S

N

G

I

®

F

D

E

D

N

E

M

M

O

C

E

R

T

O

N

L

E

E

Data Sheet August 1, 2005

E

S

E

N

R

O

6

6

5

7

W

S

E

D

EL7556D

FN7339.1

Integrated Adjustable 6 Amp

Synchronous Switcher

The EL7556D is an adjustable synchronous DC:DC

switching regulator optimized for a 5V input and 1.0V-3.8V

output. By combining integrated NMOS power FETS with a

fused-lead package, the EL7556D can supply up to 6A

continuous output current without the use of external power

devices or discrete heat sinks, thereby minimizing design

effort and overall system cost.

On-chip resistorless current sensing is used to achieve

stable, highly efficient, current-mode control. The EL7556D

also incorporates the VCC2DET function to directly interface

with the Intel P54 and P55 microprocessors. Depending on

the state of VCC2DET, the output voltage is internally preset

to 3.5V or a user-adjustable voltage using two external

resistors. In both internal and external feedback modes the

active-high PWRGD output indicates when the regulator

output is within ±10% of the programmed voltage. An onboard sensor monitors die temperature (OT) for overtemperature conditions and can be connected directly to

OUTEN to provide automatic thermal shutdown. Adjustable

oscillator frequency and slope compensation allow added

flexibility in overall system design.

The EL7556D is available in a 28-pin SO package and is

specified for operation over the full -40°C to +85°C

temperature range.

Ordering Information

PART

NUMBER PACKAGE

EL7556DCM 28-Pin SO - MDP0027

EL7556DCM-T13 28-Pin SO 13” MDP0027

EL7556DCMZ

(See Note)

EL7556DCMZ-T13

(See Note)

NOTE: Intersil Pb-free plus anneal products employ special Pb-free

material sets; molding compounds/die attach materials and 100%

matte tin plate termination finish, which are RoHS compliant and

compatible with both SnPb and Pb-free soldering operations. Intersil

Pb-free products are MSL classified at Pb-free peak reflow

temperatures that meet or exceed the Pb-free requirements of

IPC/JEDEC J STD-020.

28-Pin SO

(Pb-free)

28-Pin SO

(Pb-free)

TAPE &

REEL PKG. DWG. #

- MDP0027

13” MDP0027

Features

• Improved temperature and voltage ranges

• 6A continuous load current

• Precision internal 1% reference

• 1.0V to 3.8V output voltage

• Internal power MOSFETs

• >90% efficiency

• Synchronous switching

• Adjustable slope compensation

• Over-temperature indicator

• Pulse-by-pulse current limiting

• Operates up to 1MHz

• 1.5% typical output accuracy

• Adjustable oscillator with sync

• Remote enable/disable

• Intel P54- and P55-compatible

• VCC2DET interface

• Internal soft-start

• Pb-free plus anneal available (RoHS compliant)

Applications

• PC motherboards

• Local high power CPU supplies

• 5V to 1.0V DC:DC conversion

• Portable electronics/instruments

• P54 and P55 regulators

• GTL+ Bus power supply

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright Intersil Americas Inc. 2003, 2005. All Rights Reserved

All other trademarks mentioned are the property of their respective owners.

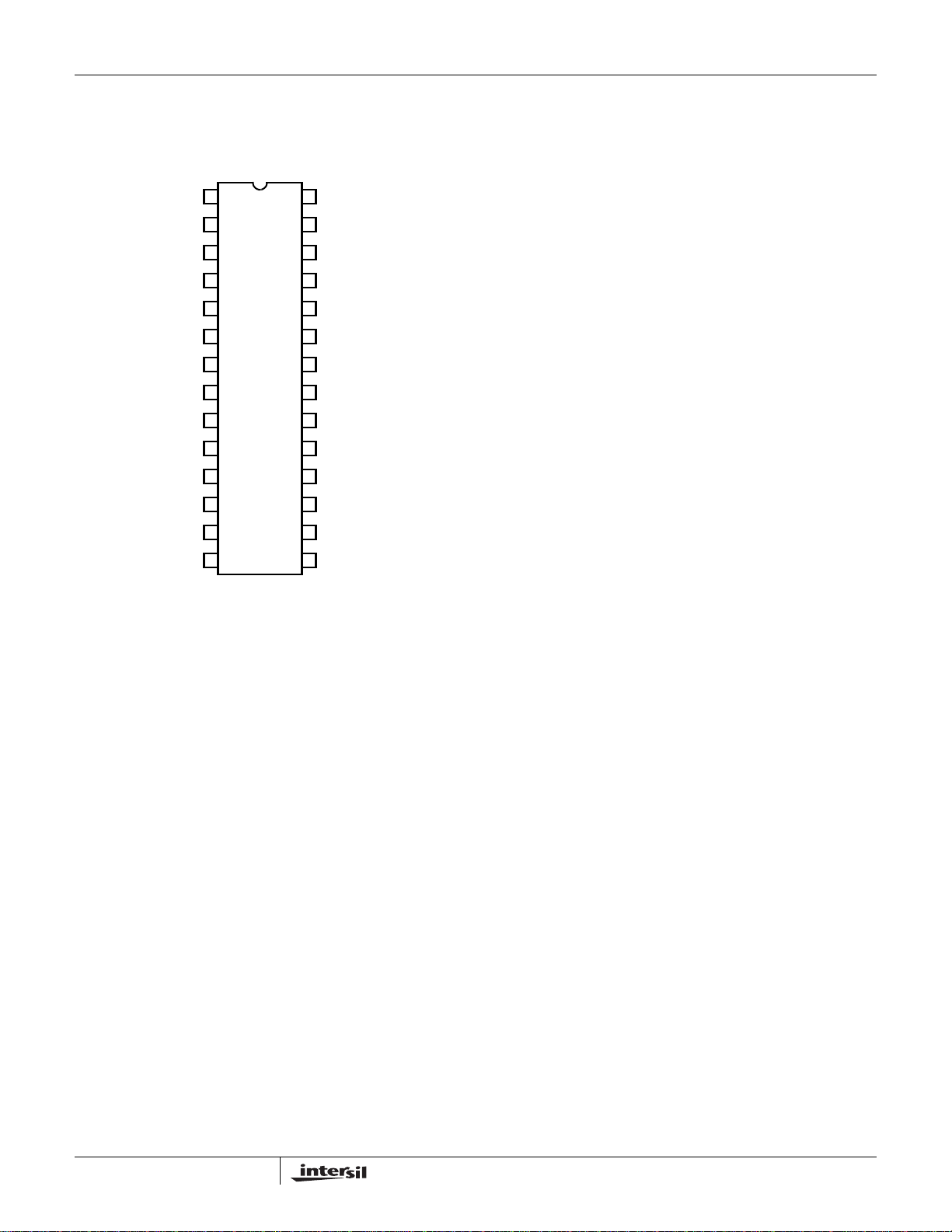

Pinout

EL7556D

EL7556D

(28-PIN SO)

TOP VIEW

1

2

3

4

5

6

7

8 21

9

10

11

12

13

14 15

28

FB2FB1

27

CPCREF

26

C2VCSLOPE

25

VSSCOSC

VHIVDD

24

LXVIN

23

LXVSSP

22

LXVIN

LXVSSP

20

VSSPVSSP

19

VSSPVSSP

18

TESTVSSP

17

PWRGDVCC2DET

16

OTOUTEN

2

EL7556D

Absolute Maximum Ratings (T

Storage Temperature Range . . . . . . . . . . . . . . . . . .-65°C to +150°C

Supply (V

Output Pins . . . . . . . . . . . . . . .-0.3V below GND, +0.3V above V

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

IMPORTANT NOTE: All parameters having Min/Max specifications are guaranteed. Typ values are for information purposes only. Unless otherwise noted, all tests are

at the specified temperature and are pulsed tests, therefore: T

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.0V

IN

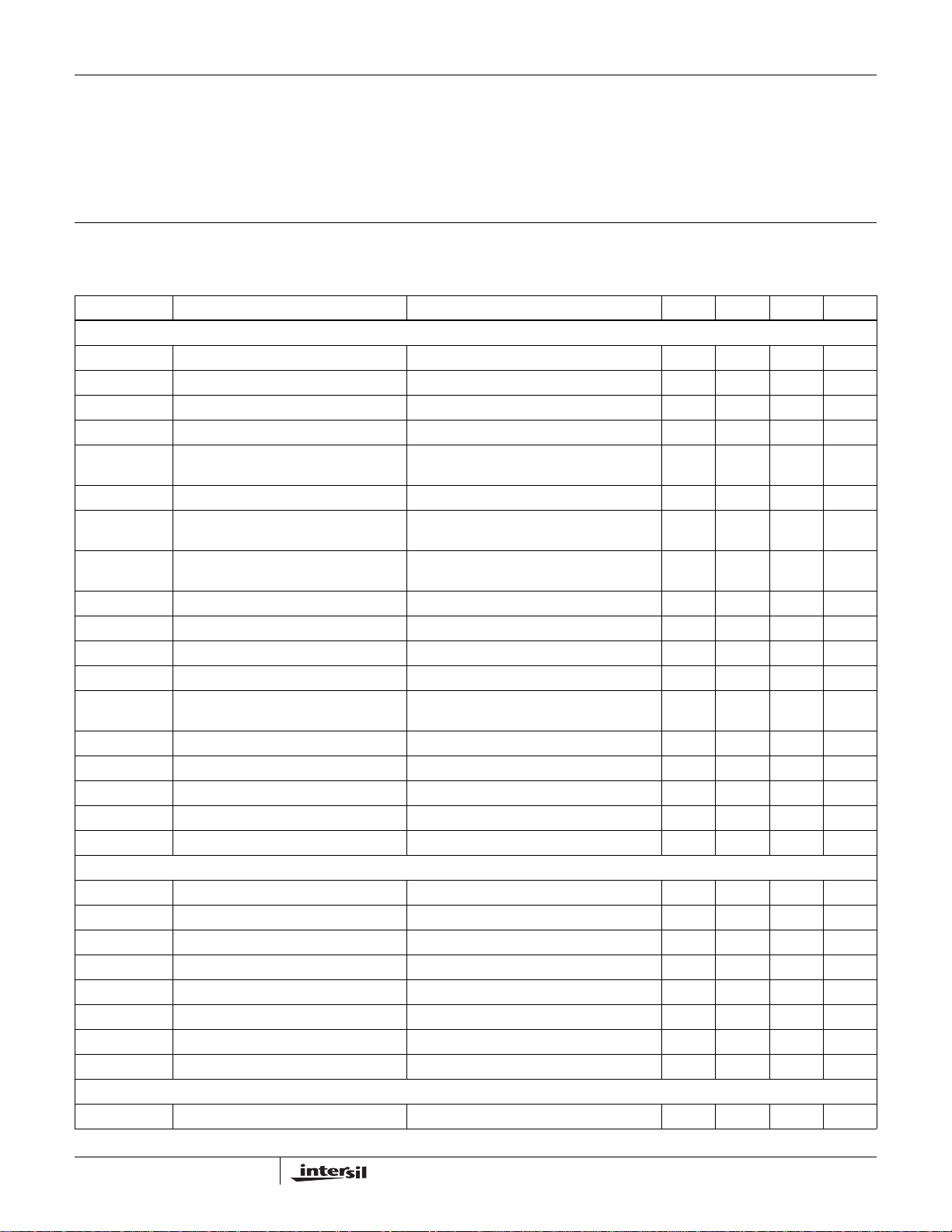

Electrical Specifications V

DD

= 25°C)

A

= V

= 5V, C

IN

= TC = T

J

= 1nF, C

OSC

A

DD

SLOPE

Ambient Operating Temperature . . . . . . . . . . . . . . . . -40°C to +85°C

Operating Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . 135°C

Peak Output Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9A

= 470pF, TA = 25°C, unless otherwise specified.

PARAMETER DESCRIPTION CONDITIONS MIN TYP MAX UNIT

GENERAL

I

DD

I

DDOFF

I

VIN

V

OUT1

V

OUT2

V

OUTLINE

V

OUTLOAD

VDD Supply Current OUTEN = 4V, F

= 120kHz 11 25 mA

OSC

VDD Standby Current OUTEN = 0 0.1 mA

V

No Load Current OUTEN = 0 3 5 mA

IN

Output Initial Accuracy VCC2DET = 4V, IL = 3A (see Fig. 1) 3.450 3.500 3.550 V

Output Initial Accuracy VCC2DET = 0V, IL = 3A, R3 = 150Ω, R4 =

2.450 2.500 2.550 V

100Ω (see Fig. 1)

Output Line Regulation VDD = 5V, ±10% -1 1 %

Output Load Regulation 0A < I

< 6A, relative to IL = 3A,

LOAD

-1 1 %

continuous mode of operation (see Fig.1)

R

SHORT

I

I MAX

V

OUTTC

T

OT

T

HYS

V

PWRGD

V

DDOFF

V

DDON

V

HYS

M

SS

D

MAX

Short Circuit Load Resistance IL = 6A, prior to continuous application of

R

, OUTEN connected to OT

SHORT

100 mΩ

Current Limit 9A

Output Tempco -40°C < TA < 85°C ±1 %

Over-temperature Threshold 135 °C

Over-temperature Hysteresis 40 °C

Power Good Threshold Relative to

Programmed Output Voltage

VCC2SEL = 4V, V

= 3.50V ±6 ±10 ±14 %

OUT

Minimum VDD for Shutdown 3.15 V

Maximum VDD for Startup 4.15 V

Input Hysteresis V

HYS

= V

DDON

- V

DDOFF

0.5 V

Soft-start Slope 7V/ms

Maximum Duty Cycle 96 %

CONTROLLER - INPUTS

I

PUP

I

CSLOPE

VCC2DET, OUTEN Pull-up Current VCC2DET, OUTEN = 0 10 14 18 µA

C

Charging Current 23 28.5 34 µA

SLOPE

IFB1 FB1 Input Pull-up Current 2µA

R

OT

V

IH

V

IL

V

OH PWGD

V

OL PWGD

Over-temperature Pull-up Resistance OT = 0V 30 40 50 kΩ

VCC2DET, OUTEN Input High 4 V

VCC2DET, OUTEN Input Low 0.8 V

Powergood Drive High I

Powergood Drive Low I

= 1mA 3.5 V

LOAD

= -1mA 1.0 V

LOAD

CONTROLLER - REFERENCE

V

REF

Reference Accuracy I

= 0 1.247 1.260 1.273 V

REF

3

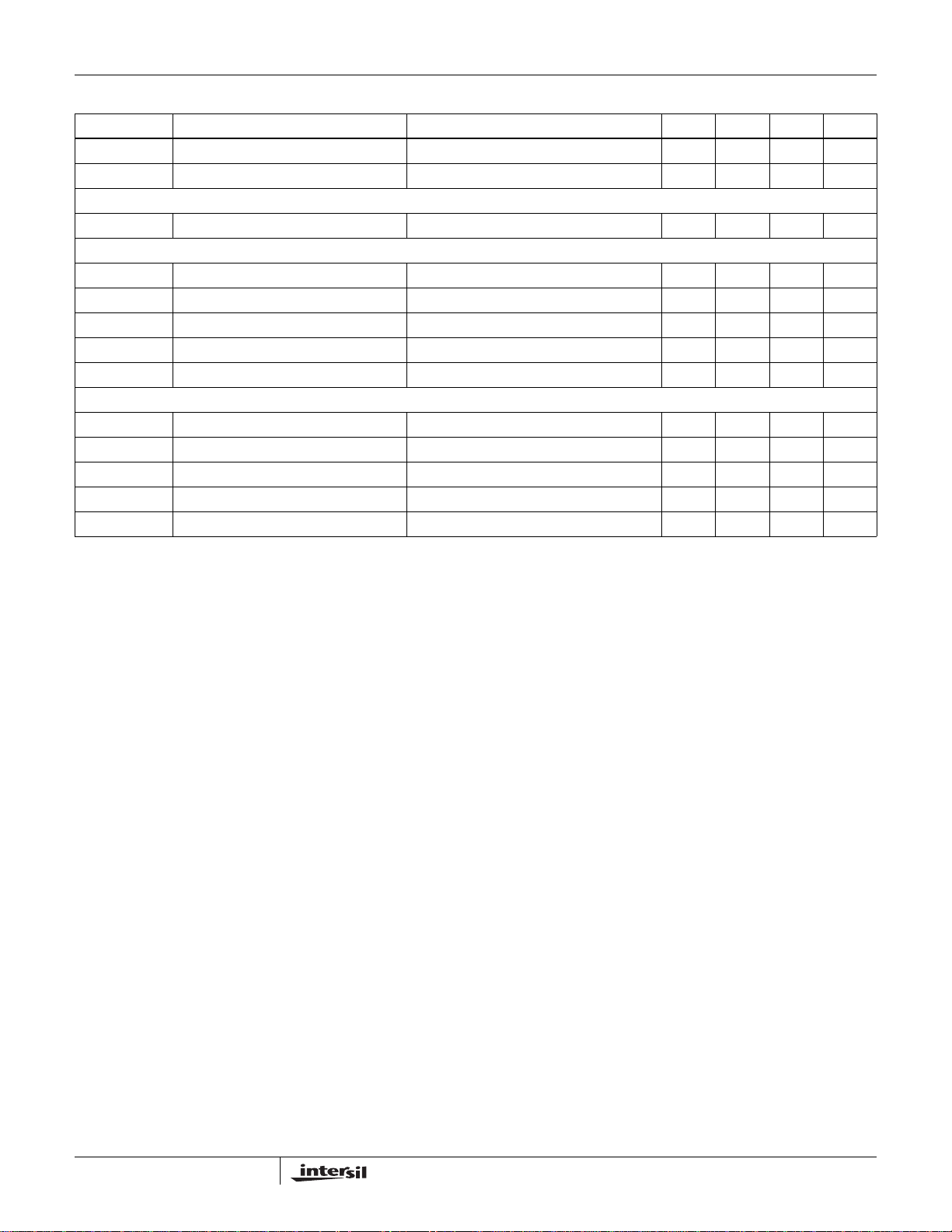

EL7556D

Electrical Specifications V

DD

= V

= 5V, C

IN

OSC

= 1nF, C

= 470pF, TA = 25°C, unless otherwise specified. (Continued)

SLOPE

PARAMETER DESCRIPTION CONDITIONS MIN TYP MAX UNIT

V

REFTC

V

REFLOAD

Reference Voltage Tempco 50 ppm/°C

Reference Load Regulation 0 < I

< 100µA 0.5 0.5 %/°C

LOAD

CONTROLLER - DOUBLER

VC2V Voltage Doubler Output V

DD

= 5V, I

= 10mA 7.5 8.1 8.7 V

LOAD

CONTROLLER - OSCILLATOR

F

RAMP

I

OSC CHG

I

OSC DIS

F

OSC

t

SYNC

Oscillator Ramp Amplitude 1.2 V

Oscillator Charge Current 0.2V < V

Oscillator Discharge Current 0.2V < V

< 1.4V 150 µA

OSC

< 1.4V 5 mA

OSC

Oscillator Initial Accuracy 105 125 145 kHz

Minimum Oscillator Sync Width 50 ns

POWER - FET

I

LEAK

R

DSON

R

DSONTC

t

BRM

t

LEB

LX Output Leakage to V

SS

LX = 0V 100 µA

Composite FET Resistance 18 30 mΩ

R

Tempco 0.1 mΩ/°C

DSON

FET Break Before Make Delay 10 ns

High Side FET Minimum on Time (LEB) 140 ns

4

Typical Performance Curves

EL7556D

Efficiency vs I

VDD=VIN=5.0V (±10%)

96

94

LOAD

(V

OUT

VDD=4.5V

=3.5V)

92

90

VDD=5V

88

VDD=5.5V

86

Efficiency (%)

84

82

TA=25°C

80

0.5 1.5 2.5 3.5 4.5 5.5

Line Regulation (C

3.54

TA=25°C

3.53

I

OUT

SLOPE

(A)

=100pF)

3.52

I

=0.5A

3.51

(V)

3.50

OUT

V

3.49

OUT

I

OUT

=3A

3.48

I

=6A

3.47

3.46

4.5 5.0 5.5

OUT

VIN (V)

6.5

Efficiency vs I

LOAD

(VDD=5.0V)

100

95

90

VCC=3.5V

VCC=2.5V

85

80

Efficiency (%)

VCC=1V

75

70

0.5

1.5

2.5 3.5 4.5 6.0

I

(A)

OUT

Load Regulation (C

3.54

TA=25°C

3.53

3.52

3.51

(V)

3.50

OUT

V

3.49

SLOPE

VIN=5V

=100pF)

VIN=5.5V

3.48

OUT

VIN=4.5V

(A)

3.47

3.46

0.5 3.0 6.0

I

5.5

Line Regulation vs C

VDD=VIN=5.0V ±10%

0.8

TA=25°C TA=25°C

0.7

SLOPE

(I

=3A)

OUT

0.6

0.5

V

(±) (%)

OUT

∆V

0.4

0.3

OUT

=3.5A

V

=2.5A

OUT

0.2

0.1

0.0

50 75

Line Regulation vs C

VIN=VDD=5.0V ±10%

0.8

TA=25°C TA=25°C

0.7

V

=1A

OUT

100 125 150 175

(pF)

C

SLOPE

SLOPE

0.6

0.5

I

(±) (%)

OUT

∆V

0.4

0.3

0.2

=6A VIN=4.5V

OUT

I

=0.5A

OUT

0.1

0.0

50 75

100 125 150 175

C

(pF)

SLOPE

Load Regulation vs C

I

=3A, +3A, -2.5A

OUT

0.6

SLOPE (VIN

=5.0V)

0.5

V

=3.5A

OUT

V

OUT

=1A

V

=2.5A

OUT

(±) (%)

OUT

∆V

0.4

0.3

0.2

0.1

0.0

50 75 100 125 150 175

Load Regulation vs C

I

=3A, +3A, -2.5A

OUT

0.8

C

SLOPE

(pF)

SLOPE

0.7

0.6

0.5

(±) (%)

0.4

OUT

0.3

∆V

0.2

VIN=5.5VVIN=5V

0.1

0.0

50 75

100 125 150 175

C

(pF)

SLOPE

5

Typical Performance Curves

EL7556D

V

vs C

OUT

SLOPE

(VIN=5.0V, I

1.5

TA=25°C TA=25°C

1.0

LOAD

=0.5A)

0.5

V

=1V

OUT

(±) (%)

OUT

∆V

0.0

-0.5

-1.0

-1.5

V

OUT

=3.5V

V

=2.5V

OUT

-2.0

-2.5

-3.0

50 75

F

OSC

10k

vs C

100 125 150 175

C

(pF)

SLOPE

OSC

TA=25°C

1k

(kHz)

100

OSC

F

10

V

OUT

Voltage [V

1.5

1.0

(%)

0.5

OUT

0.0

-0.5

Deviation in V

-1.0

Loop Gain Induced Error

-1.5

1.0 1.5

F

OSC

520

510

500

490

(kHz)

480

OSC

F

470

Variation vs Programmed Output

IDEAL

C

=(1+R3/R4)]

C

S

L

O

P

E

=

O

S

C

=

2

20

1

0

0

p

F

p

F

2.0 2.5 3.0 4.0

V

(V)

IDEAL

vs Temperature

VDD=4.5V

VDD=5.5V

VDD=5V

460

1

10

C

(pF)

OSC

100k100 1k

450

20

0

40 60 80 140

Temperature (°C)

100

3.5

120

I(VDD) + I(VIN) vs F

60

TA=25°C

OUTEN=V

50

OSC

DD

VDD=5.5V

I(VIN) vs F

16

14

TA=25°C

OUTEN=V

OSC

DD

12

(mA)

Q

I

40

30

VDD=4.5V

VDD=5V

20

(mA)

VIN

I

10

8

6

4

10

0

200 1000400 600 800 200 1000400 600 800

I(VDD) vs F

50

TA=25°C

45

OUTEN=V

40

35

OSC

DD

F

OSC

VDD=5.5V

Continuous ModeDiscontinuous Mode

(kHz)

30

25

(mA)

DD

I

20

15

VDD=4.5V

VDD=5V

2

Discontinuous Mode

0

I

DD

2.0

IN

1.5

(mA) + IV

DD

I

+ IVIN vs F

OSC

F

(kHz)

OSC

VDD=5.5V

VDD=4.5V

10

5

0

200 1000400 600 800

F

OSC

(kHz)

1.0

10

100 1000

F

(kHz)

OSC

VDD=5.5V

VDD=5V

VDD=4.5V

Continuous Mode

VDD=5V

6

Typical Performance Curves

EL7556D

Power On Reset

40

TA=25°C

OUTEN=V

DD

30

20

(mA)

Q

I

10

0

41

39

37

35

33

(°C/W)

JA

31

Θ

29

27

25

0.00 3.00

3.0

2.5

ΘJA vs Cu Area

F

=500k

OSC

3.5 4.5 5.0

4.0

V

(V)

DD

Board with no

Components

Board with

Inductor

Bare Cu Area (in2)

Minimum Output Voltage vs F

2.3

TJ=120°C

2.1

1.9

1.7

(V)

1.5

OUT

V

1.3

1.1

0.9

0.7

Maximum I

7556 Demo Board (31°C/W)

8.0

7.5

7.0

6.5

(A)

6.0

LOAD

I

5.5

5.0

4.5

OUTEN connected to OT

6.004.002.001.00 5.00

4.0

25 50

vs Temperature

LOAD

F

OSC

4535

(kHz)

TA (°C)

OSC

VDD=5.5V

VDD=4.5V

100 LFPM

Still Air

55

VDD=5V

70604030 65

R

vs Temperature

DSON

38

36

34

32

30

(mΩ)

28

DSON

R

26

24

22

20

0

Temperature (°C)

125755025 100

7

EL7556D

Pin Descriptions

I = Input, O = Output, S = Supply

PIN

NUMBER PIN NAME PIN TYPE FUNCTION

1 FB1 I Voltage feedback pin for the buck regulator. Active when VCC2DET is logic low. Normally connected to

external resistor divider between V

that FB1 is floating and VCC2DET is inadvertently connected to GND.

2 CREF I Bandgap reference bypass capacitor. Typically 0.1µF to V

3 CSLOPE I Slope compensation capacitor. Ramp width corresponds to LX duty cycle. C

normally 1:1.5.

4 COSC I Oscillator timing capacitor. F

Farads.

OSC

5 VDD S Power Supply for PWM control circuitry. Normally the same potential as V

6 VIN S Power supply for the buck regulator. Connected to the drain of the high-side NMOS FET.

7 VSSP S Ground return for the buck regulator. Connected to the source of the low-side synchronous NMOS FET.

8 VIN S Same as pin 6.

9 VSSP S Same as pin 7.

10 VSSP S Same as pin 7.

11 VSSP S Same as pin 7.

12 VSSP S Same as pin 7.

13 VCC2DET I VCC2DET interface logic input. When driven to logic 1 V

uses FB1 to determine V

OUT

: V

14 OUTEN I The switching regulator output is enabled when logic 1. The reference voltage output operates whenever

the power supply is qualified (V

15 OT O Over temperature indicator. Normally high. Pulls low when die temperature exceeds 135°C, returns to

the high state when die temperature has cooled to 100°C.

16 PWRGD O Power good window comparator output. Logic 1 when regulator output is within ±10% of programmed

voltage.

17 TEST I Test pin. Must be connected to VSSP in normal operation.

18 VSSP S Same as pin 7.

19 VSSP S Same as pin 7.

20 LX O Inductor drive pin. High current switching output whose average voltage equals the regulator output

voltage.

21 LX O Same as pin 20.

22 LX O Same as pin 20.

23 LX O Same as pin 20.

24 VHI I Gate drive to high-side driver. Bootstrapped from LX with a 0.1µF capacitor.

25 VSS S Ground return for the control circuitry.

26 C2V I Connected to voltage doubler output. Supplies gate drive to the low-side driver.

27 CP O Drives the negative side of charge pump capacitor at one-half the oscillator frequency F

28 FB2 I Voltage feedback pin. Active when VCC2DET is logic 1. Internally preset to V

and GND. A 2µA pull-up current forces V

OUT

.

SS

(Hz) can be approximated by: F

= 1.0V*(1+R3/R4).

OUT

>VPOR) regardless of the state of this pin.

DD

OUT

OSC

= 3.500V. When driven to logic 0 the PWM

OUT

SLOPE

(Hz) = 0.0001/C

.

IN

= 3.5V.

OUT

to VSS in the event

to C

OSC

OSC

OSC

ratio is

. C

OSC

.

in

8

Block Diagram

EL7556D

FB1, Pin 1

FB2, Pin 28

VCCDET, Pin 13

CSLOPE, Pin 3

CREF, Pin 27

OUTEN, Pin 14

COSC, Pin 4

VDD

1.26V

PWRGD, Pin 16

CP, Pin 27

C2V, Pin 26

VHI, Pin 24

VDD and VIN,

Pin 5,6,8

LX, Pin 20-23

VSSP, Pin 912, 18-19

OT, Pin 15

V

Pin 25

SS,

S

-

+

-

+

-

+

Current Sense

-

+

Current Limit

-

+

PWM

VDD

R

SS

C

SS

V2X

-

+

LEB T

DELAY

Q

R

Q

S

FF

R

S

Zero Cross Detect

Over Temp

Sensor

+

-

2-1 MUX

4V

UVLO

-

S

+

-

R

+

Applications Information

Circuit Description

General

The EL7556D is a fixed frequency, current mode controlled

DC:DC converter with integrated N-channel power

MOSFETS and a high precision reference. The device

incorporates all of the active circuitry required to implement a

cost effective, user-programmable 6A synchronous buck

converter suitable for use in CPU power supplies. By

combining fused-lead packaging technology with an efficient

synchronous switching architecture, high power outputs

(21W) can be realized without the use of discrete external

heat sinks.

Theory of Operation

The EL7556D is composed of 7 major blocks:

1. PWM Controller

2. Output Voltage Mode Select

3. NMOS Power FETS and Drive Circuitry

4. Bandgap Reference

5. Oscillator

6. Temperature Sensor

7. Power Good and Power On Reset

PWM Controller

The EL7556D regulates output voltage through the use of

current-mode controlled pulse width modulation. The three

main elements in a PWM controller are the feedback loop

and reference, a pulse width modulator whose duty cycle is

controlled by the feedback error signal, and a filter which

averages the logic level modulator output. In a step-down

(buck) converter, the feedback loop forces the timeaveraged output of the modulator to equal the desired output

voltage. Unlike pure voltage-mode control systems currentmode control utilizes dual feedback loops to provide both

output voltage and inductor current information to the

controller. The voltage loop minimizes DC and transient

errors in the output voltage by adjusting the PWM duty-cycle

in response to changes in line or load conditions. Since the

output voltage is equal to the time-average of the modulator

output the relatively large LC time constants found in power

supply applications generally results in low bandwidth and

poor transient response. By directly monitoring changes in

inductor current via a series sense resistor the controller’s

response time is not entirely limited by the output LC filter

and can react more quickly to changes in line or load

conditions. This feed-forward characteristic also simplifies

AC loop compensation since it adds a zero to the overall

loop response. Through proper selection of the currentfeedback to voltage-feedback ratio, the overall loop

response will approach a one pole system. The resulting

system offers several advantages over traditional voltage

9

EL7556D

control systems, including simpler loop compensation, pulse

by pulse current limiting, rapid response to line variation and

good load step response.

The heart of the controller is a triple-input direct summing

comparator which sums voltage feedback, current feedback

and slope compensating ramp signals together. Slope

compensation is required to prevent system instability which

occurs in current-mode topologies operating at duty-cycles

greater than 50% and is also used to define the open-loop

gain of the overall system. The compensation ramp

amplitude is user adjustable and is set using a single

external capacitor (C

). Each comparator input is

SLOPE

weighted and determines the load and line regulation

characteristics of the system. Current feedback is measured

by sensing the inductor current flowing through the high-side

switch whenever it is conducting. At the beginning of each

oscillator period the high-side NMOS switch is turned on and

C

ramps positively from its reset state (V

SLOPE

REF

potential). The comparator inputs are gated off for a

minimum period of time (LEB) after the high-side switch is

turned on to allow the system to settle. The Leading Edge

Blanking (LEB) period prevents the detection of erroneous

voltages at the comparator inputs due to switching noise.

When programming low regulator output voltages the LEB

delay will limit the maximum operating frequency of the

circuit since the LEB will result in a minimum duty-cycle

regardless of the PWM error voltage. This relationship is

shown in the performance curves. If the inductor current

exceeds the maximum current limit (I

), a secondary

LMAX

over-current comparator will terminate the high-side switch.

If I

is then compared to the reference voltage V

has not been reached, the regulator output voltage

LMAX

REF

. The

resultant error voltage is summed with the current feedback

and slope compensation ramp. The high-side switch

remains on until all three comparator inputs have summed to

zero, at which time the high-side switch is turned off and the

low-side switch is turned on. In order to eliminate crossconduction of the high-side and low-side switches a 10ns

break-before-make delay is incorporated in the switch driver

circuitry. In the continuous mode of operation the low-side

switch will remain on until the end of the oscillator period. In

order to improve the low current efficiency of the EL7556D, a

zero-crossing comparator senses when the inductor

transitions through zero. Turning off the low-side switch at

zero inductor current prevents forward conduction through

the internal clamping diodes (LX to V

) when the low-side

SSP

switch turns off, reducing power dissipation. The output

enable (OUTEN) input allows the regulator output to be

disabled by an external logic control signal.

Output Voltage Mode Select

The VCC2DET multiplexes the FB1 and FB2 pins to the

PWM controller. A logic 1 on VCC2DET selects the FB2

input and forces the output voltage to the internally

programmed value of 3.50V. A logic zero on VCC2DET

selects FB1 and allows the output to be programmed from

1.0 to 3.8V. In general:

R

V

OUT

1V 1

× Volt×=

3

-------+

R

4

However, due to the relatively low open loop gain of the

system, gain errors will occur as the output voltage and loopgain are changed. This is shown in the performance curves.

(The output voltage is factory trimmed to minimize error at a

2.50V output). A 2uA pull-up current from FB1 to V

V

to GND in the event that FB1 is not used and the

OUT

forces

IN

VCC2DET is inadvertently toggled between the internal and

external feedback mode of operation.

NMOS Power FETs and Drive Circuitry

The EL7556D integrates low resistance (25mΩ) NMOS

FETS to achieve high efficiency at 6A. Gate drive for both

the high-side and low-side switches is derived through a

charge pump consisting of the CP pin and external

components D1-D3 and C5-C6. The CP output is a low

resistance inverter driven at one-half the oscillator

frequency. This is used in conjunction with D2-D3 to

generate a 7.5V (typical) voltage on the C2V pin which

provides gate drive to the low-side NMOS switch and

associated level shifter. In order to use an NMOS switch for

the high-side drive it is necessary to drive the gate voltage

above the source voltage (LX). This is accomplished by

boot-strapping the V

pin above the C2V voltage with

HI

capacitor C6 and diode D1. When the low-side switch is

turned on the LX voltage is close to GND potential and

capacitor C6 is charged through diodes D1-D3 to

approximately 6.9V. At the beginning of the next cycle the

high side switch turns on and the LX pin begins to rise from

GND to V

potential. As the LX pin rises the positive plate

DD

of capacitor C6 follows and eventually reaches a value of

approximately 11.2V, for V

=5V. This voltage is then level

DD

shifted and used to drive the gate of the high-side FET, via

the V

pin.

HI

Reference

A 1% temperature compensated band gap reference is

integrated in the EL7556D. The external C

REF

capacitor

acts as the dominant pole of the amplifier and can be

increased in size to maximize transient noise rejection. A

value of 0.1uF is recommended.

Oscillator

The system clock is generated by an internal relaxation

oscillator with a maximum duty-cycle of approximately 96%.

Operating frequency can be adjusted through the C

or can be driven by an external clock source. If the oscillator

is driven by an external source, care must be taken in the

selection of C

SLOPE

. Since the C

OSC

and C

SLOPE

determine the open loop gain of the system, changes to

C

require corresponding changes to C

OSC

SLOPE

pin

OSC

values

in order to

10

EL7556D

maintain a constant gain ratio. The recommended ratio of

C

OSC

to C

SLOPE

is 1.5:1

Temperature Sensor

An internal temperature sensor continuously monitors die

temperature. In the event that die temperature exceeds the

thermal trip-point, the OT pin will output a logic 0. The upper

and lower trip points are set to 135°C and 100°C,

respectively. To enable thermal shutdown this pin should be

tied directly to OUTEN. Use of this feature is recommended

during normal operation

Power Good and Power On Reset

During power up the output regulator will be disabled until

V

reaches a value of approximately 4.0V. Approximately

IN

500mV of hysteresis is present to eliminate noise induced

oscillations.

Under-voltage and over-voltage conditions on the regulator

output are detected through an internal window comparator.

A logic 1 on the PWRGD output indicates that regulated

output voltage is within ±10% of the nominally programmed

output voltage. Although small, the typical values of the

PWRGD threshold will vary with changes to external

feedback (and resultant loop gain) of the system. This

dependence is shown in the typical performance curves.

Additional information can be found in Application Note #8

(Measuring the Thermal Resistance of Power SurfaceMount Packages).

If the thermal shutdown pin is connected to OUTEN the IC

will enter thermal shutdown when the maximum junction

temperature is reached. For a thermal shutdown of 135ºC

and power dissipation of 2.2W the ambient temperature is

limited to a maximum value of 67ºC (typical). The ambient

temperature range can be extended with the application of

air flow. For example, the addition of 100LFM reduces the

thermal resistance by approximately 15% and can extend

the operating ambient to 77ºC (typical). Since the thermal

performance of the IC is heavily dependent on the board

layout, the system designer should exercise care during the

design phase to ensure that the IC will operate under the

worst-case environmental conditions.

Thermal Management

The EL7556D utilizes “fused lead” packaging technology in

conjunction with the system board layout to achieve a lower

thermal resistance than typically found in standard 28-pin

SO packages. By fusing (or connecting) multiple external

leads to the die substrate within the package, a very

conductive heat path to the outside of the package is

created. This conductive heat path MUST then be connected

to a heat sinking area on the PCB in order to dissipate heat

out and away from the device. The conductive paths for the

EL7556D package are the fused leads: # 7, 9, 10, 11, 12, 18,

and 19. If a sufficient amount of PCB metal area is

connected to the fused package leads, a junction-to-ambient

thermal resistance of approximately 31°C/W can be

achieved (compared to 78°C/W for a standard SO28

package). The general relationship between PCB heatsinking metal area and the thermal resistance for this

package is shown in the Performance Curves section of this

data sheet. It can be readily seen that the thermal resistance

for this package approaches an asymptotic value of

approximately 31°C/W without any airflow.

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

11

Loading...

Loading...