Page 1

查询5962-9859101NXB供应商

TM

HI5905N/QML

Data Sheet July 1999

14-Bit, 5 MSPS, Military A/D Converter

The HI5905N/QML is a monolithic, 14-bit, 5MSPS Analogto-Digital Converter fabricated in an advanced BiCMOS

process. It is designed for high speed, high resolution

applications where wide bandwidth, low power consumption

and excellent SINAD performance are essential. With a

100MHz full power input bandwidth and high frequency

accuracy, the converter is ideal for many Military types of

communication systems employing digital IF architectures.

The HI5905N/QMLis designed in a fully differential pipelined

architecture with a front end differential-in-differential-out

sample-and-hold amplifier (S/H). Consuming 350mW (typ)

power at 5MSPS, the HI5905N/QML has excellent dynamic

performance over the full Military temperature range.

Data output latches are provided which present valid data to

the output bus with a data latency of only 4 clock cycles.

Specifications for QML devices are controlled by the

Defense Supply Center in Columbus (DSCC). The SMD

numbers listed below must be used when ordering.

Detailed Electrical Specifications for the HI5905N/QML

are contained in SMD 5962-98591. That document may

be easily downloaded from our website.

http://www.Intersil.com/data/sm/index.htm

Pinout

HI5905 (MQFP) (MO-108AA-2 ISSUE A)

TOP VIEW

File Number 4718.1

Features

• QML Compliant per SMD 5962-9859101NXB

• Sampling Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . .5MSPS

• Low Power at 5MSPS. . . . . . . . . . . . . . . . . 400mW (Max)

• Internal Sample and Hold

• Fully Differential Architecture

• Full Power Input Bandwidth . . . . . . . . . . . . . . . . . 100MHz

• SINAD at 1MHz . . . . . . . . . . . . . . . . . . . . . . >69dB (Min)

• Internal Voltage Reference

• TTL Compatible Clock Input

• CMOS Compatible Digital Data Outputs

Applications

• Digital Communication Systems

• Undersampling Digital IF

• Asymmetric Digital Subscriber Line (ADSL)

• Document Scanners

• Reference Literature

- AN9214, Using Intersil High Speed A/D Converters

- AN9785, Using the Intersil HI5905 EVAL2 Evaluation

Board

Ordering Information

D

NC

NC

GND1

NC

AV

A

GND

NC

NC

V

IN+

V

V

CC

IN-

DC

CC1

CC1

GND1

NC

DV

DV

D

44 43 42 41 40

1

2

3

4

5

6

7

8

9

10

11

12 13 14 15 16 17

NC

RIN

GND

V

ROUT

A

V

4-1

CLKNCD0D1D2NCNC

39 38 37 36 35 34

CC

NC

D13

AV

D12

D11

2221201918

D10

33

32

31

30

29

28

27

26

25

24

23

NC

ORDERING

NUMBER

INTERNAL INTERSIL

MKT. NUMBER

TEMP.

RANGE(oC)

5962-9859101NXB HI5905N/QML -55 to 125

HI5905EVAL2 Low Frequency Platform 25

D3

D4

D5

D6

D7

NC

DV

CC2

D

GND2

D8

D9

NC

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-724-7143

| Copyright © Intersil Corporation 1999

Page 2

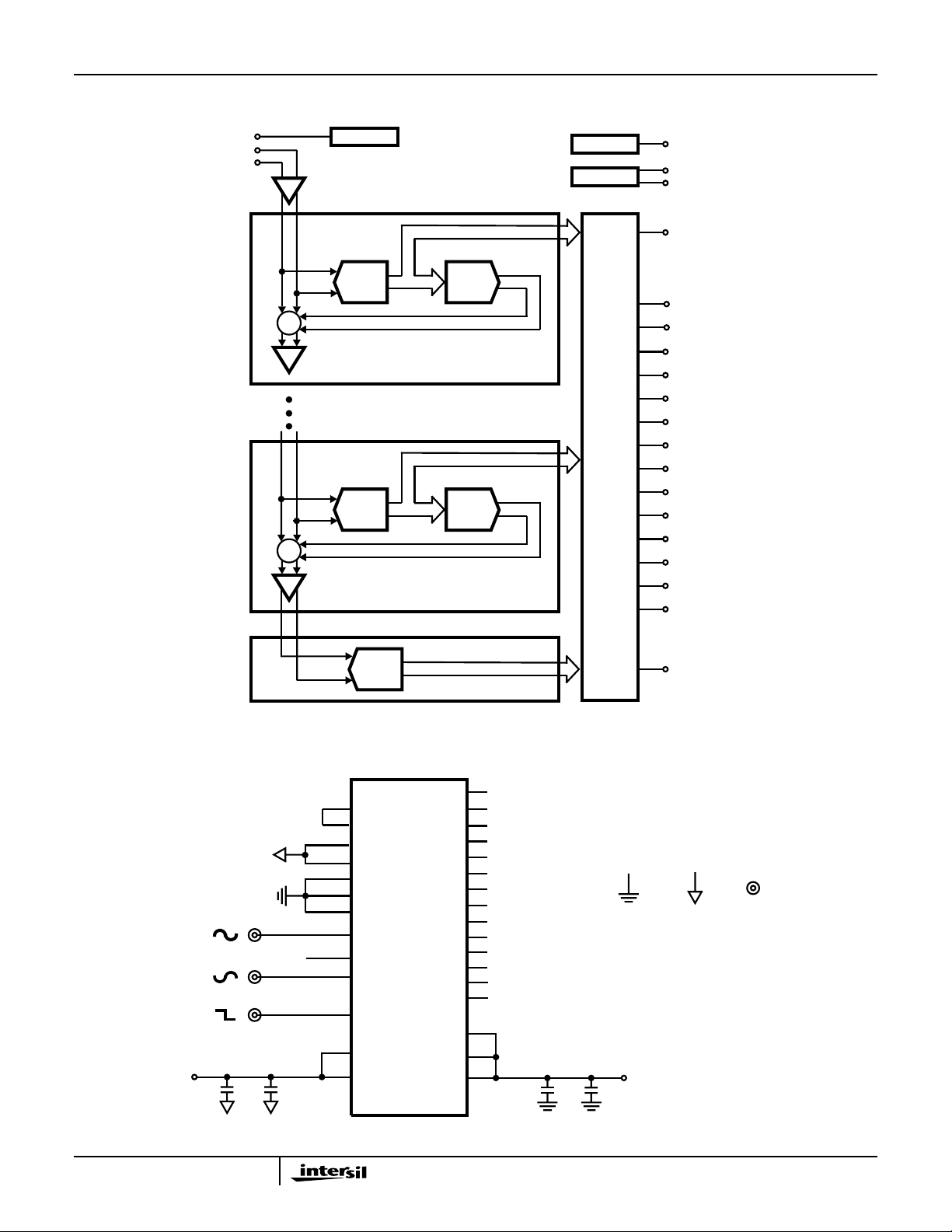

Functional Block Diagram

V

DC

V

IN

VIN+

-

BIAS

S/H

CLOCK

REF

CLK

V

ROUT

V

RIN

STAGE 1

DV

CC2

X8

4-BIT

FLASH

+

-

∑

4-BIT

DAC

D13 (MSB)

D12

D11

D10

D9

STAGE 4

D8

D7

X8

AND

4-BIT

FLASH

4-BIT

DAC

+

-

∑

DIGITAL DELAY

DIGITAL ERROR CORRECTION

D6

D5

D4

D3

D2

D1

D0 (LSB)

STAGE 5

AV

CCAGNDDVCC1DGND1

Typical Application Schematic

+

V

IN

VIN-

CLOCK

+5V

10µF

+

0.1µF

4-BIT

FLASH

V

ROUT

V

(14)

RIN

A

(6)

GND

A

(15)

GND

D

GND1

D

GND1

D

GND2

VIN+ (9)

VDC (11)

V

- (10)

IN

(MSB) D13 (18)

CLK (40)

AVCC (5)

AV

(16)

CC

(LSB) D0 (38)

D1 (37)

(13)

D2 (36)

D3 (33)

D4 (32)

D5 (31)

(3)

D6 (30)

(42)

D7 (29)

(26)

D8 (25)

D9 (24)

D10 (21)

D11 (20)

D12 (19)

DV

CC1

DV

(43)

CC1

(27)

DV

CC2

(41)

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

0.1µF

D

GND2

D

GND

A

GND

BNC

10µF AND 0.1µF CAPS ARE PLACED

AS CLOSE TO PART AS POSSIBLE

+5V

+

10µF

4-2

HI5905

Page 3

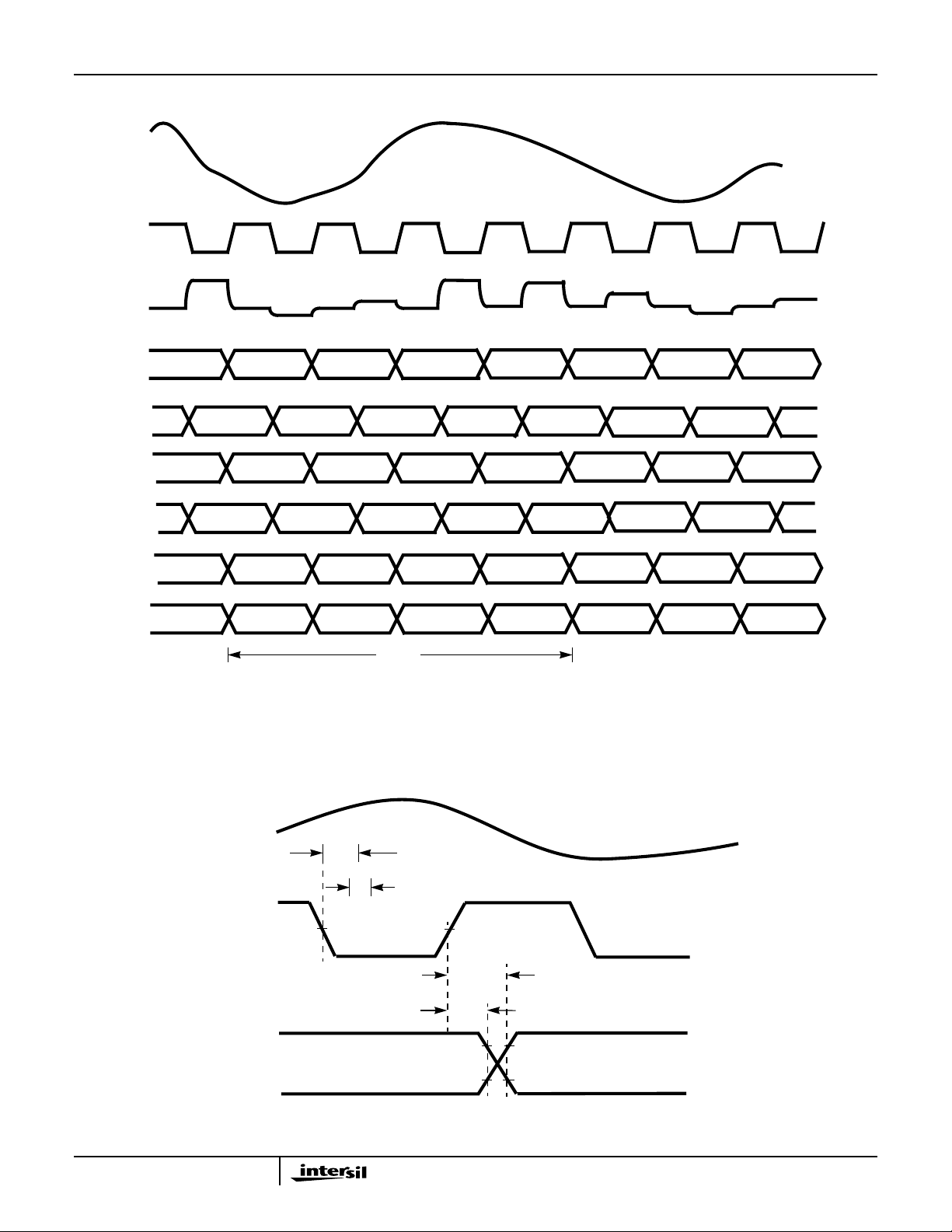

Timing Waveforms

ANALOG

INPUT

CLOCK

INPUT

S

N - 1HN - 1SN

INPUT

S/H

1ST

STAGE

2ND

STAGE

B2,

3RD

STAGE

4TH

STAGE

B4,

5TH

STAGE

DAT A

OUTPUT

NOTES:

1. SN: N-th sampling period.

2. HN: N-th holding period.

N - 2

N - 3

B1,

B3,

B

5, N - 3

D

N - 1

N - 2

N - 4

HNS

N + 1HN + 1SN + 2HN + 2SN + 3HN + 3SN + 4HN + 4SN + 5HN + 5SN + 6HN + 6

B2,

B4,

N - 1

N - 2

B

B3,

B5,

D

1, N

N - 1

N - 2

N - 3

B2,

B4,

t

LAT

N

N - 1

B

1, N + 1

B3,

B5,

D

N

N - 1

N - 2

B2,

B4,

N + 1

N

B

B3,

B5,

3. B

B

N + 2

N + 1

1, N + 3

B3,

B5,

D

N + 2

N + 1

N

1, N + 2

B2,

N + 1

B4,

N

D

N - 1

:M-thstage digital output corresponding to N-th sampledinput.

M, N

B2,

B4,

N + 3

N + 2

B

1, N + 4

B3,

B5,

D

B2,

N + 3

B4,

N + 2

N + 1

4. DN: Final data output corresponding to N-th sampled input.

FIGURE 1. INTERNAL CIRCUIT TIMING

N + 4

N + 3

B

1, N + 5

B3,

B5,

D

N + 4

N + 3

N + 2

ANALOG

INPUT

CLOCK

INPUT

DAT A

OUTPUT

4-3

1.5V

t

AP

t

AJ

1.5V

t

OD

t

H

3.5V

DATA N-1 DATA N

1.5V

FIGURE 2. INPUT-TO-OUTPUT TIMING

Page 4

Pin Descriptions

PIN # NAME DESCRIPTION

1 NC No Connection

2 NC No Connection

3D

4 NC No Connection

5AVCCAnalog Supply (5.0V)

6A

7 NC No Connection

8 NC No Connection

9V

10 VIN- Negative Analog Input

11 V

12 NC No Connection

13 V

14 V

15 A

16 AV

17 NC No Connection

18 D13 Data Bit 11 Output (MSB)

19 D12 Data Bit 11 Output

20 D11 Data Bit 11 Output

21 D10 Data Bit 10 Output

22 NC No Connection

23 NC No Connection

24 D9 Data Bit 9 Output

25 D8 Data Bit 8 Output

26 D

27 DV

28 NC No Connection

29 D7 Data Bit 7 Output

30 D6 Data Bit 6 Output

31 D5 Data Bit 5 Output

32 D4 Data Bit 4 Output

33 D3 Data Bit 3 Output

34 NC No Connection

35 NC No Connection

36 D2 Data Bit 2 Output

37 D1 Data Bit 1 Output

38 D0 Data Bit 0 Output (LSB)

39 NC No Connection

40 CLK Input Clock

41 DV

42 D

43 DV

44 NC No Connection

GND1

GND

IN

DC

ROUT

RIN

GND

GND2

GND1

Digital Ground

Analog Ground

+ Positive Analog Input

DC Bias Voltage Output

Reference Voltage Output

Reference Voltage Input

Analog Ground

Analog Supply (5.0V)

CC

Digital Ground

Digital Supply (5.0V)

CC2

Digital Supply (5.0V)

CC1

Digital Ground

Digital Supply (5.0V)

CC1

Detailed Description

Theory of Operation

The HI5905 is a 14-bit fully differential sampling pipeline A/D

converter with digital error correction. Figure 3 depicts the

circuit for the front end differential-in-differential-out sampleand-hold (S/H). The switches are controlled by an internal

clock which is a non-overlapping two phase signal, φ

φ

, derived from the master clock. During the sampling

2

phase, φ

capacitors, C

, the input signal is applied to the sampling

1

. At the same time the holding capacitors, CH,

S

are discharged to analog ground. At the falling edge of φ

the input signal is sampled on the bottom plates of the

sampling capacitors. In the next clock phase, φ

bottom plates of the sampling capacitors are connected

together and the holding capacitors are switched to the op

amp output nodes. The charge then redistributes between

C

and CH completing one sample-and-hold cycle. The

S

output is a fully-differential, sampled-data representation of

the analog input. The circuit not only performs the sampleand-hold function but will also convert a single-ended input

to a fully-differential output for the converter core. During the

sampling phase, the V

switch and C

. The relatively small values of these

S

pins see only the on-resistance of a

IN

components result in a typical full power input bandwidth of

100MHz for the converter.

φ

1

φ

1

C

VIN+

V

-

IN

FIGURE 3. ANALOG INPUT SAMPLE-AND-HOLD

S

φ

2

C

S

φ

1

φ

1

-

+ -

+

φ

C

C

1

H

H

φ

1

As illustrated in the functional block diagram and the timing

diagram in Figure 1, four identical pipeline subconverter

stages, each containing a four-bit flash converter, a four-bit

digital-to-analog converter and an amplifier with a voltage

gain of 8, follow the S/H circuit with the fifth stage being only

a 4-bit flash converter. Each converter stage in the pipeline

will be sampling in one phase and amplifying in the other

clock phase. Each individual sub-converter clock signal is

offset by 180 degrees from the previous stage clock signal,

with the result that alternate stages in the pipeline will

perform the same operation.

The output of each of the four-bit subconverter stages is a

four-bit digital word containing a supplementary bit to be

used by the digital error correction logic. The output of each

subconverter stage is input to a digital delay line which is

controlled by the internal sampling clock. The function of the

digital delay line is to time align the digital outputs of the four

, the two

2

V

OUT

V

OUT

and

1

+

-

1

4-4

Page 5

identical four-bit subconverter stages with the corresponding

output of the fifth stage flash converter before applying the

twenty bit result to the digital error correction logic. The

digital error correction logic uses the supplementary bits to

correct any error that may exist before generating the final

fourteen bit digital data output of the converter.

Because of the pipeline nature of this converter, the digital

data representing an analog input sample is output to the

digital data bus on the 4th cycle of the clock after the analog

sample is taken. This time delay is specified as the data

latency. After the data latency time, the digital data

representing each succeeding analog sample is output

during the following clock cycle. The digital output data is

synchronized to the external sampling clock with a latch. The

digital output data is available in two’s complement binary

format (see Table 1, A/D Code Table).

Internal Reference Generator, V

ROUT

and V

RIN

The HI5905 has an internal reference generator, therefore, no

external reference voltage is required. V

connected to V

when using the internal reference voltage.

RIN

ROUT

must be

The HI5905 can be used with an external reference. The

converter requires only one external reference voltage

connected to the V

The HI5905 is tested with V

to V

. Internal to the converter, two reference voltages of

RIN

pin with V

RIN

left open.

ROUT

, equal to 4.0V, connected

ROUT

1.3V and 3.3V are generated for a fully differential input

signal range of ±2V.

In order to minimize overall converter noise, it is

recommended that adequate high frequency decoupling be

provided at the reference voltage input pin, V

RIN

.

Analog Input, Differential Connection

The analog input to the HI5905 can be configured in various

ways depending on the signal source and the required level

of performance. A fully differential connection (Figure 4) will

give the best performance for the converter.

Since the HI5905 is powered off a single +5V supply, the

analog input must be biased so it lies within the analog input

common mode voltage range of 1.0V to 4.0V. The

performance of the ADC does not change significantly with

the value of the analog input common mode voltage.

V

IN

-V

IN

FIGURE 4. AC COUPLED DIFFERENTIAL INPUT

A 2.3V DC bias voltage source, V

DC

VIN+

HI5905

V

DC

VIN-

, half way between the

top and bottom internal reference voltages, is made

available to the user to help simplify circuit design when

using a differential input. This low output impedance voltage

source is not designed to be a reference but makes an

excellent bias source and stays within the analog input

common mode voltage range over temperature.

The difference between the con v erter’s tw o internal voltage

references is 2V. For the A C coupled diff erential input,(Figure

4), if V

phase with V

bias voltage equal to V

on a DC bias voltage equal to V

IN

is a 2V

P-P

, then VIN+ is a 2V

IN

sinewav ewith -VINbeing180 degrees out of

sinewav e riding on a DC

P-P

and VIN- is a 2V

DC

. Consequently ,theconverter

DC

sinewav e riding

P-P

will be at positive full scale,resulting in a digital data output code

with D13 (MSB) equal to a logic “0” and D0-D12 equal to logic

“1” (see Table 1, A/D Code Table), when the V

V

+1V and the VIN- input is at VDC-1V (VIN+- VIN- = 2V).

DC

+ input is at

IN

Conversely, the ADC will be at negative full scale, resulting in a

digital data output code with D13 (MSB) equal to a logic “1” and

D0-D12 equal to logic “0” (see Table 1, A/D Code Table), when

the V

+ input is equal to VDC-1V and VIN- is at VDC+1V

IN

(V

+-VIN- = -2V). From this, the con v erter is seen to hav e a

IN

peak-to-peak differential analog input v oltage range of 2V.

The analog input can be DC coupled (Figure 5) as long as

the inputs are within the analog input common mode voltage

range (1.0V ≤ VDC ≤ 4.0V).

TABLE 1. A/D CODE TABLE

DIFFERENTIAL

CODE

CENTER

DESCRIPTION

+Full Scale

(+FS) - 1/4 LSB

+FS - 1 1/4 LSB 1.99969V 0 1 1 1 1 1 1 1 1 1 1 1 1 0

+ 3/4 LSB 183.105µV 00000000000000

- 1/4 LSB -61.035µV 11111111111111

-FS + 1 3/4 LSB -1.99957V 1 0 0 0 0 0 0 0 0 0 0 0 0 1

-Full Scale

(-FS) + 3/4 LSB

INPUTVOLTAGE

(USING INTERNAL

REFERENCE)

+1.99994V 0 1 1 1 1 1 1 1 1 1 1 1 1 1

-1.99982V 1 0 0 0 0 0 0 0 0 0 0 0 0 0

†

MSB LSB

D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

TWO’S COMPLEMENT BINARY OUTPUT CODE

† The voltages listed above represent the ideal center of each two’s complement binary output code shown.

4-5

Page 6

V

IN

VDC

R

-V

IN

VDC

FIGURE 5. DC COUPLED DIFFERENTIAL INPUT

R

VIN+

V

DC

VIN-

HI5905

C

The resistors, R, in Figure 5 are not absolutely necessary

but may be used as load setting resistors. A capacitor, C,

connected from V

+ to VIN- will help filter any high

IN

frequency noise on the inputs, also improving performance.

Values around 20pF are sufficient and can be used on AC

coupled inputs as well. Note, however, that the value of

capacitor C chosen must take into account the highest

frequency component of the analog input signal.

Analog Input, Single-Ended Connection

The configuration shown in Figure 6 may be used with a

single ended AC coupled input. Sufficient headroom must

be provided such that the input voltage never goes above

+5V or below A

GND

.

The resistor, R, in Figure 7 is not absolutely necessary but

may be used as a load setting resistor . A capacitor, C,

connected from V

+toVIN- will help filter any high frequency

IN

noise on the inputs, also improving performance. Values

around 20pF are sufficient and can be used on AC coupled

inputs as well. Note, howe ver, that the value of capacitor C

chosen must take into account the highest frequency

component of the analog input signal.

A single ended source will give better overall system

performance if it is first converted to differential before

driving the HI5905.

Digital I/O and Clock Requirements

The HI5905 provides a standard high-speed interface to

external TTL/CMOS logic families. The digital CMOS clock

input has TTL level thresholds. The low input bias current

allows the HI5905 to be driven by CMOS logic. The digital

CMOS outputs have a separate +5.0V digital supply input pin.

In order to ensure rated performance of the HI5905, the duty

cycle of the clock should be held at 50% ±5%. It must also

have low jitter and operate at standard TTL levels.

Performance of the HI5905 will only be guaranteed at

conversion rates above 0.5MSPS. This ensures proper

performance of the internal dynamic circuits.

V

IN

VDC

FIGURE 6. AC COUPLED SINGLE ENDED INPUT

VIN+

HI5905

VIN-

Again, the difference between the two internal voltage

references is 2V. If V

4V

sinewav eriding on a positive voltage equal to VDC. The

P-P

converter will be at positivefull scale when V

(V

+ - VIN- = 2V) and will be at negative full scale when VIN+

IN

is equal to VDC - 2V (V

is a 4V

IN

+ - VIN- = -2V). In this case, VDC

IN

sinewav e , then VIN+ is a

P-P

+isatVDC+2V

IN

could range between 2V and 3V without a significant change in

ADC performance. The simplest way to produce VDC is to use

the V

bias voltage output of the HI5905.

DC

The single ended analog input can be DC coupled (Figure 7)

as long as the input is within the analog input common mode

voltage range.

V

IN

VDC

R

VDC

FIGURE 7. DC COUPLED SINGLE ENDED INPUT

VIN+

C

HI5905

VIN-

Supply and Ground Considerations

The HI5905 has separate analog and digital supply and ground

pins to keepdigital noise out of the analog signal path. The part

should be mounted on a board that provides separate low

impedance connections for the analog and digital supplies and

grounds. For best perf ormance, the supplies to the HI5905

should be driven by clean, linear regulated supplies. The board

should also have good high frequency decoupling capacitors

mounted as close as possible to the converter . If the part is

powered off a single supply then the analog supply and ground

pins should be isolated by ferrite beads from the digital supply

and ground pins.

Refer to the Application Note AN9214, “Using Intersil High

Speed A/D Converters” for additional considerations when

using high speed converters.

Static Performance Definitions

Offset Error (VOS)

The midscale code transition should occur at a level 1/4 LSB

above half-scale. Offset is defined as the deviation of the

actual code transition from this point.

Full-Scale Error (FSE)

The last code transition should occur foran analog input that

is 3/4 LSB below positive full-scale with the offset error

removed. Full-scale error is defined as the deviation of the

actual code transition from this point.

Differential Linearity Error (DNL)

DNL is the worst case deviation of a code width from the

ideal value of 1 LSB.

4-6

Page 7

Integral Linearity Error (INL)

INL is the worst case deviation of a code center from a best

fit straight line calculated from the measured data.

Power Supply Rejection Ratio (PSRR)

Each of the power supplies are moved plus and minus 5%

and the shift in the offset and gain error (in LSBs) is noted.

Dynamic Performance Definitions

Fast F ourier Transform (FFT) techniques are used to ev aluate

the dynamic performance of the HI5905. A low distortion sine

wave is applied to the input, it is coherently sampled, and the

output is stored in RAM. The data is then transformed into the

frequency domain with an FFT and analyzed to evaluate the

dynamic performance of the A/D . The sine wa ve input to the

part is -0.5dB down from full-scale for all these tests. SNR and

SINAD are quoted in dB. The distortion numbers are quoted in

dBc (decibels with respect to carrier) and DO NOT include any

correction factors for normalizing to full scale.

Signal-to-Noise Ratio (SNR)

SNR is the measured RMS signal to RMS noise at a

specified input and sampling frequency. The noise is the

RMS sum of all of the spectral components except the

fundamental and the first five harmonics.

Signal-to-Noise + Distortion Ratio (SINAD)

SINAD is the measured RMS signal to RMS sum of all

other spectral components below the Nyquist frequency,

f

/2, excluding DC.

S

Effective Number Of Bits (ENOB)

The effective number of bits (ENOB) is calculated from the

SINAD data by:

ENOB = SINAD + V

where: V

V

CORR

fullscale.

= 0.5dB (Typical)

CORR

adjusts the ENOB for the amount the input is below

Total Harmonic Distortion (THD)

THD is the ratio of the RMS sum of the first 5 harmonic

components to the RMS value of the fundamental input signal.

2nd and 3rd Harmonic Distortion

This is the ratio of the RMS value of the applicable harmonic

component to the RMS value of the fundamental input signal.

Spurious Free Dynamic Range (SFDR)

SFDR is the ratio of the fundamental RMS amplitude to the

RMS amplitude of the next largest spur or spectral

component (excluding the first 5 harmonic components) in

the spectrum below f

Intermodulation Distortion (IMD)

Nonlinearities in the signal path will tend to generate

intermodulation products when two tones, f

CORR

/2.

S

-1.76()/6.02

and f2, are

1

present at the inputs. The ratio of the measured signal to the

distortion terms is calculated. The terms included in the

calculation are (f

(f

+ 2f2), (f1- 2f2). The ADC is tested with each tone 6dB

1

below full scale.

), (f1-f2), (2f1), (2f2), (2f1+f2), (2f1-f2),

1+f2

Transient Response

Transient response is measured by providing a fullscale

transition to the analog input of the ADC and measuring the

number of cycles it takes for the output code to settle within

14-bit accuracy.

Over-Voltage Recovery

Over-voltage Recovery is measured by providing a fullscale

transition to the analog input of the ADC which overdrives

the input by 200mV, and measuring the number of cycles it

takes for the output code to settle within 14-bit accuracy.

Full Power Input Bandwidth (FPBW)

Full power input bandwidth is the analog input frequency at

which the amplitude of the digitally reconstructed output has

decreased 3dB below the amplitude of the input sinewave.

The input sinewave has an amplitude which swings from -f

to +fS. The bandwidth given is measured at the specified

sampling frequency.

Timing Definitions

Refer to Figure 1, Internal Circuit Timing, and Figure 2,

Input-To-Output Timing, for these definitions.

Aperture Delay (tAP)

Aperture delay is the time delay between the external

sample command (the falling edge of the clock) and the time

at which the signal is actually sampled. This delay is due to

internal clock path propagation delays.

Aperture Jitter (tAJ)

Aperture Jitter is the RMS variation in the aperture delay due

to variation of internal clock path delays.

Data Hold Time (tH)

Data hold time is the time to where the previous data (N - 1)

is still valid.

Data Output Delay Time (tOD)

Data output delay time is the time to where the new data (N)

is valid.

Data Latency (t

After the analog sample is taken, the digital data is output on

the bus at the third cycle of the clock. This is due to the

pipeline nature of the converter where the data has to ripple

through the stages. This delay is specified as the data

latency. After the data latency time, the data representing

each succeeding sample is output at the following clock

pulse. The digital data lags the analog input sample by 4

clock cycles.

LAT

)

S

4-7

Page 8

HI5905N/QML

Metric Plastic Quad Flatpack Packages (MQFP/PQFP)

E

E1

0.40

0.016

0o MIN

0o-7

-H-

-A-

o

MIN

D

D1

-D-

Q44.10x10 (JEDEC MO-108AA-2 ISSUE A)

44 LEAD METRIC PLASTIC QUAD FLATPACK PACKAGE

SYM-

BOL

INCHES MILLIMETERS

NOTESMIN MAX MIN MAX

A - 0.093 - 2.35 -

A1 0.004 0.010 0.10 0.25 -

-B-

A2 0.077 0.083 1.95 2.10 -

B 0.012 0.018 0.30 0.45 6

B1 0.012 0.016 0.30 0.40 -

D 0.510 0.530 12.95 13.45 3

D1 0.390 0.398 9.90 10.10 4, 5

E 0.510 0.530 12.95 13.45 3

e

PIN 1

E1 0.390 0.398 9.90 10.10 4, 5

L 0.026 0.037 0.65 0.95 N44 447

e 0.032 BSC 0.80 BSC -

5o-16

A2

SEATING

PLANE

A

0.10

o

A1

0.20

0.008

A-B SD SCM

0.004

-C-

B

B1

NOTES:

1. Controlling dimension: MILLIMETER. Converted inch

dimensions are not necessarily exact.

2. All dimensions and tolerances per ANSI Y14.5M-1982.

3. Dimensions D andE to be determined at seating plane .

4. Dimensions D1 and E1 to be determined at datum plane

.

-H-

5. Dimensions D1 and E1 do not include mold protrusion.

Rev. 1 1/94

-C-

Allowable protrusion is 0.25mm (0.010 inch) per side.

0.13/0.17

o

L

5o-16

0.005/0.007

BASE METAL

WITH PLATING

0.13/0.23

0.005/0.009

6. Dimension B does not include dambar protrusion. Allowable

dambar protrusion shall be 0.08mm (0.003 inch) total.

7. “N” is the number of terminal positions.

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil semiconductor products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without notice. Accordingly ,the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (321) 724-7000

FAX: (321) 724-7240

4-8

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Intersil Ltd.

8F-2, 96, Sec. 1, Chien-kuo North,

Taipei, Taiwan 104

Republic of China

TEL: 886-2-2515-8508

FAX: 886-2-2515-8369

Loading...

Loading...