Page 1

HFA1113

Data Sheet February 1999 File Number 1342.5

850MHz, Low Distortion, Output Limiting,

Programmable Gain, Buffer Amplifier

The HFA1113 is a high speed Buffer featuring user

programmable gain and output limiting coupled with ultra

high speed performance. This buffer is the ideal choice for

high frequency applications requiring output limiting,

especially those needing ultra fast overload recovery times.

The output limiting function allows the designer to set the

maximum positive and negative output levels, thereby

protecting later stages from damage or input saturation. The

sub-nanosecond overdrive recovery time quickly returns the

amplifier to linear operation following an overdrive condition.

A unique feature of the pinout allows the user to select a

voltage gain of +1, -1, or +2, without the use of any external

components, as described in the “Application Information”

section. Compatibility with existing op amp pinouts provides

flexibility to upgrade low gain amplifiers, while decreasing

component count. Unlike most buffers, the standard pinout

provides an upgrade path should a higher closed loop gain

be needed at a future date.

Component and composite video systems will also benefit

from this buffer’s performance, as indicated by the excellent

gain flatness, and 0.02%/0.04 Degree Differential

Gain/Phase specifications (R

= 150Ω).

L

For Military product, refer to the HFA1113/883 data sheet.

Ordering Information

PART NUMBER

(BRAND)

HFA1113IB

(H1113I)

HFA11XXEVAL DIPEvaluation Board For High Speed Op Amps

TEMP.

RANGE (oC) PACKAGE

-40 to 85 8 Ld SOIC M8.15

PKG.

NO.

Pinout

HFA1113

(SOIC)

TOP VIEW

NC

-IN

+IN

1

2

3

V-

4

300

300

-

+

8

V

H

7

V+

OUT

6

V

5

L

Features

• User Programmable Output Voltage Limiting

• User Programmable For Closed-Loop Gains of +1, -1 or

+2 Without Use of External Resistors

• Wide -3dB Bandwidth. . . . . . . . . . . . . . . . . . . . . .850MHz

• Excellent Gain Flatness (to 100MHz). . . . . . . . . . ±0.07dB

• Low Differential Gain and Phase . . . 0.02%/0.04 Degrees

• Low Distortion (HD3, 30MHz). . . . . . . . . . . . . . . . . -73dBc

• Very Fast Slew Rate . . . . . . . . . . . . . . . . . . . . . 2400V/µs

• Fast Settling Time (0.1%). . . . . . . . . . . . . . . . . . . . . 13ns

• High Output Current. . . . . . . . . . . . . . . . . . . . . . . . .60mA

• Excellent Gain Accuracy . . . . . . . . . . . . . . . . . . . 0.99V/V

• Overdrive Recovery . . . . . . . . . . . . . . . . . . . . . . . . . <1ns

• Standard Operational Amplifier Pinout

Applications

• RF/IF Processors

• Driving Flash A/D Converters

• High-Speed Communications

• Impedance Transformation

• Line Driving

• Video Switching and Routing

• Radar Systems

• Medical Imaging Systems

Pin Descriptions

PIN

NAME

NC 1 No Connection

-IN 2 Inverting Input

+IN 3 Non-Inverting Input

V- 4 Negative Supply

V

L

OUT 6 Output

V+ 7 Positive Supply

V

H

NUMBER DESCRIPTION

5 Lower Output Limit

8 Upper Output Limit

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

| Copyright © Intersil Corporation 1999

Page 2

HFA1113

Absolute Maximum Ratings Thermal Information

Voltage Between V+ and V-. . . . . . . . . . . . . . . . . . . . . . . . . . . . .12V

DC Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

Voltage at VH or VL Terminal. . . . . . . . . . . . . . (V+) + 2V to (V-) - 2V

Output Current (50% Duty Cycle) . . . . . . . . . . . . . . . . . . . . . . 60mA

SUPPLY

Operating Conditions

Temperature Range. . . . . . . . . . . . . . . . . . . . . . . . . . -40oC to 85oC

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

1. θJA is measured with the component mounted on an evaluation PC board in free air.

Thermal Resistance (Typical, Note 1) θJA (oC/W)

SOIC Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Maximum Junction Temperature (Plastic Package) . . . . . . . .150oC

Maximum Storage Temperature Range. . . . . . . . . . -65oC to 150oC

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . 300oC

(SOIC - Lead Tips Only)

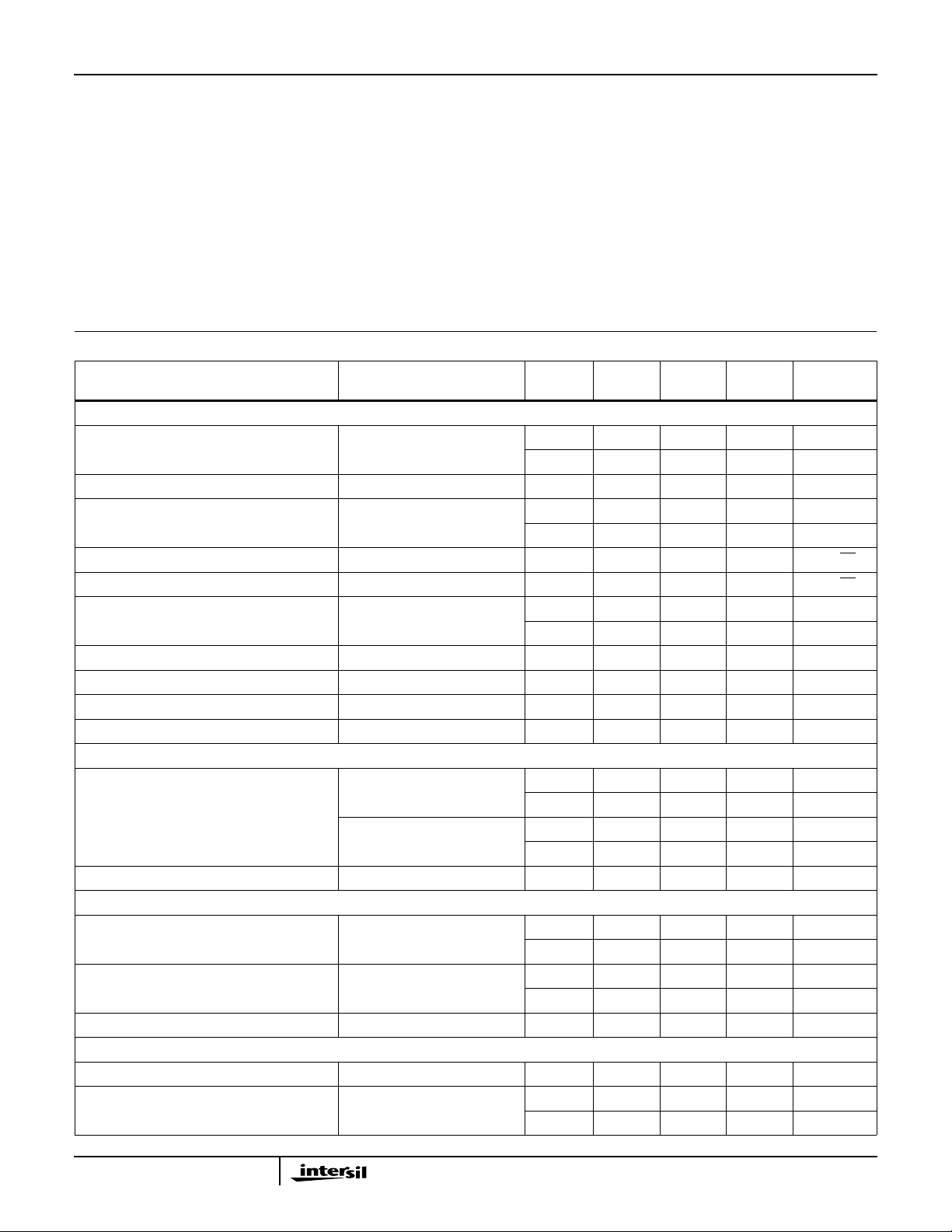

Electrical Specifications V

PARAMETER TEST CONDITIONS

INPUT CHARACTERISTICS

Output Offset Voltage 25 - 8 25 mV

Output Offset Voltage Drift Full - 10 - µV/

PSRR 25 39 45 - dB

Input Noise Voltage (Note 3) 100kHz 25 - 9 - nV/√

+Input Noise Current (Note 3) 100kHz 25 - 37 - pA/√

Non-Inverting Input Bias Current 25 - 25 40 µA

Non-Inverting Input Resistance 25 25 50 - kΩ

Inverting Input Resistance (Note 2) 25 240 300 360 Ω

Input Capacitance 25 - 2 - pF

Input Common Mode Range Full ±2.5 ±2.8 - V

TRANSFER CHARACTERISTICS

Gain A

DC Non-Linearity (Note 3) A

OUTPUT CHARACTERISTICS

Output Voltage (Note 3) A

Output Current (Note 3) R

Closed Loop Output Impedance DC, AV = +2 25 - 0.3 - Ω

POWER SUPPLY CHARACTERISTICS

Supply Voltage Range Full ±4.5 - ±5.5 V

Supply Current (Note 3) 25 - 21 26 mA

= ±5V, AV = +1, RL = 100Ω, Unless Otherwise Specified

SUPPLY

= +1, VIN = +2V 25 0.980 0.990 1.020 V/V

V

AV = +2, VIN = +1V 25 1.96 1.98 2.04 V/V

= +2, ±2V Full Scale 25 - 0.02 - %

V

= -1 25 ±3.0 ±3.3 - V

V

= 50Ω 25, 85 50 60 - mA

L

TEMP.

(oC) MIN TYP MAX UNITS

Full - - 35 mV

Full 35 - - dB

Full - - 65 µA

Full 0.975 - 1.025 V/V

Full 1.95 - 2.05 V/V

Full ±2.5 ±3.0 - V

-40 35 50 - mA

Full - - 33 mA

o

C

Hz

Hz

2

Page 3

HFA1113

Electrical Specifications V

PARAMETER TEST CONDITIONS

AC CHARACTERISTICS

-3dB Bandwidth

= 0.2V

(V

OUT

Slew Rate

= 5V

(V

OUT

Full Power Bandwidth

= 5V

(V

OUT

Gain Flatness

(to 30MHz, Notes 2, 3)

Gain Flatness

(to 50MHz, Notes 2, 3)

Gain Flatness

(to 100MHz, Notes 2, 3)

Linear Phase Deviation

(to 100MHz, Note 3)

2nd Harmonic Distortion

(30MHz, V

3rd Harmonic Distortion

(30MHz, V

2nd Harmonic Distortion

(50MHz, V

3rd Harmonic Distortion

(50MHz, V

2nd Harmonic Distortion

(100MHz, V

3rd Harmonic Distortion

(100MHz, V

P-P

P-P

P-P

OUT

OUT

OUT

OUT

OUT

OUT

, Notes 2, 3)

, Note 2)

, Note 3)

= 2V

P-P

= 2V

P-P

= 2V

P-P

= 2V

P-P

= 2V

P-P

= 2V

P-P

, Notes 2, 3)

, Notes 2, 3)

, Notes 2, 3)

, Notes 2, 3)

, Notes 2, 3)

, Notes 2, 3)

= ±5V, AV = +1, RL = 100Ω, Unless Otherwise Specified (Continued)

SUPPLY

TEMP.

(oC) MIN TYP MAX UNITS

AV = -1 25 450 800 - MHz

= +1 25 500 850 - MHz

A

V

= +2 25 350 550 - MHz

A

V

AV = -1 25 1500 2400 - V/µs

= +1 25 800 1500 - V/µs

A

V

= +2 25 1100 1900 - V/µs

A

V

AV = -1 25 - 300 - MHz

= +1 25 - 150 - MHz

A

V

= +2 25 - 220 - MHz

A

V

= -1 25 - ±0.02 - dB

A

V

A

= +1 25 - ±0.1 - dB

V

= +2 25 - ±0.015 ±0.04 dB

A

V

= -1 25 - ±0.05 - dB

A

V

= +1 25 - ±0.2 - dB

A

V

= +2 25 - ±0.036 ±0.08 dB

A

V

= -1 25 - ±0.10 - dB

A

V

= +2 25 - ±0.07 ±0.22 dB

A

V

= -1 25 - ±0.13 - Degrees

A

V

= +1 25 - ±0.83 - Degrees

A

V

= +2 25 - ±0.05 - Degrees

A

V

AV = -1 25 - -52 - dBc

= +1 25 - -57 - dBc

A

V

A

= +2 25 - -52 -45 dBc

V

AV = -1 25 - -71 - dBc

= +1 25 - -73 - dBc

A

V

= +2 25 - -72 -65 dBc

A

V

AV = -1 25 - -47 - dBc

= +1 25 - -53 - dBc

A

V

= +2 25 - -47 -40 dBc

A

V

AV = -1 25 - -63 - dBc

= +1 25 - -68 - dBc

A

V

= +2 25 - -65 -55 dBc

A

V

AV = -1 25 - -41 - dBc

A

= +1 25 - -50 - dBc

V

= +2 25 - -42 -35 dBc

A

V

AV = -1 25 - -55 - dBc

= +1 25 - -49 - dBc

A

V

= +2 25 - -62 -45 dBc

A

V

3

Page 4

HFA1113

Electrical Specifications V

= ±5V, AV = +1, RL = 100Ω, Unless Otherwise Specified (Continued)

SUPPLY

TEMP.

PARAMETER TEST CONDITIONS

3rd Order Intercept

(AV = +2, Note 3)

1dB Compression

= +2, Note 3)

(A

V

Reverse Isolation

, Note 3)

(S

12

100MHz 25 - 28 - dBm

300MHz 25 - 13 - dBm

100MHz 25 - 19 - dBm

300MHz 25 - 12 - dBm

40MHz 25 - -70 - dB

100MHz 25 - -60 - dB

(oC) MIN TYP MAX UNITS

600MHz 25 - -32 - dB

TRANSIENT CHARACTERISTICS

Rise Time

= 0.5V Step, Note 2)

(V

OUT

Rise Time

(V

= 2V Step)

OUT

Overshoot

= 0.5V Step,

(V

OUT

Input tR/tF = 200ps, Notes 2, 3, 4)

0.1% Settling Time (Note 3) V

0.05% Settling Time V

Differential Gain A

Differential Phase A

OUTPUT LIMITING CHARACTERISTICS A

Clamp Accuracy (Note 3) V

AV = -1 25 - 500 800 ps

= +1 25 - 480 750 ps

A

V

= +2 25 - 700 1000 ps

A

V

AV = -1 25 - 0.82 - ns

= +1 25 - 1.06 - ns

A

V

= +2 25 - 1.00 - ns

A

V

AV = -1 25 - 12 30 %

= +1 25 - 45 65 %

A

V

= +2 25 - 6 20 %

A

V

= 2V to 0V 25 - 13 20 ns

OUT

= 2V to 0V 25 - 20 33 ns

OUT

= +1, 3.58MHz, RL = 150Ω 25 - 0.03 - %

V

= +2, 3.58MHz, RL = 150Ω 25 - 0.02 - %

A

V

= +1, 3.58MHz, RL = 150Ω 25 - 0.05 - Degrees

V

= +2, 3.58MHz, RL = 150Ω 25 - 0.04 - Degrees

A

V

= +2, VH = +1V, VL = -1V, Unless Otherwise Specified

V

= ±1.6V, AV = -1 25 - ±100 ±150 mV

IN

Full - - ±200 mV

Clamp Overshoot V

Overdrive Recovery Time (Note 3) V

Negative Clamp Range 25 - -5.0 to

= ±1V, Input tR/tF = 500ps 25 - 7 - %

IN

= ±1V 25 - 0.75 1.5 ns

IN

-V

+2.0

Positive Clamp Range 25 - -2.0 to

-V

+5.0

Clamp Input Bias Current (Note 3) 25 - 50 200 µA

Full - - 300 µA

Clamp Input Bandwidth (Note 3) V

or VL = 100mV

H

P-P

25 - 500 - MHz

NOTES:

2. This parameter is not tested. The limits are guaranteed based on lab characterization, and reflect lot-to-lot variation.

3. See Typical Performance Curves for more information.

4. Overshoot decreases as input transition times increase, especially for A

= +1. Please refer to Typical Performance Curves.

V

4

Page 5

HFA1113

Application Information

Closed Loop Gain Selection

The HFA1113features a novel design which allows the user

to select from three closed loop gains, without any external

components. The result is a more flexible product, fewerpart

types in inventory, and more efficient use of board space.

This “buffer” operates in closed loop gains of -1, +1, or +2,

and gain selection is accomplished via connections to the

±Inputs. Applying the input signal to +IN and floating -IN

selects a gain of +1, while grounding -IN selects a gain of

+2. A gain of -1 is obtained by applying the input signal to

-IN with +IN grounded.

The table below summarizes these connections:

CONNECTIONS

+INPUT

GAIN (ACL)

-1 GND Input

+1 Input NC (Floating)

+2 Input GND

(PIN 3)

-INPUT

(PIN 2)

PC Board Layout

The frequency response of this amplifier depends greatly on

the amount of care taken in designing the PC board. The

use of low inductance components such as chip

resistors and chip capacitors is strongly recommended,

while a solid ground plane is a must!

Attention should be given to decoupling the power supplies.

A large value (10µF) tantalum in parallel with a small value

chip (0.1µF) capacitor works well in most cases.

Terminated microstrip signal lines are recommended at the

input and output of the device. Capacitance directly on the

output must be minimized, or isolated as discussed in the

next section.

avoided by placing a resistor (R

) in series with the output

S

prior to the capacitance.

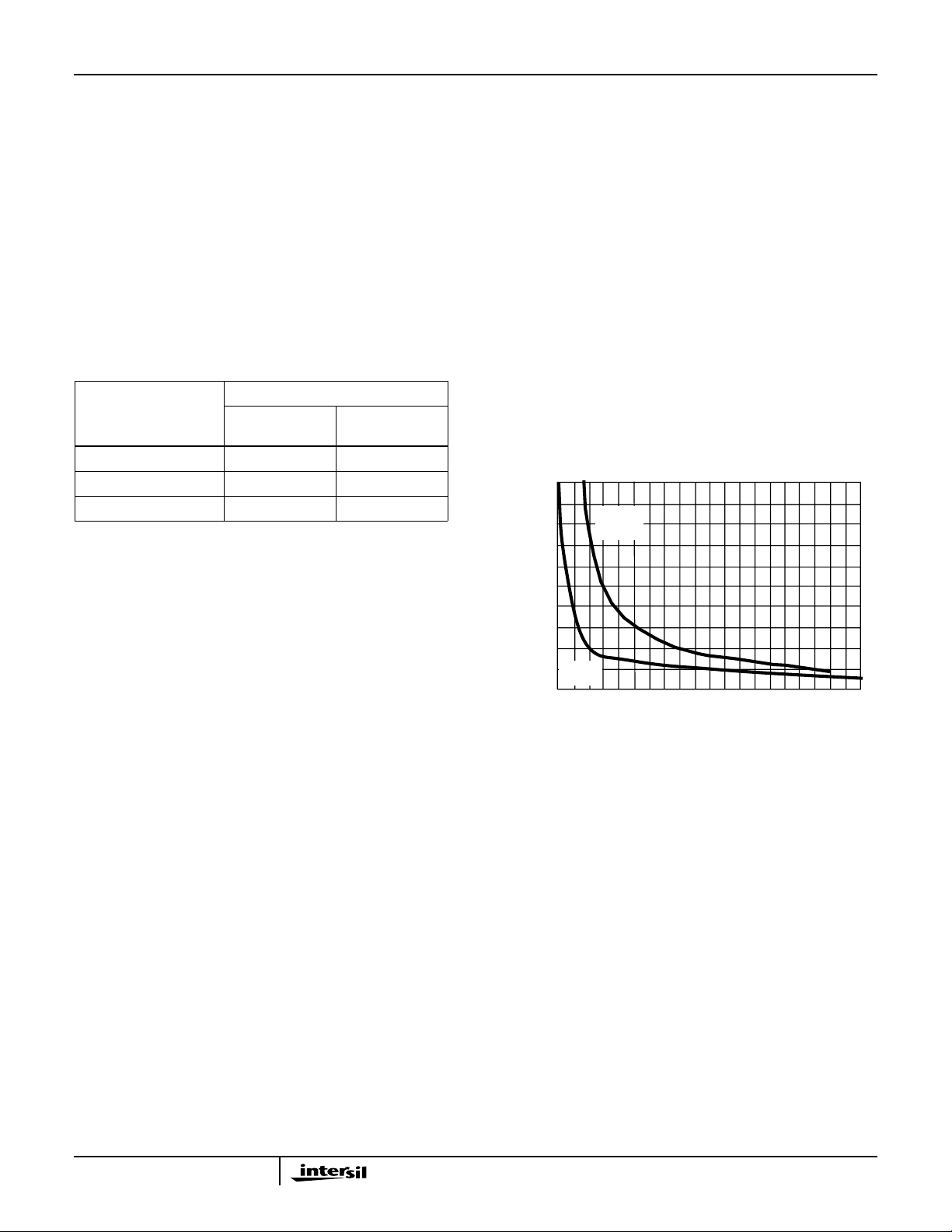

Figure 1 details starting points for the selection of this

resistor. The points on the curve indicate the R

and C

S

L

combinations for the optimum bandwidth, stability, and

settling time, but experimental fine tuning is recommended.

Picking a point above or to the right of the curve yields an

overdampedresponse, while points below or left of the curve

indicate areas of underdamped performance.

R

and CLform a low pass network at the output, thus

S

limiting system bandwidth well belowthe amplifier bandwidth

of 850MHz. By decreasing R

as CLincreases (as illustrated

S

in the curves), the maximum bandwidth is obtained without

sacrificing stability. Even so, bandwidth does decrease as

you move to the right along the curve. For example, at

A

= +1, RS = 50Ω, CL = 30pF, the overall bandwidth is

V

limited to 300MHz, and bandwidth drops to 100MHz at

A

= +1, RS = 5Ω, CL = 340pF.

V

50

45

40

35

30

25

(Ω)

S

20

R

15

10

5

0

0 40 80 120 160 200 240 280 320 360 400

FIGURE 1. RECOMMENDED SERIES RESISTOR vs LOAD

AV = +1

AV = +2

LOAD CAPACITANCE (pF)

CAPACITANCE

For unity gain applications, care must also be taken to

minimize the capacitance to ground seen by the amplifier’s

inverting input. At higher frequencies this capacitance will

tend to short the -INPUT to GND, resulting in a closed loop

gain which increases with frequency. This will cause

excessive high frequency peaking and potentially other

problems as well.

An example of a good high frequency layout is the

Evaluation Board shown in Figure 3.

Driving Capacitive Loads

Capacitive loads, such as an A/D input, or an improperly

terminated transmission line will degrade the amplifier’s

phase margin resulting in frequency response peaking and

possible oscillations. In most cases, the oscillation can be

5

Evaluation Board

The performance of the HFA1113 may be evaluated using

the HFA11XX Evaluation Board, slightly modified as follows:

1. Remove the 500Ω feedback resistor (R

connection open.

2. a. For A

resistor (R

b. For A

= +1 evaluation, remove the 500Ω gain setting

V

), and leave pin 2 floating.

1

=+2, replace the 500Ω gain setting resistor with

V

a 0Ω resistor to GND.

The modified schematic and layout of the board are shown

in Figures 2 and 3.

To order evaluation boards (part number HFA11XXEVAL),

please contact your local sales office.

NOTE: The SOIC version may be evaluated in the DIP board by

using a SOIC-to-DIP adapter such as Aries Electronics Part Number

08-350000-10.

), and leave the

2

Page 6

HFA1113

.

∞ (A

= +1)

V

OR 0Ω (A

IN

= +2)

V

V

R

1

1

50Ω

0.1µF0µF

2

3

4

-5V

8

7

6

5

GND

H

50Ω

GND

FIGURE 2. MODIFIED EVALUATION BOARD SCHEMATIC

TOP LAYOUT

V

H

1

+IN

OUT

V

L

V+

V-

GND

BOTTOM LAYOUT

OUT

V

L

between the positive and negative inputs. This buffer forces

-IN to track +IN, and sets up a slewing current of:

- V

(V

-IN

10µF0.1µF

+5V

This current is mirrored onto the high impedance node (Z) by

Q

X3-QX4

)/RF + V

OUT

-IN/RG

, where it is converted to a voltage and fed to the

output via another unity gain buffer. If no clamping is utilized,

the high impedance node may swing within the limits defined

by Q

and QN4. Note that when the output reaches its

P4

quiescent value, the current flowing through -IN is reduced to

only that small current (-I

) required to keep the output at

BIAS

the final voltage.

Tracing the path from V

clamp voltage on the high impedance node. V

by 2V

+IN

BE(QN6

and QP6) to set up the base voltage on QP5.

Q

P3

Q

P1

VV+

Q

N1

to Z illustrates the effect of the

H

V+

Q

P4

Q

N2

I

CLAMP

Q

P2

Z

+1

Q

N5

Q

Q

H

50K

(30K

FOR VL)

N6

P6

decreases

R

1

200Ω

V

H

FIGURE 3. EVALUATION BOARD LAYOUT

Limiting Operation

General

The HFA1113 features user programmable output clamps to

limit output voltage excursions. Clamping action is obtained

by applying voltages to the V

5) of the amplifier. V

sets the upper output limit, while V

H

sets the lower clamp level. If the amplifier tries to drive the

output above V

output voltage at V

, or below VL, the clamp circuitry limits the

H

or VL (± the clamp accuracy),

H

respectively. The low input bias currents of the clamp pins

allow them to be driven by simple resistive divider circuits, or

active elements such as amplifiers or DACs.

Clamp Circuitry

Figure 4 shows a simplified schematic of the HFA1113 input

stage, and the high clamp (V

feedback amplifiers, there is a unity gain buffer (Q

and VL terminals (pins 8 and

H

) circuitry. As with all current

H

- QX2)

X1

L

Q

Q

N3

V

V-

300Ω

-IN

R

(INTERNAL)

-IN

P5

Q

N4

G

RF= 300Ω

(INTERNAL)

V

OUT

FIGURE 4. HFA1113 SIMPLIFIED VH CLAMP CIRCUITRY

begins to conduct whenever the high impedance node

Q

P5

reaches a voltage equal to Q

’s base voltage + 2VBE(Q

P5

P5

and QN5). Thus, QP5 clamps node Z whenever Z reaches

V

. R1 provides a pull-up network to ensure functionality

H

with the clamp inputs floating. A similar description applies to

the symmetrical low clamp circuitry controlled by V

.

L

When the output is clamped, the negative input continues to

source a slewing current (I

output to the quiescent voltage defined by the input. Q

) in an attempt to force the

CLAMP

P5

must sink this current while clamping, because the -IN

current is always mirrored onto the high impedance node.

The clamping current is calculated as:

I

CLAMP

= (V

- V

-IN

OUT CLAMPED

)/300Ω + V

-IN/RG

.

As an example, a unity gain circuit with VIN = 2V, and VH=1V,

would have I

(R

= ∞ because -IN is floated for unity gain applications).

G

Note that I

CLAMP

CC

= (2V - 1V)/300Ω + 2V/∞ = 3.33mA

will increase by I

when the output is

CLAMP

clamp limited.

6

Page 7

HFA1113

Clamp Accuracy

The clamped output voltage will not be exactly equal to the

voltage applied to V

mismatches, necessitate a clamp accuracy parameter which

is found in the device specifications. Clamp accuracy is a

function of the clamping conditions. Referring again to

Figure 4, it can be seen that one component of clamp

accuracy is the VBE mismatch between the Q

and the Q

transistors. If the transistors always ran at the

X5

same current level there would be no V

contribution to the inaccuracy. The Q

biased at a constant current, but as described earlier, the

current through Q

as I

increases, causing the clamped output voltage to

CLAMP

increase as well. I

(A

x VIN - V

VCL

degrades as the overdrive increases. As an example, the

specified accuracy of ±100mV (A

overdrivedegrades to ±240mV for a 3X (200%) overdrive,as

shown in Figure 43.

Consideration must also be given to the fact that the clamp

voltages have an affect on amplifier linearity. The

“Nonlinearity Near Clamp Voltage” curve, Figure 48,

illustrates the impact of several clamp levels on linearity.

or VL. Offset errors, mostly due to V

H

mismatch, and no

BE

transistors are

X6

is equivalent to I

X5

is a function of the overdrive level

CLAMP

OUT CLAMPED

CLAMP

), so clamp accuracy

= -1, VH = 1V) for a 1.6X

V

BE

transistors,

X6

. VBE increases

restrictions indicated in the specifications. For example, the

HFA1113 could be limited to ECL output levels by setting

V

= -0.8V and VL= -1.8V. VHand VLmay be connected to

H

the same voltage (GND for instance) but the result won’t be

in a DC output voltage from an AC input signal. A

150mV - 200mV AC signal will still be present at the output.

Recovery from Overdrive

The output voltage remains at the clamp level as long as the

overdrive condition remains. When the input voltage drops

below the overdrive level (V

CLAMP/AVCL

return to linear operation. A time delay, known as the

Overdrive Recovery Time, is required for this resumption of

linear operation. The plots of “Unclamped Performance” and

“Clamped Performance” (Figures 41 and 42) highlight the

HFA1113’s subnanosecond recovery time. The difference

between the unclamped and clamped propagation delays is

the overdrive recovery time. The appropriate propagation

delays are 8.0ns for the unclamped pulse, and 8.8ns for the

clamped (2X overdrive) pulse yielding an overdrive recovery

time of 800ps. The measurement uses the 90% point of the

output transition to ensure that linear operation has

resumed. Note: The propagation delay illustrated is

dominated by the fixturing. The delta shown is accurate, but

the true HFA1113 propagation delay is 500ps.

) the amplifier will

Clamp Range

Unlike some competitor devices, both VH and VL have

usableranges that cross 0V. While V

than V

, both may be positive or negative, within the range

L

Typical Performance Curves V

200

AV = +2

150

100

50

0

-50

-100

OUTPUT VOLTAGE (mV)

-150

-200

TIME (5ns/DIV.)

FIGURE 5. SMALL SIGNAL PULSE RESPONSE FIGURE 6. LARGE SIGNAL PULSE RESPONSE

must be more positive

H

= ±5V, TA = 25oC, RL = 100Ω, Unless Otherwise Specified

SUPPLY

Overdrive recovery time is also a function of the overdrive

level. Figure 47 details the overdrive recovery time for

various clamp and overdrive levels.

2.0

AV = +2

1.5

1.0

0.5

0

-0.5

OUTPUT VOLTAGE (V)

-1.0

-1.5

-2.0

TIME (5ns/DIV.)

7

Page 8

HFA1113

Typical Performance Curves V

200

AV = +1

150

100

50

0

-50

-100

OUTPUT VOLTAGE (mV)

-150

-200

TIME (5ns/DIV.)

FIGURE 7. SMALL SIGNAL PULSE RESPONSE FIGURE 8. LARGE SIGNAL PULSE RESPONSE

200

AV = -1

150

100

= ±5V, TA = 25oC, RL = 100Ω, Unless Otherwise Specified (Continued)

SUPPLY

2.0

= +1

A

V

1.5

1.0

0.5

0

-0.5

OUTPUT VOLTAGE (V)

-1.0

-1.5

-2.0

2.0

1.5

1.0

AV = -1

TIME (5ns/DIV.)

50

0

-50

-100

OUTPUT VOLTAGE (mV)

-150

-200

TIME (5ns/DIV.)

0.5

-0.5

OUTPUT VOLTAGE (V)

-1.0

-1.5

-2.0

0

TIME (5ns/DIV.)

FIGURE 9. SMALL SIGNAL PULSE RESPONSE FIGURE 10. LARGE SIGNAL PULSE RESPONSE

6

V

= 200mV

OUT

3

GAIN

0

-3

-6

-9

NORMALIZED GAIN (dB)

PHASE

0.3 1 10 100 1000

P-P

FREQUENCY (MHz)

AV = +1

A

= +2

V

= -1

A

V

AV = +1

AV = -1

A

= +2

V

0

-90

-180

-270

-360

NORMALIZED PHASE (DEGREES)

AV = +2, V

9

6

3

GAIN (dB)

0

0.3 1 10 100 1000

= 200mV

OUT

GAIN

PHASE

FREQUENCY (MHz)

P-P

= 50Ω

R

L

= 100Ω

R

L

RL = 1kΩ

RL = 100Ω

R

= 50Ω

L

R

= 1kΩ

L

0

-90

-180

-270

PHASE (DEGREES)

-360

FIGURE 11. FREQUENCY RESPONSE FIGURE 12. FREQUENCY RESPONSE FOR VARIOUS LOAD

RESISTORS

8

Page 9

HFA1113

Typical Performance Curves V

6

AV = +1, V

3

GAIN

OUT

= 200mV

P-P

= ±5V, TA = 25oC, RL = 100Ω, Unless Otherwise Specified (Continued)

SUPPLY

0

= 1kΩ

R

-3

GAIN (dB)

-6

-9

L

RL = 100Ω

= 50Ω

R

L

PHASE

R

= 100Ω

L

= 50Ω

R

L

R

= 1kΩ

L

0.3 1 10 100 1000

FREQUENCY (MHz)

FIGURE 13. FREQUENCY RESPONSE FOR VARIOUS LOAD

RESISTORS

12

AV = +2

9

6

3

GAIN (dB)

0

GAIN

PHASE

4.0V

2.5V

1V

4.0V

2.5V

P-P

P-P

P-P

P-P

P-P

1V

P-P

0

-90

-180

-270

-360

0

-90

-180

-270

-360

PHASE (DEGREES)

PHASE (DEGREES)

6

AV = -1, V

3

0

-3

GAIN (dB)

-6

GAIN

OUT

= 200mV

P-P

RL = 1kΩ

RL = 100Ω

R

L

= 50Ω

-9

PHASE

RL = 100Ω

180

90

= 50Ω

R

L

RL = 1kΩ

0.3 1 10 100 1000

0

-90

-180

FREQUENCY (MHz)

FIGURE 14. FREQUENCY RESPONSE FOR VARIOUS LOAD

RESISTORS

6

AV = +1

3

0

-3

GAIN (dB)

-6

GAIN

PHASE

V

V

V

OUT

OUT

OUT

V

OUT

V

OUT

V

OUT

= 4V

= 2.5V

= 1V

= 4V

= 2.5V

= 1V

P-P

P-P

P-P

P-P

P-P

P-P

0

-90

-180

-270

-360

PHASE (DEGREES)

PHASE (DEGREES)

0.3 1 10 100 1000

FREQUENCY (MHz)

FIGURE15. FREQUENCYRESPONSEFOR VARIOUSOUTPUT

VOLTAGES

6

AV = -1

3

0

-3

GAIN (dB)

-6

GAIN

PHASE

V

V

V

OUT

OUT

OUT

= 2.5V

= 4V

= 1V

P-P

P-P

P-P

180

90

V

= 4V

OUT

V

V

OUT

OUT

= 2.5V

= 1V

P-P

P-P

P-P

0

-90

-180

0.3 1 10 100 1000

FREQUENCY (MHz)

FIGURE17. FREQUENCYRESPONSEFOR VARIOUSOUTPUT

VOLTAGES

FIGURE16. FREQUENCYRESPONSEFOR VARIOUSOUTPUT

NORMALIZED GAIN (dB)

PHASE (DEGREES)

0.3 1 10 100 1000

FREQUENCY (MHz)

VOLTAGES

15

V

= 5V

OUT

12

P-P

9

6

3

0

-3

-6

= -1

A

V

= +2

A

V

AV = +1

-9

-12

-15

0.3 1 10 100 1000

FREQUENCY (MHz)

FIGURE 18. FULL POWER BANDWIDTH

9

Page 10

HFA1113

Typical Performance Curves V

900

850

800

750

700

650

BANDWIDTH (MHz)

600

550

500

-50 -25 0 25 50 75 100 125

AV = +1

AV = -1

AV = +2

TEMPERATURE (

o

C)

= ±5V, TA = 25oC, RL = 100Ω, Unless Otherwise Specified (Continued)

SUPPLY

0.35

0.30

0.25

0.20

0.15

0.10

0.05

0

NORMALIZED GAIN (dB)

-0.05

-0.10

-0.15

1 10 100

FREQUENCY (MHz)

FIGURE 19. -3dB BANDWIDTH vs TEMPERATURE FIGURE 20. GAIN FLATNESS

4

3

2

1

0

-1

-2

-3

DEVIATION (DEGREES)

-4

-5

-6

0 15 30 45 60 75 90 105 120 135

FREQUENCY (MHz)

AV = +1

AV = -1

AV = +2

150

AV = +2, V

0.6

0.4

0.2

0.1

0

-0.1

-0.2

-0.4

SETTLING ERROR (%)

-0.6

-2 3 8 13 18 23 28 33 38 43 48

OUT

AV = +1

= 2V

TIME (ns)

AV = -1

AV = +2

FIGURE 21. DEVIATION FROM LINEAR PHASE FIGURE 22. SETTLING RESPONSE

-24

-30

-36

-42

-48

-54

-60

GAIN (dB)

-66

AV = +2

-72

-78

-84

0

AV = +1

AV = -1

20 40 60 80 100 120 140 160 180 200

FREQUENCY (MHz)

AV = +2

AV = -1

PHASE

AV = -1

-24

-30

-36

-42

-48

GAIN (dB)

-54

-60

100 190 280 370 460 550 640 730 820 910 1000

AV = +2

GAIN

AV = -1

FREQUENCY (MHz)

AV = -1

AV = +1

AV = +2

235

180

90

45

0

FIGURE 23. LOW FREQUENCY REVERSE ISOLATION (S12) FIGURE 24. HIGH FREQUENCY REVERSE ISOLATION (S12)

10

PHASE (DEGREES)

Page 11

HFA1113

Typical Performance Curves V

20

18

16

14

12

10

8

6

4

2

0

OUTPUT POWER AT 1dB COMPRESSION (dBm)

100 200 300 400 500

AV = +2

AV = +1

AV = -1

FREQUENCY (MHz)

= ±5V, TA = 25oC, RL = 100Ω, Unless Otherwise Specified (Continued)

SUPPLY

30

20

10

INTERCEPT POINT (dBm)

0

100 200 300 400

2 - TONE

AV = +1

FREQUENCY (MHz)

AV = -1

AV = +2

FIGURE 25. 1dB GAIN COMPRESSION vs FREQUENCY FIGURE 26. THIRD ORDER INTERMODULATIONINTERCEPT

vs FREQUENCY

-20

AV = +2

-30

-40

-50

-60

-70

DISTORTION (dBc)

-80

-90

-100

-6 -3 0 3 6 9 12 15

100MHz

OUTPUT POWER (dBm)

50MHz

30MHz

-20

AV = +2

-30

-40

-50

-60

-70

DISTORTION (dBc)

-80

-90

-100

-6 -3 0 3 6 9 12 15 18

100MHz

OUTPUT POWER (dBm)

50MHz

30MHz

FIGURE 27. SECOND HARMONIC DISTORTION vs P

-20

AV = +1

-30

-40

-50

-60

-70

DISTORTION (dBc)

-80

-90

-100

-6 -3 0 3 6 9 12 15

100MHz

50MHz

OUTPUT POWER (dBm)

30MHz

FIGURE 29. SECOND HARMONIC DISTORTION vs P

11

OUT

OUT

FIGURE 28. THIRD HARMONIC DISTORTION vs P

-20

AV = +1

-30

-40

-50

-60

-70

DISTORTION (dBc)

-80

-90

-100

-6 -3 0 3 6 9 12 15

100MHz

50MHz

OUTPUT POWER (dBm)

30MHz

FIGURE 30. THIRD HARMONIC DISTORTION vs P

OUT

OUT

Page 12

HFA1113

Typical Performance Curves V

-20

-30

-40

-50

-60

-70

DISTORTION (dBc)

-80

-90

-100

FIGURE 31. SECOND HARMONIC DISTORTION vs P

0.04

0.02

AV = -1

100MHz

-6 -3 0 3 6 9 12 15

50MHz

30MHz

OUTPUT POWER (dBm)

= ±5V, TA = 25oC, RL = 100Ω, Unless Otherwise Specified (Continued)

SUPPLY

OUT

-20

-30

-40

-50

-60

-70

DISTORTION (dBc)

-80

-90

-100

FIGURE 32. THIRD HARMONIC DISTORTION vs P

60

50

40

AV = -1

100MHz

-6 -3 0 3 6 9 12 15

V

= 0.5V

OUT

50MHz

OUTPUT POWER (dBm)

AV = +1

30MHz

OUT

PERCENT ERROR (%)

-0.02

-0.04

0

-3.0

-2.0 -1.0 0 1.0 2.0 3.0

INPUT VOLTAGE (V)

30

20

OVERSHOOT (%)

10

AV = +2

0

100 300 500 700 900 1100 1300

AV = -1

INPUT RISE TIME (ps)

FIGURE 33. INTEGRAL LINEARITY ERROR FIGURE 34. OVERSHOOT vs INPUT RISE TIME

60

V

= 1V

OUT

50

40

30

20

OVERSHOOT (%)

AV = -1

10

0

100 300 500 700 900 1100 1300

AV = +2

INPUT RISE TIME (ps)

AV = +1

60

V

= 2V

OUT

50

40

AV = +1

30

AV = -1

20

OVERSHOOT (%)

AV = +2

10

0

100 300 500 700 900 1100 1300

INPUT RISE TIME (ps)

FIGURE 35. OVERSHOOT vs INPUT RISE TIME FIGURE 36. OVERSHOOT vs INPUT RISE TIME

12

Page 13

HFA1113

Typical Performance Curves V

22

21

20

19

18

17

16

15

14

13

12

11

10

9

SUPPLY CURRENT (mA)

8

7

6

5

59

678 10

TOTAL SUPPLY VOLTAGE (V+ - V-, V)

= ±5V, TA = 25oC, RL = 100Ω, Unless Otherwise Specified (Continued)

SUPPLY

FIGURE 37. SUPPLY CURRENT vs SUPPLY VOLTAGE

3.6

AV = -1

3.5

+V

3.4

3.3

3.2

3.1

3.0

2.9

OUTPUT VOLTAGE (V)

2.8

2.7

2.6

|-V

| (RL= 100Ω)

OUT

|-V

| (RL= 50Ω)

OUT

-50 -25 0 25 50 75 100 125

TEMPERATURE (

(RL= 50Ω)

OUT

+V

o

(RL= 100Ω)

OUT

C)

25

24

23

22

21

20

19

18

SUPPLY CURRENT (mA)

17

16

15

-50 -25 0 25 50 75 100 125

TEMPERATURE (

o

C)

FIGURE 38. SUPPLY CURRENT vs TEMPERATURE

50

40

30

20

E

NOISE VOLTAGE (nV/√Hz)

10

0

0.1 1 10 100

FREQUENCY (kHz)

NI

I

NI

130

110

90

70

50

30

NOISE CURRENT (pA/√Hz)

FIGURE 39. OUTPUT VOLTAGE vs TEMPERATURE FIGURE 40. INPUT NOISE CHARACTERISTICS

AV = +2

IN

0V TO

0.5V

OUT

0V TO

1V

TIME (20ns/DIV.)

0V TO

1V

OUT

0V TO

1V

IN

AV = +2

TIME (20ns/DIV.)

FIGURE 41. UNCLAMPED PERFORMANCE FIGURE 42. CLAMPED PERFORMANCE

13

Page 14

HFA1113

Typical Performance Curves V

350

AV = ±1

300

250

= 1V

V

200

150

100

CLAMP ACCURACY (mV)

50

0

0 100 200 300 400 500

OVERDRIVE (% OF V

H

= 2V

V

H

VH = 100mV

)

H

= ±5V, TA = 25oC, RL = 100Ω, Unless Otherwise Specified (Continued)

SUPPLY

250

AV = ±1

VH = 500mV

200

150

100

CLAMP ACCURACY (mV)

50

0

0

100 200 300 400 500

OVERDRIVE (% OF V

)

L

FIGURE 43. VH CLAMP ACCURACY vs OVERDRIVE FIGURE 44. VL CLAMP ACCURACY vs OVERDRIVE

400

300

200

A

= ±2

V

VH = 500mV

= 1V

V

H

V

= 2V

H

250

200

150

100

AV = +2

VL = -1V

= -2V

V

L

VL = -500mV

= -1V

V

L

= -2V

V

L

VL = -100mV

VL = -500mV

100

CLAMP ACCURACY (mV)

0

0 100 200 300 400 500

OVERDRIVE (% OF VH)

VH = 100mV

CLAMP ACCURACY (mV)

50

0

0 100 200 300 400 500

OVERDRIVE (% OF VL)

FIGURE 45. VH CLAMP ACCURACY vs OVERDRIVE FIGURE 46. VL CLAMP ACCURACY vs OVERDRIVE

3500

3000

2500

2000

1500

1000

500

OVERDRIVE RECOVERY TIME (ps)

0

100 200 300 400 500

OVERDRIVE LEVEL (% OF CLAMP LEVEL)

V

= 2V

H

VH = 1V

VH = 0.1V

V

= 0.5V

H

20

15

VL = -3V

10

) (mV)

5

IN

x V

0

V

- (A

-5

OUT

V

-10

-15

-20

-3 -2 -1 0 1 2 3

VL = -2V

VL = -1V

VH = 1V

x VIN (V)

A

V

VH = 2V

VL = -100mV

AV = -1

VH = 3V

FIGURE 47. OVERDRIVE RECOVERY vs OVERDRIVE FIGURE 48. NON-LINEARITY NEAR CLAMP VOLTAGE

14

Page 15

HFA1113

Typical Performance Curves V

140

AV = -1, VIN = ±1.6V

= 1V, VL = -1V

V

130

H

120

110

100

90

80

CLAMP ACCURACY (mV)

70

60

-75

-25

-50 0 50 100 150

TEMPERATURE (oC)

V

H

V

L

25

= ±5V, TA = 25oC, RL = 100Ω, Unless Otherwise Specified (Continued)

SUPPLY

130

120

110

100

90

80

70

60

50

CLAMP BIAS CURRENT (µA)

40

30

12575

20

-75

-25

-50 0 50 100 150

V

L

V

H

25

TEMPERATURE (oC)

VH = 1V, VL = -1V

FIGURE 49. CLAMP ACCURACY vs TEMPERATURE FIGURE 50. CLAMP BIAS CURRENT vs TEMPERATURE

6

3

0

-3

GAIN (dB)

-6

-9

-12

VH = 600mV

VH = 1.2V

P-P

P-P

VH = 300mV

P-P

6

3

0

-3

GAIN (dB)

-6

-9

-12

VL = 600mV

VL = 1.2V

VL = 300mV

P-P

P-P

12575

P-P

1 10 100 1000

FREQUENCY (MHz)

FIGURE 51. VH CLAMP INPUT BANDWIDTH

15

1 10 100 1000

FREQUENCY (MHz)

FIGURE 52. VL CLAMP INPUT BANDWIDTH

Page 16

Die Characteristics

HFA1113

DIE DIMENSIONS:

63 mils x 44 mils x 19 mils

1600µm x 1130µm x 483µm

METALLIZATION:

Type: Metal 1: AICu(2%)/TiW

Thickness: Metal 1: 8k

Å ±0.4kÅ

Type: Metal 2: AICu(2%)

Thickness: Metal 2: 16k

Å ±0.8kÅ

Metallization Mask Layout

PASSIVATION:

Type: Nitride

Thickness: 4k

Å ±0.5kÅ

TRANSISTOR COUNT:

52

SUBSTRATE POTENTIAL (POWERED UP):

Floating (Recommend Connection to V-)

HFA1113

NC

+IN

V-

NC

V

L

OUT

-IN

V

V+

H

16

Page 17

Small Outline Plastic Packages (SOIC)

HFA1113

N

INDEX

AREA

123

-A-

E

-B-

SEATING PLANE

D

A

-C-

0.25(0.010) BM M

H

L

h x 45

o

α

e

B

0.25(0.010) C AM BS

M

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of

Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm (0.006

inch) per side.

4. Dimension “E” does not include interlead flash or protrusions. Interlead flash and protrusions shall not exceed 0.25mm (0.010 inch) per

side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width “B”, as measured 0.36mm (0.014 inch) or greater

above the seating plane, shall not exceed a maximum value of

0.61mm (0.024 inch).

10. Controlling dimension: MILLIMETER. Converted inch dimensions

are not necessarily exact.

A1

C

0.10(0.004)

M8.15 (JEDEC MS-012-AA ISSUE C)

8 LEAD NARROW BODY SMALL OUTLINE PLASTIC

PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.0532 0.0688 1.35 1.75 -

A1 0.0040 0.0098 0.10 0.25 -

B 0.013 0.020 0.33 0.51 9

C 0.0075 0.0098 0.19 0.25 D 0.1890 0.1968 4.80 5.00 3

E 0.1497 0.1574 3.80 4.00 4

e 0.050 BSC 1.27 BSC H 0.2284 0.2440 5.80 6.20 h 0.0099 0.0196 0.25 0.50 5

L 0.016 0.050 0.40 1.27 6

N8 87

o

α

0

o

8

o

0

o

8

Rev. 0 12/93

NOTESMIN MAX MIN MAX

-

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil semiconductor products are sold by description only.Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (321) 724-7000

FAX: (321) 724-7240

17

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Intersil (Taiwan) Ltd.

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

Loading...

Loading...