HC55120, HC55121, HC55130, HC55131, HC55140,

TM

HC55141, HC55142, HC55143, HC55150, HC55151

Data Sheet June 2000

Low Power Universal SLIC Family

The UniSLIC14 is a family of Ultra Low Power SLICs. The

feature set and common pinouts of the UniSLIC14 family

positions it as a universal solution for: Plain Old Telephone

Service (POTS),PBX,Central Office, Loop Carrier,Fiber in the

Loop, ISDN-TA and NT1+, Pairgain and Wireless Local Loop.

The UniSLIC14 family achieves its ultra low power operation

through: Its automatic single and dual battery selection

(based on line length) and battery tracking anti clipping to

ensure the maximum loop coverage on the lowest battery

voltage. This architecture is ideal for power critical

applications such as ISDN NT1+, Pairgain and Wireless

local loop products.

The UniSLIC14 family has many user programmable

features. This family of SLICs delivers a low noise, low

component count solution for Central Office and Loop

Carrier universal voice grade designs. The product family

integrates advanced pulse metering, test and signaling

capabilities, and zero crossing ring control.

The UniSLIC14 family is designed in the Intersil “Latch” free

Bonded Wafer process. This process dielectrically isolates

the active circuitry toeliminate anyleakage paths as foundin

our competition’s JI process. This makes the UniSLIC14

family compliant with “hot plug” requirements and operation

in harsh outdoor environments.

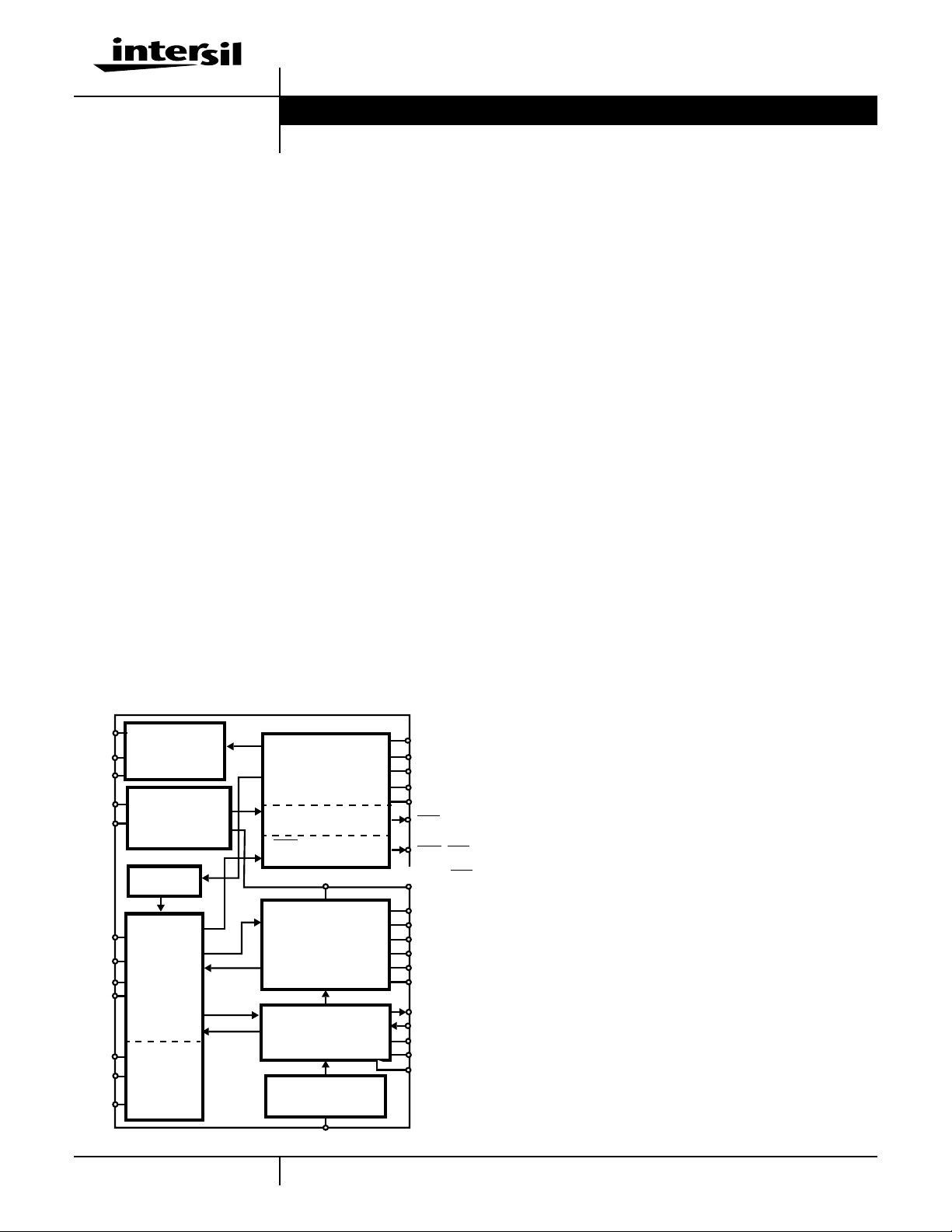

Block Diagram

RRLY

TRLY1

TRLY2

DT

DR

TIP

RING

BGND

AGND

V

BH

V

BL

V

CC

RING AND TEST

RELAY DRIVERS

ZERO CURRENT

CROSSING

RING TRIP

DETECTOR

POLARITY

REVERSAL

2-WIRE

INTERFACE

BATTERY

SELECTION

AND

BIAS

NETWORK

STATE

DECODER

AND

DETECTOR

LOGIC

LOOP CURRENT

DETECTOR

GKD/LOOP LENGTH

DETECTOR

LINE FEED

CONTROL

4-WIRE INTERFACE

VF SIGNAL PATH

PULSE METERING

SIGNAL PATH

SPM

C1

C2

C3

C4

C5

SHD

GKD_LVM

CRT_REV_LVM

ILIM

RSYNC_REV

ROH

CDC

RDC_RAC

RD

V

TX

V

RX

PTG

ZT

C

H

File Number 4659.5

Features

• Ultra Low Active Power (OHT) < 60mW

• Single/Dual Battery Operation

• Automatic Silent Battery Selection

• Power Management/Shutdown

• Battery Tracking Anti Clipping

• Single 5V Supply with 3V Compatible Logic

• Zero Crossing Ring Control

- Zero Voltage On/Zero Current Off

• Tip/Ring Disconnect

• Pulse Metering Capability

• 4 Wire Loopback

• Programmable Current Feed

• Programmable Resistive Feed

• Programmable Loop Detect Threshold

• Programmable On-Hook and Off-Hook Overheads

• Programmable Overhead for Pulse Metering

• Programmable Polarity Reversal Time

• Selectable Transmit Gain 0dB/-6dB

• 2 Wire Impedance Set by Single Network

• Loop and Ground Key Detectors

• On-Hook Transmission

• Common Pinout

• HC55121

- Polarity Reversal

• HC55130

- -63dB Longitudinal Balance

• HC55140

- Polarity Reversal

- Ground Start

- Line Voltage Measurement

- 2 Wire Loopback

- -63dB Longitudinal Balance

• HC55142

- Polarity Reversal

- Ground Start

- Line Voltage Measurement

- 2.2V

Pulse Metering

RMS

- 2 Wire Loopback

• HC55150

- Polarity Reversal

- Line Voltage Measurement

- 2.2V

Pulse Metering

RMS

- 2 Wire Loopback

Applications

• Related Literature

- AN9871, User’s Guide for UniSLIC14 Eval Board

4-1

1-888-INTERSIL or 321-724-7143 | Intersil and Design is a trademark of Intersil Corporation. | Copyright © Intersil Corporation 2000

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

HC55120, HC55121, HC55130, HC55131, HC55140, HC55141, HC55142, HC55143, HC55150, HC55151

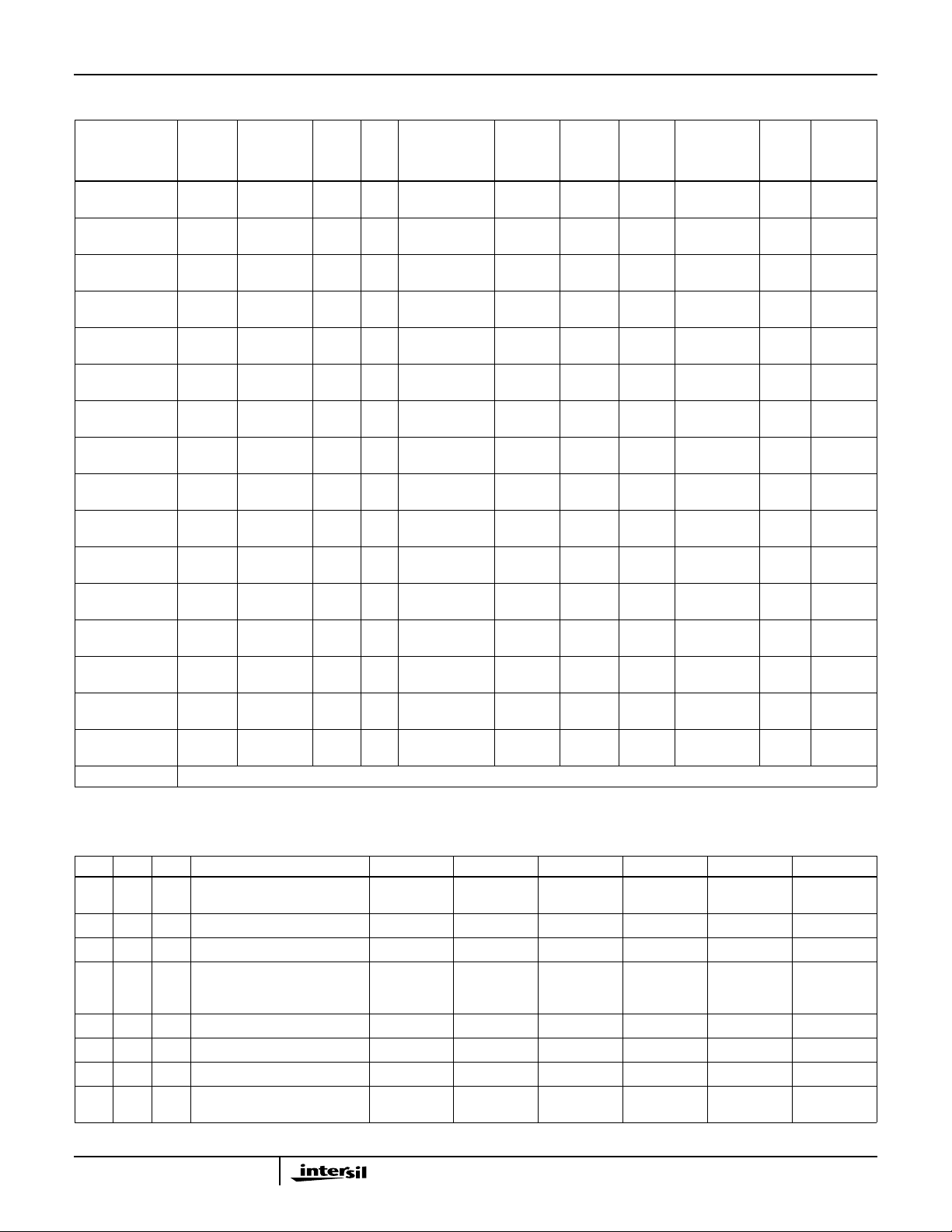

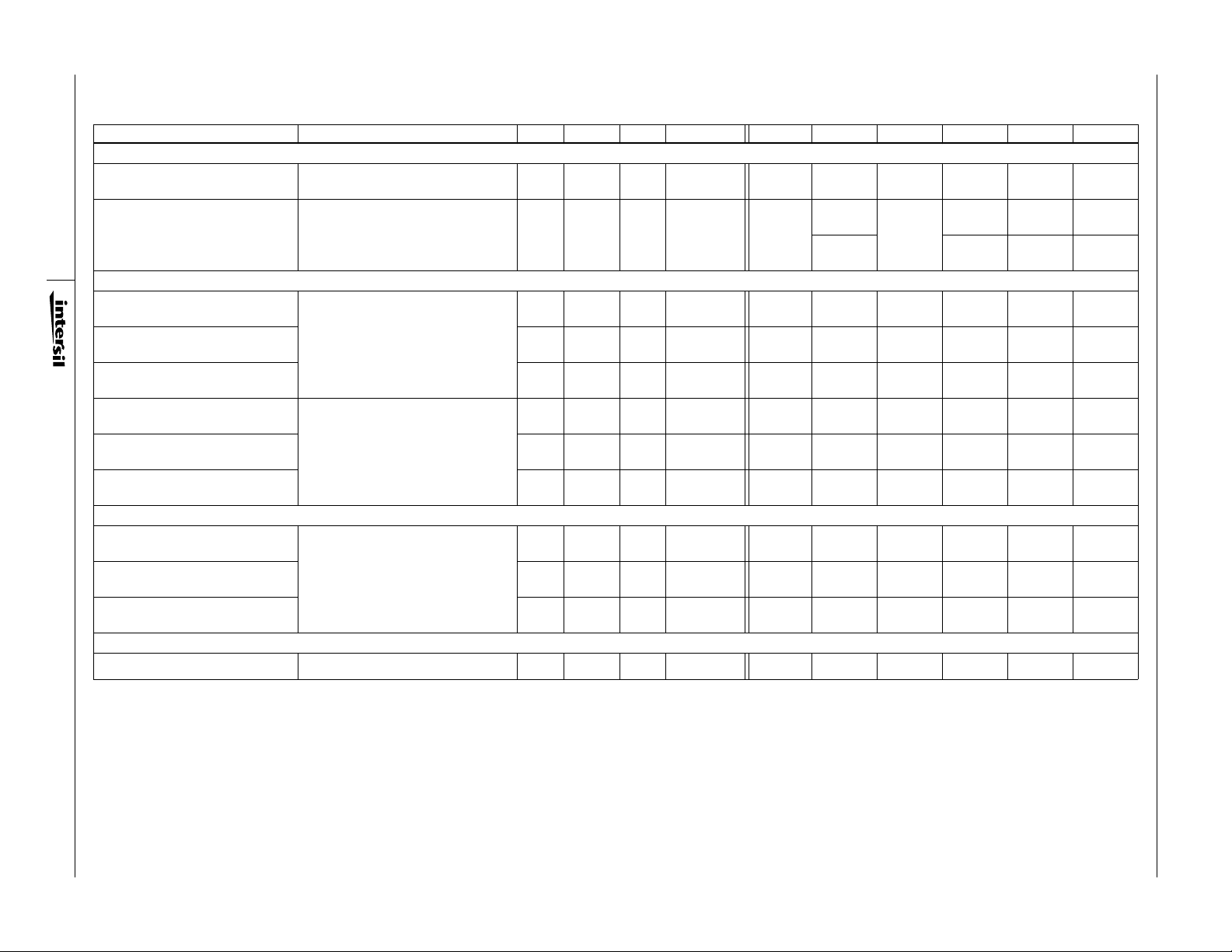

Ordering Information

MAX

PART

NUMBER

HC55120CB 30

HC55120CM 30

HC55121IB 30

HC55121IM 30

HC55130IB 45 63dB -40 to85M28.3

HC55130IM 45 63dB -40 to85N28.45

HC55131IM 45

HC55140IB 45

HC55140IM 45

HC55141IM 45

HC55142IB 45

HC55142IM 45

HC55143IM 45

HC55150CB 45

HC55150CM 45

HC55151CM 45

HC5514XEVAL1 Evaluation board

LOOP

CURRENT

(mA)

POLARITY

REVERSAL

GND

START

GND

KEY

•

•

•• • •

•• • •

••• • •

••• • •

••• • ••

••• • • •

••• • • •

••• • •••

••••

••••

•••••

LINE

VOLTAGE

MEASUREMENT

†

PULSE

METERING

2 TEST

RELAY

DRIVERS

† Available by placing SLIC in Test mode.

2 WIRE

LOOP-

BACK

LONGITUDINAL

†

•

BALANCE

53dB 0 to 70 M28.3

53dB 0 to 70 N28.45

53dB -40 to85M28.3

53dB -40 to85N28.45

63dB -40 to85N32.45x55

63dB -40 to85M28.3

63dB -40 to85N28.45

63dB -40 to85N32.45x55

63dB -40 to85M28.3

63dB -40 to85N28.45

63dB -40 to85N32.45x55

55dB 0 to 70 M28.3

55dB 0 to 70 N28.45

55dB 0 to 70 N32.45x55

TEMP

RANGE

o

C)

(

PKG.

NO.

SOIC

PLCC

SOIC

PLCC

SOIC

PLCC

PLCC

SOIC

PLCC

PLCC

SOIC

PLCC

PLCC

SOIC

PLCC

PLCC

Device Operating Modes

C3 C2 C1 DESCRIPTION HC55120 HC55121 HC55130/1 HC55140/1 HC55142/3 HC55150/1

0 0 0 Open Circuit

4-Wire Loopback

0 0 1 Ringing

0 1 0 Forward Active

0 1 1 Test Forward Active

2 Wire Loopback and

Line Voltage Measurement

1 0 0 Tip Open Ground Start

1 0 1 Reserved

1 1 0 Reverse Active

1 1 1 Test Reverse Active

Line Voltage Measurement

4-2

••••••

••••••

••••••

• •••

••

••••••

• •••

•••

HC55120, HC55121, HC55130, HC55131, HC55140, HC55141, HC55142, HC55143, HC55150, HC55151

Absolute Maximum Ratings T

Temperature, Humidity

Storage Temperature Range . . . . . . . . . . . . . . . . -65oC to 150oC

Operating Temperature Range. . . . . . . . . . . . . . . -40oC to 110oC

Operating Junction Temperature Range. . . . . . . . -40oC to 150oC

Power Supply (-40oC ≤ TA≤ 85oC)

Supply Voltage VCC to GND . . . . . . . . . . . . . . . . . . . .-0.4V to 7V

Supply Voltage VBLto GND. . . . . . . . . . . . . . . . . . . .-VBHto 0.4V

Supply Voltage VBH to GND, Continuous. . . . . . . . . .-75V to 0.4V

Supply Voltage VBH to GND, 10ms . . . . . . . . . . . . . .-80V to 0.4V

Relay Driver

=25oC Thermal Information

A

Thermal Resistance (Typical, Note 1) θ

28 Lead PLCC Package. . . . . . . . . . . . . . . . . . . . . . 52oC/W

28 Lead SOIC Package . . . . . . . . . . . . . . . . . . . . . . 45oC/W

32 Lead PLCC Package. . . . . . . . . . . . . . . . . . . . . . 66.2oC/W

Continuous Power Dissipation at 85oC

28 Lead PLCC Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.5W

28 Lead SOIC Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.0W

32 Lead PLCC Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.4W

Lead Temperature (Soldering 10s). . . . . . . . . . . . . . . . . . . . . . . . 300oC

(PLCC, SOIC - Lead Tips Only) Derate above 70oC

JA

Ring Relay Supply Voltage . . . . . . . . . . . . . . . . . . . . . .0V to 14V

Ring Relay Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50mA

Digital Inputs, Outputs (C1, C2, C3, C4, C5, SHD, GKD_LVM)

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.4V to V

Output Voltage (SHD, GKD_LVM Not Active). . . . . . -0.4V to V

CC

CC

Output Current (SHD,GKD_LVM) . . . . . . . . . . . . . . . . . . . . . 5mA

ESD Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .500V

Gate Count. . . . . . . . . . . . . . . . . . . . . . . .543 Transistors, 51 Diodes

Tip and Ring Terminals

Tipx or Ringx, Current, Pulse < 10ms, T

Tipx or Ringx, Current, Pulse < 1ms, T

Tipx or Ringx, Current, Pulse < 10µs, T

Tipx or Ringx, Current, Pulse < 1µs, T

Tipx or Ringx, Pulse < 250ns, T

REP

> 10s . . . . . . . . . .2A

REP

> 10s . . . . . . . . . . .5A

REP

> 10s . . . . . . . . .15A

REP

> 10s . . . . . . . . . .20A

REP

> 10s 20A

Tipx and Ringx Terminals (-40oC ≤ TA ≤ 85oC)

Tipx or Ringx Current. . . . . . . . . . . . . . . . . . . . -100mA to 100mA

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

1. θJA is measured with the component mounted on an evaluation PC board in free air.

Typical Operating Conditions

These represent the conditions under which the device was developed and are suggested as guidelines.

PARAMETER CONDITIONS MIN TYP MAX UNITS

Ambient Temperature HC55120, HC55150/1 0 - 70

HC55121, HC55130/1, HC55140/1,

-40 - 85

HC55142/3

o

C

o

C

VBH with Respect to GND -58 - -8 V

VBL with Respect to GND V

BH

-0 V

VCC with Respect to GND 4.75 - 5.25 V

4-3

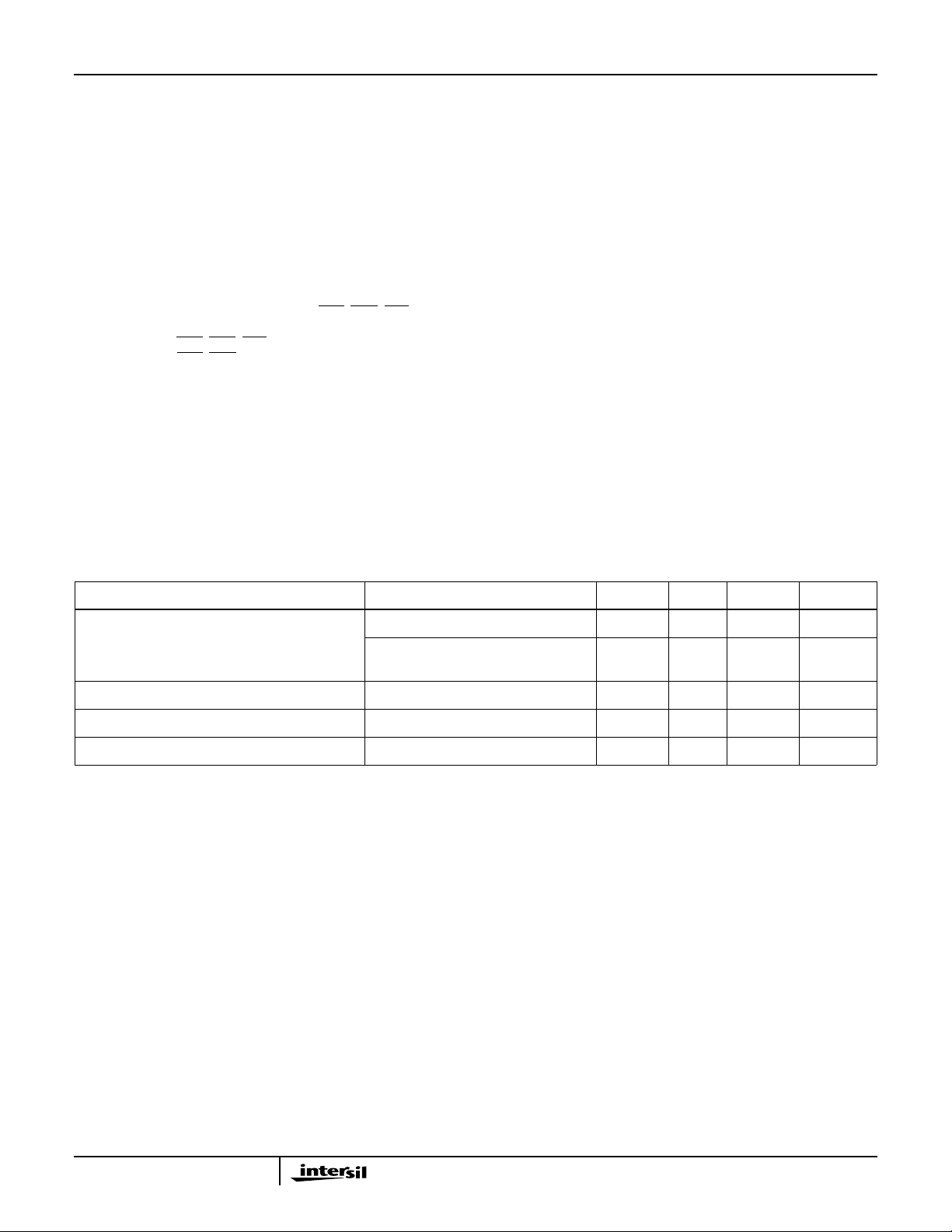

Electrical Specifications T

= -40oCto85oC, VCC= +5V ±5%, VBH= -48V,VBL= -24V,PTG = Open, RP1=RP2=0Ω, ZT= 120kΩ,R

A

R

= 40kΩ,CH= 0.1µF, CDC= 4.7µF, C

OH

= 0.47µF, GND = 0V, RL = 600Ω. Unless Otherwise Specified.

RT/REV

to the part. (NA) symbol used to indicate the test does not apply to the part.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS HC55120 HC55121 HC55130/1 HC55140/1 HC55142/3 HC55150/1

2-WIRE PORT

Overload Level, Off Hook

Forward and Reverse

Overload Level, On Hook

Forward and Reverse

4-4

Input Impedance (Into Tip and Ring) - ZT/200 - Ω

Longitudinal Impedance (Tip, Ring)

1% THD, I

DCMET

≥ 18mA

3.2 - - V

(Note 2, Figure 1)

1% THD, IDCMET ≤ 5mA

1.3 - - V

(Note 3, Figure 1)

0 < f < 100Hz (Note 4, Figure 2) - 0 - Ω/Wire Forward

Forward and Reverse

LONGITUDINAL CURRENT LIMIT (TIP, RING)

On-Hook, Off-Hook (Active),

RL = 736Ω

Forward and Reverse

No False Detections, (Loop

Current), LB > 45dB (Notes 5, 6,

Figures 3A, 3B)

28 - - mA

PEAK

PEAK

Wire Forward

/

RMS

= 38.3kΩ,RD= 50kΩ, RDC_RAC = 20kΩ,

LIM

Symbol used to indicate the test applies

(•)

Forward

Only

Forward

Only

Forward

•

•

Only

Forward

Only

•••

•••

••••••

Forward

Only

Only

•

Only

Forward

•

Only

•••

•••

HC55120, HC55121, HC55130, HC55131, HC55140, HC55141, HC55142, HC55143, HC55150, HC55151

V

TIP

V

R

TR

L

I

DCMET

RING VRX

TX

E

RX

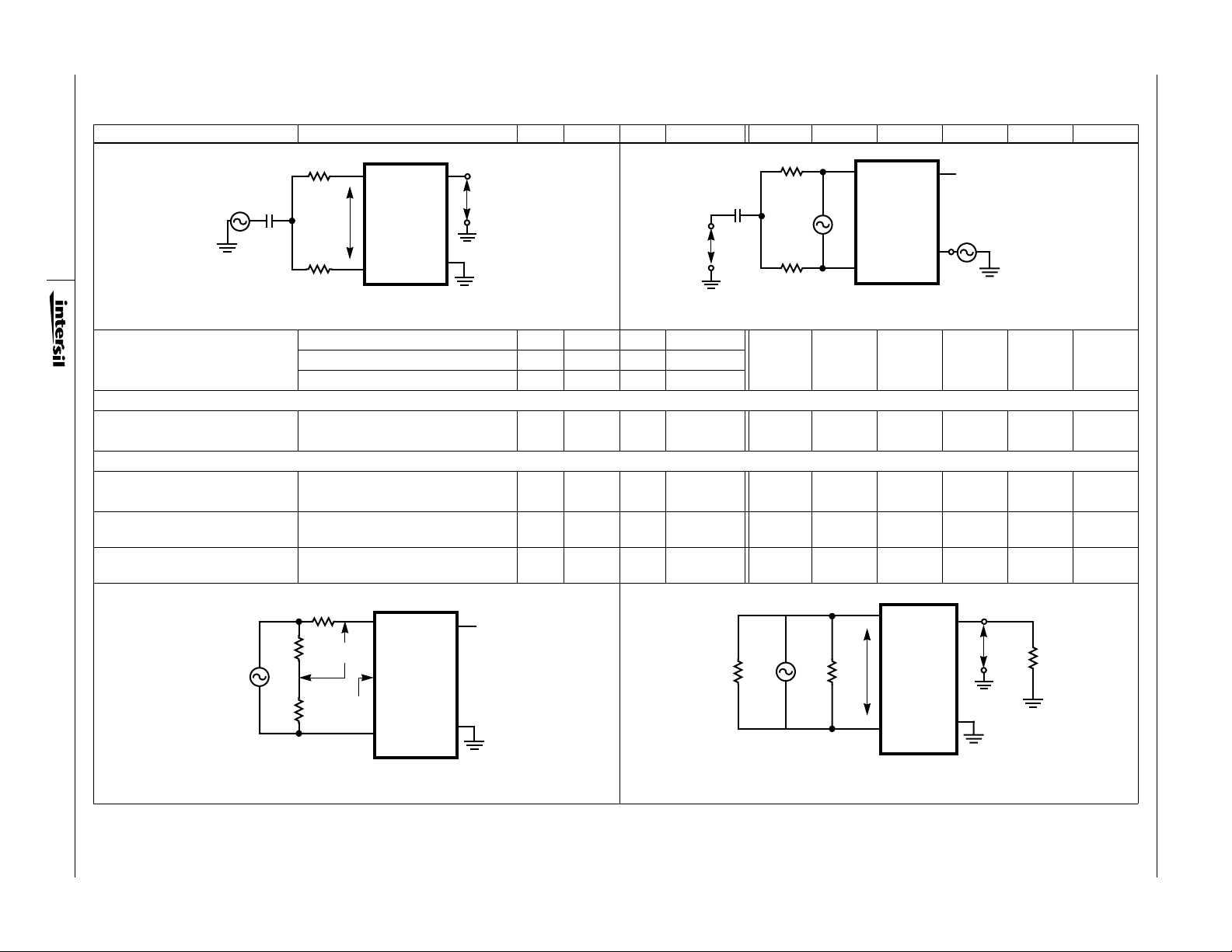

FIGURE 1. OVERLOAD LEVEL (OFF HOOK, ON HOOK)

368Ω

E

L

C10µF

C10µF

368Ω

TIP

A

RING

A

SHD

V

TX

VRX

A

300Ω

300Ω

A

LZT = VT/A

T

R

1V

RMS

0 < f < 100Hz

E

L

C

FIGURE 2. LONGITUDINAL IMPEDANCE

368Ω

A

E

C

L

368Ω

A

T

V

T

V

TIP

RING

R

TIP

RING

SHD

V

TX

VRX

LZR = VR/A

V

TX

VRX

R

V

TX

FIGURE 3A. LONGITUDINAL CURRENT LIMIT ON-HOOK (ACTIVE) FIGURE 3B. LONGITUDINAL CURRENT LIMIT OFF-HOOK (ACTIVE)

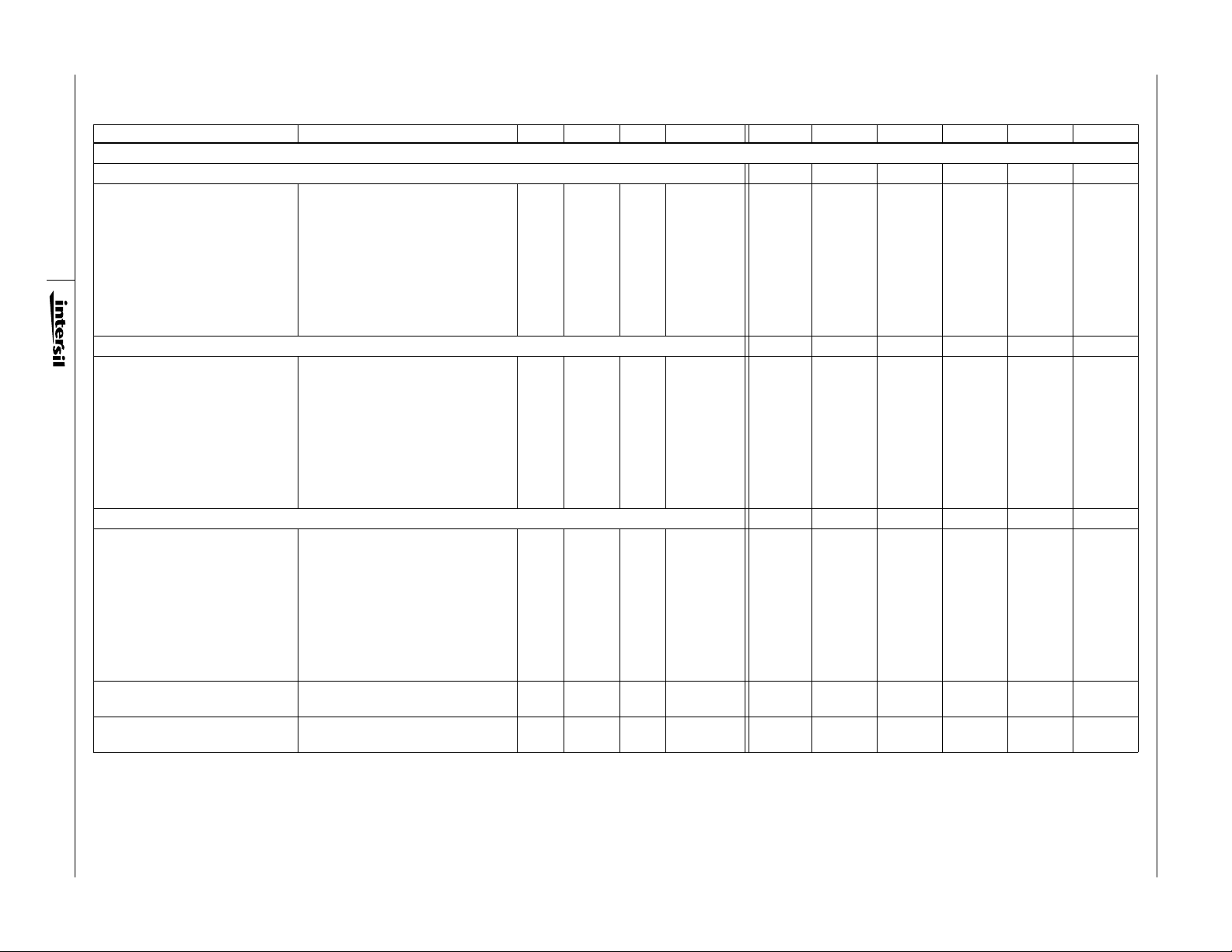

Electrical Specifications T

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS HC55120 HC55121 HC55130/1 HC55140/1 HC55142/3 HC55150/1

OFF-HOOK LONGITUDINAL BALANCE

Longitudinal to Metallic (Note 7)

Forward and Reverse

4-5

Longitudinal to Metallic (Note 7)

Forward and Reverse

Longitudinal to 4-Wire (Note 9)

(Forward and Reverse)

Metallic to Longitudinal (Note 10)

Forward and Reverse

4-Wire to Longitudinal (Note 11)

Forward and Reverse

= -40oCto85oC, VCC= +5V ±5%, VBH= -48V,VBL= -24V,PTG = Open, RP1=RP2=0Ω, ZT= 120kΩ,R

A

ROH= 40kΩ,CH= 0.1µF, CDC= 4.7µF, C

to the part. (NA) symbol used to indicate the test does not apply to the part. (Continued)

IEEE 455 - 1985, RLR, RLT = 368Ω

Normal Polarity:

0.2kHz < f < 1.0kHz, 0oC to 70oC - - - dB 53 NA NA NA NA 55

1.0kHz < f < 3.4kHz, 0oC to 70oC - - - dB 53 NA NA NA NA 55

0.2kHz < f < 1.0kHz, -40oC to 85oC - - - dB NA 53 63 63 63 NA

1.0kHz < f < 3.4kHz, -40oC to 85oC - - - dB NA 53 58 58 58 NA

Reverse Polarity 0.2kHz < f < 3.4kHz,

(Figure 4)

RLR, RLT = 300Ω,

Normal Polarity:

0.2kHz < f < 1.0kHz, 0oC to 70oC - - - dB 53 NA NA NA NA 55

1.0kHz < f < 3.4kHz, 0oC to 70oC - - - dB 53 NA NA NA NA 55

0.2kHz < f < 1.0kHz, -40oC to 85oC - - - dB NA 53 63 63 63 NA

1.0kHz < f < 3.4kHz, -40oC to 85oC - - - dB NA 53 58 58 58 NA

Reverse Polarity 0.2kHz < f < 3.4kHz,

(Figure 4)

Normal Polarity: Forward

o

0.2kHz < f < 1.0kHz, 0

1.0kHz < f < 3.4kHz, 0

0.2kHz < f < 1.0kHz, -40oC to 85oC - - - dB NA 53 63 63 63 NA

1.0kHz < f < 3.4kHz, -40

Reverse Polarity 0.2kHz < f < 3.4kHz,

(Figure 4)

FCC Part 68, Para 68.310 (Note 8)

0.2kHz < f < 3.4kHz, (Figure 5)

0.2kHz < f < 3.4kHz, (Figure 5) 40 - - dB Forward

C to 70oC - - - dB 53 NA NA NA NA 61

o

C to 70oC - - - dB 53 NA NA NA NA 61

o

C to 85oC - - - dB NA 53 58 58 58 NA

= 0.47µF, GND = 0V, RL = 600Ω. Unless Otherwise Specified.

RT/REV

MIN MIN MIN MIN MIN MIN

Forward

Only

--- dB NA53 NA 58 58 55

MIN MIN MIN MIN MIN MIN

Forward

Only

--- dB NA53 NA 58 58 55

MIN MIN MIN MIN MIN MIN

Only

- - dB NA 53 NA 58 58 61

40 50 - dB Forward

Only

Only

•

•

= 38.3kΩ,RD= 50kΩ, RDC_RAC = 20kΩ,

LIM

Symbol used to indicate the test applies

(•)

Forward

Only

Forward

Only

Forward

Only

Forward

Only

Forward

Only

•••

•••

HC55120, HC55121, HC55130, HC55131, HC55140, HC55141, HC55142, HC55143, HC55150, HC55151

Electrical Specifications T

= -40oCto85oC, VCC= +5V ±5%, VBH= -48V,VBL= -24V,PTG = Open, RP1=RP2=0Ω, ZT= 120kΩ,R

A

ROH= 40kΩ,CH= 0.1µF, CDC= 4.7µF, C

= 0.47µF, GND = 0V, RL = 600Ω. Unless Otherwise Specified.

RT/REV

to the part. (NA) symbol used to indicate the test does not apply to the part. (Continued)

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS HC55120 HC55121 HC55130/1 HC55140/1 HC55142/3 HC55150/1

R

4-6

LT

E

L

C

2.16µF

R

LR

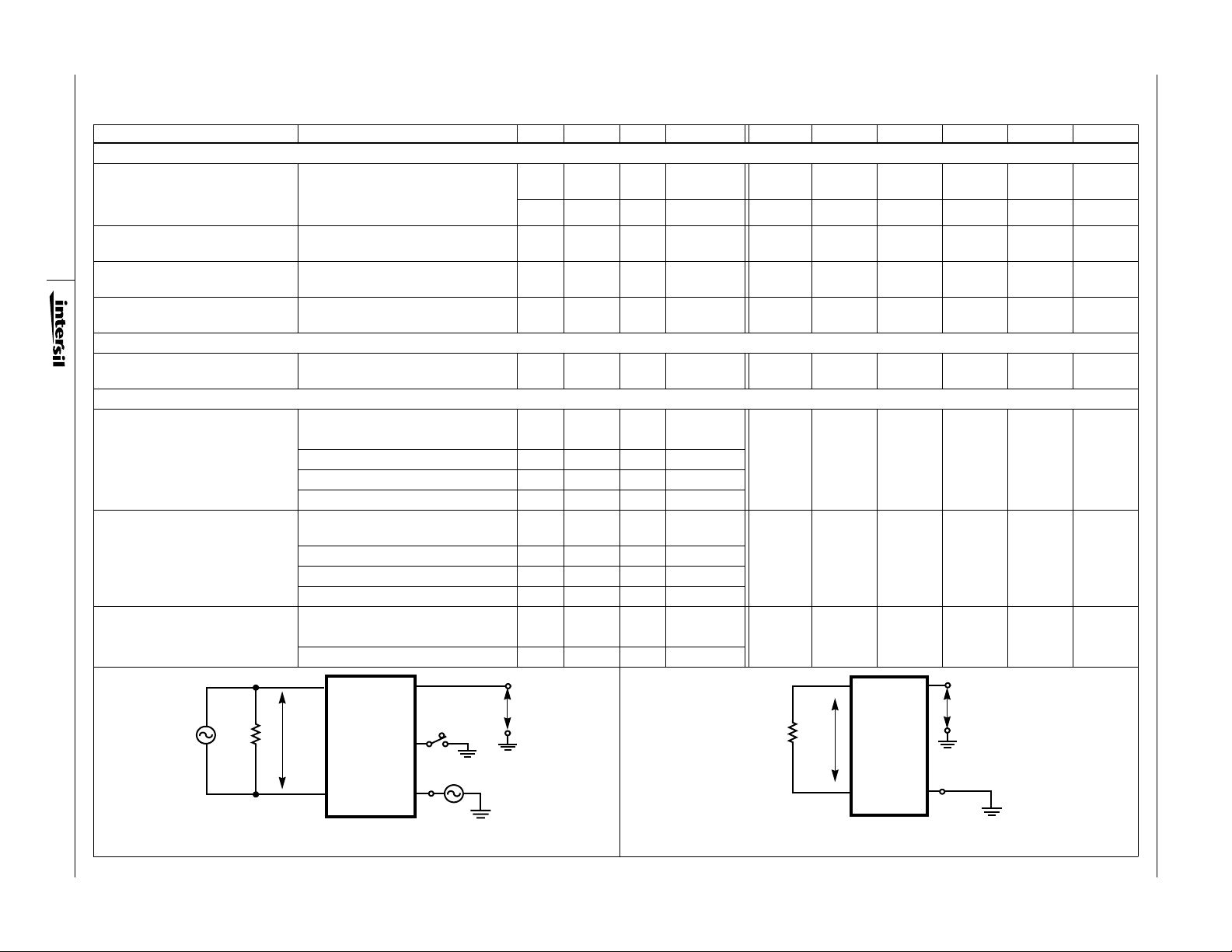

FIGURE 4. LONGITUDINAL TO METALLIC AND LONGITUDINAL TO 4-WIRE BALANCE

TIP

V

TR

RING

V

TX

VRX

V

TX

FIGURE 5. METALLIC TO LONGITUDINAL AND 4-WIRE TO LONGITUDINAL

BALANCE

2-Wire Return Loss

Forward and Reverse

0.2kHz to 1.0kHz (Note 12, Figure 6) 30 35 - dB Forward

1.0kHz to 3kHz (Note 12, Figure 6) 23 25 - dB

3kHz to 3.4kHz (Note 12, Figure 6) 21 23 - dB

TIP IDLE VOLTAGE (User Programmable)

TIPX Idle Voltage Active, IL < 5mA -2.6 -2.2 -1.8 V Forward

Forward and Reverse

RING IDLE VOLTAGE (User Programmable)

RINGX Idle Voltage

Forward and Reverse

V

TR

Forward and Reverse

V

TR(ROH)

Pulse Metering

Active, I

Tip open, IL < 5mA -46.4 -45.3 -44.2 V

Active, I

Active, IL≥ 8.5mA, ROH = 50kΩ 36 38.1 - V NA

< 5mA -46.4 -45.3 -44.2 V Forward

L

< 5mA 41 43.1 45 V Forward

L

Forward and Reverse

2.16µF

C

V

L

300Ω

300Ω

Only

Only

Only

Only

= 38.3kΩ,RD= 50kΩ, RDC_RAC = 20kΩ,

LIM

Symbol used to indicate the test applies

(•)

R

LT

R

LR

TIP

E

TR

RING

V

TX

VRX

E

RX

HC55120, HC55121, HC55130, HC55131, HC55140, HC55141, HC55142, HC55143, HC55150, HC55151

Forward

•

•

•

•

•

Only

Forward

Only

Forward

Only

Forward

Only

NA NA

•••

•••

•••

•••

••

Z

D

TIP

R

V

S

R

R

LR

V

M

Z

IN

RING

FIGURE 6. TWO-WIRE RETURN LOSS

V

TX

VRX

TIP

V

TX

V

TX

Z

L

600Ω

V

TR

E

G

R

L

VRX

RING

FIGURE 7. OVERLOAD LEVEL (4-WIRE TRANSMIT PORT), OUTPUT OFFSET

VOLTAGE AND HARMONIC DISTORTION

Electrical Specifications T

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS HC55120 HC55121 HC55130/1 HC55140/1 HC55142/3 HC55150/1

4-WIRE TRANSMIT PORT (VTX)

Overload Level, Off Hook (IL≥ 18mA)

Forward and Reverse

Overload Level, On Hook (IL≤ 5mA)

4-7

Forward and Reverse

VTX Output Offset Voltage

Forward and Reverse

Output Impedance

(Guaranteed by Design)

4-WIRE RECEIVE PORT (VRX)

VRX Input Impedance

(Guaranteed by Design)

FREQUENCY RESPONSE (OFF-HOOK)

2-Wire to 4-Wire

Forward and Reverse

4-Wire to 2-Wire

Forward and Reverse

4-Wire to 4-Wire

Forward and Reverse

= -40oCto85oC, VCC= +5V ±5%, VBH= -48V,VBL= -24V,PTG = Open, RP1=RP2=0Ω, ZT= 120kΩ,R

A

ROH= 40kΩ,CH= 0.1µF, CDC= 4.7µF, C

to the part. (NA) symbol used to indicate the test does not apply to the part. (Continued)

(ZL > 20kΩ, IL 1% THD) (Note 13,

Figure 7) TA = 0oC to 85oC

TA = -40oC to 0oC

(ZL > 20kΩ, 1% THD)

(Note 14, Figure 7)

EG = 0, ZL= ∞, (Note 15, Figure 7) -200 - 200 mV Forward

0.2kHz < f < 03.4kHz - 0.1 1 Ω

0.2kHz < f < 3.4kHz - 500 600 kΩ

Relative to 0dBm at 1.0kHz, ERX= 0V Forward

0.3kHz < f < 3.4kHz -0.15 - 0.15 dB

f = 8.0kHz (Note 16, Figure 8) - 0.24 0.5 dB

f = 12kHz (Note 16, Figure 8) - 0.58 1.0 dB

f = 16kHz (Note 16, Figure 8) - 1.0 1.5 dB

Relative to 0dBm at 1.0kHz, EG= 0V

0.3kHz < f < 3.4kHz -0.15 - 0.15 dB

f = 8kHz (Note 17, Figure 8) -0.5 0.24 - dB

f = 12kHz (Note 17, Figure 8) -1.0 0.58 - dB

f = 16kHz (Note 17, Figure 8) -1.5 1.0 - dB

Relative to 0dBm at 1.0kHz, EG= 0V Forward

0.3kHz < f < 3.4kHz (Note 18, Figure 8) -0.15 - 0.15 dB

8kHz, 12kHz, 16kHz (Note 18, Figure 8) -0.5 0 0.5 dB

= 0.47µF, GND = 0V, RL = 600Ω. Unless Otherwise Specified.

RT/REV

Forward

3.2 - - V

3.0 - - V

1.3 - - V

PEAK

PEAK

PEAK

Only

Forward

Only

Only

••••••

••••••

Only

Forward

Only

Only

•

•

•

•

•

•

= 38.3kΩ,RD= 50kΩ, RDC_RAC = 20kΩ,

LIM

Symbol used to indicate the test applies

(•)

Forward

Only

Forward

Only

Forward

Only

Forward

Only

•••

•••

•••

•••

Forward

Only

•••

Forward

Only

•••

HC55120, HC55121, HC55130, HC55131, HC55140, HC55141, HC55142, HC55143, HC55150, HC55151

TIP

R

600Ω

L

V

TR

RING VRX

E

G

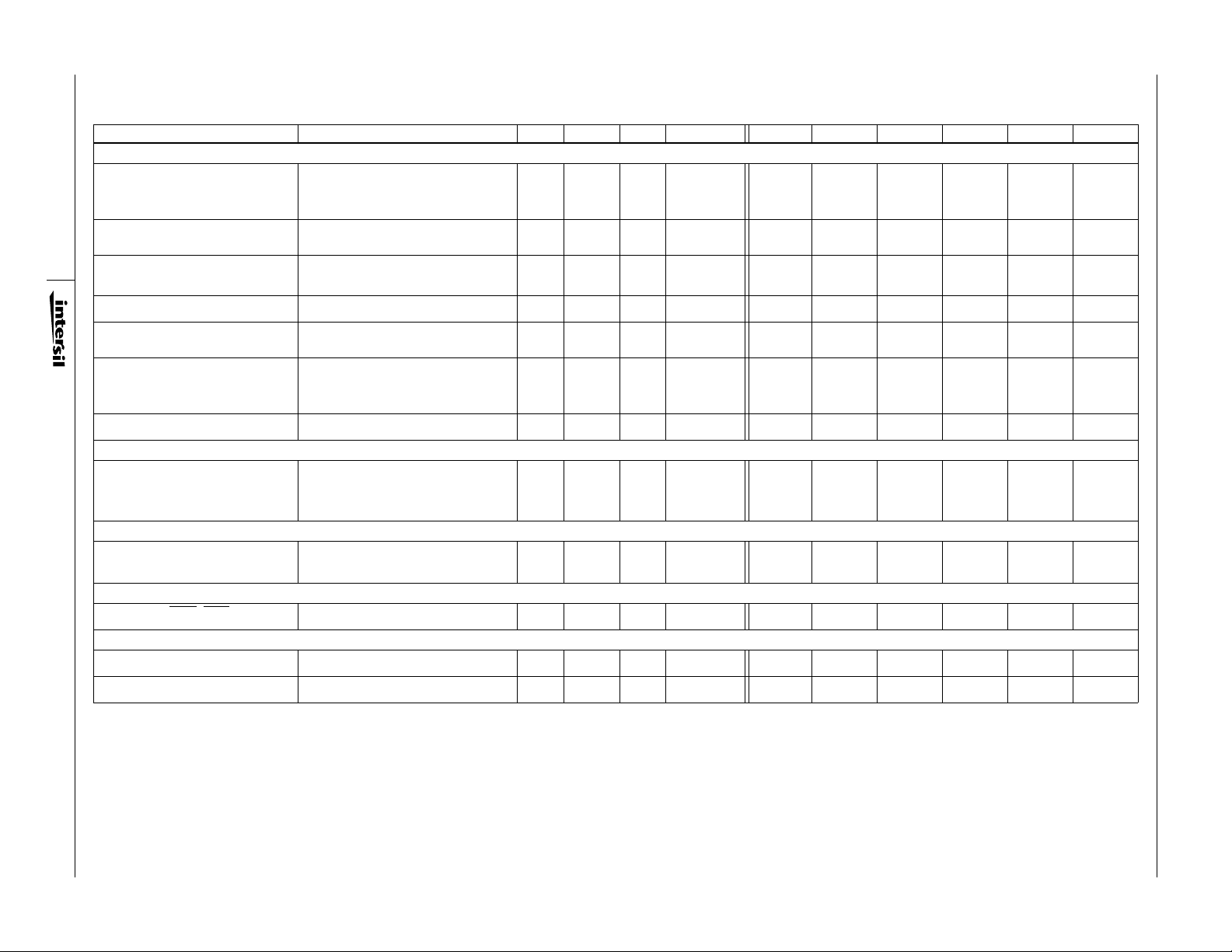

FIGURE 8. FREQUENCY RESPONSE, INSERTION LOSS, GAIN TRACKING

AND HARMONIC DISTORTION

V

PTG

TX

OPEN

E

RX

V

TX

V

TIP

R

L

600Ω

V

TR

RING

FIGURE 9. IDLE CHANNEL NOISE

TX

VRX

V

TX

Electrical Specifications T

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS HC55120 HC55121 HC55130/1 HC55140/1 HC55142/3 HC55150/1

INSERTION LOSS

2-Wire to 4-Wire

Forward and Reverse

4-Wire to 2-Wire

4-8

Forward and Reverse

GAIN TRACKING (Ref = -10dBm, at 1.0kHz)

2-Wire to 4-Wire

Forward and Reverse

4-Wire to 2-Wire

Forward and Reverse

NOISE

Idle Channel Noise at 2-Wire C-Message Weighting - 10.5 13 dBrnC Forward

Forward and Reverse Psophometric Weighting (Note 24,

Idle Channel Noise at 4-Wire C-Message Weighting - 10.5 13 dBrnC Forward

Forward and Reverse Psophometrical Weighting

HARMONIC DISTORTION

2-Wire to 4-Wire

Forward and Reverse

4-Wire to 2-Wire

Forward and Reverse

= -40oCto85oC, VCC= +5V ±5%, VBH= -48V,VBL= -24V,PTG = Open, RP1=RP2=0Ω, ZT= 120kΩ,R

A

ROH= 40kΩ,CH= 0.1µF, CDC= 4.7µF, C

to the part. (NA) symbol used to indicate the test does not apply to the part. (Continued)

0dBm, 1kHz

PTG = Open (Note 19, Figure 8) -0.2 - 0.2 dB Forward

PTG = GND (Note 20, Figure 8) -6.22 -6.02 -5.82 dB

0dBm, 1kHz (Note 21, Figure 8) -0.2 - 0.2 dB Forward

-40dBm to +3dBm (Note 22, Figure 8) -0.1 - 0.1 dB Forward

-55dBm to -40dBm (Note 22, Figure 8) -0.2 - 0.2 dB

-40dBm to +3dBm (Note 23, Figure 8) -0.1 - 0.1 dB Forward

-55dBm to -40dBm (Note 23, Figure 8) -0.2 - 0.2 dB

Note 30, Figure 9)

(Note 25, Note 30, Figure 9)

0dBm, 0.3kHz to 3.4kHz

(Note 26, Figure 7)

0dBm, 0.3kHz to 3.4kHz

(Note 27, Figure 8)

= 0.47µF, GND = 0V, RL = 600Ω. Unless Otherwise Specified.

RT/REV

- -79.5 -77 dBmp

- -79.5 -77 dBmp

- -67 -50 dB Forward

- -67 -50 dB Forward

Only

Only

Only

Only

Only

Only

Only

Only

= 38.3kΩ,RD= 50kΩ, RDC_RAC = 20kΩ,

LIM

Symbol used to indicate the test applies

(•)

Forward

• •••

•

•

•

•

•

•

•

Only

Forward

Only

Forward

Only

Forward

Only

Forward

Only

Forward

Only

Forward

Only

Forward

Only

•••

•••

•••

•••

•••

•••

•••

HC55120, HC55121, HC55130, HC55131, HC55140, HC55141, HC55142, HC55143, HC55150, HC55151

TIP

V

TX

R

R

L

V

600Ω

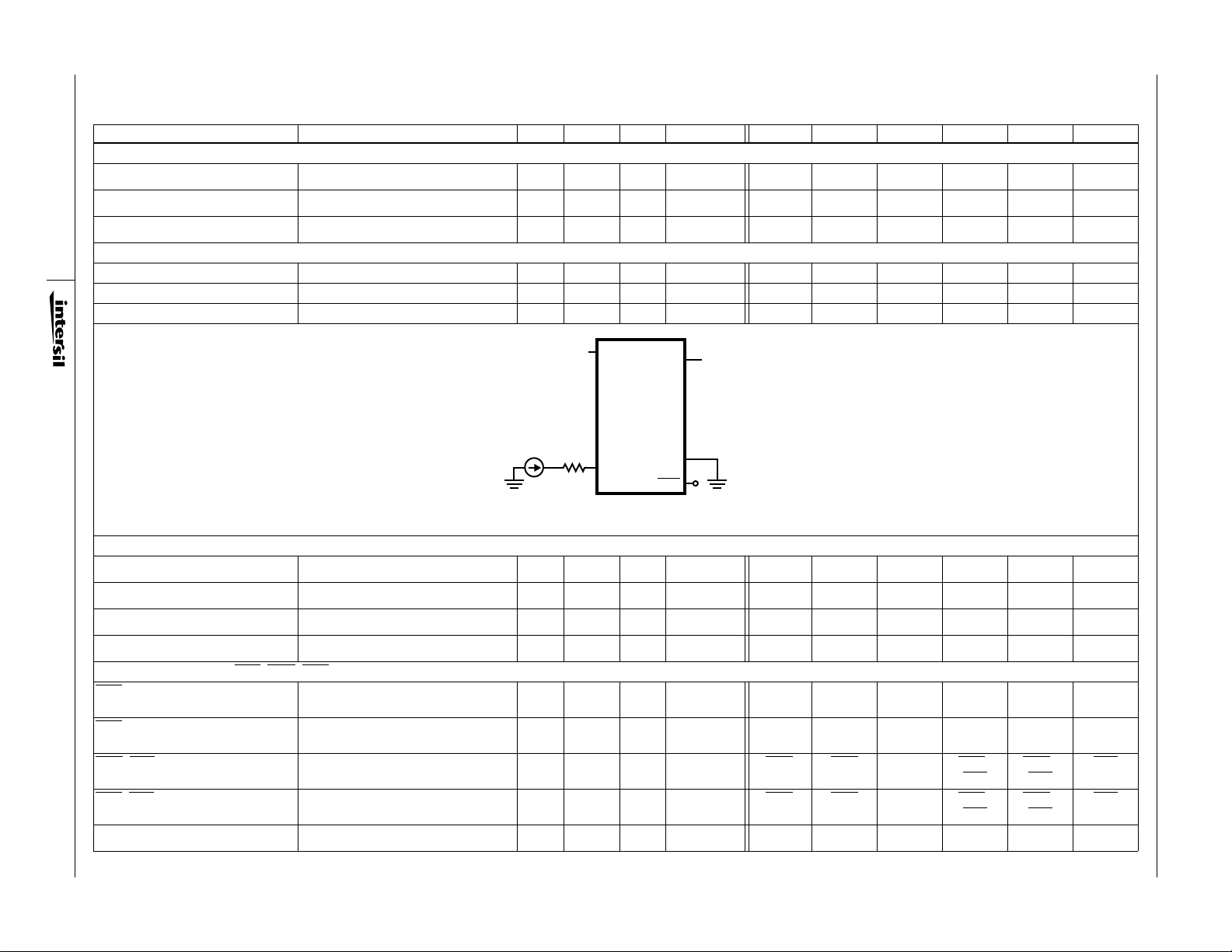

FIGURE 10. CONSTANT LOOP CURRENT TOLERANCE

TR

RING

LIM

VRX

R

LIM

38.3kΩ

7kΩ

V

BH

I

R1

R

1

FIGURE 11. TIPX VOLTAGE

TIP

S

RING

V

VRX

TX

Electrical Specifications T

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS HC55120 HC55121 HC55130/1 HC55140/1 HC55142/3 HC55150/1

BATTERY FEED CHARACTERISTICS

Constant Loop Current Tolerance 18mA ≤ IL ≤ 45mA, Forward

IL = 26.5mA, R

Forward and Reverse

Tip Open State TIPX Leakage

4-9

Current

Tip Open State RINGX Current R1= 0Ω, VBH = -48V, R

Tip Open State RINGX Voltage 5mA < IR1 < 26mA (Figure 11) - 42.8 - V

Tip Voltage (Ground Start) Active State, (S Open) R1= 150Ω

Tip Voltage (Ground Start) Active State, (S Closed) Tip Lead to

Open Circuit State Loop Current (Active) RL = 0Ω -20 0 20 µA

LOOP CURRENT DETECTOR

Programmable Threshold I

Forward and Reverse I

GROUND KEY DETECTOR

Ground Key Detector Threshold

Tip/Ring Current Difference

LINE VOLTAGE MEASUREMENT

Pulse Width (

RING TRIP DETECTOR (DT, DR)

Ring Trip Comparator Current Source Res = 2MΩ -2- µA

Input Common-Mode Range Source Res = 2MΩ --±200 V

= 38.3kΩ

LIM

GKD_LVM) Pulse Width = (20)(C

= -40oCto85oC, VCC= +5V ±5%, VBH= -48V,VBL= -24V,PTG = Open, RP1=RP2=0Ω, ZT= 120kΩ,R

A

ROH= 40kΩ,CH= 0.1µF, CDC= 4.7µF, C

to the part. (NA) symbol used to indicate the test does not apply to the part. (Continued)

(Note 27, Figure 10) 0.92I

S = Closed (Figure 11) - - -200 µA

= 38.3kΩ 22.6 26.8 31 mA

LIM

R1 = 2.5kΩ, VBH = -48V (Figure 11) 15.5 17.1 18.2 mA

(Figure 11)

-48V Through 7kΩ, Ring Lead to

Ground Through 150Ω (Figure 11)

= (500/ RD) ≥ 5mA, 0.9I

LTh

= 8.5mA

LTh

R

= 58.8kΩ

D

Tip Open 5 8 11 mA

Active (Note 29, R1 =2.5kΩ, Figure 12) 12.5 20 27.5 mA

REV.../ILIM

) 0.32 0.36 0.4 ms/V NA NA NA

= 0.47µF, GND = 0V, RL = 600Ω. Unless Otherwise Specified.

RT/REV

I

L

-5.3 -4.8 -4.3 V NA NA NA

-5.3 -4.8 -4.3 V NA NA NA NA

LThILTh

1.08I

L

1.1I

LTh

mA

L

mA Forward

= 38.3kΩ,RD= 50kΩ, RDC_RAC = 20kΩ,

LIM

Symbol used to indicate the test applies

(•)

Forward

Only

•

Only

•••

••••••

••••••

••••••

••

NA

••

••••••

Forward

Only

•

••

Only

NA

•••

••

NA

•••

••••••

••••••

HC55120, HC55121, HC55130, HC55131, HC55140, HC55141, HC55142, HC55143, HC55150, HC55151

Electrical Specifications T

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS HC55120 HC55121 HC55130/1 HC55140/1 HC55142/3 HC55150/1

RING RELAY DRIVER

V

at 30mA IOL = 30mA - 0.2 0.5 V

SAT

V

at 40mA IOL = 40mA - 0.52 0.8 V

SAT

Off State Leakage Current VOH = 13.2V - 0.1 10 µA

4-10

TEST RELAY DRIVER (TRLY1, TRLY2)

V

at 30mA I

SAT

V

at 40mA I

SAT

Off State Leakage Current V

= -40oCto85oC, VCC= +5V ±5%, VBH= -48V,VBL= -24V,PTG = Open, RP1=RP2=0Ω, ZT= 120kΩ,R

A

ROH= 40kΩ,CH= 0.1µF, CDC= 4.7µF, C

to the part. (NA) symbol used to indicate the test does not apply to the part. (Continued)

= 30mA - 0.3 0.5 V NA NA NA/• NA/• NA/• NA/•

OL

= 40mA - 0.62 0.9 V NA NA NA/• NA/• NA/• NA/•

OL

= 13.2V - - 10 µA NA NA NA/• NA/• NA/• NA/•

OH

= 0.47µF, GND = 0V, RL = 600Ω. Unless Otherwise Specified.

RT/REV

= 38.3kΩ,RD= 50kΩ, RDC_RAC = 20kΩ,

LIM

Symbol used to indicate the test applies

(•)

••••••

••••••

••••••

HC55120, HC55121, HC55130, HC55131, HC55140, HC55141, HC55142, HC55143, HC55150, HC55151

TIP

RING

2.5kΩ

FIGURE 12. GROUND KEY DETECT

DIGITAL INPUTS (C1, C2, C3)

Input Low Voltage, V

Input High Voltage, V

Input Low Current, I

Input High Current, I

DETECTOR OUTPUTS (SHD, GKD_LVM)

SHD Output Low Voltage, V

Forward, Reverse

SHD Output High Voltage, V

Forward, Reverse

GKD_LVM Output Low Voltage,

VOLForward and Tip Open

GKD_LVM Output High Voltage,

VOHForward and Tip Open

Internal Pull-Up Resistor - 15 - kΩ

IL

IH

IL

IH

OL

OH

VIL = 0.4V - - -10 µA

VIH = 2.5V - 25 50 µA

IOL = 1mA - - 0.5 V Forward

IOH = 100µA 2.7 - - V Forward

IOL = 1mA

R1 = 2.5kΩ (Figure 11)

IOH = 100µA 2.7 - - V GKD GKD NA GKD_

0 - 0.8 V

2.0 - V

- - 0.5 V GKD GKD NA GKD_

CC

V

TX

VRX

SHD

V

••••••

••••••

••••••

••••••

Forward

Only

Only

•

•

Only

Forward

Only

•••

•••

LVM

LVM

GKD_

LVM

GKD_

LVM

LVM

LVM

••••••

Electrical Specifications T

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS HC55120 HC55121 HC55130/1 HC55140/1 HC55142/3 HC55150/1

POWER DISSIPATION (VBH = -48V, VBL = -24V)

Open Circuit State C1, C2, C3 = 0, 0, 0 - 25 - mW Forward

On-Hook, Active C1, C2, C3 = 0, 1, 0

4-11

Forward and Reverse IL= 0mA, Longitudinal

POWER SUPPLY CURRENTS (VBH = -48V, VBL = -24V)

VCC Current, I

VBH Current, I

VBL Current, I

VCC Current, I

Forward and Reverse

VBH Current, I

Forward and Reverse

VBL Current, I

Forward and Reverse

POWER SUPPLY REJECTION RATIOS

VCC to 2 or 4 Wire Port

Forward and Reverse

VBH to 2 or 4 Wire Port

Forward and Reverse

VBL to 2 or 4 Wire Port

Forward and Reverse

TEMPERATURE GUARD

Junction Threshold Temperature - 175 -

CC

BH

BL

CC

BH

BL

= -40oCto85oC, VCC= +5V ±5%, VBH= -48V,VBL= -24V,PTG = Open, RP1=RP2=0Ω, ZT= 120kΩ,R

A

ROH= 40kΩ,CH= 0.1µF, CDC= 4.7µF, C

to the part. (NA) symbol used to indicate the test does not apply to the part. (Continued)

C1, C2, C3 = 1, 1, 0

Current = 0mA

Open Circuit State - 2.25 3.0 mA Forward

Active State

IL= 0mA, Longitudinal

Current = 0mA

Active State RL = 600Ω

50Hz < f < 3400Hz, V

=100mV

IN

= 0.47µF, GND = 0V, RL = 600Ω. Unless Otherwise Specified.

RT/REV

- 52 - mW Forward

- 0.3 0.45 mA Forward

- 0.022 0.035 mA Forward

- 2.7 3.6 mA Forward

- 0.8 1.06 mA Forward

- - 0.01 mA Forward

- 40 - dB Forward

- 40 - dB Forward

- 40 - dB Forward

o

C•

Only

Only

Only

Only

Only

Only

Only

Only

Only

Only

Only

= 38.3kΩ,RD= 50kΩ, RDC_RAC = 20kΩ,

LIM

Symbol used to indicate the test applies

(•)

Forward

•

Only

•••

• •••

Forward

•

•

•

•

•

•

•

•

•

•

Only

Forward

Only

Forward

Only

Forward

Only

Forward

Only

Forward

Only

Forward

Only

Forward

Only

Forward

Only

Forward

Only

•••

•••

•••

•••

•••

•••

•••

•••

•••

•••

•••••

HC55120, HC55121, HC55130, HC55131, HC55140, HC55141, HC55142, HC55143, HC55150, HC55151

HC55120, HC55121, HC55130, HC55131, HC55140, HC55141, HC55142, HC55143, HC55150, HC55151

Notes

2. Overload Level (Two-WirePort, Off Hook) - The overload

levelis specified at the 2-wire port (VTR) with the signal source at

the 4-wire receive port (ERX). RL = 600Ω, I

Increase the amplitude of ERXuntil 1% THD is measured at VTR.

Reference Figure 1.

3. Overload Level (Two-WirePort, On Hook) - The overload

levelis specified at the 2-wire port (VTR) with the signal source at

the 4-wire receive port (ERX). RL = ∞, I

DCMET

the amplitude of ERX until 1% THD is measured at VTR.

Reference Figure 1.

4. Longitudinal Impedance - The longitudinal impedance is

computed using the following equations, where TIP and RING

voltages are referenced to ground. LZT,LZR,VT,VR,ARand A

are defined in Figure 2.

(TIP) LZT = VT/A

(RING) LZR = VR/A

where: EL = 1V

T

R

(0Hz to 100Hz)

RMS

5. Longitudinal Current Limit (On-Hook Active) - On-Hook

longitudinal current limit is determined by increasing the (60Hz)

amplitude of EL (Figure 3A) until the 2-wire longitudinal current

is greater than 28mA

remains low (no false detection) and the 2-wire to 4-wire

/Wire. Under this condition, SHD pin

RMS

longitudinal balance is verified to be greater than 45dB

(LB

= 20log VTX/EL).

2-4

6. Longitudinal Current Limit (Off-Hook Active) - Off-Hook

longitudinal current limit is determined by increasing the (60Hz)

amplitude of EL (Figure 3B) until the 2-wire longitudinal current

is greater than 28mA

remains high (no false detection) and the 2-wire to 4-wire

/Wire. Under this condition, SHD pin

RMS

longitudinal balance is verified to be greater than 45dB

(LB

= 20log VTX/EL).

2-4

7. Longitudinal to Metallic Balance - The longitudinal to

metallic balance is computed using the following equation:

BLME = 20 log (EL/VTR), where: EL and VTR are defined in

Figure 4.

8. Metallic to Longitudinal FCC Part 68, Para 68.310 - The

metallic to longitudinal balance is defined in this spec.

9. Longitudinal to Four-WireBalance - The longitudinal to4-wire

balance is computed using the following equation:

BLFE = 20 log (EL/VTX), EL and VTX are defined in Figure 4.

10. Metallic to Longitudinal Balance - The metallic to longitudinal

balance is computed using the following equation:

BMLE = 20 log (ETR/VL), ERX = 0

where: E

and ERX are defined in Figure 5.

TR,VL

11. Four-Wire to LongitudinalBalance - The 4-wire tolongitudinal

balance is computed using the following equation:

BFLE = 20 log (ERX/VL), ETR = source is removed.

where: E

and ETR are defined in Figure 5.

RX,VL

12. Two-WireReturn Loss - The 2-wire return loss is computed

using the following equation:

r = -20 log (2VM/VS) where: ZD= The desired impedance; e.g.,

the characteristic impedance of the line, nominally 600Ω.

(Reference Figure 6).

13. Overload Level (4-Wire Port Off-Hook) - The overload level

is specified at the 4-wire transmit port (VTX) with the signal

source (EG) at the 2-wire port, ZL = 20kΩ, RL = 600Ω

(Reference Figure 7). Increase the amplitude of EG until 1%

THD is measured at VTX. Note the PTG pin is open, and the

gain from the 2-wire port to the 4-wire port is equal to 1.

≥ 18mA.

DCMET

= 0mA. Increase

14. Overload Level (4-Wire Port On-Hook) - Theoverload levelis

specified at the 4-wire transmit port (VTX) with the signal source

(EG) at the 2-wire port, ZL= 20kΩ, RL= ∞(Reference Figure 7).

Increase the amplitude of EGuntil 1% THD is measured at VTX.

Note the PTG pin is open, and the gain from the 2-wire port to

the 4-wire port is equal to 1.

15. Output OffsetVoltage - The output offset voltage is specified

with the following conditions: EG=0,RL= 600Ω,ZL= ∞ and is

measured at VTX. EG,RL, VTX and ZLare defined in Figure 7.

16. Two-Wireto Four-Wire Frequency Response - The 2-wire to

4-wire frequency response is measured with respect to

EG= 0dBm at 1.0kHz, ERX= 0V (VRX input floating), RL= 600Ω.

The frequency response is computed using the following equation:

F

= 20 log (VTX/VTR), vary frequency from 300Hz to 3.4kHz

T

2-4

and compare to 1kHz reading.

VTX, VTR,RLand EG are defined in Figure 8.

17. Four-Wireto Two-WireFrequencyResponse - The 4-wire to 2wire frequency response is measured with respectto ERX= 0dBm

at 1.0kHz, EG source removed from circuit, RL = 600Ω. The

frequency response is computed using the following equation:

F

= 20 log (VTR/ERX), vary frequency from 300Hz to 3.4kHz

4-2

and compare to 1kHz reading.

VTR,RLand ERX are defined in Figure 8.

18. Four-Wire to Four-Wire FrequencyResponse - The 4-wire

to 4-wire frequency response is measured with respect to

ERX= 0dBm at 1.0kHz, EG source removed from circuit,

RL= 600Ω. The frequency response is computed using the

following equation:

F

= 20 log (VTX/ERX), vary frequency from 300Hz to 3.4kHz

4-4

and compare to 1kHz reading.

V

and ERX are defined in Figure 8.

TX ,RL

19. Two-WiretoFour-WireInsertionLoss(PTG = Open) - The

2-wire to 4-wire insertion loss is measured with respect to

EG= 0dBm at 1.0kHz input signal, ERX = 0 (VRX input floating),

RL= 600Ω and is computed using the following equation:

L

= 20 log (VTX/VTR)

2-4

where: VTX, VTR,RLand EG are defined in Figure 8. (Note:

The fuse resistors, RF, impact the insertion loss. The specified

insertion loss is for RF1 = RF2 = 0).

20. Two-WiretoFour-WireInsertion Loss (PTG = AGND) - The

2-wire to 4-wire insertion loss is measured with respect to EG=

0dBm at 1.0kHz input signal, ERX = 0 (VRX input floating), RL =

600Ω and is computed using the following equation:

L

= 20 log (VTX/VTR)

2-4

where: VTX, VTR,RLand EG are defined in Figure 8. (Note:

The fuse resistors, RF, impact the insertion loss. The specified

insertion loss is for RF1 = RF2 = 0).

21. Four-Wire to Two-WireInsertion Loss - The 4-wire to 2-wire

insertion loss is measured based upon ERX = 0dBm, 1.0kHz

input signal, EG source removed from circuit, RL = 600Ω and is

computed using the following equation:

L

= 20 log (VTR/ERX)

4-2

where: VTR,RLand ERX are defined in Figure 8.

22. Two-Wireto Four-Wire Gain Tracking - The 2-wire to 4-wire

gain tracking is referenced to measurements taken for

EG= -10dBm, 1.0kHz signal, ERX = 0 (VRX output floating),

RL= 600Ω and is computed using the following equation.

G

=20• log (VTX/VTR) vary amplitude -40dBm to +3dBm, or

2-4

-55dBm to -40dBm and compare to -10dBm reading.

VTX,RLand VTR are defined in Figure 8.

4-12

HC55120, HC55121, HC55130, HC55131, HC55140, HC55141, HC55142, HC55143, HC55150, HC55151

23. Four-Wire to Two-WireGain Tracking - The 4-wire to 2-wire

gain tracking is referenced to measurements taken for

ERX= -10dBm, 1.0kHz signal, EG source removed from circuit,

RL= 600Ω and is computed using the following equation:

G

= 20 • log (VTR/ERX) vary amplitude -40dBm to +3dBm,

4-2

or -55dBm to -40dBm and compare to -10dBm reading.

VTR, RL and ERX are defined in Figure 8. The level is specified at

the 4-wire receiveport and referenced to a 600Ω impedance level.

24. Two-WireIdle Channel Noise - The 2-wire idle channel noise

at VTR is specified with the 2-wire port terminated in 600Ω (RL)

and with the 4-wire receive port (VTX) floating (Reference

Figure 9).

25. Four-Wire Idle ChannelNoise - The 4-wire idlechannel noise

at VTXis specified with the 2-wire port terminated in 600Ω (RL).

The noise specification is with respect to a 600Ω impedance

level at VTX. The 4-wire receive port (VTX) floating (Reference

Figure 9).

Circuit Operation and Design Information

The UniSLIC14 family of SLICs are voltage feed current

sense Subscriber Line Interface Circuits (SLIC). For short

loop applications, the voltage between the tip and ring

terminals variesto maintain a constant loop current. Forlong

loop applications, the voltage between the tip and ring

terminals are relatively constant and the loop current varies

in proportion to the load.

The tip and ring voltages for various loop resistances are

shown in Figure 13. The tip voltage remains relatively

constant as the ring voltage moves to limit the loop current

for short loops.

The loop current for various loop resistances are shown in

Figure 14. For short loops, the loop current is limited to the

programmed current limit, set by RILIM. For long loop

applications, the loop current varies in accordance with

Ohms law for the given tip to ring voltage and the loop

resistance.

26. Harmonic Distortion (2-Wire to 4-Wire) - The harmonic

distortion is measured within the voice band with the following

conditions. EG = 0dBm at 1kHz, RL = 600Ω. Measurement

taken at VTX. (Reference Figure 7).

27. Harmonic Distortion (4-Wire to 2-Wire) - The harmonic

distortion is measured within the voice band with the following

conditions. ERX = 0dBm0. Vary frequency between 300Hz and

3.4kHz, RL = 600Ω. Measurement taken at VTR. (Reference

Figure 8).

28. Constant LoopCurrent - The constant loop current is

calculated using the following equation:

IL = 1000/R

= VTR/600 (Reference Figure 10).

LIM

29. Ground KeyDetector - (TRIGGER) Ground the Ring pin

through a 2.5kΩ resistor and verify that GKD goes low.

(RESET) Disconnect the Ring pin and verify that GKD goes

high.

(Hysteresis) Compare difference between trigger and reset.

30. Electrical Test - Not tested in production at -40oC.

.

35

30

25

CONSTANT

LOOP CURRENT

20

REGION

15

10

LOOP CURRENT (mA)

5

0

200 600 1K 1.4K 1.8K 2.2K 2.6K 3.8K3.0K 3.4K

CONSTANT TIP TO RING

VOLTAGE REGION

VBH = -48V

RD = 41.2kΩ

ROH = 38.3kΩ

RDC_RAC = 19.6kΩ

RILim = 33.2kΩ

LOOP RESISTANCE (Ω)

FIGURE 14. LOOP CURRENT vs LOOP RESISTANCE

0

TIP

-5

-10

-15

-20

-25

-30

-35

CONSTANT

-40

LOOP CURRENT

TIP AND RING VOLTAGES (V)

REGION

-45

-50

200 600 1000 1400 1800 2000 4K 10K6K 8K

RING

LOOP RESISTANCE (Ω)

CONSTANT TIP TO RING

VOLTAGE REGION

VBH = -48V

RD = 41.2kΩ

ROH = 38.3kΩ

RDC_RAC = 19.6kΩ

RILim = 33.2kΩ

-2.5V

-44.5V

FIGURE 13. TIP AND RING VOLTAGES vs LOOP RESISTANCE

4-13

The followingdiscussion separates the SLIC’s operation into

its DC and AC paths, then follows up with additional circuit

and design information.

DC Feed Curve

The DC feed curve for the UniSLIC14 family is user

programmable. The user defines the on hook and off hook

overhead voltages (including the overhead voltage for off

hook pulse metering if applicable), the maximum and

minimum loop current limits, the switch hook detect

threshold and the battery voltage. From these requirements,

the DC feed curve is customized for optimum operation in

any given application.An Excel spread sheet to calculate the

external components can be downloaded off our web site

www.intersil.com/telecom/unislic14.xls.

HC55120, HC55121, HC55130, HC55131, HC55140, HC55141, HC55142, HC55143, HC55150, HC55151

VBH

2.5V

†

SLIC SELF PROGRAMMING

VOH(on) AT LOAD

CONSTANT

R

SAT

VOH(off) AT LOAD

CURRENT

REGION

60kΩ SLOPE

I

SHD

IOH

TIP TO RING ABSOLUTE VOLTAGE (V)

RLOOP(max)

ISH- ILOOP(min) ILOOP(max)

†Internal overhead voltage automatically generated by the SLIC.

FIGURE 15. UniSLIC14 DC FEED CURVE

On Hook Overhead Voltage

DC FEED CURVE

V

BH

2.5V

V

OH(on)

TIP TO RING VOLTAGE

ISH- = I

SHD

ON HOOK

OVERHEAD

ISH-

I

SHD

LOOP CURRENT

(0.6)

Switch Hook Detect threshold (I

current for a constant on hook overhead voltage is defined

as ISH-.

The on hook overhead voltage, required for a given signal

levelat the load, must take into account the AC voltage drop

across the 2 external protection resistors (R

internal sense resistors (R

on hook overload voltage is calculated using Equation 1.

V

OH on()at LoadVsp on()

where

V

OH(on) at Load

V

= Required on hook transmission for speech

sp(on)

= On hook overhead voltage at load

RP = Protection Resistors (Typically 30Ω)

RS = Internal Sense Resistors (40Ω)

ZL = AC load impedance for (600Ω)

1.5V = Additional on hook overhead voltage requirement

Theon hook overheadvoltage

at the load (V

(on) at Load)

OH

is independent of the V

battery voltage. Once set, the

on hook voltage remains

constant as the V

BH

battery

voltagechanges. The on hook

voltage also remains constant

over temperature and line

leakages up to 0.6 times the

). The maximum loop

SHD

) and the 2

) as shown in Figure 16. The AC

S

2RP2RS+

× 1.5V+=

1

----------------------------- -+

Z

P

L

BH

(EQ. 1)

LOOP CURRENT (mA)

To account for any process and temperature variations in the

performance of the SLIC, 1.5V is added to the ov erhead

voltage requirement for the on hook case in Equation 1 and

2.0V for the off hook case in Equation 3. Note the 2.5V

overhead is automatically generated in the SLIC and is not

part of the external overhead programming.

EXTERNAL PROTECTION

RESISTOR

2R

V

ZL

(LOAD)

Z

L

P

V

OH ON OFF,()

Where:

VZL is the required on hook or offhook

transmission delivered to the load.

FIGURE 16. OVERHEAD VOLTAGE OF THE TIP AND RING

AMPLIFIERS

REQUIRED

OVERHEAD VOLTAGE

(ON, OFF)

V

OH

2R

S

INTERNAL SENSE

RESISTORS

UniSLIC14

2RP2RS+

----------------------------- -

=

Z

L

Off Hook Overhead Voltage

DC FEED CURVE

V

V

SAT

V

OH(off)

TIP TO RING VOLTAGE

BH

2.5V

I

LOOP(min)

LOOP CURRENT

OFF HOOK

OVER HEAD

The off hook overhead

voltage V

(off) at Load is

OH

also independent ofthe V

battery voltage and remains

constant over temperature.

The required off hook

overheadvoltage is the sum

of the AC and DC voltage

drops across the internal

sense resistors (R

TIP AND RING

AMPLIFIERS

V

ZL

BH

, the

S)

4-14

HC55120, HC55121, HC55130, HC55131, HC55140, HC55141, HC55142, HC55143, HC55150, HC55151

protection resistors (R

voltage for speech (V

voltage for the pulse metering (V

), the required (peak) off hook

P

) and the required (peak) off hook

sp(off)

pm(off)

), if applicable.

The off hook overhead voltage is defined in Equation 2 and

calculated using Equation 3.

V

OH off()at LoadVOH Rsense()Vsp off()Vpm off()

++=

(EQ. 2)

where:

V

OH(off) at Load

VOH(R

sense

across sense resistors (2R

V

= Required (peak) off hook AC voltage for speech

sp(off)

V

pm(off)

= Off hook overhead voltage at load

) = Required overhead for the DC voltage drop

x Iloop

S

(max)

)

= Required (peak) off hook AC voltage for pulse

metering

+

2R

V

OH(off) at Load

80 I

× V

LOOP max()

+V

× 2.0V+

pm off()

×+=

sp off()

2R

1

2RS+

P

----------------------------- -+

Z

pm

P2RS

1

----------------------------- -+

Z

L

(EQ. 3)

where:

80 = 2R

s

+ 2R

(reference Figure 17)

INT

Zpm= Pulse metering load impedance (typically 200Ω).

2.0V = Additional off hook overhead voltage requirement

R

Resistance Calculation

SAT

The R

resistance of the DC feed curve is used to

SAT

determine the value of the RDC_RAC resistor (Equation 6).

The value of this resistor has an effect on both the on hook

and off hook overheads. In most applications the off hook

condition will dominate the overhead requirements.

Therefore,we’ll start by calculating the R

value for the off

SAT

hook conditions and then verify that the on hook conditions

are also satisfied.

DC FEED CURVE

V

BH

V

SAT

V

OH(off)

2.5V

R

SAT

When considering the Off

hook condition, R

to V

OH(off) at Load

Iloop

(Equation 4).

(min)

is equal

SAT

divided by

For the given system

requirements (recommended

TIP TO RING VOLTAGE

I

LOOP(min)

LOOP CURRENT

application circuit in back of

data sheet): Iloop (min) =

20mA, Iloop (max) = 30mA,

V

OH(off) AT LOAD

value of R

R

SAT(off)

=

SAT(off)

V

OH(off) at Load

--------------------------------------- -

I

LOOP(min)

R

SAT

I

LOOP(min)

V

V

V

= 3.2V

sp(off)

spm(off)

OH(off) at Load

= 0V

,

PEAK

,

PEAK

= 8.34V the

is equal to 417Ω as calculated in Equation 4.

8.34V

---------------- 417Ω==

20mA

(EQ. 4)

Before using this R

value, to calculate the RDC_RAC

SAT

resistor, we need to verify that the on hook requirements will

also be met.

DC FEED CURVE

V

BH

V

SAT

V

OH(on)

2.5V

R

SAT

The on hook overhead voltage

calculated with the off hook

R

SAT

(R

SAT(off)

), is given in

Equation 5 and equals 3.0V.

The on hook overhead

calculated with Equation 1

TIP TO RING VOLTAGE

V

OH(on) AT LOAD

R

SAT on()

ISH-(min)

LOOP CURRENT

R

ISH-

(min)

2.85V

----------------- - 395Ω==

7.2mA

equals 2.85V for the given

system requirements

(recommended application

circuit in back of data sheet):

SAT

Switch Hook Detect threshold

= 12mA, ISH- = (0.6)12mA =

7.2mA, V

sp(on)

Thus, the on hook overhead

= 0.775V

RMS

requirements of 2.85V will be

met if we use the R

V

OH on()

V

OH on()

V

OH on()

ISH-()R

7.2mA 417Ω×=

3.0V=

()=

SAT(off)

SAT off()

value.

(EQ. 5)

If the on hook overhead requirement is not met, then we

need to use the R

SAT(on)

value to determine the RDC_RAC

resistor value. The external saturation guard resistor

RDC_RAC is equal to 50 times R

In the example above R

would equal 417Ω and

SAT

SAT

.

RDC_RAC would then equal to 20.85kΩ (closest standard

value is 21kΩ).

RDC_RAC = 50 x R

SAT

(EQ. 6)

The Switch Hook Detect threshold current is set by resistor

R

and is calculated using Equation 7. For the above

D

example R

is calculated to be 41.6kΩ (500/12mA). The

D

next closest standard value is 41.2kΩ.

500

------------

RD=

I

SHD

The true value of ISH-, for the selected value of R

(EQ. 7)

is given

D

by Equation 8:

ISH- =

500

--------- -

R

(0.6)

D

(EQ. 8)

Forthe example above,ISH- equals7.28mA (500 x0.6/ 41.2K).

Verify that the value of ISH- is above the suspected line

leakage of the application. The UniSLIC family will provide a

constant on hook voltage level for leakage currents up to this

value of line leakage.

4-15

HC55120, HC55121, HC55130, HC55131, HC55140, HC55141, HC55142, HC55143, HC55150, HC55151

DC FEED CURVE

V

BH

V

SAT

V

OH(off)

TIP TO RING VOLTAGE

2.5V

I

OH

ISH-

I

LOOP(min)

LOOP CURRENT

OFF HOOK

OVER HEAD

for ISH- into Equation 9 and solving for R

terms of I

R

OH

LOOP(min)

500

--------- -

I

OH

and RD.

500

--------------------------------------------==

I

LOOP(min)

- ISH-

The ROH resistor, which

isused to set the offhook

overhead voltage , is

calculated using

Equations 9 and 10.

I

is defined as the

OH

difference between the

I

LOOP(min)

and ISH-.

Substituting Equation 8

defines ROH in

OH

(EQ. 9)

Equation 10 can be used to determine the actual ISH- value

resulting from the R

resistor selected. The value of R

D

D

should be the next standard value that is lower than that

calculated. This will insure meeting the I

LOOP(min)

requirement. ROH for the above example equals 39.1kΩ.

R

500

----------------------------------------------------------- -

ROH=

RDI

LOOP(min)

D

- 500(.6)

(EQ. 10)

The current limit is set by a single resistor and is calculated

using Equation 11.

1000

-----------------------------

R

=

LIM

I

LOOP(max)

DC FEED CURVE

V

BH

V

SAT

TIP TO RING VOLTAGE

2.5V

R

LOOP(MAX)

LOOP CURRENT

I

LOOP(min)

overhead voltage. If R

V

OH(off)

LOOP(MAX)

The maximum loop

resistance is calculated

using Equation 12. The

resistance of the

protection resistors

(2R

) is subtracted out

P

to obtain the maximum

loop length to meet the

required off hook

meets the loop length

(EQ. 11)

requirements you are done. If the loop length needs to be

longer, then consider adjusting one of the following: 1) the

SHD threshold, 2) minimum loop current requirement or 3)

the on and off hook signal levels.

2V V

R

LOOP(max)

V

BHVSAT

-------------------------------------------------------------------------------

=

++[]–

I

LOOP(min)

OH off()

-2R

P

(EQ. 12)

SLIC in the Active Mode

Figure 17 shows a simplified AC transmission model. Circuit

analysis yields the following design equations:

VA= IM2R

I

M

-------

V

A

Z

2

1

--------- -

S

80k

–()=

TR2RP

200× Z

–()× 5××

TR2RP

(EQ. 13)

(EQ. 14)

Node Equation

V

RX

------------ -

500k

-

V

A

------------ -

500k

=I

X

(EQ. 15)

Substitute Equation 14 into Equation 15

V

RX

------------ -

500k

-

-----------------------------------------

I

=

X

Loop Equation

500k - VTX′ +IX500k = 0

I

X

–()

I

MZTR2RP

1000k

(EQ. 16)

(EQ. 17)

Substitute Equation 16 into Equation 17

V

′ 2VRXIMZTR2RP–()–=

TX

Loop Equation

V

TR-IM2RP+VTX

′ = 0

(EQ. 18)

(EQ. 19)

Substitute Equation 18 into Equation 19

V

TRIMZTR2VRX

Substituting -V

to solve for V

1

V

TR

–=

TR/ZL

TR

Z

TR

---------- -+

=

Z

L

into Equation 20 for IMand rearranging

results in Equation 21

2– V

RX

(EQ. 20)

(EQ. 21)

where:

VRX = The input voltage at the VRX pin.

= An internal node voltage that is a function of the loop

V

A

current detector and the impedance matching networks.

I

= Internal current in the SLIC that is the difference

X

between the input receive current and the feedback current.

I

= The AC metallic current.

M

= A protection resistor (typical 30Ω).

R

P

= An external resistor/network for matching the line

Z

T

impedance.

V

´= The tip to ring voltage at the output pins of the SLIC.

TX

= The tip to ring voltage including the voltage across the

V

TR

protection resistors.

Z

= The line impedance.

L

= The input impedance of the SLIC including the

Z

TR

protection resistors.

(AC) 4-Wire to 2-Wire Gain

The 4-wire to 2-wire gain is equal to VTR/VRX.

From Equation 21 and the relationship ZT= 200(ZTR-2RP).

V

TR

-----------

G

=

4-2

V

RX

Notice that the phase of the 4-wire to 2-wire signal is 180

out of phase with the input signal.

=-2

Z

L

-------------------------

ZL+Z

TR

Z

----------------------------------------------

–=

2

Z

L

Z

T

--------- - 2RP+

+

L

200

(EQ. 22)

o

4-16

HC55120, HC55121, HC55130, HC55131, HC55140, HC55141, HC55142, HC55143, HC55150, HC55151

I

X

+

-

I

M

+

TIP

-

I

M

+

+

E

-

Z

TR

Z

L

+

V

TR

-

G

RING

-

R

P

-

VTX´

+

I

+

M

-

R

P

500K

R

R

S

INT

-

INT

I

X

20Ω

-

+

UniSLIC14

+

-

1/80K

I

Z

= 200 (ZTR - 2RP)

T

500K

I

I

X

X

5

500K

VA = IM(ZTR-2RP)

20Ω

R

20Ω

20Ω

R

S

+

500K

I

X

500K

2

A = 1

+

500K

V

TX

PTG

V

RX

+

V

TX

-

+

V

RX

-

FIGURE 17. SIMPLIFIED AC TRANSMISSION CIRCUIT

(AC) 2-Wire to 4-Wire Gain

The 2-wire to 4-wire gain is equal to VTX/EG with VRX = 0

Loop Equation

E–GZLIM2RPIMVTX′–++ 0=

From Equation 18 with V

′ IMZTR2RP–()–=

V

TX

RX

= 0

Substituting Equation 24 into Equation 23 and simplifying.

E

GIMZLZTR

+()=

By design, VTX = -VTX´, therefore

I

V

TX

----------

--------------------------------------- -

=

=

G

2-4

E

G

–()

MZTR2RP

I

+()

MZLZTR

ZTR2RP–()

---------------------------------=

+()

Z

LZTR

A more useful form of the equation is rewritten in terms of

V

TX/VTR

from E

V

TR

Rearranging Equation 27 in terms of E

. A voltage divider equation is written to convert

to VTR as shown in Equation 27.

G

Z

TR

------------------------

=

ZTRZL+

E

G

, and substituting

G

into Equation 26 results in an equation for 2-wire to 4-wire

gain that’s a function of the synthesized input impedance of

the SLIC (Z

=

G

2-4

) and the protection resistors (RP).

TR

Z

V

TX

---------- -

V

TR

TR

-----------------------------

=

Z

-2R

TR

P

(EQ. 23)

(EQ. 24)

(EQ. 25)

(EQ. 26)

(EQ. 27)

(EQ. 28)

Notice that the phase of the 2-wire to 4-wire signal is in

phase with the input signal.

(AC) 4-Wire to 4-Wire Gain

The 4-wire to 4-wire gain is equal to VTX/VRX, EG = 0.

From Equation 18.

VTX′ V–

TX

Substituting -V

2– V

RXIMZTR2RP

into Equation 29 for IMresults in

TR/ZL

–()+==

(EQ. 29)

Equation 30.

V

TX

VTRZTR2RP–()

2– V

---------------------------------------------–=

RX

Z

L

(EQ. 30)

Substituting Equation 21 for VTR in Equation 30 and

simplifying results in Equation 31.

G

44–

V

TX

==

----------- 2–

V

RX

ZL+2R

------------------------

ZLZTR+

P

(EQ. 31)

(AC) 2-Wire Impedance

The AC 2-wire impedance (ZTR) is the impedance looking

into the SLIC, including the fuse resistors. The formula to

calculate the proper Z

shown in Equation 32.

ZT200 ZTR2RP–()•=

Equation 32 can now be used to match the SLIC’s

impedance to any known line impedance (Z

formatching the 2-wire impedance is

T

(EQ. 32)

).

TR

4-17

HC55120, HC55121, HC55130, HC55131, HC55140, HC55141, HC55142, HC55143, HC55150, HC55151

EXAMPLE:

Calculate Z

R

= 30Ω.

P

ZT200 600

= 114kΩ in series with 0.0108µF.

Z

T

to make ZTR = 600Ω in series with 2.16µF.

T

=

1

----------------------------------- 2()30()–+

jω2.16X10

6–

(EQ. 33)

Note: Some impedance models, with a series capacitor, will

cause the op-amp feedback to behave as an open circuit

DC. A resistor with a value of about 10 times the reactance

of the Z

capacitor (2.16µF/200 = 10.8nF) at the low

T

frequency of interest (200Hz for example) can be placed in

parallel with the capacitor in order to solve the problem

(736kΩ for a 10.8nF capacitor).

Calculating Tip and Ring Voltages

The on hook tip to ground voltage is calculated using

Equation 34. The minus 1.0 volt results from the SLIC self

programming. ISH- is the maximum loop current for a

constant on hook overhead voltage (ISH- = I

the value of R

is calculated in Equation 4.

SAT(off)

On hook Tip Voltage

R

SAToff

V

TIP onhook()

+=

1.0V– ISH-()–

----------------------

2

SHD

(0.6)) and

(EQ. 34)

Off hook Ring Voltage in Current Limit

V

RING CL()VTIP offhook()ILOOP MAX()RL

– 0.2V–=

(EQ. 37)

The off hook ring to ground voltage (not in current limit) is

calculated using Equation 38. The 1.5V results from the

SLIC self programming. I

LOOP(min)

current allowed by the design and the value of R

is the minimum loop

SAT(off)

calculated in Equation 4.

Off hook Ring Voltage not in Current Limit

R

SAT off()

V

RING NCL()VBH

I

LOOP MIN()RP

×–

++=

1.5V I

()

LOOP min()

--------------------------

2

(EQ. 38)

Layout Considerations

Systems with Dual Supplies (VBH and VBL)

If the VBL supply is not derived from the VBH supply, it is

recommended that an additional diode be placed in series

with the V

on pin 8 of the device and cathode to the external supply.

This external diode will inhibit large currents and potential

damage to the SLIC, in the event the V

to GND. If V

required.

supply. The orientation of this diode is anode

BH

supply is shorted

is derived from VBH then this diode is not

BL

BH

is

The off hook tip to ground voltage is calculated using

Equation 35. I

LOOP(min)

allowedby the design andthe valueof R

is the minimum loop current

SAT(off)

is calculated

in Equation 4.

Off hook Tip Voltage

R

SAT off()

V

TIP offhook()

I

LOOP MAX()RP

1V– I

()

–=

LOOP min()

×–

--------------------------

2

(EQ. 35)

The on hook ring to ground voltage is calculated using

Equation 36. The 1.5 volt results from the SLIC self

programming. ISH- is the maximum loop current for a

constant on hook overhead voltage (ISH- = I

the value of R

is calculated in Equation 4.

SAT(off)

SHD

(0.6)) and

On hook Ring Voltage

R

SAT off()

V

RING onhook()VBH

1.5V ISH()

++=

--------------------------

2

(EQ. 36)

The calculation of the ring voltage with respect to ground in

the off hook condition is dependent upon whether the SLIC

is in current limit or not.

The off hook ring to ground voltage (in current limit) is

calculated using Equation 37. I

current limit and R

is the load resistance across tip and

L

is the programmed loop

LIM

ring. The minus 0.2V is a correction factor forthe 60kΩ slope

in Figure 15.

Floating the PTG Pin

The PTG pin is a high impedance pin (500kΩ) that is used to

program the 2-wire to 4-wire gain to either 0dB or -6dB.

If 0dB is required, it is necessary to float the PTG pin. The

PC board interconnect should be as short as possible to

minimize stray capacitance on this pin. Stray capacitance on

this pin forms a low pass filter and will cause the 2-wire to

4-wire gain to roll off at the higher frequencies.

If a 2-wire to 4-wire gain of -6dB is required, the PTG pin

should be grounded as close to the device as possible.

SPM Pin

For optimum performance, the PC board interconnect the

SPM pin should be as short as possible. If pulses metering

is not being used, then this pin should be grounded as close

to the device pin as possible.

RLIM Pin

The current limiting resistor R

RLIM pin as possible.

needs to be as close to the

LIM

Layout of the 2-Wire Impedance Matching

Resistor Z

Proper connection to the ZT pin is to have the external Z

network as close to the device pin as possible.

The ZT pin is a high impedance pin that is used to set the

proper feedback for matching the impedance of the 2-wire

side. This will eliminate circuit board capacitance on this pin

to maintain the 2-wire return loss across frequency.

T

T

4-18

HC55120, HC55121, HC55130, HC55131, HC55140, HC55141, HC55142, HC55143, HC55150, HC55151

TABLE 1. DETECTOR STATES

OUTPUT

STATE C3 C2 C1 SLIC OPERATING STATE ACTIVE DETECTOR

0 0 0 0 Open Circuit State 4 wire loopback test capability HIGH HIGH

1 0 0 1 Ringing State

(Previous State cannot be Reverse

Active State)

2 0 1 0 Forward Active State Loop Current Detector

Ring Trip Detector HIGH

Ground Key Detector

SHD GKD_ LVM

3 0 1 1 Test Active State

Requires previous state to be in the

ForwardActivestate to determine the

On hook or Off hook status ofthe line.

4 1 0 0 Tip Open - Ground Start State Ground Key Detector

5 1 0 1 Reserved Reserved N/A N/A

6 1 1 0 Reverse Active State Loop Current Detector

7 1 1 1 Test Reversal Active State

Requires previous state to be in the

ReverseActivestatetodeterminethe

On hook or Off hook status ofthe line.

8 X X X Thermal Shutdown LOW LOW

Digital Logic Inputs

Table 1 is the logic truth table for the 3V to 5V logic input

pins. A combination of the control pins C3, C2 and C1 select

1 of the possible 6 operating states. The 8th state listed is

Thermal Shutdown.Thermal Shutdown protection is invoked

if a fault condition on the tip or ring causes the junction

temperature of the die to exceed 175

each operating state and the control logic follows:

Open Circuit State (C3 = 0, C2 = 0, C1 = 0)

In this state, the tip and ring outputs are in a high impedance

condition (>1MΩ). No supervisory functions are available

and

SHD and GKD outputs are at a TTL high level.

4-wire loopback testing can be performed in this state. With

the PTG pin floating,the signal on the V

of phase and approximately 2 times the V

the PTG pin is grounded, then the amplitude will be

approximately the same as its input and 180

Ringing State (C3 = 0, C2 = 0, C1 = 1)

In this state, the output of the ring relay driver pin (RRLY)

goes low (energizing the ring relay to connect the ringing

signal to the phone) if either of the following two conditions

are satisfied:

o

C. A description of

output is 180oout

TX

input signal. If

RX

o

out of phase.

On Hook Loopback Detector LOW

Ground Key Detector HIGH

Off Hook Loop Current Detector LOW

Line Voltage Detector

Ground Key Detector

On Hook Loop Current Detector HIGH

Off Hook Loop Current Detector LOW

Line Voltage Detector

(1) The RSYNC_REV pin is grounded through a resistor -

This connection enables the RRLY pin to go low the instant

the ringing state is invoked,without anyregard forthe ringing

voltage (90V

RMS

-120V

) across the relay contacts. The

RMS

resistor (34.8kΩ to 70kΩ) is required to limit the current into

the RSYNC_REV pin.

(2) A ring sync pulse is applied to the RSYNC_REV pin -

This connection enables the RRLY pin to go low at the

command of a ring sync pulse. A ring sync pulse should go

low at zero voltage crossing of the ring signal. This pulse

should have a rise and fall time <400µs and a minimum

pulse width of 2ms.

Zero ring current detection is performed automatically

inside the SLIC. This feature de-energizes the ring relay

slightly before zero current occurs to partially compensate

for the delay in the opening of the relay.

The

SHD output will go low when the subscriber goes off

hook. Once

SHD is activated, an internal latch will prohibit

the re-ringing of the line until the ringing code is removed

and then reapplied.

The state prior to ringing the phone, can not be the Reverse

Active State. In the reverse active state the polarity of the

voltageon the CRT_REV_

LVM capacitor, will make it appear

as if the subscriber is off hook. This subsequently will

activate an internal latch prohibiting the ringing of the line.

4-19

HC55120, HC55121, HC55130, HC55131, HC55140, HC55141, HC55142, HC55143, HC55150, HC55151

The GKD_LVM output is disabled (TTL high level) during the

ringing state. Reference the Section titled “Ringing the

Phone” for more information.

Forward Active State (C3 = 0, C2 = 1, C1 = 0)

In this state, the SLIC is fully functional. The tip voltage is more

positive than the ring voltage. The tip and ring output voltages

are an unbalanced DC feed, reference Figure 13. Both

and

GKD supervisory functions are active. Reference the

section titled “DC Feed Curve” for more inf ormation.

SHD

Test Active State (C3 = 0, C2 = 1, C1 = 1)

Proper operation of the Test Active State requires the

previous state be the Forward Active state to determine the

on hook or off hook status of the line. In this state, the SLIC

can perform two different tests.

If the subscriber is on hook when the state is entered, a

loopback test is performed by s witching an internal 600Ω

resistor between tip and ring. The current flows through the

internal 600Ω is unidirectional via blocking diodes. (Cannot be

used in reverse.) When the loopbac k current flo ws , the

output will go low and remain there until the state is exited.This

is intended to be a short test since the ability to detect

subscriber off hook is lost during loopback testing. Reference

the section titled “Loopback Tests” for more information.

If the subscriber is off hook when the state is entered, a Line

V oltage Measurement test is perf ormed. The output of the

GKD_LVM pin is a pulse train. The pulse width of the active low

portion of the signal is proportional to the voltage across the tip

and ring pins. If the loop length is such that the SLIC is

operatingin constantcurrent, the tip to ring voltage canbe used

to determine the length of the line under test. The longer the

line, the larger the tip to ring voltage and the wider the pulse.

This relationship can determine the length of the line for setting

gains in the system. Reference the section titled “Operation of

Line V oltageMeasurement” for more information.

SHD

Tip Open State (C3 = 1, C2 = 0, C1 = 0)

In this state, the tip output is in a high impedance state

(>250kΩ) and the ring output is capable of full operation, i.e.

has full longitudinal current capability. The Tip Open/Ground

Start state is used to interface to a PBX incoming 2-wire

trunk line. When a ground is applied through a resistor to the

ring lead, this current is detected and presented as a TTL

logic low on the

SHD and GKD_LVM output pins.

Reserved (C3 = 1, C2 = 0, C1 = 1)

This state is undefined and reserved for future use.

Reverse Active State (C3 = 1, C2 = 1, C1 = 0)

In this state, the SLIC is fully functional. The ring voltage is

more positive than the tip voltage. The tip and ring output

voltages are an unbalanced DC feed, reference Figure 13.

The polarity reversal time is determined by the RC time

constant of the RSYNC_REV resistor and the

CRT_REV_

LVM capacitor.Capacitor CRT_REV_LVM

performs three different functions: Ring trip filtering, polarity

reversal time and line v oltage measurement. It is

recommended that programming of the rev ersal time be

accomplished by changing the value of RSYNC_REV resistor

(see Figure 18). The value of RSYNC_REV resistor is limited

between 34.8K (10ms) and 73.2k (21ms). Equation 39 gives

the formula for programming the reversal time.

RSYNC REV– 3.47kΩ ReversalTime ms()×=

Both

SHD and GKD supervisory functions are active.

Reference the section titled “Polarity Reversal” for more

information.

(EQ. 39)

Test Reversal Active State (C3 = 1, C2 = 1, C1 = 1)

Proper operation of the Test Reversal Active State requires

the previous state be the Reverse Active state to determine

the on hook or off hook status of the line.

If the subscriber is on hook when the state is entered, the

SLIC’s tip and ring voltages are the same as the Reverse

Activestate. The

goes off hook and the

level high). (Note: operation is the same as the Reverse

Active state with the GKD_LVM output disabled.)

If the subscriber is off hook when the state is entered, a

Line Voltage Measurement test is performed.

The output of the

ofthe active lowportion ofthe signal isproportional tothe voltage

across the tip and ring pins. If the loop length is such that the

SLIC is operatingin constantcurrent mode,the tip to ring voltage

can be used to determine the length of the line under test. The

longer the line, the larger the tip to ring voltage and the wider the

pulse. This relationship can determine the length of the line for

setting gains in the system. Reference the section titled

“Operation of

SHD output will go low when the subscriber

GKD_LVM output is disabled (TTL

GKD_LVM pin is a pulse train.The pulse width

Line Voltage Measurement” for more information.

Thermal Shutdown

The UniSLIC14’sthermal shutdown protection is invoked if a

fault condition causes the junction temperature of the die to

exceed about 175

both detector outputs go low (

of two things can happen.

For marginal faults where loop current is flowing during the

time of the over-temperature condition, foldback loop current

limiting reduces the loop current by reducing the tip to ring

voltage. An equilibrium condition will exist that maintains the

junction temperature at about 175

is removed.

For short circuit faults (tip or ring to ground, or to a supply,

etc.) that result in an over-temperature condition, the

foldback current limiting will try to maintain an equilibrium at

about 175

device will thermally shutdown and disconnect tip and ring

until the junction temperature falls to approximately 150

o

o

C. Once the thermal limit is exceeded,

SHD and GKD_LVM) and one

o

C until the fault condition

C. If the junction temperature keeps rising, the

o

C.

4-20