®

www.BDTIC.com/Intersil

HI-565A

Data Sheet May 2002

High Speed, Monolithic D/A Converter

with Reference

The HI-565A is a fast, 12-bit, current output, digital-to-analog

converter. The monolithic chip includes a precision voltage

reference, thin-film R2R ladder, reference control amplifier

and twelve high speed bipolar current switches.

The Intersil dielectric isolation process provides latch free

operation while minimizing stray capacitance and leakage

currents, to produce an excellent combination of speed and

accuracy. Also, ground currents are minimized to produce a

low and constant current through the ground terminal, which

reduces error due to code dependent ground currents.

HI-565A dice are laser trimmed for a maximum integral

nonlinearity error of ±0.5 LSB at 25

noise buried zener reference is trimmed both for absolute

value and temperature coefficient. Power dissipation is

typically 250mW, with ±15V supplies.

The HI-565A is offered in both commercial and military

grades. See Ordering Information.

o

C. In addition, the low

FN3109.4

Features

• 12-Bit DAC and Reference on a Single Chip

• Pin Compatible With AD565A

• Very High Speed: Settles to ±0.5 LSB in 250ns (Max)

Full Scale Switching Time 30ns (Typ)

• Guaranteed For Operation With ±12V Supplies

• Monotonicity Guaranteed Over Temperature

• Nonlinearity Guaranteed Over Temp (Max). . . . ±0.5 LSB

• Low Gain Drift (Max, DAC Plus Ref) . . . . . . . . .25ppm/oC

• Low Power Dissipation . . . . . . . . . . . . . . . . . . . . .250mW

Applications

• CRT Displays

• High Speed A/D Converters

• Signal Reconstruction

• Waveform Synthesis

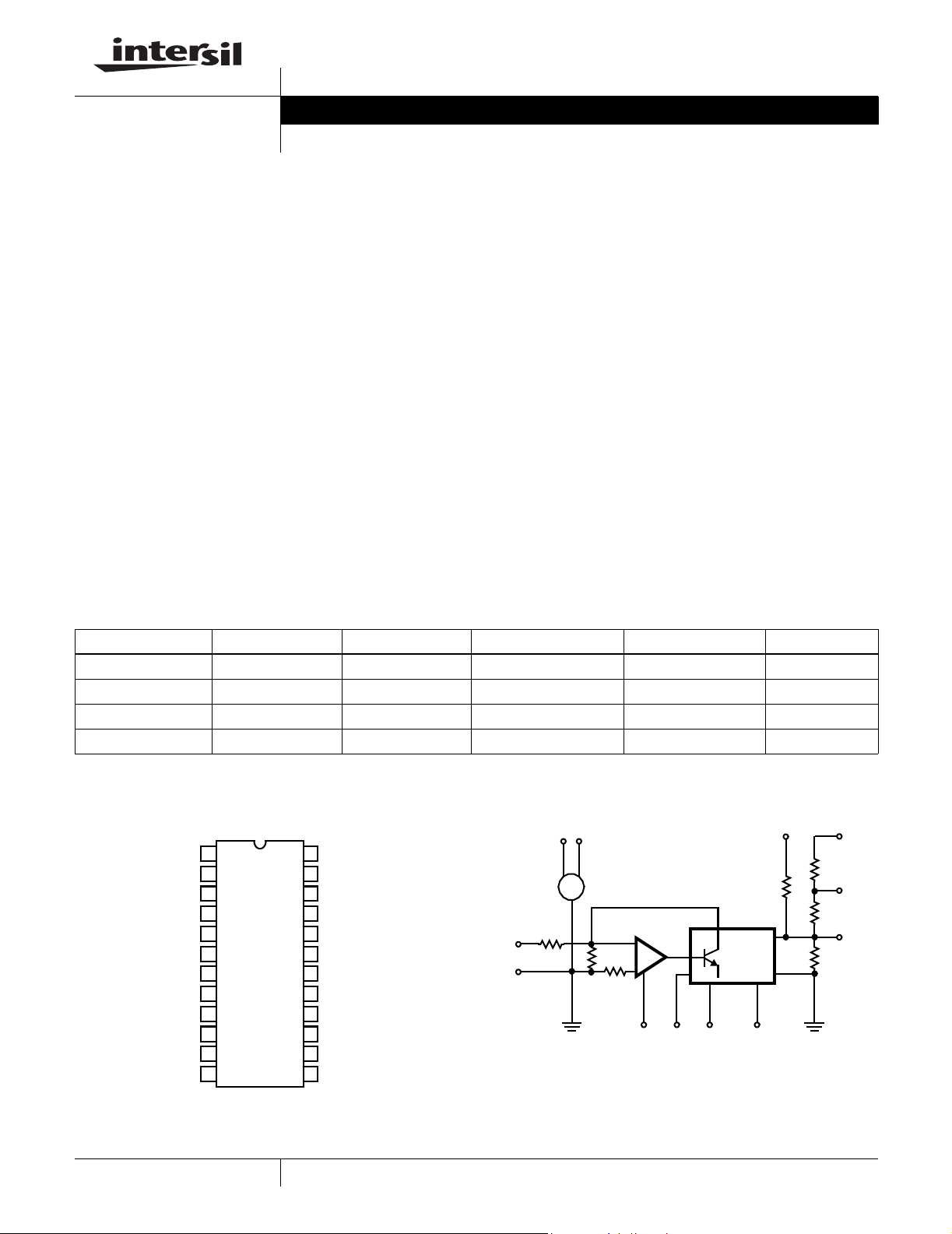

Ordering Information

PART NUMBER LINEARITY (INL) LINEARITY (DNL) TEMP. RANGE (oC) PACKAGE PKG. NO.

HI1-565AJD-5 0.50 LSB 0.75 LSB 0 to 75 24 Ld SBDIP D24.6

HI1-565ATD-2 0.25 LSB 0.50 LSB -55 to 125 24 Ld SBDIP D24.6

HI1-565ASD/883 0.50 LSB 0.50 LSB -55 to 125 24 Ld SBDIP D24.6

HI1-565ATD/883 0.25 LSB 0.50 LSB -55 to 125 24 Ld SBDIP D24.6

Pinout

REF OUT (+10V)

NC

NC

V

CC

REF GND

REF IN

-V

EE

BIPOLAR R IN

IDAC OUT

10V SPAN R

20V SPAN R

POWER GND

HI-565A (SBDIP)

TOP VIEW

1

2

3

4

5

6

7

8

9

10

11

12

24

BIT 1 (MSB) IN

23

BIT 2 IN

BIT 3 IN

22

21

BIT 4 IN

20

BIT 5 IN

19

BIT 6 IN

18

BIT 7 IN

17

BIT 8 IN

16

BIT 9 IN

15

BIT 10 IN

14

BIT 11 IN

13

BIT 12 (LSB) IN

Functional Diagram

REF

OUT

V

CC

REF

IN

6

5

REF

GND

43

+

-

19.95K

3.5K

3K

HI-565A

0.5mA

I

REF

+

-

712

-V

EE

PWR

GND

BIP. OFF

9.95K

DAC

(4X I

REF

X CODE)

24 . . . . . .13

MSB LSB

8

I

O

2.5K

5K

5K

11

10

9

20V

SPAN

10V

SPAN

OUT

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright © Intersil Americas Inc. 2002. All Rights Reserved

HI-565A

www.BDTIC.com/Intersil

Absolute Maximum Ratings Thermal Information

VCC to Power GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0V to +18V

V

to Power GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0V to -18V

EE

Voltage on DAC Output (Pin 9) . . . . . . . . . . . . . . . . . . . -3V to +12V

Digital Inputs (Pins 13-24) to Power GND . . . . . . . . . . .-1V to +7.0V

REF In to REF GND. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±12V

Bipolar Offset to REF GND . . . . . . . . . . . . . . . . . . . . . . . . . . . ±12V

10V Span R to REF GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±12V

20V Span R to REF GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±24V

REF Out. . . . . . . . . . . . . . . . . . . . . . Indefinite Short to Power GND,

Momentary Short to V

CC

Operating Conditions

Temperature Ranges

HI1-565AX-2, /883 . . . . . . . . . . . . . . . . . . . . . . . . -55

HI1-565AX-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

is measured with the component mounted on an evaluation PC board in free air.

1. θ

JA

o

C to 125oC

o

C to 75oC

Thermal Resistance (Typical, Note 1) θ

SBDIP Package . . . . . . . . . . . . . . . . . . 60 20

Maximum Package Power Dissipation

SBDIP Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .500mW

Maximum Junction Temperature. . . . . . . . . . . . . . . . . . . . . . .175

Maximum Storage Temperature Range . . . . . . . . . -65

Maximum Lead Temperature (Soldering 10s). . . . . . . . . . . . .300

Die Characteristics

Transistor Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bipolar-DI

(oC/W) θJC (oC/W)

JA

o

C to 150oC

o

o

C

C

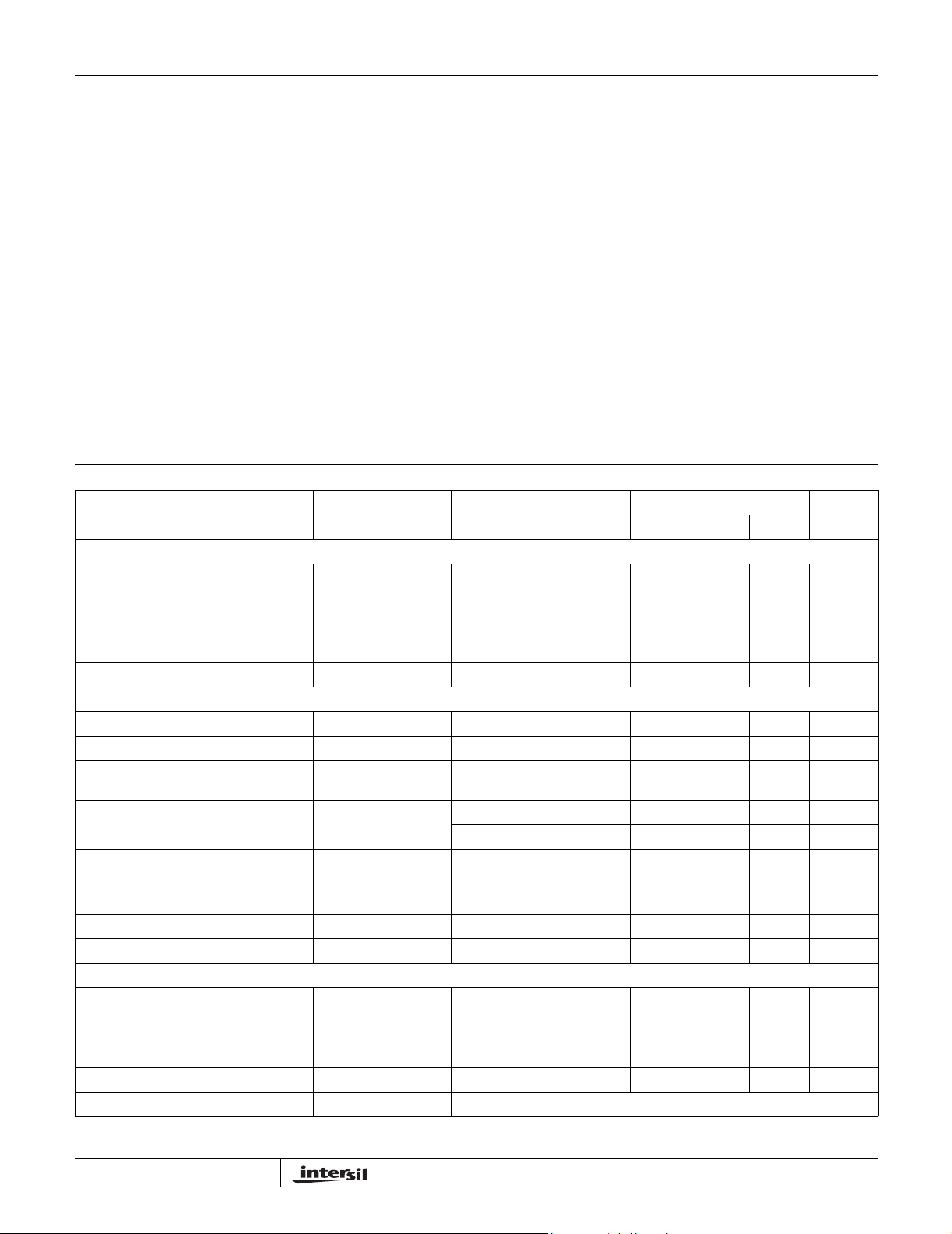

Electrical Specifications T

PARAMETER TEST CONDITIONS

DATA INPUTS (Pins 13 to 24)

Input Voltage Bit ON Logic “1” (T

Input Voltage Bit OFF Logic “0” (T

Logic Current Bit ON Logic “1” (T

Logic Current Bit OFF Logic “0” (T

Resolution (Note 2) 12 - - 12 - - Bits

OUTPUT

Unipolar Current (All Bits ON) -1.6 -2.0 -2.4 -1.6 -2.0 -2.4 mA

Bipolar Current (All Bits ON or OFF) ±0.8 ±1.0 ±1.2 ±0.8 ±1.0 ±1.2 mA

Resistance (Exclusive of Span

Unipolar Offset (25

Bipolar Offset (25

Bipolar Offset (T

/883 Versions Only

Capacitance - 20 - - 20 - pF

Compliance Voltage (T

ACCURACY (Error Relative to Full Scale)

Integral Non-Linearity (25

Integral Non-Linearity

/883 Versions Only

Differential Non-Linearity 25

Differential Non-Linearity T

o

C) -0.05 0.01 0.05 -0.05 0.01 0.05 % of FS

o

C) -0.15 0.05 0.15 -0.1 0.05 0.1 % of FS

MlN

to T

MAX

)

= 25oC, VCC = +15V, VEE = -15V, Unless Otherwise Specified

A

HI-565AJ, HI-565AS HI-565AT

to T

MlN

to T

MlN

to T

MlN

to T

MlN

Resistors) (Note 2)

(Figure 2, R3 = 50Ω) -0.25 0.05 0.25 -0.2 0.05 0.2 % of FS

to T

MIN

o

C)

End Point Method

to T

(T

MIN

End Point Method

o

C-±0.50 ±0.75 - ±0.25 ±0.50 LSB

to T

MIN

) +2.0 - +5.5 +2.0 - +5.5 V

MAX

) - -+0.8- -+0.8 V

MAX

) - 0.01 +1.0 - 0.01 +1.0 µA

MAX

) - -2.0 -20 - -2.0 -20 µA

MAX

1.8K 2.5K 3.2K 1.8K 2.5K 3.2K Ω

-0.07 0.01 0.07 -0.07 0.01 0.07 % of FS

)(Note 2) -1.5 - +10 -1.5 - +10 V

MAX

MAX

MAX

- ±0.25

(0.006)

)

- ±0.50

(0.012)

±0.50

(0.012)

±0.75

(0.018)

MONOTONICITY GUARANTEED

- ±0.12

(0.003)

- ±0.25

(0.006)

±0.25

(0.006)

±0.50

(0.012)

UNITSMIN TYP MAX MIN TYP MAX

LSB

% of FS

LSB

% of FS

2

HI-565A

www.BDTIC.com/Intersil

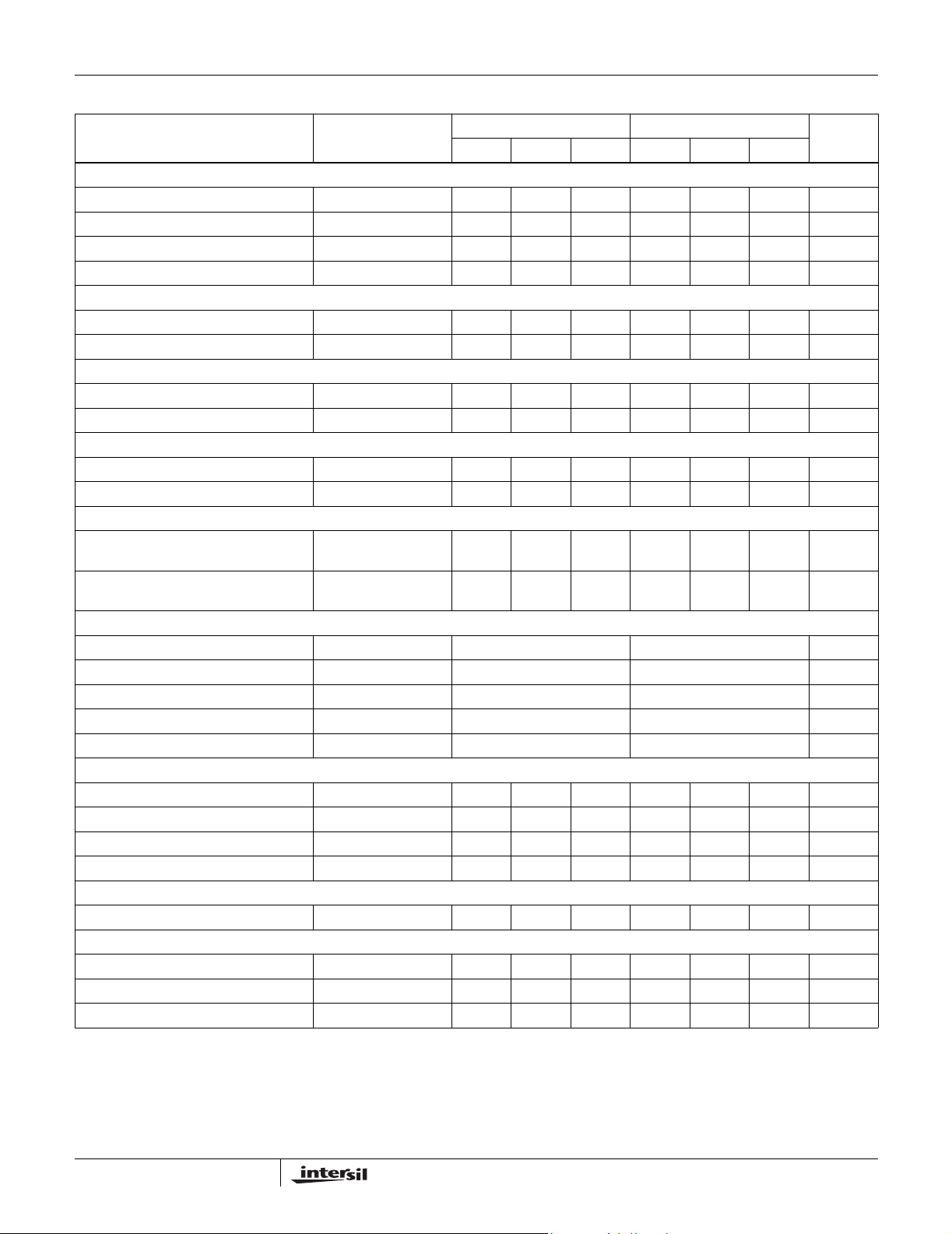

Electrical Specifications T

PARAMETER TEST CONDITIONS

TEMPERATURE COEFFIClENTS

Unipolar Offset Drift - 1 2 - 1 2 ppm/

Bipolar Zero Drift Internal Reference - 5 10 - 5 10 ppm/

Gain Drift, Uni- and Bipolar (Full Scale) Internal Reference - 15 40 - 10 25 ppm/

Differential Nonlinearity Error Drift Int. Ref. - 2 - - 2 - ppm/

SETTLING TIME T0 ±0.5 LSB

With High, Z External Load (Notes 2, 3) - 350 500 - 350 500 ns

With 75Ω External Load (Notes 2, 3) - 150 250 - 150 250 ns

FULL SCALE TRANSITION From 50% of Logic Input to 90% of Analog Output

Rise Time (Note 2) - 15 30 - 15 30 ns

Fall Time (Note 2) - 30 50 - 30 50 ns

POWER REQUIREMENTS

I

CC

I

EE

POWER SUPPLY GAIN SENSITIVITY (Note 4)

V

CC

V

EE

PROGRAMMABLE OUTPUT RANGES (See Table 2)

Unipolar 5 (Note 2) 0 to +5 0 to +5 V

Bipolar 5 (Note 2) -2.5 to +2.5 -2.5 to +2.5 V

Unipolar 10 (Note 2) 0 to +10 0 to +10 V

Bipolar 10 (Note 2) -5 to +5 -5 to +5 V

Bipolar 20 (Note 2) -10 to +10 -10 to +10 V

EXTERNAL ADJUSTMENTS

Gain Error R2 = 50Ω (Figure 2) - ±0.1 ±0.25 - ±0.1 ±0.25 % of FS

Bipolar Zero Error R3 = 50Ω (Figure 3) - ±0.05 ±0.15 - ±0.05 ±0.1 % of FS

Gain Adjustment Range (Figure 1) (Note 2) ±0.25 - - ±0.25 - - % of FS

Bipolar Zero Adjustment Range (Note 2) ±0.15 - - ±0.15 - - % of FS

REFERENCE INPUT

Input Impedance (Note 2) 15K 20K 25K 15K 20K 25K Ω

REFERENCE OUTPUT

Voltage, Commercial Versions 9.90 10.00 10.10 9.90 10.00 10.10 V

Voltage, /883 Versions 9.95 10.00 10.05 9.95 10.00 10.05 V

Current (Available for External Loads) 1.5 2.5 - 1.5 2.5 - mA

NOTES:

2. Guaranteed by characterization or design but not tested over the operating temperature range.

3. See settling time discussion and Figure 3.

4. The Power Supply Gain Sensitivity is tested in reference to a V

= 25oC, VCC = +15V, VEE = -15V, Unless Otherwise Specified (Continued)

A

HI-565AJ, HI-565AS HI-565AT

- 9.0 11.8 - 9.0 11.8 mA

- -9.5 -14.5 - -9.5 -14.5 mA

(+11.4 to +16.5VDC)

All Bits = 2V, Unipolar

(-11.4 to -16.5VDC)

All Bits = 2V, Unipolar

- 3 10 - 3 10 ppm of

- 15 25 - 15 25 ppm of

, VEE of ± 15V.

CC

UNITSMIN TYP MAX MIN TYP MAX

FS/%

FS/%

o

C

o

C

o

C

o

C

3

HI-565A

www.BDTIC.com/Intersil

Definitions of Specifications

Digital Inputs

The HI-565A accepts digital input codes in binary format and

may be user connected for any one of three binary codes.

Straight Binary, Two’s Complement (Note 5), or Offset

Binary, (See Operating Instructions).

TABLE 1.

ANALOG OUTPUT

(NOTE 5)

DIGITAL

INPUT

MSB...LSB

000...000 Zero -FS

100...000

111...111 +FS - 1 LSB +FS - 1 LSB Zero - 1 LSB

011...111 1/2FS - 1 LSB Zero - 1 LSB +FS - 1 LSB

NOTE:

5. Invert MSB with external inverter to obtain Two’s Complement

Coding.

Nonlinearity of a D/A converter is an important measure of

its accuracy. It describes the deviation from an ideal straight

line transfer curve drawn between zero (all bits OFF) and full

scale (all bits ON) (End Point Method).

Differential Nonlinearity for a D/A converter, it is the

difference between the actual output voltage change and the

ideal (1 LSB) voltage change for a one bit change in code. A

Differential Nonlinearity of ±1 LSB or less guarantees

monotonicity; i.e., the output always increases for an

increasing input.

Settling Time is the time required for the output to settle to

within the specified error band for any input code transition.

It is usually specified for a full scale or major carry transition,

settling to within ±0.5 LSB of final value.

Gain Drift is the change in full scale analog output over the

specified temperature range, expressed in parts per million

of full scale range per

measured with respect to 25

temperatures. Gain drift is calculated for both high (T

-25oC) and low ranges (25oC -TL) by dividing the gain error

by the respective change in temperature. The specification is

the larger of the two representing worst-case drift.

Offset Drift is the change in analog output with all bits OFF

over the specified temperature range expressed in parts per

million of full scale range per

is measured with respect to 25

temperatures. Offset Drift is calculated for both high (T

-25oC) and low (25oC -TL) ranges by dividing the offset error

by the respective change in temperature. The specification

given is the larger of the two, representing worst-case drift.

STRAIGHT

BINARY

1

/2FS Zero -FS

o

OFFSET

BINARY

(Full Scale)

C (ppm of FSR/oC). Gain error is

o

C at high (TH) and low (TL)

o

C (ppm of FSR/oC). Offset error

o

C at high (TH) and low (TL)

TWO'S

COMPLEMENT

Zero

H

H

Power Supply Sensitivity is a measure of the change in

gain and offset of the D/A converter resulting from a change

in -15V or +15V supplies. It is specified under DC conditions

and expressed as parts per million of full scale range per

percent of change in power supply (ppm of FSR/%).

Compliance Voltage is the maximum output voltage range

that can be tolerated and still maintain its specified accuracy.

Compliance Limit implies functional operation only, and

makes no claims to accuracy.

Glitch a glitch on the output of a D/A converter is a transient

spike resulting from unequal internal ON-OFF switching

times. Worst case glitches usually occur at half-scale or the

major carry code transition from 011...1 to 100...0 or vice

versa. For example, if turn ON is greater than turn OFF for

011...1 to 100...0, an intermediate state of 000...0 exists,

such that, the output momentarily glitches toward zero

output. Matched switching times and fast switching will

reduce glitches considerably.

Detailed Description

Op Amp Selection

The Hl-565As current output may be converted to voltage

using the standard connections shown in Figures 1 and 2.

The choice of operational amplifier should be reviewed for

each application, since a significant trade-off may be made

between speed and accuracy.

For highest precision, use an HA-5135. This amplifier

contributes negligible error, but requires about 11µs to settle

within ±0.1% following a 10V step.

The Intersil HA-2600/05 is the best all-around choice for this

application, and it settles in 1.5µs (also to ±0.1% following a

10V step). Remember, settling time for the DAC amplifier

combination is the square root of t

are settling times for the DAC and amplifier.

No-Trim Operation

The Hl-565A will perform as specified without calibration

adjustments. To operate without calibration, substitute 50Ω

resistors for the 100Ω trimming potentiometers: In Figure 1

replace R2 with 50Ω also remove the network on pin 8 and

connect 50Ω to ground. For bipolar operation in Figure 2,

replace R3 and R4 with 50Ω resistors.

With these changes, performance is guaranteed as shown

under Specifications, “External Adjustments”. Typical unipolar

zero will be ±0.5

The feedback capacitor, C, must be selected to minimize

settling time.

LSB plus the op amp offset.

Calibration

Calibration provides the maximum accuracy from a

converter by adjusting its gain and offset errors to zero. For

the Hl-565A, these adjustments are similar whether the

current output is used, or whether an external op amp is

D

2

plus t

2

, where tD, tA

A

4

HI-565A

www.BDTIC.com/Intersil

added to convert this current to a voltage. Refer to Table 2

for the voltage output case, along with Figure 1 or Figure 2.

Calibration is a two step process for each of the five output

ranges shown in Table 2. First adjust the negative full scale

(zero for unipolar ranges). This is an offset adjust which

translates the output characteristic, i.e., affects each code by

the same amount.

TABLE 2. OPERATING MODES AND CALIBRATION

CIRCUIT CONNECTIONS CALIBRATION

OUTPUT

MODE

Unipolar

(See Figure 1)

Bipolar

(See Figure 2)

PRANGE PIN 10 TO PIN 11 TO RESlSTOR (R)

0 to +10V V

0 to +5V V

O

O

Pin 10 1.43K All 0’s

Pin 9 1.1K All 0’s

±10V NC V

±5V V

±2.5V V

O

O

Pin 10 1.43K All 0’s

Pin 9 1.1K All 0’s

Next adjust positive FS. This is a gain error adjustment, which

rotates the output characteristic about the negative FS value.

For the bipolar ranges, this approach leaves an error at the

zero code, whose maximum value is the same as for integral

nonlinearity error. In general, only two values of output may

be calibrated exactly; all others must tolerate some error.

Choosing the extreme end points (plus and minus full scale)

minimizes this distributed error for all other codes.

APPLY

INPUT CODE ADJUST

R1

All 1’s

R2

R1

All 1’s

O

1.69K All 0’s

All 1’s

R2

R3

R4

R3

All 1’s

R4

R3

All 1’s

R4

TO SET

V

O

0V

+9.99756V

0V

+4.99878V

-10V

+9.99512V

-5V

+4.99756V

-2.5V

+2.49878V

R2

100Ω

REF

IN

REF

GND

REF OUT

19.95K

6

5

+

-

V

CC

43

10V

3.5K

BIP.

8

OFF.

3K

HI-565A

I

REF

0.5mA

+

-

71224 13

EE

PWR

GND

MSB LSB

-V

DAC

(4 x I

x CODE)

CODE

INPUT

9.95K

REF

5K

5K

I

O

2.5K

FIGURE 1. UNIPOLAR VOLTAGE OUTPUT

11

20V SPAN

10

10V SPAN

9

DAC

OUT

C

-

+

R (SEE

TABLE 2)

100kΩ

V

100Ω

O

R1

50kΩ

+15V

-15V

5

HI-565A

www.BDTIC.com/Intersil

R3

100Ω

HI-565A

I

REF

0.5mA

+

-

71224 13

-V

EE

PWR

GND

R4

100Ω

REF

IN

REF

GND

REF OUT

19.95K

6

5

V

CC

43

+

10V

-

3.5K

3K

FIGURE 2. BIPOLAR VOLTAGE OUTPUT

Settling Time

This is a challenging measurement, in which the result

depends on the method chosen, the precision and quality of

test equipment and the operating configuration of the DAC

(test conditions). As a result, the different techniques in use

by converter manufacturers can lead to consistently different

results. An engineer should understand the advantage and

limitations of a given test method before using the specified

settling time as a basis for design.

The previous approach calls for a strobed comparator to

sense final perturbations of the DAC output waveform. This

gives the LSB a reasonable magnitude (814µV for the

HI-565A), which provides the comparator with enough

overdrive to establish an accurate ±0.5 LSB window about the

final settled value. Also, the required test conditions simulate

the DACs environment for a common application - use in a

successive approximation A/D converter. Considerable

experience has shown this to be a reliable and repeatable

way to measure settling time.

The usual specification is based on a 10V step, produced by

simultaneously switching all bits from off-to-on (t

to-off (t

). The slower of the two cases is specified, as

OFF

measured from 50% of the digital input transition to the final

entry within a window of ±0.5 LSB about the settled value.

Four measurements characterize a given type of DAC:

(a) t

(b) t

(c) t

(d) t

, to final value +0.5 LSB

ON

, to final value -0.5 LSB

ON

, to final value +0.5 LSB

OFF

, to final value -0.5 LSB

OFF

ON

) or on-

BIP.

OFF.

8

11

20V SPAN

9.95K

DAC

I

O

(4 x I

REF

x CODE)

CODE

INPUT

MSB LSB

5K

5K

2.5K

10

9

DAC

OUT

10V SPAN

C

-

+

R(SEE

TABLE 2)

V

O

(Cases (b) and (c) may be eliminated unless the overshoot

exceeds 0.5 LSB). For example, refer to Figure 3 for the

measurement of case (d).

Procedure

As shown in Figure 3B, settling time equals tX plus the

comparator delay (t

• Adjust the delay on generator No. 2 for a tX of several

microseconds. This assures that the DAC output has

settled to its final value.

• Switch on the LSB (+5V).

• Adjust the V

COMPARA TOR OUT. This is indicated by traces of

equal brightness on the oscilloscope display as shown

in Figure 3B. Note DVM reading.

• Switch the LSB to Pulse (P).

• Readjust the V

and note DVM reading. One LSB equals one tenth the

difference in the DVM readings noted above.

• Adjust the V

5 LSBs (DVM reads 10X, so this sets the comparator to

sense the final settled value minus 0.5

Comparator output disappears.

• Reduce generator No. 2 delay until comparator output

reappears, and adjust for “equal brightness”.

• Measure t

time equals t

= 15ns). To measure tX:

D

supply for 50% triggering at

LSB

supply for 50% triggering as before,

LSB

supply to reduce the DVM reading by

LSB

from scope as shown in Figure 3B. Settling

X

+ tD, i.e., tX + 15ns.

X

LSB).

6

HI-565A

www.BDTIC.com/Intersil

(A)

OUT

+5V

GENERATOR

24

23

14

P

13

LSB

~100kHz

PULSE

NO. 1

HI-565A

9.95K

2mA

12

SYNC

TRIG

OUT

5K

5K

2.5K

DVM

IN

GENERATOR

20V ±20%

BIAS

8

11

10

NC

9

5

PULSE

NO. 2

TURN ON

TURN OFF

10

OUT

(B)

SCHOTTKY

DIODES

90

(C)

STROBE

200K

0.1µF

IN (D)

COMP

OUT

V

LSB

SUPPLY

(A)

(B)

(TURN

OFF)

(C)

(D)

+3V

0V

0V

-400mV

2V

0.8V

4V

0V

50%

t

X

50%

DIGITAL

INPUT

-0.5 LSB

DAC

OUTPUT

SETTLING TIME

tD = COMPARATOR DELAY

COMP.

STROBE

EQUAL

BRIGHTNESS

COMP.

OUT

FIGURE 3A. FIGURE 3B.

Other Considerations

Grounds

The Hl-565A has two ground terminals, pin 5 (REF GND)

and pin 12 (PWR GND). These should not be tied together

near the package unless that point is also the system signal

ground to which all returns are connected. (If such a point

exists, then separate paths are required to pins 5 and 12).

The current through pin 5 is near-zero DC (Note 1); but pin

12 carries up to 1.75mA of code-dependent current from bits

1, 2, and 3. The general rule is to connect pin 5 directly to

the system “quiet” point, usually called signal or analog

ground. Connect pin 12 to the local digital or power ground.

Then, of course, a single path must connect the

analog/signal and digital/power grounds.

Layout

Connections to pin 9 (I

for high speed performance. Output capacitance of the DAC

is only 20pF, so a small change or additional capacitance

may alter the op amp’s stability and affect settling time.

Connections to pin 9 should be short and few. Component

leads should be short on the side connecting to pin 9 (as for

feedback capacitor C). See the Settling Time section.

) on the Hl-565A are most critical

OUT

Bypass Capacitors

Power supply bypass capacitors on the op amp will serve

the HI-565A also. If no op amp is used, a 0.01µF ceramic

capacitor from each supply terminal to pin 12 is sufficient,

since supply current variations are small.

Current Cancellation

Current cancellation is a two step process within the

HI-565A in which code dependent variations are eliminated,

then the resulting DC current is supplied internally. First an

auxiliary 9-bit R-2R ladder is driven by the complement of

the DACs input code. Together, the main and auxiliary

ladders draw a continuous 2.25mA from the internal ground

node, regardless of input code. Part of this DC current is

supplied by the zener voltage reference, and the remainder

is sourced from the positive supply via a current mirror which

is laser trimmed for zero current through the external

terminal (pin 5).

7

Die Characteristics

www.BDTIC.com/Intersil

HI-565A

DIE DIMENSIONS:

179 mils x 107 mils x 19 mils ±1 mil

METALLIZATION:

Type: Al

Thickness: 16k

Å ±2kÅ

Metallization Mask Layout

V

OUT

REF

V

REF

GND

V+

HI-565A

PASSIVATION:

Type: Nitride Over Silox

Nitride Thickness: 3.5k

Å ±0.5kÅ

Silox Thickness: 12kÅ ±1.5kÅ

WORST CASE CURRENT DENSITY:

5

2

0.75 x 10

A/cm

TRANSISTOR COUNT:

200

(MSB)

BIT 1

BIT 2

BIT 3

BIT 4

V

REF

BIPOLAR

12

IDAC

OUT

10V

SPAN

BIT 5

IN

-V

S

20V

SPAN

POWER

GND

(LSB)

BIT 11BIT 12

BIT 6

BIT 7

BIT 8

BIT 9

BIT 10

8

HI-565A

www.BDTIC.com/Intersil

Ceramic Dual-In-Line Metal Seal Packages (SBDIP)

LEAD FINISH

c1

-A-

-B-

S

bbb C A - B

BASE

PLANE

SEATING

PLANE

S1

b2

b

ccc

CA - BM

NOTES:

1. Index area: A notch or a pin one identification mark shall be located adjacent to pin one and shall be located within the shaded

area shown. The manufacturer’s identification shall not be used

as a pin one identification mark.

2. The maximum limits of lead dimensions b and c or M shall be

measured at the centroid of the finished lead surfaces, when

solder dip or tin plate lead finish is applied.

3. Dimensions b1 and c1 apply to lead base metal only. Dimension

M applies to lead plating and finish thickness.

4. Corner leads (1, N, N/2, and N/2+1) may be configured with a

partial lead paddle. For this configuration dimension b3 replaces

dimension b2.

5. Dimension Q shall be measured from the seating plane to the

base plane.

6. Measure dimension S1 at all four corners.

7. Measure dimension S2 from the top of the ceramic body to the

nearest metallization or lead.

8. N is the maximum number of terminal positions.

9. Braze fillets shall be concave.

10. Dimensioning and tolerancing per ANSI Y14.5M - 1982.

11. Controlling dimension: INCH.

D

A

A

e

DS S

-DBASE

E

S

S

D

Q

S2

-C-

aaa

METAL

b1

M

(b)

SECTION A-A

A

L

eA/2

CA - BM DS S

(c)

M

eA

c

D24.6 MIL-STD-1835 CDIP2-T24 (D-3, CONFIGURATION C)

24 LEAD CERAMIC DUAL-IN-LINE METAL SEAL PACKAGE

INCHES MILLIMETERS

SYMBOL

A - 0.225 - 5.72 -

b 0.014 0.026 0.36 0.66 2

b1 0.014 0.023 0.36 0.58 3

b2 0.045 0.065 1.14 1.65 b3 0.023 0.045 0.58 1.14 4

c 0.008 0.018 0.20 0.46 2

c1 0.008 0.015 0.20 0.38 3

D - 1.290 - 32.77 E 0.500 0.610 12.70 15.49 -

e 0.100 BSC 2.54 BSC eA 0.600 BSC 15.24 BSC -

eA/2 0.300 BSC 7.62 BSC -

L 0.120 0.200 3.05 5.08 -

Q 0.015 0.075 0.38 1.91 5

S1 0.005 - 0.13 - 6

S2 0.005 - 0.13 - 7

o

α

aaa - 0.015 - 0.38 bbb - 0.030 - 0.76 ccc - 0.010 - 0.25 -

M - 0.0015 - 0.038 2

N24 248

90

105

o

90

o

105

NOTESMIN MAX MIN MAX

o

Rev. 0 4/94

-

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil semiconductor products are sold b y de scr ip tion on ly. In tersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or othe rwise under any patent or patent righ ts of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site www.intersil.com

9

Loading...

Loading...