HIP6021A

Data Sheet November 1999

Advanced PWM and Triple Linear Power

Controller

The HIP6021A provides the power control and protection for

four output voltages in high-performance, graphics intensive

microprocessor and computer applications. The IC

integrates a voltage-mode PWM controller and three linear

controllers, as well as the monitoring and protection

functions into a 28 lead SOIC package.

The synchronous-rectified buck converter includes an Intelcompatible, TTL 5-input digital-to-analog converter (DAC)

that adjusts the core PWM output voltage from 1.3V

2.05V

in 0.05V steps and from 2.1VDCto 3.5VDCin 0.1V

DC

DC

to

increments. The precision reference and voltage-mode

control provide ±1% static regulation. A TTL-compatible

signal applied to the SELECT pin dictates which method of

control is used for the AGP bus power: a low state results in

linear control of the AGP bus to 1.5V, while a high state

transitions theoutputthrough a linearly controlled softstart to

3.3V, followed by full enhancement of the external MOSFET

to pass the input voltage. The other two linear regulators

provide fixed output voltages of 1.5V GTL bus power and

1.8V power for the North/South Bridge core and/or cache

memory. These levels are user-adjustable by means of an

external resistor divider and pulling the FIX pin low. All linear

controllers can employ either N-Channel MOSFETs or

bipolar NPNs for the pass transistor.

The HIP6021A monitors all the output voltages. A single

Power Good signal is issued when the core is within ±10% of

the DAC setting and all other outputs are above their undervoltage levels. Additional built-in over-voltage protection for

the core output uses the lower MOSFET to prevent output

voltages above 115% of the DAC setting. The PWM

controller’s over-current function monitors the output current

by using the voltage drop across the upper MOSFET’s

r

DS(ON)

.

Ordering Information

TEMP.

PART NUMBER

HIP6021ACB 0 to 70 28 Ld SOIC M28.3

HIP6021EVAL1 Evaluation Board

RANGE (oC) PACKAGE

PKG.

NO.

File Number 4793

Features

• Provides 4 Regulated Voltages

- Microprocessor Core, AGP Bus, Memory, and GTL Bus

Power

• Drives N-Channel MOSFETs

• Linear Regulator Drives Compatible with both MOSFET

and Bipolar Series Pass Transistors

• Fixed or Externally Resistor-Adjustable Linear Outputs

• Simple Single-Loop Control Design

- Voltage-Mode PWM Control

• Fast PWM Converter Transient Response

- High-Bandwidth Error Amplifier

- Full 0% to 100% Duty Ratio

• Excellent Output Voltage Regulation

- Core PWM Output: ±1% Over Temperature

- Other Outputs: ±3% Over Temperature

• TTL-Compatible 5-Bit DAC Core Output Voltage Selection

- Shutdown Feature Removed When All Inputs High

- Wide Range 1.3VDC to 3.5V

DC

• Power-Good Output Voltage Monitor

• Over-Voltage and Over-Current Fault Monitors

- Switching Regulator Does Not Require Extra Current

Sensing Element, Uses Upper MOSFET’s r

DS(ON)

• Small Converter Size

- Constant Frequency Operation

- 200kHz Free-Running Oscillator; Programmable From

50kHz to Over 1MHz

- Small External Component Count

Applications

•

Motherboard Power Regulation for Computers

Pinout

DRIVE2

PGOOD

VSEN2

SELECT

FAULT/RT

VSEN4

HIP6021A (SOIC)

1

2

FIX

3

VID4

4

VID3

5

VID2

6

VID1

7

VID0

8

9

SD

10

11

SS

12

13

14

TOP VIEW

28

27

26

25

24

23

22

21

20

19

18

17

16

15

VCC

UGATE

PHASE

LGATE

PGND

OCSET

VSEN1

FB

COMP

VSEN3

DRIVE3

GND

VAUX

DRIVE4

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 407-727-9207

| Copyright © Intersil Corporation 1999

Block Diagram

OCSET

200µA

+

-

+

PWM

COMP1

TTL D/A

CONVERTER

(DAC)

PWM1

x 1.10

x 0.90

x 1.15

ERROR

AMP1

DACOUT

VSEN1

+

-

+

-

+

-

OC1

+

-

VSEN3

VAUX

2

DRIVE3

DRIVE4

VSEN4

DRIVE2

VSEN2

SELECT

-

+

+

-

+

-

+

-

x 0.75

+

1.5V

OR

-

3.3V

IN

x 0.75

+

1.26V

-

+

+

-

OSCILLATOR

FIX

LUV

LINEAR

UNDER-

VOLTAGE

INHIBIT

FAULT

SD

SOFT-

START

AND FAULT

LOGIC

28µA

OV

VCC

4.5V

VCC

POWER-ON

RESET (POR)

DRIVE1

GATE

CONTROL

SYNCH

DRIVE

VAUX

PGOOD

HIP6021A

VCC

UGATE

PHASE

VCC

LGATE

PGND

GND

FAULT / RT

SS

FB

COMP

VID0

VID1

VID2

VID4

VID3

Simplified Power System Diagram

+5V

IN

+3.3V

IN

Q3

V

OUT2

HIP6021A

LINEAR

CONTROLLER

HIP6021A

PWM

CONTROLLER

Q1

Q2

V

OUT1

V

Typical Application

+12V

IN

+5V

IN

+3.3V

IN

V

OUT2

1.5V OR 3.3V

TYPEDET

V

OUT3

1.5V

IN

L

IN

OUT3

Q4

C

IN

Q4

C

Q3

OUT2

DRIVE2

VSEN2

SELECT

VAUX

DRIVE3

VSEN3

LINEAR

CONTROLLER

HIP6021A

VCC

LINEAR

CONTROLLER

OCSET

PGOOD

UGATE

PHASE

LGATE

PGND

VSEN1

FB

COMP

Q2

Q1

Q5

L

OUT1

C

OUT1

V

OUT4

POWERGOOD

1.3V TO 3.5V

V

OUT1

V

OUT4

1.8V

C

C

OUT3

OUT4

Q5

FIX

DRIVE4

VSEN4

SS

C

SS

GND

FAULT / RT

VID0

VID1

VID2

VID3

VID4

3

HIP6021A

Absolute Maximum Ratings Thermal Information

Supply Voltage, VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +15V

PGOOD, RT/FAULT, DRIVE, PHASE,

and GATE Voltage . . . . . . . . . . . . . . . GND - 0.3V to VCC + 0.3V

Input, Output or I/O Voltage. . . . . . . . . . . . . . . . . . GND -0.3V to 7V

ESD Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Class 1

Operating Conditions

Supply Voltage, VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . +12V ±10%

Ambient Temperature Range. . . . . . . . . . . . . . . . . . . . 0oC to 70oC

Junction Temperature Range. . . . . . . . . . . . . . . . . . . 0oC to 125oC

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

1. θJA is measured with the component mounted on an evaluation PC board in free air.

Electrical Specifications Recommended Operating Conditions, Unless Otherwise Noted. Refer to Block and Simplified Power System

Diagrams, and Typical Application Schematic

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

VCC SUPPLY CURRENT

Nominal Supply Current I

CC

POWER-ON RESET

Rising VCC Threshold V

Falling VCC Threshold V

Rising VAUX Threshold V

VAUX Threshold Hysteresis V

Rising V

Threshold - 1.26 - V

OCSET

OSCILLATOR

Free Running Frequency F

OSC

Total Variation 6kΩ < RT to GND < 200kΩ -15 - +15 %

Ramp Amplitude ∆V

OSC

DAC AND BANDGAP REFERENCE

DAC(VID0-VID4) Input Low Voltage - - 0.8 V

DAC(VID0-VID4) Input High Voltage 2.0 - - V

DACOUT Voltage Accuracy -1.0 - +1.0 %

Bandgap Reference Voltage V

BG

Bandgap Reference Tolerance -2.5 - +2.5 %

LINEAR REGULATORS (OUT2, OUT3, AND OUT4)

Regulation (All Linears) Except OUT2 when SELECT > 2.0V - 3 - %

VSEN2 Regulation Voltage VREG2SELECT < 0.8V - 1.5 - V

VSEN3 Regulation Voltage VREG

VSEN4 Regulation Voltage VREG

Under-Voltage Level (VSEN/VREG) VSEN

Under-Voltage Hysteresis (VSEN/VREG) VSEN Falling - 7 - %

Output Drive Current (All Linears) VAUX-V

UGATE, LGATE, DRIVE2, DRIVE3, and

DRIVE4 Open

OCSET

OCSET

OCSET

OCSET

RT = OPEN 185 200 215 kHz

RT = Open - 1.9 - V

3

4

VSEN Rising - 75 - %

UV

Thermal Resistance (Typical, Note 1) θJA (oC/W)

SOIC Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Maximum Junction Temperature (Plastic Package) . . . . . . . 150oC

Maximum Storage Temperature Range. . . . . . . . . . -65oC to 150oC

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . 300oC

(SOIC - Lead Tips Only)

-9- mA

= 4.5V - - 10.4 V

= 4.5V 8.2 - - V

= 4.5V - 2.5 - V

= 4.5V - 0.5 - V

- 1.265 - V

- 1.5 - V

- 1.8 - V

> 0.6V 20 40 - mA

DRIVE

P-P

4

HIP6021A

Electrical Specifications Recommended Operating Conditions, Unless Otherwise Noted. Refer to Block and Simplified Power System

Diagrams, and Typical Application Schematic (Continued)

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

SYNCHRONOUS PWM CONTROLLER ERROR AMPLIFIER

DC Gain -88- dB

Gain-Bandwidth Product GBWP - 15 - MHz

Slew Rate SR COMP = 10pF - 6 - V/µs

PWM CONTROLLER GATE DRIVER

UGATE Source I

UGATE Sink R

LGATE Source I

LGATE Sink R

UGATE

UGATEVGATE-PHASE

LGATE

LGATE

PROTECTION

VSEN1 Over-Voltage (VSEN1/DACOUT) VSEN1 Rising - 115 120 %

FAULT Sourcing Current I

OCSET1 Current Source I

Soft-Start Current I

OVP

OCSET

SS

POWER GOOD

VSEN1 Upper Threshold

(VSEN1/DACOUT)

VSEN1 Under-Voltage

(VSEN1/DACOUT)

VSEN1 Hysteresis (VSEN1/DACOUT) Upper/Lower Threshold - 2 - %

PGOOD Voltage Low V

PGOODIPGOOD

VCC = 12V, V

= 6V - 1 - A

UGATE

= 1V - 1.7 3.5 Ω

VCC = 12V, V

V

= 1V - 1.4 3.0 Ω

LGATE

V

FAULT/RT

V

OCSET

= 2.0V - 8.5 - mA

= 4.5V

= 1V - 1 - A

LGATE

DC

170 200 230 µA

-28- µA

VSEN1 Rising 108 - 110 %

VSEN1 Rising 92 - 94 %

= -4mA - - 0.8 V

Typical Performance Curve

1000

100

RESISTANCE (kΩ)

10

RT PULLUP

TO +12V

RT PULLDOWN TO V

10 100 1000

SWITCHING FREQUENCY (kHz)

FIGURE 1. RT RESISTANCE vs FREQUENCY

SS

5

HIP6021A

Functional Pin Descriptions

VCC (Pin 28)

Provide a 12V bias supply for the IC to this pin. This pin also

provides the gate bias charge for all the MOSFETs

controlled by the IC. The voltage at this pin is monitored for

Power-On Reset (POR) purposes.

GND (Pin 17)

Signal ground for theIC. All voltage levelsare measured with

respect to this pin.

PGND (Pin 24)

This is the power ground connection. Tie the synchronous

PWM converter’s lower MOSFET source to this pin.

VAUX (Pin 16)

This pin provides boost current for the linear regulators’

output drives in the event bipolar NPN transistors (instead

of N-Channel MOSFETs) are employed as pass elements.

The voltage at this pin is monitored for power-on reset

(POR) purposes.

SS (Pin 12)

Connect a capacitor from this pin to ground. This capacitor,

along with an internal 28µA current source, sets the softstart

interval of the converter.

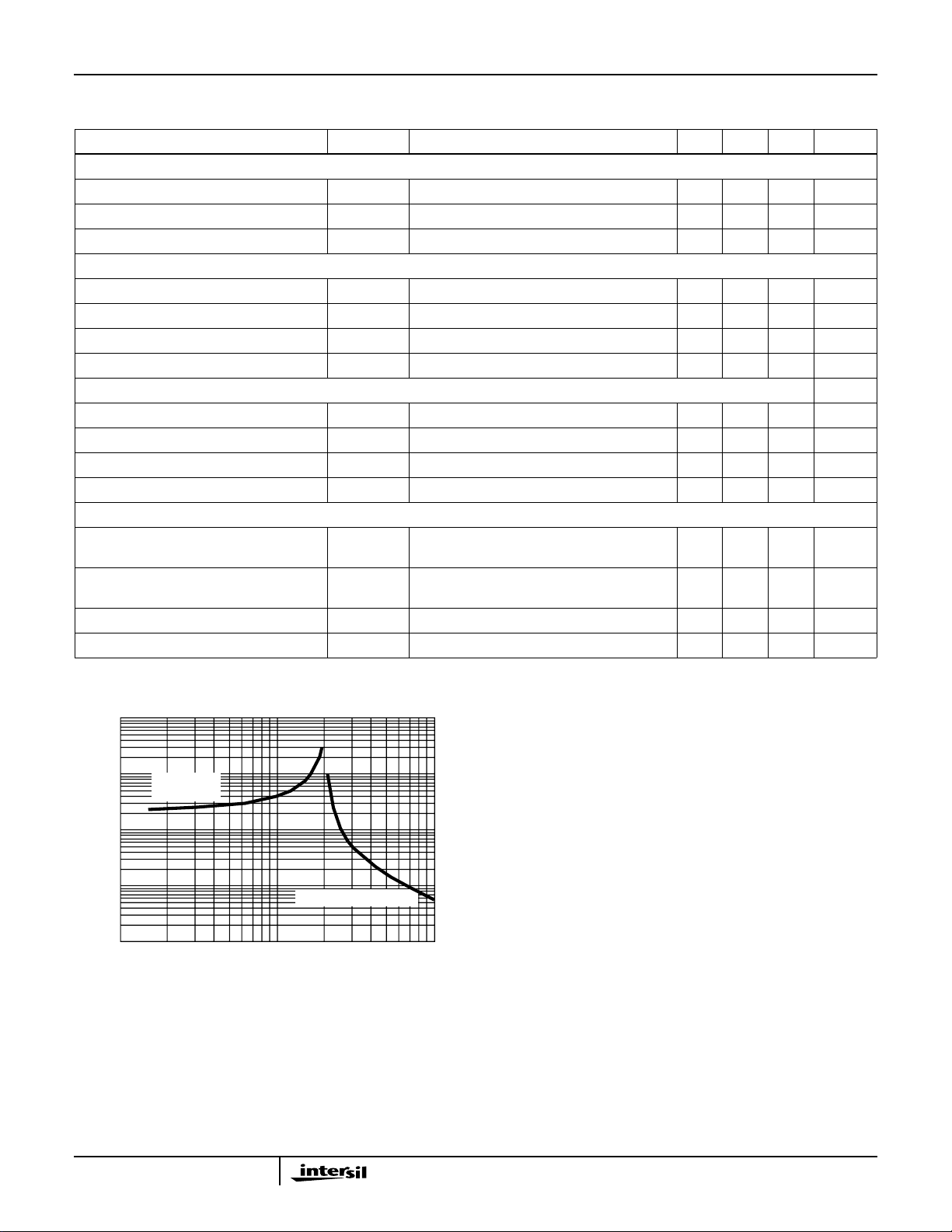

FAULT / RT (Pin 13)

This pin provides oscillator switching frequency adjustment.

By placing a resistor (R

200kHz switching frequency is increased according to the

following equation:

510

Fs 200kHz

×

-------------------- -+≈

RTkΩ()

Conversely, connecting a resistor from this pin to VCC

reduces the switching frequency according to the following

equation:

410

Fs 200kHz

×

-------------------- -–≈

RTkΩ()

Nominally, the voltage at this pin is 1.26V. In the event of an

over-voltage or over-current condition, this pin is internally

pulled to VCC.

PGOOD (Pin 8)

PGOOD is an open collector output used to indicate the

status of the output voltages. This pin is pulled low when the

synchronous regulator output is not within ±10% of the

DACOUT referencevoltage or when any of the other outputs

are below their under-voltage thresholds.

The PGOOD output is open for ‘11111’ VID code.

SD (Pin 9)

This pin shuts down all the outputs. A TTL-compatible, logic

level high signal applied at this pin immediately discharges

) from this pin to GND, the nominal

T

6

(RT to GND)

7

(R

to 12V)

T

the soft-start capacitor, disabling all the outputs. Dedicated

internal circuitry insures the core output voltage does not go

negative during this process. When re-enabled, the IC

undergoes a new soft-start cycle. Left open, this pin is pulled

low by an internal pull-down resistor, enabling operation.

FIX (Pin 2)

Grounding this pin bypasses the internal resistor dividers

that set the output voltage of the 1.5V and 1.8V linear

regulators. This way, the output voltage of the two regulators

can be adjusted from 1.26V up to the input voltage (+3.3V or

+5V) by way of an external resistor divider connected at the

corresponding VSEN pin. The new output voltage set by the

external resistor divider can be determined using the

following formula:

R

1.265V 1

V

OUT

where R

×=

is the resistor connected from VSEN to the

OUT

output of the regulator, and R

OUT

---------------- -+

R

GND

is the resistor connected

GND

from VSEN to ground. Left open, the FIX pin is pulled high,

enabling fixed output voltage operation.

VID0, VID1, VID2, VID3, VID4 (Pins 7, 6, 5, 4 and 3)

VID0-4 are the TTL-compatible input pins to the 5-bit DAC.

The logic states of these five pins program the internal

voltage reference (DACOUT).The level of DACOUT sets the

microprocessor core converter output voltage, as well as the

corresponding PGOOD and OVP thresholds.

OCSET (Pin 23)

Connect a resistor from this pin to the drain of the respective

upper MOSFET. This resistor, an internal 200µA current

source, and the upper MOSFET’s on-resistance set the

converter over-current trip point. An over-current trip cycles

the soft-start function.

The voltage at this pin is monitored for power-on reset (POR)

purposes and pulling this pin low with an open drain device

will shutdown the IC.

PHASE (Pin 26)

Connect the PHASE pin to the PWM converter’s upper

MOSFET source. This pin represents the gate drive return

current path and is used to monitor the voltage drop across

the upper MOSFET for over-current protection.

UGATE (Pin 27)

Connect UGATEpin to the PWM converter’supper MOSFET

gate. This pin provides the gate drive for the upper MOSFET.

LGATE (Pin 25)

Connect LGATE to the PWM converter’s lower MOSFET

gate. This pin provides the gate drive for the lower MOSFET.

COMP and FB (Pin 20 and 21)

COMP and FB are the available external pins of the PWM

converter error amplifier. The FB pin is the inverting input of the

6

HIP6021A

error amplifier. Similarly, the COMP pin is the error amplifier

output. These pins are used to compensate the voltage-mode

control feedback loop of the synchronous PWM conv erter .

VSEN1 (Pin 22)

This pin is connected to the PWM converter’s output voltage.

The PGOOD and OVP comparator circuits use this signal to

report output voltage status and for over-voltage protection.

DRIVE2 (Pin 1)

Connect this pin to the gate of an external MOSFET. This pin

provides the drive for the AGP regulator’s pass transistor.

VSEN2 (Pin 10)

Connect this pin to the output of the AGP linear regulator.

The voltage at this pin is regulated to the level

predetermined by the logic-level status of the SELECT pin.

This pin is also monitored for under-voltage events.

SELECT (Pin 11)

This pin determines the output voltageof the AGP bus linear

regulator. A low TTL input sets the output voltage to 1.5V

and the linear controller regulates this voltage to within ±3%.

A TTL high input turns Q3 on continuously, providing a DC

current path from the input (+3.3V

of the AGP controller.

) to the output (V

IN

OUT2

DRIVE3 (Pin 18)

Connect this pin to the gate of an external MOSFET. This pin

provides the drive for the 1.5V regulator’s pass transistor.

VSEN3 (Pin 19)

Connect this pin to the output of the 1.5V linear regulator.

This pin is monitored for under-voltage events.

DRIVE4 (Pin 15)

Connect this pin to the gate of an external MOSFET. This pin

provides the drive for the 1.8V regulator’s pass transistor.

VSEN4 (Pin 14)

Connect this pin to the output of the linear 1.8V regulator.

This pin is monitored for under voltage events.

Description

Operation

The HIP6021A monitors and precisely controls 4 output

voltage levels (Refer to Block and Simplified Power System

Diagrams,and Typical ApplicationSchematic). It is designed

for microprocessor computer applications with 3.3V, 5V,

and 12V bias input from an ATX power supply. The

microprocessor core voltage (V

synchronous-rectified buck converter configuration. The

PWM controller regulates the microprocessor core voltage

to a level programmed by the 5-bit digital-to-analog

converter (DAC).

) is controlled in a

OUT1

The AGPbus voltage(VOUT2) is set using the SELECT pin

to either a 1.5V linear regulated output or to the 3.3V

through a pass device. Selection of either output voltage is

set depending on the logic level of the SELECT pin.

The two remaining linear controllers supply the 1.5V GTL

bus power (V

These output voltages are user adjustable. All linear

controllers are designed to employ an external pass

transistor.

) and the 1.8V memory power (V

OUT3

IN

OUT4

).

Initialization

The HIP6021A automatically initializes upon receipt of input

power. Special sequencing of the input supplies is not

necessary. The Power-On Reset (POR) function continually

monitors the input supply voltages. The POR monitors the

bias voltage (+12V

(+5V

) on the OCSET pin, and the 3.3V input voltage

IN

(+3.3V

equal to +5V

protection). The POR function initiates soft-start operation

after all supply voltages exceed their POR thresholds.

) at the VAUX pin. The normal level on OCSET is

IN

IN

) at the VCC pin, the 5V input voltage

IN

less a fixed voltage drop (see over-current

Soft-Start

)

The POR function initiates the soft-start sequence. Initially,

the voltage on the SS pin rapidly increases to approximately

1V (this minimizes the softstart interval). Then an internal

28µA current source charges an external capacitor (C

the SS pin to 4.5V. The PWM error amplifier reference input

(+ terminal) and output (COMP pin) are clamped to a level

proportional to the SS pin voltage. As the SS pin voltage

slews from 1V to 4V, the output clamp allows generation of

PHASE pulses of increasing width that charge the output

capacitor(s). After the output voltage increases to

approximately 70% of the set value, the reference input

clamp slows the output voltage rate-of-rise and provides a

smooth transition to the final set voltage. Additionally, all

linear regulators’ reference inputs are clamped to a voltage

proportional to the SS pin voltage. This method provides a

rapid and controlled output voltage rise.

Figure 2 shows the soft-start sequence for the typical

application. At T0 the SS voltage rapidly increases to

approximately 1V. At T1, the SS pin and error amplifier

output voltage reach the valley of the oscillator’s triangle

wave. The oscillator’s triangular waveform is compared to

the clamped error amplifier output voltage. As the SS pin

voltage increases, the pulse width on the PHASE pin

increases. The interval of increasing pulse width continues

until each output reaches sufficient voltage to transfer

control to the input reference clamp. If we consider the 2.5V

core output (V

During the interval between T2 and T3, the error amplifier

reference ramps to the final value and the converter

regulates the output a voltage proportional to the SS pin

voltage. At T3 the input clamp voltage exceeds the

reference voltage and the output voltage is in regulation.

) in Figure 2, this time occurs at T2.

OUT1

SS

)on

7

0V

0V

VOLTAGES

0V

PGOOD

SOFT-START

(1V/DIV)

V

OUT2

V

OUT1

V

OUT4

OUTPUT

(0.5V/DIV)

T1 T2 T3T0 T4

FIGURE 2. SOFT-START INTERVAL

TIME

V

OUT3

(= 3.3VIN)

(DAC = 2.5V)

(= 1.8V)

(= 1.5V)

The remaining outputs are also programmed to follow the

SS pin voltage. The PGOOD signal toggles ‘high’ when all

output voltage levels have exceeded their under-voltage

levels.The waveform for V

represents the case where

OUT2

SELECT is held ‘high’. The AGPbus voltage is controlled in

the same manner as the other linear regulators during the

softstart sequence. Once the softstart sequence is

complete (T4), the gate of the external pass device is fully

enhanced and V

tracks the 3.3VIN voltage. See the

OUT2

Soft-Start Interval sectionunder Applications Guidelines for

a procedure to determine the soft-start interval.

HIP6021A

Over-Voltage Protection

During operation,a short on the upper MOSFET of the PWM

regulator (Q1) causes V

exceedsthe over-voltagethreshold of 115% of DACOUT, the

over-voltage comparator trips to set the fault latch and turns

Q2 on. This blows the input fuse and reduces V

fault latch raises the FAULT/RT pin to VCC.

A separate over-voltage circuit provides protection during

the initial application of power. For voltages on the VCC pin

below the power-on reset (and above ~4V), the output level

is monitored for voltages above1.3V. Should VSEN1 exceed

this level, the lower MOSFET, Q2 is driven on.

Over-Current Protection

All outputs are protected against excessive over-currents.

The PWM controller uses the upper MOSFET’s

on-resistance, r

against shorted output. All linear controllers monitor their

respective VSEN pins for under-voltage events to protect

against excessive currents.

LUV

OVER-

CURRENT

LATCH

OC1

0.15V

+

-

SS

OV

+

-

4V

FIGURE 3. FAULT LOGIC - SIMPLIFIED SCHEMATIC

SRQ

COUNTER

R

UP

POR

to increase. When the output

OUT1

to monitor the current for protection

DS(ON)

INHIBIT

FAULT

LATCH

SRQ

OUT1

VCC

FAULT

. The

Fault Protection

All four outputs aremonitored and protected against extreme

overload. A sustained overload on any output or an overvoltage on V

drives the FAULT/RT pin to VCC.

Figure 3 shows a simplified schematic of the fault logic. An

over-voltage detected on VSEN1 immediately sets the fault

latch. A sequence of three over-current fault signals also

sets the fault latch. The over-current latch is set dependent

upon the states of the over-current (OC), linear undervoltage (LUV) and the soft-start signals. A window

comparator monitors the SS pin and indicates when C

fully charged to 4V (UP signal). An under-voltage on either

linear output (VSEN2, VSEN3, or VSEN4) is ignored until

after the soft-start interval (T4 in Figure 2). This allows

V

OUT2,VOUT3

up.Cycling the bias input voltage (+12V

then on) resets the counter and the fault latch.

output (VSEN1) disables all outputs and

OUT1

, and V

to increase without fault at start-

OUT4

on theVCC pin off

IN

8

SS

is

Figure 4 illustrates the over-current protection with an

overload on OUT1. The overload is applied at T0 and the

current increases through the inductor (L

). At time T1,

OUT1

the OVER-CURRENT comparator trips when the voltage

across Q1 (i

D•rDS(ON)

) exceeds the level programmed by

ROCSET. This inhibits all outputs, discharges the soft-start

capacitor (C

the counter. C

) with a 10mA current sink, and increments

SS

recharges at T2 and initiates a soft-start

SS

cycle with the error amplifiers clamped by soft-start. With

OUT1 still overloaded, the inductor current increases to trip

the over-current comparator. Again, this inhibits all outputs,

but the soft-start voltage continues increasing to 4V before

discharging. The counter increments to 2. The soft-start

cycle repeats at T3 and trips the over-current comparator.

The SS pin voltage increases to 4V at T4 and the counter

increments to 3. This sets the fault latch to disable the

converter. The fault is reported on the FAULT/RT pin.

The linear controllers operate in the same way as the PWM

in response to over-current faults. The differentiating factor

HIP6021A

for the linear controllers is that they monitor the VSEN pins

for under-voltage events. Should excessive currents cause

the voltage at the VSEN pins to fall below the linear undervoltage threshold, the LUV signal sets the over-current

latch if C

the C

is fully charged. Blanking the LUV signal during

SS

charge interval allows the linear outputs to build

SS

abovethe under-voltagethreshold during normal operation.

Cycling the bias input power off then on resets the counter

and the fault latch.

FAULT

10V

0V

FAULT/RT

4V

2V

0V

0A

INDUCTOR CURRENT SOFT-START

FIGURE 4. OVER-CURRENT OPERATION

A resistor (R

COUNT

= 1

OVERLOAD

APPLIED

T1 T2 T3T0 T4

) programs the over-current trip levelfor

OCSET

REPORTED

COUNT

= 2

TIME

COUNT

= 3

the PWM converter. As shown in Figure 5, the internal

200µA current sink, I

R

OCSET(VSET

) that is referenced to VIN. The DRIVE

develops a voltage across

OCSET

signal enables the over-current comparator (OVERCURRENT). When the voltage across the upper MOSFET

(V

) exceeds V

DS

set the over-current latch. Both V

referenced to V

helps V

OCSET

, the over-current comparator trips to

SET

and a small capacitor across R

IN

and VDS are

SET

OCSET

track the variations of VIN due to MOSFET

switching. The over-current function will trip at a peak

inductor current (I

I

OCSETROCSET

I

PEAK

--------------------------------------------------- -

=

r

DS ON()

×

determined by:

PEAK)

OVER-CURRENT TRIP:

VDSV

>

× I

iDr

DS ON()

OVER-

CURRENT

OC

PWM

SET

×>

OCSETROCSET

R

OCSET

I

OCSET

200µA

DRIVE

+

-

GATE

CONTROL

FIGURE 5. OVER-CURRENT DETECTION

OCSET

V

VCC

UGATE

PHASE

V

PHASEVINVDS

V

OCSETVINVSET

The OC trip point varies with MOSFET’s r

SET

VIN = +5V

i

+

DS(ON)

D

+

V

DS

–=

–=

temperature variations.Toavoid over-currenttripping in the

normal operating load range, determine the R

OCSET

resistor from the equation above with:

1. The maximum r

2. The minimum I

3. Determine I

PEAK

DS(ON)

OCSET

at the highest junction temperature.

from the specification table.

for I

PEAK>IOUT(MAX)

+(∆I)/2, where

∆I is the output inductor ripple current.

For an equation for the ripple current see the section under

component guidelines titled ‘PWM Output Inductor

Selection’.

OUT1 Voltage Program

The output voltage of the PWM converter is programmed to

discrete levels between 1.3V

(OUT1) is designed to supply the core voltage of Intel’s

advanced microprocessors. The voltage identification (VID)

pins programan internal voltage reference(DACOUT) with a

TTL-compatible 5-bit digital-to-analog converter. The level of

DACOUT also sets the PGOOD and OVP thresholds.

Table 1 specifies the DACOUT voltage for the different

combinations of connections on the VID pins. The VID pins

can be left open for a logic 1 input, because they are

internally pulled up to an internal voltage of about 5V by a

10µA current source. Changing the VID inputs during

operation is not recommended and could toggle the PGOOD

signal and exercise the over-voltage protection.

and 3.5VDC. This output

DC

9

HIP6021A

TABLE 1. OUT1 VOLTAGE PROGRAM

PIN NAME NOMINAL

DACOUT

VOLTAGEVID4 VID3 VID2 VID1 VID0

011111.30

011101.35

011011.40

011001.45

010111.50

010101.55

010011.60

010001.65

001111.70

001101.75

001011.80

001001.85

000111.90

000101.95

000012.00

000002.05

111112.00

111102.1

111012.2

111002.3

110112.4

110102.5

110012.6

110002.7

101112.8

101102.9

101013.0

101003.1

100113.2

100103.3

100013.4

100003.5

NOTE: 0 = connected to GND,1 = open or connected to 5V through

pull-up resistors.

OUT2 Voltage Selection

The AGP output voltage is internally set to one of two levels,

based on the status of the SELECT pin. Grounding the

SELECT pin enables the internal 1.5V regulator control

circuitry.Left open, the SELECT pin is internally pulled ‘high’

and the AGPvoltage is regulated to 3.3V during the softstart

sequence. Once complete, the gate drive is increased and

the regulator becomes a simple pass circuit for the 3.3V

input voltage.

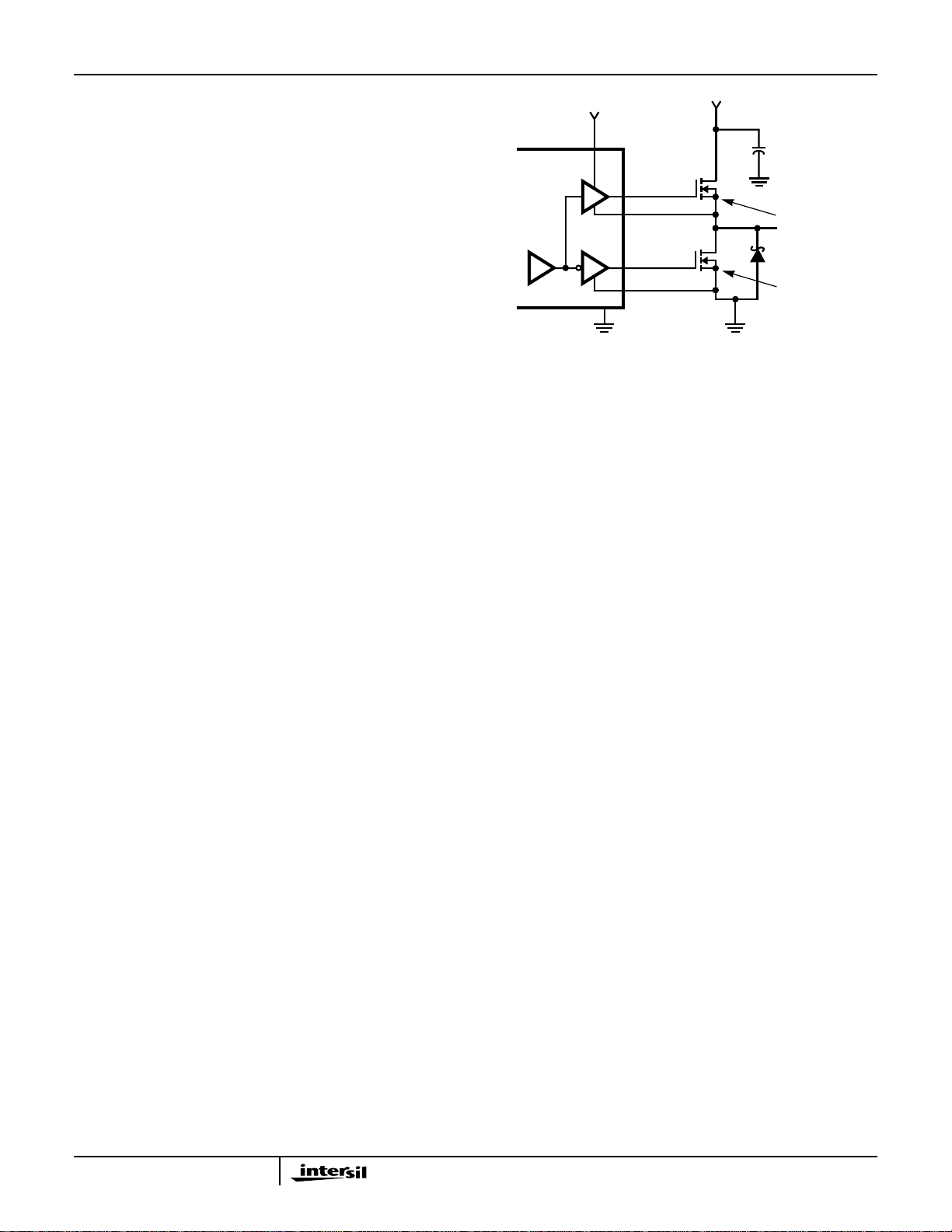

OUT3 and OUT4 Voltage Adjustability

The GTL bus voltage (1.5V, OUT3) and the chip set and/or

cache memory voltage (1.8V, OUT4) are internally set for

simple, low-cost implementation in typical Intel motherboard

architectures. However, if different voltage settings are

desired for these two outputs, the FIX pin provides the

necessary adaptability. Left open (NC), this pin sets the fixed

output voltages described above. Grounding this pin allows

both output voltages to be set by means of external resistor

dividers as shown in Figure 6.

R

R

--------+

R

P3

S

P

VAUX

DRIVE3

VSEN3

HIP6021A

DRIVE4

VSEN4

FIX

+3.3V

IN

Q4

V

OUT3

R

C

OUT3

Q5

V

OUT4

C

OUT4

V

OUTVBG

FIGURE 6. ADJUSTING THE OUTPUT VOLTAGE OF

OUTPUTS 3 AND 4

S3

R

S4

R

P4

1

×=

Application Guidelines

Soft-Start Interval

Initially, the soft-start function clamps the error amplifier’s

output of the PWM converter. This generatesPHASE pulses

of increasing width that charge the output capacitor(s). After

the output voltage increases to approximately70% of the set

value, the reference input of the error amplifier is clamped to

a voltage proportional to the SS pin voltage. The resulting

output voltages start-up as shown in Figure 2.

The soft-start function controls the output voltage rate of rise

to limitthe current surge atstart-up. The soft-start interval and

the surge current are programmed by the soft-start capacitor,

C

. Programming a faster soft-start interval increases the

SS

peak surge current. The peak surge current occurs during the

initial output voltage rise to 70% of the set value.

10

HIP6021A

Shutdown

The HIP6021A features a dedicated shutdown pin (SD). A

TTL-compatible, logic high signal applied to this pin shuts

down (disables) all four outputs and discharges the soft-start

capacitor. Following a shutdown, a logic low signal

re-enables the outputs through initiation of a new soft-start

cycle. Left open this pin willasses a logic lowstate, due to its

internal pull-down resistor, thus enabling normal operation of

all outputs.

The PWM output does not switch until the soft-start voltage

(V

) exceeds the oscillator’s valley voltage. The references

SS

on each linear’s error amplifier are clamped to the soft-start

voltage. Holding the SS pin low (with an open drain or

collector signal) turns off all four regulators.

The ‘11111’ VID code also shuts down the IC.

Layout Considerations

MOSFETs switch very fast and efficiently. The speed with

which the current transitions from one device to another

causes voltage spikes across the interconnecting

impedances and parasitic circuit elements. The voltage

spikes can degrade efficiency, radiate noise into the circuit,

and lead to device over-voltage stress. Careful component

layout and printed circuit design minimizes the voltage

spikes in the converter. Consider, as an example, the turnoff transition of the upper PWM MOSFET. Prior to turn-off,

the upper MOSFET was carrying the full load current.

During the turn-off, current stops flowing in the upper

MOSFET and is picked up by the lower MOSFET or

Schottky diode. Any inductance in the switched current

path generates a large voltage spike during the switching

interval. Careful component selection, tight layout of the

critical components, and short, wide circuit traces minimize

the magnitude of voltage spikes. See Application Note

AN9836 for evaluation board drawings of the component

placement and the printed circuit board layout of a typical

application.

There are two sets of critical components in a DC-DC

converter using a HIP6021A controller. The switching power

components are the most critical because they switch large

amounts of energy, and as such, they tend to generate

equally large amounts of noise. The critical small signal

components are those connected to sensitive nodes or

those supplying critical bypass current.

The power components and the controller IC should be

placed first. Locate the input capacitors, especially the highfrequency ceramicdecoupling capacitors, closeto the power

switches. Locate the output inductor and output capacitors

between the MOSFETs and the load. Locate the PWM

controller close to the MOSFETs.

The critical small signal components include the bypass

capacitor for VCC and the soft-start capacitor, C

these components close to their connecting pins on the

. Locate

SS

control IC. Minimize any leakage current paths from SS

node, since the internal current source is only 28µA.

A multi-layer printed circuit board is recommended.

Figure 7 shows the connections of the critical components

in the converter. Note that the capacitors C

and C

IN

OUT

each represent numerous physical capacitors. Dedicate

one solid layer for a ground plane and make all critical

component ground connections with vias to this layer.

Dedicate another solid layer as a power plane and break

this plane into smaller islands of common voltage levels.

The power plane should support the input power and

output power nodes. Use copper filled polygons on the top

and bottom circuit layers for the PHASE nodes, but do not

unnecessarily oversize these particular islands. Since the

PHASE nodes are subjected to very high dV/dt voltages,

the stray capacitor formed between these islands and the

surrounding circuitry will tend to couple switching noise.

Use the remaining printed circuit layers for small signal

wiring. The wiring traces from the control IC to the

MOSFET gate and source should be sized to carry 2A

peak currents.

PWM Controller Feedback Compensation

The PWM controller uses voltage-mode control for output

regulation. This section highlights the design consideration

for a PWM voltage-mode controller. Apply the methods and

considerations only to the PWM controller.

Figure 8 highlights the voltage-mode control loop for a

synchronous-rectified buck converter. The output voltage

(V

) is regulated to the Reference voltage level. The

OUT

referencevoltage levelis the DACoutput voltage(DACOUT).

The error amplifier (Error Amp) output (V

) is compared

E/A

with the oscillator (OSC) triangular wave to provide a pulsewidth modulated (PWM) wave with an amplitude of V

IN

at

the PHASE node. The PWM waveis smoothed bythe output

filter (L

and CO).

O

The modulator transfer function is the small-signal transfer

function of V

OUT/VE/A

Gain, given by V

with a double pole break frequency at F

at F

ESR

.

. This function is dominated by a DC

IN/VOSC

, and shaped by the output filter,

and a zero

LC

Modulator Break Frequency Equations

--------------------------------------- -=

2π L

1

××

OCO

F

ESR

F

LC

The compensation network consists of the error amplifier

(internal to the HIP6021A) and the impedance networks Z

and ZFB. Thegoal of the compensation network is to provide

a closed loop transfer function with high 0dB crossing

frequency (f

) and adequate phase margin. Phase margin

0dB

is the difference between the closed loop phase at f

180 degrees. The equations below relate the compensation

network’spoles, zeros and gain to the components (R1, R2,

-----------------------------------------=

2π ESR CO××

1

and

0dB

IN

11

HIP6021A

R3, C1, C2, and C3) in Figure 7. Use these guidelines for

locating the poles and zeros of the compensation network:

1. Pick Gain (R2/R1) for desired converter bandwidth

ST

2. Place 1

3. Place 2

4. Place 1

5. Place 2

Zero Below Filter’s Double Pole (~75% FLC)

ND

Zero at Filter’s Double Pole

ST

Pole at the ESR Zero

ND

Pole at Half the Switching Frequency

6. Check Gain against Error Amplifier’s Open-Loop Gain

7. Estimate Phase Margin - Repeat if Necessary

L

IN

IN

OUT2

LOAD

OUT3

LOAD

+3.3V

IN

C

C

IN

C

IN

OUT2

OUT3

Q3

C

Q4

SS

+12V

C

VCC

GNDVCC

OCSET1

DRIVE2

UGATE1

PHASE1

LGATE1

SS

HIP6021A

DRIVE4

DRIVE3

PGND

KEY

ISLAND ON POWER PLANE LAYER

ISLAND ON CIRCUIT PLANE LAYER

VIA CONNECTION TO GROUND PLANE

C

OCSET1

Q2

Q5

R

OCSET1

Q1

L

OUT1

C

OUT1

CR1

C

OUT4

V

V

OUT1

OUT4

LOAD

+5V

+3.3V

V

V

FIGURE 7. PRINTED CIRCUIT BOARDPOWER PLANES AND

ISLANDS

Figure 9 shows an asymptotic plot of the DC-DC converter’s

gain vs frequency. The actual Modulator Gain has a high gain

peak dependent on the quality factor (Q) of the output filter ,

which is not shown in Figure 8. Using the above guidelines

should yield a Compensation Gain similar to the curve plotted.

The gain. Check the compensation gain at F

with the

P2

capabilities of the error amplifier. The Closed Loop Gain is

constructed on the log-log graph of Figure 9 by adding the

Modulator Gain (in dB) to the Compensation Gain (in dB). This

isequivalent tomultiplying themodulator transferfunctionto the

compensation transfer function and plotting the gain.

The compensation gain uses external impedance networks

Z

and ZINto providea stable,high bandwidth (BW) overall

FB

loop. A stable control loop has a gain crossing with

-20dB/decade slope and a phase margin greater than 45

degrees. Include worst case component variations when

determining phase margin.

LOAD

V

FB

Z

FB

IN

L

O

PHASE

(PARASITIC)

Z

IN

C3

R1

C

ESR

R3

V

OUT

O

V

OUT

∆V

OSC

OSC

PWM

COMP

-

+

Z

FB

V

E/A

-

+

ERROR

AMP

DETAILED COMPENSATION COMPONENTS

COMP

DRIVER

DRIVER

REFERENCE

C2

C1

R2

Z

IN

-

+

HIP6021A

DACOUT

FIGURE 8. VOLTAGE-MODEBUCK CONVERTER

COMPENSATION DESIGN

Compensation Break Frequency Equations

F

Z1

F

Z2

100

80

60

40

20

GAIN (dB)

0

-20

-40

-60

1

-----------------------------------=

2π R× 2C1×

------------------------------------------------------ -=

2π R1 R3+()C3××

F

R2

20

log

------- -

R1

MODULATOR

GAIN

1

Z1

F

Z2

FLCF

ESR

FREQUENCY (Hz)

F

F

F

P1

P2

P1

-------------------------------------------------------=

2π R

-----------------------------------=

2π R× 3C3×

F

P2

FIGURE 9. ASYMPTOTIC BODE PLOT OF CONVERTER GAIN

1

C1 C2×

----------------------

××

2

C1 C2+

1

OPEN LOOP

ERROR AMP GAIN

V

20

log

------------

V

COMPENSATION

GAIN

CLOSED LOOP

GAIN

10M1M100K10K1K10010

IN

PP

12

HIP6021A

Component Selection Guidelines

Output Capacitors

The output capacitors for each output have unique

requirements. In general, the output capacitors should be

selected to meet the dynamic regulation requirements.

Additionally,the PWM convertersrequire an output capacitor

to filter the current ripple. The load transient for the

microprocessor core requires high quality capacitors to

supply the high slew rate (di/dt) current demands.

PWM Output

Modern microprocessors produce transientload rates above

1A/ns. High frequency capacitors initially supply the

transient current and slow the load rate-of-change seen by

the bulk capacitors. The bulk filter capacitor values are

generally determined by the ESR (effective series

resistance) and voltage rating requirements rather than

actual capacitance requirements.

High frequency decoupling capacitors should be placed as

close to the power pins of the load as physically possible. Be

careful not to add inductance in the circuit board wiring that

could cancel the usefulness of these low inductance

components. Consult with the manufacturer of the load on

specific decoupling requirements.

Use only specialized low-ESR capacitors intended for

switching-regulator applications for the b ulk capacitors. The

bulk capacitor’s ESR determines the output ripple voltage and

the initial voltage drop following a high slew-rate transient’ s

edge. An aluminum electrolytic capacitor’ s ESR value is

related to the case size with lower ESR available in larger

case sizes. However , the equivalent series inductance (ESL)

of these capacitors increases with case size and can reduce

the usefulness of the capacitor to high slew-rate transient

loading. Unfortunately,ESL is not a specifiedparameter.Work

with your capacitor supplier and measure the capacitor’s

impedance with frequency to select a suitable component. In

most cases, multiple electrolytic capacitors of small case size

perform better than a single large case capacitor.

Linear Output Capacitors

The output capacitors for the linear regulators provide

dynamic load current. The linear controllers use dominant

pole compensation integrated into the error amplifier and are

insensitive to output capacitor selection. Output capacitors

should be selected for transient load regulation.

PWM Output Inductor

The PWM converter requires an output inductor. The output

inductor is selected to meet the output voltage ripple

requirements and sets the converter’s response time to a

load transient. The inductor value determines the converter’s

ripple current and the ripple voltage is a function of the ripple

current. The ripple voltage and current are approximated by

the following equations:

∆I

VINV

–

------------------------------- -

F

S

OUT

L×

V

--------------- -

×=

OUT

V

IN

∆ I∆ ESR×=

V

OUT

Increasing thevalue of inductance reduces the ripple current

and voltage. However, the large inductance values increase

the converter’s response time to a load transient.

One of the parameters limiting the converter’s response to a

load transient is the time required to change the inductor

current. Given a sufficiently fast control loop design, the

HIP6021A will provide either 0% or 100% duty cycle in

response to a load transient. The response time is the time

interval required to slew the inductor current from an initial

current value to the post-transient current level. During this

interval the difference between the inductor current and the

transient current level must be supplied by the output

capacitor(s). Minimizing the response time can minimize the

output capacitance required.

The response time to a transient is different for the

application of load and the removal of load. The following

equations give the approximate response time interval for

application and removal of a transient load:

LOI

×

TRAN

t

RISE

where: I

------------------------------- -=

–

V

INVOUT

is the transient load current step, t

TRAN

t

FALL

response time to the application of load, and t

LOI

×

------------------------------ -=

V

TRAN

OUT

RISE

FALL

is the

is the

response time to the removal of load. Be sure to check both

of these equations at the minimum and maximum output

levels for the worst case response time.

Input Capacitors

The important parameters for the bulk input capacitors are

the voltage rating and the RMS current rating. For reliable

operation, select bulk input capacitors with voltage and

current ratingsabove the maximum input voltage and largest

RMS current required by the circuit. The capacitor voltage

rating should be at least 1.25 times greater than the

maximum input voltage and a voltage rating of 1.5 times is a

conservative guideline. The RMS current rating requirement

for the input capacitor of a buck regulator is approximately

1/2 of the summation of the DC load current.

Use a mix of input bypass capacitors to control the voltage

overshoot across the MOSFETs. Use ceramic capacitance

for the high frequency decoupling and bulk capacitors to

supply the RMS current. Small ceramic capacitors can be

placed very close to the upper MOSFET to suppress the

voltage induced in the parasitic circuit impedances.

For a through-hole design, sev er al electrolytic capacitors

(PanasonicHFQ series or NichiconPL series or SanyoMV-GX

or equivalent) maybe needed. Forsurface mount designs, solid

tantalum capacitors can be used, but caution must be

exercised with regard to the capacitor surge current rating.

These capacitors must be capable of handling the surgecurrent at power-up. The TPS series av ailab le from AVX, and

the 593D series from Sprague are both surge current tested.

13

HIP6021A

MOSFET Considerations

The HIP6021A requires 5 external transistors. TwoN-Channel

MOSFETs are used in the synchronous-rectified buck

topology of PWM1 converter. It is recommended that the

AGP linear regulator pass element be a N-Channel

MOSFET as well. The GTL and memory linear controllers

can also each drive a MOSFET or a NPN bipolar as a pass

transistor. All these transistors should be selected based

upon r

DS(ON)

, current gain, saturation voltages, gate supply

requirements, and thermal management considerations.

PWM MOSFETs

In high-current PWM applications, the MOSFET power

dissipation, package selection and heatsink are the

dominant design factors.The power dissipation includes two

loss components; conduction loss and switching loss. These

losses are distributed between the upper and lower

MOSFETs according to duty factor (see the equations

below). The conduction losses are the main component of

power dissipation for the lower MOSFETs. Only the upper

MOSFET has significant switching losses, since the lower

device turns on and off into near zero voltage.

The equations below assume linear voltage-current

transitions and do not model power loss due to the reverserecovery of the lower MOSFET’s body diode. The gatecharge losses are dissipated by the HIP6021A and don't

heat the MOSFETs. However, large gate-charge increases

the switching time, t

switchinglosses. Ensure thatboth MOSFETs are withintheir

maximum junction temperature at high ambient temperature

by calculating the temperature rise according to package

thermal-resistance specifications. A separate heatsink may

be necessary depending upon MOSFET power, package

type, ambient temperature and air flow.

2

I

× V

P

UPPER

P

LOWER

The r

O

------------------------------------------------------------

2

I

× VINV

O

-------------------------------------------------------------------------------- -=

is different for the two equations above even if

DS(ON)

the same device is used for both. This is because the gate

drive applied to the upper MOSFET is different than the

lower MOSFET. Figure 10 shows the gate drive where the

upper MOSFET’s gate-to-source voltage is approximately

VCC less the input supply. For +5Vmain power and +12VDC

for the bias, the gate-to-source voltage of Q1 is 7V. The

lowergate drive voltageis +12VDC.A logic-levelMOSFET is

a good choice for Q1 and a logic-levelMOSFET can be used

for Q2 if its absolute gate-to-source voltage rating exceeds

the maximum voltage applied to VCC.

which increases the upper MOSFET

SW

r

r

×

DS ON()

V

IN

DS ON()

V

IN

OUT

× tSW× FS×

I

OVIN

----------------------------------------------------+=

–()×

OUT

2

+12V

VCC

+5V OR LESS

HIP6021A

UGATE

PHASE

-

+

IGURE 10. UPPER GATE DRIVE - DIRECT VCC DRIVE OPTION

LGATE

PGND

GND

Q1

Q2

CR1

NOTE:

V

GS

NOTE:

V

GS

≈ V

≈ V

CC

CC

-5V

Rectifier CR1 is a clamp that catches the negative inductor

swing during the dead time between the turn off of the lower

MOSFET and the turn on of the upper MOSFET. The diode

must be a Schottky type to prevent the lossy parasitic

MOSFET body diode from conducting. It is acceptable to

omit the diode and let the body diode of the lower MOSFET

clamp the negative inductor swing, but efficiency could drop

one or two percent as a result. The diode's rated reverse

breakdown voltage must be greater than the maximum input

voltage.

Linear Controller Transistors

The main criteria for selection of transistors for the linear

regulators is package selection for efficient removal of heat.

The power dissipated in a linear regulator is:

P

LINEARIOVINVOUT

Select a package and heatsink that maintains the junction

temperature below the rating with a the maximum expected

ambient temperature.

When selecting bipolar NPN transistors for use with the

linear controllers, insure the current gain at the given

operating VCE is sufficiently large to provide the desired

output load current when the base is fed with the minimum

driver output current.

–()×=

14

HIP6021A

HIP6021A DC-DC Converter Application Circuit

Figure 11 shows an application circuit of a power supply for a

microprocessor computer system. The power supply provides

the microprocessor core voltage (VOUT1), the AGP bus

voltage (VOUT2), the GTL b us v oltage (VOUT3), and the

memory voltage (VOUT4) from +3.3V, +5VDC, and +12VDC.

+12V

IN

L1

+5V

GND

+3.3V

IN

IN

1µH

C1-6

6x1000µF

FAULT/RT

+

VAUX

VCC

28

13

16

For detailed information on the circuit, including a Bill-ofMaterials and circuit board description, see Application Note

AN9836. Also see Intersil’s web page (http://www.intersil.com)

or Intersil AnswerF AX(407-724-7800) Document No. 99836 for

the latest information.

C7

1µF

23

8

OCSET

PGOOD

C8

1000pF

R1

1.0K

C9

1µF

POWERGOOD

V

OUT2

(3.3VIN OR 1.5V)

TYPEDET

HUF76107D3S

V

OUT3

(1.5V)

V

OUT4

(1.8V)

+

C10, 11

2x1000µF

Q4

+

C23, 24

2x1000µF

HUF76107D3S

+

C25, 26

2x1000µF

Q5

Q3

HUF76121D3S

DRIVE2

VSEN2

SELECT

DRIVE3

VSEN3

DRIVE4

VSEN4

SD

FIX

1

10

11

18

19

15

14

9

2

U1

HIP6021A

17

GND

27

26

25

24

22

21

20

12

7

6

5

4

3

UGATE

PHASE

LGATE

PGND

VSEN1

FB

COMP

VID0

VID1

VID2

VID3

VID4

SS

C21

10pF

C22

2.7nF

C27

0.1µF

Q1, 2

2xHUF76143S3S

R3

1.62K

R4

150K

499K

8x1000µF

R2

10.2K

R5

L2

4.2µH

C12-19

0.22µF

C20

V

OUT1

(1.3V-3.5V)

+

FIGURE 11. POWER SUPPLY APPLICATION CIRCUIT FOR A MICROPROCESSOR COMPUTER SYSTEM

15

Small Outline Plastic Packages (SOIC)

HIP6021A

N

INDEX

AREA

123

-A-

E

-B-

SEATING PLANE

D

A

-C-

0.25(0.010) BM M

H

L

h x 45

o

α

e

B

0.25(0.010) C AM BS

M

NOTES:

1. Symbolsaredefined in the “MO SeriesSymbolList” in Section 2.2

of Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate

burrs. Mold flash, protrusion and gate burrs shall not exceed

0.15mm (0.006 inch) per side.

4. Dimension “E” does not include interlead flash or protrusions. Interlead flash and protrusions shall not exceed 0.25mm (0.010

inch) per side.

5. The chamfer on the body is optional. If it is not present, a visual

index feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width “B”, as measured 0.36mm (0.014 inch) or greater

above the seating plane, shall not exceed a maximum value of

0.61mm (0.024 inch)

10. Controlling dimension: MILLIMETER. Converted inch dimensions are not necessarily exact.

A1

0.10(0.004)

M28.3 (JEDEC MS-013-AE ISSUE C)

28 LEAD WIDE BODY SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.0926 0.1043 2.35 2.65 -

A1 0.0040 0.0118 0.10 0.30 -

B 0.013 0.0200 0.33 0.51 9

C 0.0091 0.0125 0.23 0.32 D 0.6969 0.7125 17.70 18.10 3

E 0.2914 0.2992 7.40 7.60 4

e 0.05 BSC 1.27 BSC H 0.394 0.419 10.00 10.65 -

C

h 0.01 0.029 0.25 0.75 5

L 0.016 0.050 0.40 1.27 6

N28 287

o

α

0

o

8

o

0

o

8

Rev. 0 12/93

NOTESMIN MAX MIN MAX

-

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil semiconductor products are sold by description only.Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (407) 724-7000

FAX: (407) 724-7240

16

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Intersil (Taiwan) Ltd.

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

Loading...

Loading...