®

EL8108

Data Sheet June 14, 2007

Video Distribution Amplifier

The EL8108 is a dual current feedback

operational amplifier designed for

video distribution solutions. This

device features a high drive capability of 450mA while

consuming only 5mA of supply current per amplifier and

operating from a single 5V to 12V supply.

The EL8108 is available in the industry standard 8 Ld SOIC

as well as the thermally-enhanced 16 Ld QFN package. Both

are specified for operation over the full -40°C to +85°C

temperature range. The EL8108 has control pins C0 and C1

for controlling the bias and enable/disable of the outputs.

The EL8108 is ideal for driving multiple video loads while

maintaining linearity.

Ordering Information

PART

PART NUMBER

MARKING PACKAGE

EL8108IS 8108IS 8 Ld SOIC - MDP0027

EL8108IS-T7 8108IS 8 Ld SOIC 7” MDP0027

EL8108IS-T13 8108IS 8 Ld SOIC 13” MDP0027

EL8108ISZ

8108ISZ 8 Ld SOIC - MDP0027

(Note)

EL8108ISZ-T7

8108ISZ 8 Ld SOIC 7” MDP0027

(Note)

EL8108ISZ-T13

8108ISZ 8 Ld SOIC 13” MDP0027

(Note)

EL8108IL 8108IL 16 Ld 4x4 QFN - MDP0046

EL8108IL-T7 8108IL 16 Ld 4x4 QFN 7” MDP0046

EL8108IL-T13 8108IL 16 Ld 4x4 QFN 13” MDP0046

NOTE: Intersil Pb-free plus anneal products employ special Pb-free

material sets; molding compounds/die attach materials and 100%

matte tin plate termination finish, which are RoHS compliant and

compatible with both SnPb and Pb-free soldering operations. Intersil

Pb-free products are MSL classified at Pb-free peak reflow

temperatures that meet or exceed the Pb-free requirements of

IPC/JEDEC J STD-020.

TABLE 1.

150Ω 150Ω DIFF GAIN DIFF PHASE

1 0 0.03 0.01

1 1 0.03 0.01

2 1 0.05 0.02

2 2 0.06 0.03

3 2 0.08 0.03

3 3 0.11 0.03

2 0 0.04 0.01

3 0 0.05 0.02

4 0 0.07 0.02

5 0 0.08 0.03

6 0 0.10 0.03

TAPE &

REEL

PKG.

DWG. #

FN7417.1

Features

• Drives up to 450mA from a +12V supply

•20V

differential output drive into 100Ω

P-P

• -85dBc typical driver output distortion at full output at

150kHz

• -70dBc typical driver output distortion at 3.75MHz

• Low quiescent current of 5mA per amplifier

• 300MHz bandwidth

• Pb-free plus anneal available (RoHS compliant)

Applications

• Video distribution amplifiers

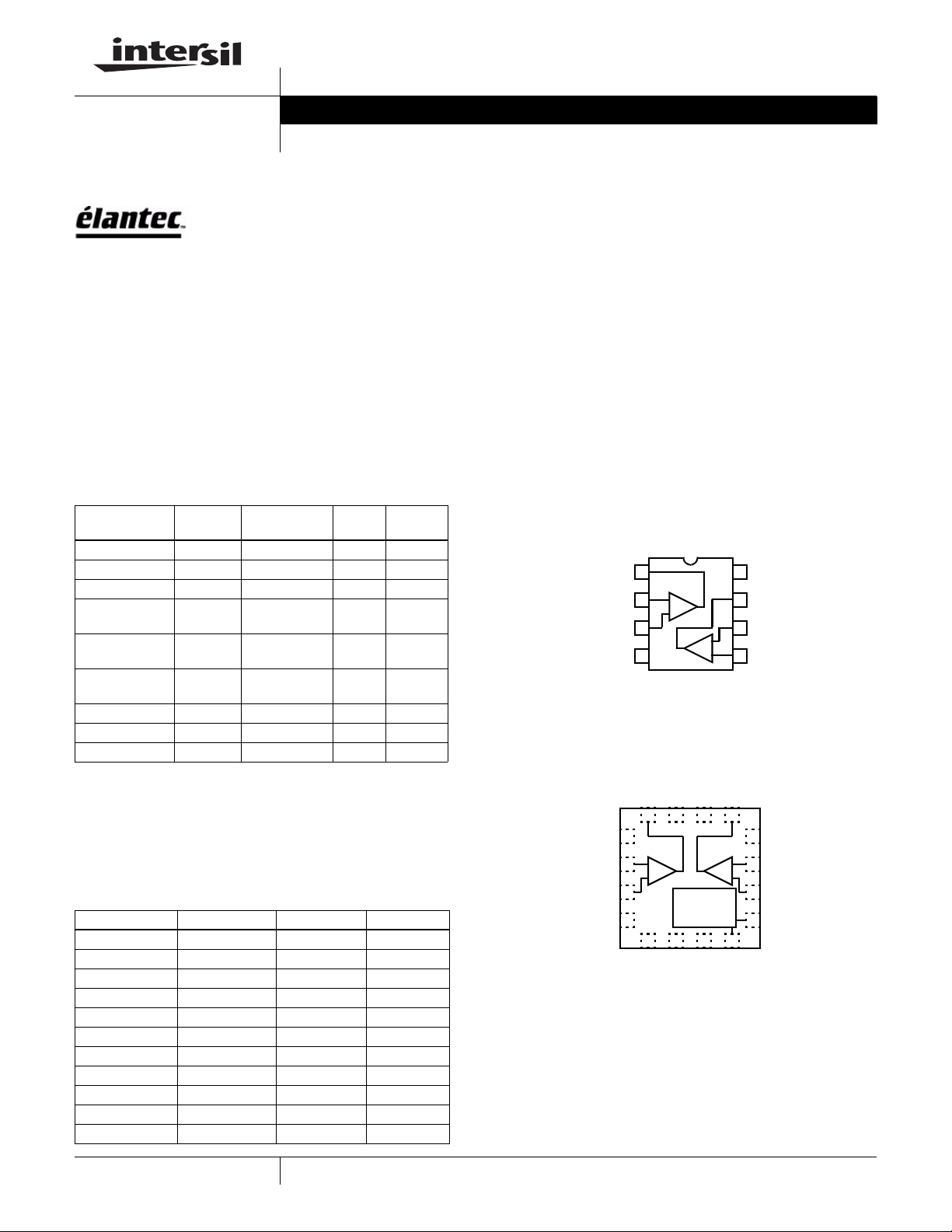

Pinouts

EL8108

(8 LD SOIC)

TOP VIEW

1

2

-

+

3

INA+

GND INB+

4

EL8108

(16 LD QFN)

TOP VIEW

OUTA

NC

16

15

1

NC

AMP A AMP B

2

INA-

INA+

GND

-

+

3

4

5

NC

POWER

CONTROL

LOGIC

6

NC

8

VSOUTA

7

OUTBINA-

INB-

6

-

+

5

VS+

OUTB

14

13

12

NC

INB-

11

-

+

INB+

10

C1

9

7

8

C0

VS-

1

Copyright © Intersil Americas Inc. 2004. All Rights Reserved. Elantec is a registered trademark of Elantec Semiconductor, Inc.

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

EL8108

Absolute Maximum Ratings (T

V

+ Voltage to Ground . . . . . . . . . . . . . . . . . . . . . . -0.3V to +13.2V

S

V

+ Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GND to VS+

IN

Current into any Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8mA

Continuous Output Current . . . . . . . . . . . . . . . . . . . . . . . . . . . 75mA

CAUTION: Do not operate at or near the maximum ratings listed for extended periods of time. Exposure to such conditions may adversely impact product reliability and

result in failures not covered by warranty.

IMPORTANT NOTE: All parameters having Min/Max specifications are guaranteed. Typical values are for information purposes only. Unless otherwise noted, all tests

are at the specified temperature and are pulsed tests, therefore: TJ = TC = T

Electrical Specifications V

= +25°C)

A

Ambient Operating Temperature Range . . . . . . . . . .-40°C to +85°C

Storage Temperature Range . . . . . . . . . . . . . . . . . .-60°C to +150°C

Operating Junction Temperature . . . . . . . . . . . . . . . . . . . . . .+150°C

Power Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Curves

A

= 12V, RF = 750Ω, RL = 100Ω connected to mid supply, T

S

= +25°C, unless otherwise specified.

A

PARAMETER DESCRIPTION CONDITIONS MIN TYP MAX UNIT

AC PERFORMANCE

BW -3dB Bandwidth R

= 500Ω, AV = +2 200 MHz

F

RF = 500Ω, AV = +4 150 MHz

HD Total Harmonic Distortion, Differential f = 200kHz, V

f = 4MHz, V

f = 8MHz, VO = 2V

f = 16MHz, V

SR Slew Rate, Single-ended V

from -3V to +3V 600 800 1100 V/µs

OUT

O

O

= 2V

O

= 16V

= 2V

, RL = 50Ω -72 -83 dBc

P-P

, RL = 100Ω -70 dBc

P-P

, RL = 100Ω -60 dBc

P-P

, RL = 100Ω -50 dBc

P-P

DC PERFORMANCE

V

ΔV

R

OS

OS

OL

Offset Voltage -25 +25 mV

VOS Mismatch -3 +3 mV

Transimpedance V

from -4.5V to +4.5V 0.7 1.4 2.5 MΩ

OUT

INPUT CHARACTERISTICS

I

+ Non-Inverting Input Bias Current -5 5 µA

B

I

- Inverting Input Bias Current -20 5 +20 µA

B

ΔIB-I

e

N

i

N

- Mismatch -18 0 +18 µA

B

Input Noise Voltage 6nV

Hz

√

-Input Noise Current 13 pA/√Hz

OUTPUT CHARACTERISTICS

V

I

OUT

OUT

Loaded Output Swing (single ended) VS = ±6V, RL = 100Ω to GND ±4.8 ±5 V

V

= ±6V, RL = 25Ω to GND ±4.7 V

S

Output Current RL = 0Ω 450 mA

SUPPLY

V

S

(EL8108IS only) Supply Current, Maximum Setting All outputs at mid supply 11 14.3 18 mA

I

S

Supply Voltage Single supply 4.5 13 V

SUPPLY (EL8108IL ONLY)

I

+ (full power) Positive Supply Current per Amplifier All outputs at 0V, C0 = C1 = 0V 11 14.3 18 mA

S

+ (medium power) Positive Supply Current per Amplifier All outputs at 0V, C0 = 5V, C1 = 0V 7 8.9 11 mA

I

S

I

+ (low power) Positive Supply Current per Amplifier All outputs at 0V, C0 = 0V, C1 = 5V 3.7 4.5 5.5 mA

S

I

+ (power down) Positive Supply Current per Amplifier All outputs at 0V, C0 = C1 = 5V 0.1 0.5 mA

S

I

I

INH

INL

, C0 or C

, C0 or C

1

1

C0, C1 Input Current, High C0, C1 = 5V 90 125 160 µA

C0, C1 Input Current, Low C0, C1 = 0V -5 +5 µA

2

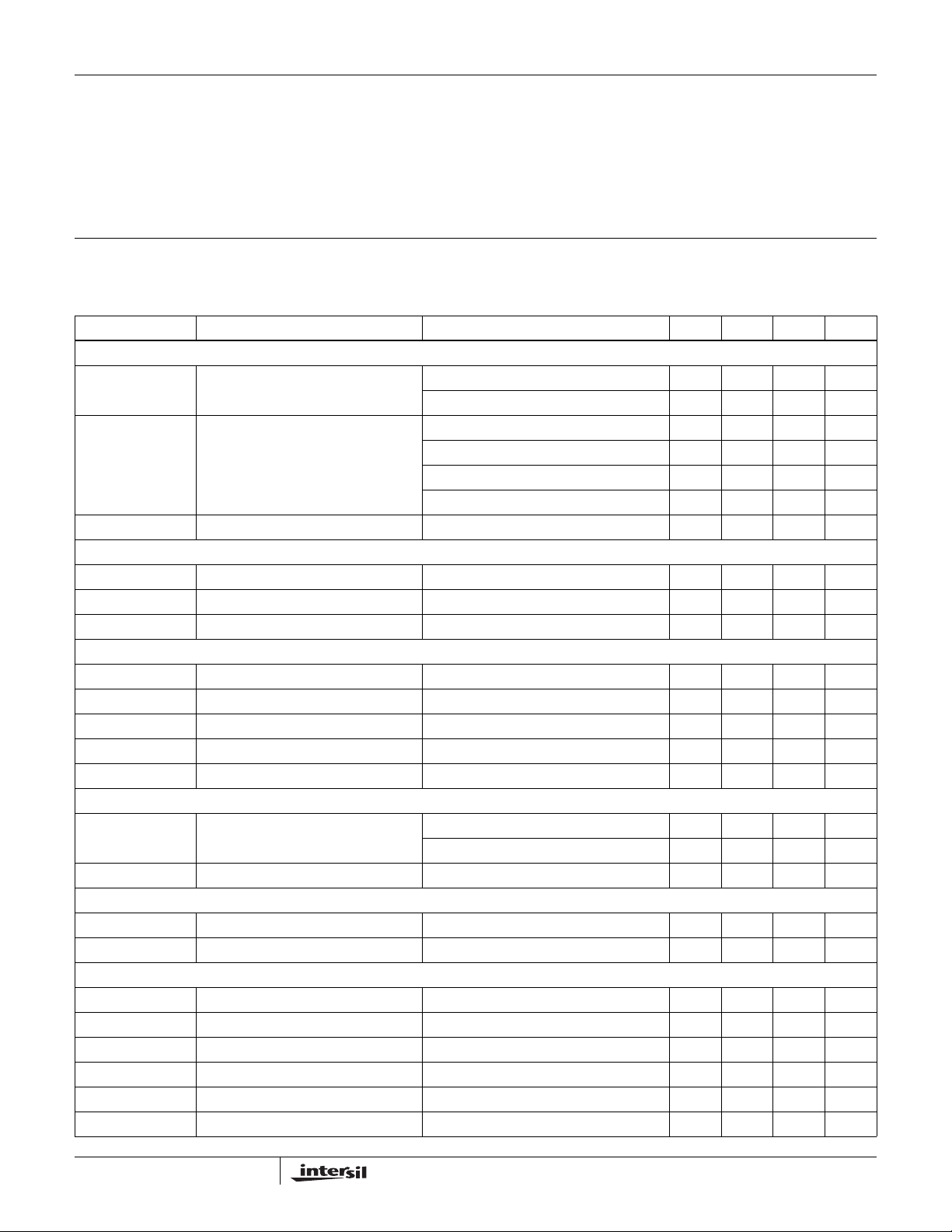

Typical Performance Curves

22

VS = ±6V, AV = 5

20

= 100Ω DIFF

R

L

18

16

14

12

10

GAIN (dB)

8

6

4

2

100K

1M

FREQUENCY (Hz)

RF = 500Ω

RF = 750Ω

RF = 1kΩ

10M 100M

FIGURE 1. DIFFERENTIAL FREQUENCY RESPONSE WITH

VARIOUS R

(FULL POWER MODE)

F

RF = 243Ω

500M

EL8108

22

VS = ±6V, AV = 5

20

= 100Ω DIFF

R

L

18

16

14

12

10

GAIN (dB)

8

6

4

2

100K

1M

RF = 500Ω

RF = 750Ω

RF = 1kΩ

10M 100M

FREQUENCY (Hz)

RF = 243Ω

500M

FIGURE 2. DIFFERENTIAL FREQUENCY RESPONSE WITH

VARIOUS RF (3/4 POWER MODE)

22

VS = ±6V, AV = 5

20

18

16

14

12

10

GAIN (dB)

8

6

4

2

100K

RL = 100Ω DIFF

RF = 500Ω

RF = 750Ω

1M

FREQUENCY (Hz)

RF = 243Ω

RF = 1kΩ

10M 100M

500M

FIGURE 3. DIFFERENTIAL FREQUENCY RESPONSE WITH

28

26

24

22

20

18

16

GAIN (dB)

14

12

10

8

100K

VARIOUS R

VS = ±6V, AV = 10

R

= 100Ω DIFF

L

(1/2 POWER MODE)

F

RF = 750Ω

1M

10M 100M

FREQUENCY (Hz)

RF = 243Ω

RF = 500Ω

RF = 1kΩ

500M

FIGURE 5. DIFFERENTIAL FREQUENCY RESPONSE WITH

VARIOUS R

(3/4 POWER MODE)

F

28

VS = ±6V, AV = 10

26

R

= 100Ω DIFF

L

24

22

20

18

16

GAIN (dB)

14

12

10

8

100K

1M

FREQUENCY (Hz)

RF = 243Ω

RF = 750Ω

RF = 1kΩ

10M 100M

RF = 500Ω

500M

FIGURE 4. DIFFERENTIAL FREQUENCY RESPONSE WITH

VARIOUS RF (FULL POWER MODE)

28

VS = ±6V, AV = 10

26

R

= 100Ω DIFF

L

24

22

20

18

16

GAIN (dB)

14

12

10

8

100K

RF = 243Ω

1M

FREQUENCY (Hz)

RF = 1kΩ

10M 100M

RF = 500Ω

RF = 750Ω

500M

FIGURE 6. DIFFERENTIAL FREQUENCY RESPONSE WITH

VARIOUS RF (1/2 POWER MODE)

3

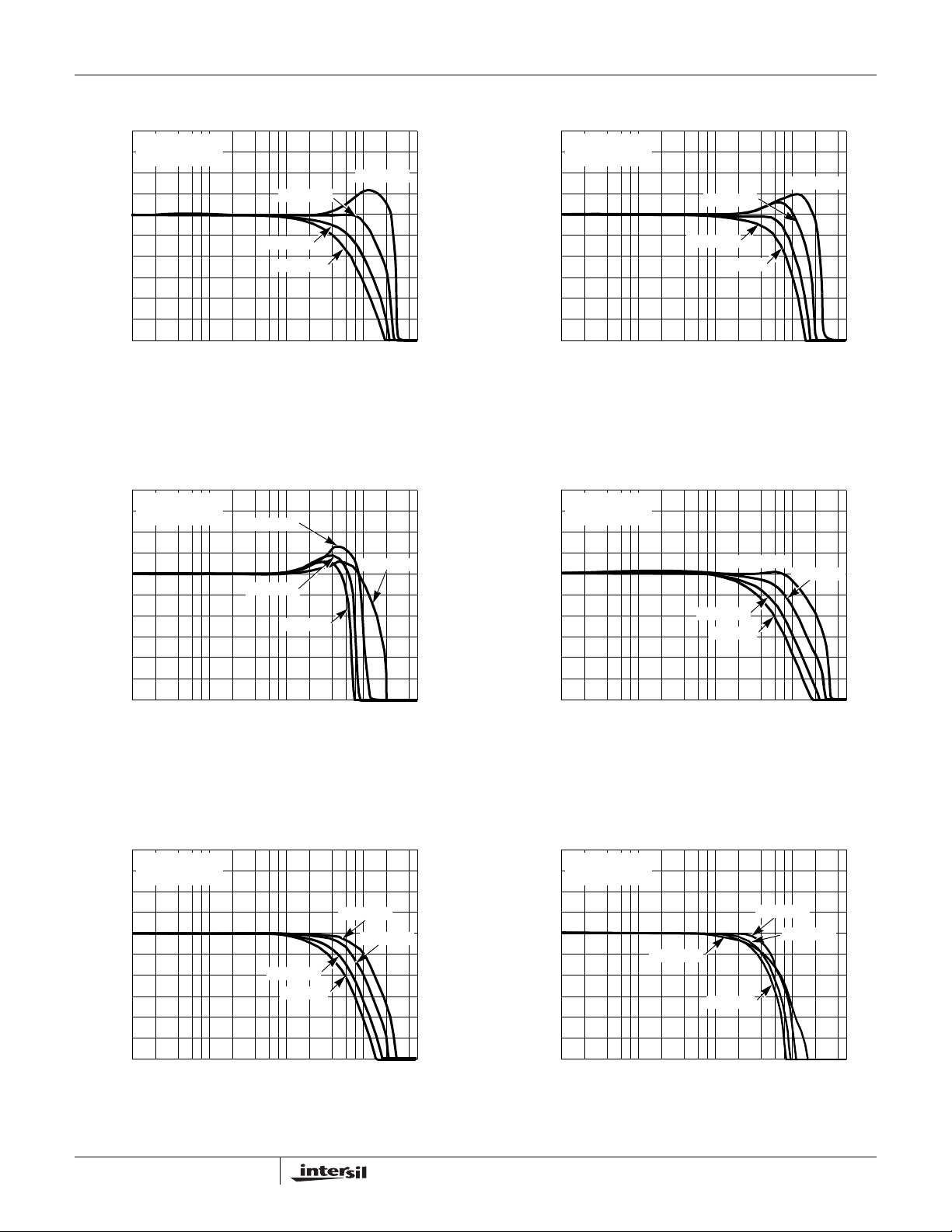

Typical Performance Curves (Continued)

EL8108

VS=±6V

14

A

=2

V

R

=100Ω DIFF

L

12

10

8

6

4

GAIN (dB)

2

0

-2

100K 1M 10M 100M 500M

FREQUENCY (Hz)

RF=248Ω

RF=500Ω

RF=1kΩ

RF=750Ω

FIGURE 7. DIFFERENTIAL FREQUENCY RESPONSE WITH

VARIOUS R

-50

VS=±6V

A

=5

V

-55

R

=50Ω DIFF

L

R

=750

F

-60

-65

-70

HD (dB)

-75

-80

-85

123456789

F

EL8108IL

EL8108IS

3rd HD

2nd HD

V

(V)

OP-P

FIGURE 9. DISTORTION BETWEEN EL8108IL vs EL8108IS

AT 2MHz

VS=±6V

8

A

=2

V

R

=500Ω

F

6

4

2

0

-2

-4

NORMALIZED GAIN (dB)

-6

-8

100K 1M 10M 100M 500M

FREQUENCY (Hz)

RL=25Ω

RL=50Ω

FIGURE 8. FREQUENCY RESPONSE FOR VARIOUS R

-50

VS=±6V

A

=5

V

-55

R

=50Ω DIFF

L

R

=750

F

-60

-65

HD (dB)

-70

-75

-80

123456789

3rd HD

V

OP-P

2nd HD

(V)

RL=150Ω

EL8108IL

EL8108IS

LOAD

FIGURE 10. DISTORTION BETWEEN EL8108IL vs EL8108IS

AT 3MHz

-40

VS=±6V

=5

A

V

-45

R

=50Ω DIFF

L

=750

R

F

-50

-55

-60

HD (dB)

-65

-70

-75

123456789

3rd HD

V

OP-P

(V)

2nd HD

EL8108IL

EL8108IS

FIGURE 11. DISTORTION BETWEEN EL8108IL vs EL8108IS

AT 5MHz

4

-40

VS=±6V

=5

A

V

R

=50Ω DIFF

L

-45

=750

R

F

-50

HD (dB)

-55

-60

-65

123456789

V

3rd HD

OP-P

(V)

2nd HD

EL8108IL

EL8108IS

FIGURE 12. DISTORTION BETWEEN EL8108IL vs EL8108IS

AT 10MHz

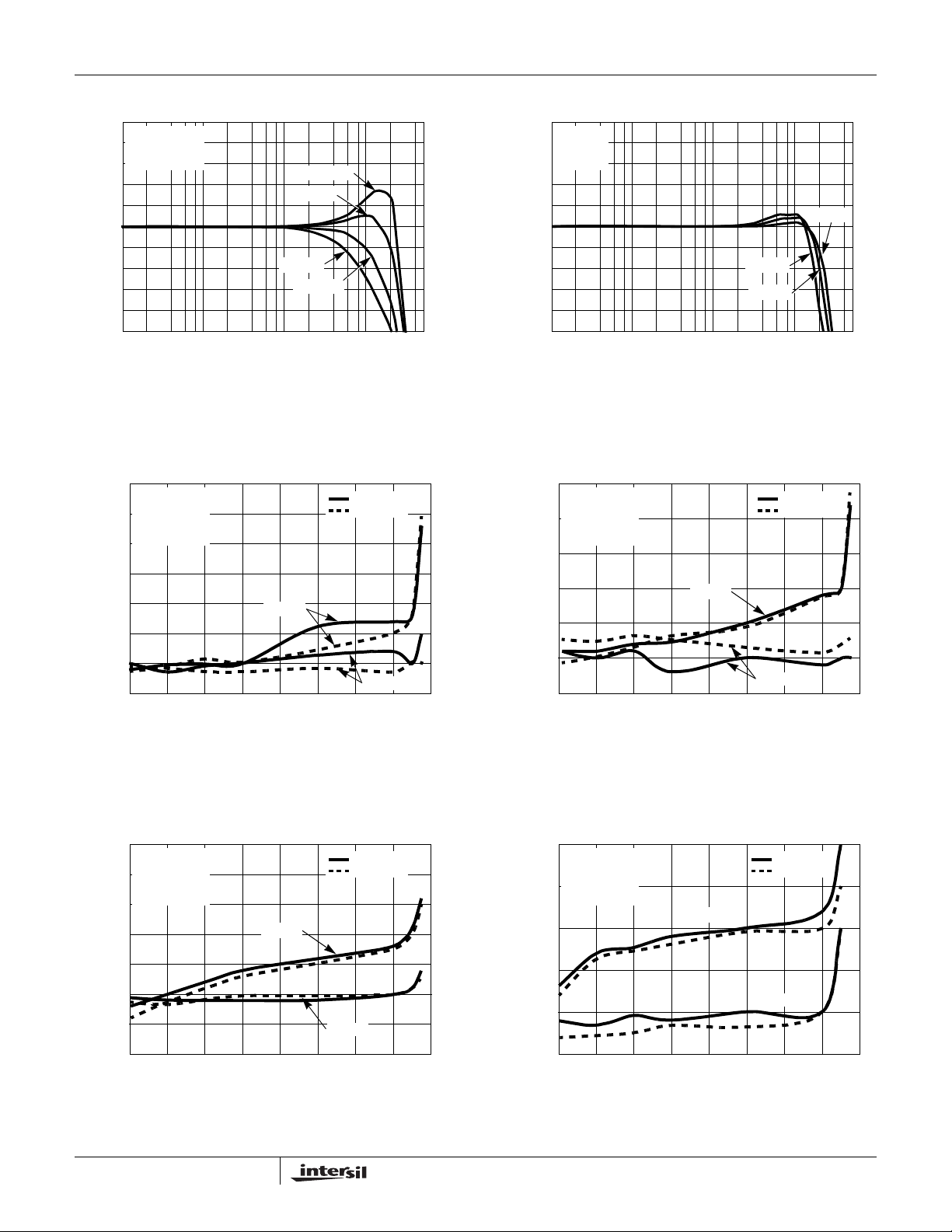

Typical Performance Curves (Continued)

-70

VS=±6V

=5

A

V

-75

=750

R

F

=4V

V

OPP

-80

-85

HD (dB)

-90

-95

3rd HD

2nd HD

EL8108

HD (dB)

-60

-65

-70

-75

-80

-85

VS=±6V

=5

A

V

=750

R

F

V

OPP

=4V

3rd HD

2nd HD

-100

50 60 70 80 90 100 110 120 150

R

LOAD

(Ω)

130 140

FIGURE 13. 2nd AND 3rd HARMONIC DISTORTION vs R

@ 2MHz (EL8108IL)

-50

VS=±6V

=5

A

V

-55

=750

R

F

=4V

V

-60

OPP

-65

-70

HD (dB)

-75

-80

-85

-90

50 60 70 80 90 100 110 120 150

2nd HD

R

LOAD

3rd HD

130 140

(Ω)

FIGURE 15. 2nd AND 3rd HARMONIC DISTORTION vs R

@ 5MHz (EL8108IL)

LOAD

LOAD

-90

50 60 70 80 90 100 110 120 150

FIGURE 14. 2nd AND 3rd HARMONIC DISTORTION vs R

R

LOAD

(Ω)

@ 3MHz (EL8108IL)

-40

-45

-50

-55

-60

HD (dB)

-65

-70

-75

-80

50 60 70 80 90 100 110 120 150

FIGURE 16. 2nd AND 3rd HARMONIC DISTORTION vs R

2nd HD

R

LOAD

3rd HD

(Ω)

@ 10MHz (EL8108IL)

130 140

VS=±6V

=5

A

V

=750

R

F

V

OPP

130 140

=4V

LOAD

LOAD

VS = ±6V, AV = 5

22

= 50Ω

R

L

R

= 750Ω

20

F

18

16

14

12

GAIN (dB)

10

8

6

0

100K

1M

FREQUENCY (Hz)

CL = 47pF

CL = 33pF

CL = 0pF

CL = 22pF

10M 100M

500M

FIGURE 17. FREQUENCY RESPONSE WITH VARIOUS C

5

24

VS = ±6V, AV = 5

22

= 50Ω

R

L

= 750Ω

R

20

F

18

16

14

12

GAIN (dB)

10

8

6

4

100K

L

FIGURE 18. FREQUENCY RESPONSE vs VARIOUS CL

1M

FREQUENCY (Hz)

(3/4 POWER MODE)

CL = 47pF

CL = 39pF

CL = 12pF

CL = 0pF

10M 100M

500M

Typical Performance Curves (Continued)

24

VS = ±6V, AV = 5

22

R

= 50Ω

L

= 750Ω

R

20

F

18

16

14

12

GAIN (dB)

10

8

6

4

100K

1M

FREQUENCY (Hz)

CL = 12pF

CL = 0pF

10M 100M

FIGURE 19. FREQUENCY RESPONSE WITH VARIOUS CL

(1/2 POWER MODE)

CL = 47pF

CL = 37pF

500M

EL8108

-10

-30

-50

A B

B A

1M 10M

FREQUENCY (Hz)

CHANNEL SEPARATION (dB)

-70

-90

-110

10K

100K

FIGURE 20. CHANNEL SEPARATION vs FREQUENCY

100M

-10

-30

-50

-70

PSRR (dB)

-90

-110

100K 1M 10M 10M 100M

FREQUENCY (Hz)

PSRR+

FIGURE 21. PSRR vs FREQUENCY FIGURE 22. TRANSIMPEDANCE (R

1000

100

EN

IN-

IN+

FREQUENCY (Hz)

0.01

0.001

0.0001

VOLTAGE/CURRENT NOISE (nV/√Hz)(nA/√Hz)

0.1

10

1

10010

1K 10K 100K 1M 10M

PSRR-

200M

10M

3M

300K

100K

30K

10K

MAGNITUDE (Ω)

3K

1K

-110

1K 10K 100K 1M 10M

VS = ±6V, AV = 1

R

= 750Ω

F

10

1

OUTPUT IMPEDANCE (Ω)

0.1

10K

FREQUENCY (Hz)

100K

FREQUENCY (Hz)

GAIN

1M 10M

PHASE

) vs FREQUENCY

OL

100M

100M

FIGURE 23. VOLTAGE AND CURRENT NOISE vs FREQUENCY FIGURE 24. OUTPUT IMPEDANCE vs FREQUENCY

200

150

100

50

0

-50

-100

-150

-200

PHASE (°)

6

Typical Performance Curves (Continued)

EL8108

150

130

120

110

100

90

BW (MHz)

80

70

60

50

3

AV = 5, RF = 750Ω,

= 100Ω DIFF

R

LOAD

FULL POWER MODE

3/4 POWER MODE

3.5

4

1/2 POWER MODE

4.5

±VS (V)

5

5.5

6

0.4

VS=±6V

0.35

0.3

0.25

0.2

0.15

0.1

DIFFERENTIAL GAIN (%)

0.05

FULL POWER MODE

0

1234

1/2 POWER MODE

3/4 POWER MODE

# OF 150Ω LOADS

FIGURE 25. DIFFERENTIAL BANDWIDTH vs SUPPLY VOL TAGE FIGURE 26. DIFFERENTIAL GAIN

0.09

VS=±6V

0.08

0.07

0.06

0.05

0.04

0.03

DIFFERENTIAL PHASE (%)

1/2 POWER MODE

0.02

0.01

1234

FULL POWER MODE

3/4 POWER MODE

# OF 150Ω LOADS

16

14

12

10

8

(mA)

S

I

6

4

2

0

1246

FULL POWER MODE

3/4 POWER MODE

35

(V)

±V

S

1/2 POWER MODE

FIGURE 27. DIFFERENTIAL PHASE FIGURE 28. SUPPLY CURRENT vs SUPPLY VOLTAGE

+IS

-IS

1

0

IB+

-1

-2

-3

INPUT BIAS CURRENT (µA)

-4

-5

0 25 50 75 100 125 150

TEMPERATURE (°C)

IB-

1.8K

1.7K

1.6K

1.5K

1.4K

SLEW RATE (V/µs)

1.3K

1.2K

-50 -25 0

25 50 75 100 125 150

TEMPERATURE (°C)

FIGURE 29. INPUT BIAS CURRENT vs TEMPERATURE FIGURE 30. SLEW RATE vs TEMPERATURE

7

Typical Performance Curves (Continued)

EL8108

5

4

3

2

1

OFFSET VOLTAGE (mV)

0

-1

-50 -25 0

25 50 75 100 125 150

TEMPERATURE (°C)

3

2.5

2

1.5

1

TRANSIMPEDANCE (MΩ)

0.5

0

-50 -25 0

25 50 75 100 125 150

TEMPERATURE (°C)

FIGURE 31. OFFSET VOLTAGE vs TEMPERATURE FIGURE 32. TRANSIMPEDANCE vs TEMPERATURE

5.1

5.05

5

4.95

4.9

4.85

OUTPUT VOLTAGE (±V)

4.8

4.75

-50 -25 0

R

LOAD

VS=±6V

=100Ω

25 50 75 100 125 150

TEMPERATURE (°C)

16

15.5

15

14.5

14

13.5

13

SUPPLY CURRENT (mA)

12.5

12

-50 -25 0

25 50 75 100 125 150

TEMPERATURE (°C)

FIGURE 33. OUTPUT VOLTAGE vs TEMPERATURE FIGURE 34. SUPPLY CURRENT vs TEMPERATURE

3

AV=5

=750Ω

R

F

=100Ω DIFF

R

L

2

1

PEAKING (dB)

0

-1

2.5 3 3.5 4 4.5 5 5.5 6

(±V)

V

S

FIGURE 35. DIFFERENTIAL PEAKING vs SUPPLY VOLTAGE

8

Typical Performance Curves (Continued)

JEDEC JESD51-7 HIGH EFFECTIVE THERMAL

CONDUCTIVITY (4-LAYER) TEST BOARD

3.5

EL8108

JEDEC JESD51-3 LOW EFFECTIVE THERMAL

CONDUCTIVITY TEST BOARD

1.4

3

2.5

2

1.5

1.136W

S

O

1

POWER DISSIPATION (W)

0.5

0

0 15050 100

AMBIENT TEMPERATURE (°C)

8

1

1

0

°

C/

W

12525 75 85

FIGURE 36. PACKAGE POWER DISSIP A TION vs AMBIENT

TEMPERATURE

JEDEC JESD51-7 HIGH EFFECTIVE THERMAL

CONDUCTIVITY TEST BOARD - LPP EXPOSED

DIEPAD SOLDERED TO PCB PER JESD51-5

4.5

4

3.125W

3.5

3

2.5

2

1.5

1

POWER DISSIPATION (W)

0.5

0

0 255075100 150

AMBIENT TEMPERATURE (°C)

QFN16

θJA=40°C/W

12585

FIGURE 38. PACKAGE POWER DISSIP A TION vs AMBIENT

TEMPERATURE

1.2

1

781mW

POWER DISSIPATION (W)

0.8

0.6

0.4

0.2

0

0

25 50 75 100 15012585

S

O

8

θ

J

A

=

1

6

0

°

C

/

W

AMBIENT TEMPERATURE (°C)

FIGURE 37. PACKAGE POWER DISSIP A TION vs AMBIENT

TEMPERATURE

JEDEC JESD51-3 LOW EFFECTIVE THERMAL

CONDUCTIVITY TEST BOARD

1.2

1

833mW

0.8

0.6

0.4

POWER DISSIPATION (W)

0.2

0

0255075100 150

AMBIENT TEMPERATURE (°C)

QFN16

θJA=150°C/W

12585

FIGURE 39. PACKAGE POWER DISSIP A TION vs AMBIENT

TEMPERATURE

Applications Information

Product Description

The EL8108 is a dual current feedback operational amplifier

designed for video distribution solutions. It is a dual current

mode feedback amplifier with low distortion while drawing

moderately low supply current. It is built using Intersil’s

proprietary complimentary bipolar process and is offered in

industry standard pinouts. Due to the current feedback

architecture, the EL8108 closed-loop 3dB bandwidth is

dependent on the value of the feedback resistor. First the

desired bandwidth is selected by choosing the feedback

resistor, R

resistor, R

Performance Curves section show the effect of varying both

R

and RG. The 3dB bandwidth is somewhat dependent on

F

the power supply voltage.

, and then the gain is set by picking the gain

F

. The curves at the beginning of the Typical

G

9

Power Supply Bypassing and Printed Circuit

Board Layout

As with any high frequency device, good printed circuit

board layout is necessary for optimum performance. Ground

plane construction is highly recommended. Lead lengths

should be as short as possible, below ¼”. The power supply

pins must be well bypassed to reduce the risk of oscillation.

A 4.7µF tantalum capacitor in parallel with a 0.1µF ceramic

capacitor is adequate for each supply pin.

For good AC performance, parasitic capacitances should be

kept to a minimum, especially at the inverting input. This

implies keeping the ground plane away from this pin. Carbon

resistors are acceptable, while use of wire-wound resistors

should not be used because of their parasitic inductance.

Similarly, capacitors should be low inductance for best

performance.

EL8108

Capacitance at the Inverting Input

Due to the topology of the current feedback amplifier, stray

capacitance at the inverting input will affect the AC and

transient performance of the EL8108 when operating in the

non-inverting configuration.

In the inverting gain mode, added capacitance at the

inverting input has little effect since this point is at a virtual

ground and stray capacitance is therefore not “seen” by the

amplifier.

Feedback Resistor Values

The EL8108 has been designed and specified with

R

= 500Ω for AV = +2. This value of feedback resistor yields

F

extremely flat frequency response with little to no peaking

out to 200MHz. As is the case with all current feedback

amplifiers, wider bandwidth, at the expense of slight

peaking, can be obtained by reducing the value of the

feedback resistor. Inversely, larger values of feedback

resistor will cause rolloff to occur at a lower frequency. See

the curves in the Typical Performance Curves section which

show 3dB bandwidth and peaking vs. frequency for various

feedback resistors and various supply voltages.

Bandwidth vs Temperature

Whereas many amplifier's supply current and consequently

3dB bandwidth drop off at high temperature, the EL8108 was

designed to have little supply current variations with

temperature. An immediate benefit from this is that the 3dB

bandwidth does not drop off drastically with temperature.

Supply Voltage Range

The EL8108 has been designed to operate with supply

voltages from ±2.5V to ±6V. Optimum bandwidth, slew rate,

and video characteristics are obtained at higher supply

voltages. However, at ±2.5V supplies, the 3dB bandwidth at

A

= +5 is a respectable 200MHz.

V

Single Supply Operation

If a single supply is desired, values from +5V to +12V can be

used as long as the input common mode range is not

exceeded. When using a single supply, be sure to either 1)

DC bias the inputs at an appropriate common mode voltage

and AC couple the signal, or 2) ensure the driving signal is

within the common mode range of the EL8108.

Driving Cables and Capacitive Loads

The EL8108 was designed with driving multiple coaxial

cables in mind. With 450mA of output drive and low output

impedance, driving six, 75

cables to ±11V with one EL8108 is practical.

When used as a cable driver, double termination is always

recommended for reflection-free performance. For those

applications, the back termination series resistor will

decouple the EL8108 from the capacitive cable and allow

extensive capacitive drive.

Other applications may have high capacitive loads without

termination resistors. In these applications, an additional

small value (5Ω-50Ω) resistor in series with the output will

Ω double terminated coaxial

+5V

EL8108

-5V

750

750

10

Small Outline Package Family (SO)

A

D

NN

(N/2)+1

EL8108

h X 45°

PIN #1

E

C

SEATING

PLANE

0.004 C

E1

B

0.010 BM CA

I.D. MARK

1

e

0.010 BM CA

(N/2)

c

SEE DETAIL “X”

L1

H

A2

GAUGE

PLANE

A1

b

DETAIL X

L

4° ±4°

MDP0027

SMALL OUTLINE PACKAGE FAMILY (SO)

SYMBOL SO-8 SO-14

(0.150”)

A 0.068 0.068 0.068 0.104 0.104 0.104 0.104 MAX -

A1 0.006 0.006 0.006 0.007 0.007 0.007 0.007 ±0.003 A2 0.057 0.057 0.057 0.092 0.092 0.092 0.092 ±0.002 -

b 0.017 0.017 0.017 0.017 0.017 0.017 0.017 ±0.003 -

c 0.009 0.009 0.009 0.011 0.011 0.011 0.011 ±0.001 D 0.193 0.341 0.390 0.406 0.504 0.606 0.704 ±0.004 1, 3

E 0.236 0.236 0.236 0.406 0.406 0.406 0.406 ±0.008 -

E1 0.154 0.154 0.154 0.295 0.295 0.295 0.295 ±0.004 2, 3

e 0.050 0.050 0.050 0.050 0.050 0.050 0.050 Basic -

L 0.025 0.025 0.025 0.030 0.030 0.030 0.030 ±0.009 -

L1 0.041 0.041 0.041 0.056 0.056 0.056 0.056 Basic -

h 0.013 0.013 0.013 0.020 0.020 0.020 0.020 Reference -

N 8 14 16 16 20 24 28 Reference -

NOTES:

1. Plastic or metal protrusions of 0.006” maximum per side are not included.

2. Plastic interlead protrusions of 0.010” maximum per side are not included.

3. Dimensions “D” and “E1” are measured at Datum Plane “H”.

4. Dimensioning and tolerancing per ASME Y14.5M-1994

SO16

SO16 (0.300”)

(SOL-16)

SO20

(SOL-20)

SO24

(SOL-24)

SO28

(SOL-28) TOLERANCE NOTES

A

0.010

Rev. L 2/01

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implicat ion or oth erwise u nde r any p a tent or p at ent r ights of Intersil or its subsidiari es.

For information regarding Intersil Corporation and its products, see www.intersil.com

11

EL8108

QFN (Quad Flat No-Lead) Package Family

A

1

2

3

2X

0.075 C

L

(E2)

C

SEATING

PLANE

0.08 C

N LEADS

& EXPOSED PAD

A

C

N

(N-2)

(N-1)

PIN #1

I.D. MARK

TOP VIEW

0.10 BAMC

b

N LEADS

(N/2)

(D2)

BOTTOM VIEW

e

SIDE VIEW

(c)

A1

DETAIL X

D

(N/2)

(N-2)

(N-1)

N

0.10

SEE DETAI L "X"

2

(L)

N LEADS

0.075

PIN #1 I.D.

1

2

3

NE

7

C

2X

B

E

C

3

5

MDP0046

QFN (QUAD FLAT NO-LEAD) PACKAGE FAMILY

(COMPLIANT TO JEDEC MO-220)

MILLIMETERS

SYMBOL

A 0.90 0.90 0.90 0.90 ±0.10 -

A1 0.02 0.02 0.02 0.02 +0.03/-0.02 -

b 0.25 0.25 0.23 0.22 ±0.02 c 0.20 0.20 0.20 0.20 Reference D 7.00 5.00 8.00 5.00 Basic -

D2 5.10 3.80 5.80 3.60/2.48 Reference 8

E 7.00 7.00 8.00 6.00 Basic -

E2 5.10 5.80 5.80 4.60/3.40 Reference 8

e 0.50 0.50 0.80 0.50 Basic L 0.55 0.40 0.53 0.50 ±0.05 -

N 44 38 32 32 Reference 4

ND 11 7 8 7 Reference 6

NE 11 12 8 9 Reference 5

MILLIMETERS

SYMBOL

A 0.90 0.90 0.90 0.90 0.90 ±0.10 A1 0.02 0.02 0.02 0.02 0.02 +0.03/

b 0.25 0.25 0.30 0.25 0.33 ±0.02 -

c 0.20 0.20 0.20 0.20 0.20 Reference -

D 4.00 4.00 5.00 4.00 4.00 Basic D2 2.65 2.80 3.70 2.70 2.40 Reference -

E 5.00 5.00 5.00 4.00 4.00 Basic E2 3.65 3.80 3.70 2.70 2.40 Reference -

e 0.50 0.50 0.65 0.50 0.65 Basic -

L 0.40 0.40 0.40 0.40 0.60 ±0.05 -

N 28 24 20 20 16 Reference 4

ND 6 5 5 5 4 Reference 6

NE 8 7 5 5 4 Reference 5

NOTES:

1. Dimensioning and tolerancing per ASME Y14.5M-1994.

2. Tiebar view shown is a non-functional feature.

3. Bottom-side pin #1 I.D. is a diepad chamfer as shown.

4. N is the total number of terminals on the device.

5. NE is the number of terminals on the “E” side of the package

(or Y-direction).

6. ND is the number of terminals on the “D” side of the package

(or X-direction). ND = (N/2)-NE.

7. Inward end of terminal may be square or circular in shape with radius

(b/2) as shown.

8. If two values are listed, multiple exposed pad options are available.

Refer to device-specific datasheet.

TOLERANCE NOTESQFN44 QFN38 QFN32

TOLER-

ANCE NOTESQFN28 QFN24 QFN20 QFN16

-0.02

Rev 11 2/07

-

12

Loading...

Loading...