®

www.BDTIC.com/Intersil

HI-200/883

Data Sheet January 30, 2006

Dual SPST CMOS Analog Switch

The HI-200/883 is a monolithic device comprising two

independently selectable SPST switchers which feature fast

switching speeds (240ns typical) combined with low power

dissipation (15mW typical @ +25°C).

Each switch provides low “ON” resistance operation for input

signal voltages up to the supply rails and for signal currents

up to 25mA continuous. Rugged DI construction eliminates

latch-up and substrate SCR failure modes.

All devices provide break-before-make switching and are

TTL and CMOS compatible for maximum application

versatility. HI-200/883 is an ideal component for use in high

frequency analog switching. Typical applications include

signal path switching, sample and hold circuits, digital filters,

and op amp gain switching networks.

Functional Diagram

LOGIC

INPUT

V+ V

REFERENCE,

LEVEL SHIFTER,

AND DRIVER

V-

REF

GATE

SOURCE

SWITCH

CELL

INPUT

GATE

DRAIN

OUTPUT

FN6059.2

Features

• This Circuit is Processed in Accordance to MIL-STD-883

and is Fully Conformant Under the Provisions of

Paragraph 1.2.1.

• Low “On” Release . . . . . . . . . . . . . . . . . . . . . . .100Ω Max

• Wide Analog Signal Range . . . . . . . . . . . . . . . . . . . .±15V

• TTL/CMOS Compatible . . . . . . . . . . . . . . 2.4V (Logic “1”)

• Turn-On Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .500ns

• Analog Current Range (Continuous) . . . . . . . . . . . . 25mA

• No Latch-Up

• Replaces DG200

Applications

• High Frequency Analog Switching

• Sample and Hold Circuits

• Digital Filters

• Op Amp Gain Switching Networks

Ordering Information

TEMP.

PART NUMBER

HI2-0200/883 -55 to 125 10 Pin Metal Can T10.B

RANGE (°C) PACKAGE

PKG.

DWG. #

Pinout

HI2-200/883 (METAL CAN)

TOP VIEW

V+

A

1

10

1

IN1

9

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

A

2

2

3

GND

4

IN2

Copyright Intersil Americas Inc. 2004, 2006. All Rights Reserved

5

OUT2

OUT1

8

7

V

REF

6

V-

HI-200/883

www.BDTIC.com/Intersil

Absolute Maximum Ratings Thermal Information

Voltage Between V+ and V- Terminals . . . . . . . . . . . . . . . . . . . .40V

±V

Analog Input Voltage, (+V

Analog Input Voltage, (-V

Digital Input Voltage, (+V

Digital Input Voltage, (-V

to Ground (V+, V-) . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±20V

SUPPLY

) . . . . . . . . . . . . . . . . . . +V

S

). . . . . . . . . . . . . . . . . . . . -V

S

) . . . . . . . . . . . . . . . . . . . +V

A

). . . . . . . . . . . . . . . . . . . . . -V

A

SUPPLY

SUPPLY

SUPPLY

SUPPLY

+2V

-2V

+4V

-4V

Thermal Resistance θ

Metal Can Package . . . . . . . . . . . . . . . 160 75

Package Power Dissipation at +75°C

Metal Can Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.62W/°C

Package Power Dissipation Derating Factor above +75°C

Metal Can Package . . . . . . . . . . . . . . . . . . . . . . . . . . .8.24mW/°C

Peak Current (S or D)

(Pulse at 1ms, 10% Duty Cycle Max). . . . . . . . . . . . . . . . . . 40mA

Continuous Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25mA

Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+175°C

Storage Temperature Range. . . . . . . . . . . . . . . . . .-65°C to +150°C

Lead Temperature (Soldering 10s) . . . . . . . . . . . . . . . . . . . . . . ≤275°C

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

Recommended Operating Conditions

Operating Temperature Range . . . . . . . . . . . . . . . .- 55°C to +125°C

Operating Supply Voltage Range (±V

Analog Input Voltage (V

Logic Low Level (VAL). . . . . . . . . . . . . . . . . . . . . . . . . . . 0V to 0.8V

Logic High Level (V

) . . . . . . . . . . . . . . . . . . . . . . . . ±V

S

) . . . . . . . . . . . . . . . . . . . . 2.4V to +V

AH

SUPPLY

(°C/W) θJC (°C/W)

JA

). . . . . . . . . . . . . . ±15V

SUPPLY

SUPPLY

Device Tested at: +V

SUPPLY

= +15V, −V

SUPPLY

= −15V, V

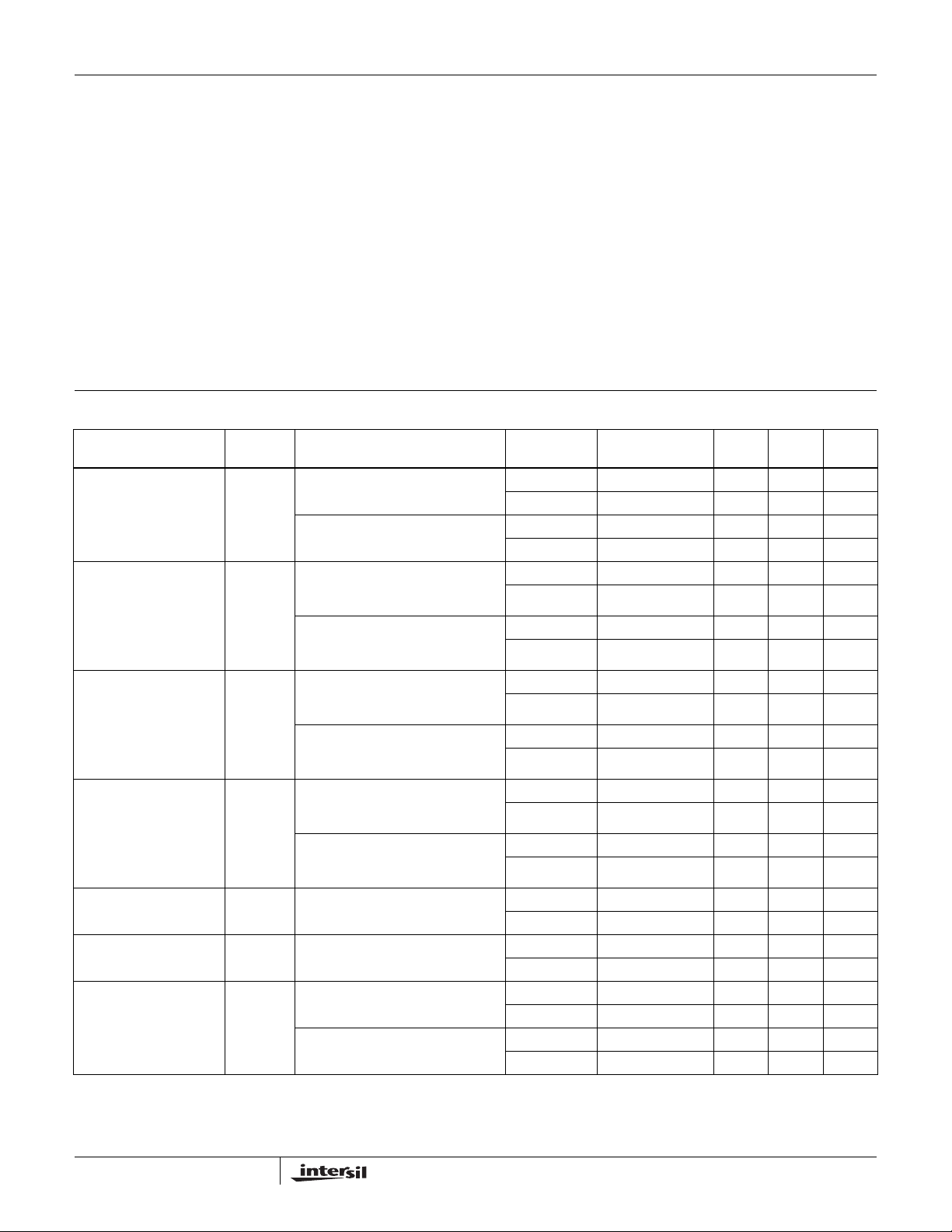

D.C. PARAMETERS SYMBOL CONDITIONS

TABLE 1. D.C. ELECTRICAL PERFORMANCE SPECIFICATIONS

Switch

“ON” Resistance r

VA = 0.8V, VS = 10V, ID = -1mA,

DS

All Unused Channels V

= 0.8V, VS = -10V, ID = 1mA,

V

A

All Unused Channels V

Source “OFF”

Leakage Current

Drain “OFF”

Leakage Current

Channel “ON”

Leakage Current

I

S(OFF)VS

I

D(OFF)VD

I

D(ON)VD

= +14V, VD = -14V, VA = 2.4V,

All Unused Channels V

= +14V, VS = -14V

V

D

= -14V, VD = +14V, VA = 2.4V,

V

S

All Unused Channels V

= -14V, VS = +14V

V

D

= -14V, VS = +14V, VA = 2.4V,

All Unused Channels V

V

= +14V, VS = -14V

D

= +14V, VS = -14V, VA = 2.4V,

V

D

All Unused Channels V

= -14V, VS = +14V

V

D

= VS = +14V, VA = 0.8V,

All Unused Channels V

= VS = -14V

V

D

= VS = -14V, VA = 0.8V,

V

D

All Unused Channels V

V

= VS = +14V

D

Low Level

Input Current

High Level

Input Current

Supply Current +I

I

I

VAL = 0.8V

AL

All Channels V

VAH = 2.4V

AH

All Channels V

All Channels VA = 0V 1 25 - 2.0 µA

CC

All Channels V

= 2.4V

A

AH

= 3V 1 25 - 2.0 mA

A

= OPEN, GND = 0V, Unless Otherwise Specified.

REF

GROUP A

TEMPERATURE

SUBGROUPS

125-70Ω

= 0.8V

A

2, 3 -55 to 125 - 100 Ω

125-70Ω

= 0.8V

A

2, 3 -55 to 125 - 100 Ω

125-55nA

= 2.4V,

A

2, 3 -55 to 125 -500 500 nA

125-55nA

= 2.4V,

A

2, 3 -55 to 125 -500 500 nA

125-55nA

= 2.4V,

A

2, 3 -55 to 125 -500 500 nA

125-55nA

= 2.4V,

A

2, 3 -55 to 125 -500 500 nA

125-55nA

= 0.8V,

A

2, 3 -55 to 125 -500 500 nA

125-55nA

= 0.8V,

A

2, 3 -55 to 125 -500 500 nA

125-1.01.0µA

2, 3 -55 to 125 -1.0 1.0 µA

125-1.01.0µA

= 4.0V

2, 3 -55 to 125 -1.0 1.0 µA

2, 3 -55 to 125 - 2.0 µA

2, 3 -55 to 125 - 2.0 mA

(°C) MIN MAX UNITS

2

FN6059.2

January 30, 2006

HI-200/883

www.BDTIC.com/Intersil

TABLE 1. D.C. ELECTRICAL PERFORMANCE SPECIFICATIONS (Continued)

Device Tested at: +V

D.C. PARAMETERS SYMBOL CONDITIONS

Supply Current -I

Device Tested at: +V

PARAMETERS SYMBOL CONDITIONS

Turn “ON” Time t

Turn “OFF” Time t

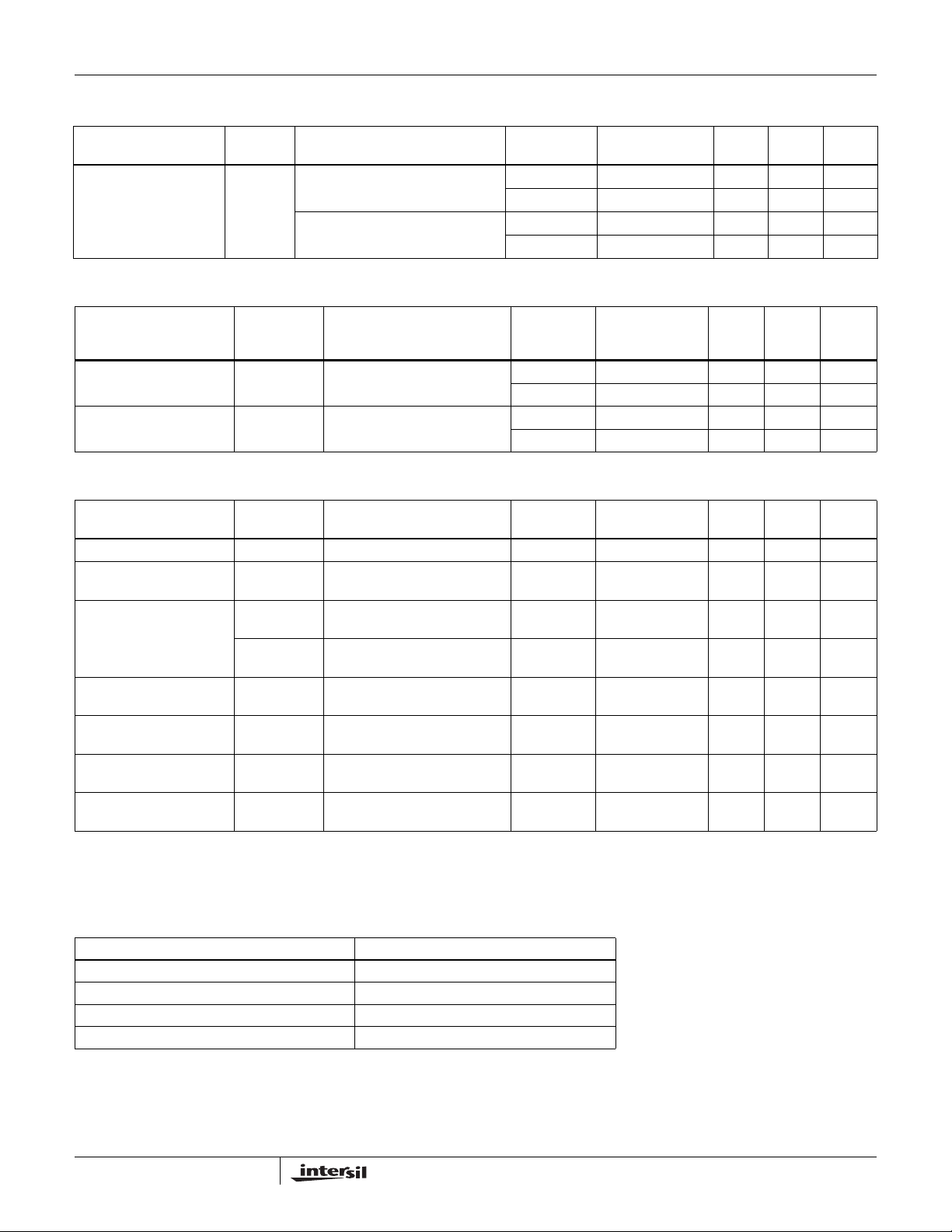

Device Tested at: +V

PARAMETERS SYMBOL CONDITIONS NOTE

Address Capacitance C

Switches Input

Capacitance

Switch Output Capacitance C

Drain to Source

Capacitance

Off Isolation V

Cross Talk V

Charge Transfer Error V

NOTE:

1. Parameters listed in Table 2 are controlled via design or process parameters and are not directly tested at final production. These parameters

are lab characterized upon initial design release, or upon design changes. These parameters are guaranteed by characterization based upon

data from multiple production runs which reflect lot to lot and within lot variation.

SUPPLY

SUPPLY

SUPPLY

= +15V, −V

CC

TABLE 2. A.C. ELECTRICAL PERFORMANCE SPECIFICATIONS

= +15V, −V

ON

OFF

TABLE 3. ELECTRICAL PERFORMANCE SPECIFICATIONS (NOTE 1)

= +15V, −V

A

C

S (OFF)

D (OFF)

C

D (ON)

C

DS

ISO

CT

CTE

= −15V, V

SUPPLY

All Channels VA = 0V 1 25 -2.0 - µA

All Channels V

= −15V, V

SUPPLY

C

= 35pF,

L

R

= 1kΩ

L

C

= 33pF,

L

= 1kΩ

R

L

= −15V, V

SUPPLY

f = 1MHz, VAL = 0V 1 25 - 20 pF

f = 1MHz, VAH = 5V,

Measured Source to GND

f = 1MHz, VAH = 5V,

Measured Output to Ground

f = 1MHz, VAL = 0V,

Measured Output to Ground

f = 1MHz, VAH = 5V 1 25 - 2.0 pF

f = 200kHz, VA = 2.4, RL = 1K,

= 1V

V

GEN

f = 200kHz, VA = 2.4, RL = 1K,

V

= 1V

GEN

f = 200kHz, VA = 0 to 4V,

= 0.01µF

C

L

= OPEN, GND = 0V, Unless Otherwise Specified.

REF

GROUP A

SUBGROUPS

2, 3 -55 to 125 -2.0 - µA

= 3V 1 25 -2.0 - µA

A

2, 3 -55 to 125 -2.0 - µA

= OPEN, GND = 0V, Unless Otherwise Specified.

REF

GROUP A

SUB-

GROUPS

9 25 - 500 ns

10, 11 55 to 125 - 800 ns

9 25 - 500 ns

10, 11 55 to 125 - 650 ns

= OPEN, GND = 0V

REF

1 25 - 20 pF

1 25 - 20 pF

1 25 - 30 pF

12555-dB

= 10pF

P-P, CL

12560-dB

1 25 -10 10 mV

P-P, CL

= 10pF

TEMPERATURE

(°C) MIN MAX UNITS

TEMPERATURE

(°C) MIN MAX UNITS

TEMPERATURE

(°C) MIN MAX UNITS

TABLE 4. ELECTRICAL TEST REQUIREMENTS

MIL-STD-883 TEST REQUIREMENTS SUBGROUPS (Tables 1 and 2)

Interim Electrical Parameters (Pre Burn-in) 1

Final Electrical Test Parameters 1 (Note 2), 2, 3, 9, 10, 11

Group A Test Requirements 1, 2, 3, 9, 10, 11

Groups C & D Endpoints 1

NOTE:

2. PDA applies to Subgroup 1 only.

3

FN6059.2

January 30, 2006

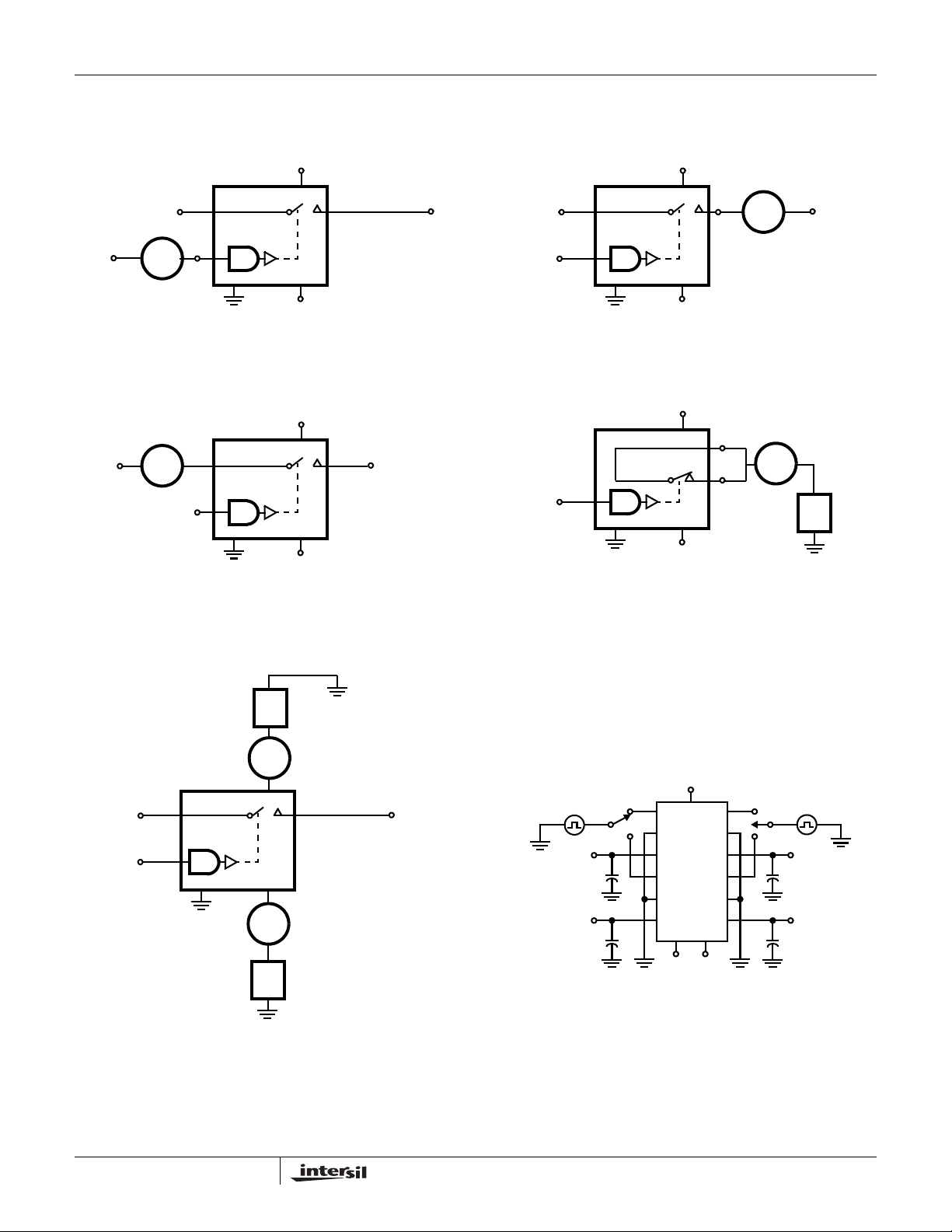

Test Circuits

www.BDTIC.com/Intersil

HI-200/883

+V

CC

S

V

IN

I

IN

-V

GND

CC

D

FIGURE 1. INPUT LEAKAGE CURRENT

+V

CC

V

S

I

S

V

IN

-V

GND

FIGURE 3. IS

CC

(OFF)

S

V

D

S

V

S

V

IN

GND

FIGURE 2. I

V

IN

GND

FIGURE 4. I

+V

CC

D

I

D

-V

CC

V

D

D (OFF)

+V

CC

S

I

D(ON)

D

V

-V

CC

D (ON)

+V

CC

I

1

STEP

S

V

IN

GND

I

2

-V

CC

D

FIGURE 5. SUPPLY CURRENTS

GENERATOR

TEST

POINT

0.01µF

TEST

POINT

0.01µF

FIGURE 6. CHARGE TRANSFER ERROR

15V

V+

IN

1

S

1

D

1

IN

2

S

2

D

2

GNDV-

-15V GND

IN

3

S

3

D

3

IN

4

S

4

D

4

STEP

GENERATOR

(SEE NOTE)

TEST

POINT

0.01µF

TEST

POINT

0.01µF

4

FN6059.2

January 30, 2006

Test Circuits (Continued)

www.BDTIC.com/Intersil

S

V

IN

GND

FIGURE 7. R

+V

HI-200/883

15V

CC

D

V

D

-V

CC

DS

SINE WAVE

GENERATOR

V+

IN

1

S

1

D

1

IN

2

S

2

D

2

GNDV-

-15V GND

IN

3

S

3

D

3

1kΩ

IN

4

2.4V

S

4

D

4

1kΩ

TEST

POINT

TEST

POINT

24V

1kΩ

2.4V

1kΩ

FIGURE 8. OFF CHANNEL ISOLATION

SINE WAVE

GENERATOR

TEST

POINT

TEST

POINT

TEST

POINT

1kΩ

TEST

POINT

1kΩ

0.8V

24V

0.8V

24V

15V

V+

IN

1

S

1

D

1

IN

2

S

2

D

2

GNDV-

-15V GND

24V

IN

3

S

3

D

3

IN

4

S

4

D

4

0.8V

24V

0.8V

1kΩ

TEST

POINT

1kΩ

STEP

GENERATOR

FIGURE 9. CROSSTALK BETWEEN CHANNELS

TEST

POINT

1kΩ

5

FN6059.2

January 30, 2006

Switching Waveforms

www.BDTIC.com/Intersil

HI-200/883

FIGURE 10.

FIGURE 11.

6

FN6059.2

January 30, 2006

Burn-In Circuit

www.BDTIC.com/Intersil

HI-200/883

NOTES:

3. R1 = R2 = 10kΩ

= C2 = 0.01µF (per socket) or 0.1µF (per row)

4. C

1

= D2 = IN4002 or equivalent

5. D

1

6. |(V+) - (V-)| = 30V

Schematic Diagrams

FIGURE 12. HI-200/883 METAL CAN (TO-99)

TTL/CMOS REFERENCE CIRCUIT V

V+

R

2

GND

V-

5K

D

Q

P1

M

P13

Q

3

Q

N2

N1

R

3

24.2K

R

4

5.4K

R

5

7.9K

Q

P2

Q

P4

M

N15

R

300

M

6

Q

Q

N14

CELL

REF

P3

Q

N4

P5

M

N16

M

N17

V

REF

TO P

V

LL

R

7

100K

2

GND

7

FN6059.2

January 30, 2006

Schematic Diagrams (Continued)

www.BDTIC.com/Intersil

’

A

HI-200/883

SWITCH CELL

N11

P1

P3

INPUT

A’

P4

P11

V+

N13

V-

N12

P12

DIGITAL INPUT BUFFER AND LEVEL SHIFTER

P5

OUTPUT

V+

R

1

200Ω

V+

V-VA

N13

N11

N12

OUTPUT

P12

V-

N1

N8

P8

P9

N9

P7

D

1

D

2

N2

TO V

TO V

P2

LL

REF

N4

N3

P6

N7

N6

N5

V-

N10

P10

INPUT

P11

8

FN6059.2

January 30, 2006

HI-200/883

www.BDTIC.com/Intersil

Test Circuits and Waveforms T

80

70

60

50

40

30

ON RESISTANCE (Ω)

20

10

0

-25-50 0 25 50 75 100 125

TEMPERATURE (°C)

VIN = 0V

= 25°C, V

A

= ±15V, VAH = 2.4V, VAL = 0.8V and V

SUPPLY

100

50

ON RESISTANCE (Ω)

0

-15 -10 -5 0 5 10 15

= Open

REF

V+ = +10V

V- = -10V

V+ = +12.5V

V- = -12.5V

V+ = +15V

V- = -15V

ANALOG SIGNAL LEVEL (V)

FIGURE 13. ON RESISTANCE vs TEMPERATURE FIGURE 14. ON RESISTANCE vs ANALOG SIGNAL

LEVEL AND POWER SUPPLY VOLTAGE

100

I

10

CURRENT (nA)

1.0

0.1

25 50 75 100

S(OFF)/ID(OFF)

I

TEMPERATURE (°C)

D(ON)

125

90

80

70

60

50

40

30

SWITCH CURRENT (mA)

20

10

0

1234 567

0

VOLTAGE ACROSS SWITCH (±V)

FIGURE 15. LEAKA G E CURRENT vs T E MPERATURE FIGURE 16. SWITCH CURRENT vs VOLTAGE

140

120

100

80

60

OFF ISOLATION (dB)

40

20

0

100Hz 1kHz 10kHz 100kHz 1MHz

RL = 1kΩ

FREQUENCY (Hz)

FIGURE 17. OFF ISOLATION vs FREQUENCY

9

January 30, 2006

FN6059.2

Die Characteristics

www.BDTIC.com/Intersil

DIE ATTACH:

Material: Gold/Silicon Eutectic Alloy

Temperature: Metal Can - 420°C (Max)

Metallization Mask Layout

HI-200/883

HI-200

IN 2

GND

3

A

2

A

1

V+

91012

IN 1

8

OUT 2

4 5 6 7

V-

10

V

REF

OUT 1

FN6059.2

January 30, 2006

Metal Can Packages (Can)

www.BDTIC.com/Intersil

HI-200/883

REFERENCE PLANE

A

ØD ØD1

F

Q

Øb1

NOTES:

1. (All leads) Øb applies between L1 and L2. Øb1 applies between

L2 and 0.500 from the reference plane. Diameter is uncontrolled

in L1 and beyond 0.500 from the reference plane.

2. Measured from maximum diameter of the product.

α is the basic spacing from the centerline of the tab to terminal 1

3.

and β is the basic spacing of each lead or lead position (N -1

places) from

4. N is the maximum number of terminal positions.

5. Dimensioning and tolerancing per ANSI Y14.5M - 1982.

6. Controlling dimension: INCH.

α, looking at the bottom of the package.

L

L2

L1

A

A

Øe

Øb1

Øb

BASE AND

SEATING PLANE

BASE METAL LEAD FINISH

SECTION A-A

Øb2

e1

ØD2

2

β

N

1

α

k

T10.B MIL-STD-1835 MACY1-X10 (A2)

10 LEAD METAL CAN PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.165 0.185 4.19 4.70 -

Øb 0.016 0.019 0.41 0.48 1

k1

C

L

Øb1 0.016 0.021 0.41 0.53 1

Øb2 0.016 0.024 0.41 0.61 -

ØD 0.335 0.375 8.51 9.52 ØD1 0.305 0.335 7.75 8.51 ØD2 0.110 0.160 2.79 4.06 -

e 0.230 BSC 5.84 BSC -

e1 0.115 BSC 2.92 BSC -

F - 0.040 - 1.02 k 0.027 0.034 0.69 0.86 -

k1 0.027 0.045 0.69 1.14 2

L 0.500 0.750 12.70 19.05 1

L1 - 0.050 - 1.27 1

L2 0.250 - 6.35 - 1

Q 0.010 0.045 0.25 1.14 -

α

β 36

N10 104

36o BSC 36o BSC 3

o

BSC 36o BSC 3

NOTESMIN MAX MIN MAX

Rev. 0 5/18/94

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is ca utioned to verify that data she ets are current before pl acing orders. Information fur nished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or othe rwise under any patent or patent rights of Intersil or its subsidia ries.

For information regarding Intersil Corporation and its products, see www.intersil.com

11

FN6059.2

January 30, 2006

Loading...

Loading...