HC5503

Low Cost 24V SLIC For PABX/Key

Systems

The Intersil HC5503 low cost SLIC is optimized for use in

small Analog or mixed Analog and Digital Key Telephone

Systems (KTS) or PBX products. The low component count

solution and surface mount package options,enable a small

desktop Key System/PBX product to be achieved. The

internal power dissipationofthe end product is minimized by

the low power consumption and minimal power supply

voltage requirements of the HC5503.

The HC5503 integrated solution provides higher quality,

higher reliability and better performance solution than a

transformer, thick film hybrid or discrete analog subscriber

interface design.

The HC5503 is designed in a Dielectrically isolated bipolar

technology andisinherently latch proof and doesnot require

hot plug or power supply sequencing precautions.

March 1999 File Number

4344.3

Description

• Wide Operating Battery Range (-21V to -44V)

• Single Additional +5V Supply

• 25mA Short Loop Current Limit

• Ring Relay Driver

• Switch Hook and Ring Trip Detect

• Low On-Hook Power Consumption

• On-Hook Transmission

• ITU-T Longitudinal Balance Performance

• Loop Power Denial Function

• Thermal Protection

• Supports Tip, Ring or Balanced Ringing Schemes

• Low Profile SO and PLCC Surface Mount Packaging

• Pin Compatible with Industry Standard HC5504B SLIC

Ordering Information

TEMP.

PART NUMBER

HC5503CM 0 to 75 28 Ld PLCC N28.45

HC5503CB 0 to 75 24 Ld SOIC M24.3

RANGE (oC) PACKAGE

PKG.

NO.

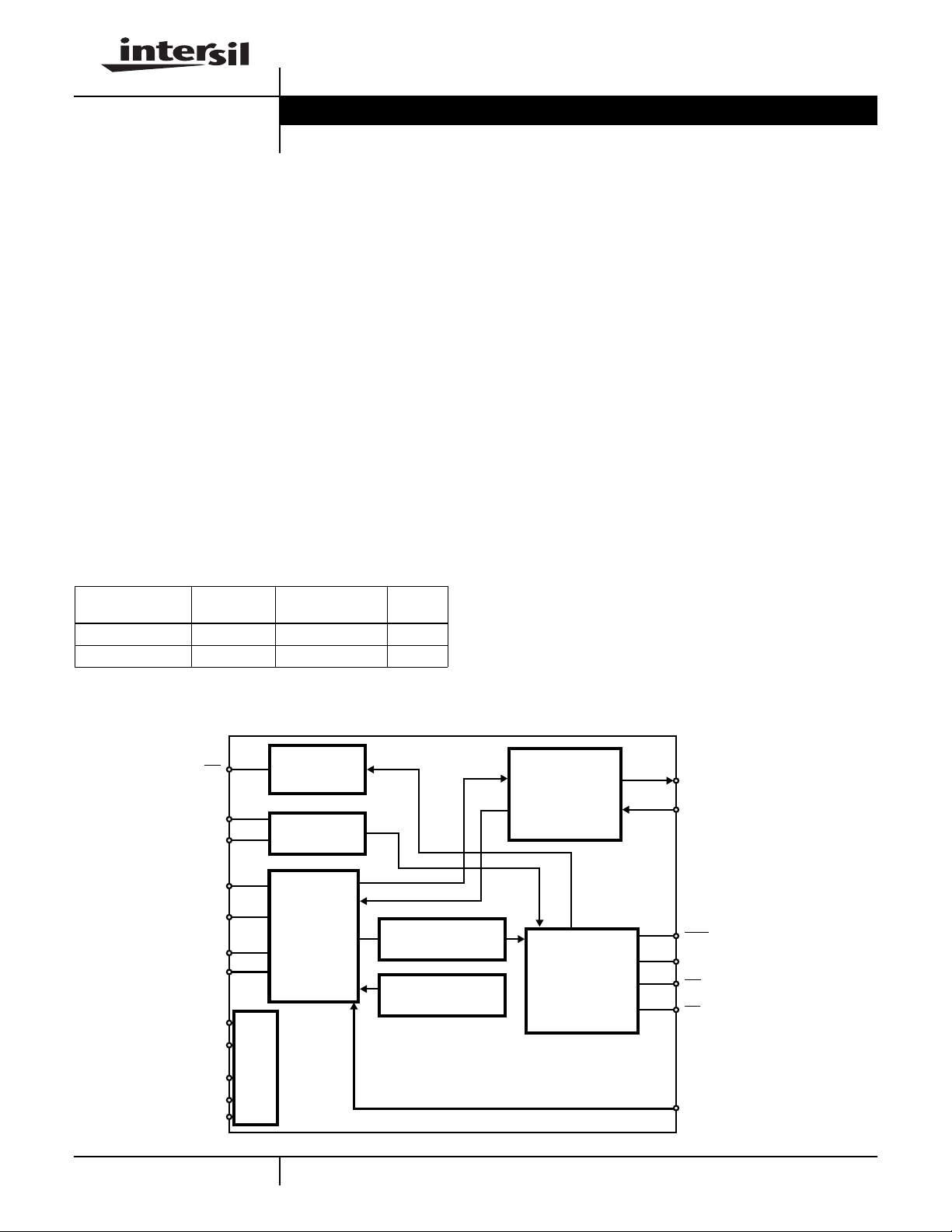

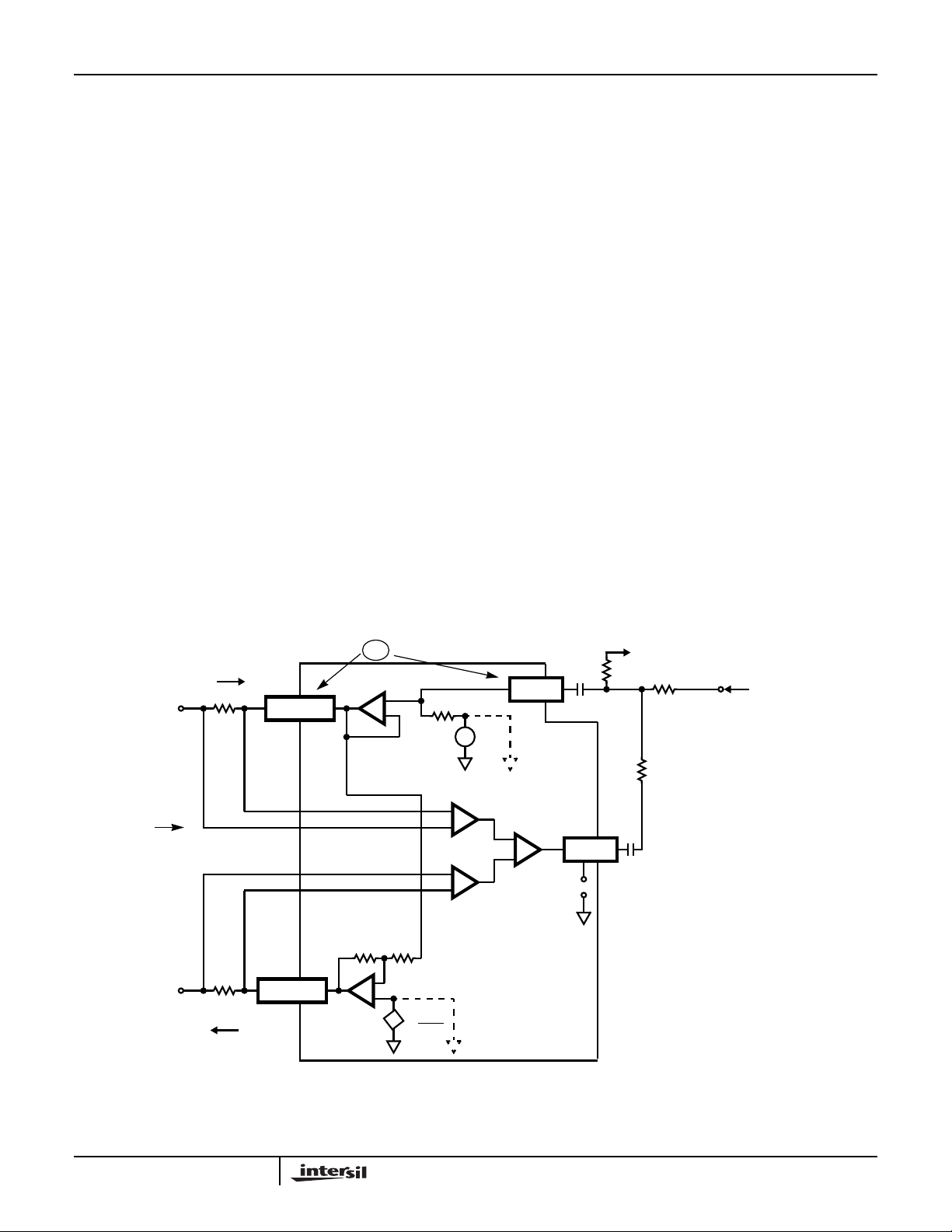

Block Diagram

BIAS

RING RELAY

DRIVER

RING TRIP

DETECTOR

2-WIRE

INTERFACE

LOOP CURRENT

THERMAL LIMIT

RD

RFS

C

TIP

TF

RING

RF

V

BAT

V

CC

AGND

BGND

DGND

2

DETECTOR

Applications

• Analog Subscriber Line Interfaces in Analog Key Systems

and Digital ISDN PABX Systems

• Related Literature

- AN571, Using Ring Sync with HC-5502A and HC-5504

SLICs

4-WIRE

INTERFACE

VF SIGNAL

PATH

LOGIC

INTERFACE

TX

RX

SHD

RS

RC

PD

C

1

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

http://www.intersil.com or 407-727-9207 | Copyright © Intersil Corporation 1999

HC5503

Absolute Maximum Ratings (Note 1) Thermal Information

Maximum Continuous Supply Voltages

(V

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -60 to 0.5V

BAT

(VCC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.5 to 15V

(VCC - V

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75V

BAT

Relay Drive Voltage (VRD). . . . . . . . . . . . . . . . . . . . . . . . -0.5 to 15V

Operating Conditions

Operating Temperature Range

HC5503 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0oC to 75oC

Relay Driver Voltage (VRD) . . . . . . . . . . . . . . . . . . . . . . . .5V to 12V

Positive Supply Voltage (VCC). . . . . . . . . . . . . . . . . . 4.75V to 5.25V

Negative Supply Voltage (V

High Level Logic Input Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . 2.4V

Low Level Logic Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . 0.6V

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operationofthe

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

1. Absolute maximum ratings are limiting values, applied individually, beyond which the serviceability of the circuit may be impaired. Functional

operability under any of these conditions is not necessarily implied.

2. θJA is measured with the component mounted on an evaluation PC board in free air.

) . . . . . . . . . . . . . . . . . .-22V to -26V

BAT

Thermal Resistance (Typical, Note 2) θJA (oC/W)

24 Lead SOIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

28 Lead PLCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Maximum Junction Temperature . . . . . . . . . . . . . . . . . . . . . . .150oC

Maximum Storage Temperature Range. . . . . . . . . . -65oC to 150oC

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . .300oC

(PLCC and SOIC - Lead Tips Only)

Die Characteristics

Transistor Count. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

Diode Count. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Die Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137 x 102

Substrate Potential. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Connected

Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bipolar-DI

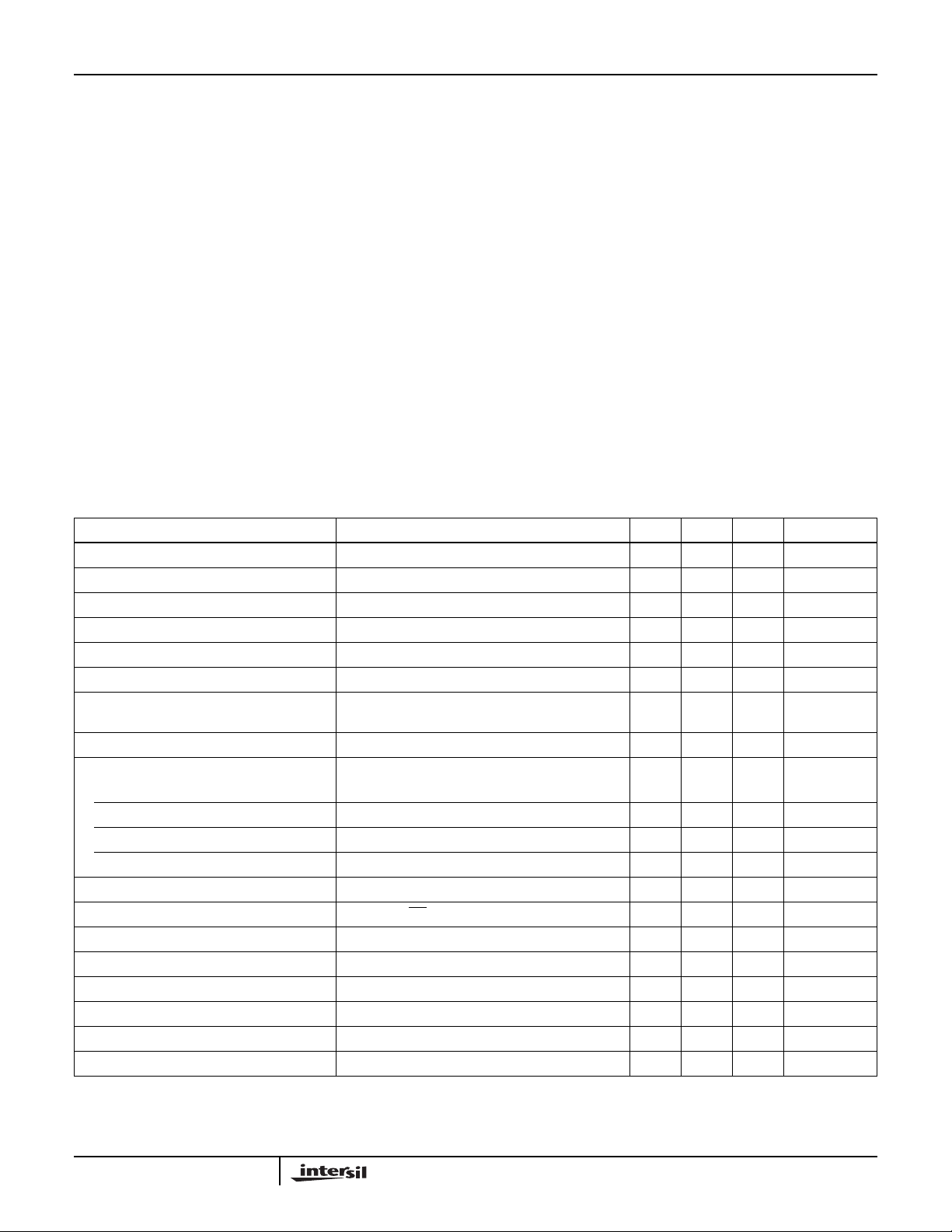

Electrical Specifications Unless Otherwise Specified, V

= -24V, VCC = 5V, AG = BG = DG = 0V, Typical Parameters

BAT

TA = 25oC. Min-Max Parameters are Over Operating Temperature Range

PARAMETER CONDITIONS MIN TYP MAX UNITS

On Hook Power Dissipation I

Off Hook Power Dissipation RL = 600Ω, I

Off Hook I

Off Hook I

Off Hook I

VCC

VCC

BAT

Off Hook Loop Current RL = 400Ω, I

Off Hook Loop Current RL = 400Ω, V

= 0 (Note 3), VCC = 5V - 80 100 mW

LONG

= 0 (Note 4), VCC = 5V - 180 200 mW

LONG

RL = 600Ω, I

RL = 600Ω, I

RL = 600Ω, I

= 0 (Note 3), TA = 0oC - - 6.0 mA

LONG

= 0 (Note 3), TA = 25oC - - 4.0 mA

LONG

= 0 (Notes 3, 4) - 19 23 mA

LONG

= 0 (Note 3) - 22.9 - mA

LONG

BAT

= -21.6V, I

LONG

= 0 (Note 3)

17.5 - - mA

TA = 25oC

Off Hook Loop Current RL = 200Ω, I

= 0 (Note 3) - 25 30 mA

LONG

Fault Currents

TIP to Ground (Note 4) - 27.5 - mA

RING to Ground -70- mA

TIP to RING (Note 4) - 30 - mA

TIP and RING to Ground - 140 - mA

Ring Relay Drive V

OL

IOL = 62mA - 0.2 0.5 V

Ring Relay Driver Off Leakage VRD = 12V, RC = 1 = HIGH, TA = 25oC--25µA

Ring Trip Detection Period RL = 600Ω,(Note 5) - 2 3 Ring Cycles

Switch Hook Detection Threshold 5 - 10.5 mA

Loop Current During Power Denial RL = 200Ω - ±2- mA

Dial Pulse Distortion (Note 4) 0 - 0.5 ms

Receive Input Impedance (Note 5) - 90 - kΩ

Transmit Output Impedance (Note 5) - 10 20 Ω

2

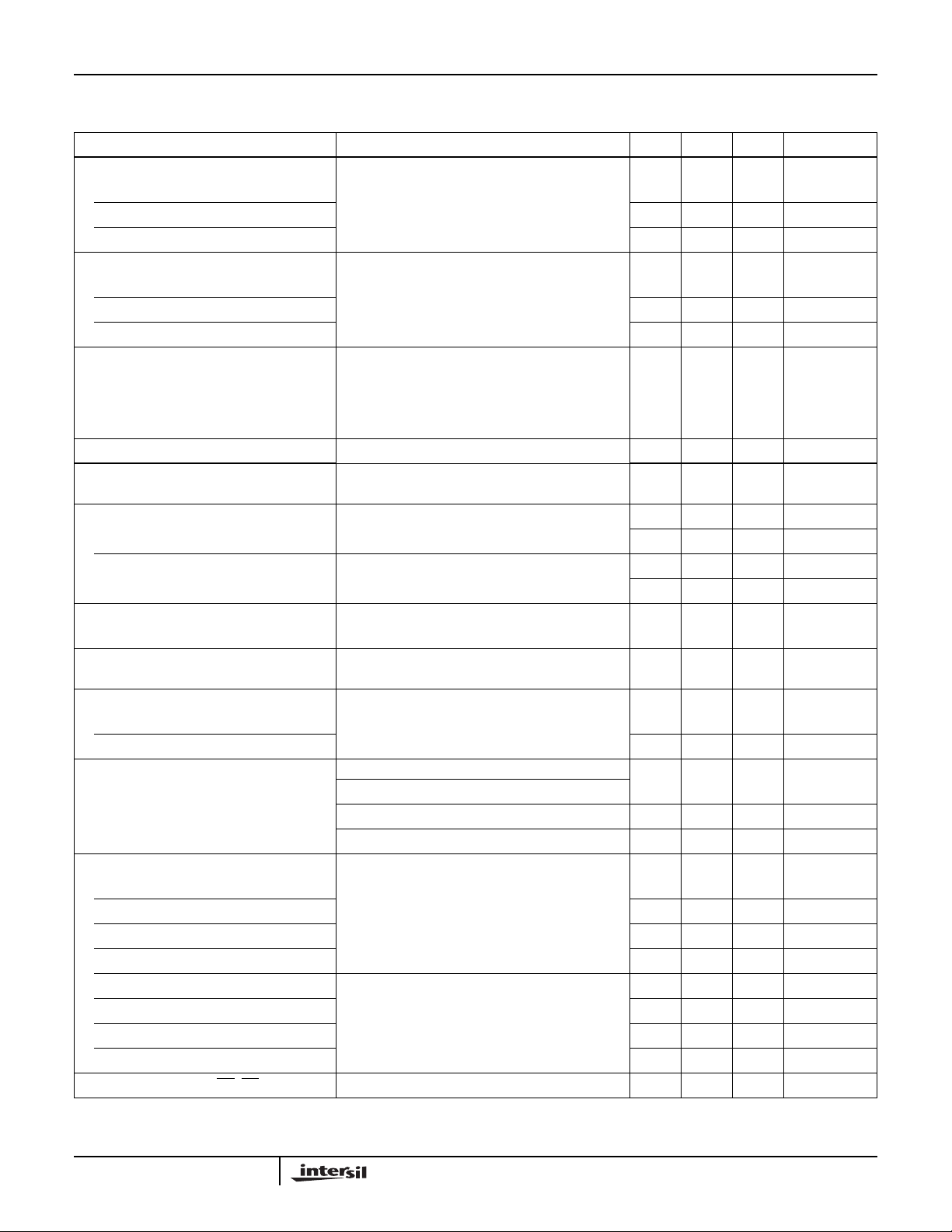

HC5503

Electrical Specifications Unless Otherwise Specified, V

= -24V, VCC = 5V, AG = BG = DG = 0V, Typical Parameters

BAT

TA = 25oC. Min-Max Parameters are Over Operating Temperature Range (Continued)

PARAMETER CONDITIONS MIN TYP MAX UNITS

2-Wire Return Loss Referenced to 600Ω +2.16µF (Note 4)

SRL LO - 15.5 - dB

ER

L

-24- dB

SRL HI -31- dB

Longitudinal Balance 1V

2-Wire Off Hook 53 58 - dB

200Hz - 3400Hz, (Note 4) IEEE Method

RMS

0oC ≤ TA≤ 75oC

2-Wire On Hook 53 58 - dB

4-Wire Off Hook at 1kHz 50 58 - dB

Insertion Loss 0dBm Input Level, Referenced 600Ω

2-Wire to 4-Wire at 3.4kHz

VTR to V

O

VO is the Output of the Transhybrid

Amplifier - ±0.05 ±0.2 dB

4-Wire to 2-Wire at 300Hz -3.8 -4.0 -4.2 dB

Frequency Response 200 - 3400Hz Referenced to Absolute Loss at 1kHz

- ±0.02 ±0.05 dB

and 0dBm Signal Level (Note 4)

Idle Channel Noise

2-Wire to 4-Wire

Idle Channel Noise

4-Wire to 2-Wire

(Note 4)

- 1 5 dBrnC

- -89 -85 dBm0p

- 1 5 dBrnC

- -89 -85 dBm0p

Absolute Delay (Note 5)

2-Wire to 4-Wire, 4-Wire to 2-Wire - - 2 µs

Trans Hybrid Loss Balance Network Set Up for 600Ω Termination at

30 40 - dB

1kHz

Overload Level VCC = +5V

2-Wire to 4-Wire (On-hook) 2.5 - - V

4-Wire to 2-Wire (Off-hook, RL = 600Ω) 3.1 - - V

PEAK

PEAK

Level Linearity At 1kHz, (Note 4) Referenced to 0dBm Level

2-Wire to 4-Wire, 4-Wire to 2-Wire +3 to -40dBm - - ±0.05 dB

-40 to -50dBm - - ±0.1 dB

-50 to -55dBm - - ±0.3 dB

Power Supply Rejection Ratio (Note 4)

VCC to 2-Wire 35 - - dB

30 - 60Hz, RL = 200Ω

VCC to Transmit 35 - - dB

V

to 2-Wire 20 - - dB

BAT

V

to Transmit 20 - - dB

BAT

VCC to 2-Wire 200 - 16kHz, RL = 200Ω 35 - - dB

VCC to Transmit 35 - - dB

V

to 2-Wire 35 - - dB

BAT

V

to Transmit 35 - - dB

BAT

Logic Input Current (RS, RC, PD) 0V ≤ VIN≤ 2.4V - - ±20 µA

3

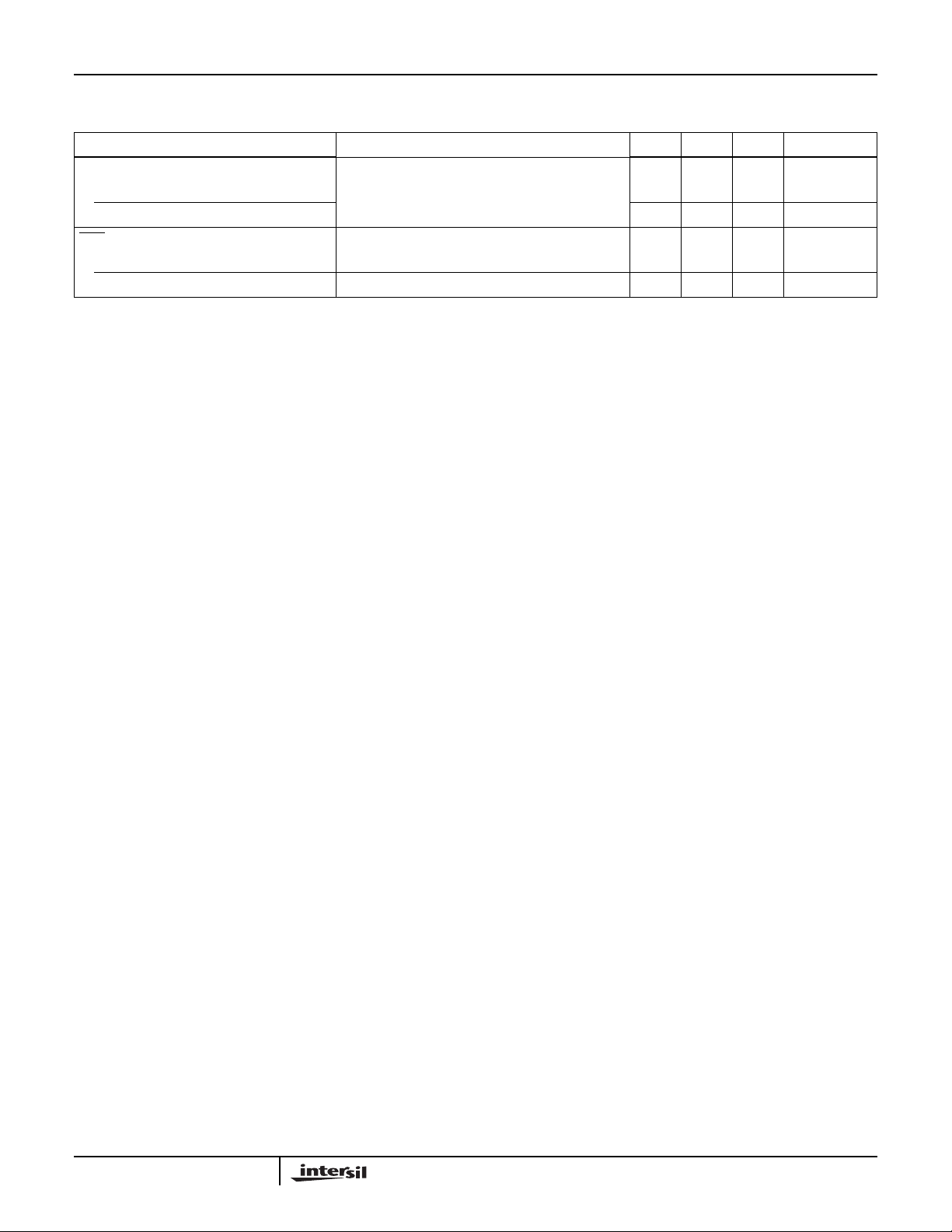

HC5503

Electrical Specifications Unless Otherwise Specified, V

TA = 25oC. Min-Max Parameters are Over Operating Temperature Range (Continued)

PARAMETER CONDITIONS MIN TYP MAX UNITS

Logic Inputs

Logic ‘0’ V

Logic ‘1’ V

SHD Output

Logic ‘1’ V

NOTES:

3. I

LONG

4. These parameters are controlled by design or process parameters and are not directly tested. These parameters are characterized upon initial

design release, upon design changes which would affect these characteristics, and at intervals to assure product quality and specification compliance.

5. Guaranteed by design, not tested.

IL

IH

OL

OH

= Longitudinal Current.

I

800µA, VCC = 5VLogic ‘0’ V

LOAD

I

40µA, VCC = 5V 2.7 - 5.0 V

LOAD

= -24V, VCC = 5V, AG = BG = DG = 0V, Typical Parameters

BAT

- - 0.8 V

2.0 - 5.5 V

- 0.1 0.4 V

4

Design Information

HC5503

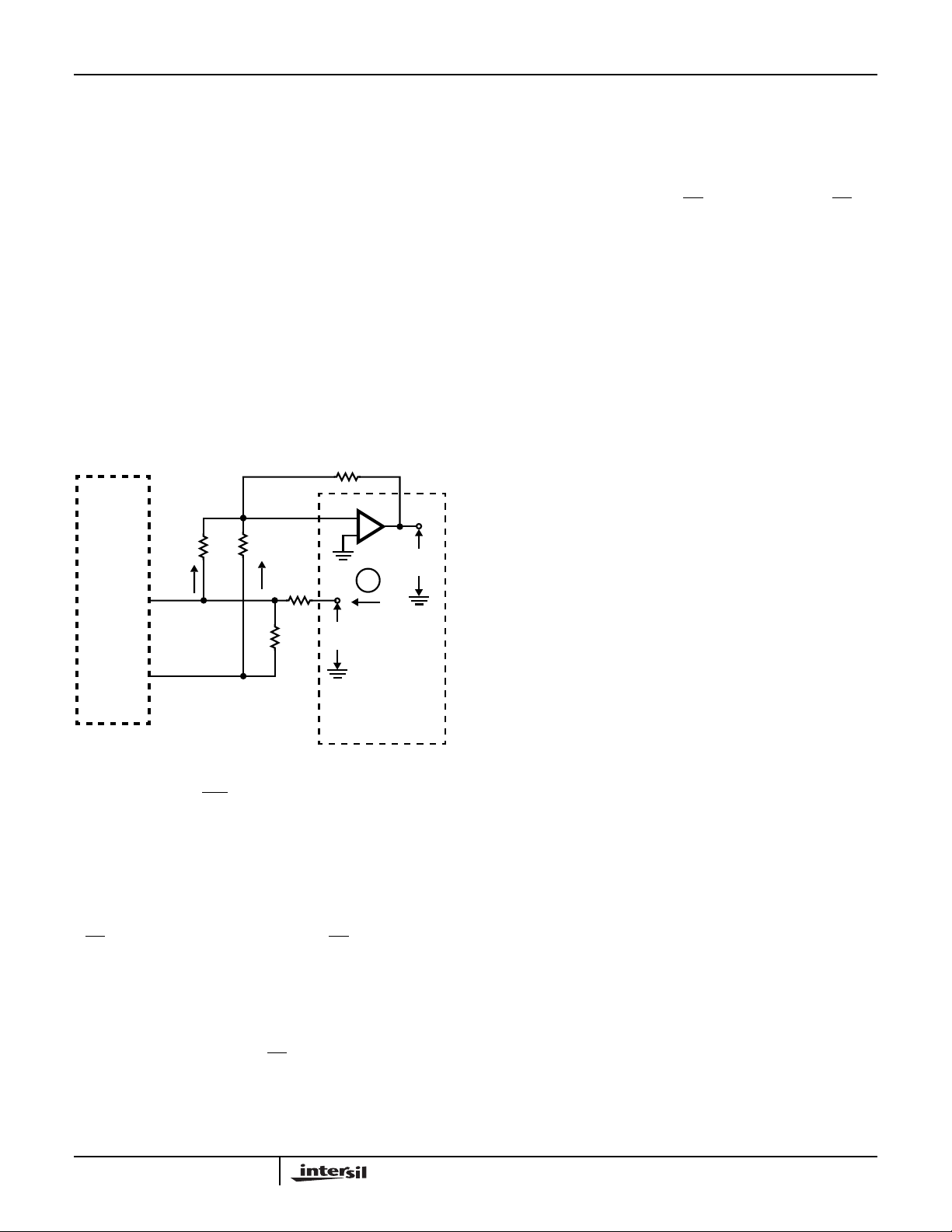

Line Feed Amplifiers

The line feed amplifiers are high power operational

amplifiers and are connected to the subscriber loop through

150Ω of feed resistance as shown in Figure 1. The feed

resistors and synthesized impedance via feedback provide a

600Ω balanced load for the 2-wire to 4-wire transmission.

The tip feed amplifier is configured as a unity gain

noninverting buffer. A -4V bias (derived from the negative

battery (V

the amplifier. Hence, the tip feed DC level is at -4V. The

principal reason for this offset is to accommodate sourcing

and sinking of longitudinal noise currents up to 15mA

without saturating the amplifier output and to provide

sufficient overhead for receive signals. The tip feed amplifier

also feeds the ring feed amplifier, which is configured as a

unity gain inverting amplifier as seen from the tip feed

amplifier. The noninverting input to the ring feed amp is

biased at a V

has a noninverting gain of 2. Thus, the DC output at ring

feed is:

V

(DC) = (4 + V

RF

For a -24V battery, VRF = -20V. Hence, the nominal battery

feed across the loop provided by the SLIC is 16V. When the

subscriber goes off-hook this DC feed causes current

(metallic current) to flow around the loop.

) in the bias network) is applied to the input of

BAT

/2. Looking into this terminal the amplifier

BAT

) Volts

BAT

RMS

The received audio signal R

is fed into the tip feed amplifier

X

and appears at the tip feed terminal. It is also fed through the

ring feed amplifier and is inverted. Thus, a differential signal of

2V

appears between tip feed and ring feed. The RX signal

RX

causes AC audio currents to flow around the loop which are

then AC coupled to the earpiece of the telephone set.

2-Wire Impedance Matching

The HC5503 is optimized for operation with a -24V battery.

Impedance matching to a 600Ω load, is achieved through

the combination of the feed resistors (R

negative feedback through resistor R

R

and RB2 are sense resistors that detect loop current

B1

and provide negative feedback to synthesize the remaining

300Ω required to match a 600Ω line.

The impedance looking into the tip terminal is 150Ω (R

plus the synthesized impedance of the tip amplifier. The

synthesized tip impedance is equal to the tip feed voltage Va

divided by ∆IL. (Note, the tip feed amplifier is a voltage

follower. Thus, the tip feed voltage is equal to the receive

input voltage V

, both are labeled Va.) The synthesized

RX

impedance of the ring terminal is calculated the same way

and is the ring feed voltage divided by ∆IL. (Note, the ring

feed voltage is equal in magnitude to the tip feed voltage, but

opposite in phase as a result of the ring feed amplifier gain.)

, RB2) and

B1

(reference Figure 1).

2

B1

)

∆I

+

L

-

TIP

Z

IN

RB1 = RB2 = RS = 150Ω

RING

NOTE: Grounded for AC analysis.

R

150Ω

R

150Ω

- ∆I

B2

B1

+

L

TIP FEED

RING FEED

Va

C

4RS∆I

3

TX

L

+

4V

DC

(NOTE)

HC5503

RX

+

2

-

L

+

-

RR

-

+

FIGURE 1. IMPEDANCE MATCHING CIRCUITRY

90kΩ

-

+

+

-

-

+

+4RS∆I

V

-

BAT

+

2

(NOTE)

TO TRANSHYBRID OP-AMP

R

3

R

1

V

IN

R

2

C

4

INPUT

FROM

CODEC

5

HC5503

The value of Va, as a result of feedback through R2from the

T

output, is given in Equation 1. Equation 1 is a voltage

X

divider equation between resistors R

combination of resistors; R

resistor R

INTERNAL

. The Voltage on the transmit out (TX) is

, R3 and the internal 90kΩ

1

the sum of the voltage drops across resistors R

and the parallel

2

B1

and R

B2

that is gained up by 2 to produce an output voltage at the

V

pin that is equal to -4RS∆IL.

TX

R190kΩ R

-------------------------------------------------

V

a

R190kΩ R3R2+

3

×=

V

TX

(EQ. 1)

Where: VTX = -4RS∆IL = -600∆IL.

To match a 600Ω line, the synthesized tip and ring impedance

must be equal to 150Ω. The impedance looking into either the

tip or ring terminalis once again the voltage at the terminal(Va)

divided by the AC current∆IL as shown in Equation 2.

V

Z

TipfeedZRingfeed

Substituting the value of 600∆IL for V

a

-------- 150Ω===

∆I

L

TX

(EQ. 2)

in Equation 1 and

dividing both sides by ∆IL results in Equation 3.

R

V

a

--------

∆I

L

Setting Va/∆IL equal to 150Ω and solving for R

R

= 10kΩ,R

1

R

to match the input impedance of 600Ω is determined to

2

90kΩ R

1

-------------------------------------------------

R190kΩ R3R2+

3

INTERNAL

600×=

(EQ. 3)

, given that

2

= 90kΩ and R3= 150kΩ the value of

be 25.47kΩ. (Note: nearest standard value is 24.9kΩ).

The amount of negative feedback is dependent upon the

additional synthesized resistance required for matching. The

sense resistors R

maintain the

and RB2 should remain at 150Ω to

B1

SHD threshold listed in the electrical

specifications. The additional synthesized resistance is

determined by the feed back factor X (Equation 4) which

needs to be applied to the transmit output and fed into the

RX pin of the HC5503. The feed back factor is equal to the

voltage divider between R2 and the parallel combination of

R

, R3 and R

1

FeedbackFactor X

R

X

INTERNAL

HC5503

24.9kΩ

T

X

T

X

, reference Figure 2.

-------------------------------------------------==

R190kΩ R3R2+

FEED BACK

R

2

= -4RS∆IL

R

1

R

150kΩ

90kΩ R

3

3

R

1

10kΩ

R

INTERNAL

90.0kΩ

(EQ. 4)

The voltage that is feed back into the RX pin is equal to the

voltage at V

VaVTXX()=

Where V

times the feedback factor (Equation 5).

TX

is equal to -4RS∆IL (RS = 150Ω)

TX

(EQ. 5)

So:

V

X

a

------------------ -=

∆IL600

(EQ. 6)

But, from Equation 2:

V

a

-------- 150Ω=

∆I

L

(EQ. 7)

Therefore:

V

150

--------- -

600

1

-- -===

4

output voltage is

X

(EQ. 8)

a

X

---------- -

V

TX

Equation 8 shows that 1/4 of the T

required to synthesize 150Ω at both the Tip feed and Ring

feed amplifiers.

To match a 900Ω load would require 300Ω worth of

synthesized impedance (300Ω from R

+ RB2 and 600Ω

B1

from the Tip feed + Ring feed amplifiers).

Setting Va/∆ILequal to 300Ω and solving for R

given that R

the value of R

= 10kΩ, R

1

to match the input impedance of 900Ω is

2

INTERNAL

= 90kΩ and R3= 150kΩ

in Equation 3,

2

determined to be 8.49kΩ (Note: nearest standard value is

8.45kΩ). The feed back factor to match a 900Ω load is 1/2

(300/600).

The selection of the value of 150kΩ for R

is arbitrary. The

3

only requirement is that it be large enough to havelittle effect

on the parallel combination between R

R

(10kΩ). R3 should be greater then 90kΩ.

1

INTERNAL

(90kΩ) and

The selection of the value of 10kΩ for R1 is also arbitrary.

The only requirement is that the value be small enough to

offset any process variations of R

INTERNAL

and large

enough to avoid loading of the CODEC’s output. A value of

10kΩ is a good compromise.

2-Wire to 4-Wire Gain

The 2-wire to 4-wire gain is defined as the output voltage

V

divided by the tip to ring voltage (VTR). Where:

TX

V

=-4RS∆IL = -600∆IL and VTR = (RL)∆IL = 600∆IL.

TX

The 2-wire to 4-wire gain is therefore equal to -1.0, as

shown in Equation 9.

24–

V

-----------

V

A

600– ∆I

TX

---------------------- 1.0–== =

600∆I

TR

L

L

(EQ. 9)

FIGURE 2. FEEDBACK EQUIVALENT CIRCUIT

6

4-Wire to 2-Wire Gain

The 4-wire to 2-wire gain is defined as the output voltage

V

divided by the input voltage, VIN. To determine the

TR

4-wire to 2-wire gain we need to define V

The voltage at V

impedance Z

V

∆ILZL×∆ILZO×==

TR

is the loop current times the load

TR

.

L

For optimum 2-wire return loss, the input impedance of the

SLIC (Z

Equations going further assume Z

) must equal the load impedance (ZL) of the line. All

O

= ZO.

L

The loop current ∆IL is the total voltage across the loop

divided by the total resistance of the loop. The total voltage

across the loop is the sum of the tip feed voltage (V

the ring feed voltage (V

) where VTF= -VRF. The total

RF

resistance is the sum of the sense resistors RB

and the load ZL (ZL +2RS). The total loop current is defined

in Equation 11.

∆I

L

VTFVRF–

---------------------------+

Z

O2RS

2V

()

TF

------------------------- -==

+

Z

O2RS

From Equation 10:

V

TR

∆I

-----------=

L

Z

O

Substituting Equation 12 into Equation 11 and solving for

V

:

TR

2VTF()

V

------------------------- -

=

TR

+

Z

O2RS

Z

O

Using Superposition, the voltage at the receive input R

given as:

V

RXVTF

R′

1

---------------------- -

R′1R2+

V

TX

R′

2

---------------------- -

+==

R′2R1+

Where R′1 is the effective impedance that is formed by the

parallel combination of R

INTERNAL

(90kΩ), R3 (150kΩ), R

(10kΩ) and is equal to 8.49kΩ. R′2 is the effective

impedance that’s formed by the parallel combination of

R

INTERNAL

(90kΩ), R3 (150kΩ), R2 (24.9kΩ) and is equal

to 17.25kΩ.

in terms of VIN.

TR

and RB

1

V

IN

(EQ. 10)

) and

TF

(EQ. 11)

(EQ. 12)

(EQ. 13)

is

X

(EQ. 14)

2

HC5503

1

V

for the recommended values of R1 and R2 is given in

RX

Equations 15 and 16. For impedance matching to a load

other than 600Ω, recalculate the parallel impedances R′

R′

and substitute into Equation 15. The 4-wire to 2-wire

2

gain is recalculated by using the Equations below.

V

RXVTF

V

RXVTF

8.49kΩ

----------------------------------------------

8.49kΩ 24.9kΩ+

0.25()V

TX

+==

0.633()V

V

TX

IN

17.25kΩ

-------------------------------------------- -

+==

17.25kΩ 10kΩ+

(EQ. 15)

(EQ. 16)

Substituting Equation 16 into Equation 13:

2 0.25()V

V

-------------------------------------------------------------------------

=

TR

0.633()V

+()

TX

+

Z

O2RS

IN

Z

O

(EQ. 17)

From Equation 10:

V

TR

∆I

-----------=

L

Z

O

(EQ. 18)

From Equation 1:

V

TX

4RS∆I

–=

L

(EQ. 19)

Substituting Equation 18 into Equation 19:

V

TR

V

TX

4RS

–=

-----------

Z

O

(EQ. 20)

Substituting Equation 20 into Equation 17:

V

V

=

TR

Assuming R

300

1

----------------------- -+

Z

O

TR

-----------

– 1.266V

2RS

300+

+

Z

O

= 150Ω and rearranging terms:

S

V

1.266Z

----------------------- -

=

TR

ZO300+

The 4-wire to 2-wire gain (Given that: R

and R

= 150kΩ) for a 600Ω load is:

3

1.266Z

TR

----------------------- -

ZO600+

IN

O

42–

V

-----------

V

A

Z

O

------------------------- -

IN

ZO2RS+

O

V

IN

0.633 3.96dB–== = =

(EQ. 21)

(EQ. 22)

= 10kΩ, R2= 24.9kΩ

1

(EQ. 23)

,

1

V

IN

7

HC5503

The Transversal Amplifier (TA)

Whereas the feed amplifiers perform the 4-wire to 2-wire

transmission function, the transversal amplifier acts as the

2-wire to 4-wire hybrid. The TA is a summing amplifier

configured to reject common mode signals. It will reject 2wire common mode signals. R

and RB2 act as loop

B1

current sense resistors. The voice signal output of the

amplifier is a function of the differential voltages appearing

across R

and RB2.

B1

The transversal amplifier also has a DC output proportional

to the metallic current in the loop. The output voltage is

given by:

V

TX

= 2(I

TIP

+ I

) (RB1 + RB2)

RING

This DC level is used as an input to a comparator whose

output feeds into the logic circuitryas SH. This signal is used

to gate

SHD output.

Voice signals on the loop are transformed by the TA into

ground referenced signals. Since the TA output has a DC

offset it is necessary to AC couple the output to any external

circuitry. Note, that during 4-wire to 2-wire transmission, the

transversal amplifier will have an audio signal at its output

proportional to the 4-wire audio receive signal and the loop’s

equivalent AC impedance. This is called the transhybrid

return, and must be cancelled (or balanced) out to prevent

an echo effect. Reference the Transhybrid Circuit section for

more information.

Loop Current Limiting

The maximum loop length for this application is a 533Ω load

across the feed amplifiers (24V

30mA

loop current). However, on a short loop the line

MAX

SUPPLY

resistance often approaches zero. Thus, a need exists to

control the maximum DC loop current that can flow around

the loop to prevent an excessive current drain from the

system battery. This limit is internally set to 30mA on the

HC5503. Figure 3 depicts the feedback network that

modifies the V

voltage as a function of metallic current.

RF

Figure 4 illustrates the loop current characteristics as a

function of line resistance.

As indicated above, the TA has a DC voltage output directly

proportional to the loop current. This voltage level is scaled

by R

and R18. The scaled level forms the ‘Metallic’ input

19

to one side of a Transconductance Amplifier.

- 8V

OVERHEAD

)/

V

TF

V

R

90K

R

90K

R

1.8K

21

19

= -600 I

TX

18

KV

TX

V

B5

FOR KVTX < V

LOOP

-

+

IGM > 0,

-4V

V

B

V

TX

B5

/2

V

RING

R

B1

R

B2

V

TIP

V

RF

V

RF

RING

FEED

FIGURE 3. DC LOOP CURRENT CHARACTERISTICS

TRANSVERSAL

AMP

-

+

A

VCL

-

+

= 2

C

1

The reference input to this amplifier is generated in the bias

network, and is equivalent to 30mA. When the metallic input

exceeds the set reference level, the transconductance

amplifier sources current. This current will charge C

positive direction causing the V

approach the V

(Tip Feed), effectively reducing the battery

TF

(Ring Feed) voltage to

RF

feed across the loop which will limit the DC loop current. C

in

1

1

will continue to charge until an equilibrium level is attained at

I

= I

LOOP

loop is set by R

mA (Max). The time constant of this feedback

LOOP

(90kΩ) and C1 which is nominally 0.33µF.

21

The VRF voltage level is also modified to reduce or control

loop current during ring line faults (e.g., ground or power line

crosses), and thermal overload. Figure 8 illustrates this. The

thermal and fault current circuitry works in parallel with the

transconductance amplifier.

Longitudinal Amplifier

The longitudinal amplifier is an operational amplifier

configured as a closed loop differential amplifier with a

nominal gain of 0.1. The output is a measure of any

imbalance between I

this amplifier is given by:

V

= 0.1(I

LONG

TIP

The gain factor is much less than one since ring voltage (up

to 150V

) can appear at the Ring or Ring Feed Sense

PEAK

terminals and are attenuated to avoid exceeding the

common mode range of the longitudinal amplifier’s input.

- I

TIP

RING

and I

) 150.

. The transfer function of

RING

8

HC5503

5330

R

LOOP

HC5503 I

(Ω)

30

(mA)

20

LOOP

I

= RB1 + RB2 + ZTF + ZRF + R

R

LOOP

10

FIGURE 4. DC LOOP CURRENT CHARACTERISTICS

SATURATION

LOOP

LINE

+ R

SET

The longitudinal amplifier’s principal functions is Ring Trip

Detection. The output of the amplifier after being filtered by

R

and C2 to attenuate AC signals is fed into a detector

20

whose output inhibits the ring relay driver to remove ringing

signals from the line in an off-hook condition, reference

Figure 8.

Ringing The Line

The Ring Command (RC) input is taken low during ringing.

This activates the ring relay driver (

telephone is not off-hook or the line is not in a power denial

state. The ring relay connects the ring generator to the

subscriber loop. The ring generator output is usually an

80V

, 20Hz signal. The ring signal should not exceed

RMS

150V peak. Since the telephone ringer is AC coupled only

ring current will flow. This ringing current flows directly into

via a set of relay contacts. The high impedance

V

BAT

terminal RFS is provided so that the low impedance V

node can be isolated from the hot end of the ring path in the

battery referenced ring scheme.

The AC ring current flowing in the subscriber circuit will be

sensed across RB2, and will give rise to an AC voltage at the

output of the longitudinal amplifier.R

signal before it reaches the ring trip detector to prevent false

ring trip. C

is nominally set at 1.0µF.

2

When the subscriber goes off-hook, a DC path is established

between the output of the ring generator and the battery

ground or V

terminal. A DC longitudinal imbalance is

BAT

established since no tip feed current is flowing through the

tip feed resistors. The longitudinal amplifier output is driven

negative. Once it exceeds the ring trip threshold of the ring

trip detector,the logic circuitry is driven by GK to trip the ring

relay establishing an off-hook condition such that

become active as loop metallic current starts to flow.

In addition to its ability to be used for tip or ring injected

systems, the HC5503 can also be configured for systems

utilizing balanced ringing. The main advantage of balanced

ringing is that it tends to minimizecross coupling effects owing

to the differential nature of the ring tone across the line.

Figure 5 illustrates the sequence of events during ring trip with

ring synchronization for a tip injected ring system. Note that

owing to the 90 degree phase shift introduced by the low pass

RD) output providing the

RF

and C2attenuate this

20

SHD will

filter (R

, C2) the RS pulse will occur at the most negative

20

point of the attenuated ring signal that is fed into the ring trip

detector. Hence, when DC conditions are established for

SHD,the AC component actually assists ring triptaking place.

For a ring side injected ring system, the RS pulse should

occur at the positive zero crossing of the ring signal as it

appears at RFS. If ring synchronization is not used, then the

RS pin should be held permanently to a logic high of 5V

nominally: ring trip will occur asynchronously with respect to

the ring voltage. Ring trip is guaranteed to take place within

three ring cycles after the telephone going off-hook.

It is recommended that an RC snubber network is placed

across the ring relay contacts to minimize inductive kickback effects from the telephone ringer. Typical values for

such a network are shown in Figure 10.

150V

V

RING

150V

THRESHOLD

RS

V

PEAK

MAX

C4

RING

TRIP

,

5V

0V

0V

SUBSCRIBER

GOES OFF-HOOK

FIGURE 5. RING TIP SEQUENCE

>50µs

DC SHIFT OWING TO

DC CURRENT DIFFERENCE

BETWEEN I

TIP

AND I

RING RELAY

HAS TRIPPED

RING

C

CHARGES

2

TO 0V

QUESCENT

VALUE

Transhybrid Circuit

The purpose of the transhybrid circuit is to remove the

receive signal (R

preventing an echo on the transmit side. This is

accomplished by using an external op amp (usually part of

the CODEC) and by the inversion of the signal from the

4-wire receive port (R

Figure 6 shows the transhybrid circuit. Because the voltage

is 180 degrees out of phase with the voltage at TX, the

at R

X

input signal will be subtracted from the output signal if I

equals I2. Node analysis yields the following Equation:

T

I1I2+

-------

R

X

4

The voltage at T

= 0.633) and 2-wire to 4-wire (A

(A

4-2

gains, and is therefore equal to 0.633. The voltage at R

when taking into account the negative feedback through R

) from the transmit signal (TX), thereby

X

) to the 4-wire transmit port (TX).

X

R

X

------- -+ 0==

R

3

is the product of the 4-wire to 2-wire

X

= -1.0) voltage

2-4

1

(EQ. 24)

,

X

,

2

9

HC5503

is the calculated value of 0.633 plus the feedback which is

(for matching to a 600Ω load, reference Equation 8).

1/4 T

X

The voltage at R

RX0.633

Substituting the values for T

is calculated in Equation 25.

x

1

-- -

0.633()– 0.474==

4

and RX into Equation 24 and

X

(EQ. 25)

setting the them equal to each other, the values of R3 and

can then be determined.

R

4

0.633

-------------- -

Setting the value of R

0.474

-------------- -=

R

R

4

3

to 150kΩ sets the value of R4 to be

3

(EQ. 26)

200kΩ.

Notice that the input voltage for the incoming signal (I

taken at R

, instead of the conventional method at the

X

) is

1

CODEC (point A, Figure 6). This alternative method is used

because the tolerance effects of R

on the transhybrid

1

balance are eliminated.

R

5

-

R

R

150kΩ

R

X

HC5503

T

X

FIGURE 6. TRANSHYBRID CIRCUIT

3

I

1

I

2

200kΩ

4

R

1

R

2

+

+

V

0

A

+

V

IN

-

CODEC/

FILTER

-

Power Denial (PD)

Power denial limits power to the subscriber loop: it does not

power down the SLIC, i.e., the SLIC will still consume its

normal on-hook quiescent power during a power denial

period. This function is intended to “isolate” from the battery,

under processor control, selected subscriberloops during an

overload or similar fault status.

PD

is selected, the logic circuitry inhibits RC and switches in

If

a current source to C

-3.5V at which point it is clamped. Since tip feed is always at

-4V, the battery feed across the loop is essentially zero, and

minimum loop power will be dissipated if the circuit goes offhook. No signalling functions are available during this mode.

After power denial is released (

hundred milliseconds (300ms) before the V

reaches its nominal battery setting. This is due to the RC

time constant of R

. The capacitor charges up to a nominal

1

PD

= 1), it will be several

output

RF

and C1.

21

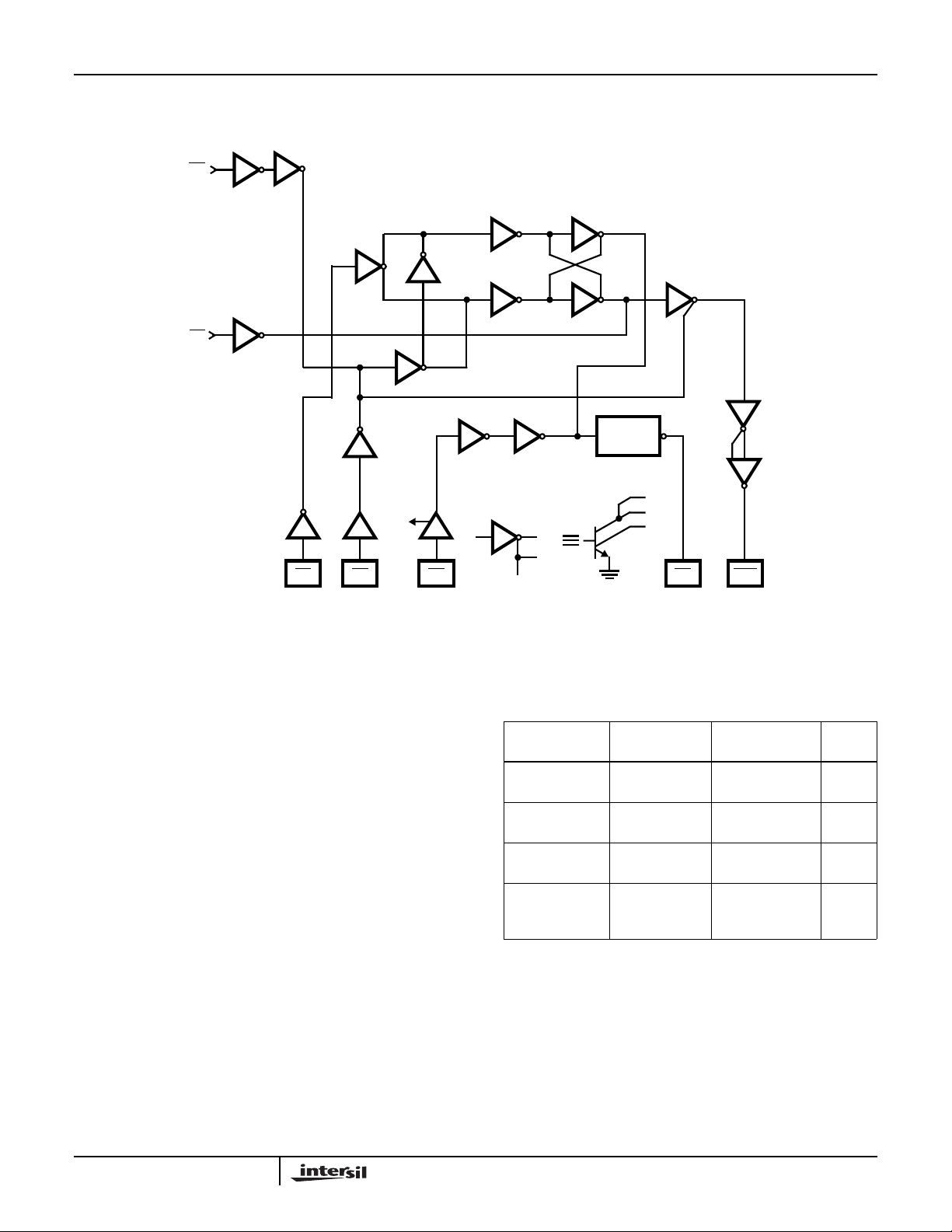

The Logic Network

The logic network utilizes I2L logic. All external inputs and

outputs are LS TTL compatible: the relay driver is an open

collector output that can sink 60mA with a V

Figure 9 is a schematic of the combination logic within the

network. The external inputs

RC (Relay Control) and

(Power Denial) allow the switch controller to ring the line or

deny power to the loop, respectively. The Ring

Synchronization input (RS) facilitates switching of the ring

relay near a ring current zero crossing in order to minimize

inductive kickback from the telephone ringer.

Line Fault Protection

The subscriber loop can exist in a very hostile electrical

environment.It is often in close proximity to very high voltage

power lines, and can be subjected to lightning induced

voltage surges. The SLIC has to provide isolation between

the subscriber loop and the PBX/Key telephone system.

The most stringent line fault condition that the SLIC has to

withstand is that of the lightning induced surge.

The Intersil monolithic SLIC, in conjunction with a simple low

cost diode bridge, can achieve up to 450V of isolation

between the loop and switch. The level of isolation is a

function of the packaging technology and geometry together

with the chip layoutgeometries. One of the principalreasons

for using DI technology for fabricating the SLIC is that it

lends itself most readily to manufacturing monolithic circuits

for high voltage applications.

Figures 10 shows the application circuit for the HC5503. A

secondary protection diode bridge is indicated which

protects the feed amplifiers during a fault. Most line systems

will have primary protection networks. They often take the

form of a carbon block or arc discharge device. These limit

the fault voltage to less than 450V peak before it reaches the

line cards. Thus when a transient high voltage fault has

occurred, it will be transmitted as a wavefront down the line.

The primary protection network must limit the voltage to

less than 450V.

down the line towards the SLIC. The feed amplifier outputs

appear to the surge as very low impedance paths to the

system battery. Once the surge reaches the feed resistors,

fault current will flow into or out of the feed amplifier output

stages until the relevant protection diodes switch on. Once

the necessary diodes have started to conduct all the fault

current will be handled by them.

If the user wishes to characterize SLIC devices under

simulated high voltage fault conditions on the bench, he

should ensure that the negative battery power supply has

sufficient current capability to source the negative peak

fault current and low series inductance. If this is not the

case, then the battery supply could be pulled more

negative and destroy the SLIC if the total (V

voltage across it exceeds 75V.

The attenuated wave front will continue

CE

CC

of 1V.

+ V

PD

BAT

)

10

HC5503

Pin Descriptions

28 PIN

PLCC

2 1 TIP An analog input connected to the TIP (more positive) side of the subscriber loop. Functions with the Ring

3 2 RING An analog input connected to the RING (more negative) side of the subscriber loop. Functions with the Tip

4 3 RFS Senses ring side of loop for ring trip detection. During ringing, the ring signal is inserted into the line at this

54VCCPositive Voltage Source - Most positive supply. VCC is typically 5V.

65C1Capacitor #1 - An external capacitor to be connected between this terminal and analog ground. Required for

7 6 DG Digital Ground - To be connected to zero potential and serves as a reference for all digital inputs and out-

9 7 RS Ring Synchronization Input - A TTL - compatible clock input. The clock should be arranged such that a pos-

10 8 RD Relay Driver - A low active open collector logic output. When enabled, the external ring relay is energized.

11 9 TF Tip Feed - A low impedance analog output connected to the TIP terminal through a 150Ω feed resistor.

12 10 RF Ring Feed - A low impedance analog output connected to the RING terminal through a 150Ω feed resistor.

13 11 V

14 12 BG Battery Ground - To be connected to zero potential. All loop current and some quiescent current flows into

16 13 SHD Switch Hook Detection - A low active LS TTL - compatible logic output. This output is enabled for loop cur-

18 15 PD Power Denial - A low active TTL - Compatible logic input. When enabled, the switch hook detect (SHD) is

19 16 RC Ring Command - A low active TTL - Compatible logic input. When enabled, the relay driver (RD) output

25 21 R

26 22 C

27 23 AG Analog Ground - To be connected to zero potential and serves as a reference for the transmit output (TX)

28 24 TX Transmit Output, F our Wire Side - A lo w impedance analog output which represents the diff erential v oltage

17 14 NC Used during production testing. For proper operation of the SLIC, this pin should float.

1, 8, 15,

20, 21, 22,

23, 24

NOTE: All grounds (AG, BG, and DG) must be applied before VCC or V

wishes to run separate grounds off a line card, the AG must be applied first.

24 PIN

DIP/SOIC SYMBOL DESCRIPTION

terminal to receive voice signals from the telephone and for loop monitoring purposes.

terminal to receive voice signals from the telephone and for loop monitoring purposes.

node and RF is isolated from RFS via a relay.

proper operation of the loop current limiting function, and for filtering V

puts on the SLIC microcircuit.

itive pulse transition occurs on the zero crossing of the ring voltage source, as it appears at the RFS terminal. For Tip side injected systems, the RS pulse should occur on the negative going zero crossing and for

Ring injected systems, on the positive going zero crossing. This ensures that the ring relay activates and

deactivates when the instantaneous ring voltage is near zero. If synchronization is not required, the pin

should be tied to 5V.

Functions with the RF terminal to provide loop current, feed voice signals to the telephone set, and sink

longitudinal current.

Functions with the TF terminal to provide loop current, feed voice signals to the telephone set, and sink

longitudinal current.

17, 18, 19,

20

Negative Voltage Source - Most negative supply. V

BAT

this ground terminal.

rents exceeding 10.5mA and disabled for loop currents less than 5mA.

not necessarily valid, and the relay driver (RD) output is disabled.

goes low on the next high level of the ring sync (RS) input, as long as the SLIC is not in the power denial

state (PD = 0) or the subscriber is not already off-hook (SHD = 0).

Receive Input, Four Wire Side - A high impedance analog input which is internally biased. Capacitive coupling

X

to this input is required. AC signals appearing at this input deferentially drive the Tip feed and Ring feed terminals, which in turn drive tip and ring through 150Ω of feed resistance on each side of the line.

Capacitor #2 - An external capacitor to be connected between this terminal and analog ground. This ca-

2

pacitor prevents false ring trip detection from occurring when longitudinal currents are induced onto the

subscriberloop from nearby power lines and other noise sources. Recommended value is 1.0µF, 20V. This

capacitor should be nonpolarized.

and receive input (RX) terminals.

acrossTipand Ring. Transhybridbalancing must be performed beyondthis output to completely implement two

to four wire conversion. This output is unbalanced and ref erenced to analog g round. Since the DC le vel of this

output varies with loop current, capacitive coupling to the next stage is essential.

NC No internal connection.

. Failure to do so may result in premature failure of the part. If a user

BAT

is typically -24V. Frequently referred to as “battery”.

BAT

. Typical value is 0.3µF, 16V .

BAT

11

Pinouts

TIP

RING

RFS

V

CC

C1

DG

RS

RD

TF

RF

V

BAT

BG

HC5503 (SOIC)

TOP VIEW

1

2

3

4

5

6

7

8

9

10

11

12

HC5503

HC5503 (PLCC)

TOP VIEW

RING

24

TX

23

AG

22

C2

21

R

X

N/C

20

19

N/C

18

N/C

N/C

17

16

RC

15

PD

14

N/C

13

SHD

V

N/C

CC

C1

DG

RS

RD

TF

5

6

7

8

9

10

11

4

12

RFS

RF

13 14

BAT

V

TIP

BG

N/C

15 16

N/C

TX

SHD

AG

17 18

N/C

C2

262728123

RX

25

N/C

24

23

N/C

22

N/C

N/C

21

N/C

20

RC

19

PD

Functional Block Diagram

RING SYNC

RING COMMAND

1/2 RING

TIP

2-WIRE

LOOP

RING

RING

VOLTAGE

V

BAT

RELAY

SECONDARY

PROTECTION

1/2 RING

V

BAT

RFS

RELAY

POWER DENIAL

150Ω

150Ω

RING

RS

RC

RD

TIP

TF

V

BAT

BG

RF

PD

RING

CONTROL

BATTERY

FEED

LOOP

CURRENT

LIMITER

SLIC MICROCIRCUIT

RING

TRIP

MONITORING

+1

LINE

DRIVERS

-1

LOOP

SHD

SWITCH HOOK

DETECTION

DIFF

TX

AMP

+

-

RX

TRANSMIT

OUTPUT

RECEIVE

INPUT

12

FIGURE 7.

Schematic Diagram

V

CC

TF

V

11

BAT

TIP FEED

I

B4

A-400

AMP

HC5503

PLCC PIN NUMBERS SHOWN

25 26 13 14 27 7 5

RX C2

R

17

+

V

B2

-

V

IB1IB2IB3IB4IB5IB6IB7I

R

12

BAT ANA DIG

BAT

GND GND GND

VOLTAGE AND CURRENT

BIAS NETWORK

V

CC

IB9I

V

B8

BAT

RING TRIP DETECTOR

V

CC

B10IB11

5V

V

B1

V

B2

V

B3

V

B4

V

B5

5V

I

V

B10

5V

CC

TIP

2

RING

FEED

SENSE

4

RING

3

RF

12

RING FEED

V

BAT

A-200

LONG’L

I/V AMP

I

B7

R

5

A-100

TRANSV’L

I/V AMP

I

B6

REFERENCE

V

CC

R

20

V

+

V

BAT

I

BAT

B8

V

B4

GND SHORTS

CURRENT

LIMITING

I

B1

GK

NC

17

- +

V

V

CC

V

BAT

R

6

R

14

R

R

18

19

SWITCH HOOK

DETECTOR

V

CC

+

I

B6

Q

D27

LOAD CURRENT

LIMITING

I

B2

-

V

B1

Q

D28

THERMAL

LIMITING

V

B5

V

-

+

B5

B3

V

BAT

STTL

AND LOGIC

INTERFA CE

SH

RFC

V

BAT

SHD

16

RC

19

PD

18

R

7

R

8

R

10

R

9

R

22

R

3

R

4

R

1

R

2

R

16

R

15

A-300

AMP

I

B5

QD3Q

V

CC

V

BAT

V

CC

R

23

R

-

21

+

-

D36

+

R

11

V

BAT

+

-

V

BAT/2

V

B2

13

R

13

V

BAT

TXC1 RS RD

V

BAT

FIGURE 8. FUNCTIONAL SCHEMATIC

109286

HC5503

Schematic Diagram

GK

SH

(Continued)

1

16

TTL

TO

STTL

LOGIC GATE SCHEMATIC

2

TTL

TO

STTL

6

4

15

5

10

11 14

TTL

TO

STTL

TO

R

21

C

SCHOTTKY LOGIC

8

97

RELAY

DRIVER

A

B

12

13

STTL

C

B

A

TO

TTL

SHDRDPDRCRS

FIGURE 9. LOGIC NETWORK

Overvoltage Protection and Longitudinal

Current Protection

The SLIC device, in conjunction with an external protection

bridge, will withstand high voltage lightning surges and

power line crosses.

High voltage surge conditions are as specified in Table 1.

The SLIC will withstand longitudinal currents up to a

maximum or 10mA

performance degradation.

RMS

, 5mA

per leg, without any

RMS

TEST

PARAMETER

Longitudinal

Surge

CONDITION

10µs Rise/

1000µs Fall

Metallic Surge 10µs Rise/

1000µs Fall

T/GND

R/GND

50/60Hz Current

T/GND

R/GND

10µs Rise/

1000µs Fall

11 Cycles

Limited to

10A

RMS

TABLE 1.

PERFORMANCE

(MAX) UNITS

±450 (Plastic) V

±450 (Plastic) V

±450 (Plastic) V

315 (Plastic) V

PEAK

PEAK

PEAK

RMS

14

Application Circuit

+5V

HC5503

SYSTEM CONTROLLER

R

5

(NOTE 6)

R

S1

TIP

K

1A

Z1

PRIMARY

PROTECTION

MUST LIMIT

INPUT VOLTAGE

TO LESS THAN

450V

RING

16 18 9 19

C

S1

K

1B

PTC

D

D

2

4

V

BAT

-24V

D

5

R

B1

C

S2

R

S2

K

1

10

RD

2

TIP

TIP FEED

11

D

1

V

BAT

-24V

D

3

12

RING FEED

RING FEED SENSE

4

R

B2

V

BAT

-24V

RING

3

C

5

PD

HC5503

U1

(PINOUT FOR PLCC)

AGNDDGNDBGND-BAT

RCRSSHD

R

3

25

RX

C

28

T

X

6

C

1

26

C

2

V

CC

C

2

52771413

C

6

V

CC

+5V

R

4

3

R

C

4

C

1

CODEC/FILTER

R

1

2

U2

V

V

OUT

IN

NOTES:

6. R5 sets the 2-wire to 4-wire gain. R5 = 150kΩ then A

= 0dB. R5= 75kΩ then A

2-4

= -6.0dB.

2-4

7. Secondary protection diode bridge recommended is a 2A, 200V type.

8. All grounds (AG, BG, and DG) must be applied before VCCor V

. Failure to do so may result in premature failure of the part. If a user wishes

BAT

to run separate grounds off a line card, the AG must be applied first.

9. Application shows Ring Injected Ringing, Balanced or Tip injected configuration may be used.

FIGURE 10. -24V APPLICATION CIRCUIT

Typical Component Values:

C1 = 0.33µF, 20%, 20V.

C2 = 1.0µF, 10%, 20V.

C3 = C4 = 0.47µF, 20%, 30V.

C5, C6= 0.01µF, 30V.

CS1=CS2= 0.1µF, 200V typically,depending on V

RING

and

RS1 = RS2 = 1kΩ, 1%, 1/4W.

R1 = 10kΩ, 1%, 1/4W.

R2 = 24.9kΩ, 1%, 1/4W.

R3 = R5 = 150kΩ, 1%, 1/4W.

R4 = 200kΩ, 1%, 1/4W.

D1, D2, D3, D4, D5 = 1N40007, 100V, 3A.

line length.

Z1 = 250V to 350V transient protection.

R

= RB2 = 150 (1% absolute value).

B1

PTC used as ring generator ballast.

15

HC5503

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil semiconductor products are sold by description only.Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (407) 724-7000

FAX: (407) 724-7240

16

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Intersil (Taiwan) Ltd.

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

Loading...

Loading...