查询EL9200供应商

®

EL9200, EL9201, EL9202

Data Sheet April 7, 2005

Programmable V

The EL9200, EL9201, and EL9202 represent programmable

V

amplifiers for use in TFT-LCD displays. Featuring 1,

COM

2, and 4 channels of V

device features just a single programmable current source

for adding offset to one V

programmable using a single wire interface to one of 128

levels. The value is stored on an internal EEPROM memory.

The EL9200 is available in the 12-pin DFN package and the

EL9201 and EL9202 are available in 24-pin QFN packages.

All are specified for operation over the -40°C to +85°C

temperature range.

COM

amplification, respectively, each

COM

output. This current source is

COM

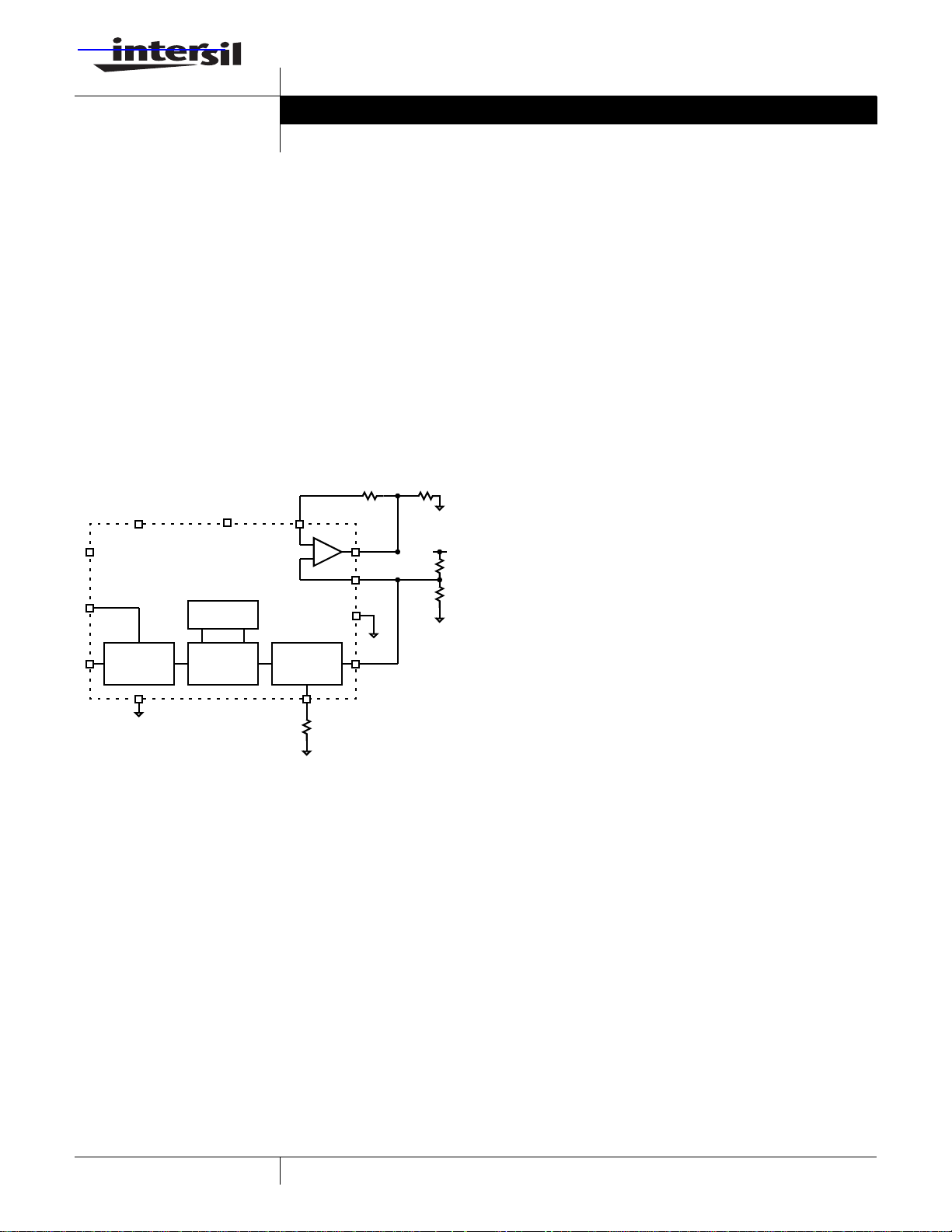

Typical Block Diagram

R

F

A

VDD

V

SD

CE

VS+

EEPROM

INN

V

-

+

OUT

INP

GND

FN7438.0

Features

• 128 step adjustable sink current

• EEPROM memory

• 2-pin adjustment and disable

• Single, dual or quad amplifiers

- 44MHz bandwidth

- 80V/µs slew rate

- 60mA continuous output

- 180mA peak output

• Up to 18V operation

• 2.6V to 3.6V logic control

• Pb-free available (RoHS compliant)

R

G

A

VDD

R

1

R

2

Applications

•TFT-LCD V

-LCD-TVs

- LCD monitors

COM

supplies for

CTL

CONTROL

GND SET

UP/DOWN

COUNTER

ANALOG

POT

R

SET

I

OUT

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright © Intersil Americas Inc. 2005. All Rights Reserved.

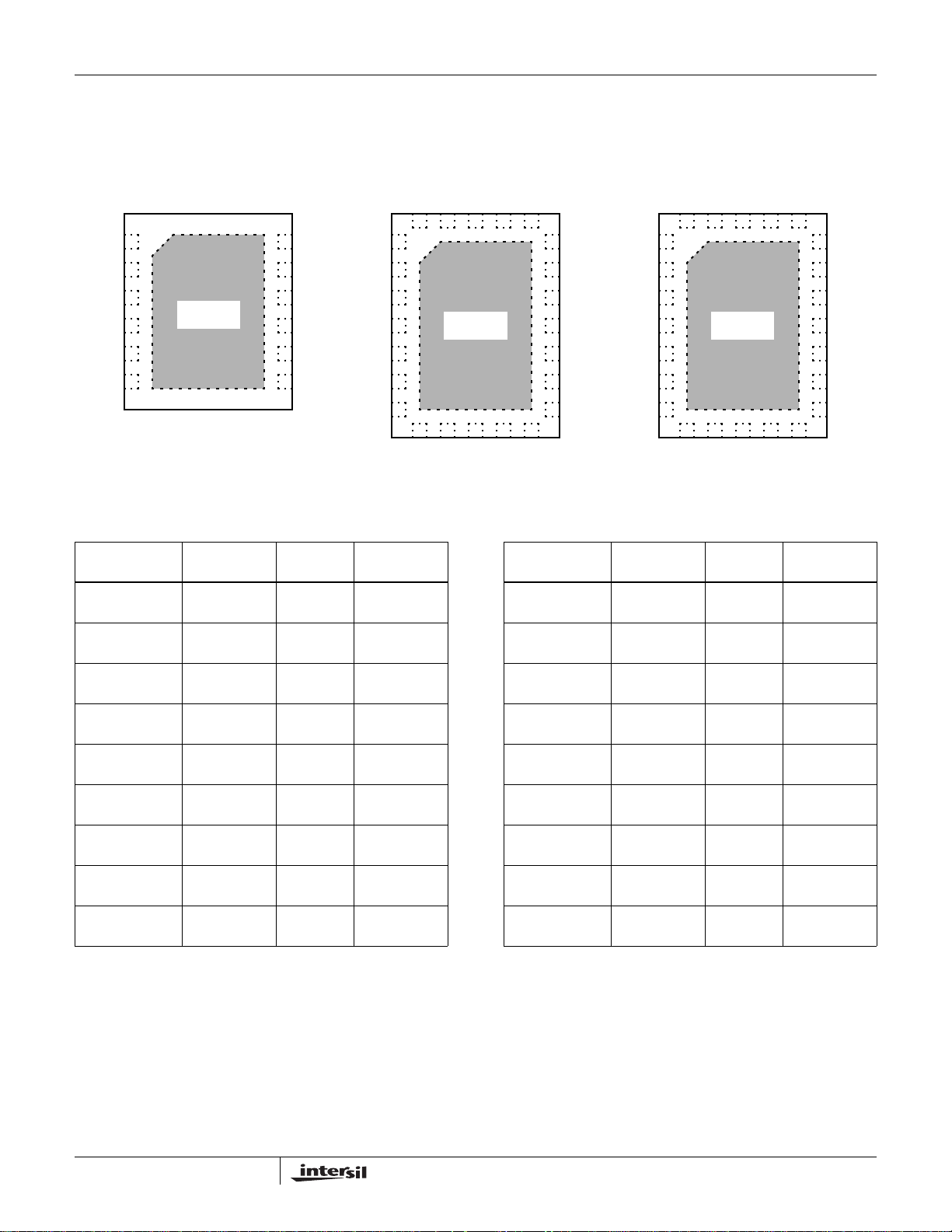

Pinouts

1

VINA-

EL9200

(12-PIN DFN)

TOP VIEW

EL9200, EL9201, EL9202

EL9201

(24-PIN QFN)

TOP VIEW

NC

GND

NC

VINA+

VINA-

24

23

22

21

20

12

VS+

NC

1

19

NC

VOUTA

1

EL9202

(24-PIN QFN)

TOP VIEW

VINA-

VINA+

24

23

VS+

VINB+

VINB-

22

21

20

19

VOUTB

GND

VINA+

IOUT

AVD D

GND

2

3

4

5

6

THERMAL

PAD

11

10

9

8

7

VOUTA

SET

CE

CTL

VSD

NC

VINB+

IOUT

NC

AVD D

GND

11

VSD

18

VOUTA

17

VS+

16

VOUTB

15

VINB-

14

SET

13

CE

12

CTL

VOUTD

VIND-

NC

VIND+

AVD D

CTL

2

3

8

CE

THERMAL

PAD

9

10

NC

SET

4

5

6

7

11

IOUT

12

NC

18

17

16

15

14

13

VOUTC

VINC-

NC

VINC+

GND

AVD D

2

3

8

NC

THERMAL

PAD

9

10

NC

NC

4

5

6

7

Ordering Information

PART NUMBER PACKAGE

EL9200IL 12-Pin DFN - MDP0047 EL9201ILZ

EL9200IL-T7 12-Pin DFN 7” MDP0047 EL9201ILZ-T7

EL9200IL-T13 12-Pin DFN 13” MDP0047 EL9201ILZ-T13

EL9200ILZ

(See Note)

EL9200ILZ-T7

(See Note)

EL9200ILZ-T13

(See Note)

12-Pin DFN

(Pb-Free)

12-Pin DFN

(Pb-Free)

12-Pin DFN

(Pb-Free)

EL9201IL 24-Pin QFN - MDP0046 EL9202ILZ

EL9201IL-T7 24-Pin QFN 7” MDP0046 EL9202ILZ-T7

EL9201IL-T13 24-Pin QFN 13” MDP0046 EL9202ILZ-T13

REEL PKG. DWG. # PART NUMBER PACKAGE

24-Pin QFN

(See Note)

(Pb-Free)

24-Pin QFN

(See Note)

(Pb-Free)

24-Pin QFN

(See Note)

(Pb-Free)

- MDP0047 EL9202IL 24-Pin QFN - MDP0046

7” MDP0047 EL9202IL-T7 24-Pin QFN 7” MDP0046

13” MDP0047 EL9202IL-T13 24-Pin QFN 13” MDP0046

24-Pin QFN

(See Note)

(Pb-Free)

24-Pin QFN

(See Note)

(Pb-Free)

24-Pin QFN

(See Note)

(Pb-Free)

NOTE: Intersil Pb-free products employ special Pb-free material sets; molding compounds/die attach materials and 100% matte tin plate termination

finish, which are RoHS compliant and compatible with both SnPb and Pb-free soldering operations. Intersil Pb-free products are MSL classified at

Pb-free peak reflow temperatures that meet or exceed the Pb-free requirements of IPC/JEDEC J STD-020.

TAPE &

TAPE &

REEL PKG. DWG. #

- MDP0046

7” MDP0046

13” MDP0046

- MDP0046

7” MDP0046

13” MDP0046

2

FN7438.0

April 7, 2005

EL9200, EL9201, EL9202

Absolute Maximum Ratings (T

V

+ Supply Voltage between VS+ and GND . . . . . . . . . . . . . .18V

S

Supply Voltage between V

Maximum Continuous Output Current . . . . . . . . . . . . . . . . . . . 65mA

Input Voltages to GND

SET, CE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to +4V

CTL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to +16V

and GND . . . . . . . . . . . . . . . . . . . .4V

SD

= 25°C)

A

A

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to +20V

VDD

ESD Rating - HBM for Device . . . . . . . . . . . . . . . . . . . . . . . . . . . 2kV

Ambient Operating Temperature . . . . . . . . . . . . . . . . -40°C to +85°C

Maximum Die Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . +150°C

Storage Temperature . . . . . . . . . . . . . . . . . . . . . . . . -65°C to +150°C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . +300°C

Output Voltages to GND

OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to +20V

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

IMPORTANT NOTE: All parameters having Min/Max specifications are guaranteed. Typical values are for information purposes only. Unless otherwise noted, all tests

are at the specified temperature and are pulsed tests, therefore: T

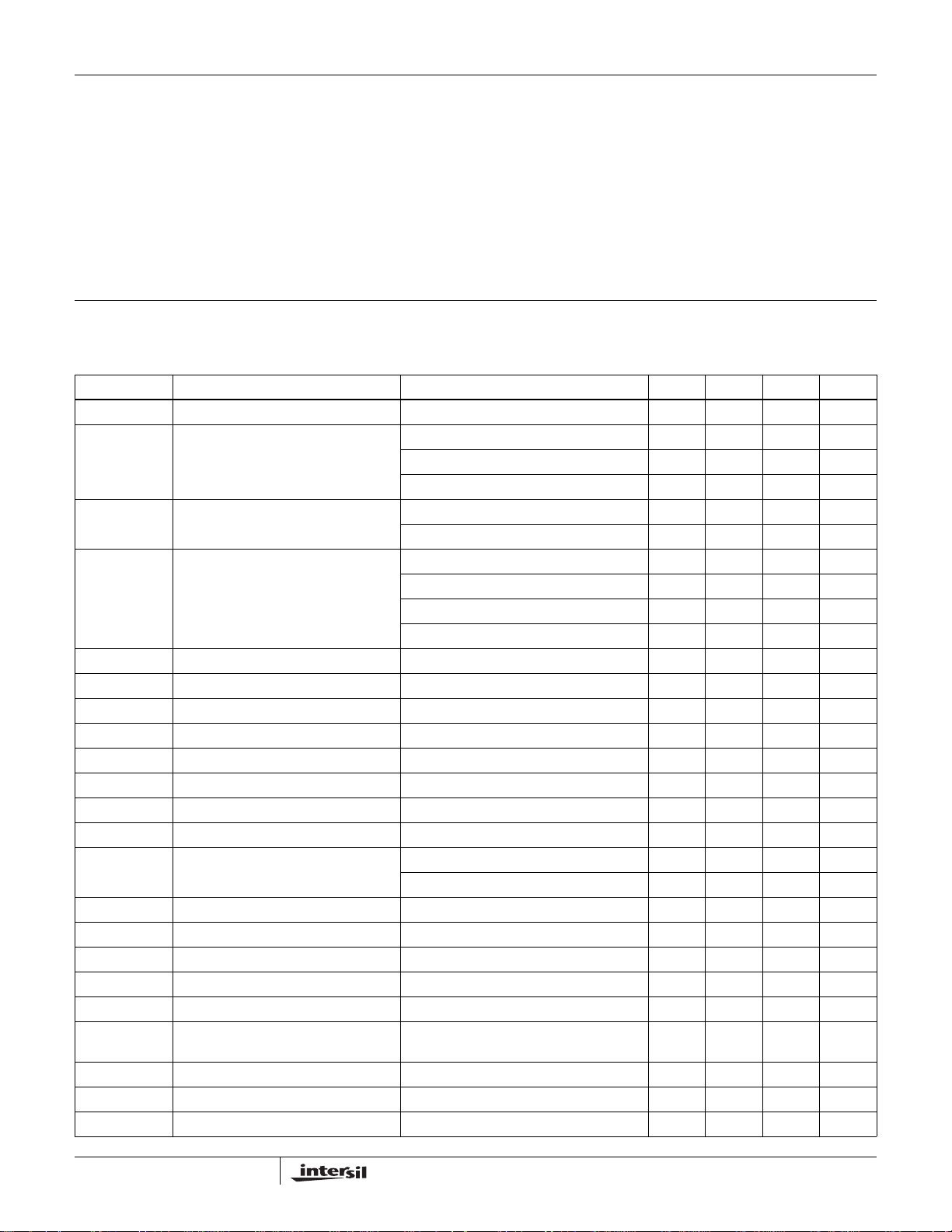

Electrical Specifications V

= 3V, VS+ = 15V, A

SD

= TC = T

J

VDD

A

= 15V, R

= 24.9kΩ, and TA = 25°C unless otherwise specified

SET

PARAMETER DESCRIPTION CONDITION MIN TYP MAX UNIT

V

S+

I

S+

Supply Voltage 4.5 16.5 V

Quiescent Current EL9200 3.8 4.8 mA

EL9201 7.6 9.6 mA

EL9202 10.5 16 mA

V

SD

Logic Supply Voltage For programming 3 3.6 V

For operation 2.6 3.6 V

I

SD

Quiescent Logic Current CE = 3.6V 50 µA

CE = GND 25 µA

Program (charge pump current) (Note 1) 23 mA

Read (Note 1) 3 mA

I

ADD

CTL

CTL

CTL

CTL

CTL

CTL

CTL

IH

IL

IHRPW

ILRPW

IHMPW

ILMPW

MTC

Supply Current Note 2 25 µA

CTL High Voltage 2.6V < VSD < 3.6V 0.7*V

CTL Low Voltage 2.6V < VSD < 3.6V 0.2*V

SD

SD

0.8*V

0.3*V

SD

SD

CTL High Rejected Pulse Width 20 µs

CTL Low Rejected Pulse Width 20 µs

CTL High Minimum Pulse Width 200 µs

CTL Low Minimum Pulse Width 200 µs

CTL Minimum Time Between Counts 10 µs

V

V

ICTL CTL Input Current CTL = GND 10 µA

CTL

CE

CE

CE

CTL

CTL

P

T

EE

SET

CAP

IL

IH

ST

PROM

PT

WC

DN

CTL = V

SD

CTL Input Capacitance 10 pF

CE Input Low Voltage 2.6V < VSD < 3.6V 0.4 V

CE Input High Voltage 2.6V < VSD < 3.6V 1.6 V

CE Minimum Start Up Time (Note 1) 1 ms

CTL EEPROM Program Voltage 2.6V < VSD < 3.6V (Note 2) 4.9 15.75 V

CTL EEPROM Programming Signal

> 4.9V 200 µs

Time

Programming Time 100 ms

EE Write Cycles Guaranteed by design 1000 cycles

SET Differential Nonlinearity Monotonic over-temperature ±1LSB

10 µA

3

FN7438.0

April 7, 2005

EL9200, EL9201, EL9202

Electrical Specifications V

= 3V, VS+ = 15V, A

SD

VDD

= 15V, R

= 24.9kΩ, and TA = 25°C unless otherwise specified

SET

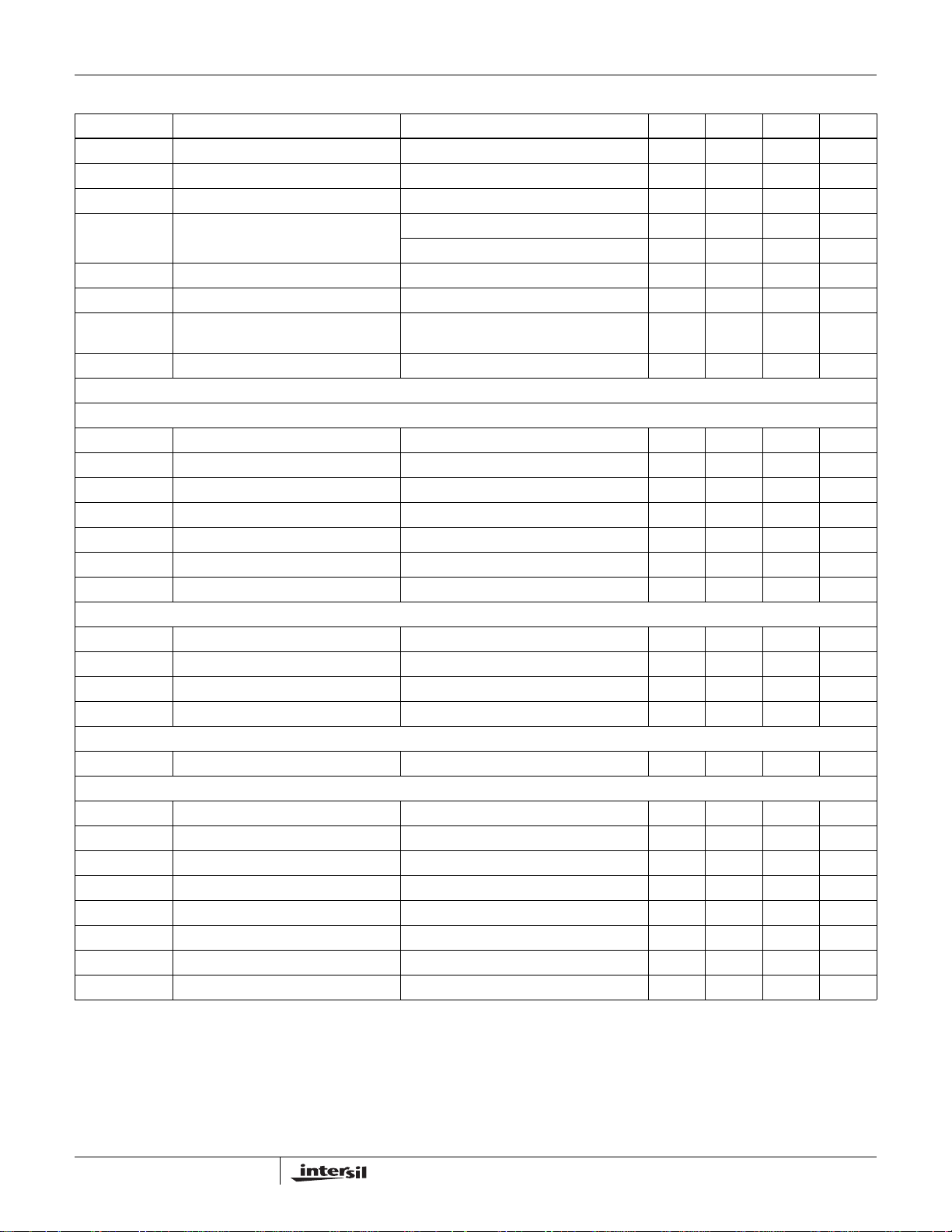

PARAMETER DESCRIPTION CONDITION MIN TYP MAX UNIT

SET

ZSE

SET

FSE

I

SET

SET

ER

A

to SET A

VDD

OUT

ST

V

OUT

SET Zero-Scale Error Note 3 ±2LSB

SET Full-Scale Error Note 3 ±8LSB

SET Current Through R

SET External Resistance To GND, A

To GND, A

to SET Voltage Attenuation 1:20 V/V

VDD

(Note 1) 120 µA

SET

= 20V (Note 1) 10 200 kΩ

VDD

= 4.5V (Note 1) 2.25 45 kΩ

VDD

OUT Settling Time To ±0.5 LSB error band (Note 1) 20 µs

OUT Voltage Range (Note 1) V

SET

+

13 V

0.5V

OUT

VD

OUT Voltage Drift (Note 1) 10 mV

AMPLIFIER CHARACTERISTICS

INPUT CHARACTERISTICS

V

OS

TCV

OS

I

B

R

IN

C

IN

CMRR Common-Mode Rejection Ratio For V

A

VOL

Input Offset Voltage VCM = 0V 3 15 mV

Average Offset Voltage Drift (Note 1) 7 µV/°C

Input Bias Current VCM = 0V 2 60 nA

Input Impedance 1GΩ

Input Capacitance 2pF

from -5.5V to +5.5V 50 70 dB

IN

Open-Loop Gain -4.5V ≤ V

≤ +4.5V 60 70 dB

OUT

OUTPUT CHARACTERISTICS

V

V

I

SC

I

OUT

OL

OH

Output Swing Low RL = 1.5kΩ to 0 0.09 0.15 V

Output Swing High 14.85 14.9 V

Short-Circuit Current ±150 ±180 mA

Output Current ±65 mA

POWER SUPPLY PERFORMANCE

PSRR Power Supply Rejection Ratio V

is moved from 4.5V to 15.5V 55 80 dB

S+

DYNAMIC PERFORMANCE

SR Slew Rate (Note 4) -4.0V ≤ V

t

S

Settling to +0.1% (AV = +1) (AV = +1), V

≤ 4.0V, 20% to 80% 60 80 V/µs

OUT

= 2V step 80 ns

OUT

BW -3dB Bandwidth 44 MHz

GBWP Gain-Bandwidth Product 32 MHz

PM Phase Margin 50 °

CS Channel Separation f = 5MHz (EL9201 & EL9202 only) 110 dB

d

G

d

P

Differential Gain (Note 5) RF = RG = 1kΩ and V

Differential Phase (Note 5) RF = RG = 1kΩ and V

= 1.4V 0.17 %

OUT

= 1.4V 0.24 °

OUT

NOTES:

1. Simulated and determined via design and not directly tested

2. Tested at A

VDD

= 20V

3. Wafer sort only

4. NTSC signal generator used

4

FN7438.0

April 7, 2005

EL9200, EL9201, EL9202

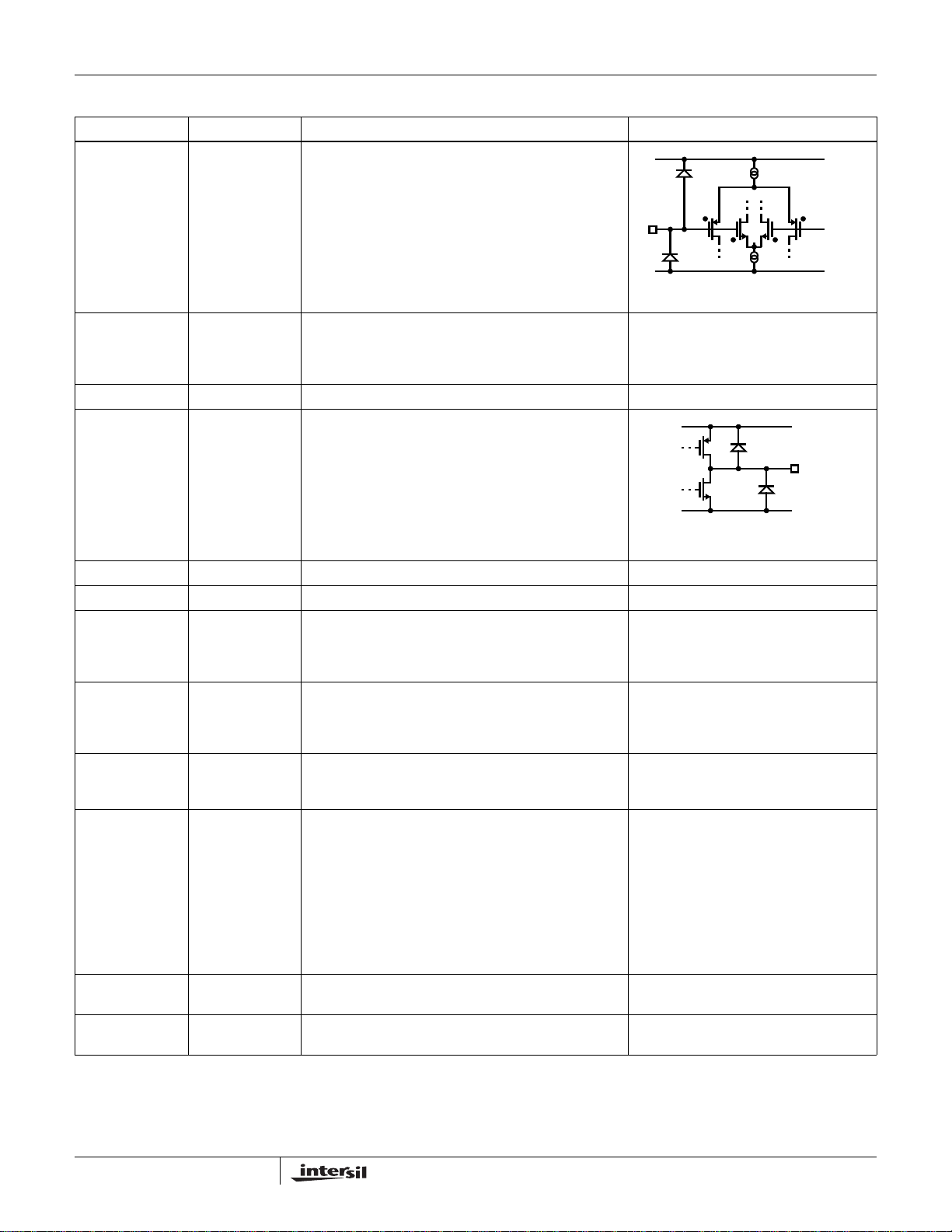

Pin Descriptions

PIN IN/OUT DESCRIPTION EQUIVALENT CIRCUIT

VINX- Input Amplifier X inverting input, where:

VINX+ Input Amplifier X non-inverting input, where:

VS+ Supply Op amp supply; bypass to GND with 0.1µF capacitor

VOUTX Output Amplifier X output, where:

X = A for EL9200

X = A, B for EL9201

X = A, B, C, D for EL9202

Reference Circuit 1

X = A for EL9200

X = A, B for EL9201

X = A, B, C, D for EL9202

X = A for EL9200

X = A, B for EL9201

X = A, B, C, D for EL9202

CIRCUIT 1

V

S+

GND

V

S+

NC - No connect; not internally connected

GND Supply Ground connection

IOUT Output Adjustable sink current output pin; the current sinks into the

OUT pin is equal to the DAC setting times the maximum

adjustable sink current divided by 128; see SET pin function

description for the maxim adjustable sink current setting

SET Output Maximum sink current adjustment point; connect a resistor

from SET to GND to set the maximum adjustable sink

current of the OUT pin; the maximum adjustable sink

current is equal to (A

/20) divided by R

VDD

SET

CE Input Counter enable pin; connect CE to VDD to enable counting

of the internal counter; connect CE to GND to inhibit

counting

CTL Input Internal counter up/down control and internal EEPROM

programming control input; if CE is high, a mid-to-low

transition increments the 7-bit counter, raising the DAC

setting, increasing the OUT sink current, and lowering the

divider voltage at OUT; a mid-to-high transition decrements

the 7-bit counter, lowering the DAC setting, decreasing the

OUT sink current, and increasing the divider voltage at

OUT; applying 4.9V and above with appropriately arranged

timing will overwrite EEPROM with the contents in the 7-bit

counter; see EEPROM Programming section for details

AVDD Supply analog voltage supply; bypass to GND with 0.1µF

capacitor

VSD Supply System power supply input; bypass to GND with 0.1µF

capacitor

GND

GND

CIRCUIT 2

5

FN7438.0

April 7, 2005

EL9200, EL9201, EL9202

Amplifier Typical Performance Curves

QUANTITY (AMPLIFIERS)

500

400

300

200

100

0

VS=5V

=25°C

T

A

-8-6-4

-12

-10

INPUT OFFSET VOLTAGE (mV)

-2

0

2

TYPICAL

PRODUCTION

DISTRIBUTION

4

6

8

10

12

0.008

VS=5V

0.004

0

-0.004

-0.008

INPUT BIAS CURRENT (µA)

-0.012

-50 -10 30 70 110 150

TEMPERATURE (°C)

FIGURE 1. INPUT OFFSET VOLTAGE DISTRIBUTION FIGURE 2. INPUT BIAS CURRENT vs TEMPERATURE

25

VS=5V TYPICAL

20

15

10

PRODUCTION

DISTRIBUTION

4.96

4.94

4.92

4.9

VS=5V

I

OUT

=5mA

5

QUANTITY (AMPLIFIERS)

0

1

3

5

7

9

11

13

15

17

19

21

INPUT OFFSET VOLTAGE DRIFT, TCV

OS

(µV/°C)

4.88

OUTPUT HIGH VOLTAGE (V)

4.86

-50 -10 30 70 110 150

TEMPERATURE (°C)

FIGURE 3. INPUT OFFSET VOLTAGE DRIFT FIGURE 4. OUTPUT HIGH VOLTAGE vs TEMPERATURE

2

1.5

1

0.5

0

INPUT OFFSET VOLTAGE (mV)

-0.5

-50 -10 30 70 110 150

TEMPERATURE (°C)

-4.85

VS=5V

=5mA

I

OUT

-4.87

-4.89

-4.91

-4.93

OUTPUT LOW VOLTAGE (V)

-4.95

-50 -10 30 70 110 150

TEMPERATURE (°C)

FIGURE 5. INPUT OFFSET VOLTAGE vs TEMPERATURE FIGURE 6. OUTPUT LOW VOLTAGE vs TEMPERATURE

6

FN7438.0

April 7, 2005

EL9200, EL9201, EL9202

Amplifier Typical Performance Curves

75

70

65

OPEN-LOOP GAIN (dB)

60

-50 -10 30 70 110 150

TEMPERATURE (°C)

VS=±5V

=1kΩ

R

L

78

VS=±V

77

76

75

74

SLEW RATE (V/µs)

73

72

-50 -10 30 70 110 150

TEMPERATURE (°C)

FIGURE 7. OPEN-LOOP GAIN vs TEMPERATURE FIGURE 8. SLEW RATE vs TEMPERATURE

0

-0.02

-0.04

-0.06

-0.08

-0.1

-0.12

-0.14

DIFFERENTIAL GAIN (%)

-0.16

-0.18

0 100 200

IRE

VS=5V

=2

A

V

=1kΩ

R

L

0.3

0.25

0.2

0.15

0.1

DIFFERENTIAL PHASE (°)

0.05

0

0 100 200

IRE

FIGURE 9. DIFFERENTIAL GAIN FIGURE 10. DIFFERENTIAL PHASE

-30

VS=5V

=2

A

V

-40

R

=1kΩ

L

FREQ=1MHz

-50

-60

-70

DISTORTION (dB)

-80

-90

0810

246

FIGURE 11. HARMONIC DISTORTION vs V

V

OP-P

2nd HD

3rd HD

(V)

OP-P

80

60

40

20

GAIN (dB)

0

-20

1K 10M 100M

10K 100K 1M

FREQUENCY (Hz)

GAIN

PHASE

FIGURE 12. OPEN LOOP GAIN AND PHASE

250

190

130

70

10

-50

PHASE (°)

7

FN7438.0

April 7, 2005

EL9200, EL9201, EL9202

Amplifier Typical Performance Curves

5

VS=5V

=1

A

V

=0pF

C

LOAD

3

1

-1

-3

MAGNITUDE (NORMALIZED) (dB)

-5

100K 100M

1M 10M

FREQUENCY (Hz)

150Ω

1kΩ

560Ω

FIGURE 13. FREQUENCY RESPONSE FOR VARIOUS R

400

350

300

250

200

150

100

OUTPUT IMPEDANCE (Ω)

50

0

10K 100M

100K 10M

1M

FREQUENCY (Hz)

25

15

5

-5

-15

VS=5V

A

MAGNITUDE (NORMALIZED) (dB)

L

FIGURE 14. FREQUENCY RESPONSE FOR VARIOUS C

)

P-P

MAXIMUM OUTPUT SWING (V

V

R

-25

100K 100M

12

10

8

6

4

VS=5V

A

V

2

R

DISTORTION <1%

0

10K 100M

1000pF

=1

=1kΩ

L

1M 10M

FREQUENCY (Hz)

=1

=1kΩ

L

100K 10M

FREQUENCY (Hz)

100pF

47pF

10pF

L

1M

FIGURE 15. CLOSED LOOP OUTPUT IMPEDANCE FIGURE 16. MAXIMUM OUTPUT SWING vs FREQUENCY

-15

-25

-35

-45

CMRR (dB)

-55

-65

1K 100M

10K

100K 10M

FREQUENCY (Hz)

1M

-80

-60

-40

PSRR (dB)

-20

0

100 10M

PSRR+ VS=5V

PSRR-

10K 1M100K1K

FREQUENCY (Hz)

T

A

=25°C

FIGURE 17. CMRR FIGURE 18. PSRR

8

FN7438.0

April 7, 2005

EL9200, EL9201, EL9202

Amplifier Typical Performance Curves

1K

100

10

VOLTAGE NOISE (nV/√Hz)

1

100 100M

10K 1M100K1K

FREQUENCY (Hz)

10M

-60

DUAL MEASURED CH A TO B

QUAD MEASURED CH A TO D OR B TO C

OTHER COMBINATIONS YIELD

-80

IMPROVED REJECTION

-100

-120

XTALK (dB)

VS=5V

-140

-160

=1kΩ

R

L

=1

A

V

=110mV

V

IN

1K 30M

RMS

100K 10M1M10K

FREQUENCY (Hz)

FIGURE 19. INPUT VOLTAGE NOISE SPECTRAL DENSITY FIGURE 20. CHANNEL SEPARATION

100

VS=5V

=1

A

V

=1kΩ

R

L

80

=50mV

V

IN

=25°C

T

A

60

40

OVERSHOOT (%)

20

STEP SIZE (V)

-1

-3

5

3

1

VS=5V

=1

A

V

=1kΩ

R

L

0.1%

0.1%

0

10 1K

LOAD CAPACITANCE (pF)

100

FIGURE 21. SMALL-SIGNAL OVERSHOOT vs LOAD

-5

55 105

75 9565

SETTLING TIME (ns)

85

FIGURE 22. SETTLING TIME vs STEP SIZE

CAPACITANCE

1V STEP

50ns/DIV

VS=±5V

T

=25°C

A

=1

A

V

=1kΩ

R

L

100mV STEP

50ns/DIV

VS=±5V

T

A

A

V

R

L

FIGURE 23. LARGE SIGNAL TRANSIENT RESPONSE FIGURE 24. SMALL SIGNAL TRANSIENT RESPONSE

=25°C

=1

=1kΩ

9

FN7438.0

April 7, 2005

EL9200, EL9201, EL9202

Amplifier Typical Performance Curves

JEDEC JESD51-7 HIGH EFFECTIVE THERMAL

CONDUCTIVITY TEST BOARD - QFN EXPOSED

DIEPAD SOLDERED TO PCB PER JESD51-5

4.5

4

3.378W

3.5

3

2.5

2

1.5

1

POWER DISSIPATION (W)

0.5

0

0 150

FIGURE 25. PACKAGE POWER DISSIPATION vs AMBIENT

TEMPERATURE

Q

F

θ

N

J

2

A

4

=

3

7

°

C

/

W

25 10050 12585

AMBIENT TEMPERATURE (°C)

75

JEDEC JESD51-3 LOW EFFECTIVE THERMAL

CONDUCTIVITY TEST BOARD

1.2

1

893mW

0.8

0.6

0.4

POWER DISSIPATION (W)

0.2

0

0 150

Q

F

θ

N

J

2

A

=

4

1

4

0

°

C

/

W

25 10050 12585

AMBIENT TEMPERATURE (°C)

75

FIGURE 26. PACKAGE POWER DISSIPATION vs AMBIENT

TEMPERATURE

Application Information

This device provides the ability to reduce the flicker of an

LCD panel by adjustment of the V

production test and alignment. A 128-step resolution is

provided under digital control which adjusts the sink current

of the output. The output is connected to an external voltage

divider, so that the device will have the capability to reduce

the voltage on the output by increasing the output sink

current.

The adjustment of the output and the programming of the

non-volatile memory are provided on one pin while the

counter enable (CE) is provided on a separate pin. The

output is adjusted via the CTL pin either by counting up with

a mid to low transition or by counting down with a mid to high

transition. Once the minimum or maximum value is reached

on the 128 steps, the device will not overflow or underflow

beyond that minimum or maximum value. An increment of

the counter will increase the output sink current which will

lower the voltage on the external voltage divider. A

decrement of the counter will decrease the output sink

current, which will raise the voltage on the external voltage

divider.

Once the desired output level is obtained, the part can store

it's setting using the non-volatile memory in the device. See

the non-volatile programming section for detailed

information.

NOTE: Once the desired output level is stored in the EEPROM, the

CE pin must go low to preserve the stored value.

voltage during

COM

Adjustable Sink Current Output

The device provides an output sink current which lowers the

voltage on the external voltage divider. The equations that

control the output are given below:

R

+

×=

2

2

---------------------------

20 R

A

VDD

()

SET

Setting

---------------------

V

1

AVDD

128

R

---------------------------

×–

20 R

()

1

SET

Setting

OUT

OUT

---------------------

128

---------------------

=

R1R

I

V

NOTE: Where setting is an integer between 1 and 128.

7-Bit Up/Down Counter

The counter sets the level to the digital potentiometer and is

connected to the non-volatile memory. When the part is

programmed, the counter setting is loaded into the nonvolatile memory. This value will be loaded from the nonvolatile memory into the counter during power-on. The

counter will not exceed its maximum level and will hold that

value during subsequent increment requests on the CTL pin.

The counter will not exceed its minimum level and will hold

that value during subsequent decrement requests on the

CTL pin.

CTL Pin

CTL should have a noise filter to reduce bouncing or noise

on the input that could cause unwanted counting when the

CE pin is high. The board should have an additional ESD

protection circuit, with a series 1kΩ resistor and a shunt

0.01µF capacitor connected on the CTL pin.

10

In order to increment the setting, pulse CTL low for more

than 200µs. The output sink current increases and lowers

the V

lever by one least-significant bit (LSB). On the

COM

other hand, to decrement the setting, pulse CTL high for

FN7438.0

April 7, 2005

EL9200, EL9201, EL9202

more than 200µs. The output sink current will decrease and

the V

level will increase by one LSB.

COM

To avoid unintentional adjustment, the EL9200, EL9201, and

EL9202 guarantees to reject CTL pulses shorter than 20µs.

Since the internal comparators come up in an unknown

state, the very first CTL pulse is ignored to avoid the

possibility of a false pulse.

See Figure 27 for the timing information.

TABLE 1. TRUTH TABLE

INPUT OUTPUT

CTL CE V

Mid to Hi Hi V

Mid to Lo Hi V

XLoV

> 4.9V X V

X X 0 to V

DD

DD

DD

DD

DD

DD

SET I

CC

Decrement Normal X

Increment Normal X

No Change Lower X

No Change Increased Program

Read Increased Read

MEMORY

NOTE: CE should be disabled (pulled low) before powering down the device to assure that the glitches and transients will not cause unwanted

EEPROM overwriting.

CTL

CTL HIGH

V

DD

CTL

MTC

/2

CTL

IHRPW

CE

COUNTER

OUTPUT

V

COM

CTL LOW

CTL

IHMPW

78 79 7A 7B 7AUNDEF

FIGURE 27. V

CTL

ADJUSTMENT

COM

ILMPW

CTL

ILRPW

11

FN7438.0

April 7, 2005

EL9200, EL9201, EL9202

Non-Volatile Memory (EEPROM)

Programming

When the CTL pin exceeds 4.9V, the non-volatile

programming cycle will be activated. The CTL signal needs

to remain above 4.9V for more than 200µs. The level and

timing needed to program the non-volatile memory is given

below. It then takes a maximum of 100ms for the

programming to be completed inside the device (see P

specification in Electrical Specification Table).

CTL VOLTAGE

4.9V

CTL

PT

FIGURE 28. EEPROM PROGRAMMING

Amplifiers’ Operating Voltage, Input, and Output

The amplifiers are specified with a single nominal supply

voltage from 5V to 15V or a split supply with its total range

from 5V to 15V. Correct operation is guaranteed for a supply

range of 4.5V to 16.5V. Most amplifier specifications are

stable over both the full supply range and operating

temperatures of -40°C to +85°C. Parameter variations with

operating voltage and/or temperature are shown in the

typical performance curves.

The input common-mode voltage range of the amplifiers

extends 500mV beyond the supply rails. The output swings

of the those typically extend to within 100mV of positive and

negative supply rails with load currents of 5mA. Decreasing

load currents will extend the output voltage range even

closer to the supply rails. Figure 27 shows the input and

output waveforms for the device in the unity-gain

configuration. Operation is from 5V supply with a 1kΩ load

connected to GND. The input is a 10V

output voltage is approximately 9.8V

5V

5V

10µs

sinusoid. The

P-P

.

P-P

AV=1

V

=5V

S

=25°C

T

A

=10V

V

IN

P-P

T

TIME

OUTPUT INPUT

Short-Circuit Current Limit

The amplifiers will limit the short circuit current to ±180mA if

the output is directly shorted to the positive or the negative

supply. If an output is shorted indefinitely, the power

dissipation could easily increase such that the device may

be damaged. Maximum reliability is maintained if the output

continuous current never exceeds ±65mA. This limit is set by

the design of the internal metal interconnects.

Output Phase Reversal

The amplifiers are immune to phase reversal as long as the

input voltage is limited from V

- -0.5V to VS+ +0.5V. Figure

S

28 shows a photo of the output of the device with the input

voltage driven beyond the supply rails. Although the device's

output will not change phase, the input's over-voltage should

be avoided. If an input voltage exceeds supply voltage by

more than 0.6V, electrostatic protection diodes placed in the

input stage of the device begin to conduct and over-voltage

damage could occur.

1V 10µs

VS=2.5V

=1

A

V

=25°C

T

A

=6V

1V

FIGURE 30. OPERATION WITH BEYOND-THE-RAILS INPUT

V

IN

P-P

Unused Amplifiers

It is recommended that any unused amplifiers in a dual and

a quad package be configured as a unity gain follower. The

inverting input should be directly connected to the output

and the non-inverting input tied to the ground plane.

Power Supply Bypassing and Printed Circuit

Board Layout

The amplifiers can provide gain at high frequency. As with

any high-frequency device, good printed circuit board layout

is necessary for optimum performance. Ground plane

construction is highly recommended, lead lengths should be

as short as possible and the power supply pins must be well

bypassed to reduce the risk of oscillation. For normal

operation a 0.1µF ceramic capacitor should be placed from

V

to pin to GND. A 4.7µF tantalum capacitor should then be

S

connected in parallel, placed in the region of the amplifier.

FIGURE 29. OPERATION WITH RAIL-TO-RAIL INPUT AND

OUTPUT

12

FN7438.0

April 7, 2005

EL9200, EL9201, EL9202

Replacing Existing Mechanical

Potentiometer Circuits

Figures 29 and 30 show the common adjustment

mechanical circuits and equivalent replacement with the

EL920X.

A

VDD

R

A

R

B

R

C

-

+

V

COM

R1R

=

R

2RBRC

R

SET

A

+=

RARBR

------------------------------------=

20R

+()

C

B

A

SET

VDD

R

SET

EL9200

IN-

V

R

OUT

IN+

OUT

A

R

VDD

G

R

1

V

COM

R

2

F

FIGURE 31. EXAMPLE OF THE REPLACEMENT FOR THE MECHANICAL POTENTIOMETER CIRCUIT USING EL9200

A

VDD

R

X

R

Y

R

Z

-

+

V

COM

R1R

=

=

R

2RZ

R

SET

X

RXRXRYR

++()

------------------------------------------------- -=

20R

Y

A

VDD

EL9200

SET

R

SET

Z

IN-

V

R

OUT

IN+

OUT

A

R

VDD

G

R

1

V

COM

R

2

F

FIGURE 32. EXAMPLE OF THE REPLACEMENT FOR THE MECHANICAL POTENTIOMETER CIRCUIT USING THE EL9200

13

FN7438.0

April 7, 2005

QFN Package Outline Drawing

EL9200, EL9201, EL9202

NOTE: The package drawing shown here may not be the latest version. To check the latest revision, please refer to the Intersil website at

http://www.intersil.com/design/packages/index.asp

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

14

FN7438.0

April 7, 2005

Loading...

Loading...