Intersil Corporation HI7190 Datasheet

March 1998

Semiconductor

HI7190

24-Bit, High Precision,

Sigma Delta A/D Converter

Features

• 22-Bit Resolution with No Missing Code

• 0.0007% Integral Non-Linearity (Typ)

• 20mV to ±2.5V Full Scale Input Ranges

• Internal PGIA with Gains of 1 to 128

• Serial Data I/O Interface, SPI Compatible

• Differential Analog and Reference Inputs

• Internal or System Calibration

• -120dB Rejection of 60/50Hz Line Noise

• Settling Time of 4 Conversions (Max) for a Step Input

Applications

• Process Control and Measurement

• Industrial Weight Scales

• Part Counting Scales

• Laboratory Instrumentation

• Seismic Monitoring

• Magnetic Field Monitoring

• Additional Reference Literature

- TB348 “HI7190/1 Negative Full Scale Error vs

Conversion Frequency”

- AN9504 “A Brief Intro to Sigma Delta Conversion”

- TB329 “Harris Sigma Delta Calibration Technique”

- AN9505 “Using the HI7190 Evaluation Kit”

- TB331 “Using the HI7190 Serial Interface”

- AN9527 “Interfacing HI7190 to a Microcontroller”

- AN9532 “Using HI7190 in a Multiplexed System”

- AN9601 “Using HI7190 with a Single +5V Supply”

Description

The Harris HI7190 is a monolithic instrumentation, sigma delta

A/D converter which operates from ±5V supplies. Both the signal and reference inputs are fully differential for maximum flexibility and performance. An internal Programmable Gain

Instrumentation Amplifier (PGIA) provides input gains from 1 to

128 eliminating the need for external pre-amplifiers. The ondemand converter auto-calibrate function is capable of removing offset and gain errors existing in external and internal circuitry. The on-board user programmable digital filter provides

over -120dB of 60/50Hz noise rejection and allows fine tuning

of resolution and conversion speed ov er a wide dynamic range .

The HI7190 and HI7191 are functionally the same device so all

discussion will refer to the HI7190 for simplicity.

The HI7190 contains a serial I/O port and is compatible with

most synchronous transfer formats including both the Motorola 6805/11 series SPI and Intel 8051 series SSR protocols.

A sophisticated set of commands gives the user control over

calibration, PGIA gain, device selection, standby mode, and

several other features. The On-chip Calibration Registers

allow the user to read and write calibration data.

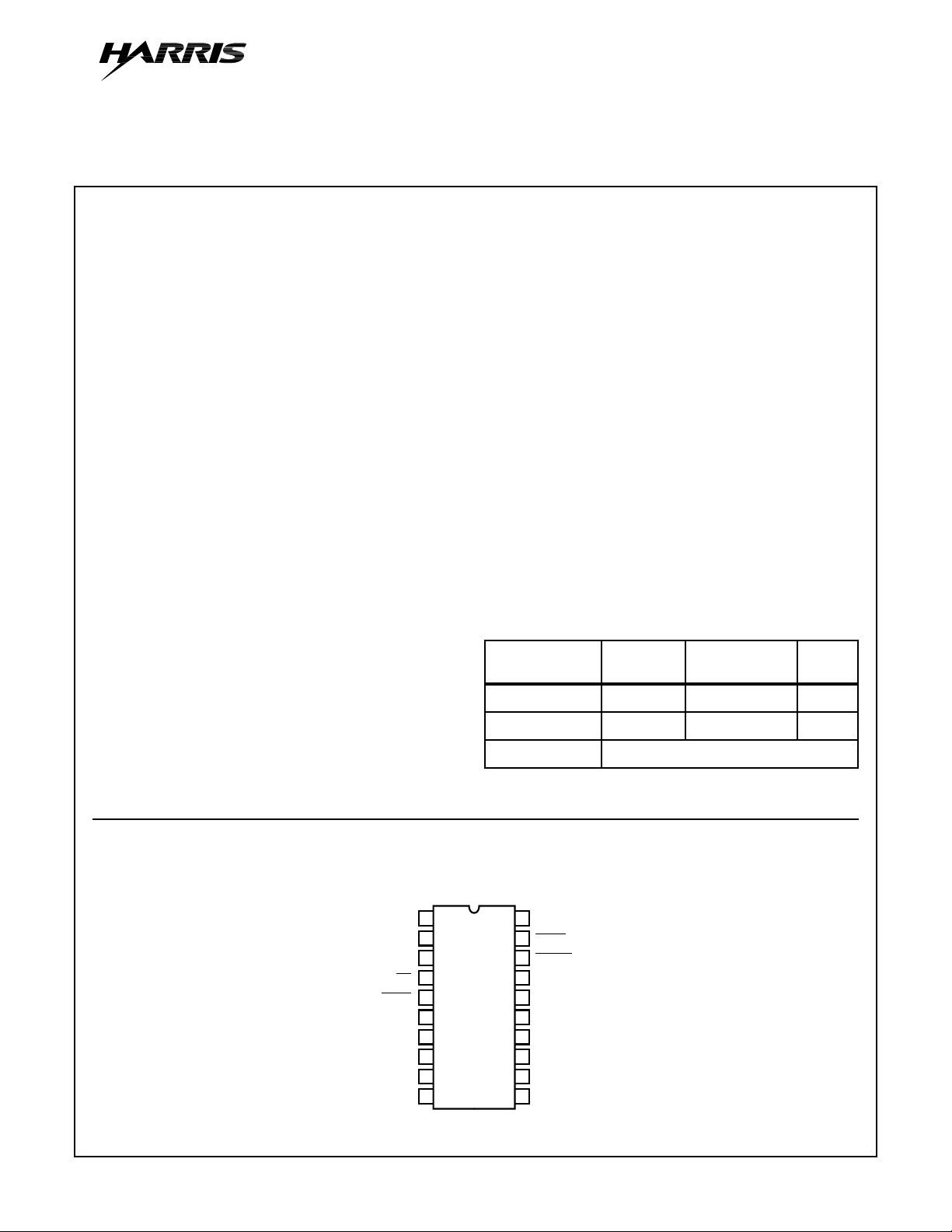

Ordering Information

TEMP.

PART NUMBER

HI7190IP -40 to 85 20 Ld PDIP E20.3

HI7190IB -40 to 85 20 Ld SOIC M20.3

HI7190EVAL Evaluation Kit

RANGE (oC) PACKAGE

PKG.

NO.

Pinout

HI7190

(PDIP, SOIC)

TOP VIEW

1

SCLK

SDO

2

SDIO

3

4

CS

5

DRDY

6

DGND

7

AV

SS

8

V

RLO

9

V

RHI

10

V

CM

CAUTION: These devices are sensitive to electrostatic discharge. Users should follow proper IC Handling Procedures.

Copyright

© Harris Corporation 1998

1871

20

19

18

17

16

15

14

13

12

11

MODE

SYNC

RESET

OSC

1

OSC

2

DV

DD

AGND

AV

DD

V

INHI

V

INLO

File Number 3612.5

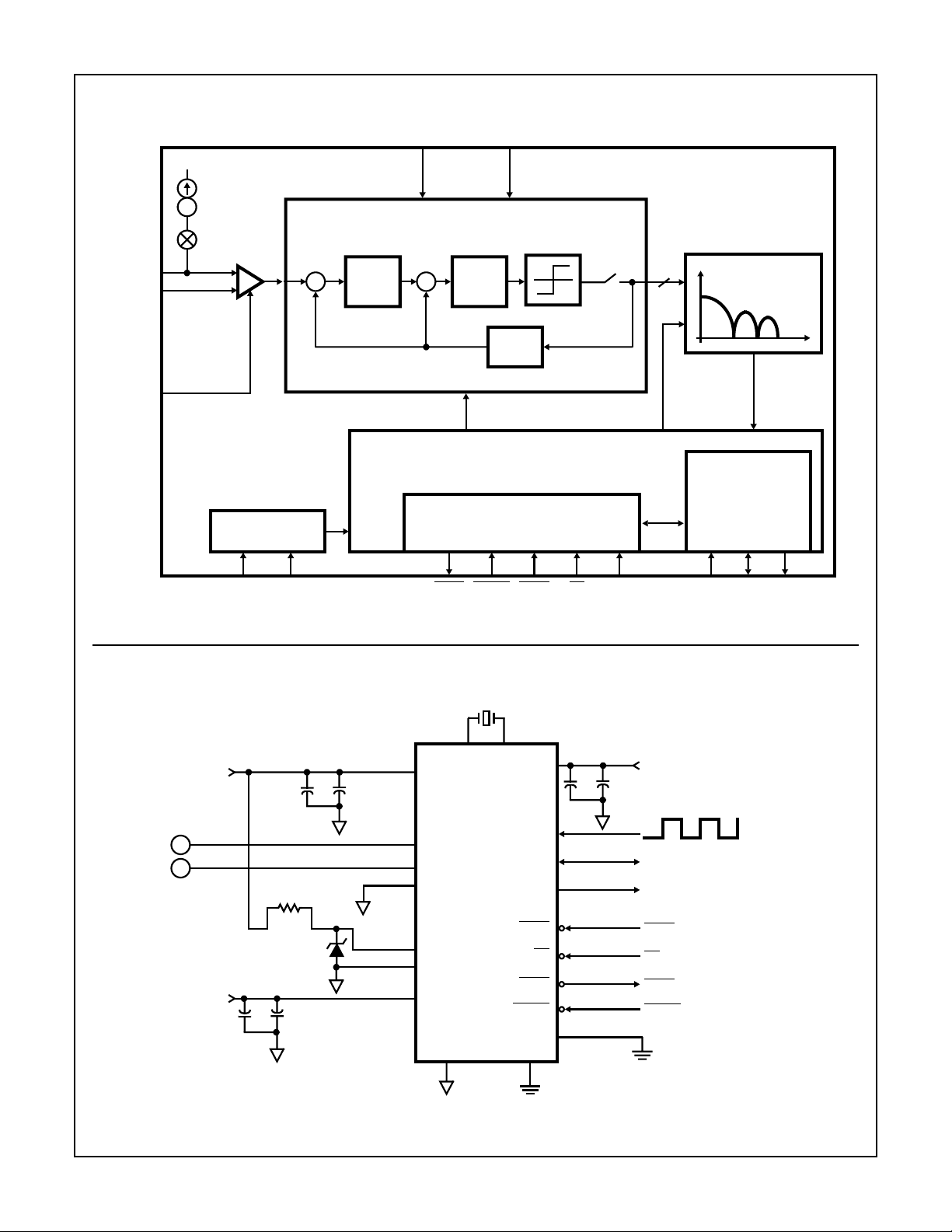

Functional Block Diagram

HI7190

V

V

INHI

INLO

V

CM

AV

DD

TRANSDUCER

BURN-OUT

CURRENT

PGIA

CLOCK

GENERATOR

V

RHI

REFERENCE

INPUTS

V

RLO

∑ − ∆

MODULATOR

∑

∫∫

∑

1-BIT

D/A

CONTROL AND SERIAL INTERFACE UNIT

CONTROL REGISTER

DIGITAL FILTER

1

SERIAL INTERFACE

UNIT

OSC1OSC

2

Typical Application Schematic

INPUT

INPUT

+5V

+

-

REFERENCE

-5V

0.1µF

R

+

+

0.1uF

1

+2.5V

4.7µF

4.7µF

DRDY RESET SYNC CS MODE S

10MHz

17 16

AV

V

INHI

V

INLO

V

CM

V

RHI

V

RLO

AV

AGND

DD

SS

OSC1OSC

14 6

13

12

11

10

9

8

7

2

RESET

MODE

DGND

DV

DD

SCLK

SDIO

SDO

SYNC

CS

DRDY

15

0.1µF

1

3

2

19

4

5

18

20

+

4.7µF

+5V

DATA I/O

DATA OUT

SYNC

CS

DRDY

RESET

CLK

SDIO SDO

1872

HI7190

Absolute Maximum Ratings Thermal Information

Supply Voltage

AVDD to AGND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+5.5V

AVSS to AGND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -5.5V

DVDD to DGND. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +5.5V

DGND to AGND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±0.3V

Analog Input Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . AVSS to AV

Digital Input, Output and I/O Pins. . . . . . . . . . . . . . . DGND to DV

ESD Tolerance (No Damage)

Human Body Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500V

Machine Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +100V

Charged Device Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1000V

Operating Conditions

Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . -40oC to 85oC

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

Thermal Resistance (Typical, Note 1) θJA (oC/W)

PDIP Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

SOIC Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Maximum Junction Temperature

Plastic Packages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .150oC

DD

Maximum Storage Temperature Range . . . . . . . . . .-65oC to 150oC

DD

Maximum Lead Temperature (Soldering, 10s) . . . . . . . . . . . . 300oC

(SOIC - Lead Tips Only)

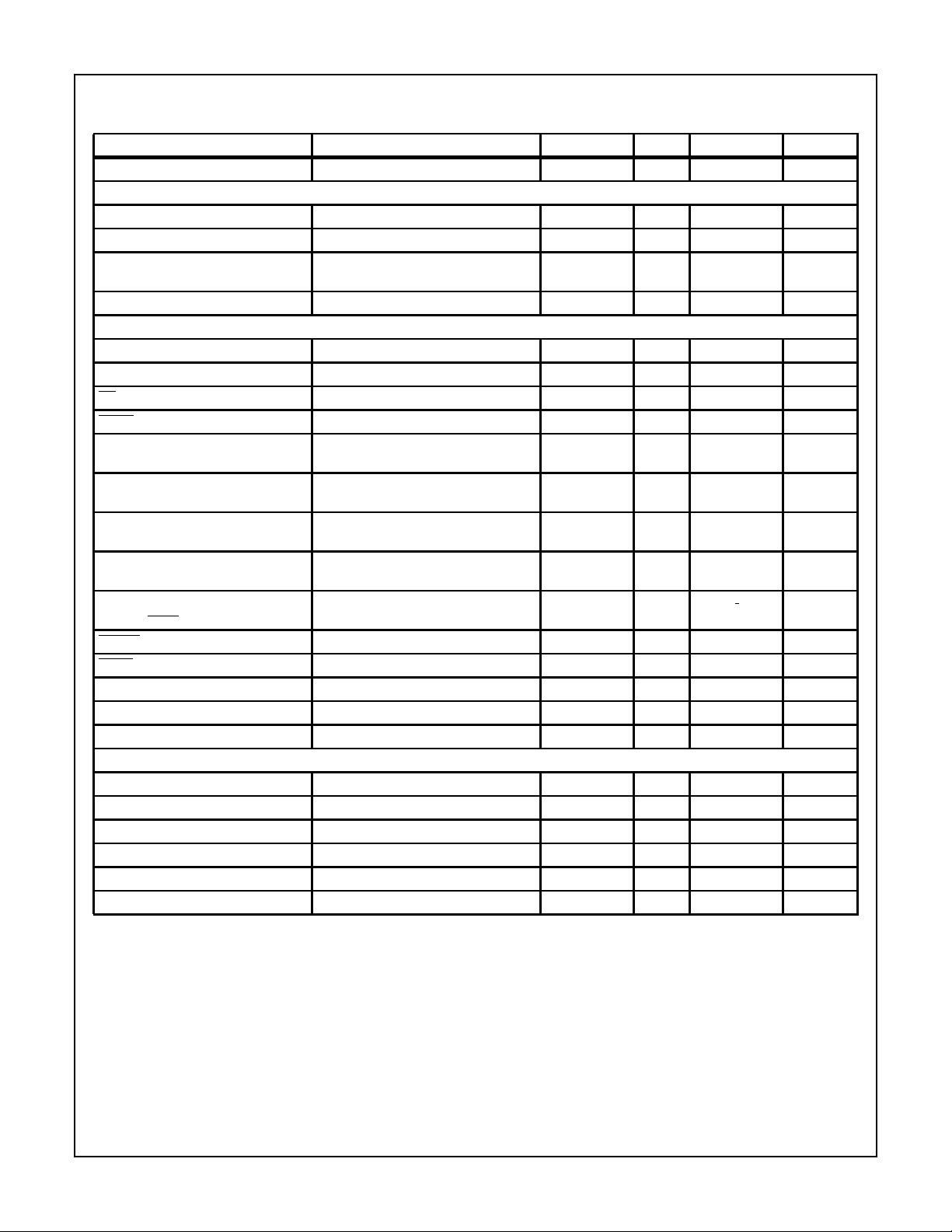

Electrical Specifications AV

= +5V, AVSS = -5V, DVDD = +5V, V

DD

= +2.5V, V

RHI

= AGND = 0V, VCM = AGND,

RLO

PGIA Gain = 1, OSCIN = 10MHz, Bipolar Input Range Selected, fN = 10Hz

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

SYSTEM PERFORMANCE

Integral Non-Linearity, INL End Point Line Method (Notes 3, 5, 6) - ±0.0007 ±0.0015 %FS

Differential Non-Linearity (Note 2) No Missing codes to 22-Bits LSB

Offset Error, V

OS

Offset Error Drift V

Full Scale Error, FSE V

Noise, e

N

Common Mode Rejection Ratio, CMRR V

See Table 1 - -- -

INHI

INHI

= V

- V

(Notes 3, 8) - 1 - µV/oC

INLO

= +2.5V (Notes 3, 5, 8, 10) - - - -

INLO

See Table 1 - - - -

CM

= 0V, V

INHI

= V

from -2V to +2V -70 - dB

INLO

Normal Mode 50Hz Rejection Filter Notch = 10Hz, 25Hz, 50Hz (Note 2) -120 - - dB

Normal Mode 60Hz Rejection Filter Notch = 10Hz, 30Hz, 60Hz (Note 2) -120 - - dB

Step Response Settling Time - 2 4 Conversions

ANALOG INPUTS

Input Voltage Range Unipolar Mode (Note 9) 0 - V

Input Voltage Range Bipolar Mode (Note 9) - V

Common Mode Input Range (Note 2) AV

Input Leakage Current, I

Input Capacitance, C

Reference Voltage Range, V

(V

= V

RHI

- V

REF

RLO

IN

IN

REF

)

Transducer Burn-Out Current, I

VIN = AVDD (Note 2) - - 1.0 nA

BO

REF

SS

- 5.0 -pF

2.5 - 5 V

- 200 - nA

-V

-AVDDV

REF

REF

V

V

CALIBRATION LIMITS

Positive Full Scale Calibration Limit - - 1.2(V

Negative Full Scale Calibration Limit - - 1.2(V

Offset Calibration Limit - - 1.2(V

Input Span 0.2(V

/Gain) - 2.4(V

REF

/Gain) -

REF

/Gain) -

REF

/Gain) -

REF

/Gain) -

REF

DIGITAL INPUTS

Input Logic High Voltage, V

Input Logic Low Voltage, V

Input Logic Current, I

I

IH

IL

(Note 11) 2.0 - - V

- - 0.8 V

VIN = 0V, +5V - 1.0 10 µA

1873

HI7190

Electrical Specifications AV

= +5V, AVSS = -5V, DVDD = +5V, V

DD

= +2.5V, V

RHI

= AGND = 0V, VCM = AGND,

RLO

PGIA Gain = 1, OSCIN = 10MHz, Bipolar Input Range Selected, fN = 10Hz (Continued)

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Input Capacitance, C

IN

VIN = 0V - 5.0 - pF

DIGITAL OUTPUTS

Output Logic High Voltage, V

Output Logic Low Voltage, V

OH

OL

Output Three-State Leakage Current,

I

OZ

Digital Output Capacitance, C

OUT

I

= -100µA (Note 7) 2.4 - - V

OUT

I

= 3mA (Note 7) - - 0.4 V

OUT

V

= 0V, +5V (Note 7) -10 1 10 µA

OUT

-10- pF

TIMING CHARACTERISTICS

SCLK Minimum Cycle Time, t

SCLK Minimum Pulse Width, t

CS to SCLK Precharge Time, t

SCLK

SCLKPW

PRE

200 - - ns

50 - - ns

50 - - ns

DRDY Minimum High Pulse Width (Notes 2, 7) 500 - - ns

Data Setup to SCLK Rising Edge

(Write), t

DSU

Data Hold from SCLK Rising Edge

(Write), t

DHLD

Data Read Access from Instruction

Byte Write, t

ACC

Read Bit Valid from SCLK Falling Edge,

t

DV

Last Data Transfer to Data Ready

Inactive,t

DRDY

(Note 7) - - 40 ns

(Note 7) - - 40 ns

(Note 7) - 35 -ns

50 - - ns

0-- ns

RESET Low Pulse Width (Note 2) 100 - - ns

SYNC Low Pulse Width (Note 2) 100 - - ns

Oscillator Clock Frequency (Note 2) 0.1 - 10 MHz

Output Rise/Fall Time (Note 2) - - 30 ns

Input Rise/Fall Time (Note 2) - - 1 µs

POWER SUPPLY CHARACTERISTICS

IAV

DD

IAV

SS

IDV

DD

Power Dissipation, Active PD

Power Dissipation, Standby PD

SCLK = 4MHz - - 3.0 mA

A

SB = ‘0’ - 15 30 mW

SB = ‘1’ - 5 - mW

S

- - 1.5 mA

- - 1.5 mA

PSRR (Note 3) - -70 - dB

NOTES:

1. θJA is measured with the component mounted on an evaluation PC board in free air.

2. Parameter guaranteed by design or characterization, not production tested.

3. Applies to both bipolar and unipolar input ranges.

4. These errors can be removed by re-calibrating at the desired operating temperature.

5. Applies after system calibration.

6. Fully differential input signal source is used.

7. See Load Test Circuit, Figure 10, R1 = 10kΩ, CL = 50pF.

8. 1 LSB = 298nV at 24 bits for a Full Scale Range of 5V.

9. V

= V

RHI

- V

RLO

REF

10. These errors are on the order of the output noise shown in Table 1.

11. All inputs except OSC1. The OSC1 input VIH is 3.5V minimum.

1874

Timing Diagrams

CS

SCLK

SDIO

HI7190

t

t

DHLD

SCLK

t

SCLKPW

t

PRE

t

DSU

1ST BIT 2ND BIT

t

SCLKPW

FIGURE 1. DATA WRITE TO HI7190

SCLK

SDIO

SDO

DRDY

CS

CS

t

ACC

1ST BIT 2ND BIT

t

DV

FIGURE 2. DATA READ FROM HI7190

t

DRDY

SCLK

SDIO

87651

FIGURE 3. DATA READ FROM HI7190

1875

HI7190

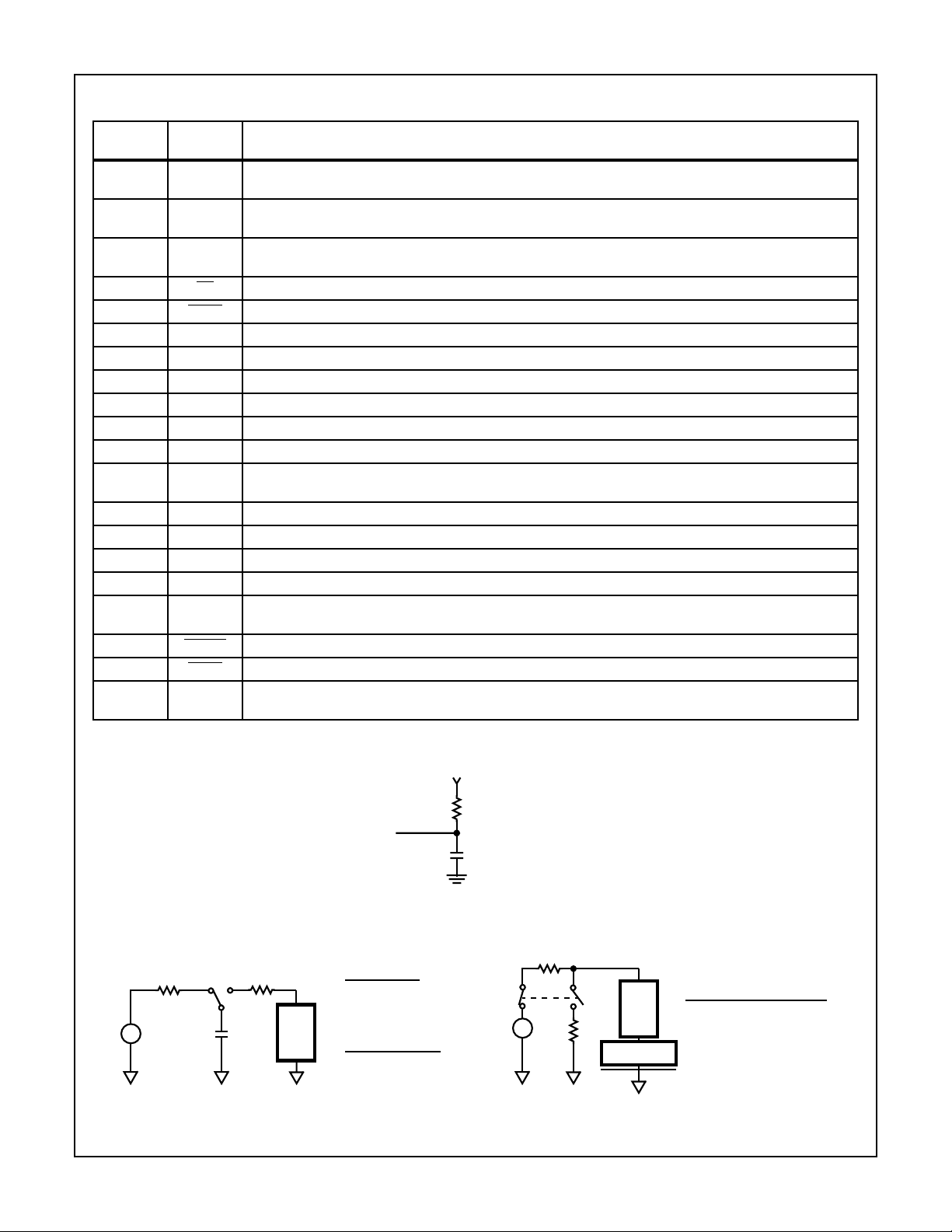

Pin Descriptions

20 LEAD

DIP, SOIC PIN NAME DESCRIPTION

1 SCLK Serial Interface Clock. Synchronizes serial data transfers. Data is input on the rising edge and output on the

falling edge.

2 SDO Serial Data OUT. Serial data is read from this line when using a 3-wire serial protocol such as the

Motorola Serial Peripheral Interface.

3 SDIO Serial Data IN or OUT. This line is bidirectional programmable and interfaces directly to the Intel Standard Serial

Interface using a 2-wire serial protocol.

4 CS Chip Select Input. Used to select the HI7190 for a serial data transfer cycle. This line can be tied to DGND.

5 DRDY An Active Low Interrupt indicating that a new data word is available for reading.

6 DGND Digital Supply Ground.

7AVSSNegative Analog Power Supply (-5V).

8V

RLO

9V

10 V

11 V

12 V

INLO

INHI

13 AV

14 AGND Analog Supply Ground.

15 DV

16 OSC2Used to connect a crystal source between OSC1 and OSC2. Leave open otherwise.

17 OSC1Oscillator Clock Input for the device. A crystal connected between OSC1 and OSC2will provide a clock to the

18 RESET Active Low Reset Pin. Used to initialize the HI7190 registers, filter and state machines.

19 SYNC Active Low Sync Input. Used to control the synchronization of a number of HI7190s . A logic ‘0’ initializes the converter .

20 MODE Mode Pin. Used to select between Synchronous Self Clocking (Mode = 1) or Synchronous External Clocking

External Reference Input. Should be negative referenced to V

External Reference Input. Should be positive referenced to V

RHI

Common Mode Input. Should be set to halfway between AVDD and AVSS.

CM

RHI

RLO

.

.

Analog Input LO. Negative input of the PGIA.

Analog Input HI. Positive input of the PGIA. The V

input is connected to a current source that can be used to check

INHI

the condition of an external transducer. This current source is controlled via the Control Register.

Positive Analog Power Supply (+5V).

DD

Positive Digital Supply (+5V).

DD

device, or an external oscillator can drive OSC1. The oscillator frequency should be 10MHz (Typ).

(Mode = 0) for the Serial Port.

Load Test Circuit

ESD Test Circuits

R

1

±

V

C

R

2

DUT

ESD

FIGURE 5A.

DUT

HUMAN BODY

= 100pF

C

ESD

R1 = 10MΩ

R2 = 1.5kΩ

MACHINE MODEL

C

= 200pF

ESD

R1 = 10MΩ

= 0Ω

R

2

V

1

R

1

CL (INCLUDES STRAY

CAPACITANCE)

FIGURE 4.

±

V

R

1

DUT

R

2

DIELECTRIC

CHARGED DEVICE MODEL

R1 = 1GΩ

R2 = 1Ω

FIGURE 5B.

1876

TABLE 1. NOISE PERFORMANCE WITH INPUTS CONNECTED TO ANALOG GROUND

P-P NOISE

HERTZ SNR ENOB

GAIN = 1

10 132.3 21.7 9.8 1.5

25 129.5 21.2 13.6 2.1

30 127.7 20.9 16.6 2.5

50 126.3 20.7 19.5 3.0

60 125.6 20.6 21.2 3.2

100 122.4 20.0 30.7 4.6

250 107.7 17.6 166.7 25.3

500 98.1 16.0 505.3 76.6

1000 85.7 13.9 2101.8 318.5

2000 68.8 11.1 14661.6 2221.4

GAIN = 2

10 129.2 21.2 14.0 2.1

25 125.7 20.6 20.9 3.2

30 124.5 20.4 24.1 3.7

50 123.4 20.2 27.3 4.1

60 122.5 20.1 30.3 4.6

100 118.1 19.3 50.0 7.6

250 106.1 17.3 199.5 30.2

500 96.9 15.8 580.1 87.9

1000 84.4 13.7 2435.6 369.0

2000 67.8 11.0 16469.7 2495.4

GAIN = 4

10 125.9 20.6 20.5 3.1

25 123.1 20.1 28.4 4.3

30 121.8 19.9 32.8 5.0

50 119.9 19.6 40.9 6.2

60 119.9 19.6 40.9 6.2

100 116.1 19.0 63.2 9.6

250 105.7 17.3 209.7 31.8

500 96.6 15.8 597.8 90.6

1000 84.3 13.7 2469.5 374.2

2000 68.2 11.0 15656.1 2372.1

GAIN = 8

10 124.7 20.4 23.4 3.5

25 120.6 19.7 37.8 5.7

30 119.2 19.5 44.3 6.7

50 117.5 19.2 53.8 8.2

60 116.8 19.1 58.6 8.9

100 112.1 18.3 100.0 15.2

250 101.4 16.5 345.2 52.3

500 95.3 15.5 691.1 104.7

1000 83.1 13.5 2838.6 430.1

2000 68.3 11.1 15494.7 2347.7

(µV)

RMS NOISE

(µV)

HI7190

GAIN = 16

GAIN = 32

GAIN = 64

GAIN = 128

P-P NOISE

HERTZ SNR ENOB

10 120.1 19.7 39.8 6.0

25 114.8 18.8 73.4 11.1

30 113.5 18.6 85.1 12.9

50 111.0 18.1 114.4 17.3

60 109.6 17.9 134.0 20.3

100 105.5 17.2 214.8 32.5

250 95.2 15.5 699.1 105.9

500 89.1 14.5 1417.7 214.8

1000 83.5 13.6 2686.0 407.0

2000 62.6 10.1 30110.0 4562.1

10 113.2 18.5 88.8 13.5

25 109.0 17.8 142.7 21.6

30 108.2 17.7 157.4 23.8

50 104.7 17.1 235.8 35.7

60 105.0 17.1 227.8 34.5

100 102.3 16.7 310.5 47.0

250 93.4 15.2 861.1 130.5

500 87.1 14.2 1782.7 270.1

1000 78.2 12.7 4990.4 756.1

2000 57.0 9.2 57311.1 8683.5

10 106.7 17.4 186.2 28.2

25 102.9 16.8 288.4 43.7

30 101.9 16.6 325.8 49.4

50 98.5 16.1 479.8 72.7

60 98.9 16.1 459.8 69.7

100 96.3 15.7 620.2 94.0

250 85.5 13.9 2133.5 323.3

500 78.1 12.7 5025.0 761.4

1000 66.7 10.8 18693.5 2832.3

2000 50.5 8.1 120163.0 18206.5

10 101.1 16.5 356.5 54.0

25 96.0 15.7 638.3 96.7

30 95.2 15.5 704.8 106.8

50 93.2 15.2 882.2 133.7

60 92.2 15.0 996.7 151.0

100 91.4 14.9 1086.6 164.6

250 79.4 12.9 4346.4 658.5

500 71.8 11.6 10439.2 1581.7

1000 60.1 9.7 39923.0 6048.9

2000 44.8 7.1 233238.2 35339.1

(µV)

RMS NOISE

(µV)

1877

HI7190

Definitions

Integral Non-Linearity, INL, is the maximum deviation of

any digital code from a straight line passing through the endpoints of the transfer function. The endpoints of the transfer

function are zero scale (a point 0.5 LSB below the first code

transition 000...000 and 000...001) and full scale (a point 0.5

LSB above the last code transition 111...110 to 111...111).

Differential Non-Linearity, DNL, is the deviation from the

actual difference between midpoints and the ideal difference

between midpoints (1 LSB) for adjacent codes. If this difference is equal to or more negative than 1 LSB, a code will be

missed.

Offset Error , V

from the ideal input voltage (V

be calibrated to the order of the noise level sho wn in Table 1.

Full Scale Error, FSE, is the deviation of the last code

transition from the ideal input full scale voltage

(V

-+V

IN

REF

to the order of the noise level shown in Table 1.

Input Span, defines the minimum and maximum input

voltages the device can handle while still calibrating properly

for gain.

Noise, e

, Table 1 shows the peak-to-peak and RMS noise

N

for typical notch and -3dB frequencies. The device programming was for bipolar input with a V

the input range is 5V. The analysis was performed on 100

conversions with the peak-to-peak output noise being the

difference between the maximum and minimum readings

over a rolling 10 conversion window . The equation to convert

the peak-to-peak noise data to ENOB is:

ENOB = Log

where: V

FS

CF = 6.6 (Imperical Crest Factor)

The noise from the part comes from two sources, the

quantization noise from the analog-to-digital conversion process and device noise. Device noise (or Wideband Noise) is

independent of gain and essentially flat across the frequency

spectrum. Quantization noise is ratiometric to input full scale

(and hence gain) and its frequency response is shaped by

the modulator.

Looking at Table 1, as the cutoff frequency increases the

output noise increases. This is due to more of the

quantization noise of the part coming through to the output

and, hence, the output noise increases with increasing 3dB frequencies. For the lower notch settings, the output

noise is dominated by the device noise and, hence, altering

the gain has little effect on the output noise. At higher notch

frequencies, the quantization noise dominates the output

noise and, in this case, the output noise tends to decrease

with increasing gain.

Since the output noise comes from two sources, the effectiv e

resolution of the device (i.e., the ratio of the input full scale to

the output RMS noise) does not remain constant with

increasing gain or with increasing bandwidth. It is possible to

, is the deviation of the first code transition

OS

- 0.5 LSB). This error can

IN

/Gain - 1.5 LSB). This error can be calibrated

of +2.5V. This implies

REF

(VFS / V

2

= 5V, V

NRMS

NRMS

= V

)

NP-P

/ CF and

do post-filtering (such as brick wall filtering) on the data to

improve the ov erall resolution for a given -3dB frequency and

also to further reduce the output noise.

Circuit Description

The HI7190 is a monolithic, sigma delta A/D converter which

operates from ±5V supplies and is intended for

measurement of wide dynamic range, low frequency signals.

It contains a Programmable Gain Instrumentation Amplifier

(PGIA), sigma delta ADC, digital filter, bidirectional serial

port (compatible with many industry standard protocols),

clock oscillator, and an on-chip controller.

The signal and reference inputs are fully differential for

maximum flexibility and performance. Normally V

V

are tied to +2.5V and AGND respectively. This allows

RLO

for input ranges of 2.5V and 5V when operating in the unipolar and bipolar modes respectively (assuming the PGIA is

configured for a gain of 1). The internal PGIA provides input

gains from 1 to 128 and eliminates the need for external preamplifiers. This means the device will convert signals ranging from 0V to +20mV and 0V to +2.5V when operating in

the unipolar mode or signals in the range of ±20mV to ±2.5V

when operating in the bipolar mode.

The input signal is continuously sampled at the input to the

HI7190 at a clock rate set by the oscillator frequency and the

selected gain. This signal then passes through the sigma

delta modulator (which includes the PGIA) and emerges as

a pulse train whose code density contains the analog signal

information. The output of the modulator is fed into the sinc

digital low pass filter. The filter output passes into the

calibration block where offset and gain errors are removed.

The calibrated data is then coded (2’s complement, offset

binary or binary) before being stored in the Data Output

Register. The Data Output Register update rate is determined by the first notch frequency of the digital filter. This

first notch frequency is programmed into HI7190 via the

Control Register and has a range of 10Hz to 1.953kHz which

corresponds to -3dB frequencies of 2.62Hz and 512Hz

respectively.

Output data coding on the HI7190 is programmable via the

Control Register. When operating in bipolar mode, data output can be either 2’s complement or offset binary. In unipolar

mode output is binary.

The

DRDY signal is used to alert the user that new output

data is available. Converted data is read via the HI7190

serial I/O port which is compatible with most synchronous

transfer formats including both the Motorola 6805/11 series

SPI and Intel 8051 series SSR protocols. Data Integrity is

always maintained at the HI7190 output port. This means

that if a data read of conversion N is begun but not finished

before the next conversion (conversion N + 1) is complete,

the

DRDY line remains active (low) and the data being read

is not overwritten.

The HI7190 provides many calibration modes that can be

initiated at any time by writing to the Control Register. The

device can perform system calibration where external components are included with the HI7190 in the calibration loop

RHI

and

3

1878

Loading...

Loading...