Page 1

®

www.BDTIC.com/Intersil

EL7630

Data Sheet February 22, 2006

White LED Boost Regulator

The EL7630 represents a high efficiency, constant frequency

PWM regulator for use in white LED driving applications.

With efficiencies up to 86%, the EL7630 operates at 1.35MHz

switching frequency while operating from an input voltage of

between 2.7V and 5.5V. The maximum output voltage of 27V

enables the EL7630 to drive up to 6 LEDs in series. It is also

possible to use the EL7630 to drive LEDs in series/parallel

combination for applications requiring up to 15 LEDs.

Available in the 6 Ld SC-70 and the 5 Ld TSOT packages, the

EL7630 features the same pinout as competitive products

but offers higher efficiency, constant frequency operation. It

is specified for operation over the -40°C to +85°C ambient

temperature range.

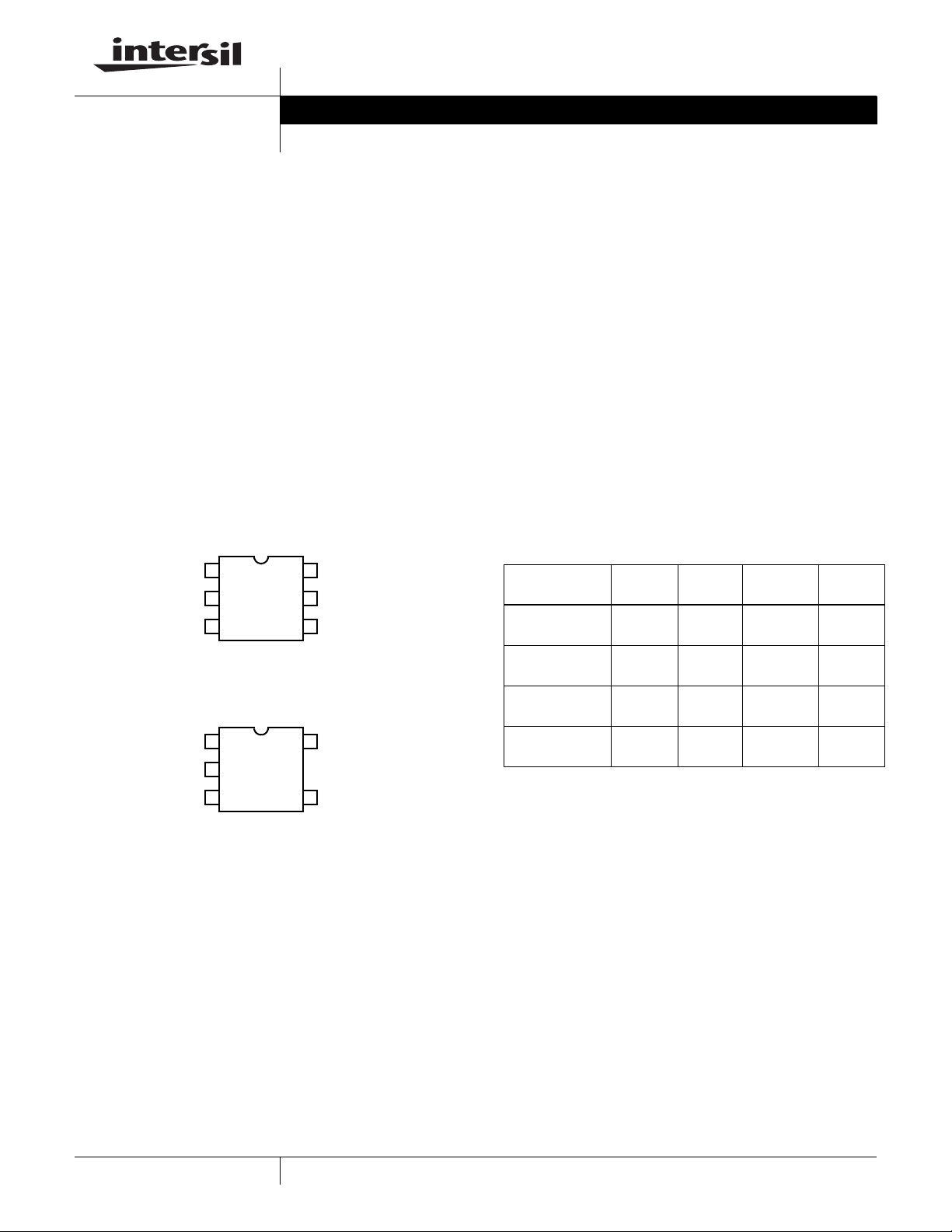

Pinouts

EL7630

(6 LD SC-70)

TOP VIEW

LX

GND

FB

LX

GND

FB

1

2

3

EL7630

(5 LD TSOT)

TOP VIEW

1

2

3

6

VIN

5PGND

ENAB

4

5

VIN

ENAB

4

FN7371.1

Features

• Up to 6 LEDs in series

• 27V maximum output

• 2.7V to 5.5V input

• Up to 86% efficient

• 1.35MHz constant frequency

• Enable/PWM dimming control

• Pb-free plus anneal available (RoHS compliant)

Applications

• LED backlighting

• Cell phones

•PDAs

• Handheld devices

Ordering Information

PART NUMBER

(See Note)

EL7630ICZ-T7 BCA 7”

EL7630ICZ-T7A BCA 7”

EL7630IWTZ-T7 BAAC 7”

EL7630IWTZ-T7A BAAC 7”

NOTE: Intersil Pb-free plus anneal products employ special Pb-free

material sets; molding compounds/die attach materials and 100%

matte tin plate termination finish, which are RoHS compliant and

compatible with both SnPb and Pb-free soldering operations. Intersil

Pb-free products are MSL classified at Pb-free peak reflow

temperatures that meet or exceed the Pb-free requirements of

IPC/JEDEC J STD-020.

PART

MARKING

TAPE &

REEL

(3K pcs)

(250 pcs)

(3K pcs)

(250 pcs)

PACKAGE

(Pb-free)

6 Ld SC-70 P6.049

6 Ld SC-70 P6.049

5 Ld TSOT MDP0049

5 Ld TSOT MDP0049

PKG.

DWG. #

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright Intersil Americas Inc. 2006. All Rights Reserved

Page 2

EL7630

www.BDTIC.com/Intersil

Absolute Maximum Ratings (T

Input Voltage (V

LX Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to +27V

FB Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to +6V

ENAB Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to +6V

PGND to GND (SC-70 package) . . . . . . . . . . . . . . . . -0.3V to +0.3V

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

IMPORTANT NOTE: All parameters having Min/Max specifications are guaranteed. Typ values are for information purposes only. Unless otherwise noted, all tests are at the

specified temperature and are pulsed tests, therefore: T

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to +6V

IN

Electrical Specifications V

PARAMETER DESCRIPTION CONDITION MIN TYP MAX UNIT

V

IN-MIN

V

IN-MAX

V

I

I

F

OSC

D

MAX

I

LIM

r

DS(ON)

I

LEAK

V

ENAB-HI

V

ENAB-LO

I

ENAB

∆I

LED

FB

FB

IN

/∆V

Minimum Operating Voltage V

Maximum Operating Voltage V

Feedback Voltage TA = 25°C 86 95 104 mV

FB Pin Bias Current 100 nA

Supply Current ENAB = 3V, output not switching 0.6 1.0 mA

Switching Frequency TA = 25°C 0.8 1.35 1.8 MHz

Maximum Duty Cycle TA = 25°C 85 90 %

Switch Current Limit TA = 25°C 280 350 mA

Switch On Resistance ILX = 100mA 750 mΩ

Switch Leakage Current VLX = 27V 0.01 1 µA

ENAB Voltage High 2.5 V

ENAB Voltage Low 0.6 V

ENAB Pin Bias Current 1µA

Line Regulation VIN = 2.7V to 5V 0.2 %/V

IN

A

= 3V, V

IN

= 25°C)

ENAB

Operating Temperature . . . . . . . . . . . . . . . . . . . . . . .-40°C to +85°C

Maximum Junction Temperature . . . . . . . . . . . . . . . . . . . . . . +125°C

Storage Temperature. . . . . . . . . . . . . . . . . . . . . . . . -65°C to +150°C

Lead Temperature (soldering, 10s) . . . . . . . . . . . . . . . . . . . . +300°C

= TC = T

J

A

= 3V, over temperature from -40°C to 85°C unless otherwise specified.

= 16V, I

OUT

= 25V, I

OUT

ENAB = 0V 1 µA

= 20mA 2.7 V

LED

= 20mA 5.5 V

LED

80 95 115 mV

0.8 1.35 1.9 MHz

82 90 %

250 350 mA

2

FN7371.1

February 22, 2006

Page 3

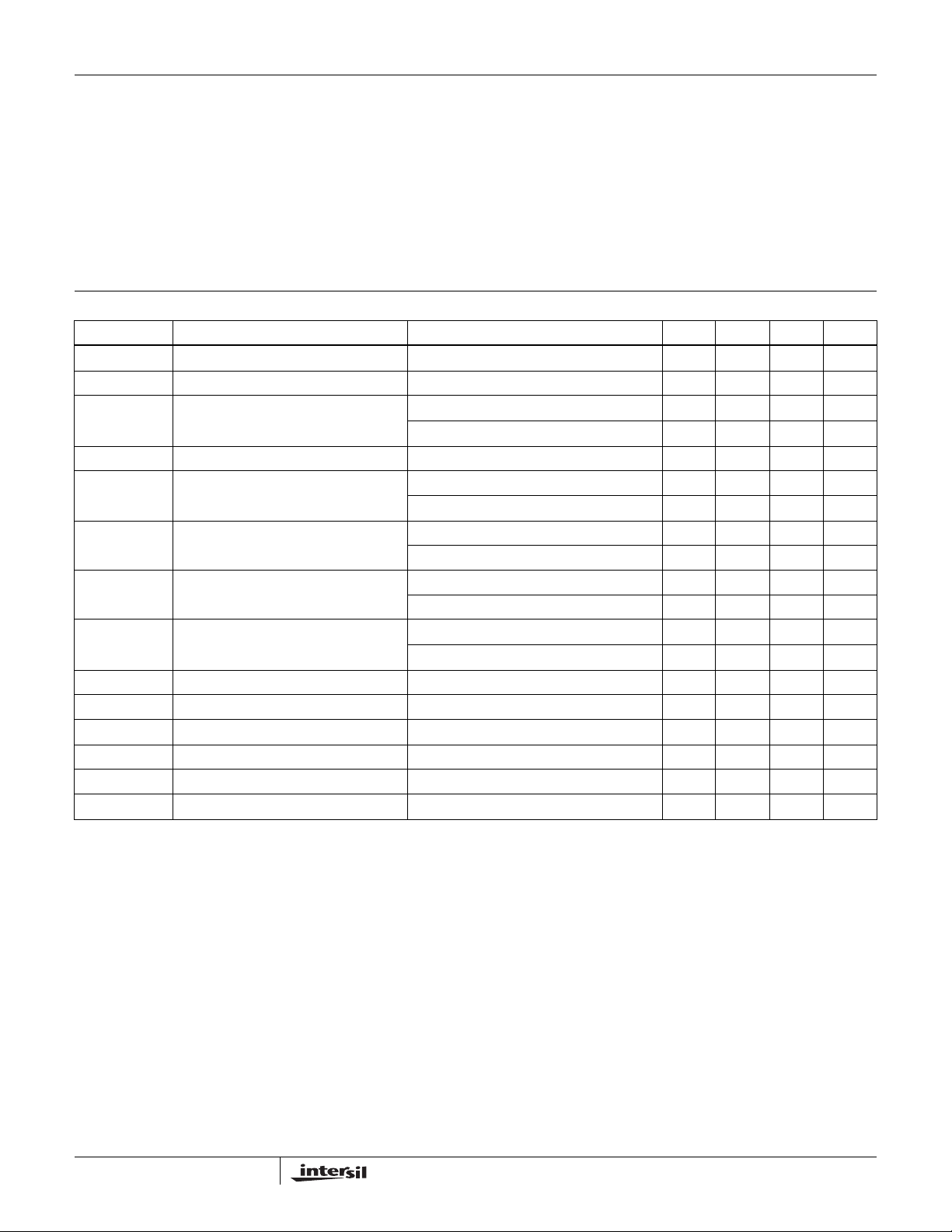

Typical Application

www.BDTIC.com/Intersil

EL7630

L1

22µH

V

IN

2.7V~5.5V

C1

1µF

OFF/ON

VDD

LX

EL7630

ENAB FB

GND

D1

R

SET

4.75Ω

FIGURE 1. TYPICAL APPLICATION CIRCUIT AND EFFICIENCY vs LED CURRENT

Typical Performance Curves

0.7

0.6

0.5

0.4

0.3

0.2

0.1

QUIESCENT CURRENT (mA)

0

0123456

V

(V)

IN

LEDs

C2

0.22µF

90

85

80

75

EFFICIENCY (%)

70

65

0 5 10 15 20 25 30

LED CURRENT (mA)

24.6

24.595

24.59

24.585

24.58

24.575

24.57

LED CURRENT (mA)

24.565

24.56

0 5 10 15 20

V

(V)

OUT

FIGURE 2. QUIESCENT CURRENT (ENABLE)

24.7

24.68

24.66

24.64

24.62

24.6

LED CURRENT (mA)

24.58

24.56

2.5 3 3.5 4 4.5 5 5.5

(V)

V

IN

FIGURE 4. LINE REGULATION FIGURE 5. SWITCHING FREQUENCY vs TEMPERATURE

3

FIGURE 3. LOAD REGULATION (V

1.34

1.32

1.3

1.28

1.26

1.24

1.22

SWITCHING FREQUENCY (MHz)

1.2

-40 10 60

TEMPERATURE (°C)

=4V)

IN

February 22, 2006

FN7371.1

Page 4

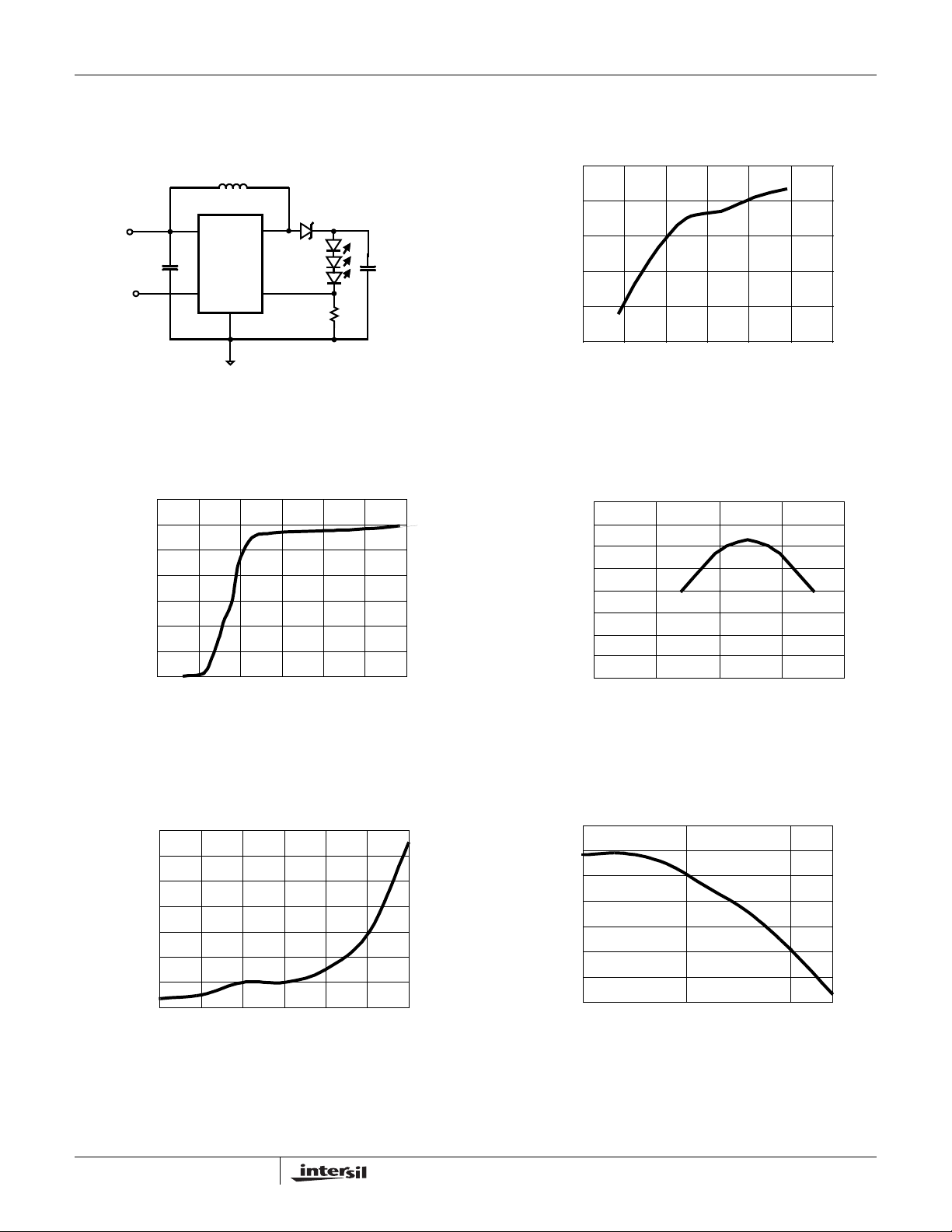

Typical Performance Curves

www.BDTIC.com/Intersil

Block Diagram

EL7630

22

20

16

12

(mA)

OUT

I

8

4

0

0 20 40 60 80 100

DUTY-CYCLE (D)

FIGURE 6. PWM DIMMING CURVE (400Hz)

Vin Enable

Vin Enable

1.2MHz Oscillator and Ramp

1.2MHz Oscillator and Ramp

Generator

Generator

PWM

PWM

Comparator

Comparator

GM Amp

GM Amp

Compensation

Compensation

(shared with PGND

(shared with PGND

in TSOT5 package)

in TSOT5 package)

FIGURE 7. EL7630 BLOCK DIAGRAM

Pin Functions

LX (Pin 1) - Switching Pin. Connect to inductor and diode.

GND (Pin 2) - Ground Pin. Connect to local ground.

FB (Pin 3) - Feedback Pin. Connect to the cathode of lowest

LED and the sense resistor.

PWM Logic

PWM Logic

Controller

Controller

GM

GM

Amplifier

Amplifier

GND

GND

EL7630

EL7630

LX

LX

FET

FET

Driver

Driver

Current

Current

Sense

Sense

PGND

PGND

FB

95mV

95mV

Bandgap

Bandgap

Reference

Reference

Generator

Generator

FB

PGND (Pin 5, SC-70 Package) - Ground Pin. Connect to

Pin 2 and to local ground.

V

(Pin5/Pin6 SC-70 Package) - Input Supply Pin.

IN

Connect to the input supply voltage.

ENAB (Pin 4) - Enable Pin. Connect to enable signal to

turn-on or off the device.

4

FN7371.1

February 22, 2006

Page 5

Detailed Description

www.BDTIC.com/Intersil

EL7630 uses a constant frequency, current mode control

scheme to provide excellent line and load regulation. It

can drive up to 6 LEDs in series or 15 LEDs in

parallel/series configuration, with efficiencies of up 86%.

EL7630 operates from an input voltage of 2.7V to 5.5V and

can boost up to 27V.

Steady-State Operation

EL7630 operates with constant frequency PWM. The

switching frequency is around 1.2MHz. Depending on the

input voltage, inductance, number of LEDs and the LED

current, the converter operates in either continuous

conduction mode or discontinuous conduction mode. Both

are normal. The forward current of the LED is set using the

R

resistor. In steady state mode, this current is given by

SET

the equation:

V

---------------=

R

FB

SET

LED

V

FB

---------------

R

SET

(EQ. 1)

D⋅=

(EQ. 2)

I

LED

Shut-Down

The ENAB pin, when taken low places EL7630 into power

down mode. When in power down, the supply current

reduced to less than 1µA.

Dimming Control

The ENAB pin also doubles as a brightness control. There

are two different types of dimming control methods. The first

dimming control is controlled through the duty-cycle of the

ENAB input PWM waveform, which can operate at

frequencies of 400Hz to 1kHz. The LEDs operate at either

zero or full current. This is called PWM dimming control

method. The relationship between the average LED current

and the duty-cycle (D) of the ENAB pin’s waveform is as

follows:

average I

The magnitude of the PWM signal should be higher than the

minimum ENAB voltage high. The bench PWM dimming test

results are shown in Figure 8. In the test, two PWM

frequencies 400Hz and 1kHz are chosen to compare the

linear dimming range. It is clear that for lower PWM

frequency, the linear dimming range is wider than one for

higher PWM frequency. In the PWM dimming test, the output

capacitor is 0.22µF.

EL7630

25

20

15

(mA)

10

OUT

I

5

0

0 10203040506070809010

FIGURE 8. PWM DIMMING LINEAR RANGE (FOR 400Hz AND

1kHz PWM FREQUENCIES CONDITION,

C

OUT

1kHz

400Hz

DUTY-CYCLE (%)

= 0.22µF)

The second dimming control is to apply a variable DC

voltage to adjust the LED current. This is called analog

dimming control. The dimming control using a DC voltage is

shown in Figure 9. As the DC dimming signal voltage

increases, the voltages drop on R

the voltage drop on R

decreases. Thus, the LED current

SET

and R2 increases and

1

decreases. The DC dimming signal voltage can be a variable

DC voltage or a DC voltage generated from a PWM control

signal. For some application areas, the PWM control signal

is a high frequency signal. To make dimming controllable

with these high frequency PWM signals, the high frequency

components of the PWM control signal should be filtered to

get the equivalent DC voltage. The equivalent DC voltage is

then used as the variable DC voltage for dimming LED

current.

I

V

LED

Dim

V

FB

---------------

R

SET

R

2

-------

R

1

+

R

1R2

---------------------

R

2

R

1

⋅⋅=

V

FB

------- F–+

R

V

DimR1

---------------------------–⋅=

R

SETR2

1

2

⋅

⋅

(EQ. 3)

(EQ. 4)

where F is the brightness with respect to the undimmed

value.

5

FN7371.1

February 22, 2006

Page 6

EL7630

www.BDTIC.com/Intersil

L1

22µH

V

IN

2.7V~5.5V

C1

1µF

OFF/ON

FIGURE 9. ANALOG DIMMING CONTROL APPLICATION

For a required LED current I

and R

, the dimming DC voltage V

2

V

DimVFBVFBILED

CIRCUIT

– R

VDD

LX

LX

EL7630

ENAB FB

GND

LED

⋅()+

SET

It is clear that as the required LED current I

the rate current V

FB/RSET

, V

Dim

D1

LEDs

C2

0.22µF

R2

R1

R

SET

4.75Ω

DIMMING SIGNAL

and chosen values of R1

can be expressed as:

Dim

R

2

-------

⋅=

R

1

is closed to

LED

is closed to VFB. As the

(EQ. 5)

required LED current is lower than the rate current, the

dimming DC voltage V

is increased in R2/R1 factor.

Dim

Open-Voltage Protection

In some applications, it is possible that the output is

opened, e.g. when the LEDs are disconnected from the

circuit or the LEDs fail. In this case the feedback voltage

will be zero. The EL7630 will then switch to a high duty

cycle resulting in a high output voltage, which may cause

the LX pin voltage to exceed its maximum 27V rating. To

implement overvoltage protection, a zener diode Dz and a

resistor R

voltage on the LX pin as shown in Figure 10. It is clear that

as the zener is turned on, due to the overvoltage, the zener

diode’s current will set up a voltage on R

voltage is applied on FB pin as the feedback node. This

feedback will prevent the output from reaching the

overvoltage condition. In the overvoltage protection circuit

design, the zener voltage should be larger than the

maximum forward voltage of the LED string.

can be used at the output and FB pin to limit the

1

and R

V

IN

2.7V~5.5V

1µF

OFF/ON

C1

L1

22µH

VDD

LX

EL7630

ENAB FB

GND

D1

Dz

R1

R

SET

4.75Ω

1

SET

LEDs

and this

C2

0.22µF

Components Selection

The input capacitance is normally 0.22µF~4.7µF and the

output capacitor is 0.22µF~1µF. X5R or X7R type of ceramic

capacitor with the correct voltage rating is recommended.

The output capacitor value will affect PWM dimming

performance. For lower output capacitor values, the range of

PWM dimming is wider than for higher values of output

capacitor.

When choosing an inductor, make sure the inductor can

handle the average and peak currents given by the following

formulas (80% efficiency assumed):

I

⋅

LEDVOUT

I

LAVG

I

LPKILAVG

∆

I

Where:

• ∆I

• L inductance in H.

•f

The boost inductor can be chosen in a wide range of

inductance (10µH~82µH). For 10µH inductor value, the

boost inductor current will be in discontinuous mode. As the

inductor value decreases further, the ripple of the boost

inductor current is increased and can even trigger

overcurrent protection. For high boost inductor value, the

boost inductor current will be in continuous mode. For

general boost converter, as the converter operates in

continuous mode, there is right half plane zero (RHPZ). If

RHPZ frequency is less than or close to the control loop

crossover frequency, there is a stability issue. In EL7630, the

compensation network is well designed and there is no

RHPZ stability issue even if the inductor value is over 82µH.

For the same series of inductors, a lower inductance has

lower DC resistance (DCR), which causes less conducting

loss, but higher peak to peak current variation, which

generates more RMS current loss. Figure 11 shows the

efficiency of the demo board with different LED load for a

specific series of inductor.

The diode used should be a schottky type with minimum

reverse voltage of 28V. The diode’s peak current is the same

as the inductor’s peak current. The schottky RMS current is:

I

RMS

---------------------------------=

⋅

0.8 V

IN

1

-- -

∆⋅+=

I

L

2

V

INVOUTVIN

---------------------------------------------------=

L

LV

⋅⋅

is the peak-to-peak inductor current ripple in Ampere

L

switching frequency, typically 1.2MHz

OSC

D2I

–()⋅

OUTfOSC

2

⋅

⋅=

LAVG

2

1

-- -

∆⋅+

I

L

6

(EQ. 6)

(EQ. 7)

(EQ. 8)

(EQ. 9)

FIGURE 10. LED DRIVER WITH OVERVOLTAGE

PROTECTION CIRCUIT

6

FN7371.1

February 22, 2006

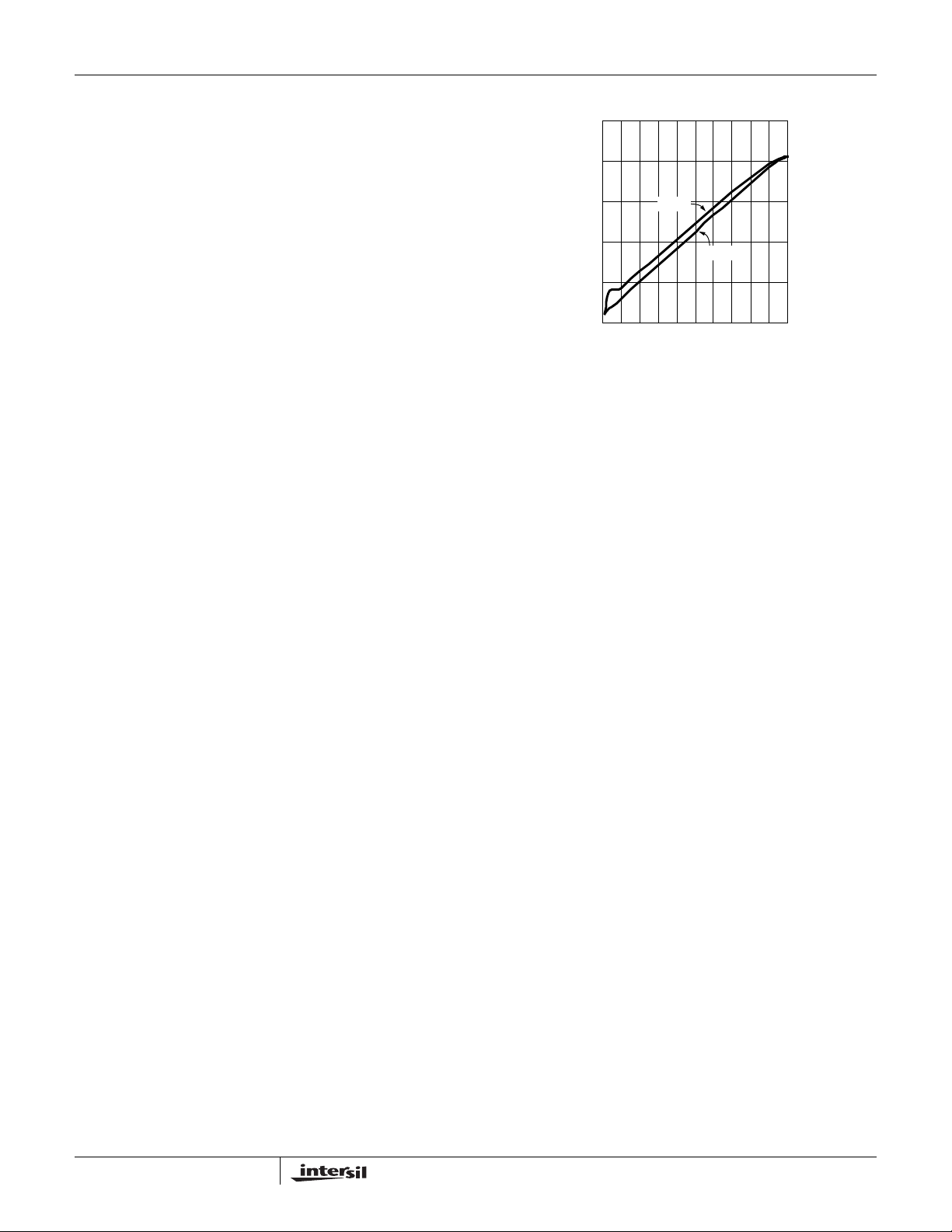

Page 7

EL7630

www.BDTIC.com/Intersil

The efficiency bench test results are shown in Figure 11. In

the test, the input voltage is 4V and 2, 3, 4, 5 and 6 LEDs are

used as the load (boost inductor L = 22µH Sumida

CDRH5D28R-220NC).

90

22µH,VIN=4V

85

80

75

70

65

EFFICIENCY (%)

60

55

0102030

FIGURE 11. EFFICIENCY CURVE WITH 2, 3, 4, 5 AND 6 LEDs

LOAD

4LED

6LED

3LED

LED CURRENT (mA)

2LED

5LED

White LED Connections

One leg of LEDs connected in series will ensure brightness

uniformity. The 27V maximum output voltage specification

enables up to 6 LEDs to be placed in series.

In order to output more power to drive more LEDs, LEDs

should be in series/parallel connection. Due to the LED's

negative temperature coefficient, in each parallel branch, the

driving source should be high impedance, to balance the

LED current in each branch. One of the ways to ensure the

brightness uniformity is to add mirror current balance circuit,

built up with three transistors for the 15 LEDs series/parallel

connection application shown in Figure 12.

PCB Layout Considerations

The PCB layout is very important for the converter to

function properly. For the SC-70 6 pin package, Power

Ground and Signal Ground should be separated to ensure

the high pulse current in the power ground does not interfere

with the sensitive signals connected to Signal Ground. Both

grounds should only be connected at one point right at the

chip. The heavy current loops (V

L1-D1-C2-PGND) should be as short as possible. For the

TSOT 5 pin package, there is no separated GND. All return

GNDs should be connected in GND pin but with no sharing

branch. Based on the signal level on each branch, the lower

power level of the branch, the closer the branch to GND pin

in order to minimize the branch interactive.

The FB

R

pin is most important. The current sense resistor

should be very close to this pin. If a long trace is

SET

required to the LEDs, a small decoupling capacitor should be

placed at this pin.

The heat of the IC is mainly dissipated through the PGND

pin. Maximizing the copper area connected to this pin is

preferable. In addition, a solid ground plane is always helpful

for the EMI performance.

The demo board is a good example of layout based on the

principle. Please refer to the EL7630 Application Brief for the

layout.

-L1-LX-PGND, and VIN-

IN

D1

D1

L1

L1

V

IN

2.7V~5.5V

C1

OFF/ON

FIGURE 12. LEDs IN SERIES/PARALLEL WITH MIRROR

VDD

VDD

LX

LX

EL7630

EL7630

ENAB FB

ENAB FB

GND

GND

CURRENT BALANCE

R

SET

C2

LEDs

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

7

FN7371.1

February 22, 2006

Loading...

Loading...