most

effective solution available.

References

For Intersil documents available on the internet, see web site

http://www.intersil.com/

Intersil Technical Support 1 (888) INTERSIL

[1] HIP6302 Data Sheet, Intersil Corporation, Power

Management Products Division, 2000.

(http://www.intersil.com/).

[2]

HIP6601A, HIP6603A Data Sheet,

Power Management Products Division, 2000.

[3]

HIP6602A Data Sheet,

Intersil Corporation, Power

Management Products Division, 2000.

Intersil Corporation,

85

80

EFFICIENCY (%)

75

70

5101520253035

CURRENT (AMPERES)

FIGURE 9. EFFICIENCY vs CURRENT

Page 5

Schematic

Application Note AN9888

5VIN

12VIN

C7

0.1µF

JP1

R3

107kΩ

16

VCC

9

GND

1

VID4

2

VID3

3

VID2

4

VID1

5

VID0

HIP6302

15

PGOOD

FS/DIS

COMP

6710

TP7

FB

R4

14.0kΩR51.00kΩ

C11

2.2nF

R6

45.3kΩ

PWM1

ISEN1

PWM2

ISEN2

VSEN

1µF

13 3

TP3

14

C12

1µF

12

TP4

11

C6

6

VCC

HIP6601

R1

2.15kΩ

672

VCC

3

PWM

HIP6601

R2

2.15kΩ

72

BOOT

UGATE

PVCC

PHASEPWM

LGATE

GND

4U1

BOOT

UGATE

PVCC

PHASE

LGATE

GND

4U3

L1

1µF

C4

C3

0.1µF

1

8

5

TP2

C8

0.1µF

1

8

5

Q1

HUF76139

Q2

HUF76139

TP1

Q3

HUF76139

Q4

HUF76139

TP6

TP5

C13-C17

1µF

L2

450nH

C9

1µF

L3

450nH

22µF

C5

100µFC11000µF

C10

100µFC21000µF

C18-C21

560µF

R8

10kΩR71kΩR91kΩ

RED GREEN

CR1

Q5

2N7002

POWER GOOD INDICATOR

D1

BAV99

R15

0.200Ω

HUF76129

Q6

HUF76129

Q7

R14, R16

0.100Ω

R10

1.50kΩ

R11

619Ω

C48

1µF

TP11

R17

46.4kΩ

TRANSIENT GENERATOR

12 6

4

HS

7

VSS

Q8

2N7002

D2

BAV99

HB

VDD

U4

HIP2100

R18

400Ω

HO

LO

HI

JP2

LI

3

8

SW1

ON

C49

10µF

R12

1.50kΩ

R13

619Ω

OFF

5

Page 6

Application Note AN9888

Bill of Materials

QTY REFERENCE DESCRIPTION PACKAGE VENDOR PART NO.

1 CR1 RED/GREEN LED SMT Lumex SSL-LXA3025IGC

2 C1, C2 1000

3 C3, C7, C8 0.1

5 C4, C6, C9, C12, C48 1.0

2 C5, C10 100

1 C11 2.2nF, 50V, X7R, Ceramic Capacitor 0603 Various

5 C13-C17, C49 10

4 C19, C20, C22, C23 560

2 C18, C21 Spare Radial

24 C24-C47 Spare 1206

2 D1, D2 Dual Diode SOT23 Various BAV99

1 JP1 5-Position Jumper Header 100mil Centers Berg 68000-236

5 Jumpers Berg 71363-102

1 JP2 1-Position Header 100mil Centers Berg 68000-236

1 Jumper Berg 71363-102

1J1 ATX Power Header Berg 39-29-9203

2 J2, J3 Female Banana Connector, Red Johnson

1J4 Female Banana Connector, Black Johnson

2 J5, J6 Terminal Connector Burndy KPA8CTP

1L1 1uH, T30-26, 6T AWG18 400x300mil Falco TTIG0803-127

2 L2, L3 450nH, T60-8/90, 5T AWG14 700x500mil Falco TTIB1506-478

4 Q1, Q2, Q3, Q4 Power MOSFETs TO-263AB Intersil HUF76139S3S

2 Q5, Q8 General Purpose MOSFET SOT23 Various 2N7002

2 Q6, Q7 Power MOSFET TO-252AA Intersil HUF76129D3S

2 R1, R2 Resistor, 2.15k

1R3 Resistor, 107k

1R4 Resistor, 14.0k

1R5 Resistor, 1.00k

1R6 Resistor, 45.3k

2 R7, R9 Resistor, 1.0k

1R8 Resistor, 10k

2 R10, R12 Resistor, 1.50k

2 R11, R13 Resistor, 619

2 R14, R16 Resistor, 0.100

1 R15 Resistor, 0.200

1 R17 Resistor, 46.4k

1 R18 Resistor, 400

1 SW1 Switch, SPDT SMT C&K Components GT11MSCKE

6 TP1, TP3, TP4, TP5, TP7, TP8 Small Test Point Jolo SPCJ-123-01

3 TP2, TP6, TP10 Large Test Point Keystone 1514-2

2 TP9, TP11 Probe Socket Tektronics 1314353-00

2 U1, U3 Synchronous Buck Driver IC 8-Lead SOIC Intersil HIP6601ACB

1U2 Multiphase Buck Controller IC 16-Lead SOIC Intersil HIP6302CB

1U4 MOSFET Driver IC 8-Lead SOIC Intersil HIP2100IB

µ F, 10V, Aluminum Capacitor Radial Panasonic EEUFC1A102L

µ

F, 25V, Y5V, Ceramic Capacitor 0603 Various

µ F, 25V, Y5V, Ceramic Capacitor 0805 Various

µ

F, 16V, OS-CON Capacitor Radial Sanyo 16SPS100M

µ

F, 10V, X7R, Ceramic Capacitor 1206 Various

µ F, 4V, OS-CON Capacitor Radial Sanyo 4SP560M

111-0702-001

Components

111-0703-001

Components

Ω

, 1%, 1/10W 0603 Various

Ω , 1%, 1/10W 0603 Various

Ω

, 1%, 1/10W 0603 Various

Ω , 1%,1/10W 0603 Various

Ω

, 1%, 1/10W 0603 Various

Ω , 5%, 1/8W 0805 Various

Ω , 5%, 1/10W 0603 Various

Ω , 1%, 1/8W 0805 Various

Ω , 1%, 1/8W 0805 Various

Ω , 1%, 1W 2512 Vishay WSL2512R100FB43

Ω

, 1%, 1W 2512 Vishay WSL2512R200FB43

Ω , 1%,1/8W 0805 Various

Ω , 1%, 1/8W 0805 Various

6

Page 7

Layout Drawing - Components

Application Note AN9888

7

Page 8

Layout Drawing - Top Copper

Application Note AN9888

8

Page 9

Layout Drawing - Ground Plane

Application Note AN9888

9

Page 10

Layout Drawing - Power Plane

Application Note AN9888

10

Page 11

Layout Drawing - Bottom Copper

Application Note AN9888

11

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

Page 12

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Intersil:

HIP6302EVAL1

Loading...

Loading...