Page 1

TM

HI5905EVAL2 Evaluation Board User’s Manual

Application Note January 1999

Description

The HI5905EV AL2 evaluation board allows the circuit

designer to evaluate the performance of the Intersil HI5905

monolithic 14-bit, 5MSPS analog-to-digital converter (ADC).

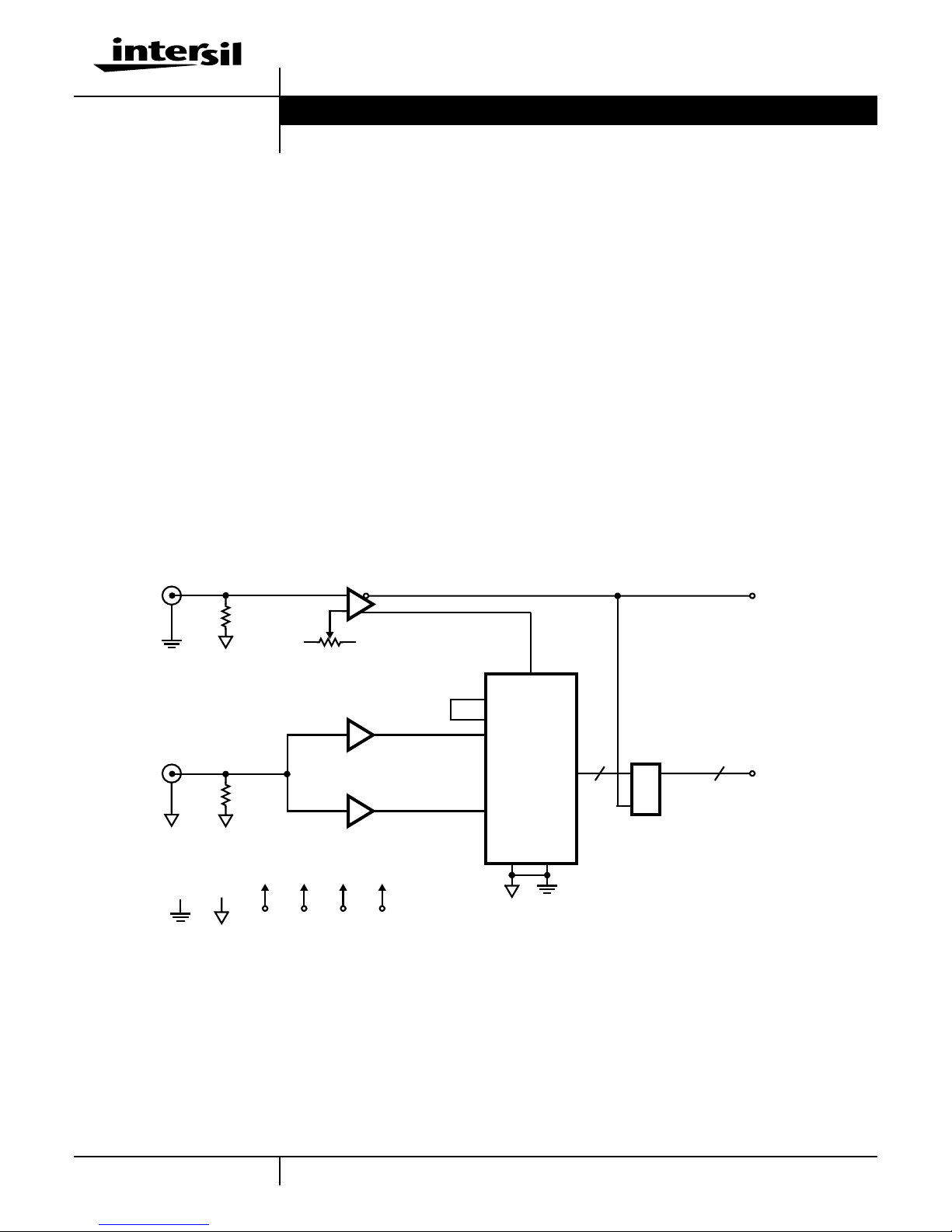

As shown in the Evaluation Board Functional Block Diagr am,

the evaluation board includes sample cloc k gener ation

circuitry, a single-ended to differential analog input amplifier

configuration and digital data output latches/buffers . The

buffered digital data outputs are conveniently provided for

easy interfacing to a ribbon connector or logic probes. In

addition, the evaluationboardincludessomeprototypingarea

for the addition of user designed custom interfaces or circuits .

The sample clock generator circuit accepts the external

sampling signal through anSMAtypeRFconnector, J2. This

input is AC-coupled and terminated in 50Ω allowing for

connection to most laboratory signal generators. In addition,

the duty cycle of the clock driving the A/D converter is

Evaluation Board Functional Block Diagram

AN9785

adjustable by way of a potentiometer. This allows the effects

of sample clock duty cycle on the HI5905 to be observed.

The analog input signal is also connected through an SMA

type RF connector, J1, and applied to a single-ended to

differential analog input amplifier. This input is AC-coupled

and terminated in 50Ω allowing for connection to most

laboratory signal generators. Also, provisions for a

differential RC lowpass filter is incorporated on the output of

the differential amplifier to limit the broadband noise going

into the HI5905 converter.

The digital data output latches/buffers consist of a pair of

74ALS574A D-type flip-flops. With this digital output

configuration the digital output data transitions seen at the

I/O connector are essentially time aligned with the rising

edge of the sampling clock.

CLK IN

J2

ANALOG

J1

DGND

TTL COMPARATOR

CLOCK

50Ω

-5V

D

IN

50Ω

AGND

+5V

-5V

D

D

+5V

G = +1

G = -1

+5VA-5V

D

CLK

V

REFOUT

V

REFIN

V

IN+

0-D13

14

D>Q

D

V

IN-

HI5905

A

14

OUT

(CLK)

DIGITAL

DAT A

OUT

(D0 - D13)

1-888-INTERSIL or 321-724-7143 | Intersil and Design is a trademark of Intersil Corporation. | Copyright © Intersil Corporation 2000

3-1

Page 2

Application Note 9785

Reference Generator, V

ROUT

and V

RIN

The HI5905 has an internal reference voltage generator,

therefore no external reference voltage is required. The eval

board, however, offers the ability to use the internal or an

external reference.V

must be connected to V

ROUT

RIN

when

using the internal reference. Internal to the converter, two

reference voltages of 1.3V and 3.3V are generated making

for a fully differential analog input signal range of

±2V.

The HI5905 can be used with an external reference. The

converter requires only one external reference voltage

connected to the V

evaluation board is configured with V

pin with V

RIN

left open. The

ROUT

ROUT

connected to V

RIN

through a 0Ωresistor , R4. If it is desired to e v aluate the

performance of the converter utilizing an externally provided

reference voltage, R4 can be remo v ed and the alternate

referencevoltagecanbebrought in through twisted pair wire or

coaxial cable. The latter would be the recommended method

since it would provide the greatest immunity to e xternally

coupled noise voltages. In order to minimize overall converter

noise it is recommended that adequate high frequency

decoupling be provided at the reference input pin, V

RIN

.

Analog Input

The fully differential analog input of the HI5905 A/D can be

configured in various ways depending on the signal source

and the required level of performance.

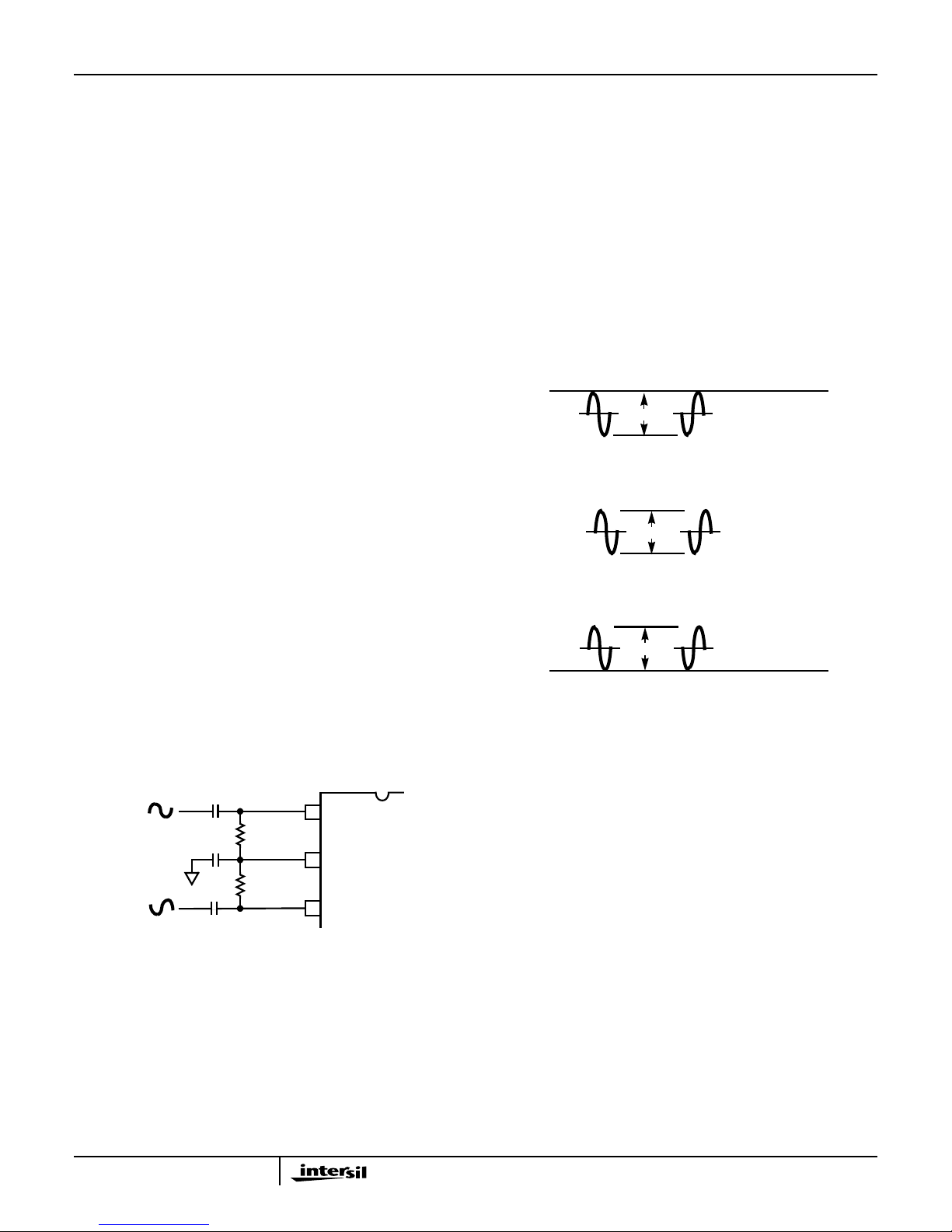

The difference between the conv erter's two internally

generated voltage references is 2V. For the AC coupled

differentialinput(Figure1),ifV

IN

is a 2V

sinewav ewith-V

P-P

being 180 degrees out of phase with VIN, the converter will be

at positivefullscalewhen the V

V

- input is at VDC - 1V (VIN+ - VIN- = +2V). Conversely, the

IN

ADC will be at negative full scale when the V

to V

- 1V and VIN- is at VDC + 1V (VIN+ - VIN- = -2V).

DC

+ input isatVDC+ 1Vandthe

IN

+ input is equal

IN

It should be noted that overdriving the analog input beyond

the ±2.0V fullscale input voltage range will not damage the

converter as long as the overdrive voltage stays within the

converters analog supply voltages. In the event of an

overdrive condition the converter will recover within one

sample clock cycle.

+5V

VIN+V

VIN+

2.0V

2.0V

P-P

FIGURE 2A.

P-P

FIGURE 2B.

-

IN

VDC = 4.0V

V

-

IN

1.0V < VDC < 4.0V

+5V

IN

Differential Analog Input Configuration

A fully differential connection (Figure 1) will yield the best

performance from the HI5905 A/D converter. Since the HI5905

is powered off a single +5V supply, the analog input must be

biased so it lies within the analog input common mode voltage

range of 1.0V to 4.0V .Figure2illustratesthedifferentialanalog

input common mode voltage range that the conv erter will

accommodate. The performance of the ADC does not change

significantly with the value of the common mode voltage.

V

IN

-V

IN

FIGURE 1. AC COUPLED DIFFERENTIAL INPUT

A 2.3V DC bias voltage source, V

DC

and bottom internally generated reference voltages, is made

availableto the user to help simplify circuit design when using a

differential input. This low output impedance voltage source is

not designed to be a reference but makes an excellent bias

source and stays within the analog input common mode

voltage range ov er temperature . The DC v oltage source has a

temperature coefficient of about +200ppm/

VIN+

HI5905

V

DC

VIN-

, half way between the top

o

C.

+

V

IN

2.0V

P-P

0V

FIGURE 2C.

FIGURE 2. DIFFERENTIAL ANALOG INPUT COMMON MODE

VOLTAGE RANGE

V

-

IN

VDC = 1.0V

0V

Evaluation Board Layout and

Power Supplies

The HI5905 evaluation board is a four layer board with a

layout optimized for the best performance of the ADC. This

application note includes an electrical schematic of the

evaluation board, a component parts list, a component

placement layout drawing and reproductions of the various

board layers used in the board stack-up. The user should

feel free to copy the layout in their application. Refer to the

component layout and the evaluation board electrical

schematic for the following discussions.

The HI5905 monolithic A/D converter has been designed

with separate analog and digital supply and ground pins to

keep digital noise out of the analog signal path. The

evaluation board provides separate low impedance analog

and digital ground planes on layer 2. Since the analog and

digital ground planes are connected together at a single

point where the power supplies enter the board, DO NOT tie

them together back at the power supplies.

3-2

Page 3

Application Note 9785

The analog and digital supplies are also kept separate on

the evaluation board and should be driven by clean linear

regulated supplies. The external power supplies are hooked

up with the twisted pair wires soldered to the plated through

holes marked +5VAIN, +5VAIN1, -5VAIN, +5VDIN,

+5VD1IN, +5VD2IN, -5VDIN, AGND and DGND near the

analog prototyping area. +5VDIN, +5VD1IN, +5VD2IN

and -5VDIN are digital supplies and are returned to DGND.

+5VAIN, +5VAIN1 and -5VAIN are the analog supplies and

are returned to AGND. Table 1 lists the operational supply

voltages, typical current consumption and the evaluation

board circuit function being powered. Single supply

operation of the converter is possible but the overall

performance of the converter may degrade.

TABLE 1. HI5905EVAL2EVALUATION BOARDPOWER

SUPPLIES

POWER

SUPPLY

+5VAIN 5.0V ±5% 80mA Op Amps, A/D AV

-5VAIN -5.0V ±5% 30mA Op Amps

+5VDIN 5.0V ±5%3 60mA CLK Comparator,

+5VD1IN 5.0V ±5% 14mA A/D DV

+5VD2IN 5.0V ±5% 6mA A/D DV

-5VDIN -5.0V ±5% 3mA CLK

NOMINAL

VALUE

CURRENT

(TYP)

FUNCTION(S)

SUPPLIED

CC

Inverter

D0-D13 D-FF’s

CC1

CC2

Comparator

Sample Clock Driver, Timing and I/O

In order to ensure rated performance of the HI5905, the duty

cycle of the sample clock should be held at 50% ±5%. It

must also have low phase noise and operate at standard

TTL levels.

A voltage comparator (U3) with TTL output levelsisprovided

on the evaluation board to generate the sampling clock for

the HI5905 when a sinewave (< ±3V) or squarewave clock is

applied to the CLK input (J2) of the evaluation board. A

potentiometer (VR1) is provided to allow the user to adjust

the duty cycle of the sampling clock to obtain the best

performance from the ADC and to allow the user to

investigate the effects of expected duty cycle variations on

the performance of the converter. The HI5905 clock input

trigger level is approximately 1.5V. Therefore, the duty cycle

of the sampling clock should be measured at this 1.5V

trigger level. Test point TP2 provides a convenient point to

monitor the sample clock duty cycle and make any required

adjustments.

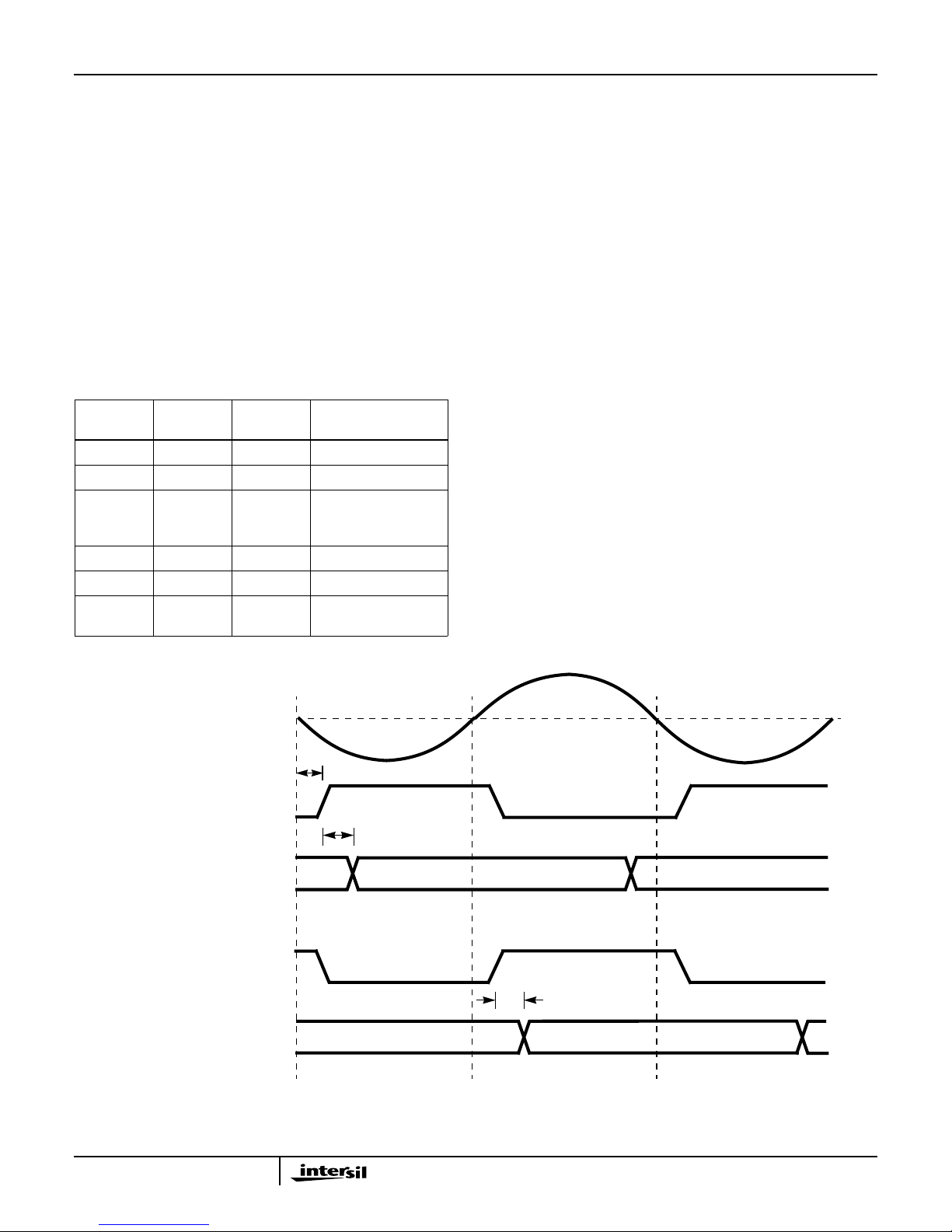

Figure 3 shows the sample clock and digital data timing

relationship for the evaluation board. The data

corresponding to a particular sample will be available at the

digital data outputs of the HI5905 after the data latency time,

t

, of 4 sample clock cycles plus the HI5905 digital data

LAT

output delay, t

expected fortheindicatedtiming delays.Refer to the HI5905

data sheet for additional timing information.

. Table 2 lists the values that can be

OD

SINEWAVE CLK IN

HI5905 SAMPLE

CLOCK INPUT

(CLK AT TP2)

HI5905 DIGITAL

DATA OUTPUT

(CLK AT TP1, P2-C20 OR P2-31)

DIGITAL DATA OUTPUTS

(J2)

(D0 - D13)

CLOCK OUT

(74ALS574)

FIGURE 3. EVALUATION BOARD CLOCK AND DATA TIMING RELATIONSHIPS

t

PD1

t

OD

DATA N-1

DATA N

t

PD2

DATA NDATA N-1

3-3

Page 4

Application Note 9785

TABLE 2. TIMING SPECIFICATIONS

PARAMETER DESCRIPTION TYP

t

t

PD1

t

PD2

OD

HI5905 Digital Output Data Delay 50ns

U4 Prop Delay 4.5ns

U2/3 Prop Delay 9ns

The sample clock and digital output data signals are made

available through two connectors contained on the

evaluation board. The line buffering provided by the data

output latches allows for driving long leads or analyzer

inputs. These data latches are not necessary for the digital

output data if the load presented to the converter does not

exceedthedatasheetloadlimits of 100µA and 15pF. TheP2

I/O connector allows the evaluation board to be interfaced to

the DSP evaluation boards available from Intersil.

Alternatively, the digital output data and sample clock can

also be accessed by clipping the test leads of a logic

analyzer or data acquisition system onto the I/O pins of

connector header P1.

HI5905 Performance Characterization

Dynamic testing is used to evaluate the performance of the

HI5905 A/D converter. Among the tests performed are

Signal-to-Noise and Distortion Ratio (SINAD), Signal-toNoise Ratio (SNR), Total Harmonic Distortion (THD),

Spurious Free Dynamic Range (SFDR) and InterModulation

Distortion (IMD).

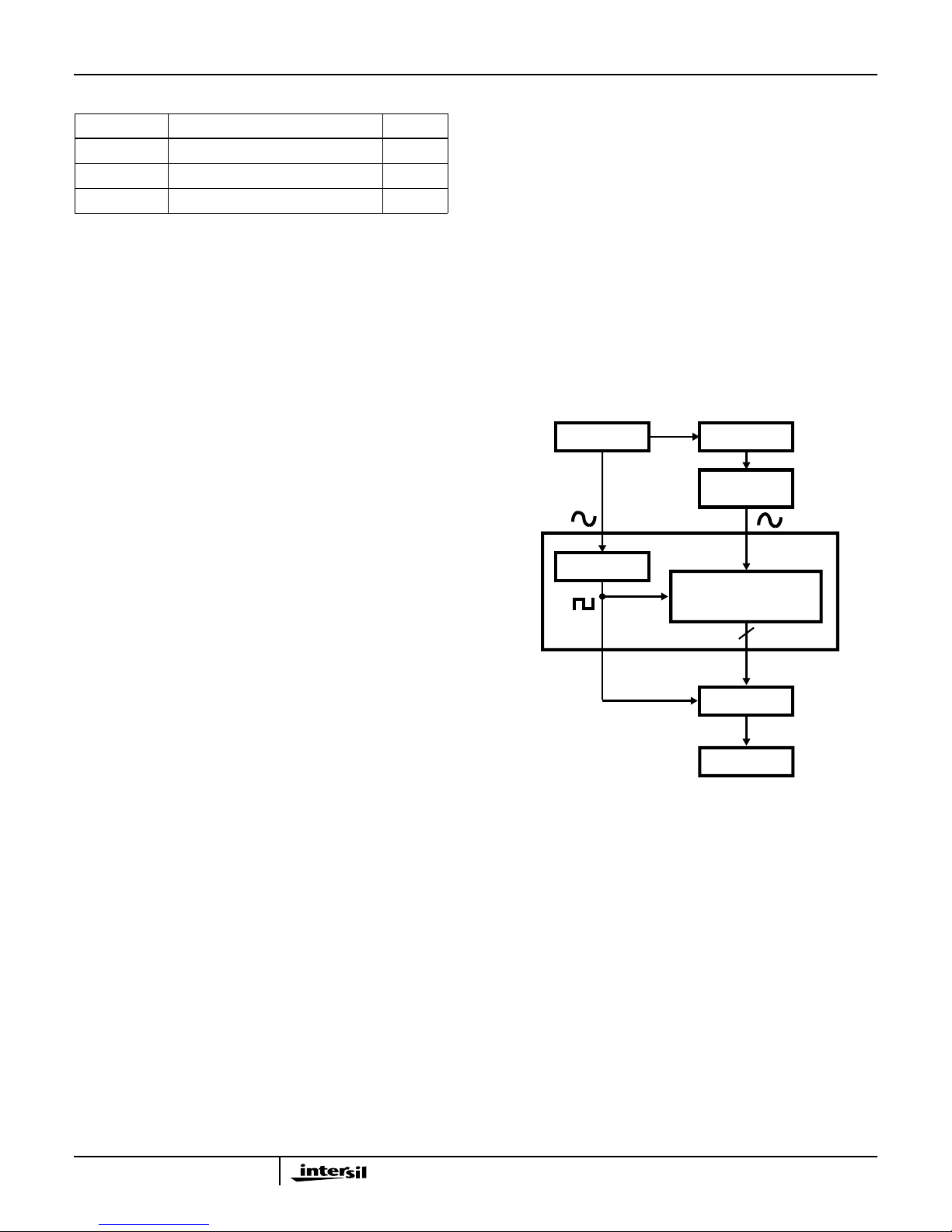

Figure 4 shows the test system used to perform dynamic

testing on high-speed ADCs at Intersil. The clock (CLK) and

analog input (V

HP8662A synthesized signal generators that are phase locked

to each other to ensure coherence. The output of the signal

generator driving the ADC analog input is bandpass filtered to

improve the harmonic distortion of the analog input signal. The

comparator on the evaluation board will con v ert the sine wav e

CLK input signal to a square wave at TTL logic le vels to drive

the sample clock input of the HI5905. The ADC data is

captured bya logic analyzer andthentransferred overtheGPIB

) signals are sourced from low phase noise

IN

bustothePC.The PC has the required software to perform the

Fast F ourier Transform (FFT) and do the data analysis.

Coherent testing is recommended in order to avoid the

inaccuracies of windowing. The sampling frequency and

analog input frequency have the following relationship: F

I/FS

= M/N, where FI is the frequency of the input analog

sinusoid, F

is the sampling frequency, N is the number of

S

samples, and M is the number of cycles over which the

samples are taken. By making M an integer and odd number

(1, 3, 5, ...) the samples are assured of being nonrepetitive.

Refer to the HI5905 data sheet for a complete list of test

definitions and the results that can be expected using the

evaluation board with the test setup shown. Evaluating the

part with a reconstruction DAC is only suggested when

doing bandwidth or video testing.

HP8662A

CLK

COMPARATOR

EVALUATION BOARD

FIGURE 4. HIGH-SPEED A/D PERFORMANCE TEST SYSTEM

REF

HI5905EVAL2

HP8662A

BANDPASS

FILTER

V

IN

V

IN

CLK

HI5905

DIGITAL DATA OUTPUT

14

DAS9200

GPIB

PC

3-4

Page 5

Application Note 9785

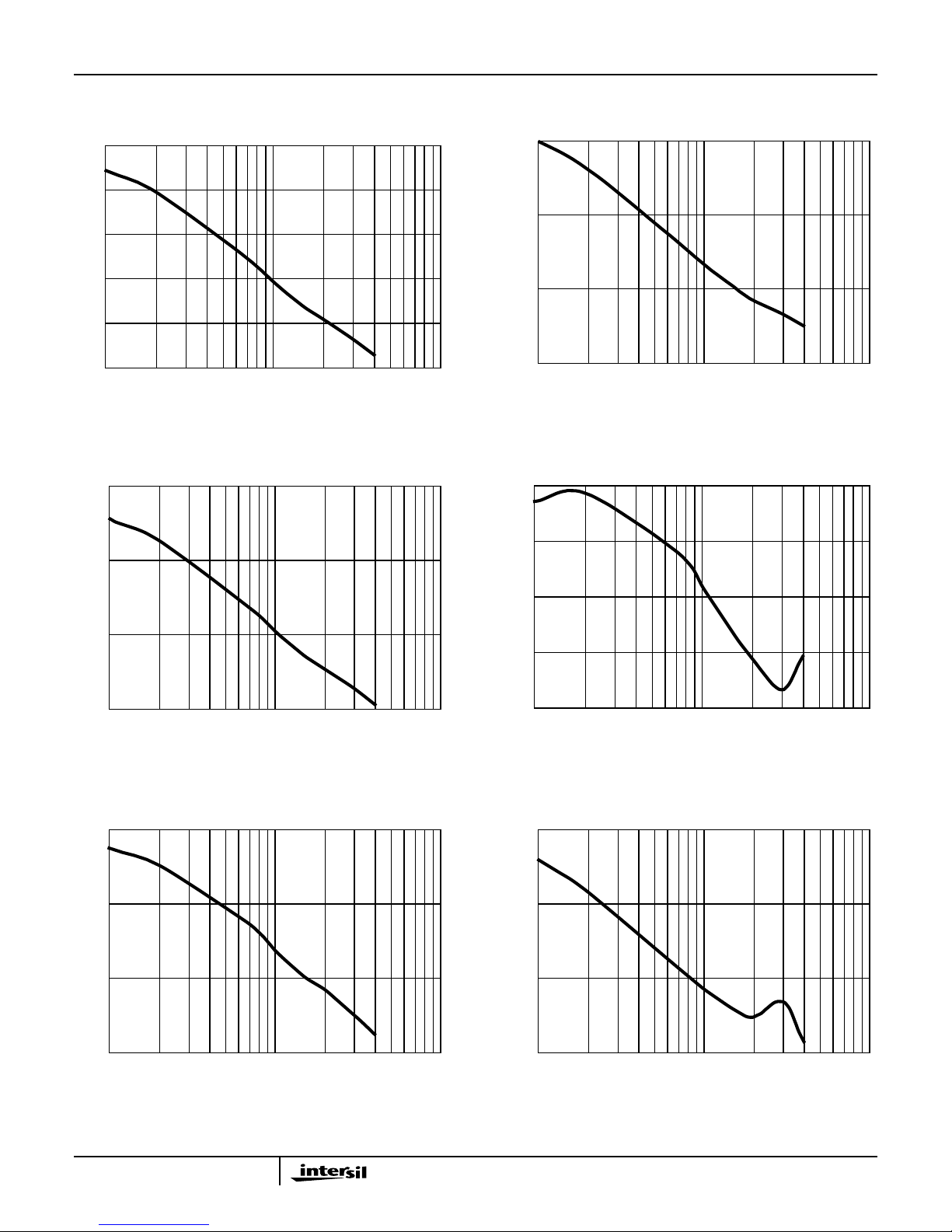

HI5905EVAL2 Typical Performance (Input Amplitude at -0.5dBFS)

12

11

10

9

ENOB (BITS)

8

7

1

INPUT FREQUENCY (MHz)

10

FIGURE 5. EFFECTIVE NUMBER OF BITS(ENOB) vs INPUT

FREQUENCY

75

65

100

75

65

-THD (dB)

55

45

1

INPUT FREQUENCY (MHz)

10

FIGURE 6. TOTAL HARMONIC DISTORTION(THD) vs INPUT

FREQUENCY

90

80

100

SINAD (dB)

55

45

1

75

65

SNR (dB)

55

70

-2HD (dB)

60

INPUT FREQUENCY (MHz)

10

100

50

1

INPUT FREQUENCY (MHz)

10

FIGURE 7. SINAD vs INPUT FREQUENCY FIGURE 8. SECOND HARMONIC DISTORTION (2HD)vs

INPUT FREQUENCY

80

70

-3HD (BITS)

60

100

45

1

INPUT FREQUENCY (MHz)

10

FIGURE 9. SNR vs INPUT FREQUENCY FIGURE10. THIRD HARMONIC DISTORTION (3HD) vsINPUT

3-5

100

50

1

INPUT FREQUENCY (MHz)

10

100

FREQUENCY

Page 6

Appendix A Board Layout

Application Note 9785

FIGURE 11. HI5905EVAL2 EVALUATION BOARD PARTS LAYOUT (NEAR SIDE)

FIGURE 12. HI5905EVAL2 EVALUATION BOARD COMPONENT NEAR SIDE (LAYER 1)

3-6

Page 7

Appendix A Board Layout (Continued)

Application Note 9785

FIGURE 13. HI5905EVAL2 EVALUATION BOARD GROUND PLANE LAYER (LAYER 2)

FIGURE 14. HI5905EVAL2 EVALUATION BOARD POWER PLANE LAYER (LAYER 3)

3-7

Page 8

Appendix A Board Layout (Continued)

Application Note 9785

FIGURE 15. HI5905EVAL2 EVALUATION BOARD COMPONENT FAR SIDE (LAYER 4)

FIGURE 16. HI5905EVAL2 EVALUATION BOARD PARTS LAYOUT (FAR SIDE)

3-8

Page 9

3-9

Appendix B Schematic Diagrams

V

CC

+

CLK

V

IN+

V

DC

V

IN-

+5V

A

+5V

D1

R4

C10

C9

C7

C6

V

CC

OE

D7

D6

D5

D4

D3

D2

D1

D0

GND

CP

Q7

Q6

Q5

Q4

Q3

Q2

Q1

Q0

‘ALS574

1

2

3

4

5

6

7

8

9

10 11

12

13

14

17

18

19

20

15

16

V

CC

OE

D7

D6

D5

D4

D3

D2

D1

D0

GND

CP

Q7

Q6

Q5

Q4

Q3

Q2

Q1

Q0

‘ALS574

1

2

3

4

5

6

7

8

9

10 11

12

13

14

17

18

19

20

15

16

JP1

U2

U3

R6

R5

D10

D9

D8

D7

D5

D4

D3

D2

D1

D0

D11

D12

D0 - D13,

CLK

+5V

D

+5V

D2

4.7µF

0.1µF

0.1µF

0.1µF

0

+

4.7µF

C18

C17 C14

0.1µF 0.1µF

P1

FB6

4.99K

4.99K

+

4.7µF

C16

C15

0.1µF

+

4.7µF

C12 C11

0.1µF

V

IN-

V

DC

V

IN+

171819

20

24

25

26

HI5905

NC

NC

NC

D6

DV

CC2

D

GND2

D8

D9

NC

D

GND1

U1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

21

22

23

27

28

29

30

31

32

331

AV

CC

A

GND

NC

NC

NC

D7

D5

D4

D3

NC

34

35

36

37

38

39

40

41

42

43

44

D2

NC

DV

CC1

D

GND1

DV

CC1

CLK

NC

D0

NC

D1

NC

V

ROUT

D10

D11

D12

D13

A

GND

V

RIN

AV

CC

NC

NC

C13

0.1µF

ALS04

U7

1

2

D6

D13

ALS04

U7

3

4

D13

CLK

CLK

CLK

Application Note 9785

Page 10

Application Note 9785

Appendix B Schematic Diagrams (Continued)

1

7

NC

3

+

-

2

0.1µF

1

NC

2

-

+

3

8

V+

V+

V-

V-

5

4

R15

22.1

R17

499

7

8

V+

V+

V-

V-

5

4

ANALOG

IN

J1

C37

0.1µF

R13

56.2

R18

499

R14

A/R

R20

249

C38

0.1µF

6

U5

OPA628AU

-5V

A

C41C40

4.7µF

+

C43

0.1µF

6

U6

OPA628U

-5V

A

+5V

+

C39

4.7µF

+5V

+

C42

4.7µF

A

C1

0.1µF

VIN+

R16

10

R2

100

R12

0

V

DC

C3

A/R

A

R19

10

C2

0.1µF

R3

100

C5

4.7µF

+

C4

0.1µF

VIN-

+5V

CLK IN

D

J2

R9

249

R8

249

C20

0.1µF

0.1µF

R7

49.9

C25

0.1µF

3(CW)

2

VR1

5K

C44C45

4.7µF

+

+5V

-5V

D

C22

4.7µF

1 (CCW)

C26

0.1µF

D

+

7

8

U4

C24

4.7µF

-5V

TP2

CLK

CLK

TP1

D

C23

0.1µF

1

V+

2

+

-

3

V-

4

+

GND

6

C21

0.1µF

Q

Q

LE

5

MAX9686BCSA

R11

249

R10

249

3-10

Page 11

Application Note 9785

Appendix B Schematic Diagrams (Continued)

P2C

C1

C2

D1 D0

C3

D3

C4

D5

C5

D6

C6

D8

C7

D10

C8

D12

C9

C10

C11

C12

C13

C14

C15

C16

C17

C18

C19

CLK

C20

C21

C22

C23

C24

C25

C26

C27

C28

C29

C30

C31

C32

D2

D4

D7

D9

D11

D13

P2A

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

A21

A22

A23

A24

A25

A26

A27

A28

A29

A30

A31

A32

D0 - D13,

V

CC

CLK

C8

0.1µF

U7

14

56

7

ALS04

U7

11

ALS04

10

U7

9

ALS04

U7

13

ALS04

8

12

3-11

Page 12

3-12

Appendix B Schematic Diagrams (Continued)

FB1

+

C27

C29

+5VDIN

-5VAIN

+5V

D

-5V

A

FB2

+

C30

C28

+5V

D1

+

+

+

+

+5V

D2

-5V

D

+5VD1IN

+5VD2IN

-5VDIN

+5V

A

+5VAIN

C46

C47

C31 C32

C33 C34

C35

C36

FB3

FB7

FB4

FB5

AGND

DGND

DGND

DGND

DGND

AGND AND DGND TIE TOGETHER

AT A SINGLE POINT WHERE

ENTER THE PWB

THE POWER SUPPLIES

4.7µF

0.1µF

4.7µF

4.7µF

4.7µF

4.7µF

4.7µF

0.1µF

0.1µF

0.1µF

0.1µF

0.1µF

E1 E2

E11 E12

E9 E10

E7 E8

E5 E6

E3 E4

(A/D AV

CC

, OP-AMPS)

(COMPARATOR, D-FF AND INVERTERVIA LPF)

(A/D DV

CC1

)

(A/D DV

CC2

)

(COMPARATOR)

(OP-AMPS)

TP4TP3

+

AGND

Application Note 9785

Page 13

Appendix C Parts List

Application Note 9785

REFERENCE

DESIGNATOR QTY DESCRIPTION

-1Printed Wiring Board

R16, R19 2 10Ω, 1/10W

805 Chip, 1%

R17, R18 2 499Ω, 1/10W

805 Chip, 1%

R13 1 56.2Ω, 1/10W

805 Chip, 1%

R14 1 A/RΩ, 1/10W

805 Chip, 1%

R15 1 22.1Ω, 1/10W

805 Chip, 1%

R2, R3 2 100Ω, 1/10W

805 Chip, 1%

R4, R12 2 0.0Ω, 1/4W

805 Chip, 5%

R5, R6 2 4.99kΩ, 1/10W

805 Chip, 1%

R7 1 49.9Ω, 1/10W

805 Chip, 1%

R8, R9, R10, R11, R20 5 249Ω, 1/10W

805 Chip, 1%

VR1 1 5kΩ Trim Pot

C5, C10, C12, C16, C18,

C22, C24, C27, C29, C31,

C33, C35, C39, C41, C42,

C44, C46

C1, C2, C4, C6, C7, C8,

C9, C11, C13, C14, C15,

C17, C20, C21, C23, C25,

C26, C28, C30, C32, C34,

C36, C37, C38, C40, C43,

C45, C47

C3 1 A/R pF Cer Cap, 50WVDC,

FB1-7 7 10µH Ferrite Bead

J1, J2 2 SMA Straight Jack PCB

- 5 Protective Bumper

JP1 1 1x2 Header

JPH1 1 1x2 Header Jumper

P1 1 2x17 Header

TP1, 2, 3, 4 4 Test Point

U1 1 Intersil HI5905IN, 14-Bit 5

U4 1 Ultrafast Voltage

U2, U3 2 Octal D-type Flip-flop

17 4.7µF Chip Tant Cap,

10WVDC, 20%, EIA Case A

28 0.1µF Cer Cap, 50WVDC,

10%, 805 Case, Y5V

Dielectric

10%, 805 Case

Mount

MSPS A/D Converter

Comparator

REFERENCE

DESIGNATOR QTY DESCRIPTION

U5, U6 2 Op-amp

U7 1 Hex Inverter

P2 64-Pin Eurocard RT Angle

Receptacle

Appendix D HI5905 Theory of Operation

The HI5905 is a 14-bit fully differential sampling pipelined A/D

converter with digital error correction. Figure 17 depicts the

internal circuit for the converters front-end differential-indifferential-outsample-and-hold(S/H).The sampling switches

are controlled byinternalsamplingclocksignals which consist

of two phase non-overlapping clock signals,φ1 and φ2,

derived from the master clock (CLK) driving the converter.

During the sampling phase, φ1, the input signal is applied to

the sampling capacitors, C

capacitors,C

, are dischargedtoanalogground.At the falling

H

edge of φ1 the input analog signal is sampled on the bottom

plates of the sampling capacitors. In the next clock phase, φ2,

the two bottom plates of the sampling capacitors are

connected togetherandtheholding capacitors are switchedto

the op amp output nodes. The charge then redistributes

between C

and CH, completing one sample-and-hold cycle.

S

The output of the sample-and-hold is a fully-differential,

sampled-data representation of the analog input. The circuit

not only performs the sample-and-hold function, but can also

convert a single-ended input to a fully-differential output for

the converter core. During the sampling phase, the V

see only the on-resistance of the switches and C

relatively small values of these components result in a typical

full power input bandwidth of 100MHz for the con verter.

As illustrated in the HI5905 Functional Block Diagram and

the timing diagram contained in Figure 18, three identical

pipeline subconverter stages, each containing a four-bit

flash converter,afour-bit digital-to-analog converter and an

amplifier with a voltage gain of 8, follow the S/H circuit with

the fourth stage being only a 4-bit flash converter. Each

converter stage in the pipeline will be sampling in one

phase and amplifying in the other clock phase. Each

individual sub-converter clock signal is offset by 180

degrees from the previous stage clock signal, with the

result that alternate stages in the pipeline will perform the

same operation. The output of each of the three identical

four-bit subconverter stages is a four-bit digital word

containing a supplementary bit to be used by the digital

error correction logic. The output of each subconverter

stage is input to a digital delay line which is controlled by

the internal clock. The function of the digital delay line is to

time align the digital outputs of the three identical four-bit

subconverter stages with the corresponding output of the

fourth stage flash converter before inputting the sixteen bit

result into the digital error correction logic. The digital error

. At the same time the holding

S

IN

. The

S

pins

3-13

Page 14

Application Note 9785

correction logic uses the supplementary bits to correct any

error that may exist before generating the final fourteen-bit

digital data output (D0-D14) of the converter.

Because of the pipeline nature of this converter, the digital

data representing an analog input sample is presented on

the digital data output bus on the 4th cycle of the clock after

the analog sample is taken. This delay is specified as the

data latency. After the data latency time, the data

representing each succeeding analog sample is output on

the following clock pulse. The output data is synchronized to

the external sampling clock with a data latch and is

presented in offset binary format.

ANALOG

INPUT

VIN+

V

IN

φ

1

φ

1

C

S

φ

2

C

S

φ

1

φ

1

-

+

φ

C

C

1

H

V

OUT

V

OUT

H

φ

1

FIGURE 17. ANALOG INPUT SAMPLE-AND-HOLD

+

-

CLOCK

INPUT

INPUT

S/H

1ST

STAGE

2ND

STAGE

3RD

STAGE

4TH

STAGE

5TH

STAGE

DAT A

OUTPUT

H

N-1

N-1

B

B

2, N-2

4, N-3

S

H

N

B

B

B

1, N-1

3, N-2

5, N-3

D

N-4

N

B

B

2, N-1

4, N-2

S

H

N+1

B

B

B

D

1, N

3, N-1

5, N-2

N-3

N+1

B

B

2, N

4, N-1

t

LAT

S

H

S

N+2

B

1, N+1

B

3, N

B

5, N-1

D

N-2

NOTES:

1. SN: N-th sampling period.

2. HN: N-th holding period.

3. BM,N: M-th stage digital output corresponding to N-th sampled input.

4. DN: Final data output corresponding to N-th sampled input.

FIGURE 18. HI5905 INTERNAL CIRCUIT TIMING

N+2

B

2, N+1

B

4, N

H

N+3

B

1, N+2

B

3, N+1

B

5, N

D

N-1

N+3

B

2, N+2

B

4, N+1

S

H

N+4

B

B

B

D

1, N+3

3, N+2

5, N+1

N

N+4

B

2, N+3

B

4, N+2

S

H

N+5

B

B

B

1, N+4

3, N+3

5, N+2

D

N+1

N+5

B

B

2, N+4

4, N+3

S

H

N+6

B

1, N+5

B

B

D

N+6

3, N+4

5, N+3

N+2

S

3-14

Page 15

HI5905 Functional Block Diagram

Application Note 9785

V

DC

V

IN-

V

IN+

S/H

+

-

∑

X8

+

-

∑

BIAS

4-BIT

FLASH

4-BIT

FLASH

STAGE 1

STAGE 4

4-BIT

DAC

4-BIT

DAC

CLOCK

REF

DIGITAL DELAY

AND

DIGITAL ERROR CORRECTION

CLK

V

ROUT

V

RIN

DV

CC2

D13 (MSB)

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

X8

FLASH

AV

CCAGNDDVCC1DGND1

3-15

4-BIT

STAGE 5

D1

D0 (LSB)

D

GND2

Page 16

Appendix E Pin Descriptions

Application Note 9785

PIN # NAME DESCRIPTION

1 NC No Connection

2 NC No Connection

3D

GND1

Digital Ground

4 NC No Connection

5AVCCAnalog Supply (5.0V)

6A

GND

Analog Ground

7 NC No Connection

8 NC No Connection

9V

+ Positive Analog Input

IN

10 VIN- Negative Analog Input

11 V

DC

DC Bias Voltage Output

12 NC No Connection

13 V

14 V

15 A

16 AV

ROUT

RIN

GND

CC

Reference Voltage Output

Reference Voltage Input

Analog Ground

Analog Supply (5.0V)

17 NC No Connection

18 D13 Data Bit 13 Output (MSB)

19 D12 Data Bit 12 Output

20 D11 Data Bit 11 Output

21 D10 Data Bit 10 Output

22 NC No Connection

PIN # NAME DESCRIPTION

23 NC No Connection

24 D9 Data Bit 9 Output

25 D8 Data Bit 8 Output

26 D

27 DV

GND2

CC2

Digital Ground

Digital Supply (5.0V)

28 NC No Connection

29 D7 Data Bit 7 Output

30 D6 Data Bit 6 Output

31 D5 Data Bit 5 Output

32 D4 Data Bit 4 Output

33 D3 Data Bit 3 Output

34 NC No Connection

35 NC No Connection

36 D2 Data Bit 2 Output

37 D1 Data Bit 1 Output

38 D0 Data Bit 0 Output (LSB)

39 NC No Connection

40 CLK Input Clock

41 DV

42 D

43 DV

CC1

GND1

CC1

Digital Supply (5.0V)

Digital Ground

Digital Supply (5.0V)

44 NC No Connection

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil semiconductor products aresold by description only .Intersil Corporation reserves the right to make changesin circuit design and/or specifications at an ytime without notice. Accordingly, the reader is cautioned to verify that data sheets are current bef ore placingorders. Information furnished by Intersil is believed to be accurate and

reliable. Howe ver, no responsibility isassumed by Intersil or its subsidiaries for its use; norfor any infringements of patents or other rights of third parties which mayresult

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For inf ormationregarding Intersil Corporation and itsproducts, see website www.intersil.com

3-16

Loading...

Loading...