T

www.BDTIC.com/Intersil

C

U

®

S

B

O

M

M

O

Data Sheet August 2003

C

E

R

E P

T

E

L

O

E

D

N

E

C

H

D

O

R

C

A

L

P

E

R

D

5

1

5

5

T

N

E

M

E

HC5523

FN4144.6

LSSGR/TR57 CO/Loop Carrier SLIC with

Low Power Standby

The HC5523 is a subscriber line interface circuit which is

interchangeable with Ericsson’s PBL3764A/4 for distributed

central office applications. Enhancements include immunity

to circuit latch-up during hot plug and absence of false

signaling in the presence of longitudinal currents.

The HC5523 is fabricated in a High Voltage Dielectrically

Isolated (DI) Bipolar Process that eliminates leakage

currents and device latch-up problems normally associated

with junction isolated ICs. The elimination of the leakage

currents results in improved circuit performance for wide

temperature extremes. The latch free benefit of the DI

process guarantees operation under adverse transient

conditions. This process feature makes the HC5523 ideally

suited for use in harsh outdoor environments.

Part Number Information

PART NUMBER

HC5523IM -40 to 85 28 Ld PLCC N28.45

HC5523IP -40 to 85 22 Ld PDIP E22.4

TEMP.

RANGE (oC) PACKAGE

PKG.

DWG. #

Features

• DI Monolithic High Voltage Process

• Programmable Current Feed (20mA to 60mA)

• Programmable Loop Current Detector Threshold and

Battery Feed Characteristics

• Ground Key and Ring Trip Detection

• Compatible with Ericsson’s PBL3764A/4

• Thermal Shutdown

• On-Hook Transmission

• Wide Battery Voltage Range (-24V to -58V)

• Low Standby Power

• Meets TR-NWT-000057 Transmission Requirements

o

C to 85oC Ambient Temperature Range

•-40

Applications

• Digital Loop Carrier Systems • Pair Gain

• Fiber-In-The-Loop ONUs • POTS

• Wireless Local Loop • PABX

• Hybrid Fiber Coax

• Related Literature

- AN9632, Operation of the HC5523/15 Evaluation Board

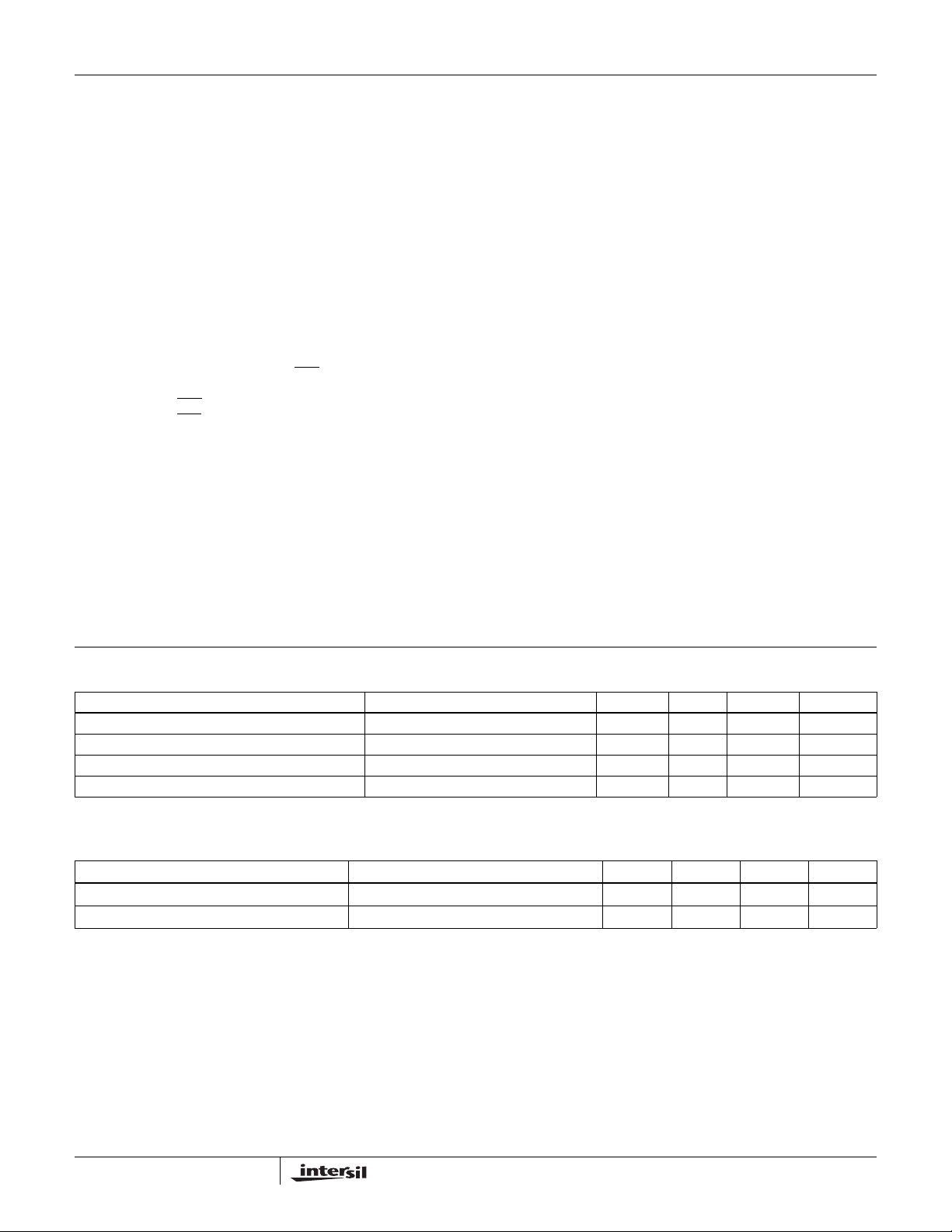

Block Diagram

RINGRLY

DT

DR

TIP

RING

HPT

HPR

V

BAT

V

CC

V

EE

AGND

BGND

1

RING RELAY

DRIVER

RING TRIP

DETECTOR

2-WIRE

INTERFACE

BIAS

LOOP CURRENT

DETECTOR

GROUND KEY

DETECTOR

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

4-WIRE

INTERFACE

VF SIGNAL

PATH

DIGITAL

MULTIPLEXER

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

V

TX

RSN

E0

E1

C1

C2

DET

R

D

R

DC

RSG

Copyright © Intersil Americas Inc. 2003. All Rights Reserved.

HC5523

www.BDTIC.com/Intersil

Absolute Maximum Ratings Thermal Information

Temperature, Humidity

Storage Temperature Range . . . . . . . . . . . . . . . . -65

Operating Temperature Range . . . . . . . . . . . . . . -40

Operating Junction Temperature Range . . . . . . . -40

Power Supply (-40

Supply Voltage V

Supply Voltage V

Supply Voltage V

Ground

Voltage between AGND and BGND. . . . . . . . . . . . . -0.3V to 0.3V

Relay Driver

Ring Relay Supply Voltage . . . . . . . . . . . . . . . . . . . . . . 0V to 20V

Ring Relay Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50mA

Ring Trip Comparator

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .V

Input Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -5mA to 5mA

Digital Inputs, Outputs (C1, C2, E0, E1, DET

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0V to V

Output Voltage (DET Not Active) . . . . . . . . . . . . . . . . . .0V to V

Output Current (DET). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5mA

Tipx and Ringx Terminals (-40

Tipx or Ringx Voltage, Continuous (Referenced to GND). . . V

+2V

Tipx or Ringx, Pulse < 10ms, T

Tipx or Ringx, Pulse < 10µs, T

Tipx or Ringx, Pulse < 250ns, T

Tipx or Ringx Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70mA

ESD Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .500V

o

C ≤ TA ≤ 85oC)

to GND . . . . . . . . . . . . . . . . . . . . 0.5V to 7V

CC

to GND . . . . . . . . . . . . . . . . . . . . -7V to 0.5V

EE

to GND . . . . . . . . . . . . . . . . . .-80V to 0.5V

BAT

)

o

C ≤ TA ≤ +85oC)

> 10s . . . . V

REP

> 10s . . . V

REP

> 10s . . V

REP

o

C to 150oC

o

C to 110oC

o

C to 150oC

-20V to +5V

BAT

-40V to +10V

BAT

-70V to +15V

BAT

BAT

to 0V

CC

CC

BAT

to

Thermal Resistance (Typical, Note 1) θ

22 Lead PDIP Package . . . . . . . . . . . . . . . . . . . . . . 53

28 Lead PLCC Package . . . . . . . . . . . . . . . . . . . . . . . 53

Continuous Power Dissipation at 70

22 Lead PDIP Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.5W

28 Lead PLCC Package . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.5W

Package Power Dissipation at 70

22 Lead PDIP Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4W

28 Lead PLCC Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4W

Derate above. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Plastic DIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18.8mW/

PLCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18.8mW/

Maximum Junction Temperature Range . . . . . . . . . -40

Maximum Storage Temperature Range . . . . . . . . . -65

Maximum Lead Temperature. . . . . . . . . . . . . . . . . . . . . . . . . .300

(Soldering 10s, PLCC Lead Tips Only)

Die Characteristics

Gate Count . . . . . . . . . . . . . . . . . . . . . . 543 Transistors, 51 Diodes

o

C

o

C, t < 100ms, t

REP

JA

> 1s

o

C to 150oC

o

C to 150oC

(oC/W)

o

o

o

o

C

C

C

C

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

is measured with the component mounted on an evaluation PC board in free air.

1. θ

JA

Typical Operating Conditions

These represent the conditions under which the part was developed and are suggested as guidelines.

PARAMETER CONDITIONS MIN TYP MAX UNITS

o

DC2

C

= 41.2kΩ,

PEAK

Case Temperature -40 - 100

with Respect to AGND -40oC to 85oC 4.75 - 5.25 V

V

CC

with Respect to AGND -40oC to 85oC -5.25 - -4.75 V

V

EE

with Respect to BGND -40oC to 85oC -58 - -24 V

V

BAT

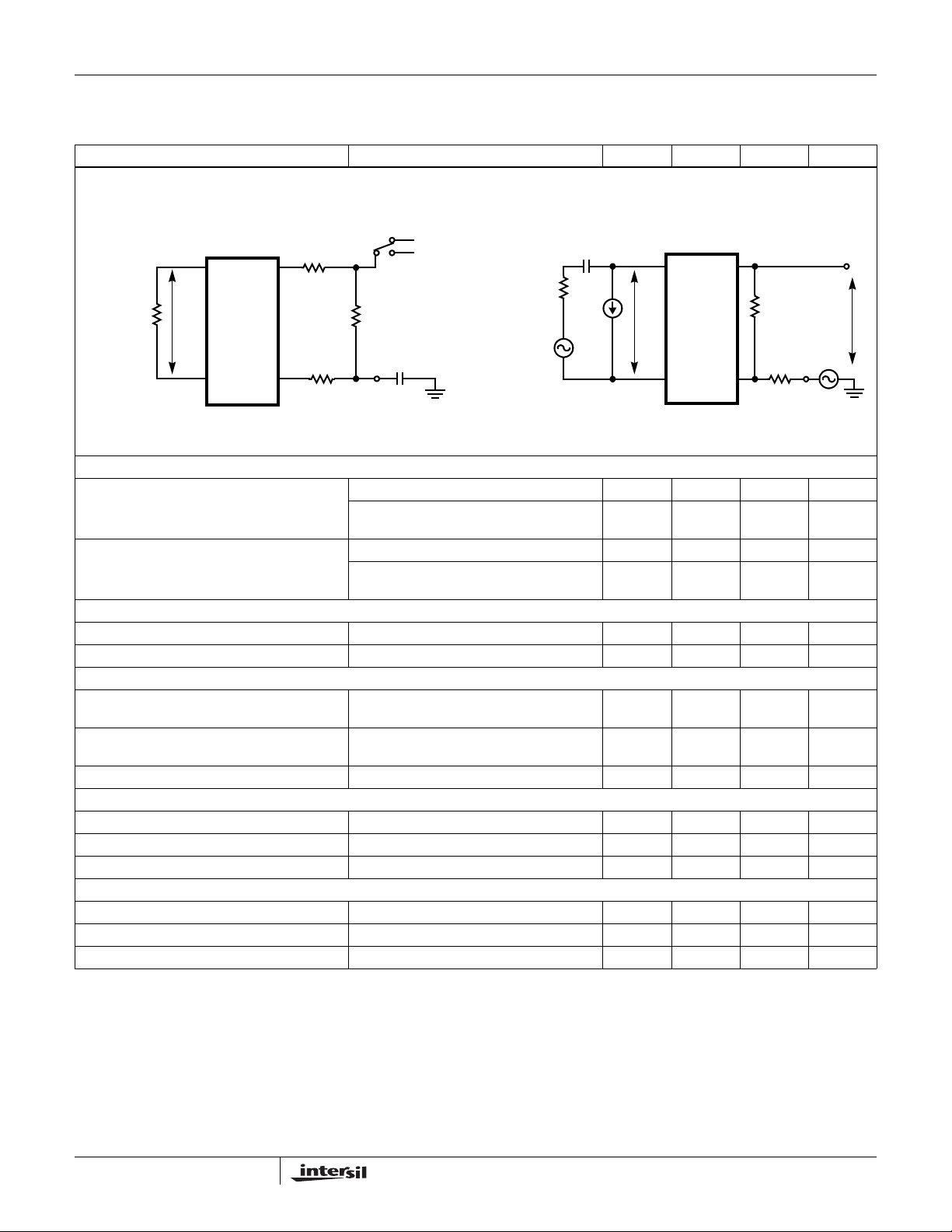

Electrical Specifications T

PARAMETER CONDITIONS MIN TYP MAX UNITS

Overload Level 1% THD, Z

Longitudinal Impedance (Tip/Ring) 0 < f < 100Hz (Note 3, Figure 2) - 20 35 Ω/Wire

= -40oC to 85oC, VCC = +5V ±5%, V

A

= 39kΩ, RSG = 0Ω, RF1 = RF2 = 0Ω, CHP = 10nF, CDC = 1.5µF, ZL = 600Ω, Unless Otherwise Specified. All pin

R

D

number references in the figures refer to the 28 lead PLCC package.

= 600Ω, (Note 2, Figure 1) 3.1 - - V

L

= -5V ±5%, V

EE

= -48V, AGND = BGND = 0V, R

BAT

DC1

= R

2

HC5523

www.BDTIC.com/Intersil

Electrical Specifications T

= -40oC to 85oC, VCC = +5V ±5%, V

A

= 39kΩ, RSG = 0Ω, RF1 = RF2 = 0Ω, CHP = 10nF, CDC = 1.5µF, ZL = 600Ω, Unless Otherwise Specified. All pin

R

D

number references in the figures refer to the 28 lead PLCC package.

= -5V ±5%, V

EE

PARAMETER CONDITIONS MIN TYP MAX UNITS

1V

0 < f < 100Hz

E

R

600Ω

I

DCMET

23mA

V

TIP

27

L

V

TRO

RING28RSN

TX

19

R

T

600kΩ

E

R

RX

16

300kΩ

RX

FIGURE 1. OVERLOAD LEVEL (TWO-WIRE PORT) FIGURE 2. LONGITUDINAL IMPEDANCE

LONGITUDINAL CURRENT LIMIT (TIP/RING)

Off-Hook (Active) No False Detections, (Loop Current),

LB > 45dB (Note 4, Figure 3A)

On-Hook (Standby), R

E

C

L

2.16µF

= ∞ No False Detections (Loop Current)

368Ω

368Ω

L

TIP

A

27

39kΩ

R

D

-5V

RING28R

A

DET

(Note 5, Figure 3B)

RSN

16

R

DC2

DC

14

41.2kΩ

R

DC1

41.2kΩ

C

DC

1.5µF

E

L

RMS

L

= -48V, AGND = BGND = 0V, R

BAT

(Continued)

A

T

C

2.16µF

300Ω

300Ω

368Ω

C2.16µF

C2.16µF

368Ω

V

T

V

R

A

R

LZT = VT/A

27 - - mA

8.5 - - mA

TIP

A

27

39kΩ

R

D

-5V

RING

A

28

TIP

27

RING28RSN

T

RSN

16

R

DC

14

DET

DC1

V

TX

19

16

R

DC2

41.2kΩ

= R

DC2

R

T

600kΩ

R

RX

300kΩ

LZR = VR/A

R

DC1

41.2kΩ

C

DC

1.5µF

= 41.2kΩ,

R

PEAK

Wire

PEAK

Wire

/

/

FIGURE 3A. OFF-HOOK FIGURE 3B. ON-HOOK

FIGURE 3. LONGITUDINAL CURRENT LIMIT

OFF-HOOK LONGITUDINAL BALANCE

Longitudinal to Metallic IEEE 455 - 1985, R

, RLT = 368Ω

LR

58 70 - dB

0.2kHz < f < 4.0kHz (Note 6, Figure 4)

Longitudinal to Metallic R

Metallic to Longitudinal FCC Part 68, Para 68.310

, RLT = 300Ω, 0.2kHz < f < 4.0kHz (Note

LR

6, Figure 4)

58 70 - dB

50 55 - dB

0.2kHz < f < 1.0kHz

1.0kHz < f < 4.0kHz (Note 7) 50 55 - dB

Longitudinal to 4-Wire 0.2kHz < f < 4.0kHz (Note 8, Figure 4) 58 70 - dB

Metallic to Longitudinal R

, RLT = 300Ω, 0.2kHz < f < 4.0kHz (Note

LR

9, Figure 5)

50 55 - dB

4-Wire to Longitudinal 0.2kHz < f < 4.0kHz (Note 10, Figure 5) 50 55 - dB

3

HC5523

www.BDTIC.com/Intersil

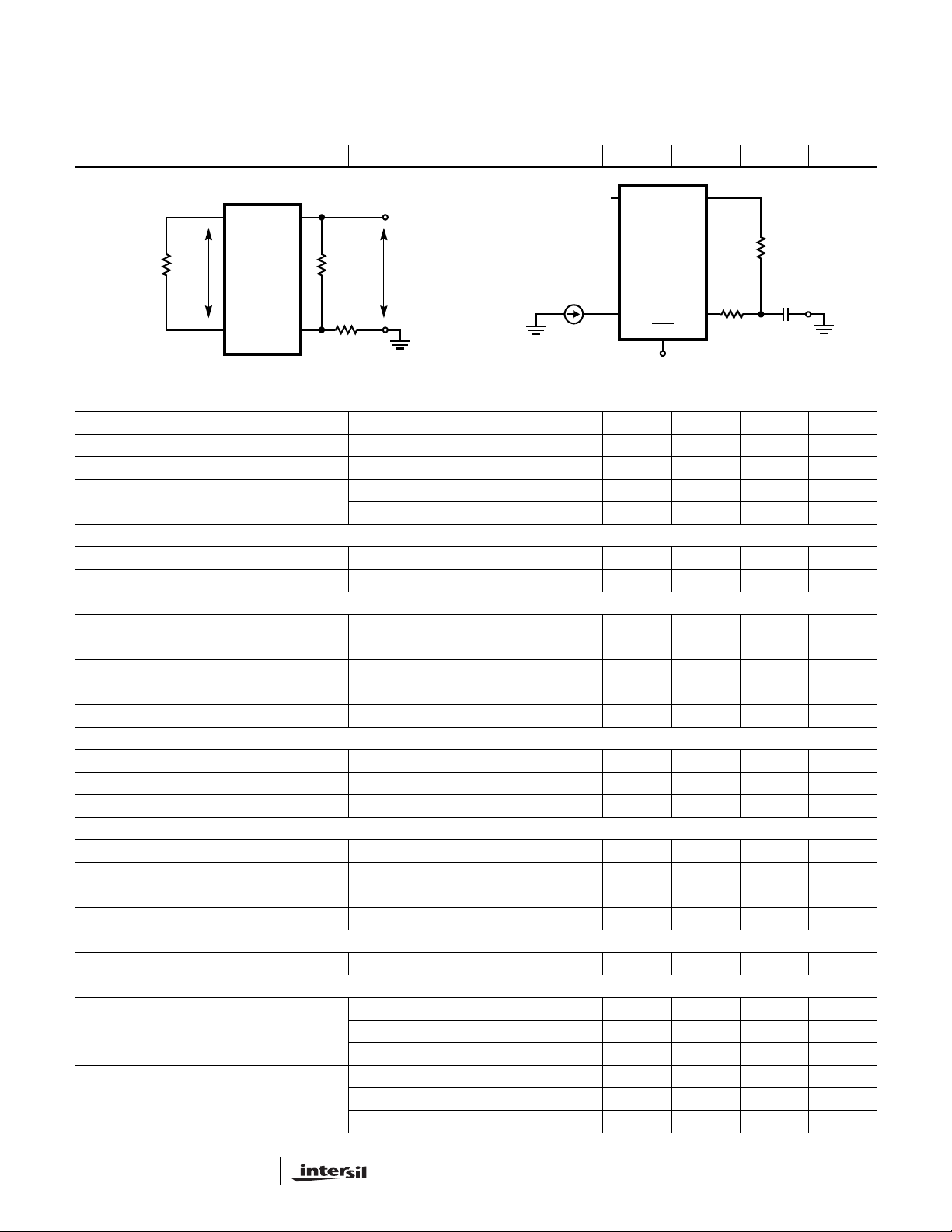

Electrical Specifications T

= -40oC to 85oC, VCC = +5V ±5%, V

A

= 39kΩ, RSG = 0Ω, RF1 = RF2 = 0Ω, CHP = 10nF, CDC = 1.5µF, ZL = 600Ω, Unless Otherwise Specified. All pin

R

D

number references in the figures refer to the 28 lead PLCC package.

PARAMETER CONDITIONS MIN TYP MAX UNITS

R

E

L

C

2.16µF

LT

R

LR

TIP

27

V

TR

RING

28

V

RSN

TX

19

16

FIGURE 4. LONGITUDINAL TO METALLIC AND

LONGITUDINAL TO 4-WIRE BALANCE

2-Wire Return Loss

= 20nF

C

HP

= -5V ±5%, V

EE

= -48V, AGND = BGND = 0V, R

BAT

DC1

= R

DC2

= 41.2kΩ,

(Continued)

R

R

T

600kΩ

R

RX

300kΩ

LT

300Ω

2.16µF

V

TX

C

V

L

R

LR

300Ω

E

TR

TIP

27

RING28RSN

FIGURE 5. METALLIC TO LONGITUDINAL AND 4-WIRE TO

LONGITUDINAL BALANCE

0.2kHz to 0.5kHz (Note 11, Figure 6) 25 - - dB

0.5kHz to 1.0kHz (Note 11, Figure 6) 27 - - dB

1.0kHz to 3.4kHz (Note 11, Figure 6) 23 - - dB

V

TX

19

R

T

600kΩ

E

R

RX

16

300kΩ

RX

4

HC5523

www.BDTIC.com/Intersil

Electrical Specifications T

= -40oC to 85oC, VCC = +5V ±5%, V

A

= 39kΩ, RSG = 0Ω, RF1 = RF2 = 0Ω, CHP = 10nF, CDC = 1.5µF, ZL = 600Ω, Unless Otherwise Specified. All pin

R

D

number references in the figures refer to the 28 lead PLCC package.

= -5V ±5%, V

EE

= -48V, AGND = BGND = 0V, R

BAT

(Continued)

DC1

= R

DC2

= 41.2kΩ,

PARAMETER CONDITIONS MIN TYP MAX UNITS

TIP IDLE VOLTAGE

Active, I

Standby, I

= 0 --4-V

L

= 0 -<0 - V

L

RING IDLE VOLTAGE

Active, I

Standby, I

TIP-RING Open Loop Metallic Voltage, V

4-WIRE TRANSMIT PORT (V

Overload Level (Z

= 0 --44- V

L

= 0 ->-48- V

L

V

= -52V, RSG = 0Ω 43 - 47 V

BAT

> 20kΩ, 1% THD) (Note 12, Figure 7) 3.1 - - V

L

TX

TR

)

Output Offset Voltage EG = 0, ZL = ∞ (Note 13, Figure 7) -60 - 60 mV

Output Impedance (Guaranteed by Design) 0.2kHz < f < 03.4kHz - 5 20 W

2- to 4-Wire (Metallic to V

R

V

S

R

R

LR

) Voltage Gain 0.3kHz < f < 03.4kHz (Note 14, Figure 7) 0.98 1.0 1.02 V/V

TX

R

600Ω

E

2.16µF

L

C

I

DCMET

23mA

G

V

TR

TIP27V

19

RING28RSN

16

TX

R

T

600kΩ

R

RX

300kΩ

Z

D

TIP

27

V

M

Z

IN

RING28RSN

V

TX

19

R

T

600kΩ

R

RX

16

300kΩ

V

V

TXO

TX

PEAK

Z

L

FIGURE 6.

TWO-WIRE RETURN LOSS FIGURE 7. OVERLOAD LEVEL (4-WIRE TRANSMIT PORT),

OUTPUT OFFSET VOLTAGE, 2-WIRE TO 4-WIRE

VOLTAGE GAIN AND HARMONIC DISTORTION

4-WIRE RECEIVE PORT (RSN)

DC Voltage I

R

Sum Node Impedance (Gtd by Design) 0.2kHz < f < 3.4kHz - - 20 W

X

= 0mA - 0 - V

RSN

Current Gain-RSN to Metallic 0.3kHz < f < 3.4kHz (Note 15, Figure 8) 980 1000 1020 Ratio

FREQUENCY RESPONSE (OFF-HOOK)

2-Wire to 4-Wire 0dBm at 1.0kHz, E

RX

= 0V

-0.2 - 0.2 dB

0.3kHz < f < 3.4kHz (Note 16, Figure 9)

4-Wire to 2-Wire 0dBm at 1.0kHz, E

0.3kHz < f < 3.4kHz (Note 17, Figure 9)

4-Wire to 4-Wire 0dBm at 1.0kHz, E

0.3kHz < f < 3.4kHz (Note 18, Figure 9)

G

G

= 0V

= 0V

-0.2 - 0.2 dB

-0.2 - 0.2 dB

INSERTION LOSS

2-Wire to 4-Wire 0dBm, 1kHz (Note 19, Figure 9) -0.2 - 0.2 dB

4-Wire to 2-Wire 0dBm, 1kHz (Note 20, Figure 9) -0.2 - 0.2 dB

GAIN TRACKING (Ref = -10dBm, at 1.0kHz)

2-Wire to 4-Wire +3dBm to +7dBm (Note 21, Figure 9) -0.15 - 0.15 dB

2-Wire to 4-Wire -40dBm to +3dBm (Note 21, Figure 9) -0.1 - 0.1 dB

2-Wire to 4-Wire -55dBm to -40dBm (Note 21, Figure 9) -0.2 - 0.2 dB

4-Wire to 2-Wire -40dBm to +7dBm (Note 22, Figure 9) -0.1 - 0.1 dB

4-Wire to 2-Wire -55dBm to -40dBm (Note 22, Figure 9) -0.2 - 0.2 dB

5

HC5523

www.BDTIC.com/Intersil

Electrical Specifications T

= -40oC to 85oC, VCC = +5V ±5%, V

A

= 39kΩ, RSG = 0Ω, RF1 = RF2 = 0Ω, CHP = 10nF, CDC = 1.5µF, ZL = 600Ω, Unless Otherwise Specified. All pin

R

D

number references in the figures refer to the 28 lead PLCC package.

= -5V ±5%, V

EE

= -48V, AGND = BGND = 0V, R

BAT

(Continued)

DC1

= R

DC2

= 41.2kΩ,

PARAMETER CONDITIONS MIN TYP MAX UNITS

GRX = ((V

Where: V

and V

- V

)(300k))/(-3)(600)

TR2

is the Tip to Ring Voltage with V

is the Tip to Ring Voltage with V

TIP

27

V

TR

RING28R

R

600Ω

TR1

TR1

TR2

L

RSN

DC

= 0V

RSN

= -3V

RSN

R

RX

300kΩ

16

R

DC2

14

41.2kΩ

R

DC1

41.2kΩ

1.5µF

V

= 0V

RSN

= -3V

V

RSN

600Ω

C

DC

1/ωC < RL

C

V

TR

TIP27V

RING28RSN

R

L

I

DCMET

E

G

TX

19

16

R

T

600kΩ

R

RX

300kΩ

V

TX

E

RX

FIGURE 8. CURRENT GAIN-RSN TO METALLIC FIGURE 9. FREQUENCY RESPONSE, INSERTION LOSS,

GAIN TRACKING AND HARMONIC DISTORTION

NOISE

Idle Channel Noise at 2-Wire C-Message Weighting (No te 2 3 , Fi gu r e 10 ) - 8.5 - dBrnC

Psophometrical Weighting

- -81.5 - dBrnp

(Note 23, Figure 10)

Idle Channel Noise at 4-Wire C-Message Weighting (Note 24, Figure 10) - 8.5 - dBrnC

Psophometrical Weighting

- -81.5 - dBrnp

(Note 23, Figure 10)

HARMONIC DISTORTION

2-Wire to 4-Wire 0dBm, 1kHz (Note 25, Figure 7) - -65 -54 dB

4-Wire to 2-Wire 0dBm, 0.3kHz to 3.4kHz (Note 26, Figure 9) - -65 -54 dB

BATTERY FEED CHARACTERISTICS

Constant Loop Current Tolerance

R

DCX

= 41.2kΩ

Loop Current Tolerance (Standby) I

Open Circuit Voltage (V

TIP

- V

)-40

RING

I

= 2500/(R

L

o

C to 85oC (Note 27)

-40

= (V

L

BAT

o

-40

C to 85oC (Note 28)

o

C to 85oC, (Active) RSG = ∞ 14 16.67 20 V

+ R

DC1

DC2

-3)/(RL +1800),

),

0.92I

0.8I

L

L

I

L

I

L

1.08I

1.2I

L

L

mA

mA

LOOP CURRENT DETECTOR

On-Hook to Off-Hook R

Off-Hook to On-Hook R

Loop Current Hysteresis R

= 39kΩ, -40oC to 85oC 372/R

D

= 39kΩ, -40oC to 85oC 325/R

D

= 39kΩ, -40oC to 85oC 25/R

D

465/R

D

405/R

D

60/R

D

558/R

D

485/R

D

95/R

D

D

mA

D

mA

D

mA

GROUND KEY DETECTOR

Tip/Ring Current Difference - Trigger (Note 29, Figure 11) 8 12 17 mA

Tip/Ring Current Difference - Reset (Note 29, Figure 11) 3 7 12 mA

Hysteresis (Note 29, Figure 11) 0 5 9 mA

6

HC5523

www.BDTIC.com/Intersil

Electrical Specifications T

= -40oC to 85oC, VCC = +5V ±5%, V

A

= 39kΩ, RSG = 0Ω, RF1 = RF2 = 0Ω, CHP = 10nF, CDC = 1.5µF, ZL = 600Ω, Unless Otherwise Specified. All pin

R

D

number references in the figures refer to the 28 lead PLCC package.

= -5V ±5%, V

EE

= -48V, AGND = BGND = 0V, R

BAT

(Continued)

DC1

= R

DC2

= 41.2kΩ,

PARAMETER CONDITIONS MIN TYP MAX UNITS

600Ω

TIP27V

R

L

V

TR V

RING28RSN

TX

19

16

R

T

600kΩ

R

RX

300kΩ

TIP

27

TX

RING28R

DET

RSN

16

DC

14

R

DC2

41.2kΩ

E1 = C1 = 0, C2 = 1

R

DC1

41.2kΩ

C

DC

1.5µF

FIGURE 10. IDLE CHANNEL NOISE FIGURE 11. GROUND KEY DETECT

RING TRIP DETECTOR (DT, DR)

Offset Voltage Source Res = 0 -20 - 20 mV

Input Bias Current Source Res = 0 -360 - 360 nA

Input Common-Mode Range Source Res = 0 V

+1 - 0 V

BAT

Input Resistance Source Res = 0, Unbalanced 1 - - MΩ

Source Res = 0, Balanced 3 - - MΩ

RING RELAY DRIVER

V

at 25mA IOL = 25mA - 0.2 0.6 V

SAT

Off-State Leakage Current V

= 12V - - 10 µA

OH

DIGITAL INPUTS (E0, E1, C1, C2)

Input Low Voltage, V

Input High Voltage, V

Input Low Current, I

Input Low Current, I

IL

IH

: C1, C2 VIL = 0.4V -200 - - µA

IL

: E0, E1 VIL = 0.4V -100 - - µA

IL

Input High Current V

DETECTOR OUTPUT (DET

Output Low Voltage, V

Output High Voltage, V

)

OL

OH

= 2.4V - - 40 µA

IH

IOL = 2mA - - 0.45 V

IOH = 100µA2.7--V

0-0.8V

2-VCCV

Internal Pull-Up Resistor 10 15 20 k

POWER DISSIPATION (V

BAT

= -48V)

Open Circuit State C1 = C2 = 0 - 26.3 41 mW

On-Hook, Standby C1 = C2 = 1 - 37.5 57 mW

On-Hook, Active C1 = 0, C2 = 1, R

Off-Hook, Active C1 = 0, C2 = 1, R

= High Impedance - 110 216 mW

L

= 600Ω -1.11.4W

L

TEMPERATURE GUARD

Thermal Shutdown 150 - 180

SUPPLY CURRENTS

Open Circuit State (C1, 2 = 0, 0)

On-Hook

Standby State (C1, 2 = 1, 1)

On-Hook

(V

BAT

= -28V)

I

CC

I

EE

I

BAT

I

CC

I

EE

I

BAT

-1.32.0mA

-0.60.9mA

- 0.35 0.55 mA

- 1.6 2.25 mA

- 0.62 0.9 mA

- 0.55 0.85 mA

Ω

ο

C

7

HC5523

www.BDTIC.com/Intersil

Electrical Specifications T

PARAMETER CONDITIONS MIN TYP MAX UNITS

Active State (C1, 2 = 0, 1)

On-Hook

PSRR

V

to 2 or 4-Wire Port (Note 30, Figure 12) - 40 - dB

CC

V

to 2 or 4-Wire Port (Note 30, Figure 12) - 40 - dB

EE

V

to 2 or 4-Wire Port (Note 30, Figure 12) - 40 - dB

BAT

= -40oC to 85oC, VCC = +5V ±5%, V

A

= 39kΩ, RSG = 0Ω, RF1 = RF2 = 0Ω, CHP = 10nF, CDC = 1.5µF, ZL = 600Ω, Unless Otherwise Specified. All pin

R

D

number references in the figures refer to the 28 lead PLCC package.

I

CC

I

EE

I

BAT

-48V SUPPLY

+5V SUPPLY

-5V SUPPLY

R

L

600Ω

TIP27V

RING28RSN

100mV

TX

19

16

= -5V ±5%, V

EE

, 50Hz TO 4kHz

RMS

R

T

600kΩ

R

RX

300kΩ

= -48V, AGND = BGND = 0V, R

BAT

PSRR = 20 log (V

V

TX

= R

DC1

(Continued)

-3.75.8mA

-1.11.8mA

-2.23.7mA

)

TX/VIN

DC2

= 41.2kΩ,

FIGURE 12. POWER SUPPLY REJECTION RATIO

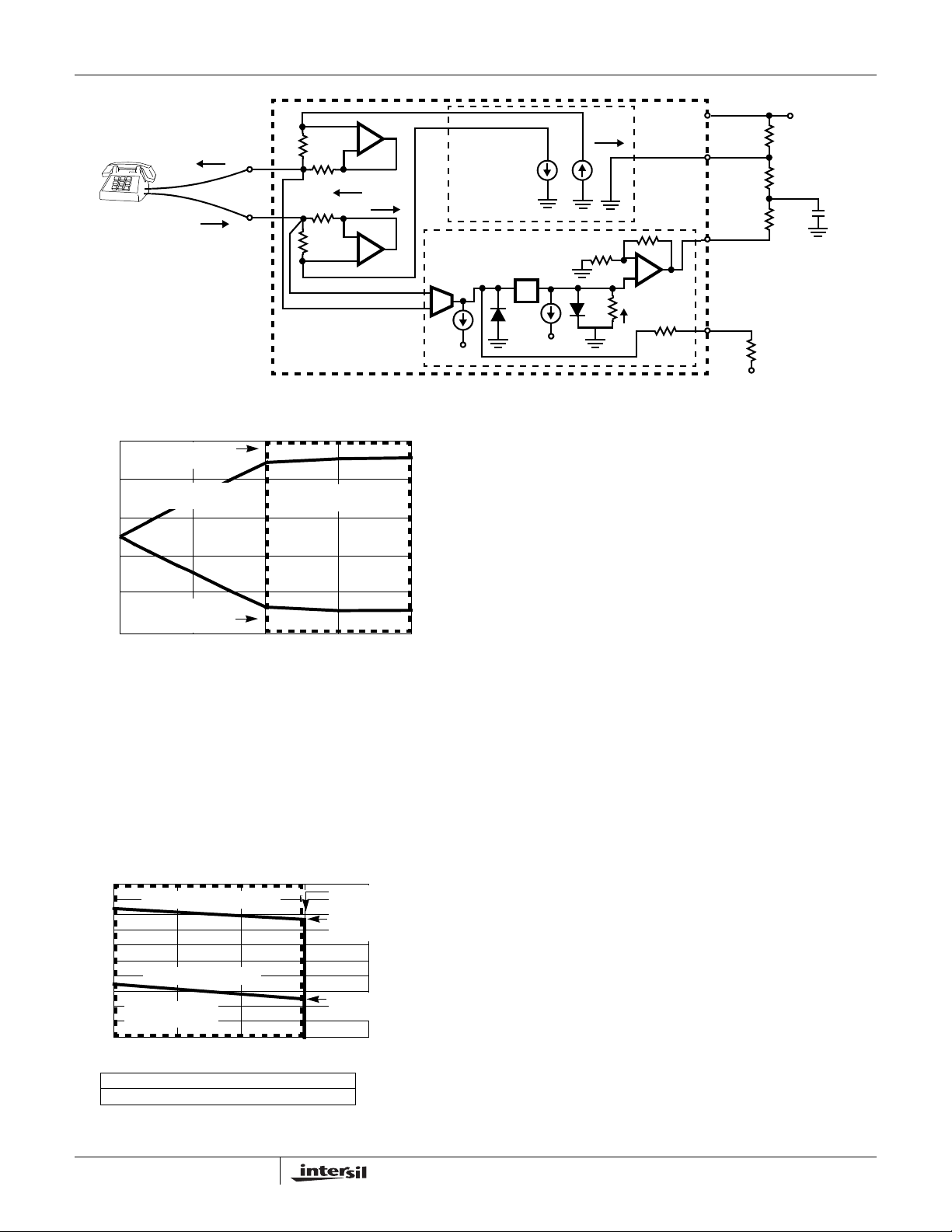

Circuit Operation and Design Information

The HC5523 is a current feed voltage sense Subscriber Line

Interface Circuit (SLIC). This means that for short loop

applications the SLIC provides a programed constant current to

the tip and ring terminals while sensing the tip to ring voltage.

The following discussion separates the SLIC’s operation into

its DC and AC paths, then follows up with additional circuit

and design information.

Constant Loop Current (DC) Path

SLIC in the Active Mode

The DC path establishes a constant loop current that flows

out of tip and into the ring terminal. The loop current is

programmed by resistors R

the R

the voltage across R

pin (Figure 13). The RDC voltage is determined by

DC

in the saturation guard circuit. Under

1

constant current feed conditions, the voltage drop across R

sets the R

flows through R

establishes a current (I

+R

DC2

voltage to -2.5V. This occurs when current

DC

into the current source I2. The RDC voltage

1

RSN

). This current is then multiplied by 1000, in the loop

current circuit, to become the tip and ring loop currents.

For the purpose of the following discussion, the saturation

guard voltage is defined as the maximum tip to ring voltage

at which the SLIC can provide a constant current for a given

battery and overhead voltage.

, R

DC1

and the voltage on

DC2

) that is equal to V

RDC

/(R

DC1

For loop resistances that result in a tip to ring voltage less

than the saturation guard voltage the loop current is defined

as:

I

L

where: I

R

Capacitor CDC between R

signals from the battery feed control loop. The value of C

2.5V

------------------------------------- - 1000×= (EQ. 1)

+

R

DC1RDC2

= Constant loop current.

L

DC1

and R

= Loop current programming resistors.

DC2

DC1

and R

removes the VF

DC2

DC

is determined by Equation 2:

DC

×=

R

DC1

C

1

T

---------------

---------------+

R

1

DC2

(EQ. 2)

where T = 30ms

NOTE: The minimum CDC value is obtained if R

1

Figure 14 illustrates the relationship between the tip to ring

DC1

= R

DC2

voltage and the loop resistance. For a 0Ω loop resistance both

tip and ring are at V

/2. As the loop resistance increases,

BAT

so does the voltage differential between tip and ring. When

this differential voltage becomes equal to the saturation guard

voltage, the operation of the SLIC’s loop feed changes from a

constant current feed to a resistive feed. The loop current in

the resistive feed region is no longer constant but varies as a

function of the loop resistance.

8

+

www.BDTIC.com/Intersil

I

I

RING

TIP

TIP

RING

-

I

TIP

I

RING

+

A

HC5523

FIGURE 13. DC LOOP CURRENT

V

= -48V, IL = 23mA, RSG = 4.0kΩ

0

-10

-20

-30

-40

TIP TO RING VOLTAGE (V)

-50

SATURATION

GUARD VOLTAGE

CONSTANT CURRENT

FEED REGION

SATURATION

GUARD VOLTAGE

01.2K

BAT

RESISTIVE FEED

LOOP RESISTANCE (Ω)

FIGURE 14. VTR vs R

REGION

L

V

TIP

V

RING

∞

Figure 15 shows the relationship between the saturation

guard voltage, the loop current and the loop resistance.

Notice from Figure 15 that for a loop resistance <1.2kΩ

(R

= 4.0kΩ) the SLIC is operating in the constant current

SG

feed region and for resistances >1.2kΩ the SLIC is operating

in the resistive feed region. Operation in the resistive feed

region allows long loop and off-hook transmission by

keeping the tip and ring voltages off the rails. Operation in

this region is transparent to the customer.

50

40

30

V

= -48V, RSG = 4.0kΩ

BAT

CONSTANT CURRENT

FEED REGION

SATURATION GUARD

VOLTAGE, V

TR

= 38V

HC5523

LOOP CURRENT

CIRCUIT

SATURATION GUARD

CIRCUIT

A

1

I

1

-5V

2

I

2

The Saturation Guard circuit (Figure 13) monitors the tip to

ring voltage via the transconductance amplifier A

generates a current that is proportional to the tip to ring

voltage difference. I

current until the tip to ring voltage exceeds 12.5V. When the

tip to ring voltage exceeds 12.5V (with no R

supplies more current than I

A

amplifies its input current by a factor of 12 and the current

2

through R

output current from A

voltage across R

decreases. This results in a corresponding decrease in the

loop current. The R

saturation guard reference voltage beyond 12.5V. Equation

3 gives the relationship between the R

the programmable saturation guard reference voltage:

V

SGREF

where:

V

SGREF

= Saturation Guard programming resistor.

R

SG

When the Saturation guard reference voltage is exceeded,

the tip to ring voltage is calculated using Equation 4:

V

TRRL

V

TX

I

-5V

RSN

-

+

R

1

-

17.3kΩ

+

is internally set to sink all of A1’s

1

RSN

R

DC

-2.5V

R

SG

-5V

R

SG

SG

can sink. When this happens

1

becomes the difference between I2 and the

1

12.5

. As the current from A2 increases, the

2

decreases and the output voltage on RDC

1

pin provides the ability to increase the

SG

resistor value and

SG

5

510•

-----------------------------------+=

RSG17300+

= Saturation Guard reference voltage.

16.66 5 105• RSG17300+()⁄+

------------------------------------------------------------ ------------------------×=

R

LRDC1RDC2

+()600⁄+

R

RX

R

DC1

R

DC2

. A1

1

resistor) A1

C

DC

(EQ. 3)

(EQ. 4)

V

= -24V, RSG = ∞

BAT

RESISTIVE FEED

REGION

10 20

LOOP CURRENT (mA)

4kΩ

1.5kΩ

FIGURE 15. VTR vs IL and R

30

2kΩ

700Ω <400Ω

<1.2kΩ

SATURATION GUARD

VOLTAGE, V

RSG = 4.0kΩ100kΩ

RSG = ∞Ω

L

TR

= 13V

where:

V

= Voltage differential between tip and ring.

TR

RL = Loop resistance.

For on-hook transmission RL = ∞, Equation 4 reduces to:

16.66

V

TR

R

R

TIP TO RING VOLTAGE (V)

20

10

0

0

L

100kΩ

L

9

-----------------------------------+=

R

SG

•

510

17300+

5

(EQ. 5)

I

HC5523

www.BDTIC.com/Intersil

M

TIP

R

F

Z

L

Z

+

V

TR

-

TR

+

E

G

-

RING

+

V

TX

-

I

M

R

F

+

-

HC5523

FIGURE 16. SIMPLIFIED AC TRANSMISSION CIRCUIT

A = 250

1

A = 4

A = 250

V

TX

RSN

1000

+

V

Z

T

I

M

TX

-

Z

RX

+

V

RX

-

The value of R

should be calculated to allow maximum

SG

(AC) Transmission Path

loop length operation. This requires that the saturation guard

reference voltage be set as high as possible without clipping

the incoming or outgoing VF signal. A voltage margin of -4V

on tip and -4V on ring, for a total of -8V margin, is

recommended as a general guideline. The value of R

SG

is

calculated using Equation 6:

--------------------------- ---------------------------- ---------------------------- ---------------------------- ---------------------------- --- 17300–

R

=

SG

V

–()1

BATVMAR

5105•

R

+()

DC1RDC2

---------------------------- ------------------+

600R

L

16.66V–×

(EQ. 6)

where:

V

= Battery voltage.

BAT

V

= Voltage Margin. Recommended value of -8V to

MAR

allow a maximum overload level of 3.1V peak.

For on-hook transmission R

510

R

--------------------------------------------------------------- -- - 17300–=

SG

V

BATVMAR

•

= ∞, Equation 6 reduces to:

L

5

16.66V––

(EQ. 7)

SLIC in the Active Mode

Figure 16 shows a simplified AC transmission model. Circuit

analysis yields the following design equations:

V

TRVTXIM2RF

V

V

TX

RX

---------- -

-----------+

Z

Z

T

RX

V

TREGIMZL

where:

V

= Is the AC metallic voltage between tip and ring,

TR

including the voltage drop across the fuse resistors R

VTX = Is the AC metallic voltage. Either at the ground

referenced 4-wire side or the SLIC tip and ring terminals.

I

= Is the AC metallic current.

M

= Is a fuse resistor.

R

F

•+=

I

M

------------ -=

1000

•–=

ZT = Is used to set the SLIC’s 2-wire impedance.

SLIC in the Standby Mode

Overall system power is saved by configuring the SLIC in the

standby state when not in use. In the standby state the tip and

ring amplifiers are disabled and internal resistors are connected

between tip to ground and ring to V

. This connection

BAT

enables a loop current to flow when the phone goes off-hook.

The loop current detector then detects this current and the SLIC

is configured in the active mode for voice transmission. The

loop current in standby state is calculated as follows:

V

I

--------------------------------≈

L

R

BAT

L

3V–

1800Ω+

(EQ. 8)

where:

I

= Loop current in the standby state.

L

RL = Loop resistance.

VRX = Is the analog ground referenced receive signal.

= Is used to set the 4-wire to 2-wire gain.

Z

RX

EG = Is the AC open circuit voltage.

ZL = Is the line impedance.

(AC) 2-Wire Impedance

The AC 2-wire impedance (ZTR) is the impedance looking

into the SLIC, including the fuse resistors, and is calculated

as follows:

Let V

= 0. Then from Equation 10

RX

I

M

V

TXZT

------------ -•=

1000

(EQ. 9)

(EQ. 10)

(EQ. 11)

.

F

(EQ. 12)

V

= Battery voltage.

BAT

10

HC5523

www.BDTIC.com/Intersil

ZTR is defined as:

V

TR

TR

-----------=

I

M

Z

Substituting in Equation 9 for V

2R

V

TX

---------- -

Z

TR

I

M

-----------------------+=

•

FIM

I

M

Substituting in Equation 12 for V

Z

T

+=

------------ - 2R

Z

TR

1000

F

TR

TX

(EQ. 13)

(EQ. 14)

(EQ. 15)

Therefore

Z

1000 ZTR2RF–()•=

T

(EQ. 16)

Equation 16 can now be used to match the SLIC’s

impedance to any known line impedance (ZTR).

Example:

Calculate ZT to make ZTR = 600Ω in series with 2.16µF.

R

=20Ω.

F

Z

T

•=

1000 600

1

----------------------------------------- 220•–+

jω 2.16• 10

•

6–

Transhybrid Circuit

The purpose of the transhybrid circuit is to remove the

receive signal (V

preventing an echo on the transmit side. This is

accomplished by using an external op amp (usually part of

the CODEC) and by the inversion of the signal from the

4-wire receive port (RSN) to the 4-wire transmit port (V

Figure 17 shows the transhybrid circuit. The input signal will

be subtracted from the output signal if I

analysis yields the following equation:

V

V

TX

TX

RX

-----------+ 0=

Z

B

-----------

R

The value of Z

R–

Z

B

TX

Where VRX/VTX equals 1/ A

Therefore

ZBR

TX

) from the transmit signal (VTX), thereby

RX

equals I2. Node

1

is then

B

V

RX

-----------•=

V

TX

4-4

Z

T

++

------------ - 2R

Z

1000

RX

--------------------------------------------•=

-----------•

Z

T

FZL

Z

2R

+

L

F

).

TX

(EQ. 21)

(EQ. 22)

(EQ. 23)

ZT = 560kΩ in series with 2.16nF

(AC) 2-Wire to 4-Wire Gain

The 2-wire to 4-wire gain is equal to VTX/ V

From Equations 9 and 10 with VRX = 0

V

A

24–

TX

-----------

V

TR

------------------------------------------==

Z

T

Z

1000⁄

T

1000⁄ 2R

+

F

TR

(AC) 4-Wire to 2-Wire Gain

The 4-wire to 2-wire gain is equal to VTR/V

From Equations 9, 10 and 11 with EG = 0

V

TR

42–

-----------

V

RX

A

Z

T

-----------–

Z

RX

Z

--------------------------------------------•==

Z

T

++

------------ - 2R

1000

L

FZL

For applications where the 2-wire impedance (Z

Equation 15) is chosen to equal the line impedance (Z

expression for A

Z

A

42–

-----------–

Z

RX

1

T

-- -•=

2

simplifies to:

4-2

RX

TR

,

(AC) 4-Wire to 4-Wire Gain

The 4-wire to 4-wire gain is equal to VTX/V

From Equations 9, 10 and 11 with EG = 0

TX

RX

Z

-----------–

Z

RX

V

44–

-----------

V

A

T

--------------------------------------------•==

Z

+

L2RF

Z

T

------------ - 2R

++

1000

FZL

RX

(EQ. 17)

(EQ. 18)

), the

L

(EQ. 19)

(EQ. 20)

Example:

Given: RTX = 20kΩ, ZRX = 280kΩ, ZT = 562kΩ (standard

value), R

= 20Ω and Z = 600Ω

F

The value of ZB = 18.7kΩ

R

FB

I

2

R

TX

I

1

Z

T

Z

RX

Z

B

-

+

+

V

TX

-

+

V

RX

-

HC5523

V

TX

RSN

CODEC/

FILTER

FIGURE 17. TRANSHYBRID CIRCUIT

Supervisory Functions

The loop current, ground key and the ring trip detector

outputs are multiplexed to a single logic output pin called

DET

. See Table 1 to determine the active detector for a

given logic input. For further discussion of the logic circuitry

see section titled “Digital Logic Inputs”.

11

Before proceeding with an explanation of the loop current

www.BDTIC.com/Intersil

detector, ground key detector and later the longitudinal

impedance, it is important to understand the difference

between a “metallic” and “longitudinal” loop currents. Figure 18

illustrates 3 different types of loop current encountered.

Case 1 illustrates the metallic loop current. The definition of

a metallic loop current is when equal currents flow out of tip

and into ring. Loop current is a metallic current.

Cases 2 and 3 illustrate the longitudinal loop current. The

definition of a longitudinal loop current is a common mode

current, that flows either out of or into tip and ring

simultaneously. Longitudinal currents in the on-hook state

result in equal currents flowing through the sense resistors R

and R

(Figure 18). And longitudinal currents in the off-hook

2

1

state result in unequal currents flowing through the sense

resistors R

flowing away from the SLIC, the current through R

and R2. Notice that for case 2, longitudinal currents

1

is the

1

metallic loop current plus the longitudinal current; whereas the

current through R

is the metallic loop current minus the

2

longitudinal current. Longitudinal currents are generated when

the phone line is influenced by magnetic fields (e.g., power

lines).

Loop Current Detector

Figure 18 shows a simplified schematic of the loop current

and ground key detectors. The loop current detector works

by sensing the metallic current flowing through resistors R

and R

. This results in a current (IRD) out of the

2

transconductance amplifier (gm

of gm

and the metallic loop current. IRD then flows out the

1

) that is equal to the product

1

1

HC5523

R

pin and through resistor RD to VEE. The value of IRD is

D

equal to:

I

I

RD

The I

–

TIPIRING

----------------------------------- -

600

current results in a voltage drop across RD that is

RD

I

L

--------- -==

300

(EQ. 24)

compared to an internal 1.25V reference voltage. When the

voltage drop across R

configured for loop current detection, the DET

exceeds 1.25V, and the logic is

D

pin goes low.

The hysteresis resistor RH adds an additional voltage

effectively across R

, causing the on-hook to off-hook

D

threshold to be slightly higher than the off-hook to on-hook

threshold.

Taking into account the hysteresis voltage, the typical value

of R

for the on-hook to off-hook condition is:

D

R

--------------------------------------------------------------- -----------=

D

I

ON HO OK to OFF– HOOK–

465

(EQ. 25)

Taking into account the hysteresis voltage, the typical value

of R

for the off-hook to on-hook condition is:

D

--------------------------------------------------------------- -----------=

R

D

I

OFF H OOK to ON– HOOK–

A filter capacitor (C

375

) in parallel with RD will improve the

D

(EQ. 26)

accuracy of the trip point in a noisy environment. The value

of this capacitor is calculated using the following Equation:

T

------- -=

C

D

R

D

(EQ. 27)

where: T = 0.5ms

Ground Key Detector

ORDERING INFORMATION

CASE 1 CASE 2 CASE 3

I

METALLIC

←

I

METALLIC

→

I

LONGITUDINAL

←

I

LONGITUDINAL

←

I

LONGITUDINAL

I

LONGITUDINAL

gm1(I

METALLIC

+

-

TIP

RING

→

→

FIGURE 18. LOOP CURRENT AND GROUND KEY DETECTORS

R

1

R

2

HC5523

gm

1

gm

2

R

H

-

+

GROUND

KEY

COMPARATOR

CURRENT

COMPARATOR

gm2(I

I

GK

+

-

D

1

DIGITAL MULTIPLEXER

LOOP

- I

TIP

RING

D

2

I

1

)

R

D

R

H

+

-

+

V

)

1.25V

REF

I

RD

C

R

D

D

-

V

EE

-5V

DET

12

A simplified schematic of the ground key detector is shown

www.BDTIC.com/Intersil

in Figure 18. Ground key, is the process in which the ring

terminal is shorted to ground for the purpose of signaling an

Operator or seizing a phone line (between the Central Office

and a Private Branch Exchange). The Ground Key detector

is activated when unequal current flow through resistors R

and R

. This results in a current (IGK) out of the

2

transconductance amplifier (gm

of gm

and the differential (I

2

less than the internal current source (I

) that is equal to the product

2

-I

TIP

) loop current. If IGK is

RING

), then diode D1 is on

1

and the output of the ground key comparator is low. If I

greater than the internal current source (I

), then diode D2 is

1

GK

1

is

on and the output of the ground key comparator is high. With

the output of the ground key comparator high, and the logic

configured for ground key detect, the DET

pin goes low. The

ground key detector has a built in hysteresis of typically 5mA

between its trigger and reset values.

HC5523

R

RT

RING

RELAY

FIGURE 19. RING TRIP CIRCUIT FOR BATTERY BACKED

RINGING

TIP

RING

C

R

3

E

RT

R4R

RG

R

1

2

V

BAT

RINGRLY

DT

DR

COMPARATOR

-

+

RING TRIP

HC5523

DET

Ring Trip Detector

Ring trip detection is accomplished with the internal ring trip

comparator and the external circuitry shown in Figure 19.

The process of ring trip is initiated when the logic input pins

are in the following states: E0 = 0, E1 = 1/0, C1 = 1 and

C2 = 0. This logic condition connects the ring trip

comparator to the DET

energize the ring relay. The ring relay connects the tip and

ring of the phone to the external circuitry in Figure 19. When

the phone is on-hook the DT pin is more positive than the

DR pin and the DET

DR is more positive than DT and DET

goes low, indicating that the phone has gone off-hook, the

SLIC is commanded by the logic inputs to go into the active

state. In the active state, tip and ring are once again

connected to the phone and normal operation ensues.

Figure 19 illustrates battery backed unbalanced ring injected

ringing. For tip injected ringing just reverse the leads to the

phone. The ringing source could also be balanced.

NOTE: The DET output will toggle at 20Hz because the DT input is

not completely filtered by C

and determine if the DET

the off-hook condition is indicated.

output, and causes the Ringrly pin to

output is high. For off-hook conditions

goes low. When DET

. Software can examine the duty cycle

RT

pin is low for more that half the time, if so

Longitudinal Impedance

The feedback loop described in Figure 20(A, B) realizes the

desired longitudinal impedances from tip to ground and from

ring to ground. Nominal longitudinal impedance is resistive

and in the order of 22Ω.

In the presence of longitudinal currents this circuit attenuates

the voltages that would otherwise appear at the tip and ring

terminals, to levels well within the common mode range of

the SLIC. In fact, longitudinal currents may exceed the

programmed DC loop current without disturbing the SLIC’s

VF transmission capabilities.

The function of this circuit is to maintain the tip and ring

voltages symmetrically around V

longitudinal currents. The differential transconductance

amplifiers G

and GR accomplish this by sourcing or sinking

T

the required current to maintain V

When a longitudinal current is injected onto the tip and ring

inputs, the voltage at V

V

/2. When VC changes by the amount DVC, this change

BAT

moves from it’s equilibrium value

C

appears between the input terminals of the differential

transconductance amplifiers G

and G

are the differential currents ∆I1 and ∆I2, which in turn

R

feed the differential inputs of current sources I

respectively. I

and IR have current gains of 250 single

T

ended and 500 differentially, thus leading to a change in I

and I

that is equal to 500(∆I) and 500(∆I2).

R

The circuit shown in Figure 20(B) illustrates the tip side of

the longitudinal network. The advantages of a differential

input current source are: improved noise since the noise due

to current source 2I

is now correlated, power savings due

O

to differential current gain and minimized offset error at the

Operational Amplifier inputs via the two 5kΩ resistors.

/2, in the presence of

BAT

at V

C

and GR. The output of GT

T

BAT

/2.

T

and IR

T

13

HC5523

www.BDTIC.com/Intersil

Digital Logic Inputs

Table 1 is the logic truth table for the TTL compatible logic

input pins. The HC5523 has two enable inputs pins (E0, E1)

and two control inputs pins (C1, C2).

The enable pin E0 is used to enable or disable the DET

output pin. The DET

pin is enabled if E0 is at a logic level 0

and disabled if E0 is at a logic level 1.

The enable pin E1 gates the ground key detector to the DET

output with a logic level 0, and gates the loop or ring trip

detector to the DET

output with a logic level 1.

I

LONG

I

I

LONG

LONG

I

LONG

∆V

∆V

TIP

+

T

-

R

LARGE

R

LARGE

RING

+

R

-

HC5523

+

V

C

-

∆I

1

∆I

2

A combination of the control pins C1 and C2 is used to select

1 of the 4 possible operating states. A description of each

operating state and the control logic follow:

Open Circuit State (C1 = 0, C2 = 0)

In this state the SLIC is effectively off. All detectors and both

the tip and ring line drive amplifiers are powered down,

presenting a high impedance to the line. Power dissipation is

∆I

1

G

T

V

BAT

G

R

∆I

2

at a minimum.

/2

RING

TIP

V

R

LARGE

C

R

LARGE

TIP CURRENT SOURCE

WITH DIFFERENTIAL IN PUTS

20Ω

5kΩ

5kΩ

∆I

1

2I

0

TIP DIFFERENTIAL

TRANSCONDUCTANCE

AMPLIFIER

-

+

∆I

1

V

BAT

/2

G

T

I

T

I

R

FIGURE 20A. FIGURE 20B.

FIGURE 20. LONGITUDINAL IMPEDANCE NETWORK

Active State (C1 = 0, C2 = 1)

The tip output is capable of sourcing loop current and for open

circuit conditions is about -4V from ground. The ring output is

capable of sinking loop current and for open circuit conditions is

about V

+4V. VF signal transmission is normal. The loop

BAT

current and ground key detectors are both active, E0 and E1

determine which detector is gated to the DET

output.

Ringing State (C1 = 1, C2 = 0)

The ring relay driver and the ring trip detector are activated.

Both the tip and ring line drive amplifiers are powered down.

Both tip and ring are disconnected from the line via the

external ring relay.

Standby State (C1 = 1, C2 = 1)

Both the tip and ring line drive amplifiers are powered down.

Internal resistors are connected between tip to ground and

ring to V

condition. The loop current and ground key detectors are

both active, E0 and E1 determine which detector is gated to

the DET

to allow loop current detect in an off-hook

BAT

output.

AC Transmission Circuit Stability

To ensure stability of the AC transmission feedback loop two

compensation capacitors C

and CRC are required.

TC

Figure 21 (Application Circuit) illustrates their use.

Recommended value is 2200pF.

AC-DC Separation Capacitor, C

HP

The high pass filter capacitor connected between pins HPT

and HPR provides the separation between circuits sensing

tip to ring DC conditions and circuits processing AC signals.

A 10nf C

will position the low end frequency response

HP

3dB break point at 48Hz. Where:

f

3dB

where R

-----------------------------------------------------=

1

2 π• R

• CHP•()

HP

= 330kΩ

HP

(EQ. 28)

Thermal Shutdown Protection

The HC5523’s thermal shutdown protection is invoked if a

fault condition on the tip or ring causes the temperature of

the die to exceed 160

a high impedance state and will remain there until the

o

C. If this happens, the SLIC goes into

14

HC5523

www.BDTIC.com/Intersil

temperature of the die cools down by about 20oC. The SLIC

will return back to its normal operating mode, providing the

fault condition has been removed.

Positive transients on tip or ring are clamped to within a

couple of volts above ground via diodes D

normal operating conditions D

and D2 are reverse biased

1

and D2. Under

1

and out of the circuit.

Surge Voltage Protection

The HC5523 must be protected against surge voltages and

power crosses. Refer to “Maximum Ratings” TIPX and

RINGX terminals for maximum allowable transient tip and

ring voltages. The protection circuit shown in Figure 21

utilizes diodes together with a clamping device to protect tip

Negative transients on tip and ring are clamped to within a

couple of volts below ground via diodes D

3

help of a Surgector. The Surgector is required to block

conduction through diodes D

and D4 under normal

3

operating conditions and allows negative surges to be

returned to system ground.

and ring against high voltage transients.

SLIC Operating States

TABLE 1. LOGIC TRUTH TABLE

E0 E1 C1 C2 SLIC OPERATING STATE ACTIVE DETECTOR DET

0 0 0 0 Open Circuit No Active Detector Logic Level High

0 0 0 1 Active Ground Key Detector Ground Key Status

0 0 1 0 Ringing No Active Detector Logic Level High

0 0 1 1 Standby Ground Key Detector Ground Key Status

0 1 0 0 Open Circuit No Active Detector Logic Level High

0 1 0 1 Active Loop Current Detector Loop Current Status

0 1 1 0 Ringing Ring Trip Detector Ring Trip Status

0 1 1 1 Standby Loop Current Detector Loop Current Status

and D4 with the

OUTPUT

1 0 0 0 Open Circuit No Active Detector

1 0 0 1 Active Ground Key Detector

1 0 1 0 Ringing No Active Detector

1 0 1 1 Standby Ground Key Detector

1 1 0 0 Open Circuit No Active Detector

1 1 0 1 Active Loop Current Detector

1 1 1 0 Ringing Ring Trip Detector

1 1 1 1 Standby Loop Current Detector

The fuse resistors (RF) serve a dual purpose of being

nondestructive power dissipaters during surge and fuses

The analog and digital grounds should be tied together at the

device.

when the line in exposed to a power cross.

Notes

Power-Up Sequence

The HC5523 has no required power-up sequence. This is a

result of the Dielectrically Isolated (DI) process used in the

fabrication of the part. By using the DI process, care is no

longer required to insure that the substrate be kept at the

most negative potential as with junction isolated ICs.

Printed Circuit Board Layout

Care in the printed circuit board layout is essential for proper

operation. All connections to the RSN pin should be made as

close to the device pin as possible, to limit the interference

that might be injected into the RSN terminal. It is good

practice to surround the RSN pin with a ground plane.

2. Overload Level (Two-Wire port) - The overload level is specified at the 2-wire port (V

receive port (E

amplitude of E

ence Figure 1.

3. Longitudinal Impedance - The longitudinal impedance is

computed using the following equations, where TIP and RING

voltages are referenced to ground. L

are defined in Figure 2.

A

T

(TIP) L

(RING) LZR = VR/A

where: EL = 1V

4. Longitudinal Current Limit (Off-Hook Active) - Off-Hook

(Active, C

by increasing the amplitude of E

Logic Level High

) with the signal source at the 4-wire

TR0

). I

RX

until 1% THD is measured at V

RX

= VT/A

ZT

T

R

(0Hz to 100Hz)

RMS

= 1, C2 = 0) longitudinal current limit is determined

1

= 30mA, RSG = 4kΩ, increase the

DCMET

, LZR, VT, VR, AR and

ZT

(Figure 3A) until the 2-wire

L

TRO

. Refer-

15

HC5523

www.BDTIC.com/Intersil

longitudinal balance drops below 45dB. DET pin remains low

(no false detection).

5. Longitudinal Current Limit (On -Hook Standby) - On-Hook

(Active, C

by increasing the amplitude of E

longitudinal balance drops below 45dB. DET

= 1, C2 = 1) longitudinal current limit is determined

1

(Figure 3B) until the 2-wire

L

pin remains high

(no false detection).

6. Longitudinal to Metallic Balance - The longitudinal to metallic balance is computed using the following equation:

BLME = 20 • log (E

Figure 4.

), where: EL and VTR are defined in

L/VTR

7. Metallic to Longitudinal FCC Part 68, Para 68.310 - The

metallic to longitudinal balance is defined in this spec.

8. Longitudinal to Four-Wire Balance - The longitudinal to 4-wire

balance is computed using the following equation:

BLFE = 20 • log (E

),: EL and VTX are defined in Figure 4.

L/VTX

9. Metallic to Longitudinal Balance - The metallic to longitudi-

nal balance is computed using the following equation:

BMLE = 20 • log (E

where: E

and ERX are defined in Figure 5.

TR, VL

TR/VL

), ERX = 0

10. Four-Wire to Longitudinal Balance - The 4-wire to longitudinal balance is computed using the following equation:

BFLE = 20 • log (E

where: E

and ETR are defined in Figure 5.

RX, VL

), ETR = source is removed.

RX/VL

11. Two-Wire Return Loss - The 2-wire return loss is computed

using the following equation:

r = -20 • log (2V

where: Z

impedance of the line, nominally 600Ω. (Reference Figure 6).

= The desired impedance; e.g., the characteristic

D

M/VS

)

12. Overload Level (4-Wire port) - The overload level is specified

at the 4-wire transmit port (V

the 2-wire port, I

= 23mA, ZL = 20kΩ, RSG = 4kΩ (Refer-

DCMET

ence Figure 7). Increase the amplitude of E

measured at V

the 4-wire port is equal to 1.

. Note that the gain from the 2-wire port to

TXO

) with the signal source (EG) at

TXO

until 1% THD is

G

13. Output Offset Voltage - The output offset vo ltage is specified

with the following conditions: E

and is measured at VTX. EG, I

in Figure 7. Note: I

resistor between tip and ring.

DCMET

= 0, I

G

DCMET

is established with a series 600Ω

14. Two-Wire to Four-Wire (Metallic to V

2-wire to 4-wire (metallic to V

using the following equation.

G

= (VTX/VTR), EG = 0dBm0, VTX, VTR, and EG are defined

2-4

in Figure 7.

) voltage gain is computed

TX

= 23mA, ZL = ∞

DCMET

, VTX and ZL are defined

) Voltage Gain - The

TX

15. Current Gain RSN to Metallic - The current gain RSN to

Metallic is computed using the following equation:

[(R

+ R

)/(V

- V

K = I

M

and V

DC1

DC2

are defined in Figure 8.

RSN

RDC

)] K, IM, R

RSN

DC1

, R

DC2

, V

RDC

16. Two-Wire to Four-Wire Frequency Response - The 2-wire to

4-wire frequency response is measured with respect to

= 0dBm at 1.0kHz, ERX = 0V, I

E

G

quency response is computed using the following equation:

F

= 20 • log (VTX/VTR), vary frequency from 300Hz to

2-4

3.4kHz and compare to 1kHz reading.

, VTR, and EG are defined in Figure 9.

V

TX

= 23mA. The fre-

DCMET

17. Four-Wire to Two-Wire Frequency Response - The 4-wire to

2-wire frequency response is measured with respect to E

0dBm at 1.0kHz, E

= 0V, I

G

= 23mA. The frequency

DCMET

RX

response is computed using the following equation:

= 20 • log (VTR/ERX), vary frequency from 300Hz to

F

4-2

=

3.4kHz and compare to 1kHz reading.

V

and ERX are defined in Figure 9.

TR

18. Four-Wire to Four-Wire Frequency Response - The 4-wire

to 4-wire frequency response is measured with respect to E

= 0dBm at 1.0kHz, EG = 0V, I

response is computed using the following equation:

= 20 • log (VTX/ERX), vary frequency from 300Hz to

F

4-4

3.4kHz and compare to 1kHz reading.

and ERX are defined in Figure 9.

V

TX

= 23mA. The frequency

DCMET

RX

19. Two-Wire to Four-Wire Insertion Loss - The 2-wire to 4-wire

insertion loss is measured with respect to E

input signal, E

the following equation:

L

= 20 • log (VTX/VTR)

2-4

where: V

fuse resistors, R

= 0, I

RX

, VTR, and EG are defined in Figure 9. (Note: The

TX

, impact the insertion loss. The specified

F

insertion loss is for R

F

DCMET

= 0).

= 23mA and is computed using

= 0dBm at 1.0kHz

G

20. Four-Wire to Two-Wire Insertion Loss - The 4-wire to 2-wire

insertion loss is measured based upon E

input signal, E

the following equation:

L

= 20 • log (VTR/ERX)

4-2

where: V

= 0, I

G

and ERX are defined in Figure 9.

TR

= 23mA and is computed using

DCMET

= 0dBm, 1.0kHz

RX

21. Two-Wire to Four-Wire Gain Tracking - The 2-wir e to 4-wire

gain tracking is referenced to measurements taken for E

-10dBm, 1.0kHz signal, E

RX

= 0, I

= 23mA and is com-

DCMET

=

G

puted using the following equation.

= 20 • log (VTX/VTR) vary amplitude -40dBm to +3dBm, or

G

2-4

-55dBm to -40dBm and compare to -10dBm reading.

and VTR are defined in Figure 9.

V

TX

22. Four-Wire to Two-Wire Gain Tracking - The 4- wire to 2-wire

gain tracking is referenced to measurements taken for E

-10dBm, 1.0kHz signal, E

puted using the following equation:

G

= 20 • log (VTR/ERX) vary amplitude -40dBm to +3dBm, or

4-2

-55dBm to -40dBm and compare to -10dBm reading.

and ERX are defined in Figure 9. The level is specified at

V

TR

= 0, I

G

= 23mA and is com-

DCMET

RX

the 4-wire receive port and referenced to a 600Ω impedance

level.

23. Two-Wire Idle Channel Noise - The 2-wire idle channel noise

is specified with the 2-wire port terminated in 600Ω (RL)

at V

TR

and with the 4-wire receive port grounded (Reference Figure

10).

24. Four-Wire Idle Channel Noise - The 4-wire idle channel noise

is specified with the 2-wire port terminated in 600Ω (RL).

at V

TX

The noise specification is with respect to a 600Ω impedance

level at V

Figure 10).

. The 4-wire receive port is grounded (Reference

TX

25. Harmonic Distortion (2-Wire to 4-Wire) - The harmonic distortion is measured with the following conditions. E

1kHz, I

Figure 7).

= 23mA. Measurement taken at VTX. (Reference

DCMET

= 0dBm at

G

26. Harmonic Distortion (4-Wire to 2-Wire) - The harmonic distortion is measured with the following conditions. E

Vary frequency between 300Hz and 3.4kHz, I

Measurement taken at V

. (Reference Figure 9).

TR

RX

DCMET

= 0dBm0.

= 23mA.

27. Constant Loop Current - The constant loop current is calculated using the following equation:

= 2500 / (R

I

L

DC1

+ R

DC2

)

28. Standby State Loop Current - The standby state loop current

is calculated using the following equation:

=

16

HC5523

www.BDTIC.com/Intersil

IL = [|V

29. Ground Key Detector - (TRIGGER) Increase the input current

to 8mA and verify that DET

(RESET) Decrease the input current from 17mA to 3mA and

verify that DET

(Hysteresis) Compare difference between trigger and reset.

30. Power Supply Rejection Ratio - Inject a 100mV

(50Hz to 4kHz) on V

puted using the following equation:

PSRR = 20 • log (V

12.

| - 3] / [RL +1800], TA = 25oC

BAT

goes low.

goes high.

, VCC and VEE supplies. PSRR is com-

BAT

). VTX and VIN are defined in Figure

TX/VIN

RMS

signal

17

HC5523

www.BDTIC.com/Intersil

Pin Descriptions

PLCC PDIP SYMBOL DESCRIPTION

1RING

2 7 BGND Battery Ground - To be connected to zero potential. All loop current and longitudinal current flow from this ground.

48 V

5 9 RINGRLY Ring relay driver output.

610 V

711 R

8 12 E1 TTL compatible logic input. The logic state of E1 in conjunction with the logic state of C1 determines which detector

9 13 E0 TTL compatible logic input. Enables the DET

11 14 DET Detector output. TTL compatible logic output. A zero logic level indicates that the selected detector was triggered

12 15 C2 TTL compatible logic input. The logic states of C1 and C2 determine the operating states (Open Circuit, Active,

13 16 C1 TTL compatible logic input. The logic states of C1 and C2 determine the operating states (Open Circuit, Active,

14 17 R

15 18 AGND Analog ground.

16 19 RSN Receive Summing Node. The AC and DC current flowing into this pin establishes the metallic loop current that

18 20 V

19 21 V

20 22 HPR RING side of AC/DC separation capacitor C

21 1 HPT TIP side of AC/DC separation capacitor C

22 2 RD Loop current programming resistor. Resistor R

23 3 DT Input to ring trip comparator. Ring trip detection is accomplished by connecting an external network to a

25 4 DR Input to ring trip comparator. Ring trip detection is accomplished by connecting an external network to a

26 TIP

27 5 TIPX Output of tip power amplifier.

28 6 RINGX Output of ring power amplifier.

3, 10,

17, 24

CC

BAT

SENSE

N/C No internal connection.

Internally connected to output of RING power amplifier.

SENS

E

Internally separate from AGND but it is recommended that it is connected to the same potential as AGND.

+5V power supply.

Battery supply voltage, -24V to -56V.

Saturation guard programming resistor pin.

SG

is gated to the DET

set to a logic level one.

(see Truth Table for selection of Ground Key detector, Loop Current detector or the Ring Trip detector). The DET

output is an open collector with an internal pull-up of approximately 15kΩ to V

Ringing or Standby) of the SLIC.

Ringing or Standby) of the SLIC.

DC feed current programming resistor pin. Constant current feed is programmed by resistors R

DC

connected in series from this pin to the receive summing node (RSN). The resistor junction point is decoupled to

AGND to isolate the AC signal components.

flows between tip and ring. The magnitude of the metallic loop current is 1000 times greater than the current into

the RSN pin. The constant current programming resistors and the networks for program receive gain and 2-wire

impedance all connect to this pin.

-5V power supply.

EE

Transmit audio output. This output is equivalent to the TIP to RING metallic voltage. The network for programming

TX

the 2-wire input impedance connects between this pin and RSN.

DC loop current. The other end of C

loop current. The other end of C

capacitor C

comparator in the SLIC with inputs DT and DR.

comparator in the SLIC with inputs DT and DR.

Internally connected to output of tip power amplifier.

output.

output when set to logic level zero and disables DET output when

. C

HP

is connected to HPT.

HP

is connected to HPR.

HP

is also connected between this pin and VEE.

D

HP

. C

HP

is required to properly separate the tip AC current from the DC

HP

sets the trigger level for the loop current detect circuit. A filter

D

CC.

is required to properly separate the ring AC current from the

DC1

and R

DC2

18

Pinouts

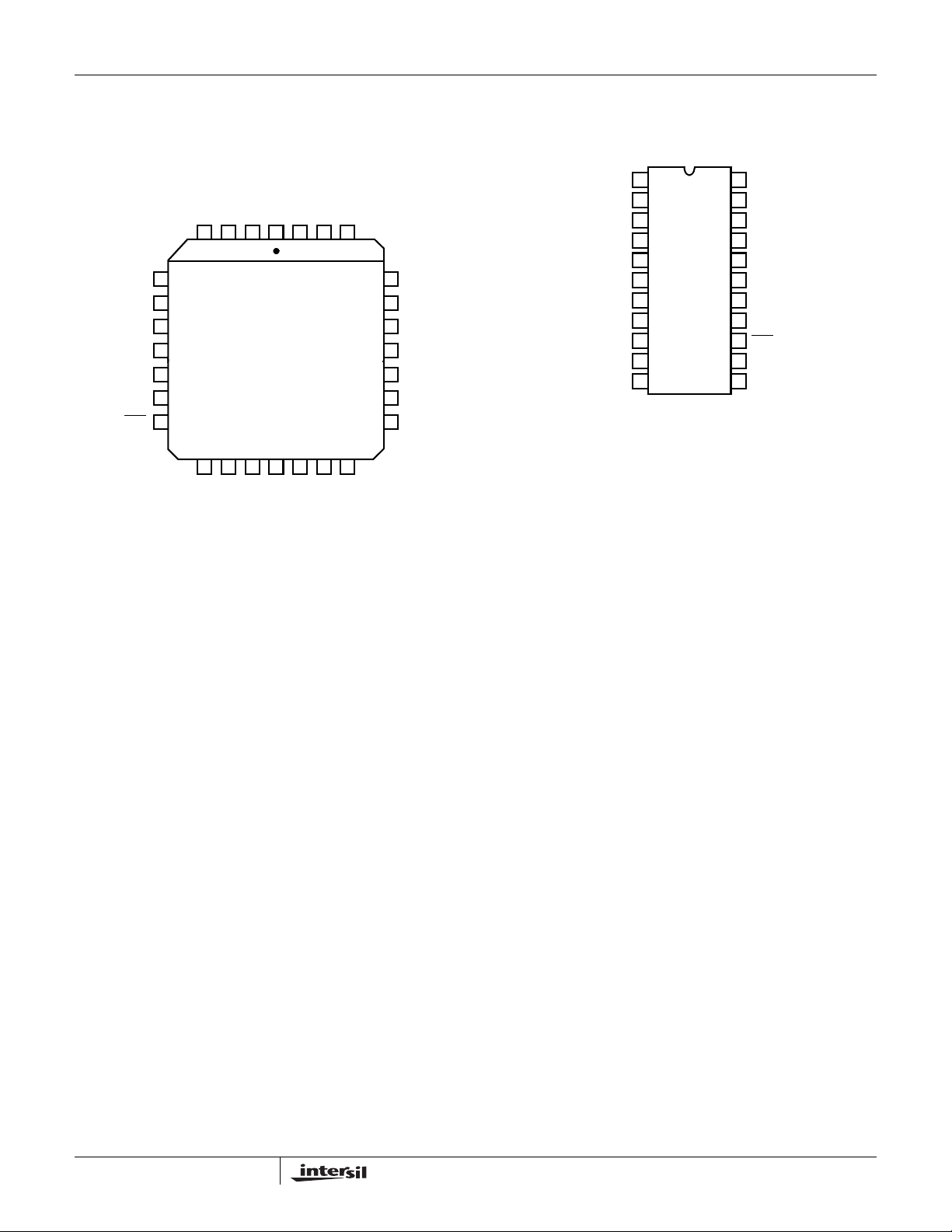

www.BDTIC.com/Intersil

RINGRLY

V

BAT

R

N/C

DET

SG

E1

E0

HC5523 (PLCC)

TOP VIEW

VCCN/C

5

6

7

8

9

10

11

12 13 14 15 16 17 18

C2

C1

HC5523

HC5523 (PDIP)

TOP VIEW

HPT

SENSE

BGND

RING

RINGX

1234

DC

R

AGND

RSN

TIPX

N/C

SENSE

TIP

262728

25

DR

24

N/C

23

DT

22

RD

21

HPT

20

HPR

19

V

TX

EE

V

RINGRLY

RD

DT

DR

TIPX

RINGX

BGND

V

CC

V

BAT

R

SG

1

2

3

4

5

6

7

8

9

10

11

22

21

20

19

18

17

16

15

14

13

12

HPR

V

TX

V

EE

RSN

AGND

R

DC

C1

C2

DET

E0

E1

19

Application Circuit

www.BDTIC.com/Intersil

HC5523

(V

BAT

R

RT

R

PTC

TIP

PTC

RING

RINGING

+ 90V

RMS

)

C

C

C

C

, CRC2200pF, 20%, 100V

TC

Relay Relay, 2C Contacts, 5V or 12V Coil

- D5IN4007 Diode

D

1

Surgector SGT27S10

PTC Polyswitch TR600-150

R

, RF2Line Resistor, 20Ω, 1% Match, 2 W

F1

C

3

R

R

F1

D

D

R

F2

+5V RELAY

OR

12V

RT

4

3

4

R

R

V

BAT

NOTE 31

Surgector

G

D

5

1

R

D

2

AK

D

6

-5V

D

1

C

TC

C

V

BAT

RC

-5V

R

SG

D

2

U1 SLIC (Subscriber Line Interface Circuit)

HC5526

U2 Combination CODEC/Filter e.g.

CD22354A or Programmable CODEC/

Filter, e.g. SLAC

1.5µF, 20%, 10V

DC

10nF, 20%, 100V (Note 2)

HP

0.39µF, 20%, 100V

RT

D

Diode, 1N4454

6

Carbon column resistor or thick film on

ceramic

21 HPT

22 RD

23 DT

25 DR

27 TIPX

2 BGND

4 V

CC

28 RINGX

6 V

BAT

5 RINGRLY

7 R

SG

R

DC1

CHP (NOTE 32)

U

HPR 20

1

V

19

TX

VEE 18

RSN 16

AGND 15

14

R

DC

C1 13

C2 12

DET

11

E

O

E

1

R1, R3200kΩ, 5%, 1/4W

910kΩ, 5%, 1/4W

R

2

1.2MΩ, 5%, 1/4W

R

4

R

18.7kΩ,1%, 1/4W

B

39kΩ, 5%, 1/4W

R

D

, R

41.2kΩ, 5%, 1/4W

DC2

R

20.0kΩ, 1%, 1/4W

FB

280kΩ, 1%, 1/4W

R

RX

562kΩ, 1%, 1/4W

R

T

R

20kΩ, 1%, 1/4W

TX

150Ω, 5%, 2W

R

RT

R

SGVBAT

V

BAT

= -28V, R

= -48V, R

R

FB

U

R

TX

-5V

R

DC2

9

8

= ∞

SG

= 21.4kΩ, 1/4W 5%

SG

R

R

B

T

R

RX

R

DC1

C

DC

2

-

+

CODEC/FILTER

NOTES:

31. It is recommended that the anodes of D

32. To meet the specified 25dB 2-wire return loss at 200Hz, C

and D4 be shorted to ground through a battery referenced surgector (SGT27S10).

3

needs to be 20nF, 20%, 100V.

HP

FIGURE 21. APPLICATION CIRCUIT

20

HC5523

www.BDTIC.com/Intersil

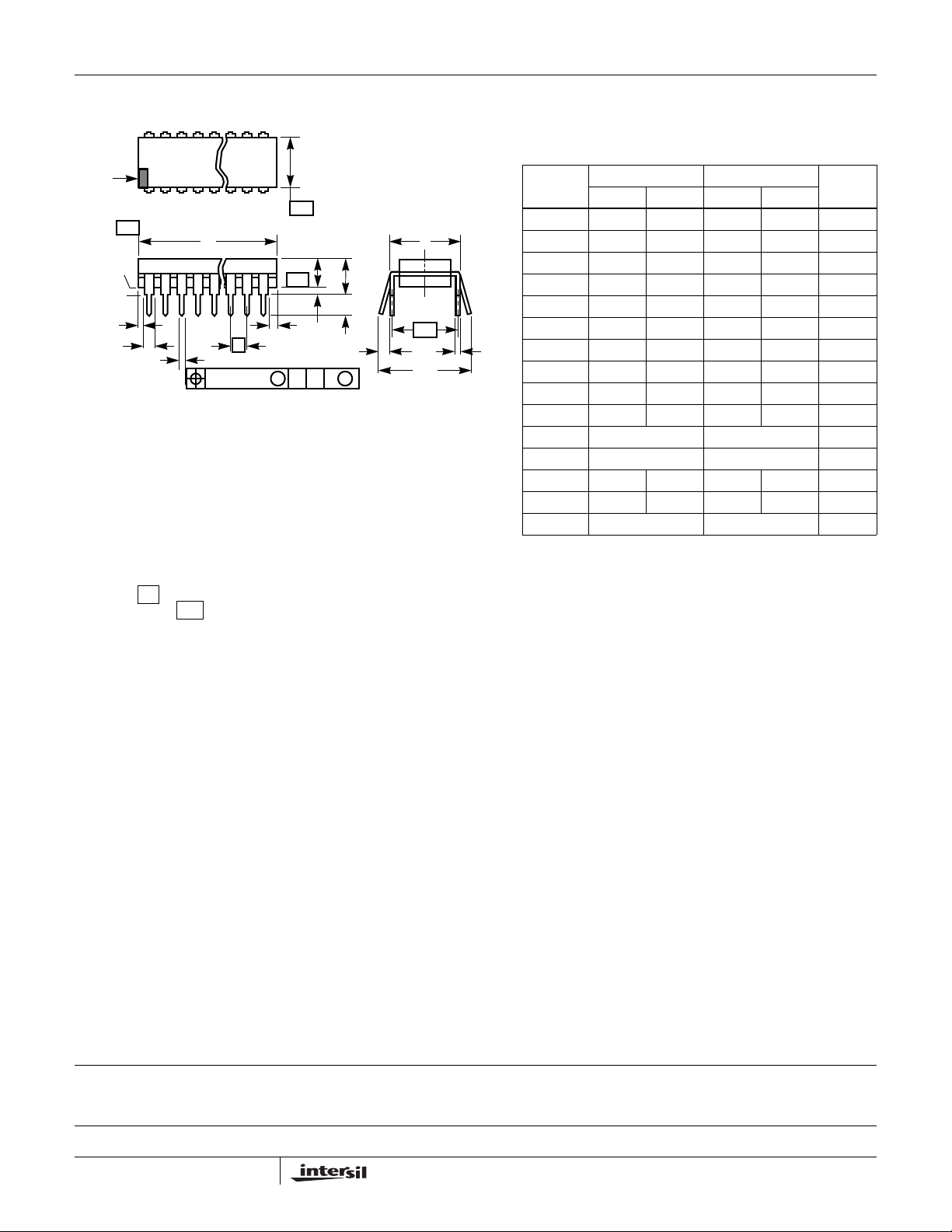

Plastic Leaded Chip Carrier Packages (PLCC)

0.042 (1.07)

0.048 (1.22)

PIN (1) IDENTIFIER

0.020 (0.51) MAX

3 PLCS

0.045 (1.14)

MIN

NOTES:

1. Controlling dimension: INCH. Converted millimeter dimensions are

not necessarily exact.

2. Dimensions and tolerancing per ANSI Y14.5M-1982.

3. Dimensions D1 and E1 do not include mold protrusions. Allowable

mold protrusion is 0.010 inch (0.25mm) per side. Dimensions D1

and E1 include mold mismatch and are measured at the extreme

material condition at the body parting line.

4. To be measured at seating plane contact point.

5. Centerline to be determined where center leads exit plastic body.

6. “N” is the number of terminal positions.

C

L

D1

D

0.026 (0.66)

0.032 (0.81)

0.050 (1.27) TP

0.042 (1.07)

0.056 (1.42)

EE1

VIEW “A” TYP.

-C-

C

L

A

0.013 (0.33)

0.021 (0.53)

0.025 (0.64)

MIN

0.004 (0.10) C

0.025 (0.64)

0.045 (1.14)

D2/E2

D2/E2

A1

-C-

VIEW “A”

0.020 (0.51)

MIN

SEATING

PLANE

N28.45 (JEDEC MS-018AB ISSUE A)

28 LEAD PLASTIC LEADED CHIP CARRIER PACKAGE

R

SYMBOL

A 0.165 0.180 4.20 4.57 -

A1 0.090 0.120 2.29 3.04 -

D 0.485 0.495 12.32 12.57 D1 0.450 0.456 11.43 11.58 3

D2 0.191 0.219 4.86 5.56 4, 5

E 0.485 0.495 12.32 12.57 -

E1 0.450 0.456 11.43 11.58 3

E2 0.191 0.219 4.86 5.56 4, 5

N28 286

INCHES MILLIMETERS

NOTESMIN MAX MIN MAX

Rev. 2 11/97

21

Dual-In-Line Plastic Packages (PDIP)

www.BDTIC.com/Intersil

HC5523

N

D1

-C-

E1

-B-

A1

A2

E

A

L

e

C

C

L

e

A

C

e

B

INDEX

AREA

BASE

PLANE

SEATING

PLANE

NOTES:

1. Controlling Dimensions: INCH. In case of conflict between English and

Metric dimensions, the inch dimensions control.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of

Publication No. 95.

4. Dimensions A, A1 and L are measured with the package seated in JEDEC seating plane gauge GS-3.

5. D, D1, and E1 dimensions do not include mold flash or protrusions.

Mold flash or protrusions shall not exceed 0.010 inch (0.25mm).

6. E and are measured with the leads constrained to be perpendicular to datum .

7. e

e

8. B1 maximum dimensions do not include dambar protrusions. Dambar

protrusions shall not exceed 0.010 inch (0.25mm).

9. N is the maximum number of terminal positions.

10. Corner leads (1, N, N/2 and N/2 + 1) for E8.3, E16.3, E18.3, E28.3,

E42.6 will have a B1 dimension of 0.030 - 0.045 inch (0.76 - 1.14mm).

12 3 N/2

-A-

D1

B1

B

e

A

and eC are measured at the lead tips with the leads unconstrained.

B

must be zero or greater.

C

D

e

0.010 (0.25) C AM BS

-C-

E22.4 (JEDEC MS-010-AA ISSUE C)

22 LEAD DUAL-IN-LINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A - 0.210 - 5.33 4

A1 0.015 - 0.39 - 4

A2 0.125 0.195 3.18 4.95 -

B 0.014 0.022 0.356 0.558 B1 0.045 0.065 1.15 1.65 8

C 0.009 0.015 0.229 0.381 -

D 1.065 1.120 27.06 28.44 5

D1 0.005 - 0.13 - 5

E 0.390 0.425 9.91 10.79 6

E1 0.330 0.390 8.39 9.90 5

e 0.100 BSC 2.54 BSC -

e

A

e

B

L 0.115 0.160 2.93 4.06 4

N22 229

0.400 BSC 10.16 BSC 6

- 0.500 - 12.70 7

NOTESMIN MAX MIN MAX

Rev. 0 12/93

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality