Intersil Corporation HIP6018 Datasheet

HIP6018

Data Sheet April 1998 File Number

Advanced PWM and Dual Linear Power

Control

The HIP6018 provides the power control and protection for

three output voltages in high-performance microprocessor

and computer applications. The IC integrates a PWM

controllers, a linear regulator and a linear controller as well

as the monitoring and protection functions into a single

package. The PWM controller regulates the microprocessor

core voltage with a synchronous-rectified buck converter.

The linear controller regulates power for the GTL bus and

the linear regulator provides power fortheclock driver circuit.

The HIP6018 includes an Intel-compatible, TTL 5-input

digital-to-analog converter (DAC)thatadjusts the core PWM

output voltage from 2.1V

and from 1.8V

to 2.05VDC in 0.05V steps. The precision

DC

reference and voltage-mode control provide±1% static

regulation. The linear regulator uses an internal pass device

to provide 2.5V±2.5%. The linear controller drives an

external N-channel MOSFET to provide 1.5V±2.5%.

The HIP6018 monitors all the output voltages. A single

Power Good signal is issued whenthecoreis within ±10% of

the DAC setting and the other levels are above their undervoltage levels. Additional built-in over-voltage protection for

the core output uses the lower MOSFET to prevent output

voltages above 115% of the DAC setting. The PWM overcurrent function monitors the output current by using the

voltage drop across the upper MOSFET’s r

eliminating the need for a current sensing resistor.

to 3.5VDC in 0.1V increments

DC

DS(ON)

,

4497.1

Features

• Provides 3 Regulated Voltages

- Microprocessor Core, Clock and GTL Power

• Drives N-Channel MOSFETs

• Operates from +3.3V, +5V and +12V Inputs

• Simple Single-Loop PWM Control Design

- Voltage-Mode Control

• Fast Transient Response

- High-Bandwidth Error Amplifier

- Full 0% to 100% Duty Ratios

• Excellent Output Voltage Regulation

- Core PWM Output: ±1% Over Temperature

- Other Outputs: ±2.5% Over Temperature

• TTL-compatible 5-Bit Digital-to-Analog Core Output

Voltage Selection

- Wide Range . . . . . . . . . . . . . . . . . . . 1.8V

- 0.1V Steps . . . . . . . . . . . . . . . . . . . . 2.1VDC to 3.5V

- 0.05V Steps . . . . . . . . . . . . . . . . . . 1.8VDC to 2.05V

• Power-Good Output Voltage Monitor

• Microprocessor Core Voltage Protection Against Shorted

MOSFET

• Over-Voltage and Over-Current Fault Monitors

- Does Not Require Extra Current Sensing Element,

Uses MOSFET’s r

DS(ON)

• Small Converter Size

- Constant Frequency Operation

- 200kHz Free-Running Oscillator; Programmable from

50kHz to over 1MHz

DC

to 3.5V

DC

DC

DC

Ordering Information

TEMP. RANGE

PART NUMBER

HIP6018CB 0 to 70 24 Ld SOIC M24.3

HIP6018EVAL1 Evaluation Board

(oC) PACKAGE

2-224

PKG.

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

NO.

Applications

•

Full Motherboard Power Regulation for Computers

•

Low-Voltage Distributed Power Supplies

Pinout

HIP6018 (SOIC)

TOP VIEW

VCC

1

2

VID4

VID3

3

VID2

4

5

VID1

VID0

6

PGOOD

http://www.intersil.com or 407-727-9207

FAULT

SS

RT

FB2

VIN2

7

8

9

10

11

12

| Copyright © Intersil Corporation 1999

24

23

22

21

20

19

18

17

16

15

14

13

UGATE1

PHASE1

LGATE1

PGND

OCSET1

VSEN1

FB1

COMP1

FB3

DRIVE3

GND

VOUT2

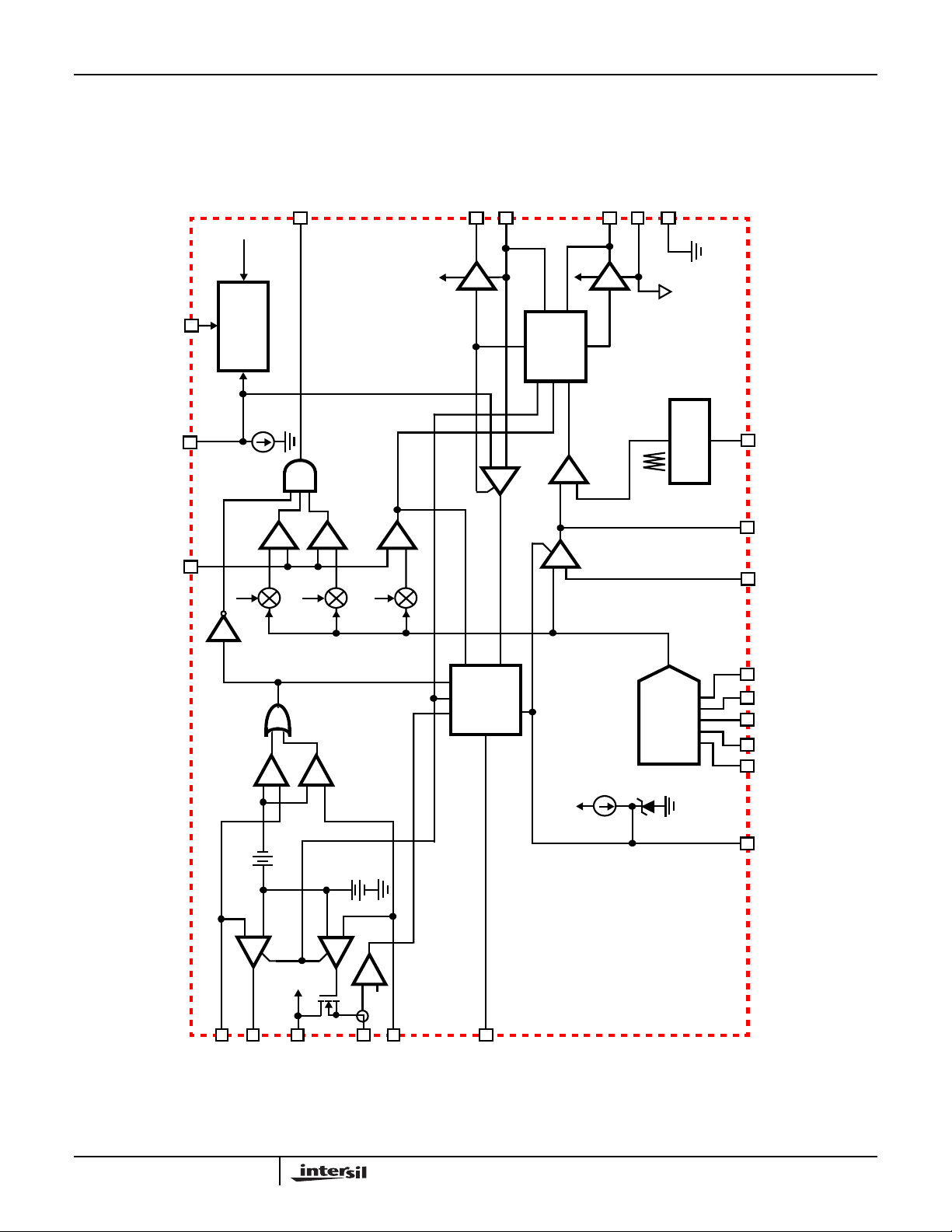

Block Diagram

HIP6018

VCC

OCSET1

VSEN1

3V

POWER-ON

RESET (POR)

200mA

110%

LINEAR

UNDER-

VOLTAGE

+

+

-

-

PGOOD

+

90%

-

+

DRIVE

LOWER

PGND

TTL D/A

4V

GND

CONVERTER

RT

OSCILLATOR

FB1 COMP1

VID4

VID3

(DAC)

VID2

VID1

VID0

UGATE1

PHASE1

VCC

DRIVE

UPPER

GATE

INHIBIT

-

+

OC1

-

+

115%

-

LUV

OC2

OV

+

SOFT-

LOGIC

START

AND FAULT

CONTROL

+

-

VCC

PWM

-

PWM

ERROR

DACOUT

LGATE1

COMP

AMP

11µA

FB3

2-225

0.3V

-

+

DRIVE3

-

+

INHIBIT

3V

VIN2

VCC

SS

1.26V

-

+

-

+

-

+

0.23A

FB2

VOUT2

FAULT

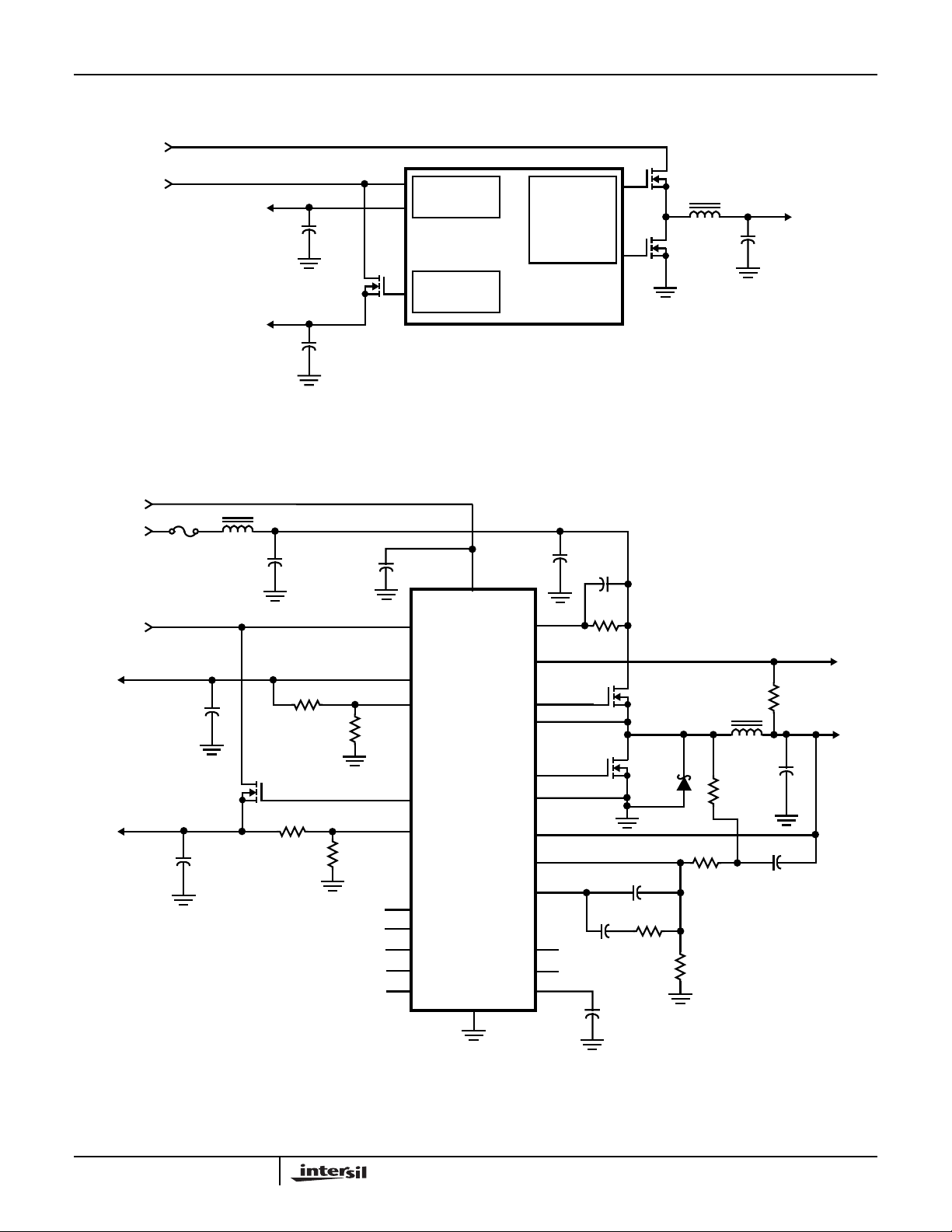

FIGURE 1.

Simplified Power System Diagram

+5V

IN

HIP6018

+3.3V

IN

V

V

Typical Application

+12V

IN

+5V

IN

+3.3V

IN

V

OUT2

2.5V

C

OUT2

OUT2

OUT3

Q1

Q2

V

OUT1

Q3

LINEAR

REGULATOR

HIP6018

LINEAR

CONTROLLER

PWM1

CONTROLLER

FIGURE 2.

C

IN

VCC

VIN2

VOUT2

FB2

OCSET1

PGOOD

UGATE1

PHASE1

Q1

POWERGOOD

L

OUT1

V

OUT1

1.8V TO 3.5V

V

OUT3

1.5V

C

Q3

OUT3

2-226

DRIVE3

FB3

VID0

VID1

VID2

VID3

VID4

HIP6018

GND

FIGURE 3.

LGATE1

PGND

VSEN1

FB1

COMP1

FAULT

RT

SS

Q2

CR1

C

SS

C

OUT1

HIP6018

Absolute Maximum Ratings Thermal Information

Supply Voltage, VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +15V

PGOOD, RT, FAULT, and GATE Voltage .GND - 0.3V to VCC + 0.3V

Input, Output or I/O Voltage. . . . . . . . . . . . . . . . . . GND -0.3V to 7V

Operating Conditions

Supply Voltage, VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . +12V ±10%

Ambient Temperature Range. . . . . . . . . . . . . . . . . . . . . 0oC to 70oC

Junction Temperature Range. . . . . . . . . . . . . . . . . . . . 0oC to 125oC

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operationofthe

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

1. θJA is measured with the component mounted on an evaluation PC board in free air.

Electrical Specifications Recommended Operating Conditions, Unless Otherwise Noted. Refer to Figures 1, 2 and 3

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

VCC SUPPLY CURRENT

Thermal Resistance (Typical, Note 1) θJA (oC/W)

SOIC Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

SOIC Package (with 3 in2 of copper) . . . . . . . . . . . 65

Maximum Junction Temperature (Plastic Package) . . . . . . . .150oC

Maximum Storage Temperature Range. . . . . . . . . . -65oC to 150oC

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . .300oC

(SOIC - Lead Tips Only)

Nominal Supply I

POWER-ON RESET

Rising VCC Threshold V

Falling VCC Threshold V

Rising VIN2 Under-Voltage Threshold 2.45 2.55 2.65 V

VIN2 Under-Voltage Hysteresis - 500 - mV

Rising V

OSCILLATOR

Free Running Frequency RT = OPEN 185 200 215 kHz

Total Variation 6kΩ < RT to GND < 200kΩ -15 - +15 %

Ramp Amplitude ∆V

REFERENCE and DAC

DAC(VID0-VID4) Input Low Voltage - - 0.8 V

DAC(VID0-VID4) Input High Voltage 2.0 - - V

DACOUT Voltage Accuracy -1.0 - +1.0 %

Reference Voltage (Pin FB2 and FB3) 1.240 1.265 1.290 V

LINEAR REGULATOR

Threshold - 1.25 - V

OCSET1

CC

OSC

UGATE1, DRIVE3, LGATE1, and VOUT2 Open - 10 - mA

= 4.5V 8.6 - 10.4 V

OCSET

= 4.5V 8.2 - 10.2 V

OCSET

RT = Open - 1.9 - V

P-P

Regulation 10mA < I

Under-Voltage Level FB2

Under-Voltage Hysteresis -6- %

Over-Current Protection 180 230 - mA

Over-current Protection During Start-Up 560 700 - mA

LINEAR CONTROLLER

Regulation VSEN3 = DRIVE3, 0 < I

Under-Voltage Level FB3

FB2 Rising - 75 87 %

UV

FB3 Rising - 75 87 %

UV

< 150mA -2.5 - 2.5 %

VOUT2

< 20mA -2.5 - 2.5 %

DRIVE3

2-227

HIP6018

Electrical Specifications Recommended Operating Conditions, Unless Otherwise Noted. Refer to Figures 1, 2 and 3 (Continued)

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

Under-Voltage Hysteresis -6- %

DRIVE3 Source Current VIN2 - DRIVE3 > 0.6V 20 40 - mA

PWM CONTROLLER ERROR AMPLIFIER

DC Gain -88- dB

Gain-Bandwidth Product GBWP - 15 - MHz

Slew Rate SR COMP = 10pF - 6 - V/µs

PWM CONTROLLER GATE DRIVER

Upper Drive Source I

Upper Drive Sink R

Lower Drive Source I

Lower Drive Sink R

UGATE

UGATEVUGATE1-PHASE1

LGATE

LGATEVLGATE1

VCC = 12V, V

VCC = 12V, V

= 1V - 1.4 3.0 Ω

UGATE1

(or V

) = 6V - 1 - A

GATE2

= 1V - 1.7 3.5 Ω

= 1V - 1 - A

LGATE1

PROTECTION

Over-Voltage Trip VSEN1 Rising 112 115 118 %

V

OUT1

V

FAULT Sourcing Current I

OCSET1 Current Source I

Soft-Start Current I

OVP

OCSETVOCSET

SS

= 10V 10 14 - mA

FAULT

= 4.5V

DC

170 200 230 µA

-11- µA

Chip Shutdown Soft-Start Threshold - - 1.0 V

POWER GOOD

Upper Threshold VSEN1 Rising 108 - 110 %

V

OUT1

Under Voltage VSEN1 Rising 92 - 94 %

V

OUT1

Hysteresis (VSEN1 / DACOUT) Upper/Lower Threshold - 2 - %

V

OUT1

PGOOD Voltage Low V

PGOODIPGOOD

= -4mA - - 0.5 V

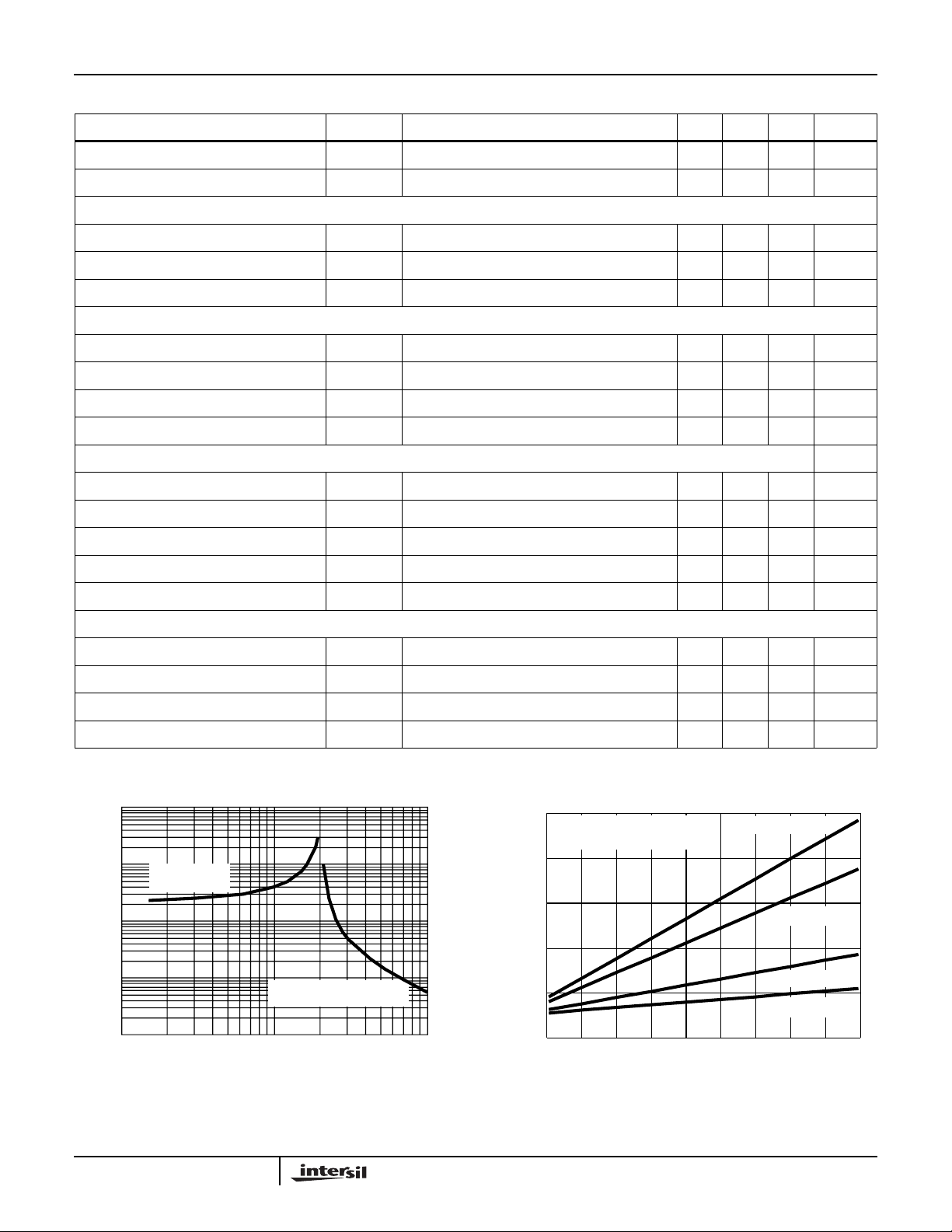

Typical Performance Curves

100

1000

100

RESISTANCE (kΩ)

10

RT PULLUP

TO +12V

RT PULLDOWN TO V

10 100 1000

SWITCHING FREQUENCY (kHz)

SS

80

60

(mA)

CC

I

40

20

0

100 200

C

V

UGATE1

= 12V, VIN = 5V

VCC

= C

300 400

= C

LGATE1

SWITCHING FREQUENCY (kHz)

GATE

600 700 800 900

500

C

FIGURE 4. RT RESISTANCE vs FREQUENCY FIGURE 5. BIAS SUPPLY CURRENT vs FREQUENCY

2-228

GATE

C

C

C

GATE

= 4800pF

GATE

GATE

= 3600pF

= 1500pF

= 660pF

1000

Loading...

Loading...